Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about "Carcasses chilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

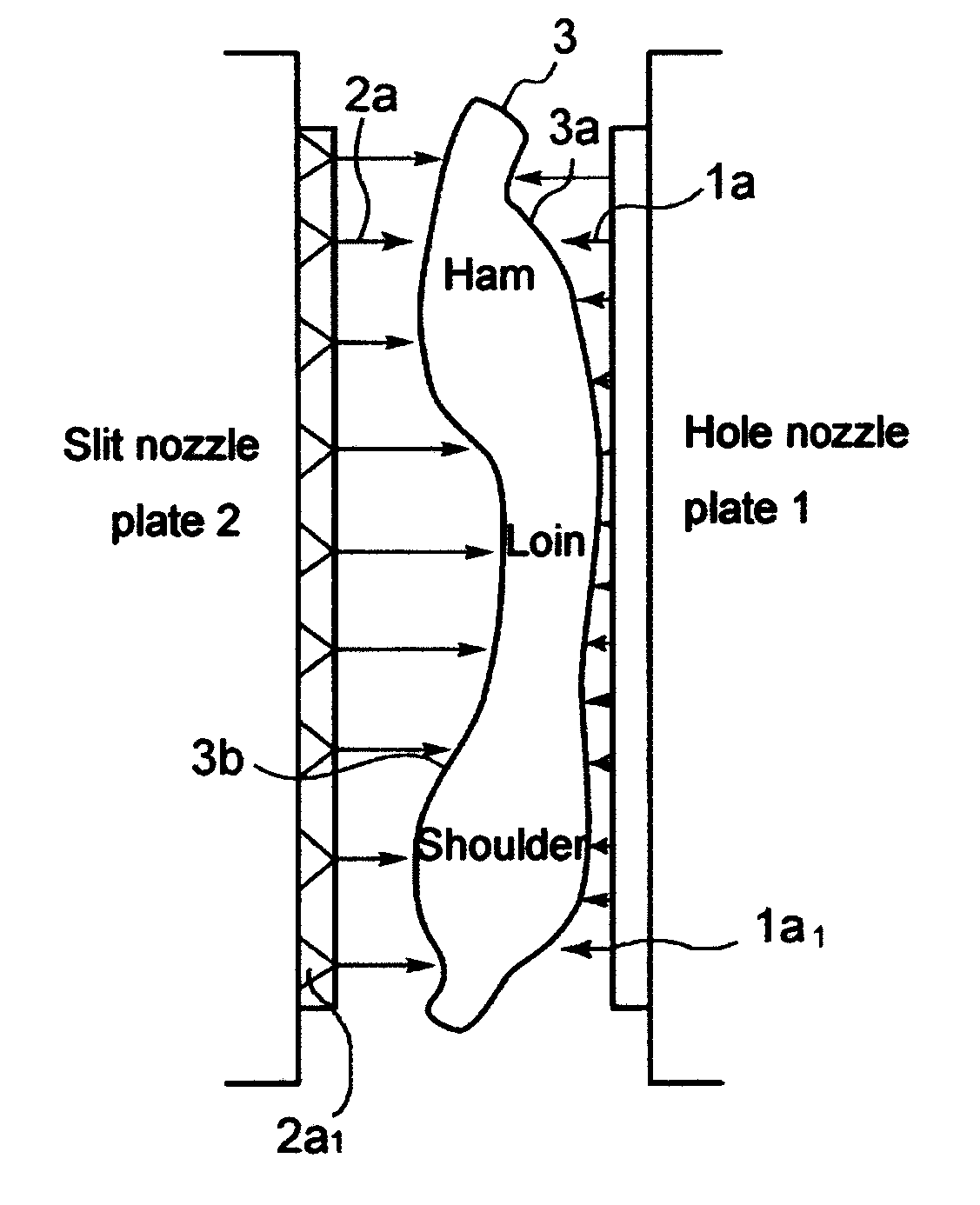

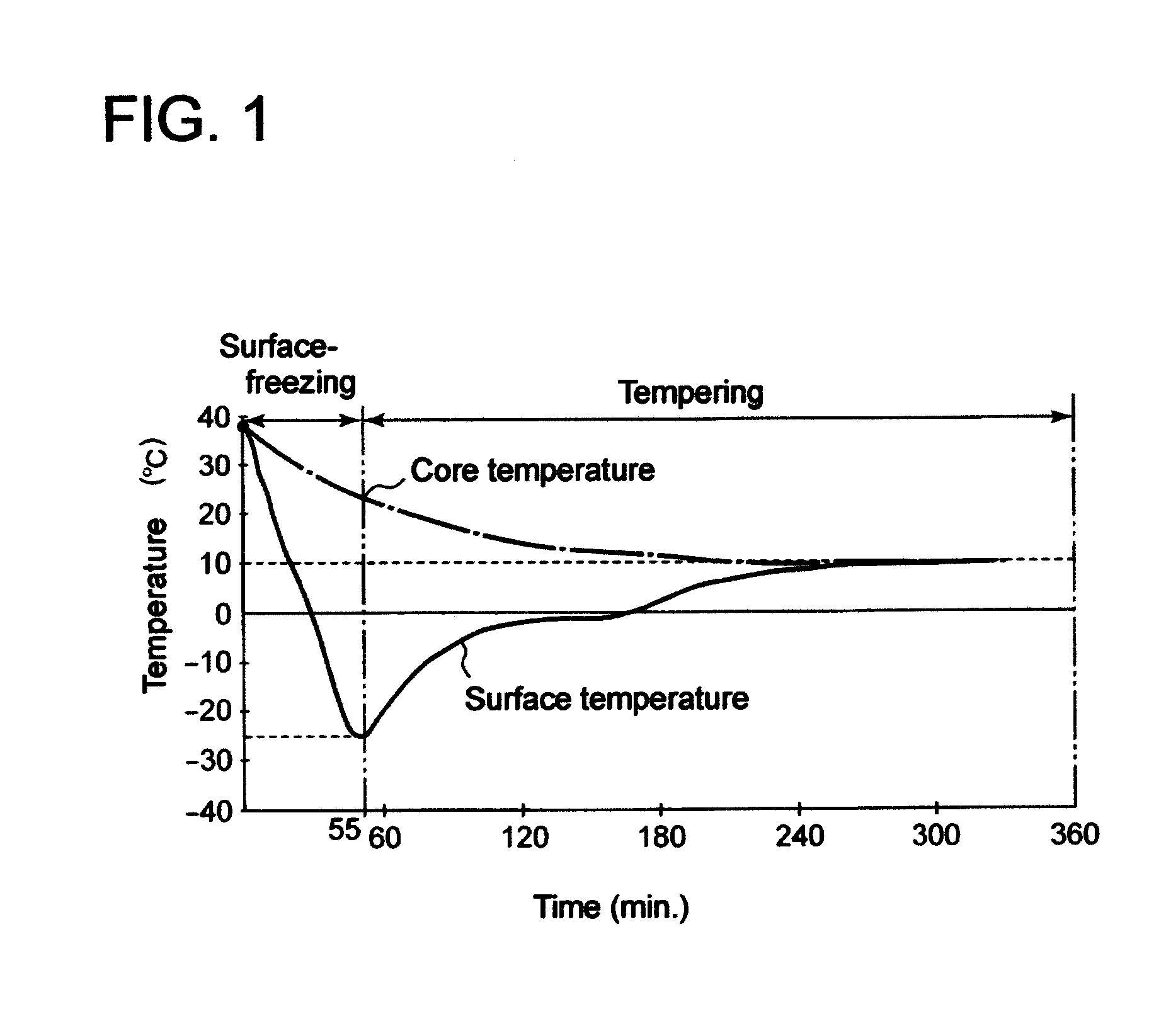

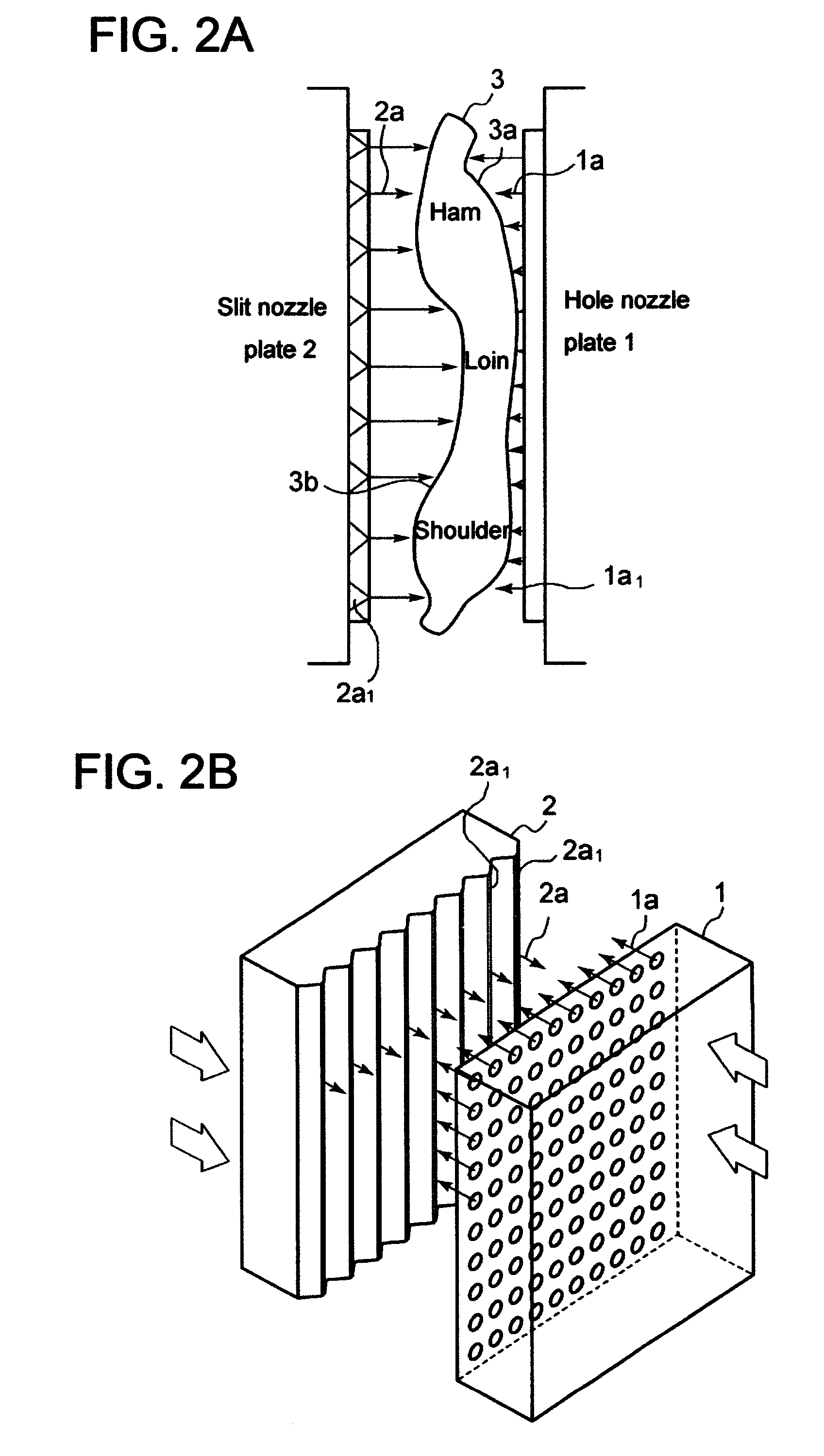

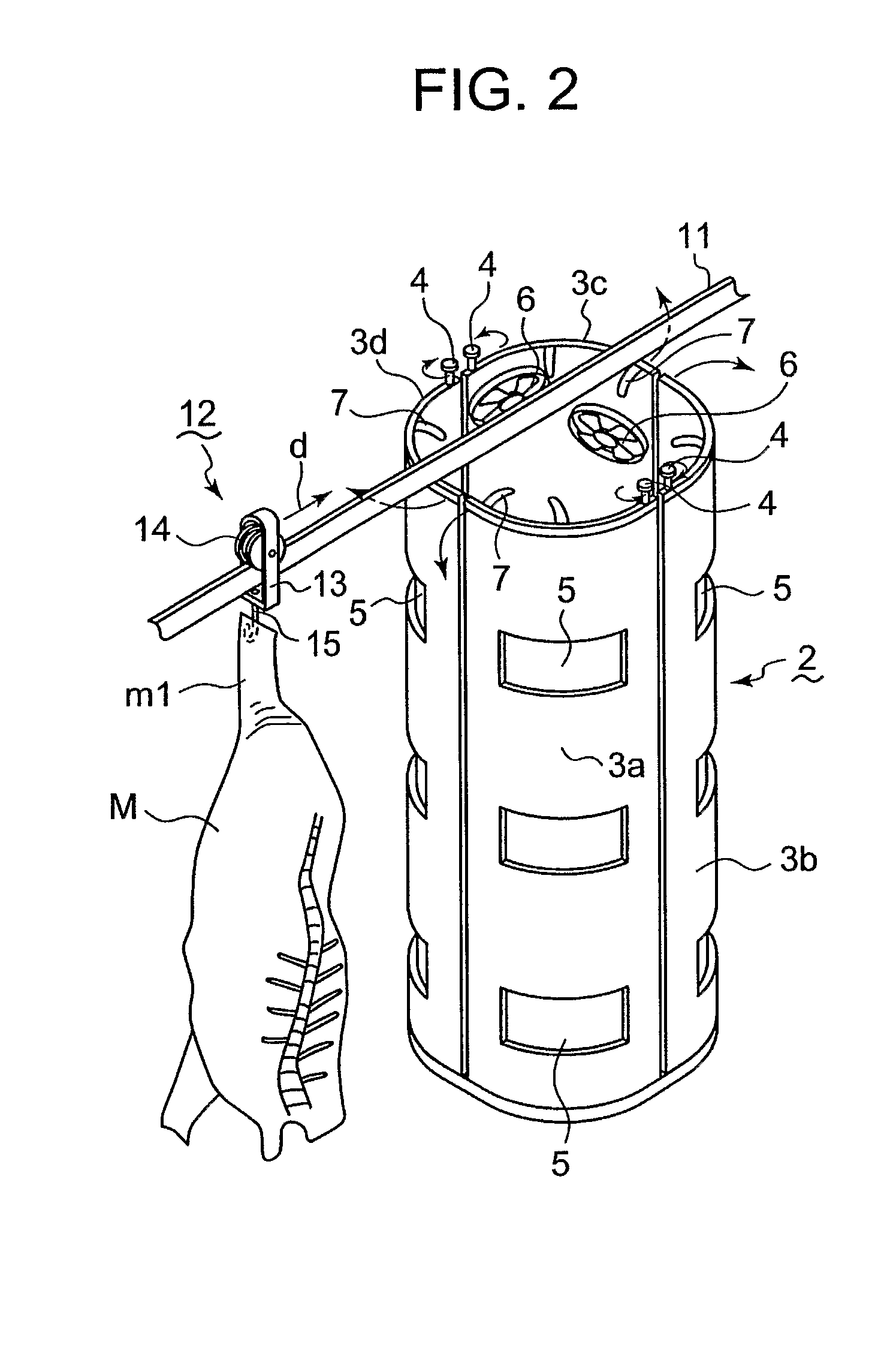

Method and apparatus for tempering of meat, tempered meat treated by the method, and refrigerated meat storage

InactiveUS20100075016A1Suppressing transpirationReduce the temperatureMilk preservationWort preparationCold airIce storage

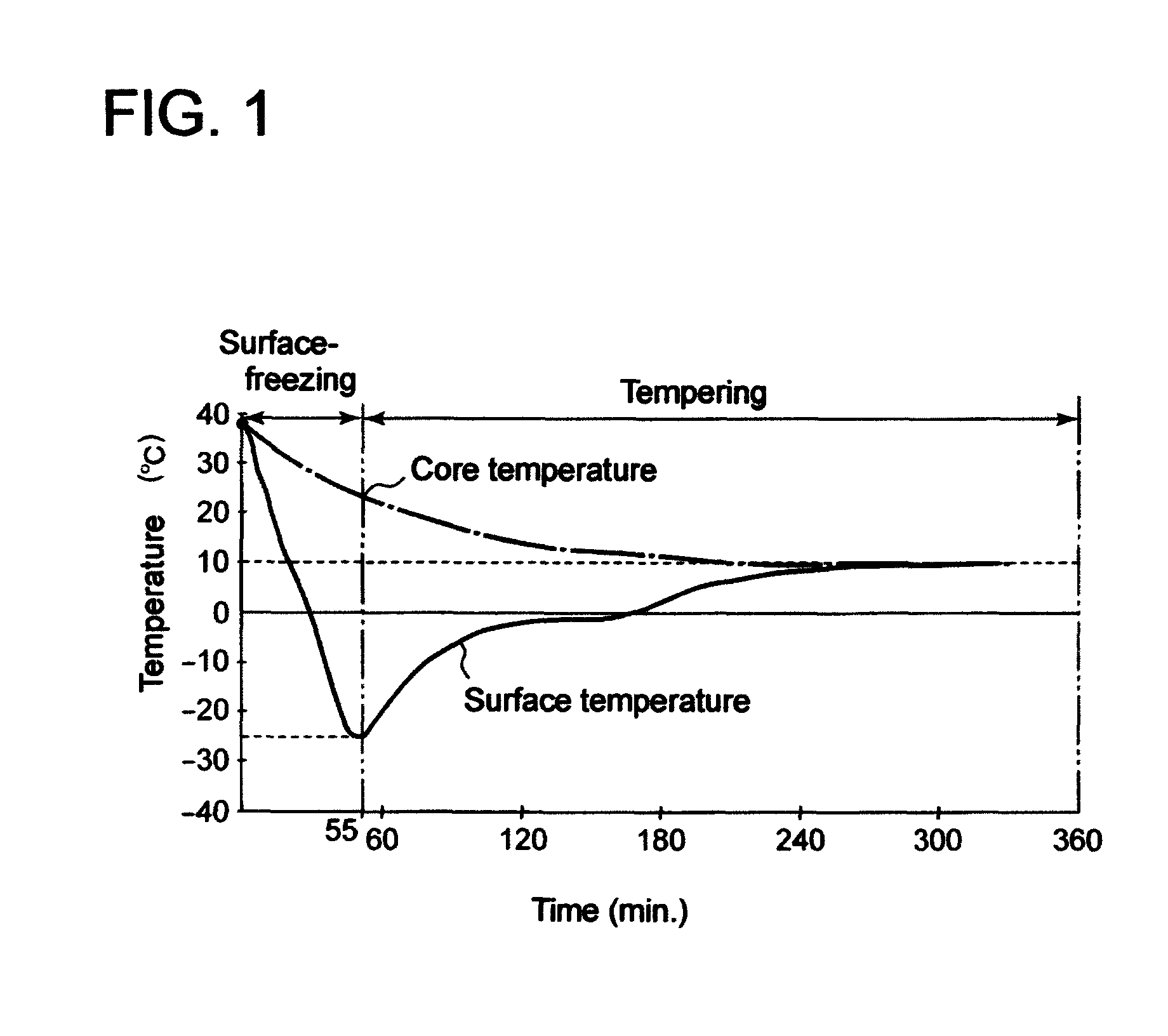

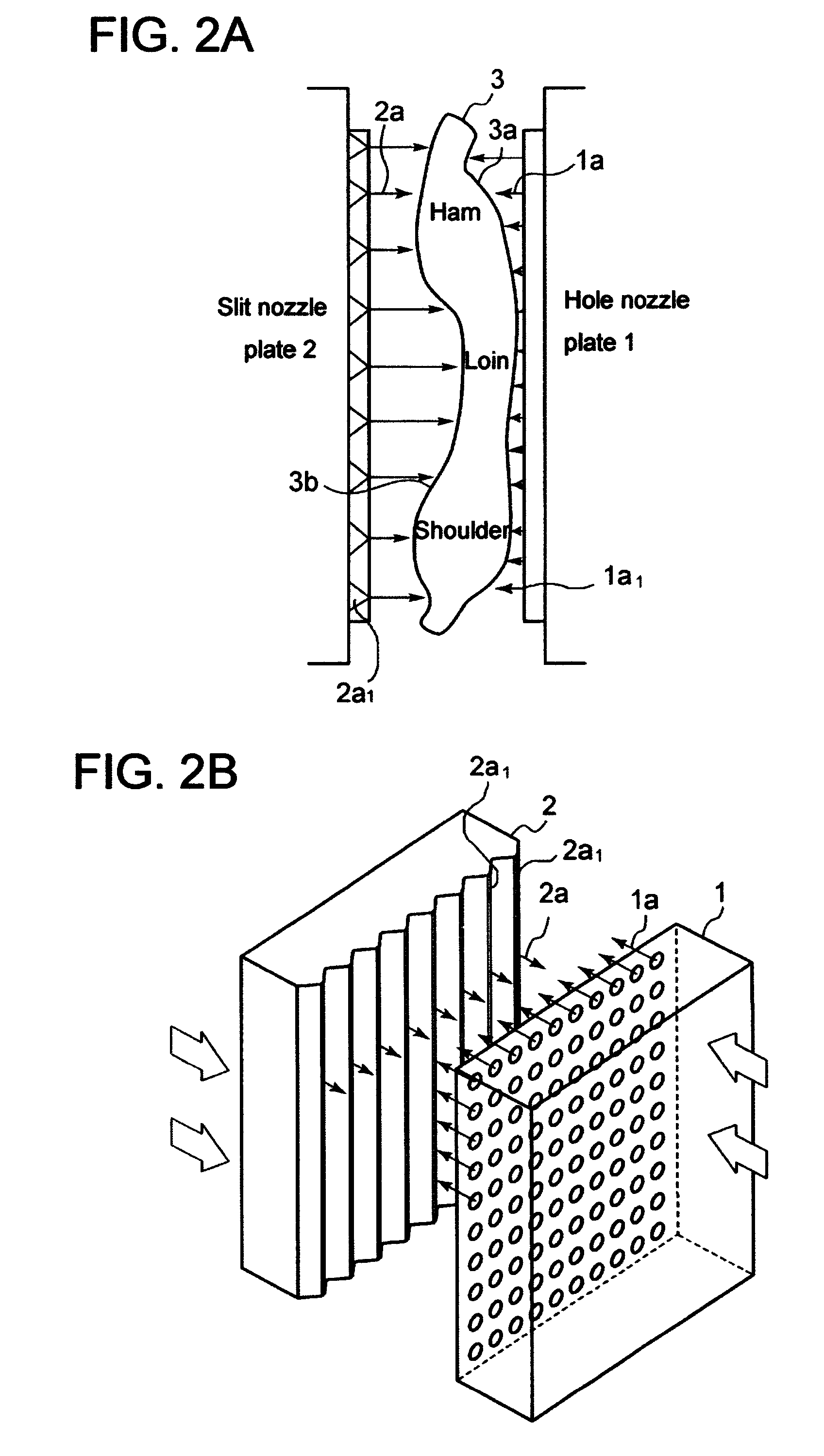

A tempering treatment method whereby the temperature of meat, which involves carcass prepared by slaughtering cattle or poultry and sterilizing and washing, is lowered as close to the ice storage temperature as possible to prevent a temperature rise caused by the actions of enzymes contained within the meat before transporting the meant to a refrigerated storage, which comprises surface-freezing the meat by blowing a cold air stream at about −20 to about −40° C. to the meant before conducting the tempering treatment, thus allowing the generation of freezing latent heat in the subcutaneous part owing to the surface-freezing (freezing the subcutaneous tissue), and then rapidly lowering the core temperature inside the meat due to the latent heat released at the melting of the freezing latent heat to thereby conduct the tempering treatment at a temperature of 0 to +15° C.

Owner:MAYEKAWA MFG CO LTD

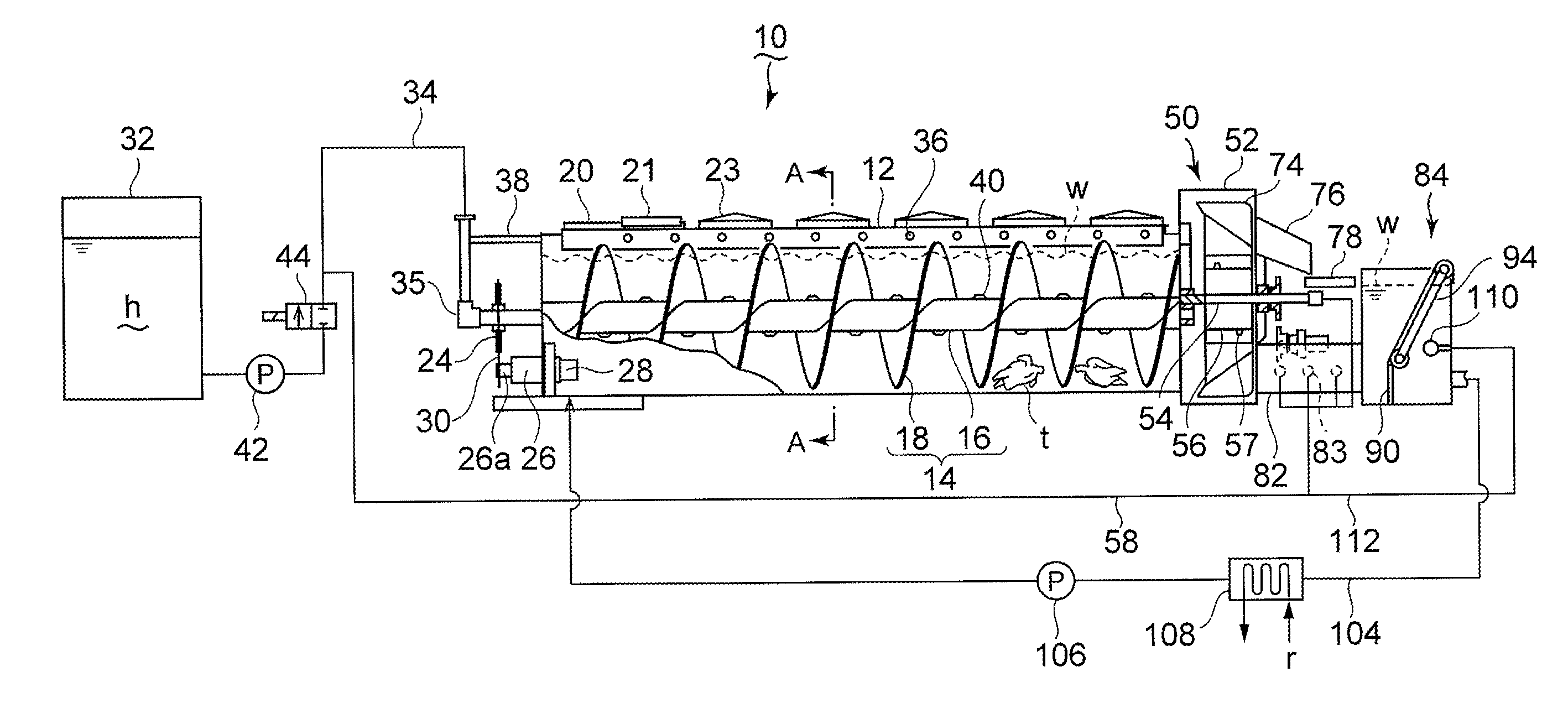

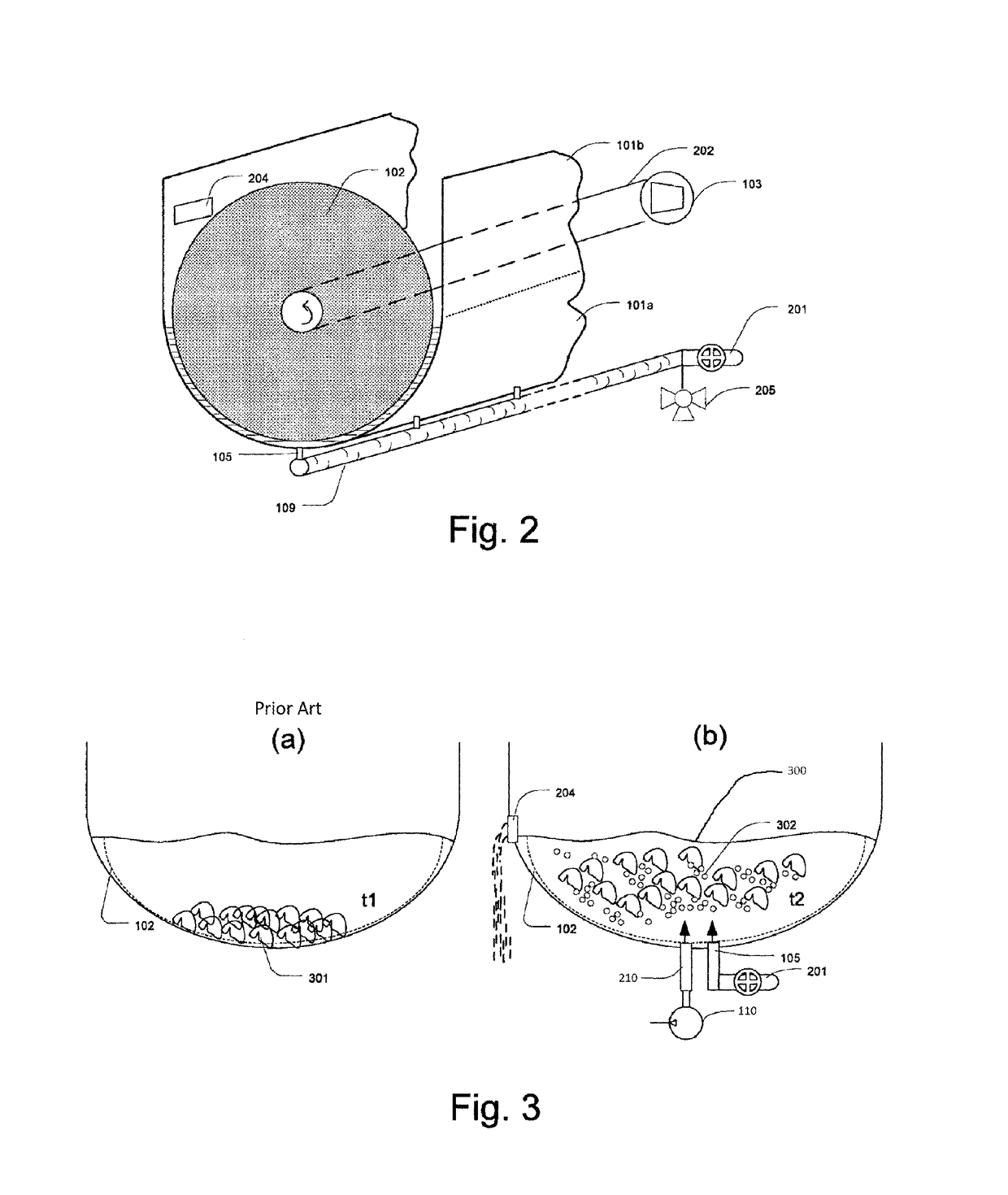

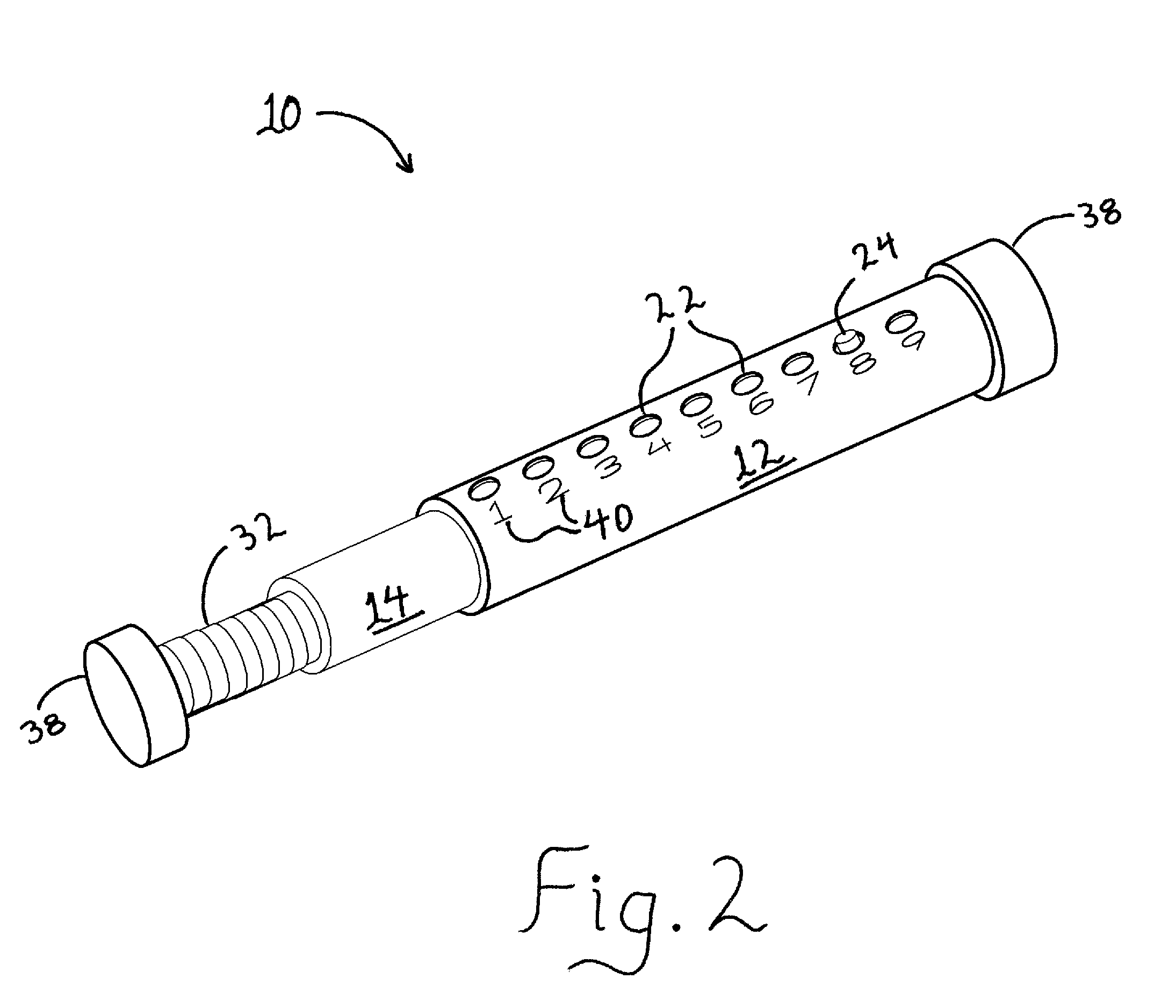

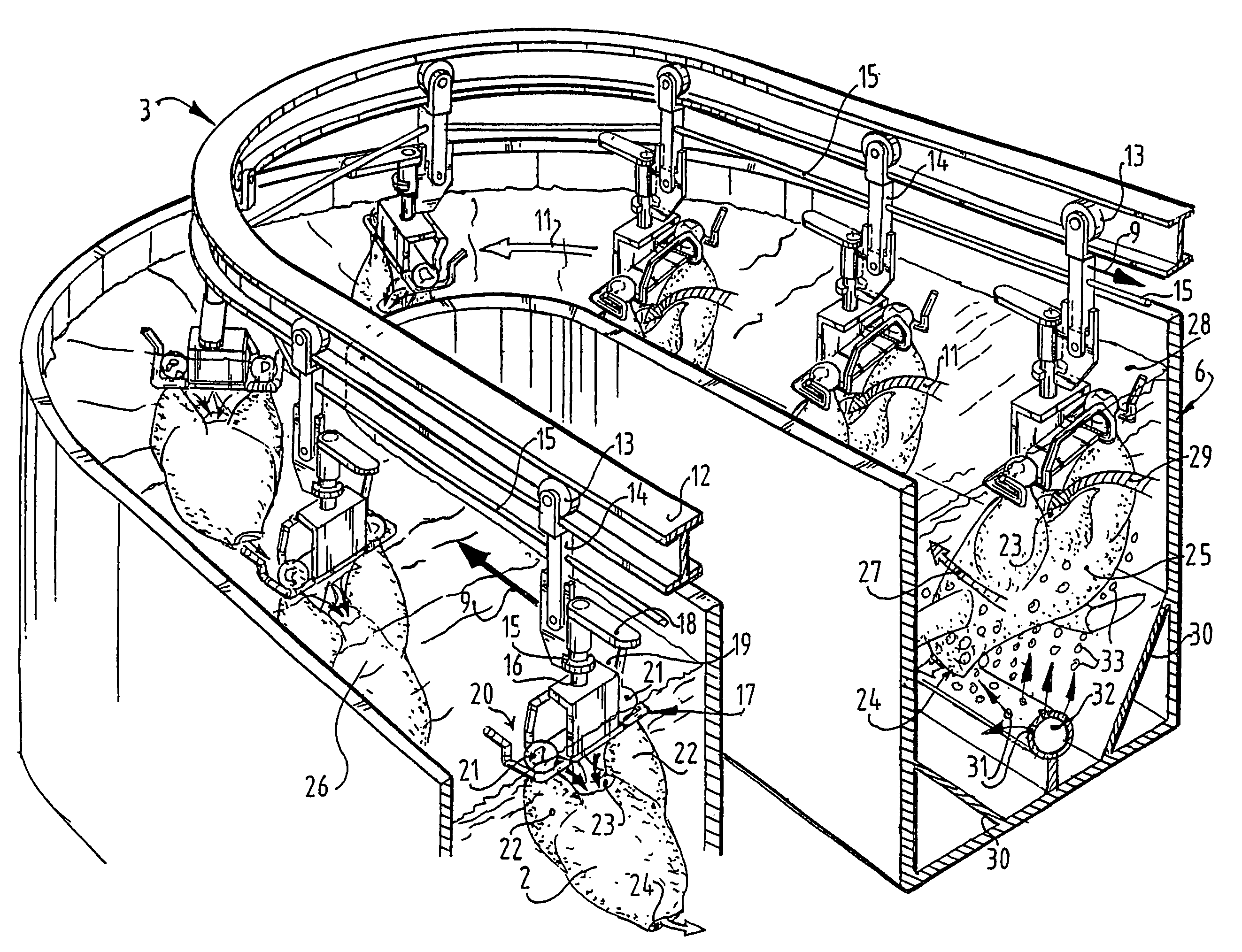

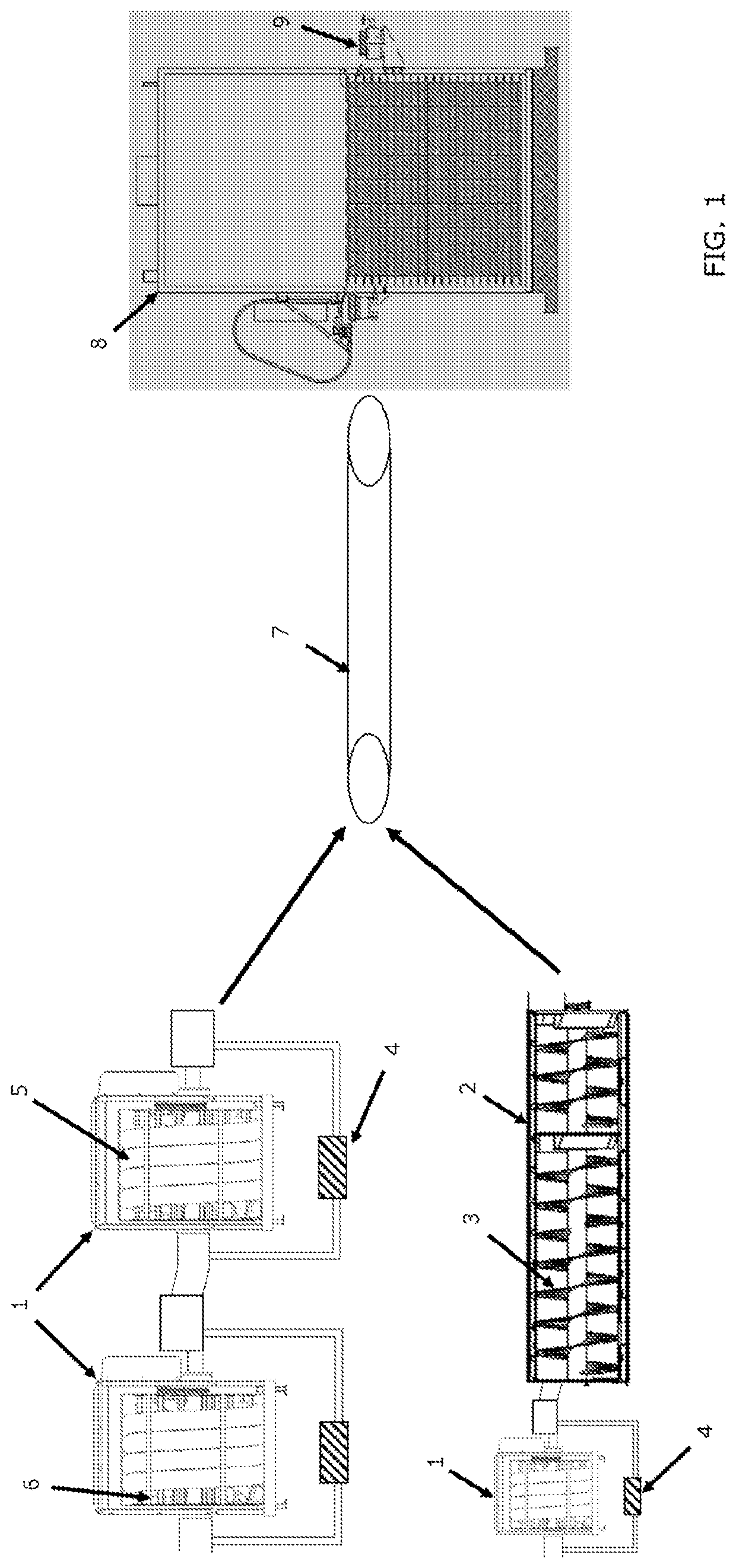

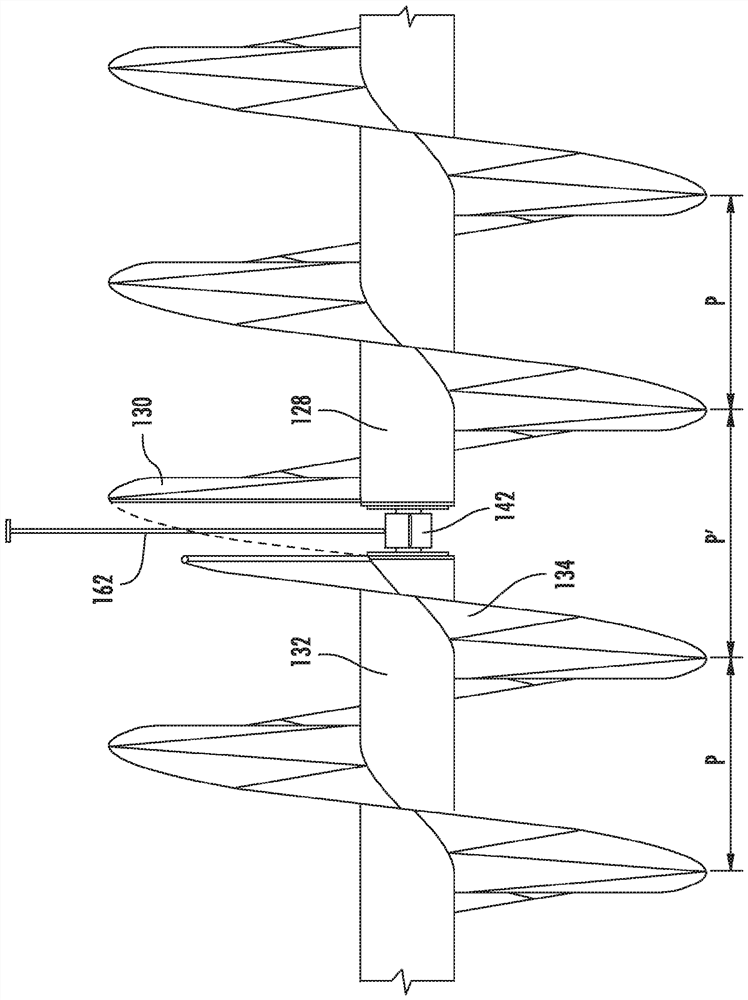

Poultry carcass cooling and conveying system

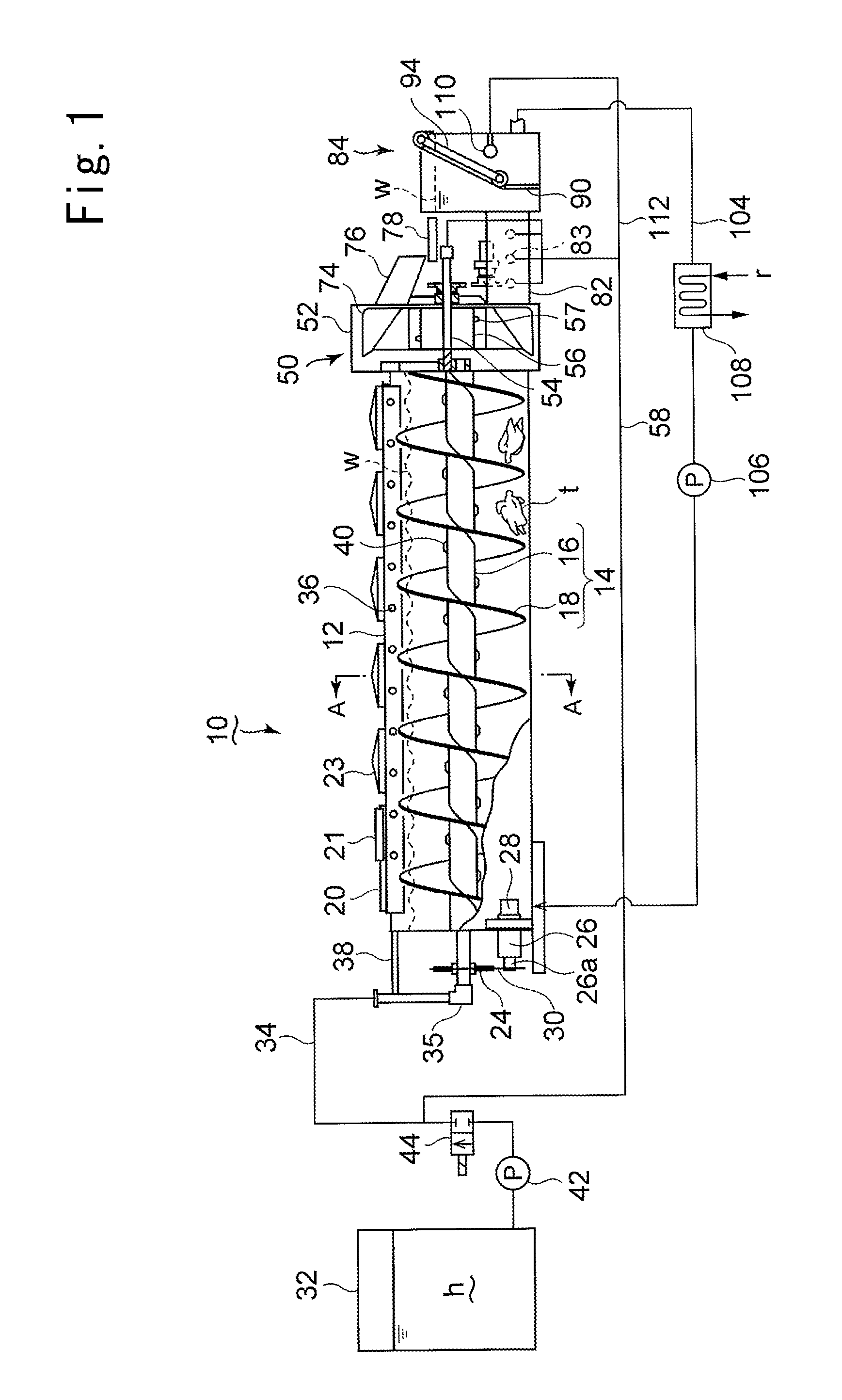

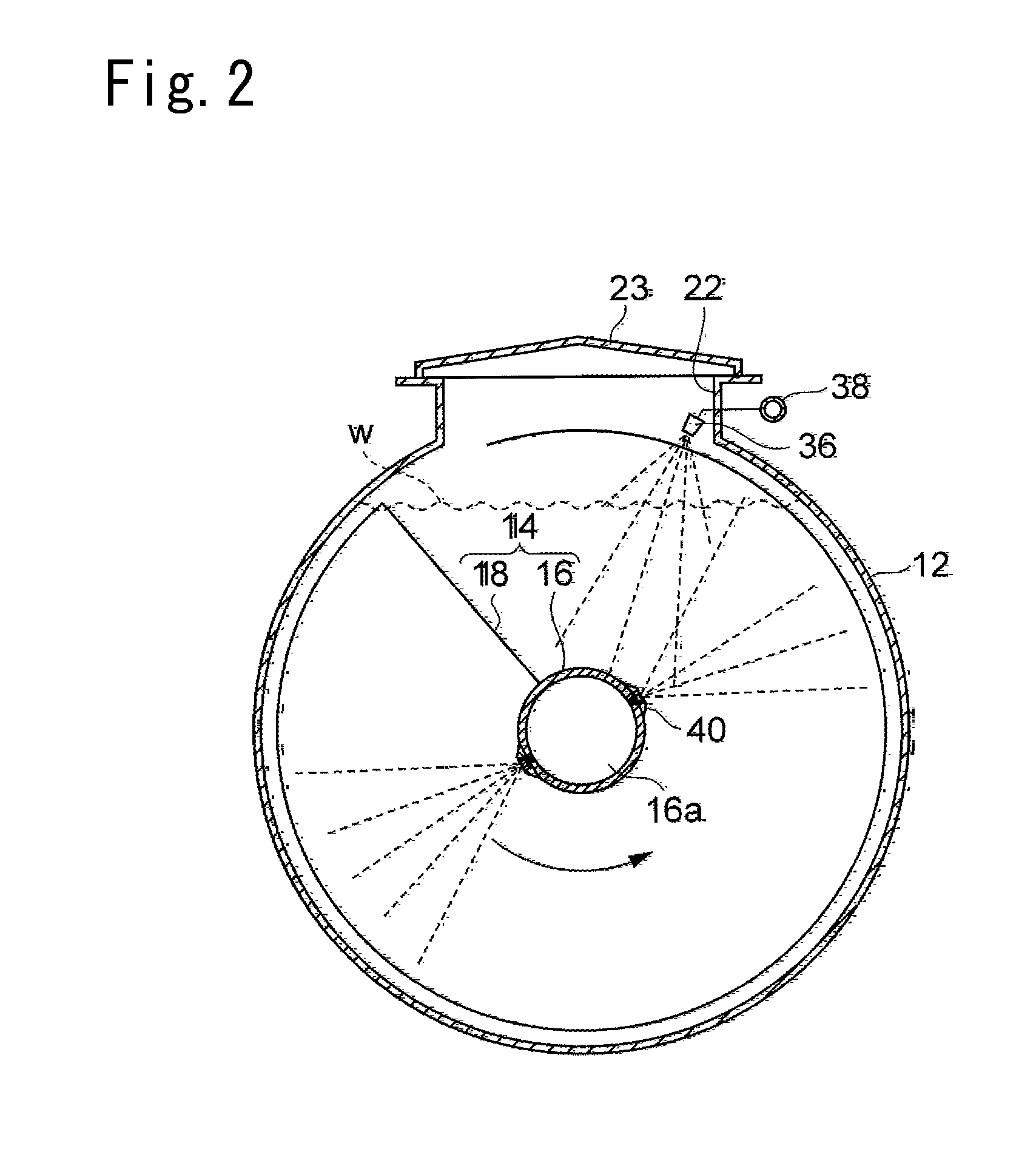

ActiveUS20140202659A1Increase the areaReduce areaMeat/fish preservationStationary refrigeration devicesWash waterEngineering

In a hollow cylindrical housing which stores a coolant, a feeding device having a rotating shaft and spiral screw vanes fixedly installed on the periphery of the rotating shaft is provided. At least one first diffusion nozzle is provided in each pitch of the screw vanes on the inner wall of the housing. A pair of second diffusion nozzles are provided for every pitch of the screw vanes on the outer periphery of the rotating shaft respectively at different positions in the axial direction of the rotating shaft and at mutually opposite positions in the circumferential direction of the rotating shaft. The first diffusion nozzles are supplied with wash water through a high-temperature water piping provided on the upper outside of the housing, while the second diffusion nozzles are supplied with wash water through a channel formed in the interior of the rotating shaft.

Owner:MAYEKAWA MFG CO LTD

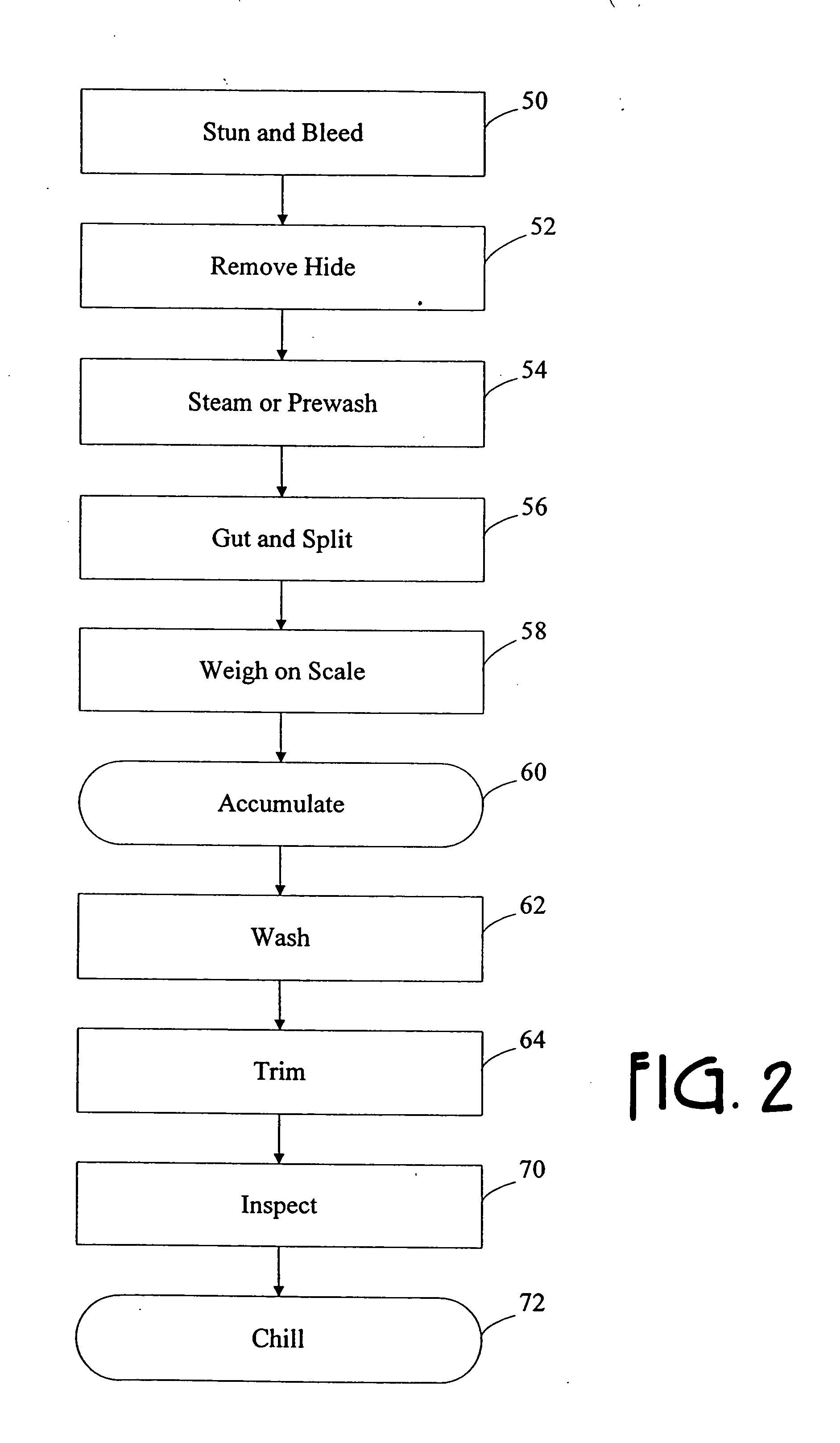

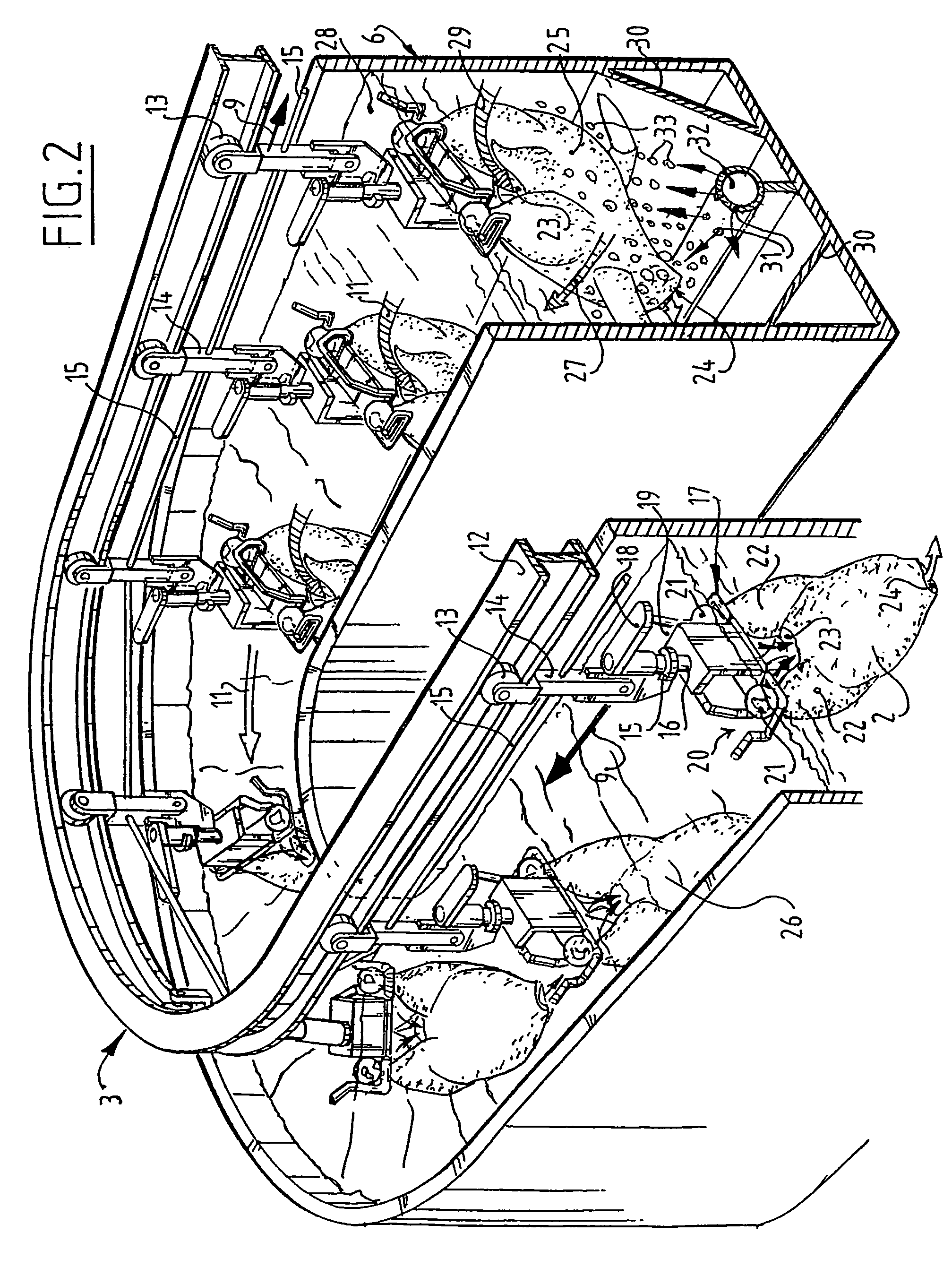

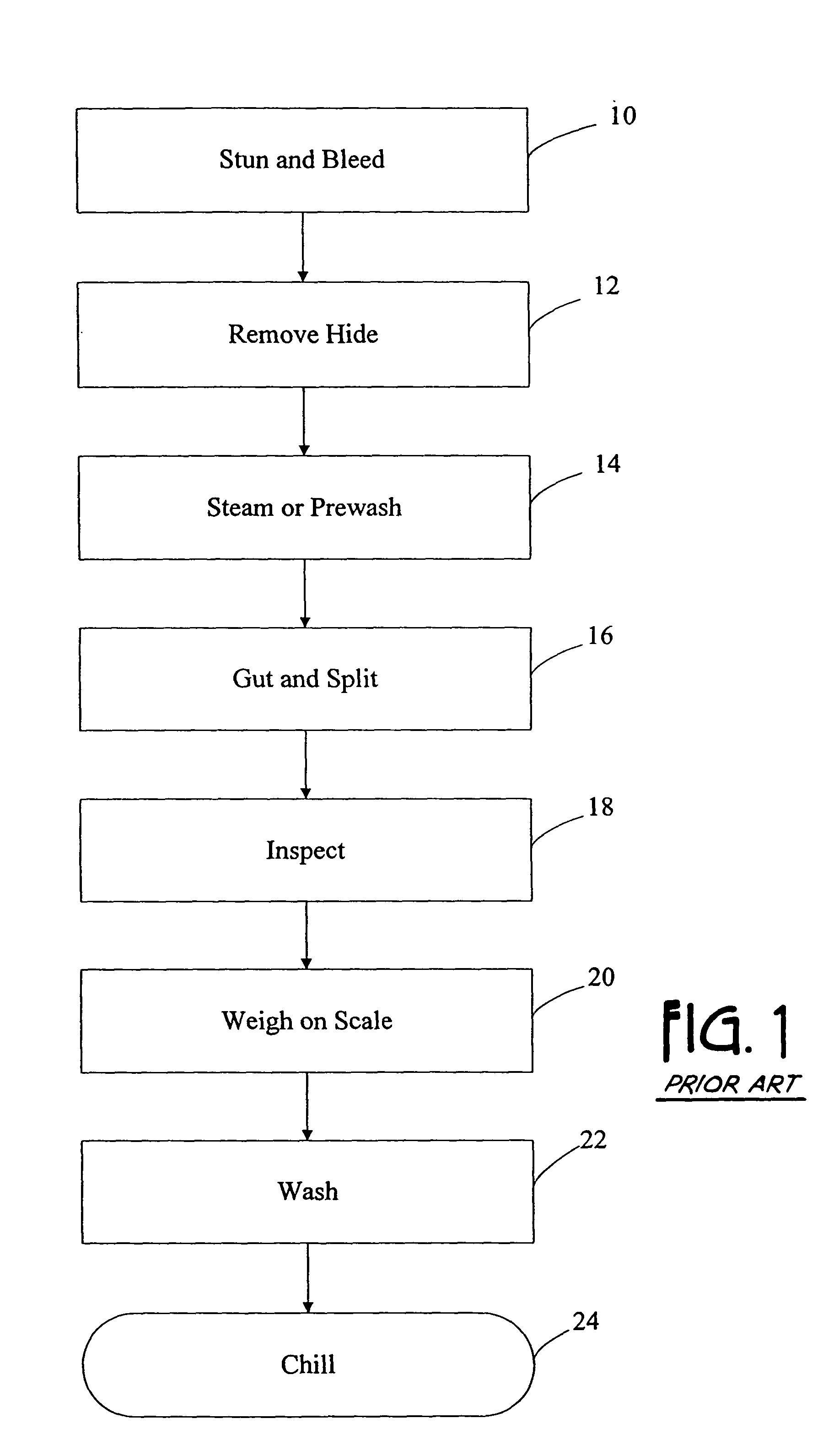

Method and apparatus for processing carcasses

InactiveUS20050042980A1Animal stomach clearanceFish washing/descalingProcess engineeringProcessed meat

A method for processing meat along a meat processing line. The method includes removing viscera from a carcass, accumulating the carcass along a dead rail stack of the meat processing line, washing the carcass, and inspecting the carcass at an inspection station following the act of washing the carcass.

Owner:CARGILL INC

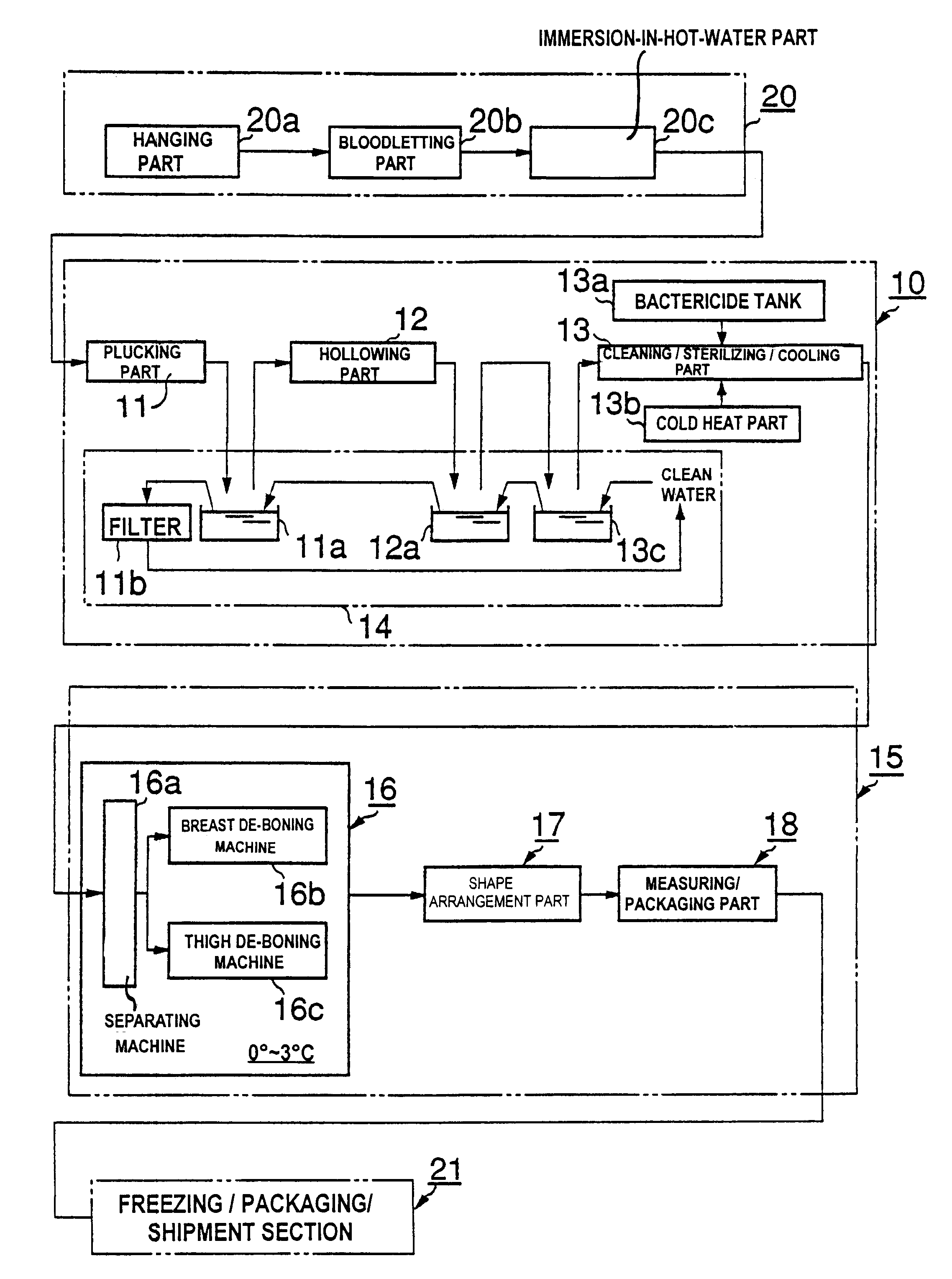

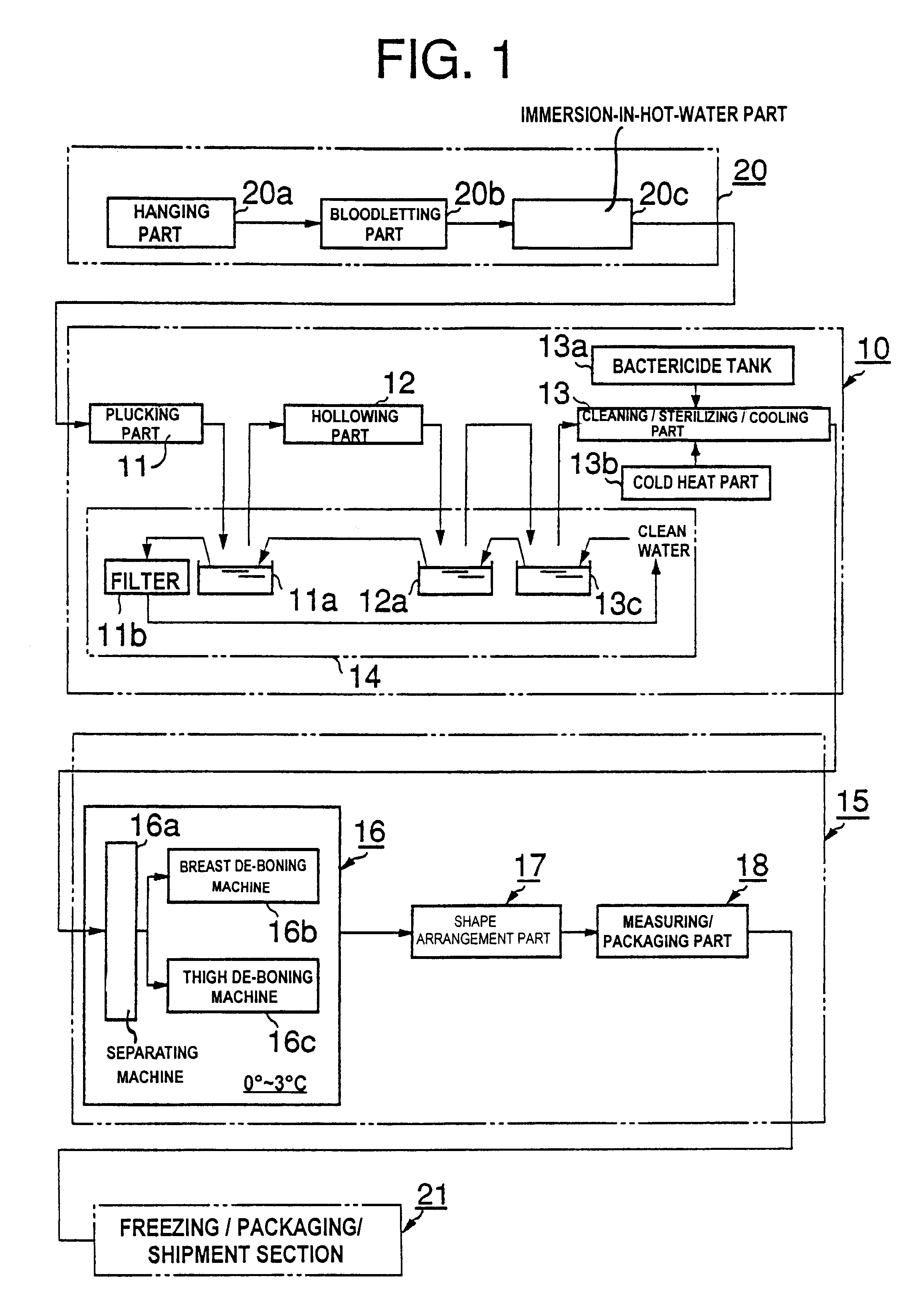

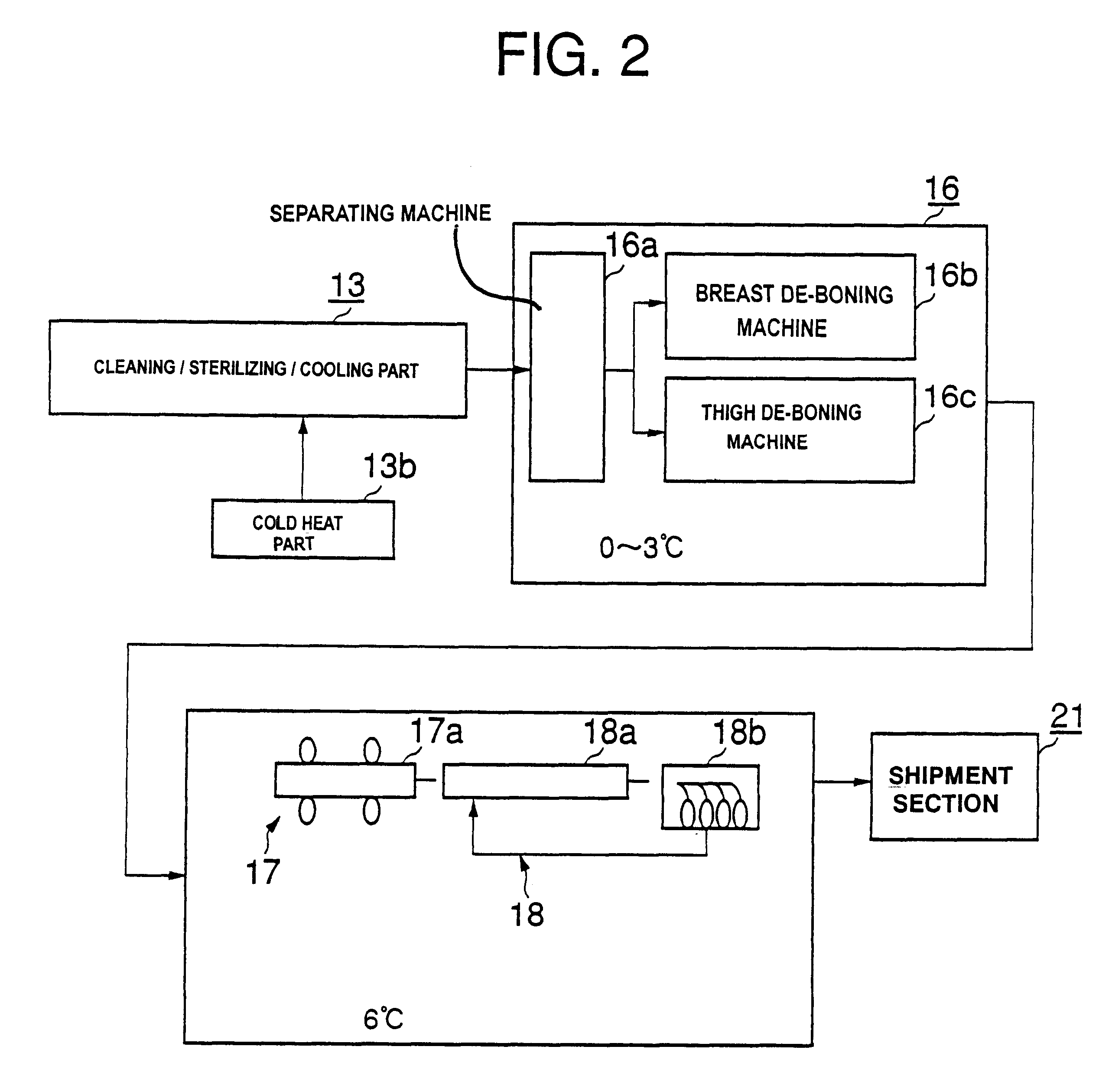

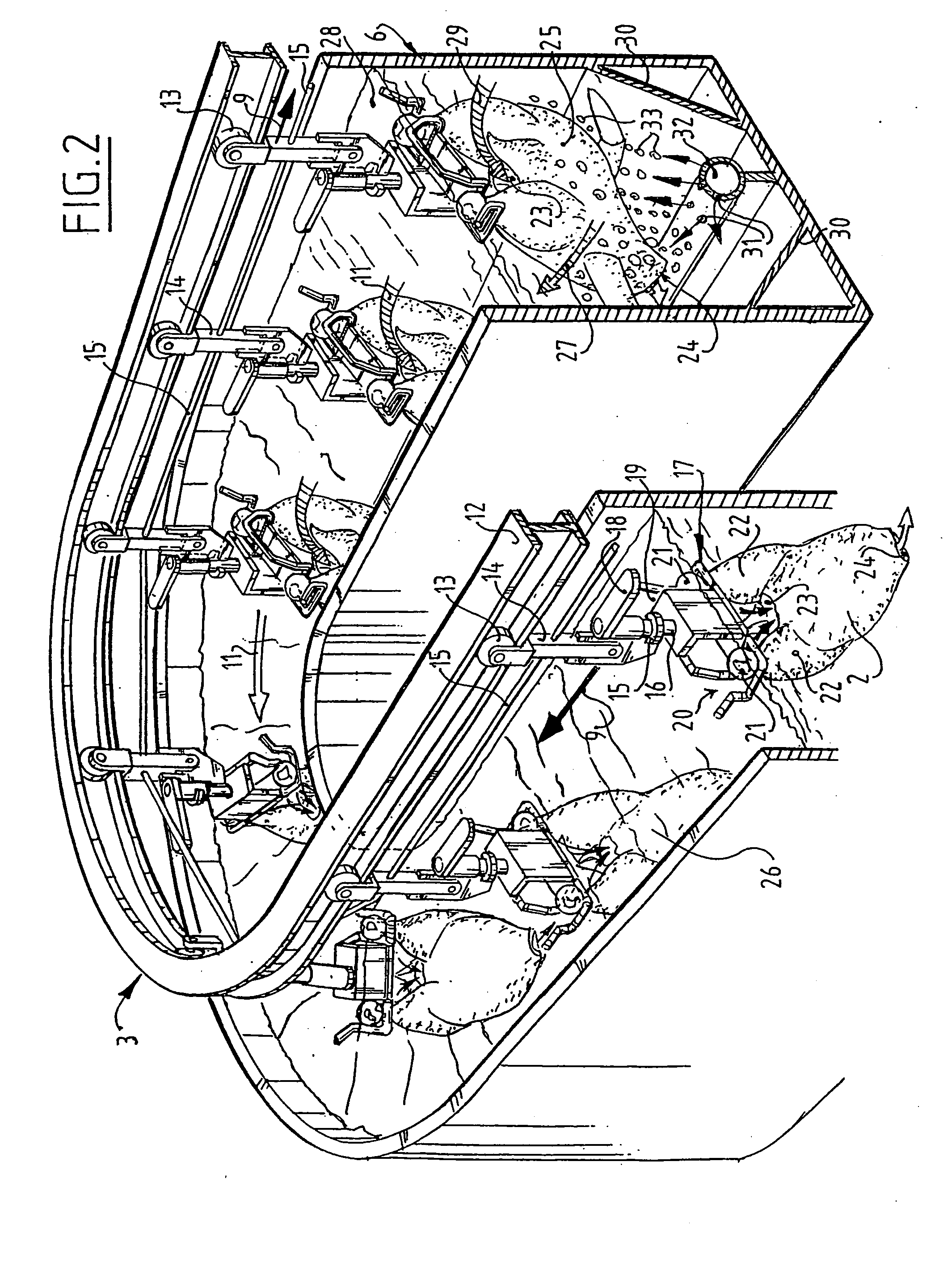

Poultry processing method and system

A poultry treatment system relating to dissection, shape arrangement, and dispensing treatment, which can prevent the growth of bacteria in cleaning, cooling, and succeeding treatment processes for making possible the securing of the least contaminated state (the number of common live bacteria carried by a packed article of 2 kg is 102), composed of; a pretreatment section 20 comprising hanging part 20a, bloodletting part 20b, immersion-in-hot-water part 20c; a treatment section 10 comprising a plucking part 11, hollowing part 12, cleaning / sterilizing / cooling part 13, and water-washing part 14; a dissecting / dispensing / packaging section comprising a automatic dissection part 16, shape arrangement part 17, dispensing / packaging part 18; and shipment section 21.

Owner:MAYEKAWA MFG CO LTD

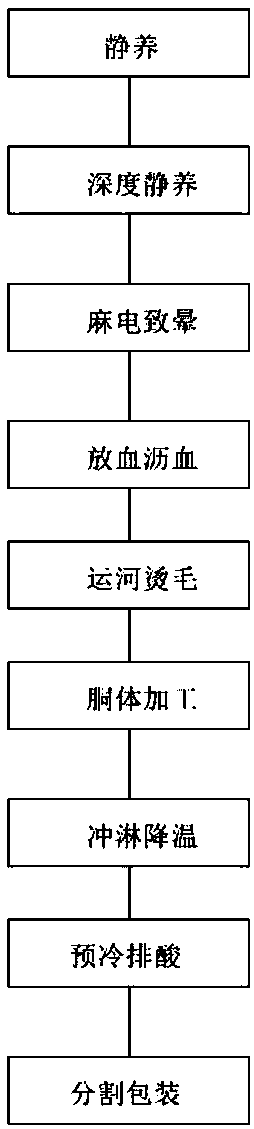

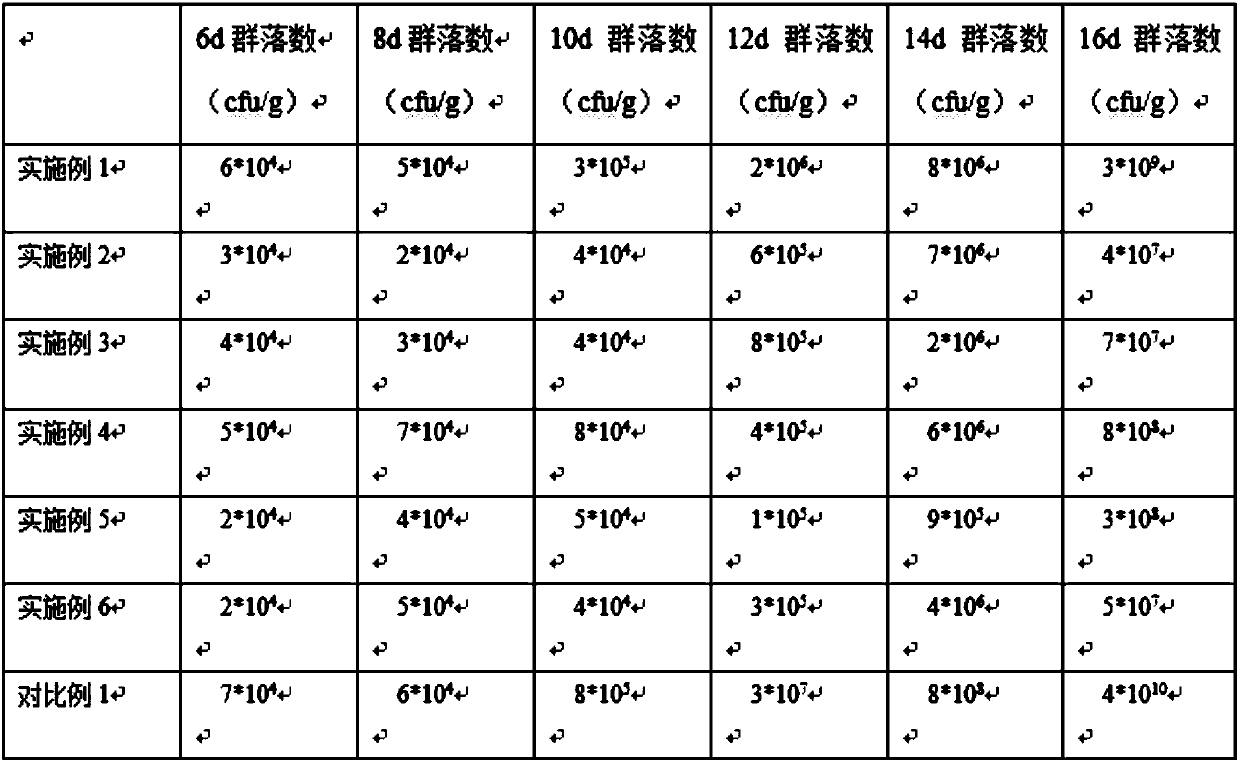

Slaughtering and producing technology of safety pigs

InactiveCN107668151AReduce formationBright colorPackaging meatElectric current slaughtering/stunningElectricityLean meat

The invention discloses a slaughtering and producing technology of safety pigs. The slaughtering and producing technology comprises the following steps of: a. performing relaxation; b. performing deeprelaxation: after the pigs to be slaughtered are in relaxation, showering the pigs with water for 3-5 minutes, wherein when the season for deep relaxation is summer, the water temperature is 20 DEG C, and when the season for deep relaxation is winter, the water temperature is 38 DEG C; c. performing electric-shock for stunning; d. performing bloodletting and bleeding; e. performing transferring and scalding; f. performing carcass processing; g. performing showering for cooling; h. performing pre-cooling and acid discharge; and i. performing segmentation and packaging: wherein in the whole segmentation process of chilled meat, the temperature of a segmentation workshop is less than or equal to 12 DEG C, the temperature of a packaging workshop is less than or equal to 10 DEG C, and the segmented chilled meat is safety pork, putting the safety pork on a tray with absorbent paper being spread, then transferring the safety pork into a packaging machine, performing overlay film packaging, and in the packaging process, charging mixed gas consisting of oxygen and carbon dioxide in the ratio of the oxygen to the carbon dioxide being 1 to 4 into an overlay film. According to the slaughtering and producing technology disclosed by the invention, the residual heat inside the product is reduced by water gradient, the product loss is smaller, and the lean meat of the product in the market isbrighter in color.

Owner:成都春源食品有限公司

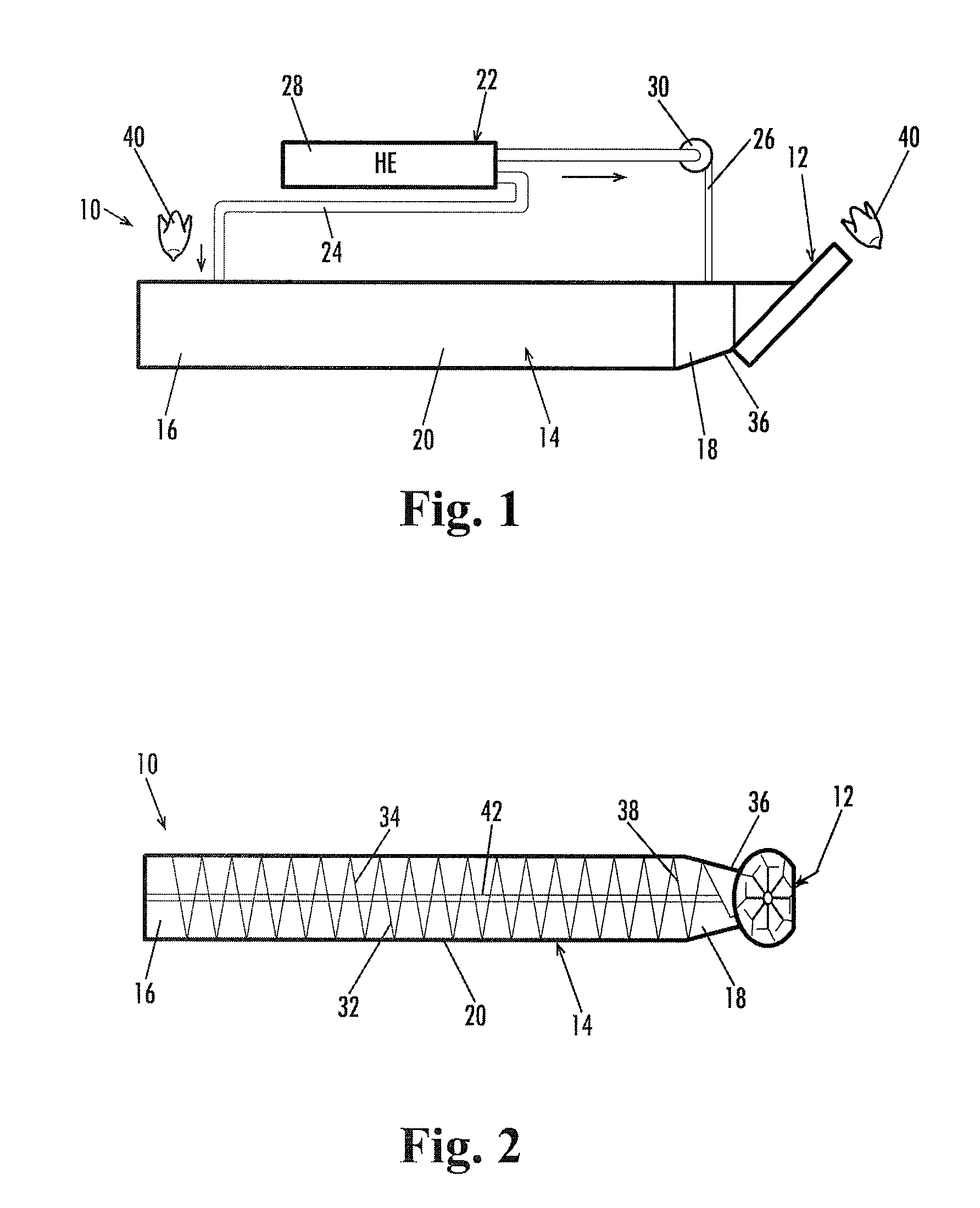

Apparatus for thawing or cooling food products

ActiveUS10149486B2Effectively thaw and coolEffective thawing or cooling systemLighting and heating apparatusStationary refrigeration devicesTemperature controlControl system

An apparatus for thawing or cooling food products includes a tank adapted to be at least partly filled with a liquid. A spiral shaped blade extends between a first end and a second end of the tank, where the spiral shaped blade is mounted to a rotation axis which operates rotational movement of the spiral shaped bladed and thus the conveying of the food products from the first end towards the second end. A temperature controlling system is provided and adapted to control the temperature of the liquid by arranging multiple heat supplying units along the tank for injecting heating or cooling agents into the liquid so as to provide a substantial temperature distribution into the thawing liquid during the thawing or cooling of the food products.

Owner:3X TECH

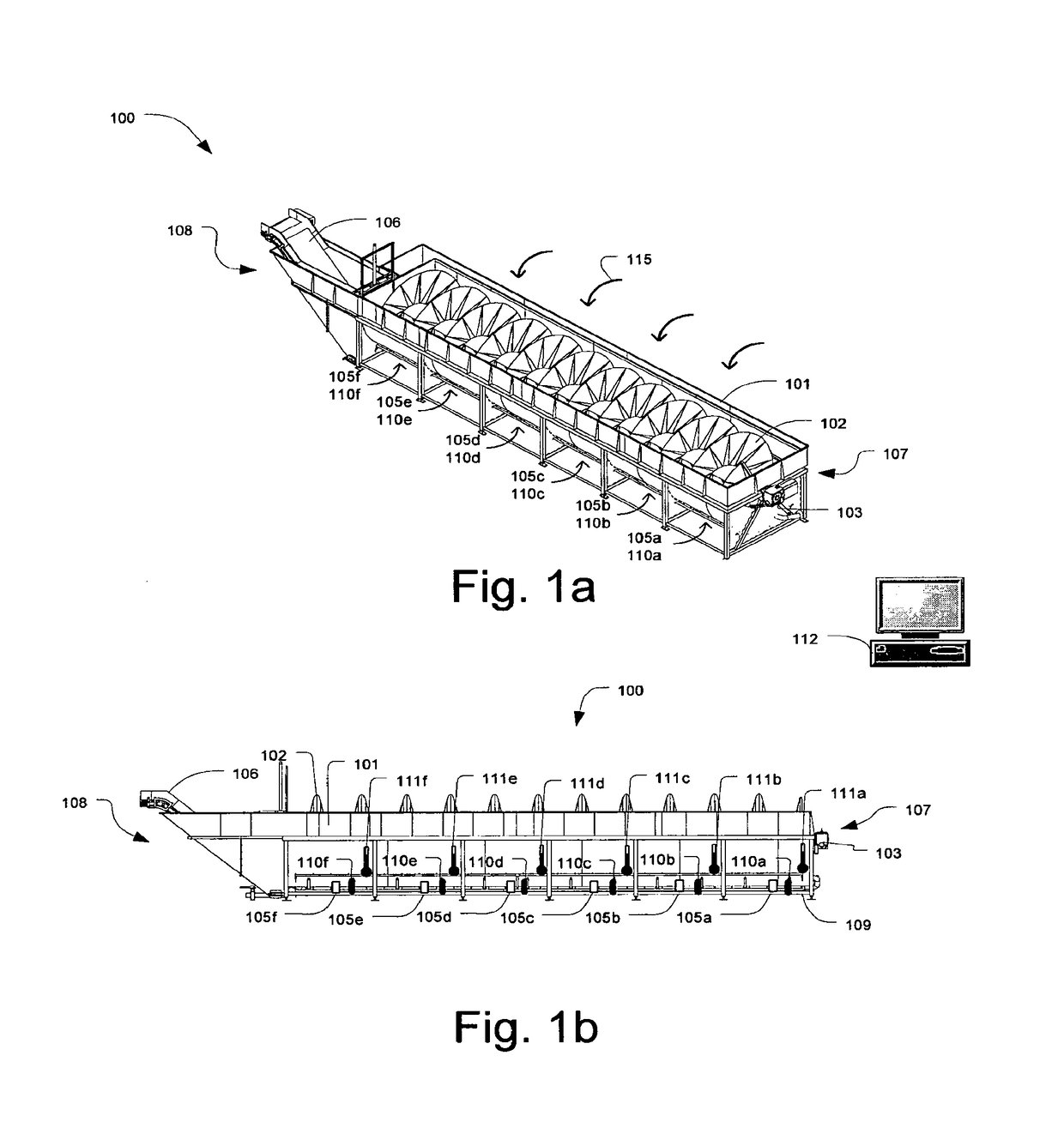

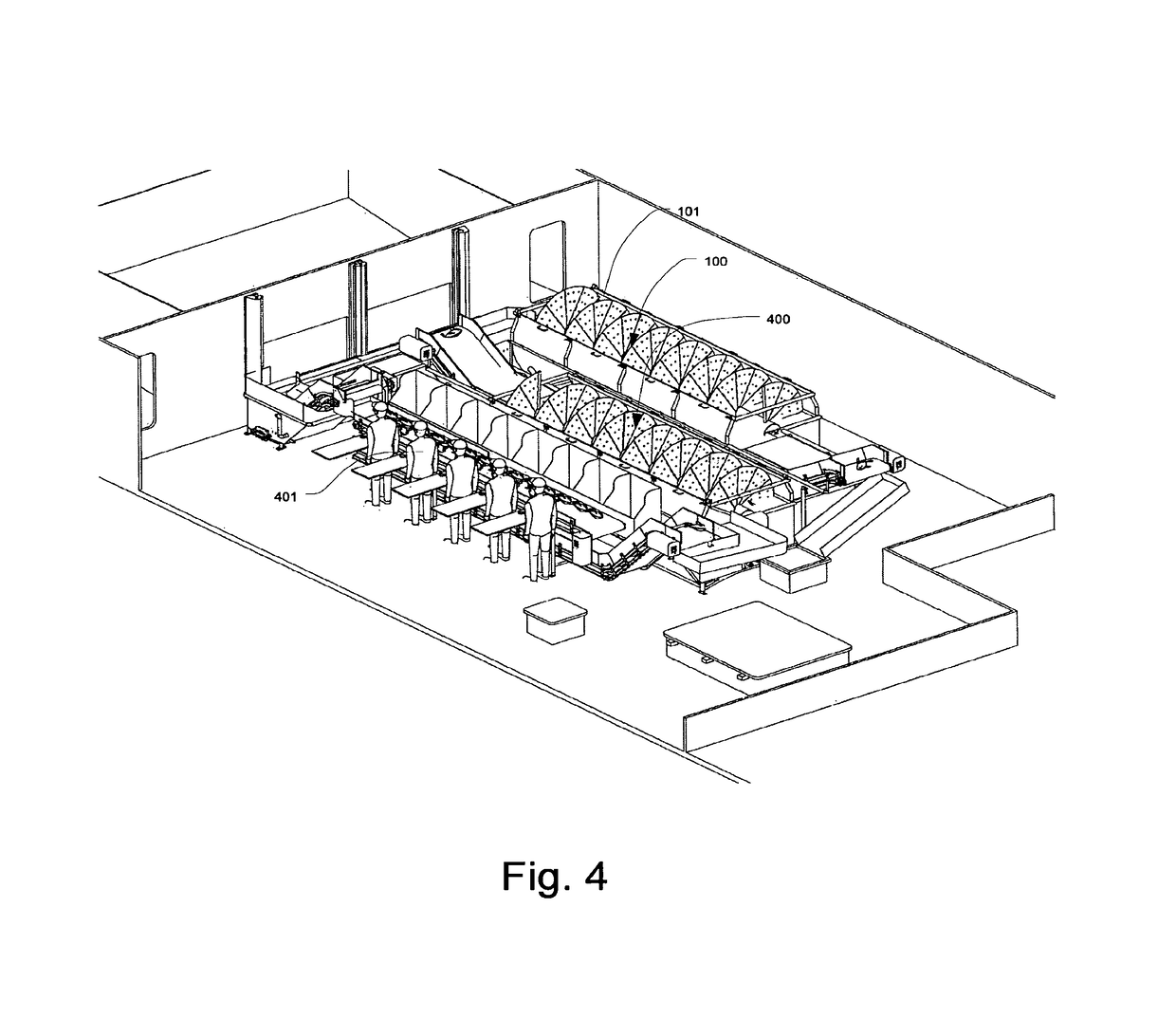

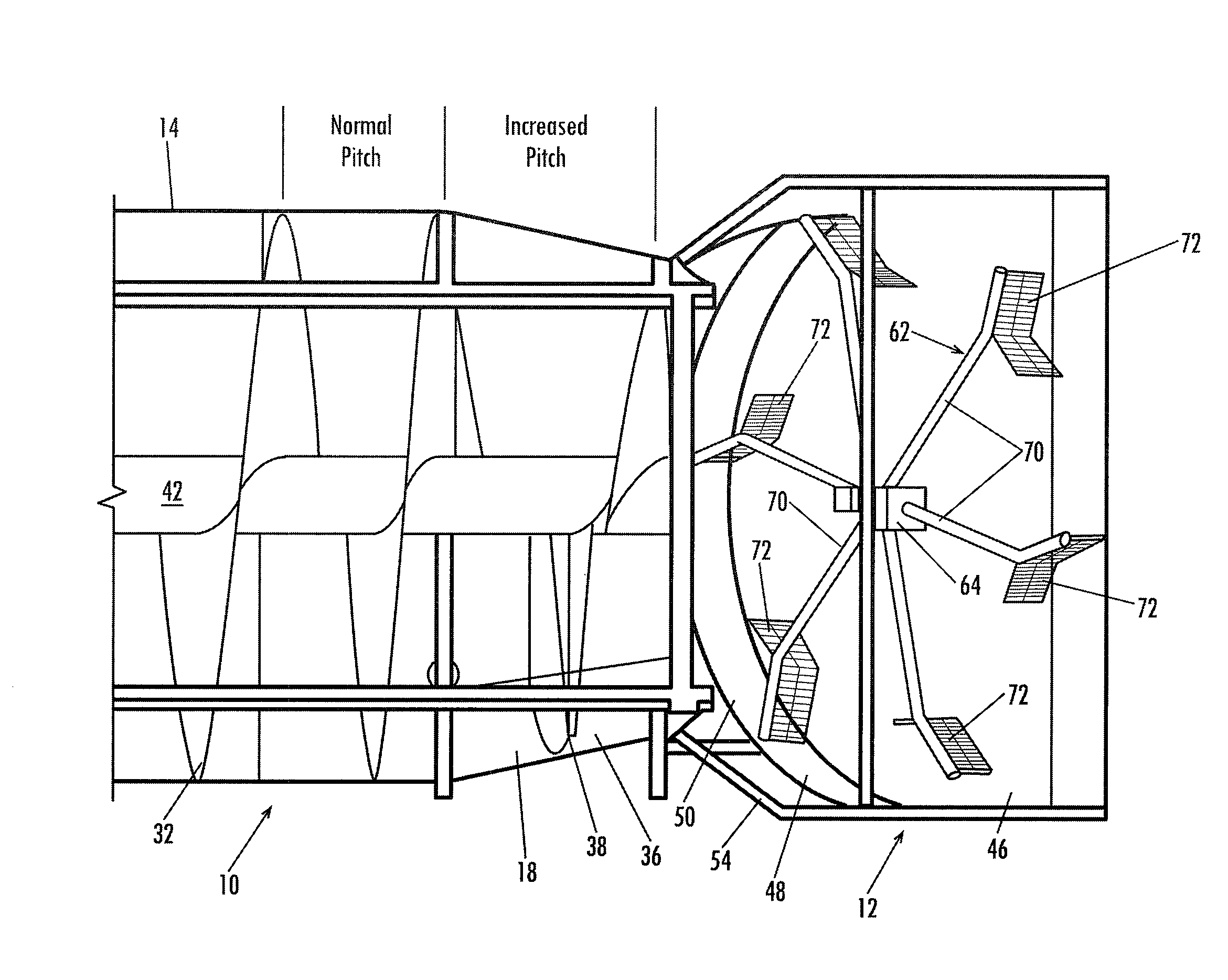

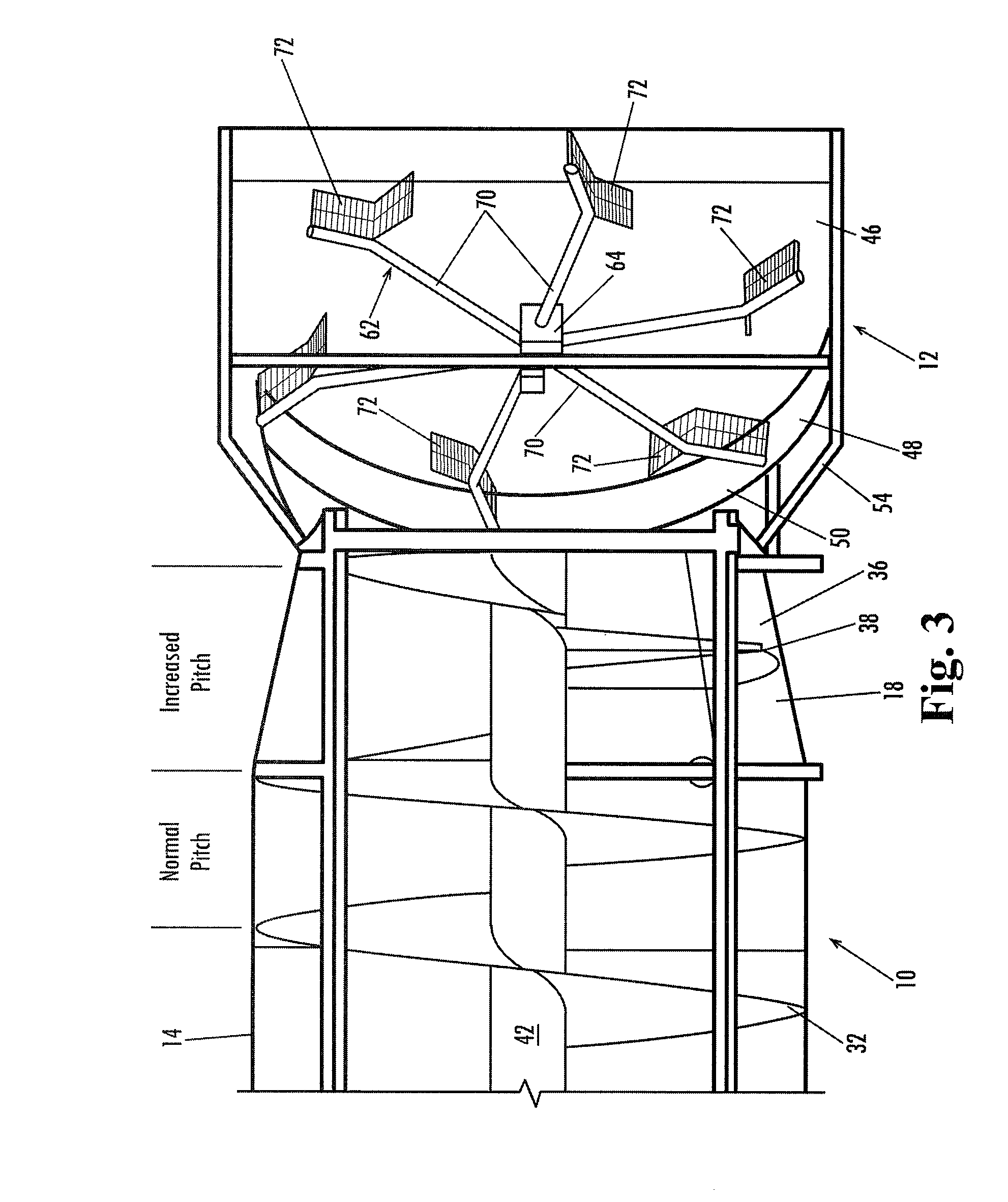

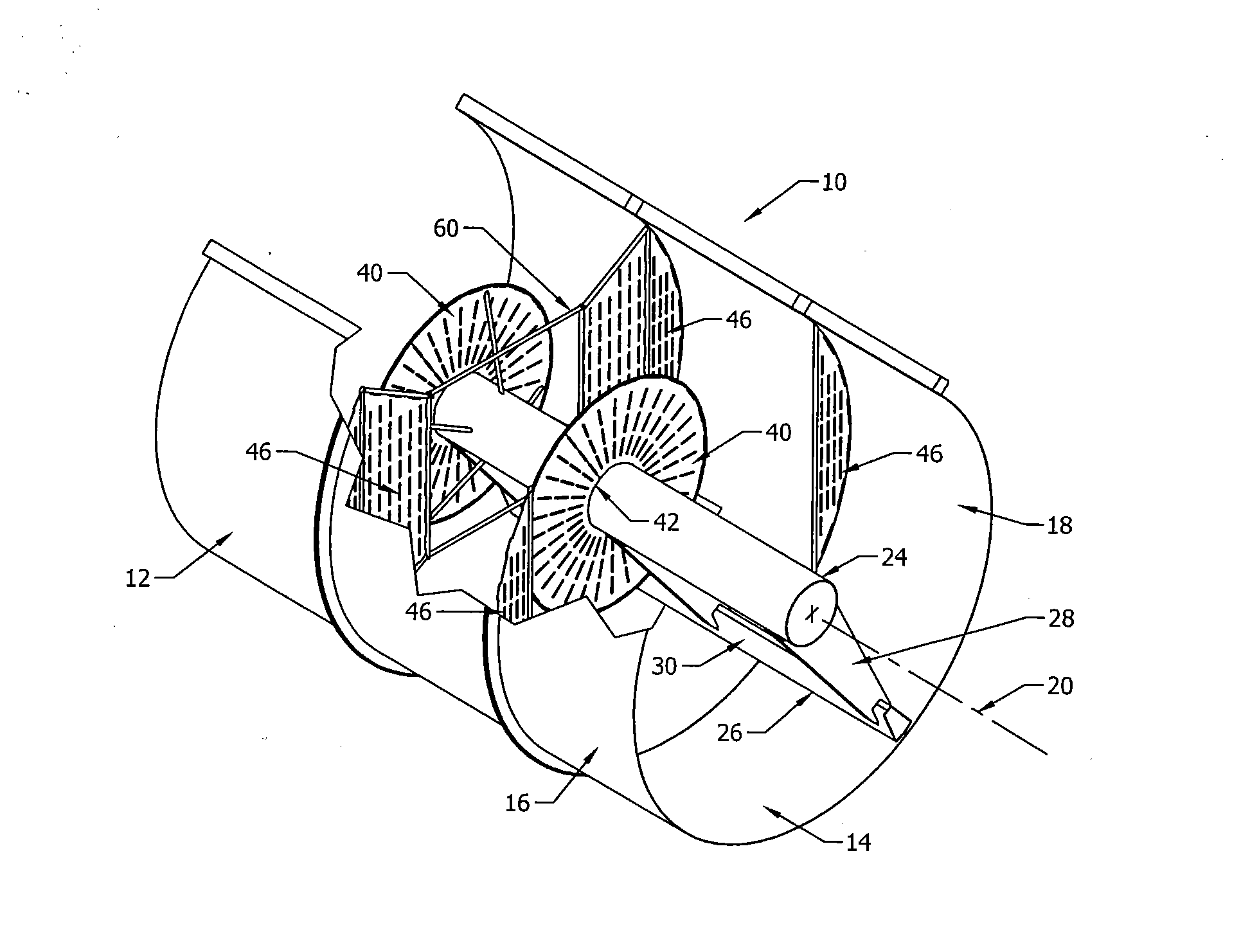

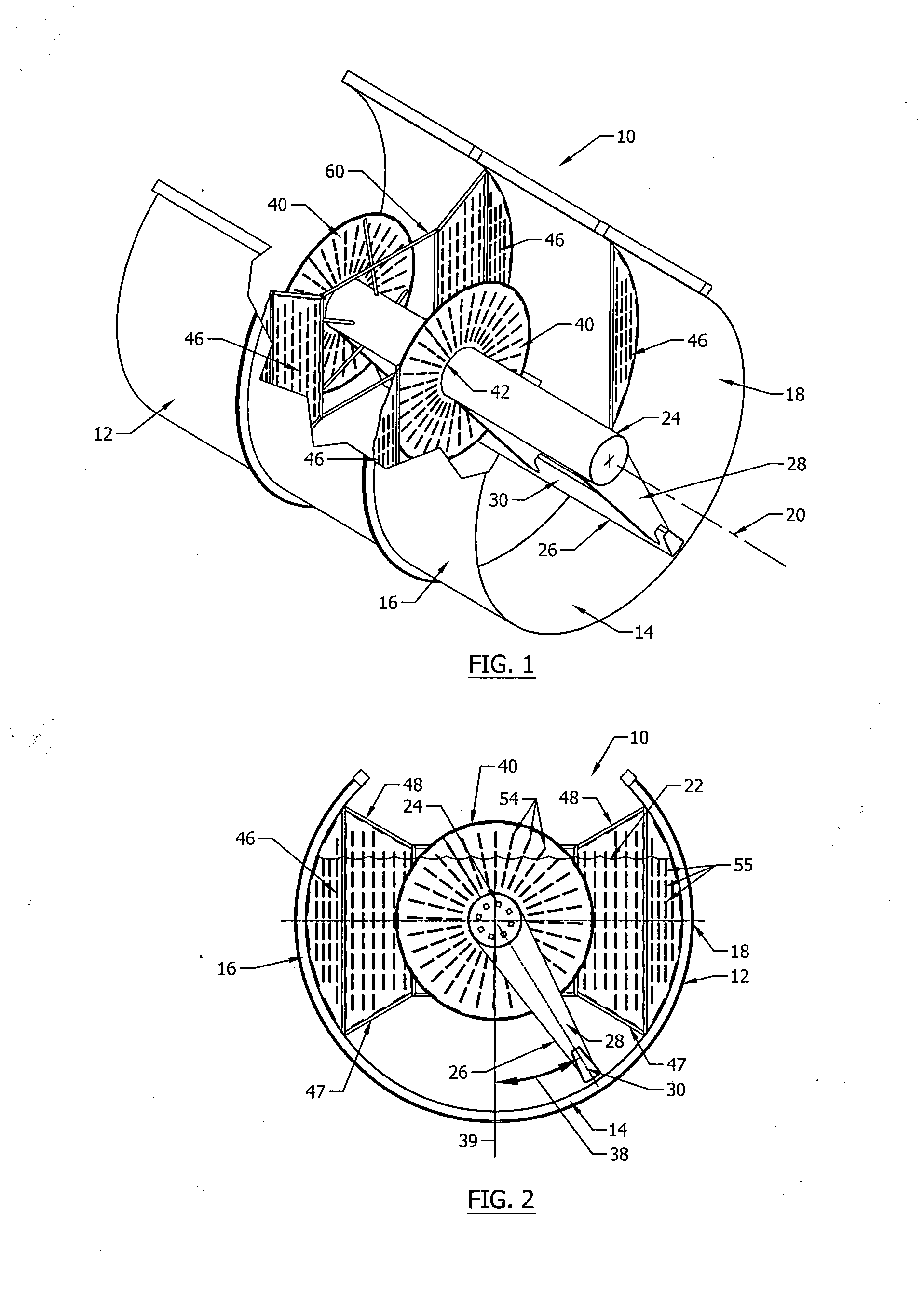

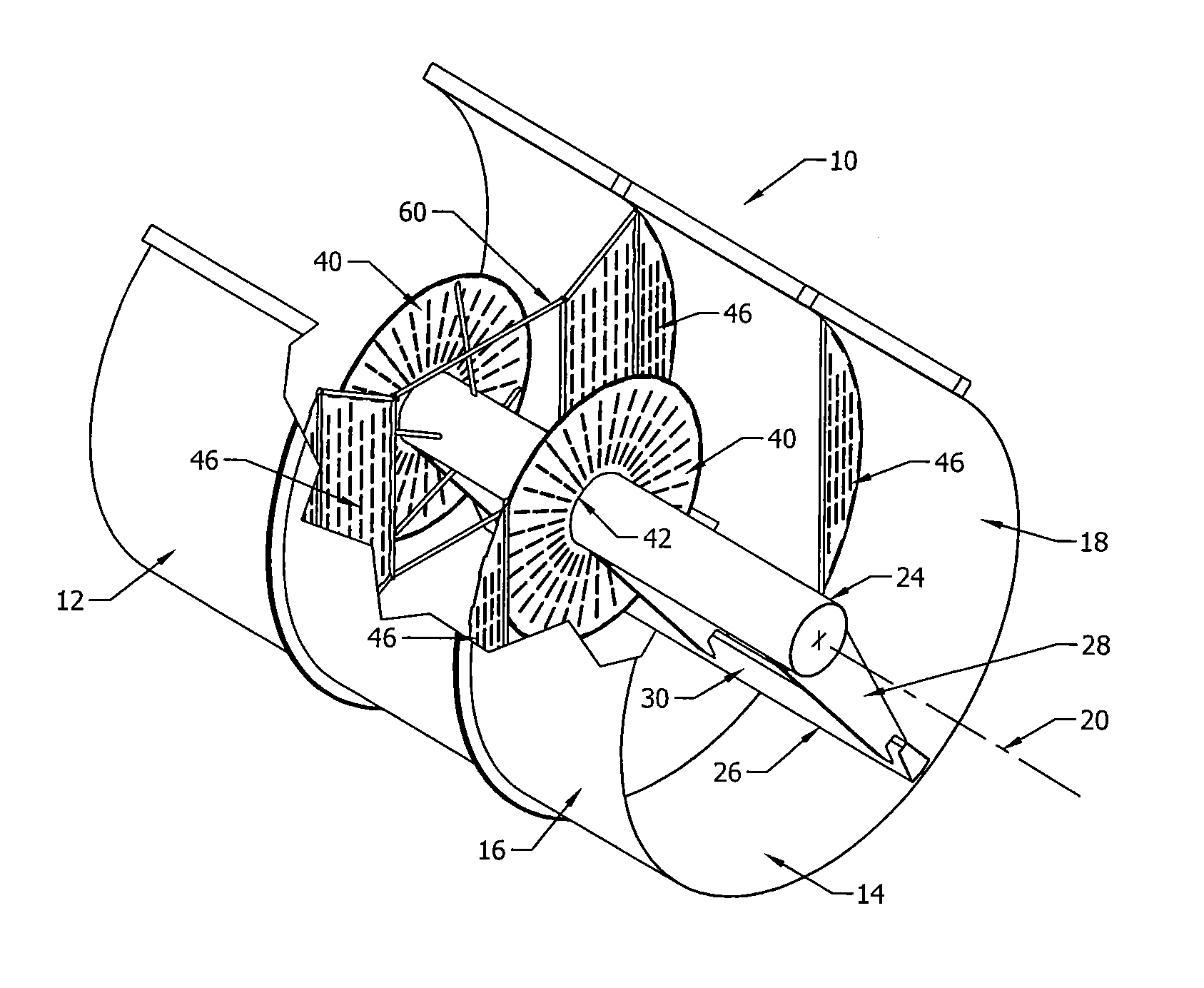

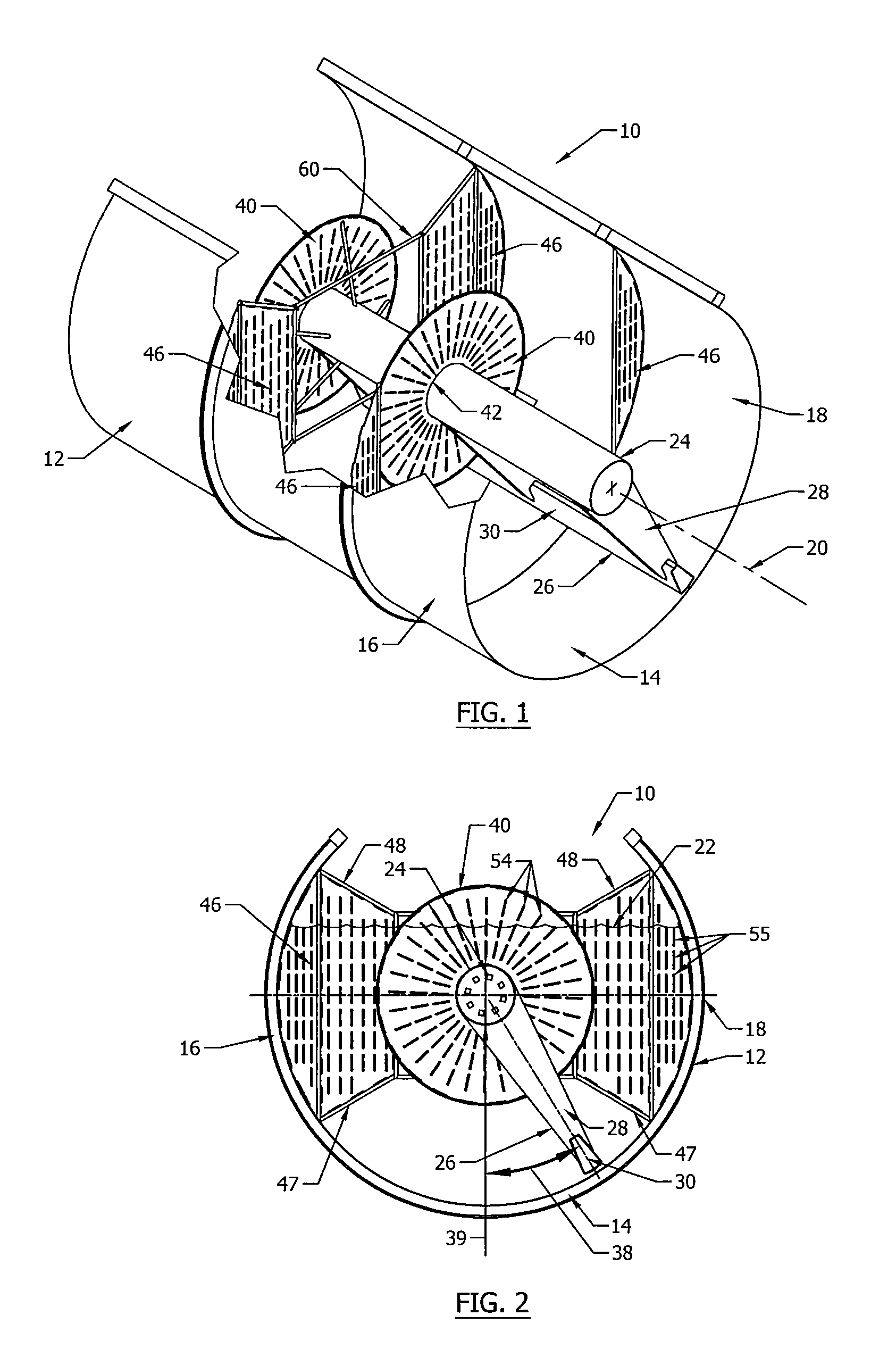

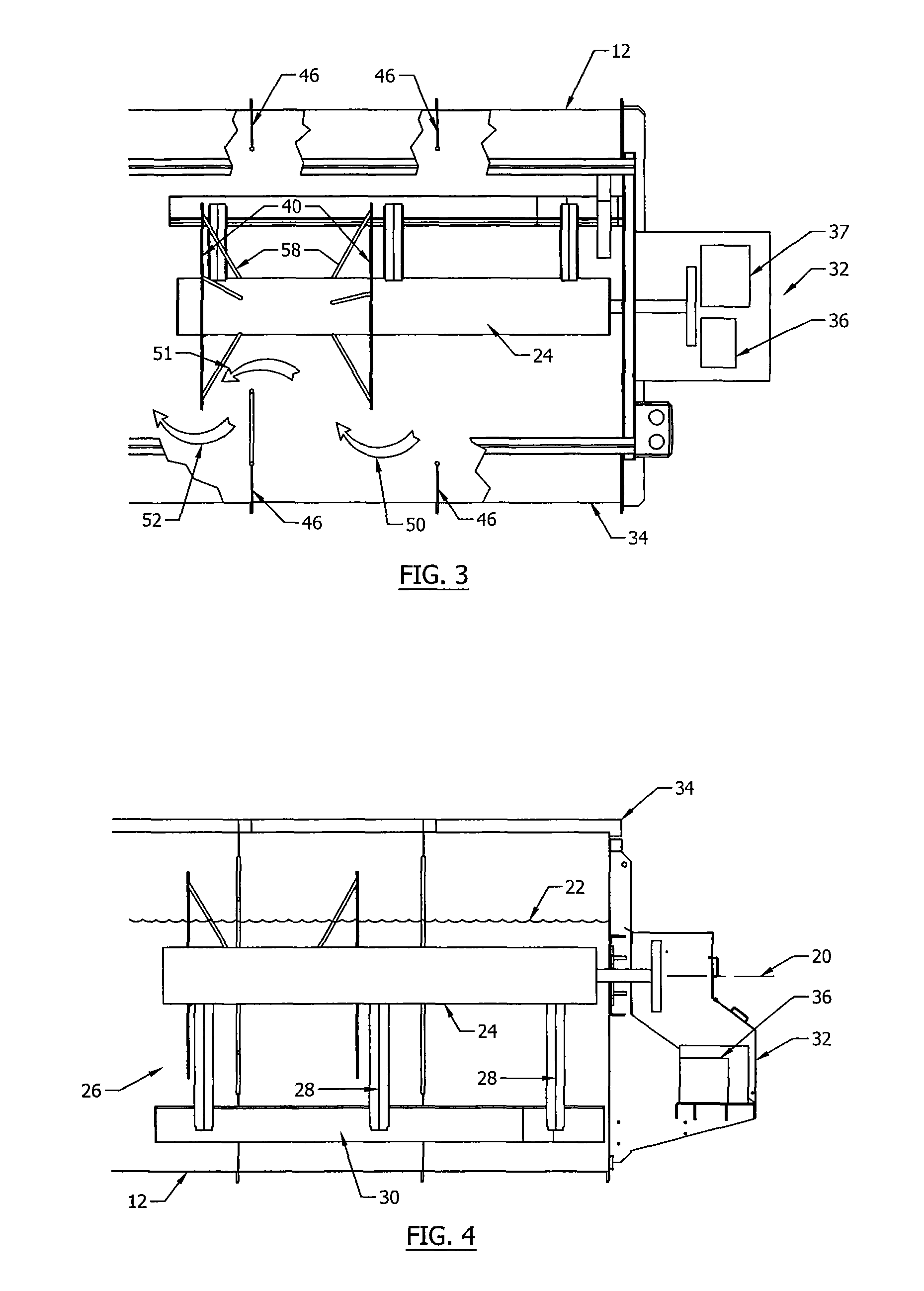

Auger Chiller with Sloped Unloader

InactiveUS20090241583A1Reduce the temperatureMeat/fish preservationLighting and heating apparatusEngineeringMechanical engineering

An auger chiller (10) includes a carcass delivery end (18) that is sloped upwardly with a reduced radius. The auger (32) includes a progressively reduced radius auger segment (38) that matches the configuration of the angled section of the chiller tank, with the pitch of the auger blade being greater in this section of the tank for advancing the birds more reliably in a first-in first-out delivery to a sloped bird unloader (46). An arcuate basin (50) is formed at the lower arc of the peripheral rim wall (48) of the bird unloader, assuring that the heavier birds tend to sink into the basin, tending not to return to the chiller tank.

Owner:MORRIS & ASSOCS

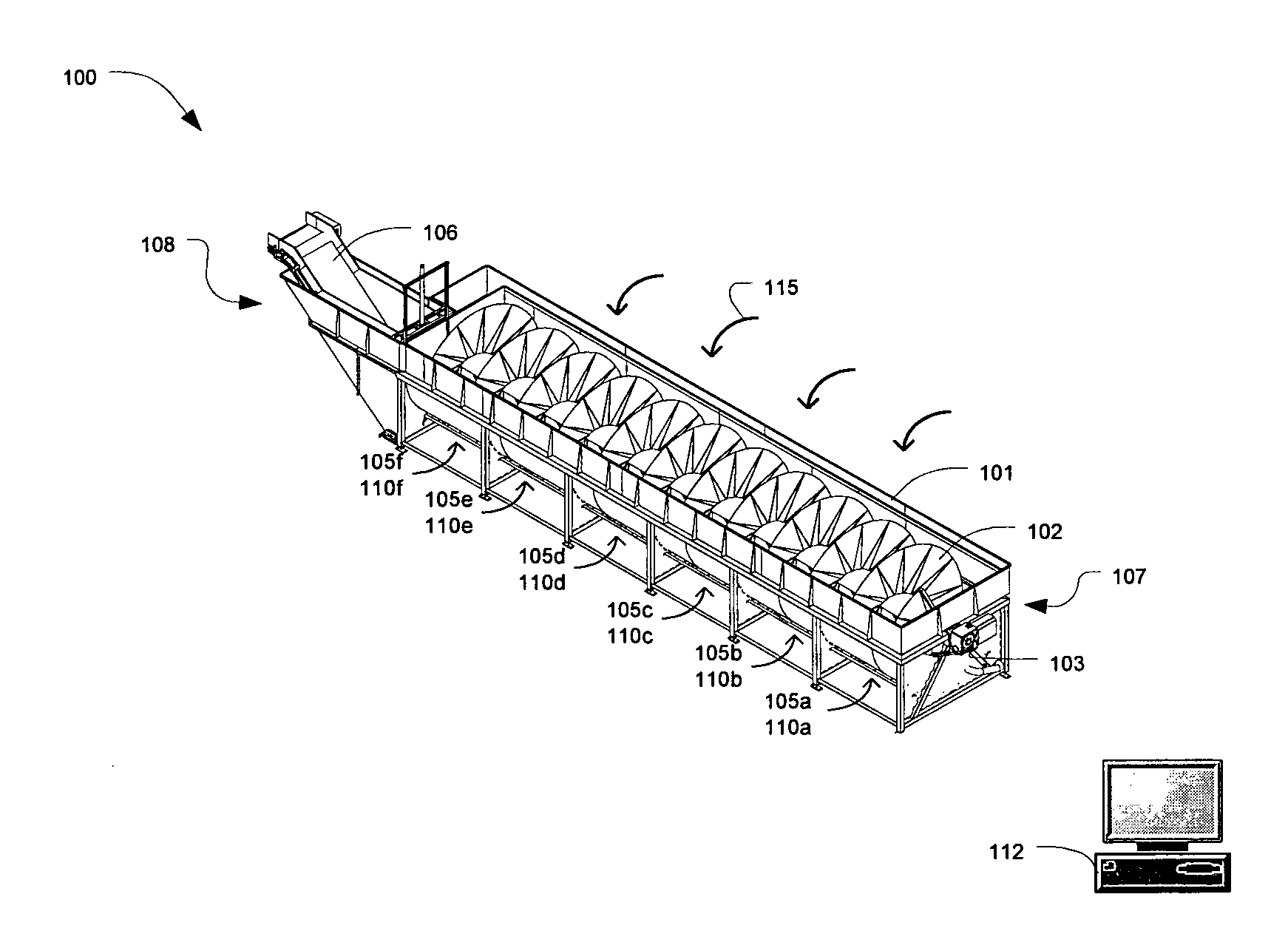

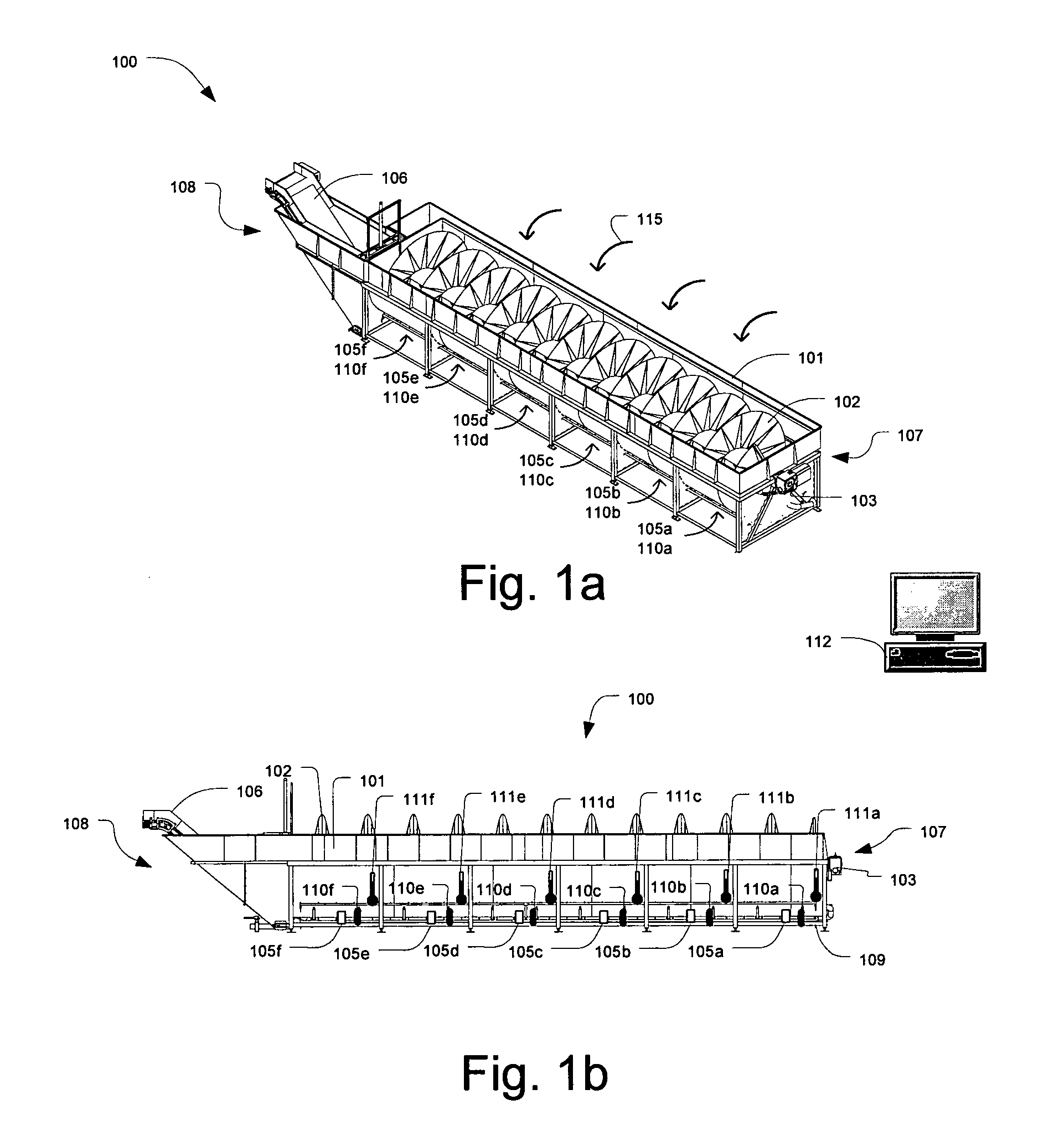

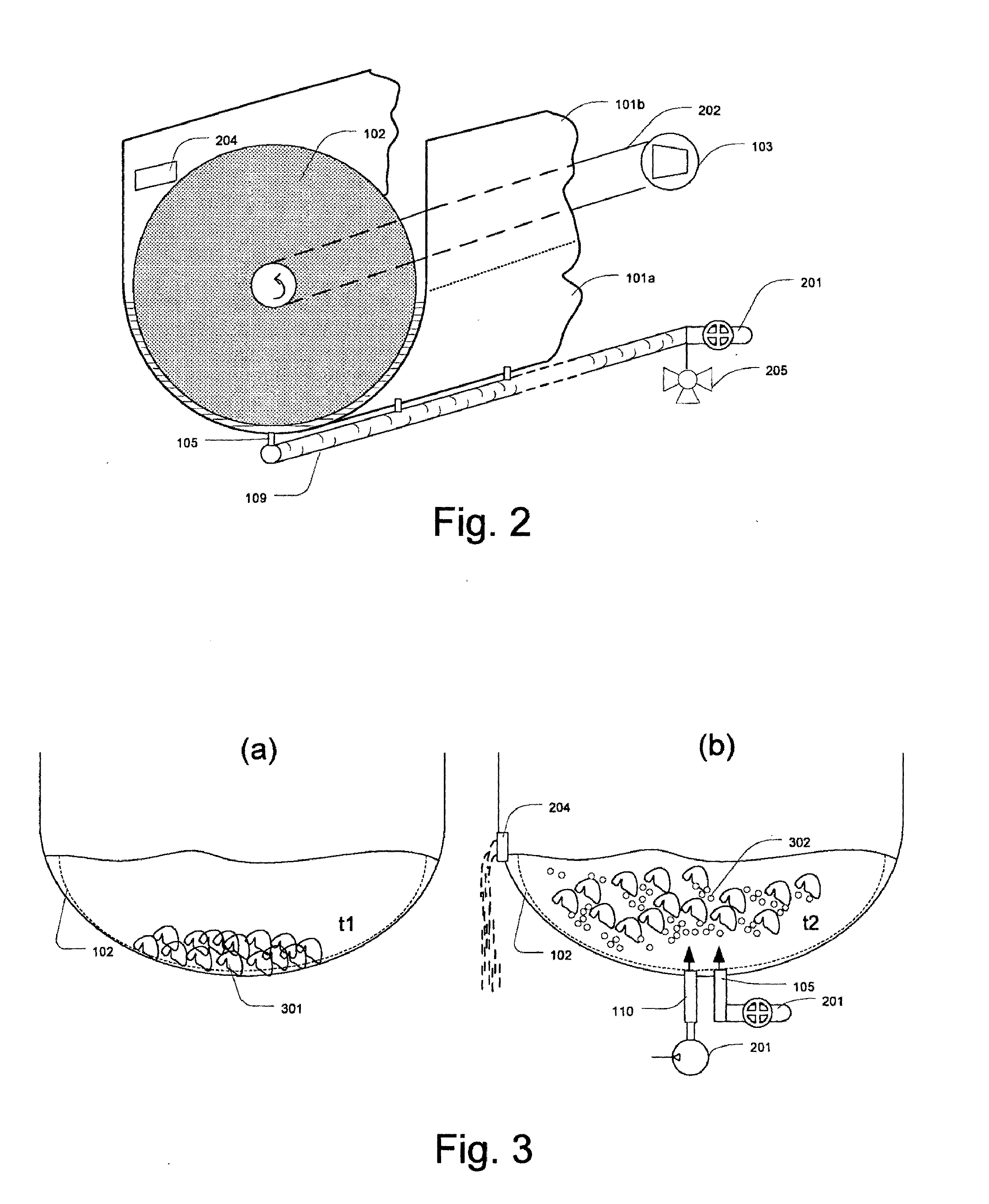

Apparatus for thawing or cooling food products

ActiveUS20120042789A1Easy to pickInhibition formationMilk preservationLighting and heating apparatusTemperature controlControl system

An apparatus for thawing or cooling food products includes a tank adapted to be at least partly filled with a liquid. A spiral shaped blade extends between a first end and a second end of the tank, where the spiral shaped blade is mounted to a rotation axis which operates rotational movement of the spiral shaped bladed and thus the conveying of the food products from the first end towards the second end. A temperature controlling system is provided and adapted to control the temperature of the liquid by arranging multiple heat supplying units along the tank for injecting heating or cooling agents into the liquid so as to provide a substantial temperature distribution into the thawing liquid during the thawing or cooling of the food products.

Owner:3X TECH

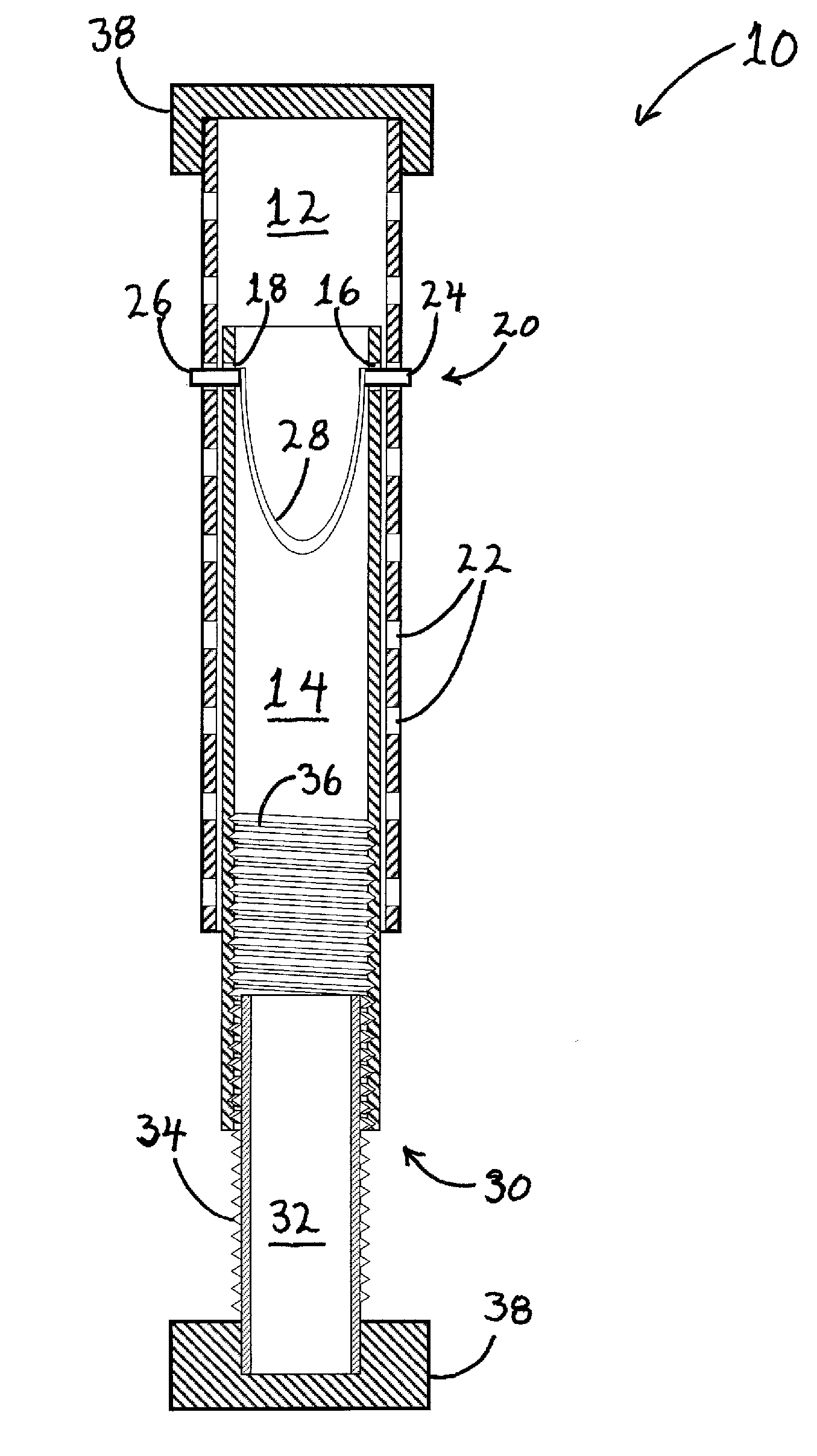

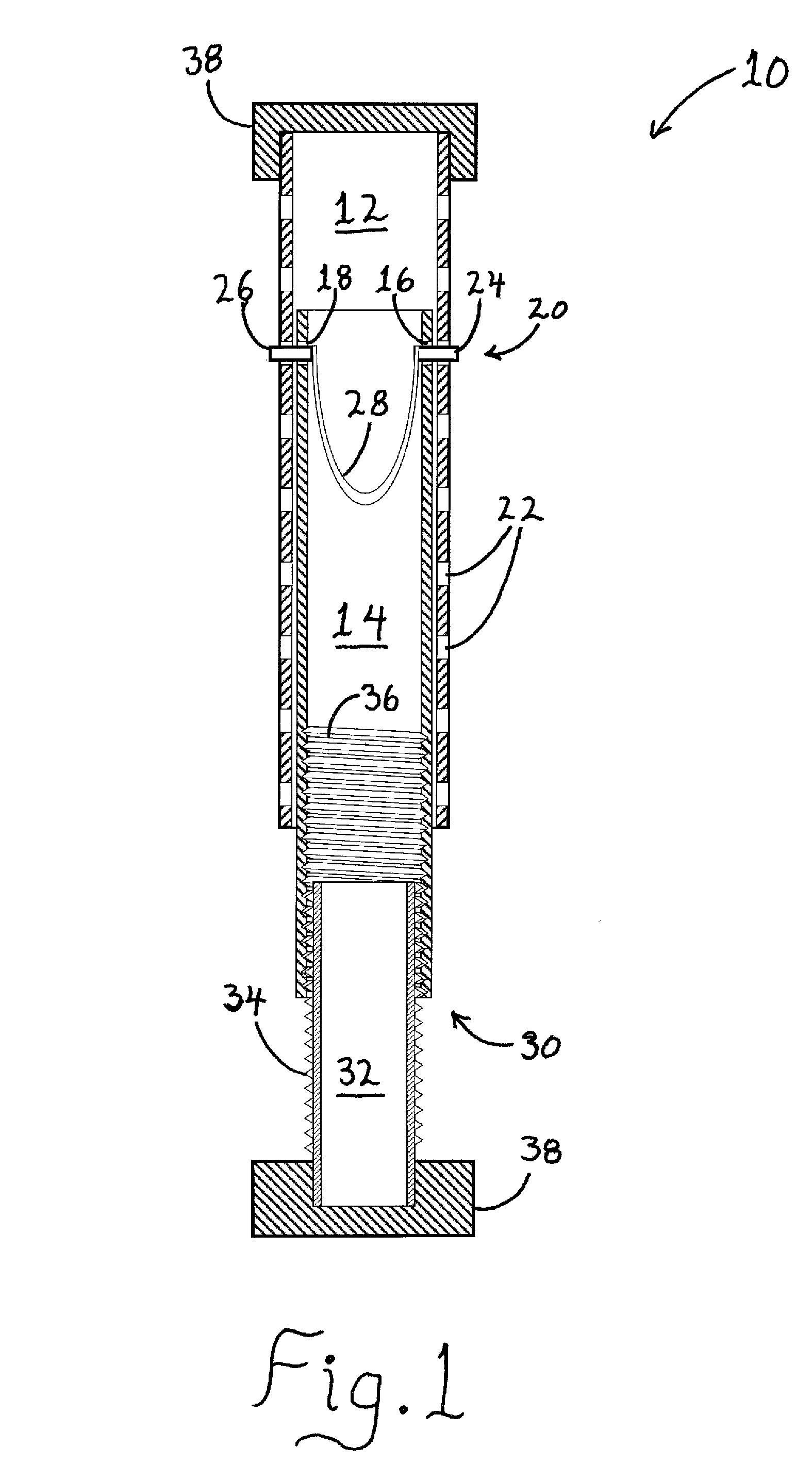

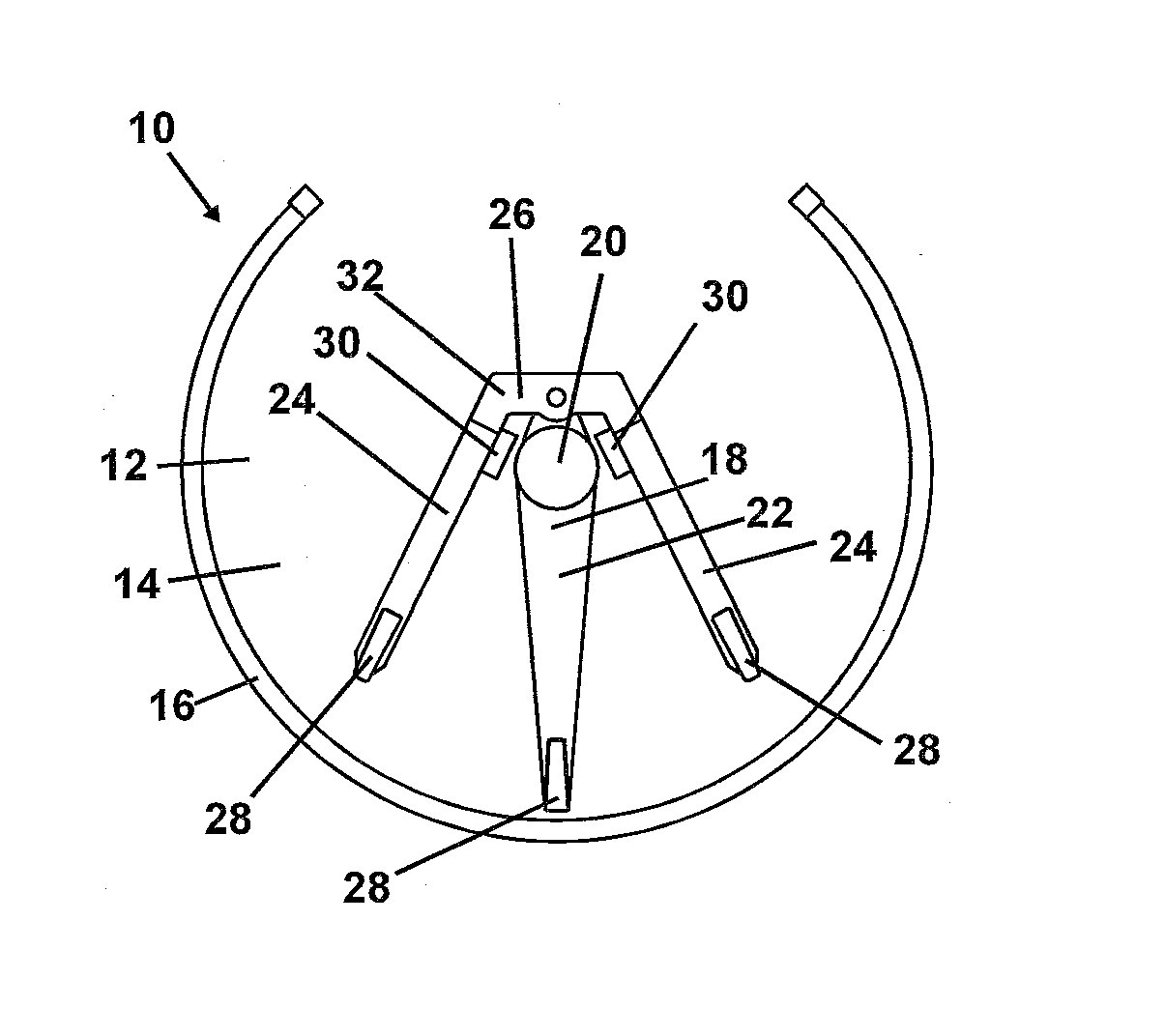

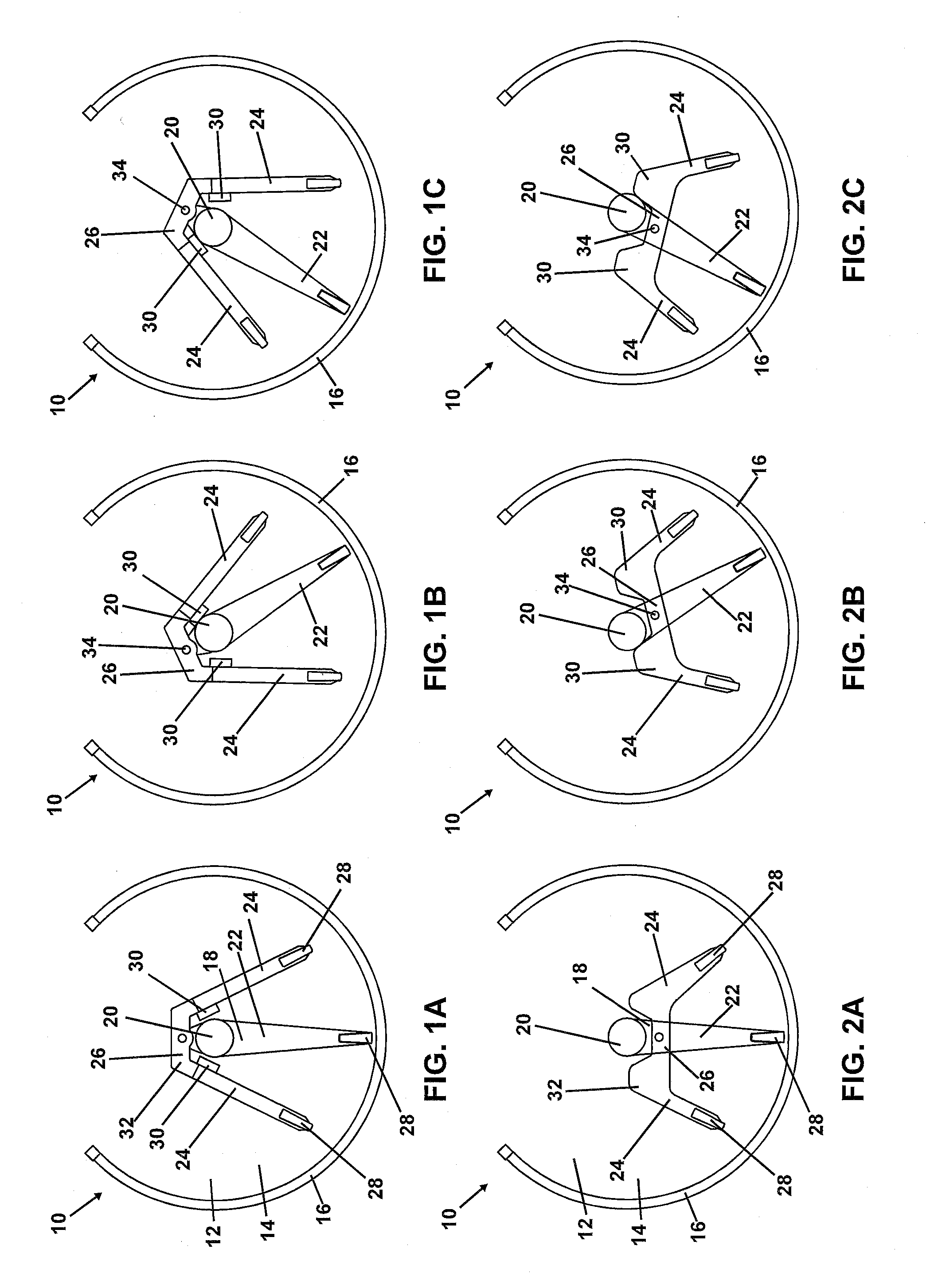

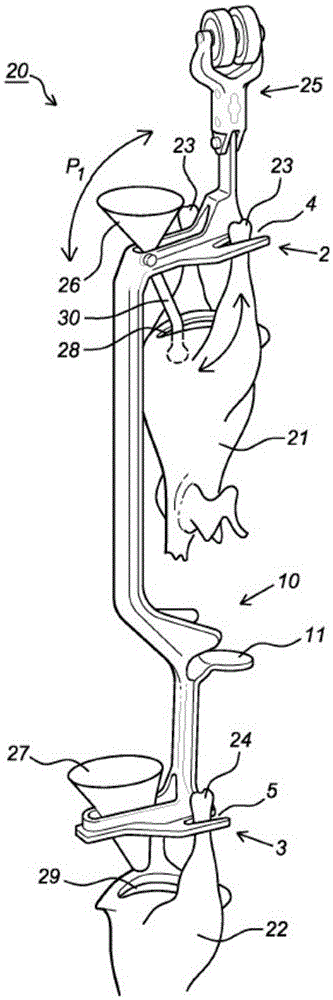

Adjustable game carcass spreader device

An adjustable game carcass spreader device. There is a first tubular member; a second tubular member, slidably coupleable to the first tubular member, having a first pin aperture; a first adjustment system, including: a plurality of securing apertures, configured to secure a pin positioned therethrough; a first pin member, selectably extendable through one of the securing apertures; and a bias member coupled to the first pin member. There is a plurality of cap members, removably coupled to end portions of the device. There is a second adjustment system, including a third tubular member, rotatably coupled to the second tubular member. An end portion of the second tubular member and an end portion of the third tubular member are threaded. The first tubular member includes indicia thereon. There is a second pin aperture and a second pin member, the second pin member is selectably extendable through one of the securing apertures.

Owner:BAILEY ALLEN

Method and installation for cooling slaughtered poultry

InactiveUS7856842B2Healthy colorLong storage timeLighting and heating apparatusMeat/fish preservation by freezing/coolingAbdominal cavityWater flow

Owner:TOPKIP

Process for chilling animal carcasses

InactiveUS6845624B2Inhibit deteriorationDelay water lossLighting and heating apparatusCarcasses chillingEngineeringCold store

A process of cooling animal carcasses from a kill temperature to a temperature at which deterioration is substantially prevented comprises circulation of refrigerated air over the carcass to freeze an outer of the carcass, followed by application of water to the carcass to form a sufficiently continuous layer of ice on the carcass. Preferably, the carcass is chilled by a multi-stage quick chill process in which the carcass is exposed to super-cooled, high velocity air. Immediately before or immediately after formation of the ice layer, the carcass is transferred to a refrigerated chamber to allow the interior and exterior of the carcass to equilibrate to the temperature at which deterioration is substantially prevented. The inventors have found that this process provides reduced moisture loss and reduced bacterial loading over prior art processes in which water is applied to the carcass during the quick chill process.

Owner:MAPLE LEAF FOODS INC

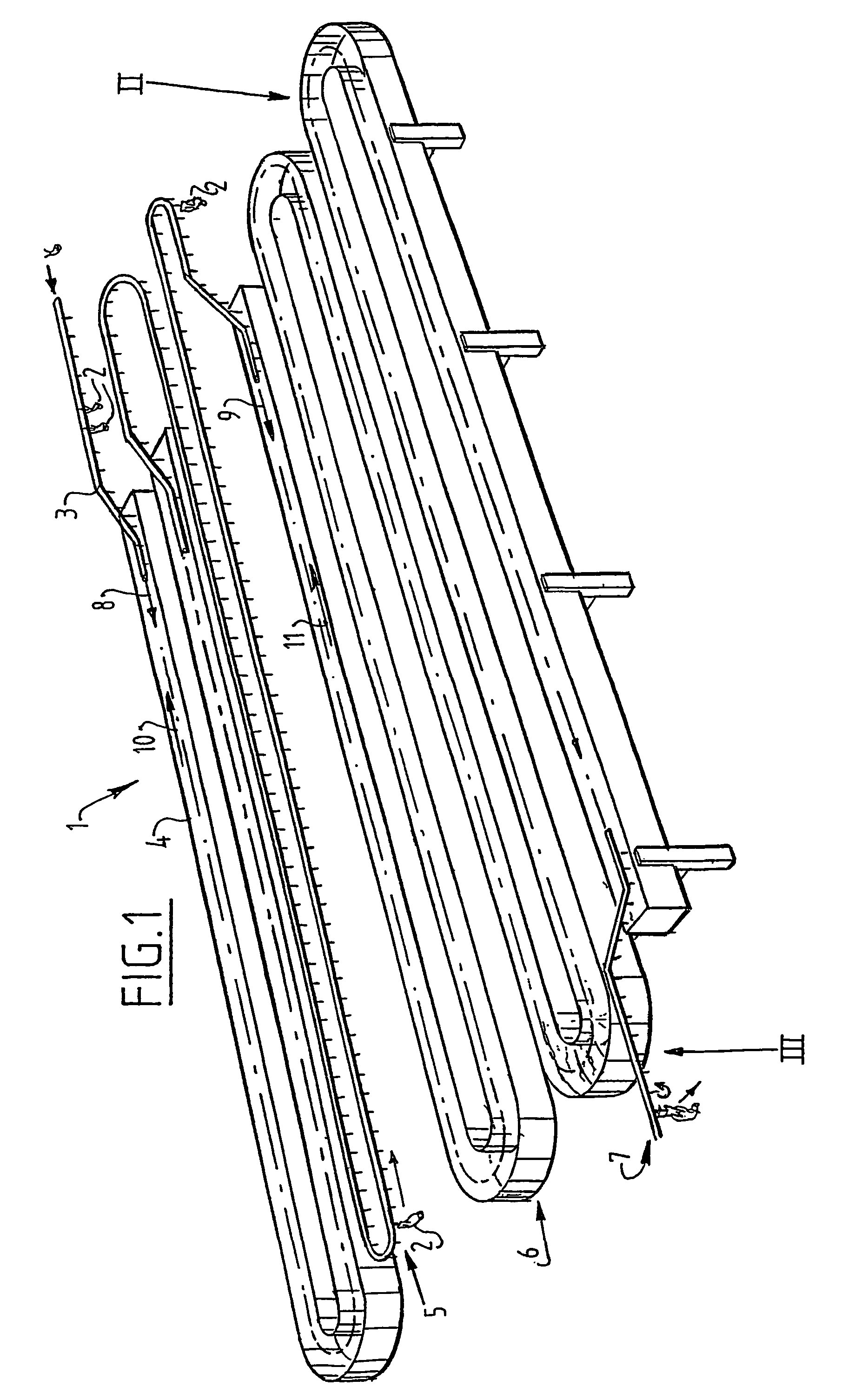

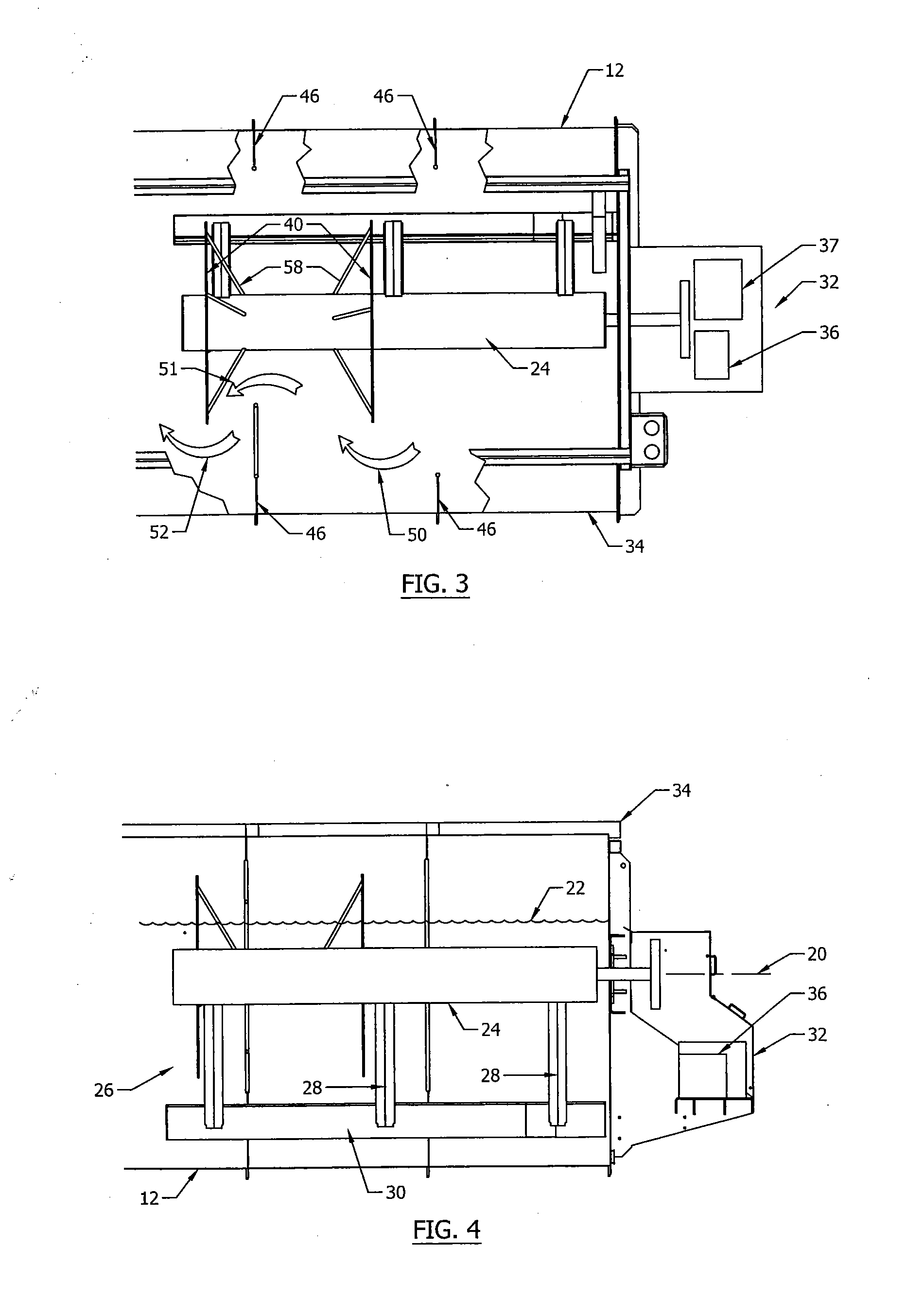

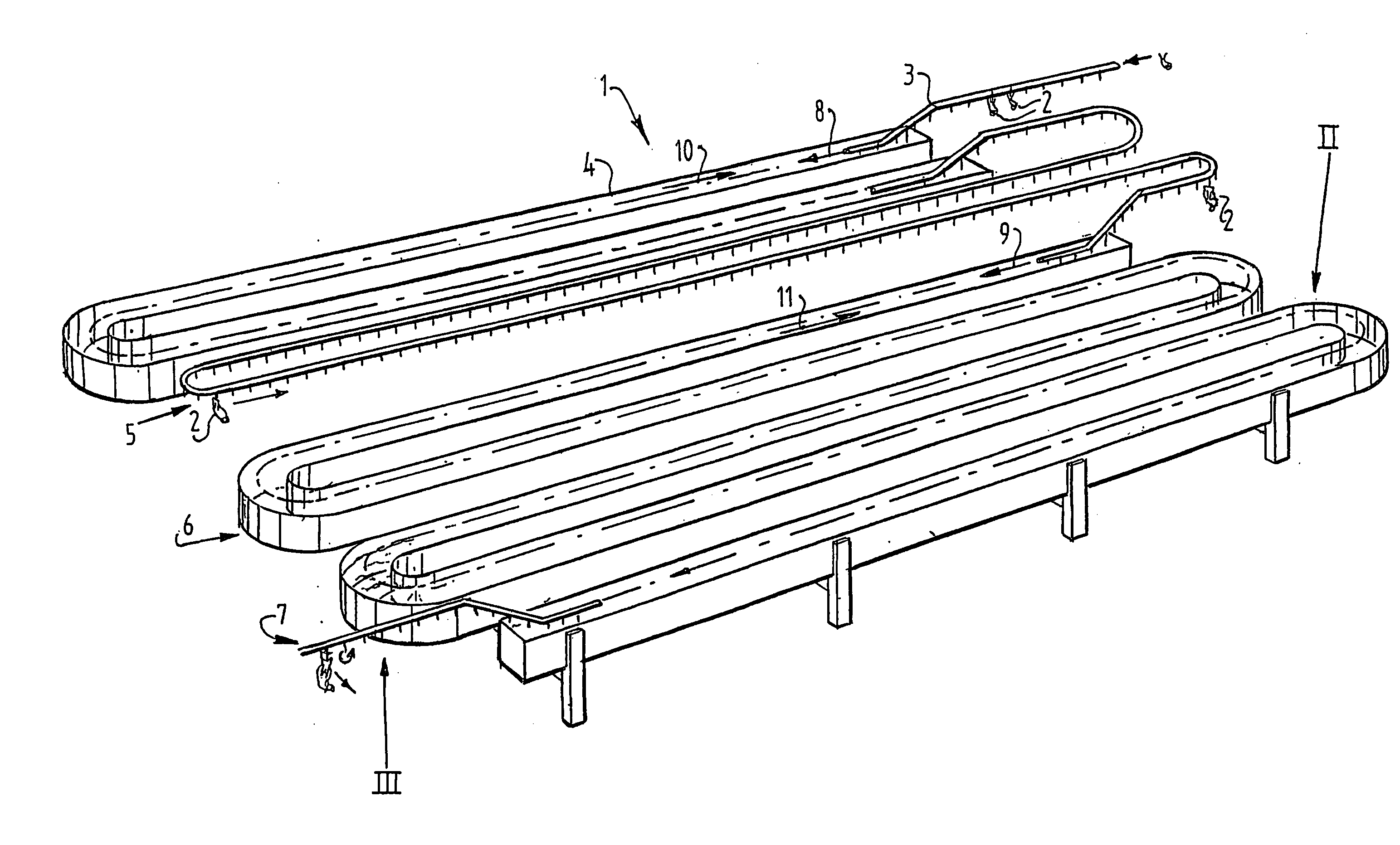

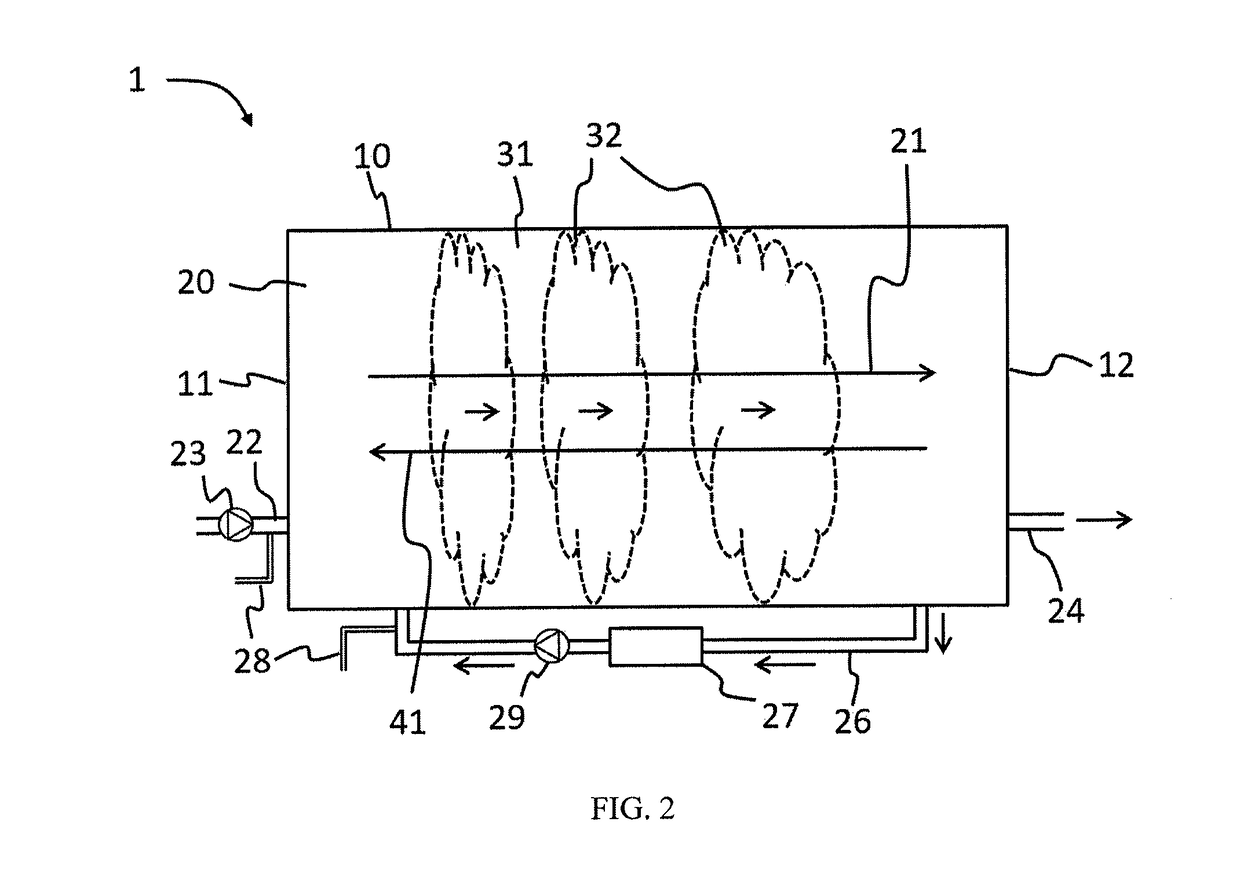

Rocker Chiller with Serpentine Carcass Flow

A rocker chiller 10 includes a tank 12 with a dasher assembly 26 that oscillates across the curved bottom wall of the tank. A series of central deflectors 40 are positioned at intervals along the length of the tank and another series of side deflectors 46 are mounted at intervals along the upwardly extending side walls 16 and 18 of the tank. The side deflectors are offset longitudinally with respect to the central deflectors. The offset relationship of the side deflectors and central deflectors creates serpentine paths through the elongated tank on both sides of the tank that require the carcasses to move through more of the heat exchanging liquid and which reduces the tendency of carcasses passing each other.

Owner:MORRIS & ASSOCS

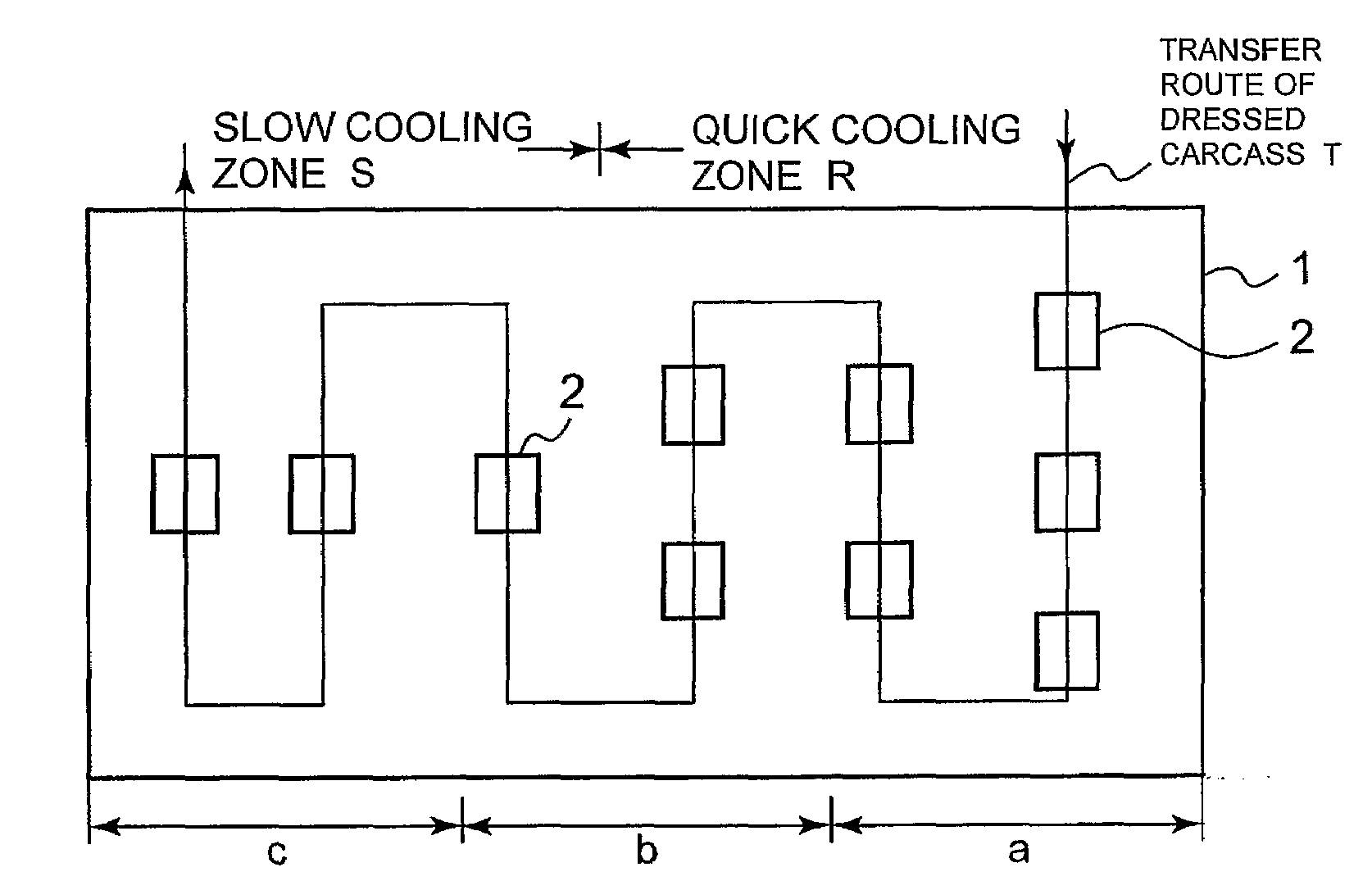

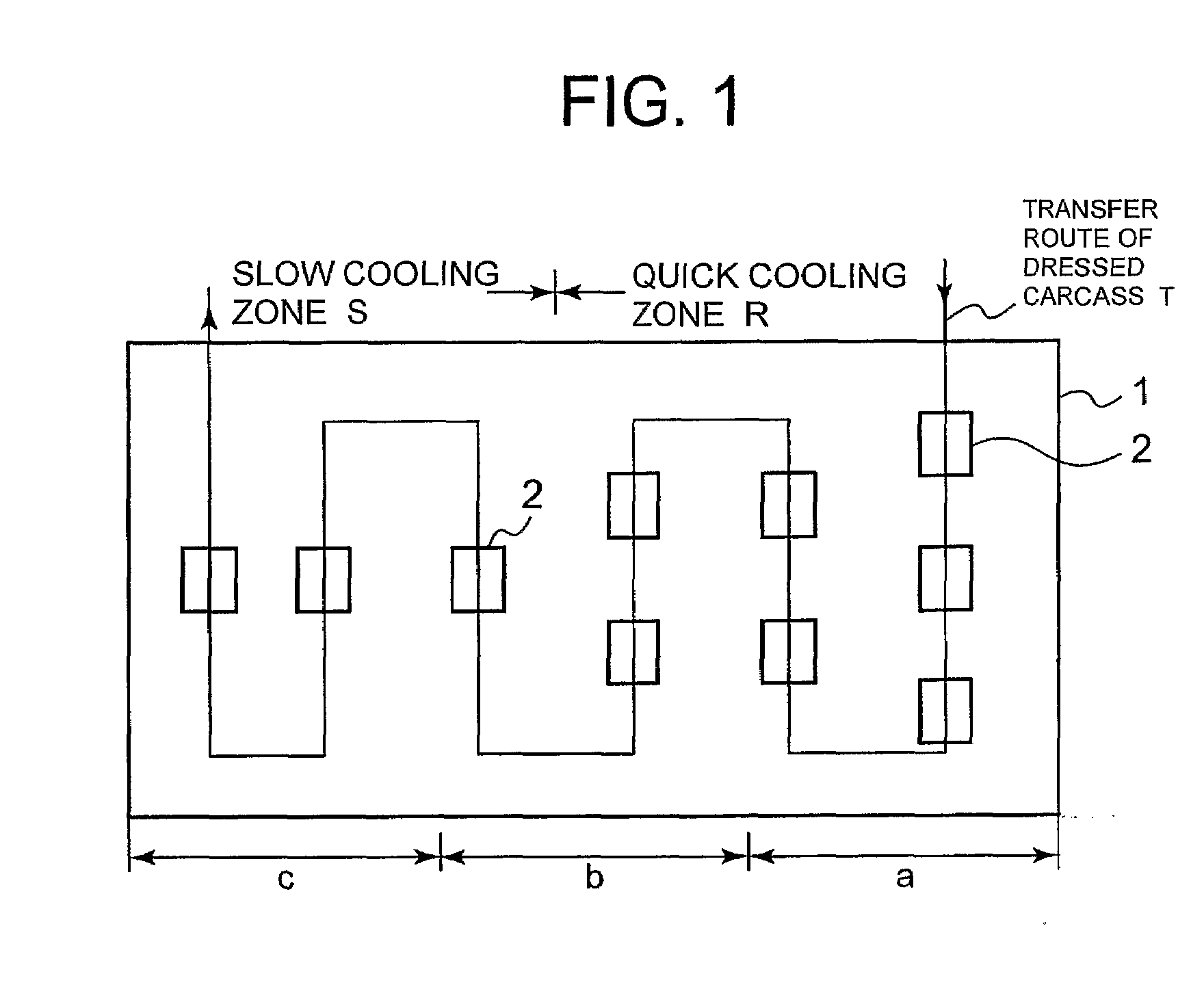

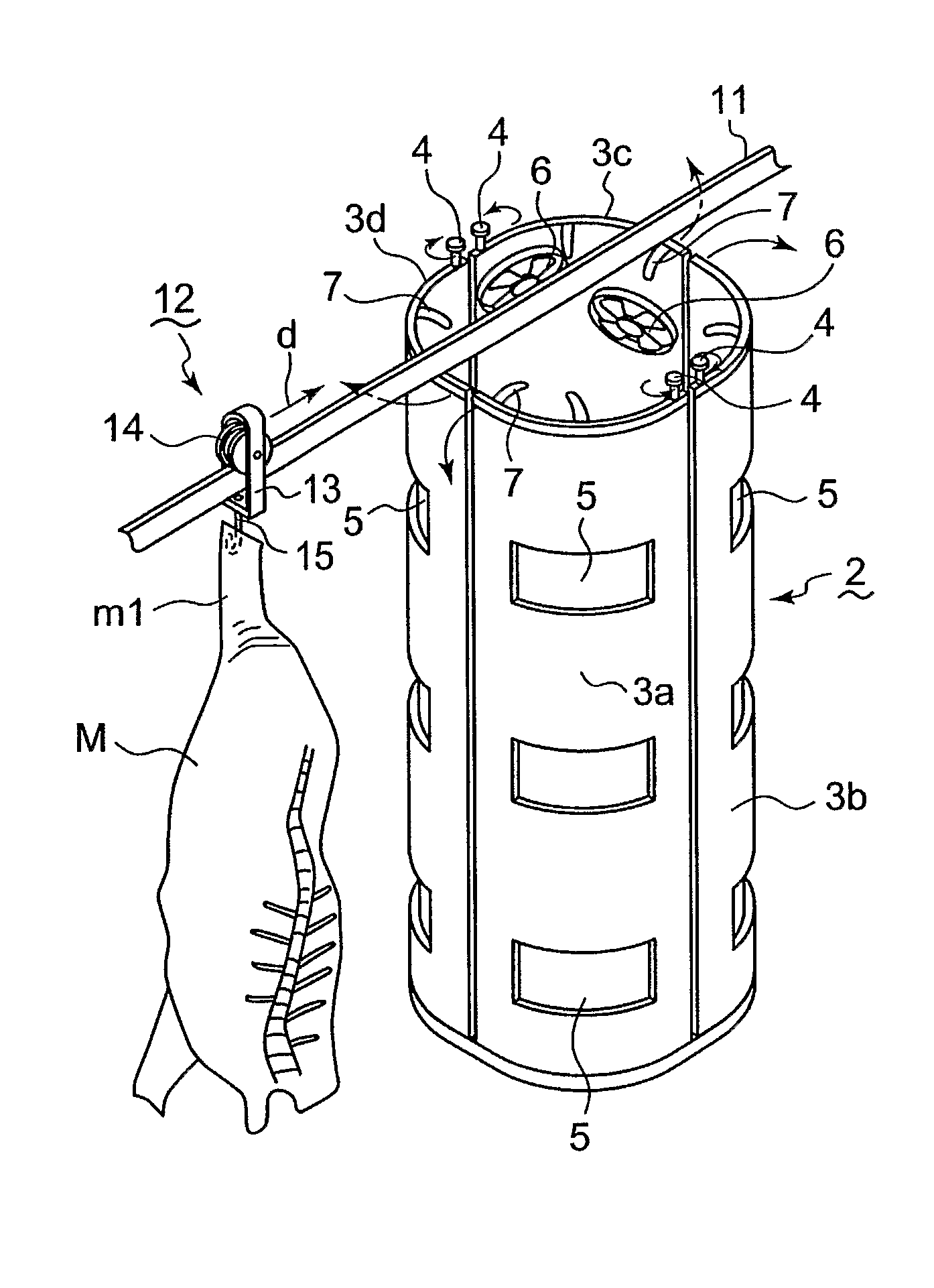

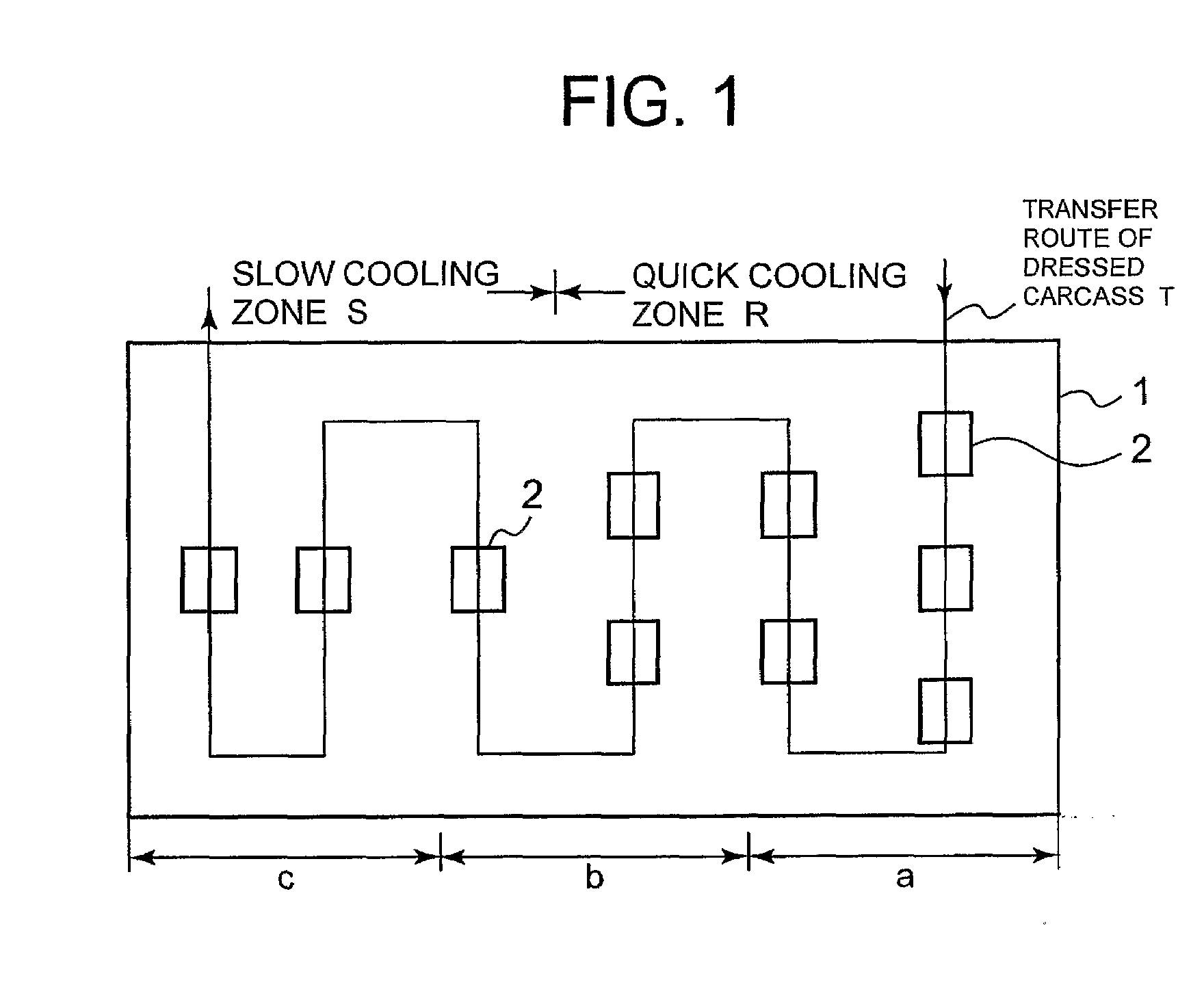

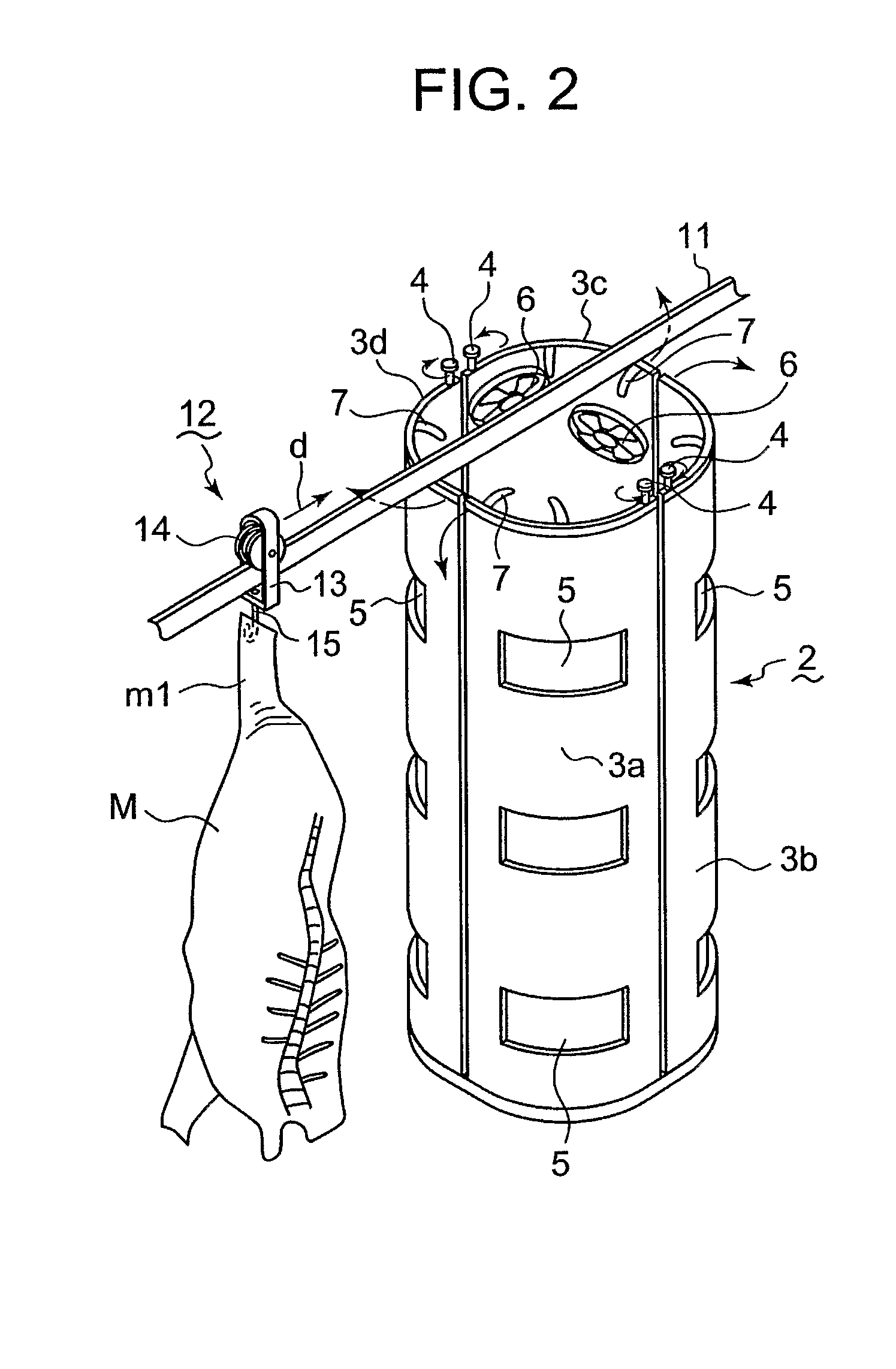

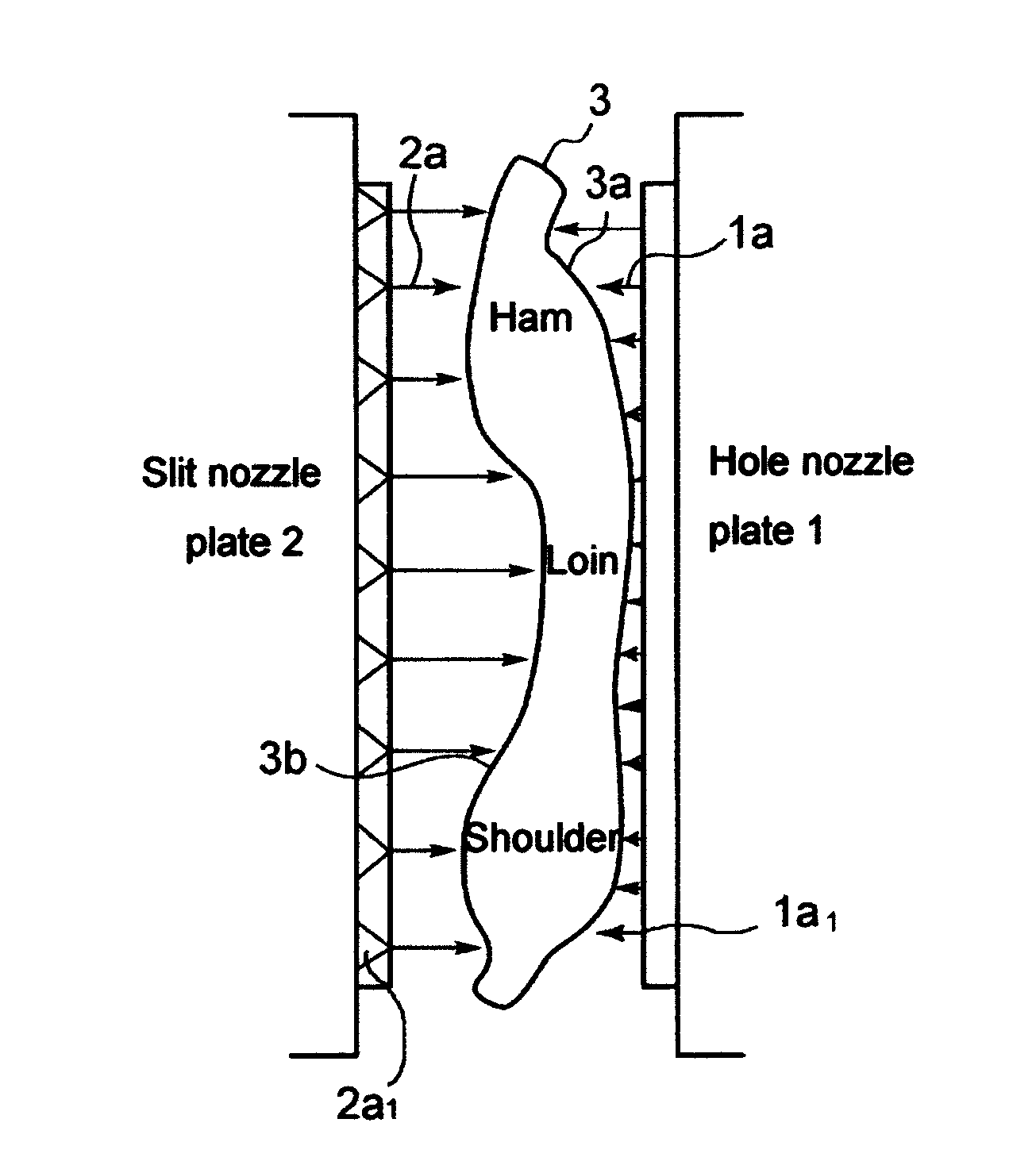

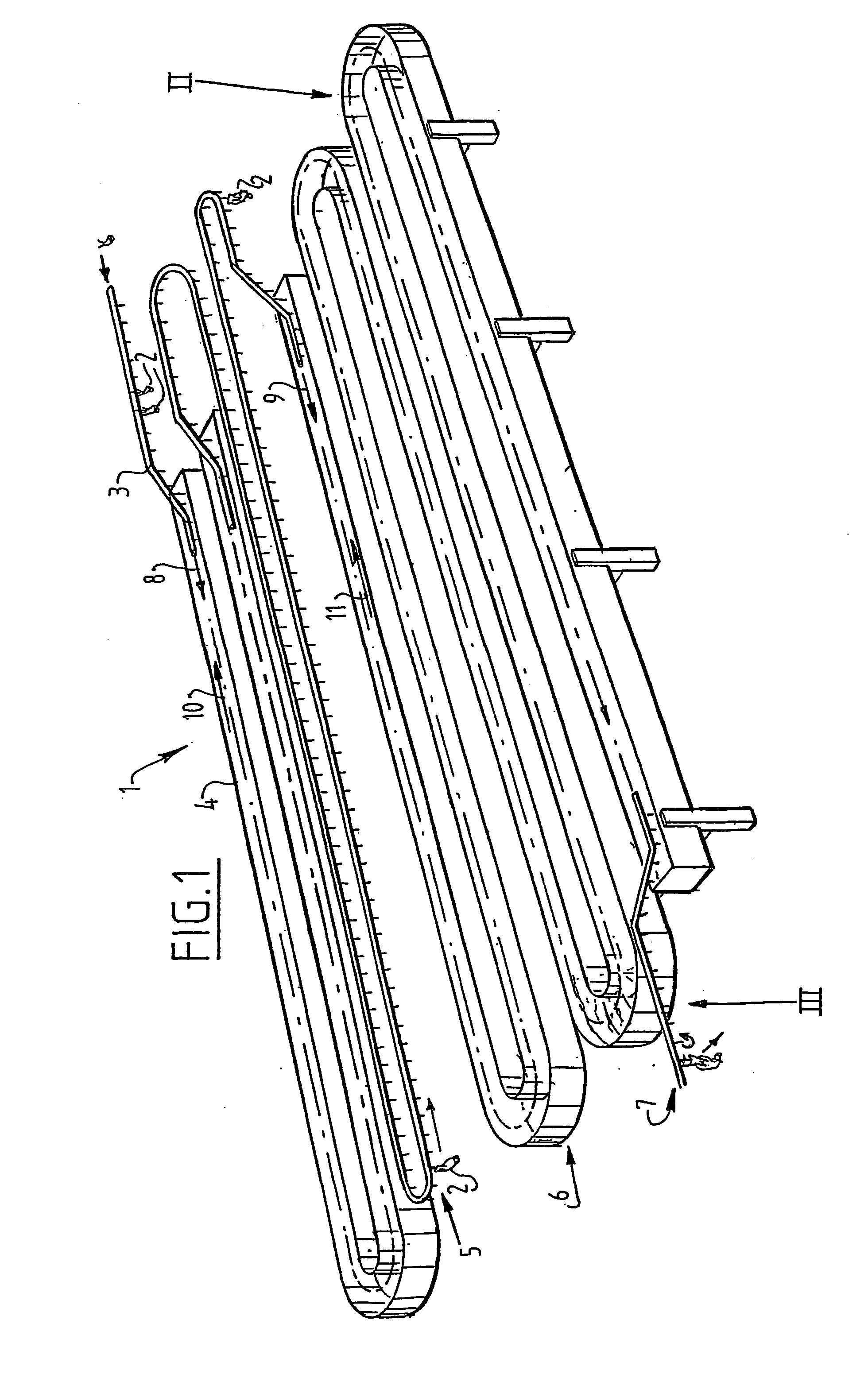

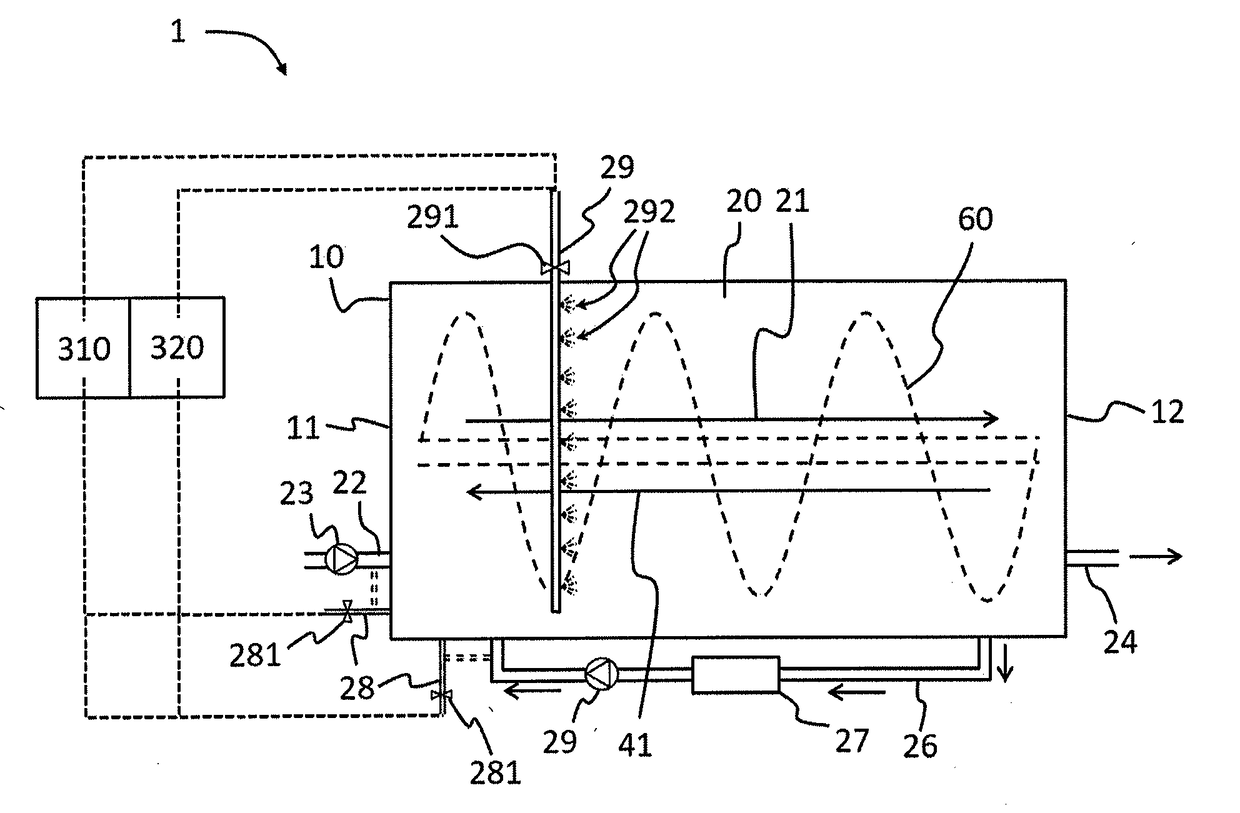

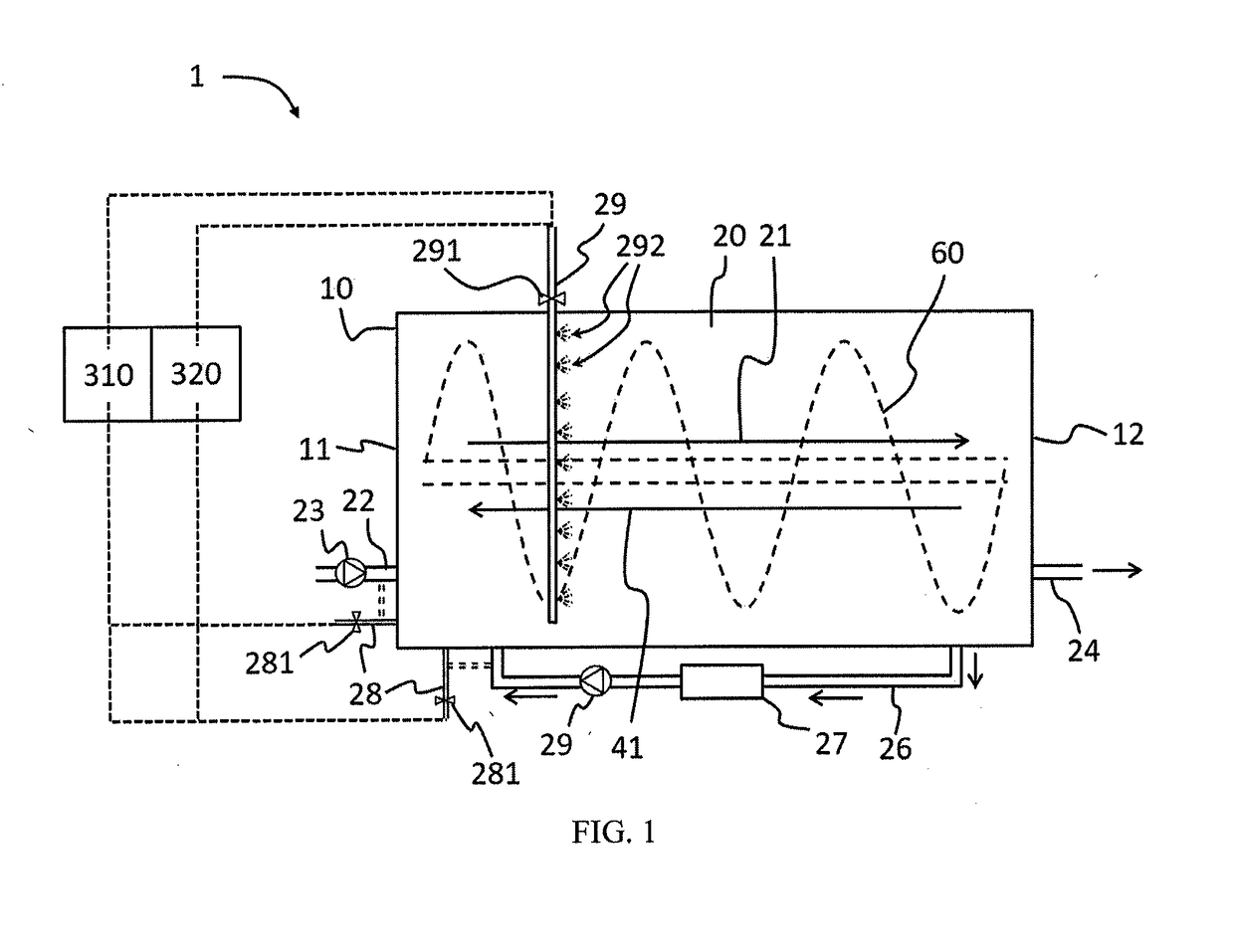

Method and system for cooling of dressed carcasses

InactiveUS7625271B2Suppress in process yieldEliminate generationMilk preservationWort preparationCold airEvaporation

A method of cooling a dressed carcass of a slaughtered animal halved along the backbone thereof while transferring the dressed carcass in a cooling chamber is provided, with which reduction in process yield in the cooling process due to evaporation of water from the dressed carcass is suppressed to a minimum, meat juice dripping together with water does not occur when cutting the dressed carcass, the cooling period of time is reduced, energy is saved in cooling process, initial cost is reduced, and productivity is improved. The dressed carcass is cooled while transferring in the cooling chamber in a hanged attitude along the transport route T, whereby a plurality of partitioned spaces are provided in the cooling chamber 1 such that they are arranged along said transport route with a relatively small distance between them in a zone where the surface of the dressed carcass is cooled quickly and with a relatively large distance between them in a zone where surface temperature of the dressed carcass has approached the temperature of the cooling chamber and the dressed carcass is cooled slowly, and water is added to the surface of the dressed carcass while blasting cold air on to the dressed carcass in the partitioned spaces.

Owner:MAYEKAWA MFG CO LTD

Method and System for Cooling of Dressed Carcasses

InactiveUS20090004958A1Reduction in process yield can be suppressedShorten the time periodMilk preservationWort preparationCold airEvaporation

A method of cooling a dressed carcass of a slaughtered animal halved along the backbone thereof while transferring the dressed carcass in a cooling chamber is provided, with which reduction in process yield in the cooling process due to evaporation of water from the dressed carcass is suppressed to a minimum, meat juice dripping together with water does not occur when cutting the dressed carcass, the cooling period of time is reduced, energy is saved in cooling process, initial cost is reduced, and productivity is improved. The dressed carcass is cooled while transferring in the cooling chamber in a hanged attitude along the transport route T, whereby a plurality of partitioned spaces are provided in the cooling chamber 1 such that they are arranged along said transport route with a relatively small distance between them in a zone where the surface of the dressed carcass is cooled quickly and with a relatively large distance between them in a zone where surface temperature of the dressed carcass has approached the temperature of the cooling chamber and the dressed carcass is cooled slowly, and water is added to the surface of the dressed carcass while blasting cold air on to the dressed carcass in the partitioned spaces.

Owner:MAYEKAWA MFG CO LTD

Production method of cooled fresh keeping beef

InactiveCN107279245AGood safety and sanitationLong retention periodMeat packaging/handling/transportingMeat processing plantsQuarantineHygiene

The invention discloses a production method of cooled fresh keeping beef. The production method of cooled fresh keeping beef comprises the following steps of performing slaughtering, performing bloodletting, performing peeling, removing internal organs, and after carcasses are qualified through quarantine, performing rinsing with water; and then precooling the rinsed carcasses, then selecting the carcasses of which the pH value is 5.6-5.8, performing deboning and segmentation, performing trimming, performing vacuum packaging, performing hot dipping, performing cold dipping, placing the carcasses after cold dipping into the environment of minus 2 to 2 DEG C, and performing storage. Compared with the prior art, the production method disclosed by the invention has the advantages that the obtained fresh keeping beef has better safety, better hygiene and longer preservation period.

Owner:王立兵

Method and apparatus for tempering treatment of meat, tempered meat treated by the method, and refrigerated meat storage

InactiveUS8347639B2Reduce the temperatureAvoid temperature riseMilk preservationWort preparationCold airIce storage

A tempering treatment method whereby the temperature of meat, which involves a carcass prepared by slaughtering cattle or poultry and sterilizing and washing, is lowered as close to the ice storage temperature as possible to prevent a temperature rise caused by the actions of enzymes contained within the meat before transporting the meat to a refrigerated storage, which comprises surface-freezing the meat by blowing a cold air stream at about −20 to about −40° C. to the meat before conducting the tempering treatment, thus allowing the generation of freezing latent heat in the subcutaneous part owing to the surface-freezing (freezing the subcutaneous tissue), and then rapidly lowering the core temperature inside the meat due to the latent heat released at the melting of the freezing latent heat to thereby conduct the tempering treatment at a temperature of 0 to +15° C.

Owner:MAYEKAWA MFG CO LTD

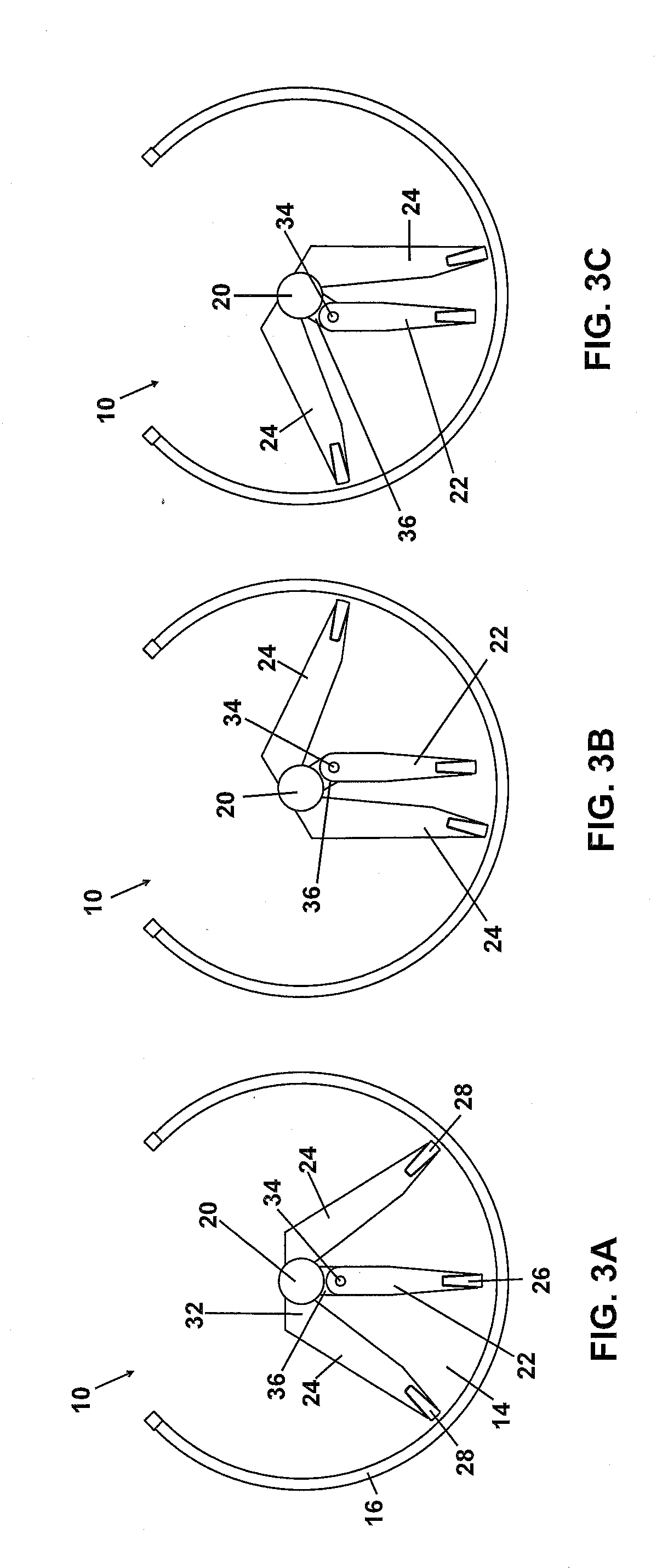

Three-Paddle Rocker Chiller

A rocker-type poultry chiller, including a tank for receiving poultry carcasses and holding chilled water, an axle mounted in the tank, a main paddle connected to the axle, and a side paddle connected to the axle. The oscillation of the main paddle and the side paddle urges the carcasses upwardly and laterally, which contributes to the cooling of the carcasses as a result of their thorough contact in the chilled water. The movement of the paddles also gently massages the carcasses by gently bumping them against the paddle blades and the wall of the tank. The repeated compression of the carcasses tends to tenderize the meat. The side paddles ensure more predictable and consistent contact between the paddles and all of the carcasses, which causes more agitation of the carcasses and more effective washing of the carcasses.

Owner:JOHN BEAN TECH CORP

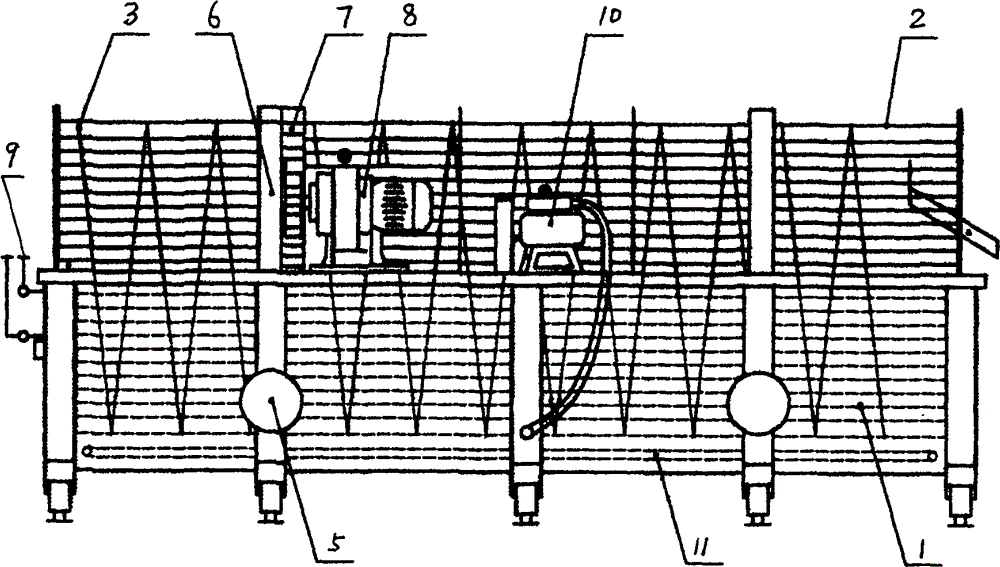

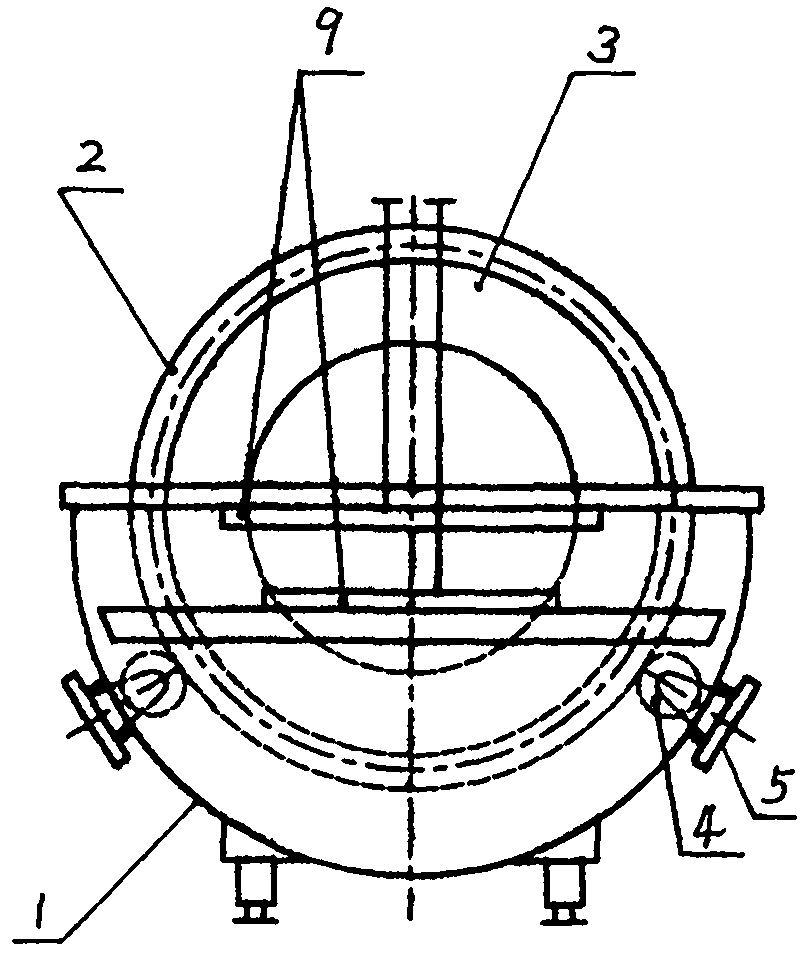

Roller cage cleaning and pre-cooling machine

ActiveCN102630735BWon't hurtUnlimited lengthCarcasses chillingPoultry processingMotor speedGear wheel

The invention provides a rolling cage type washing and pre-cooling machine, relating to a device for washing or cooling poultry carcasses when poultries are slaughtered. The rolling cage type washing and pre-cooling machine is designed to mainly solve the problems of the existing spiral pre-cooling machine that the cooling effect of the poultry carcasses is poor and the poultry carcasses are damaged. The rolling cage type washing and pre-cooling machine comprises a main machine body, wherein the main machine body is internally provided with a rolling cage; a spiral sheet is arranged on the inner wall of the rolling cage; a roller is arranged in the main machine body through a roller bracket; the rolling cage is provided with a rolling groove; the rolling groove is placed on the roller; the periphery of the rolling cage is provided with a gear ring; the main machine body is provided with a motor speed-reducing machine; a gear on a power output shaft of the motor speed-reducing machine is engaged with the gear ring arranged on the periphery of the rolling cage; an inlet is arranged at one end of the rolling cage, and an outlet is arranged at the other end of the rolling cage; the rolling cage is internally provided with an evaporator; the main machine body is fixedly provided with two evaporator collecting pipes; the evaporator in the rolling cage is communicated with the two evaporator collecting pipes on the main machine body; an air pump is additionally arranged on the main machine body; and an air outlet of the air pump is provided with an air pipe communicated with an air pipe in the main machine body. The rolling cage type washing and pre-cooling machine has the advantages of good washing and cooling effects and no damages to the poultry carcasses.

Owner:李传芳

Method and installation for cooling slaughtered poultry

InactiveUS20070181010A1Produce quicklyHealthy colorLighting and heating apparatusMeat/fish preservation by freezing/coolingAbdominal cavityWater flow

The invention relates to a method for cooling slaughtered poultry, including the steps of: positioning the poultry with spread legs, with the abdominal cavity upward and oriented in the transporting direction of the poultry; and transporting the positioned poultry through cooled flowing water, wherein the transporting direction of the poultry is opposed to the flow direction of the water such that water flows around and through the poultry from the abdominal cavity toward the neck cavity. The present invention also relates to an installation including: a positioner for receiving the slaughtered poultry with the abdominal cavity oriented upward in the transporting direction; a transporter for transporting the positioned poultry; and a cooler including a container for cooled and flowing water, wherein the flow direction is opposed to the transporting direction, and to the treated poultry.

Owner:TOPKIP

Halal cattle slaughtering and segmenting process

InactiveCN111213701AGrowth inhibitionPlay a broad-spectrum bactericidal effectSlaughtering/stunningCarcasses chillingEngineeringFood supply

The invention discloses a Halal cattle slaughtering and segmenting process. The process comprises the following steps: S1, beef cattle receiving: providing beef cattle by a qualified supplier; S2, entering into a temporary rearing pen: rearing the beef cattle for more than three months; S3, food supply stopping and water supply stopping in the pen; S4, pre-slaughter treatment; S5, entering into aturning plate box, and hanging; S6, slaughtering; S7, (synchronous) quarantine and trimming of carcasses and internal organs; S8, high-pressure washing: washing the carcass with a 32-38 DEG C warm cleaning solution under a high pressure of 0.2 MPa or above; S9, draining and cooling; S10, acid discharging: performing standing for 12-24 hours at a temperature of 0-4 DEG C and a relative humidity of70-80%; S11, segmenting and trimming: separating parts of beef according to the variety, and performing trimming; S12, weighing, packaging and quick-freezing; S13, metal detection; and S14, packagingand refrigeration of a finished product. According to the process, the safety coefficient of the slaughtered beef is increased, consumers can eat the beef more securely without worrying about the bacterial problem of the beef, the quality guarantee period of the beef is prolonged, and the chance that people will get sick from eating beef is reduced.

Owner:北京卓宸畜牧有限公司

Method and apparatus for processing carcasses

InactiveUS8002613B2Fish washing/descalingAnimal stomach clearanceProcess engineeringManufacturing line

Owner:CARGILL INC

Systems and methods for controlling water quality in food processing

ActiveUS20180279635A1Reduce bacterial loadFish washing/descalingPoultry cleaning/disinfectionHigh concentrationAlkalinity

A chiller bath includes a tank for holding a volume of chiller water; a dosing system for dosing a first solution and a second solution into the chiller water, arranged to create a plurality of zones within the volume of water, wherein each zone has a higher concentration of either the first or the second solution than surrounding portions of the volume of water; and a meat or poultry immersion arrangement for immersing and moving carcasses in the chiller water. A method for reducing bacterial load on meat or poultry includes generating a plurality of zones within a chiller bath containing water by dosing a source of alkalinity and antimicrobial into the water, wherein the plurality of zones comprises at least one alkaline zone with a pH above 8.5, and at least one antimicrobial zone with pH below 8.5; and submersing meat or poultry in the bath. The zones can also be generated using spray nozzles in a meat or poultry operation.

Owner:ECOLAB USA INC

Rocker chiller with central and side deflectors

A rocker chiller 10 includes a tank 12 with a dasher assembly 26 that oscillates across the curved bottom wall of the tank. A series of central deflectors 40 are positioned at intervals along the length of the tank and another series of side deflectors 46 are mounted at intervals along the upwardly extending side walls 16 and 18 of the tank. The side deflectors are offset longitudinally with respect to the central deflectors. The offset relationship of the side deflectors and central deflectors creates serpentine paths through the elongated tank on both sides of the tank that require the carcasses to move through more of the heat exchanging liquid and which reduces the tendency of carcasses passing each other.

Owner:MORRIS & ASSOCS

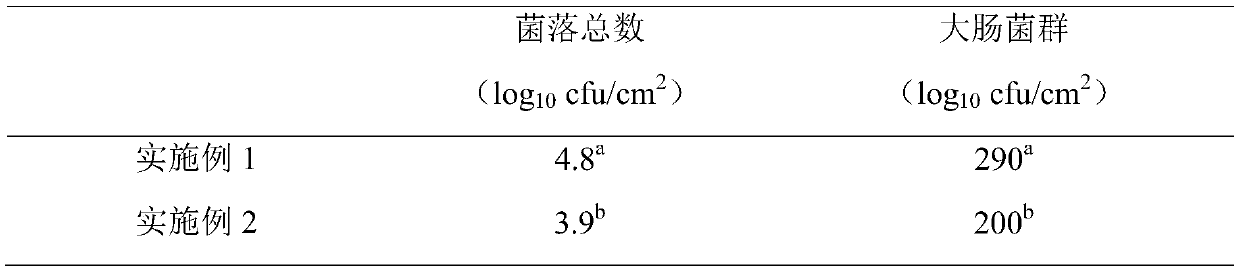

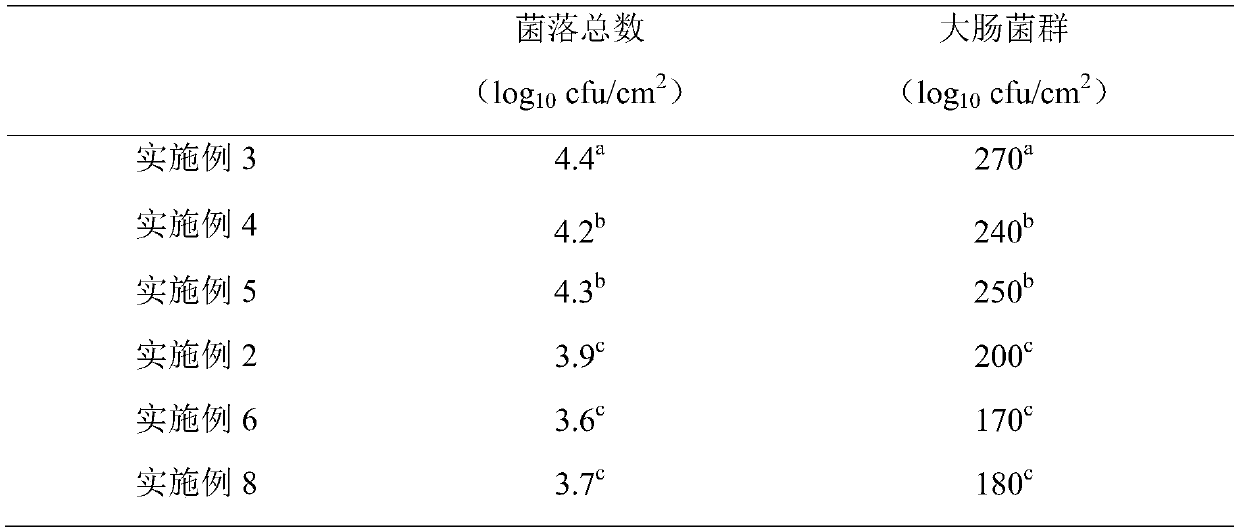

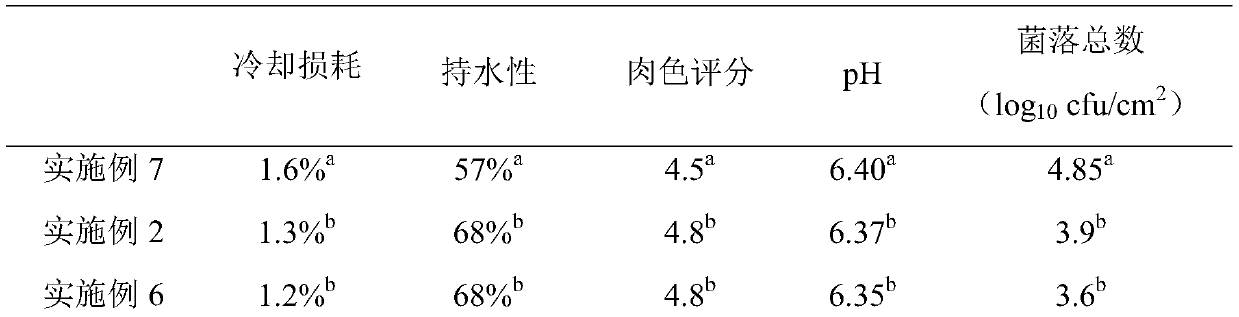

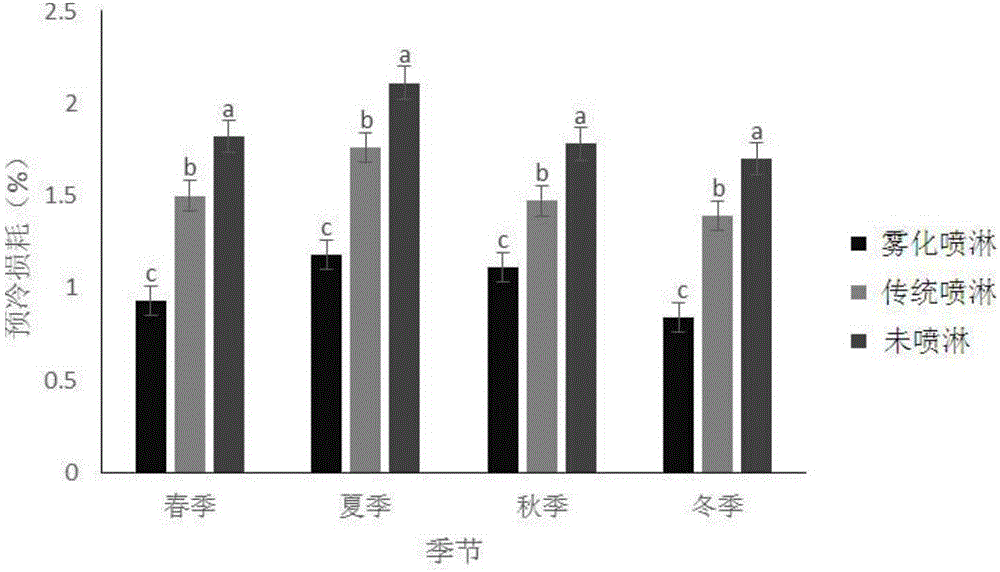

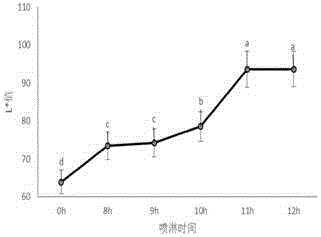

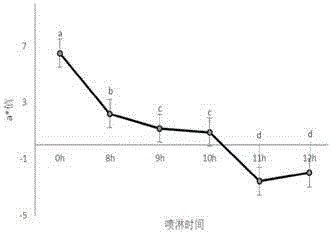

Method for cooling livestock and poultry carcass

InactiveCN110178878AImprove qualityReduce cooling lossPoultry cleaning/disinfectionCarcasses chillingMicroorganismEconomic benefits

The invention discloses a method for cooling livestock and poultry carcass. The method comprises the following steps: washing carcass for 5-8s by adopting high-pressure water with a water temperatureof 15-20 DEG C and a pressure of 1.1-1.2 atmospheres after peeling; removing viscera, and washing the carcass for 0.8-1min by adopting high-pressure water with a water temperature of 15-20 DEG C and apressure of 1.1-1.2 atmospheres; performing spraying with a mixed solution for 0.8-1min, wherein the mixed solution comprises 1.5-2% lactic acid and 0.8-1% salt aqueous solution; and performing cooling at -30 to -25 DEG C for 1-1.5h, performing cooling at 5-6 DEG C for 7.5-8h, and performing cooling at 0-4 DEG C for 14.5-38.5h. The method has the beneficial effects of effectively reducing the cooling loss of livestock and poultry after slaughtering, improving the quality of the carcass and improving the economic benefit of enterprises, obviously reducing the quantity of microorganisms on thesurface of the cooled carcass, stabilizing the color and luster of meat, and obviously improving the quality safety of the cooled carcass.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Pork carcass atomized spraying cooling system and atomized spraying cooling method

ActiveCN106035590AReduced cooling lossImprove uniformityCarcasses chillingWater storage tankSpray nozzle

The present invention discloses a pork carcass atomized spraying cooling system and an atomized spraying cooling method. The system comprises a pre-cooling storage, a water storage tank, a screw air compressor, an intelligent control system, a water pump, an atomizing nozzle and a plurality of control valves. The screw air compressor is connected with two air path spraying branched pipelines through a spraying main pipeline. The two air path spraying branched pipelines are connected with the atomizing nozzle. The atomizing nozzle is connected with the water pump via a third water path spraying pipeline. The water pump is connected with the water storage tank via a forth spraying pipeline. The first control valve is arranged on the spraying main pipeline, the second control valve is arranged on the forth spraying pipeline, and the first control valve and the second control valve are respectively connected with the intelligent control system. The pork carcass atomized spraying cooling system optimizes the previous atomized spraying system, can significantly reduces the pre-cooling loss of the pork carcasses, can also improve the uniformity of the atomized spraying, reduces the dripping phenomena of the atomizing nozzle, improves the color and luster, and sensory characteristics of the pork carcasses, and enhances the consumers' purchase desires.

Owner:NANJING AGRICULTURAL UNIVERSITY

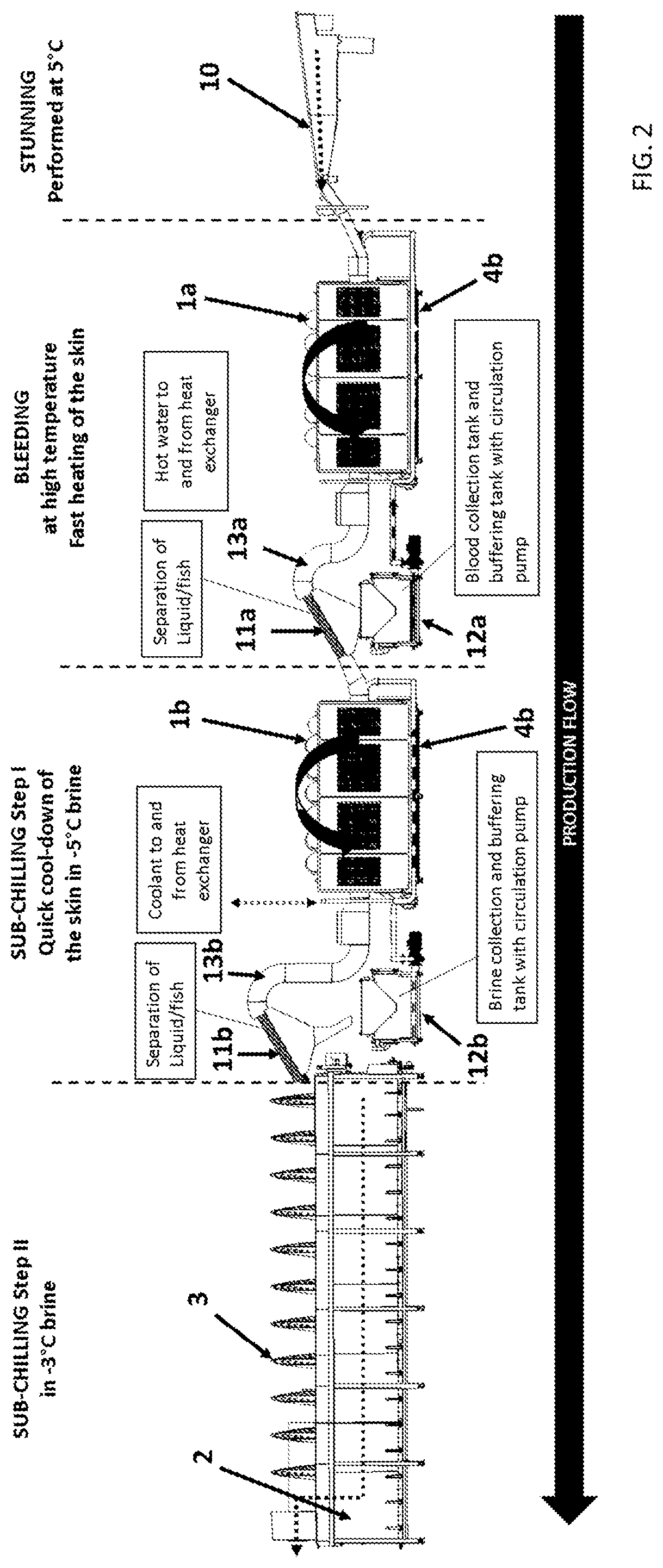

A method for freezing food items

PendingUS20210307345A1Increase valueSlaughtering/stunningMeat/fish preservation by freezing/coolingProcess engineeringBiology

Method and device for freezing food items in a gradual process, where the food items are first put through under-cooling before the food items are placed in a container or receptacle for freezing. The method and device are particularly suitable for freezing freshly slaughtered and bled fish for later processing.

Owner:LAMBHUSASUND EHF

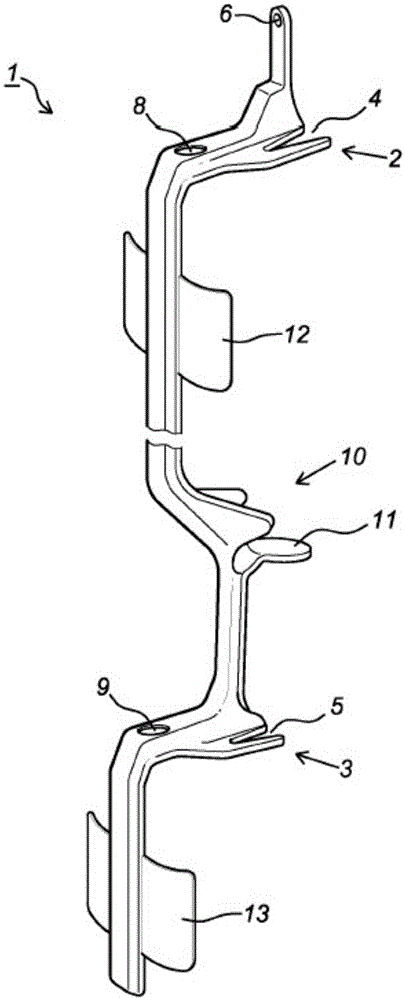

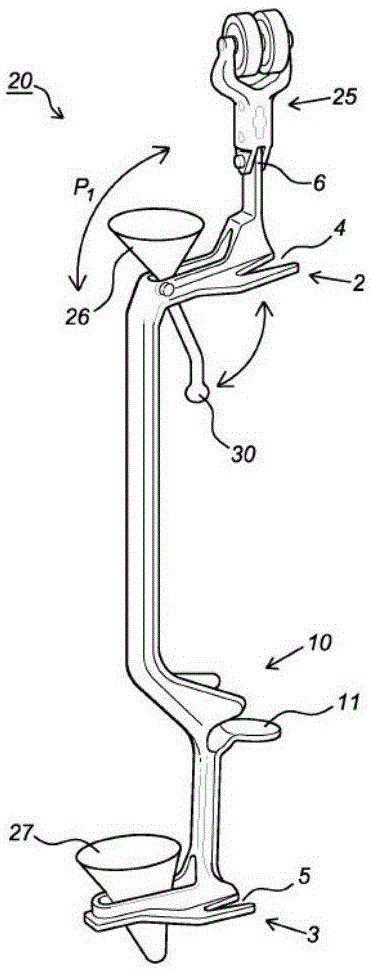

Shackle for hanging poultry transportation, poultry cooling unit, method for cooling of hanging poultry and method for hanging poultry carcasses to poultry shackles

InactiveCN105120672AClean thoroughlyEasy to cleanPoultry cleaning/disinfectionLighting and heating apparatusEngineeringShackle

The present invention relates to a shackle (1) for hanging poultry transportation provided with at least one fluid flow guide surface (12, 13) for directing a fluid flow towards a position wherein the poultry is to be held by the shackle. The invention also relates to a poultry cooling unit, a method for cooling of hanging poultry and a method for hanging poultry carcasses to multiple poultry shackles.

Owner:MAREL STORK POULTRY PROCESSING

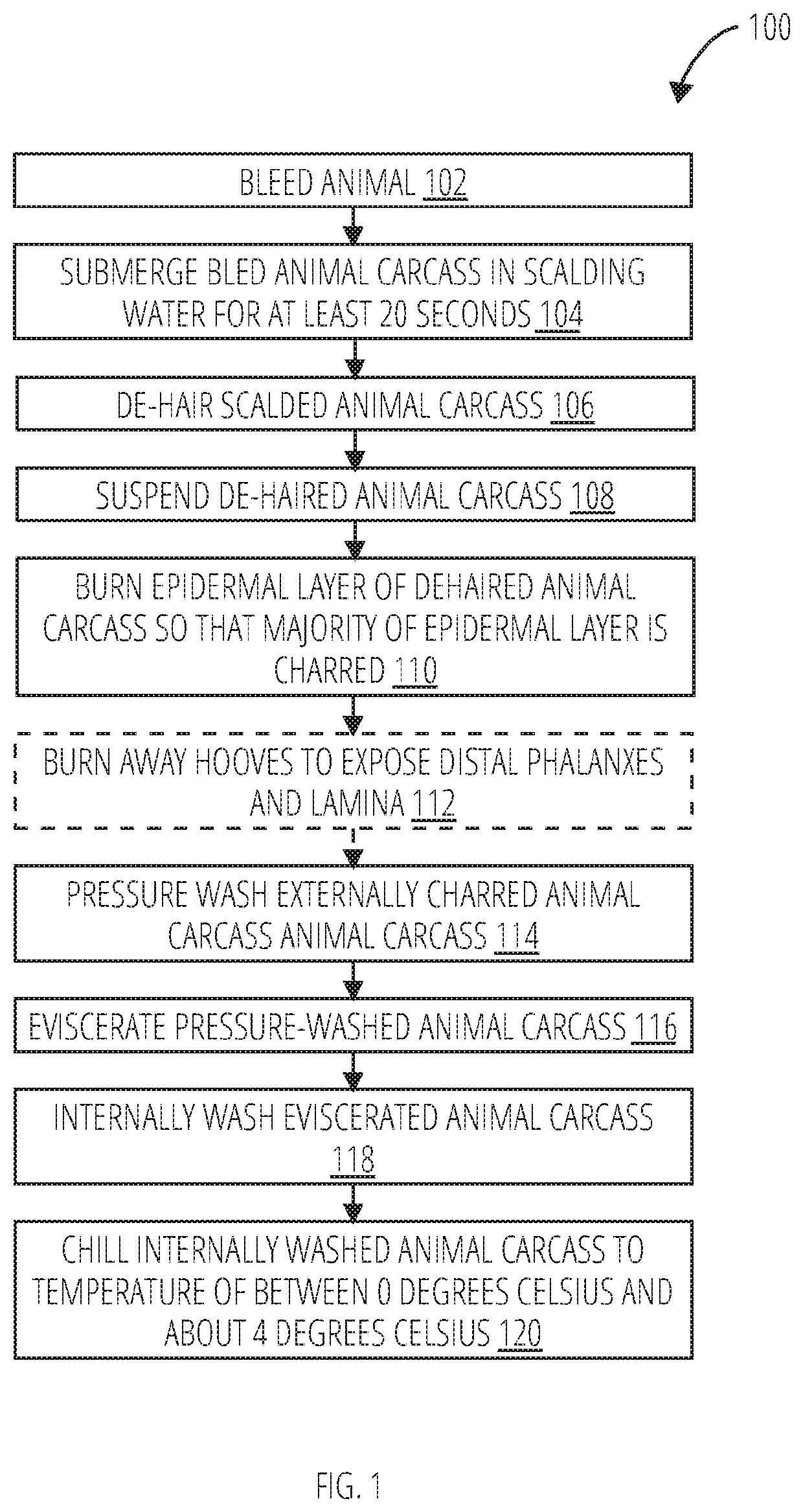

Method of processing an intact animal carcass

A method for processing an intact animal carcass comprises submerging a bled animal carcass in scalding water for at least 20 seconds to produce a scalded animal carcass, de-hairing the scalded animal carcass to produce a de-haired animal carcass, suspending the de-haired animal carcass, burning an epidermal layer of the de-haired animal carcass while suspended so that a majority of the epidermal layer is charred so as to produce a burnt animal carcass, pressure washing the burnt animal carcass to produce a pressure-washed animal carcass, eviscerating the pressure-washed animal carcass to produce an eviscerated animal carcass, internally washing the eviscerated animal carcass to produce an internally washed animal carcass, and chilling the internally washed animal carcass to a temperature of between 0 degrees Celsius and about 4 degrees Celsius to produce a chilled animal carcass.

Owner:L & M MEATS IP HLDG INC

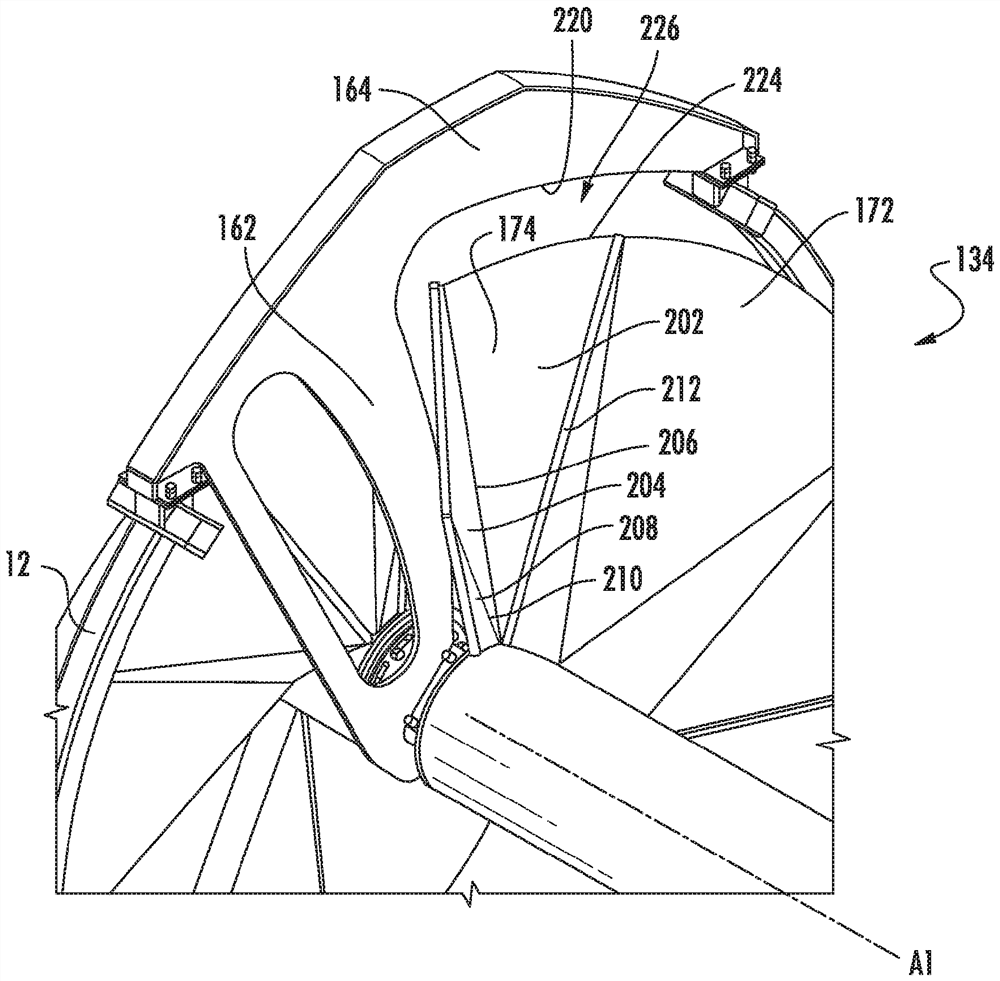

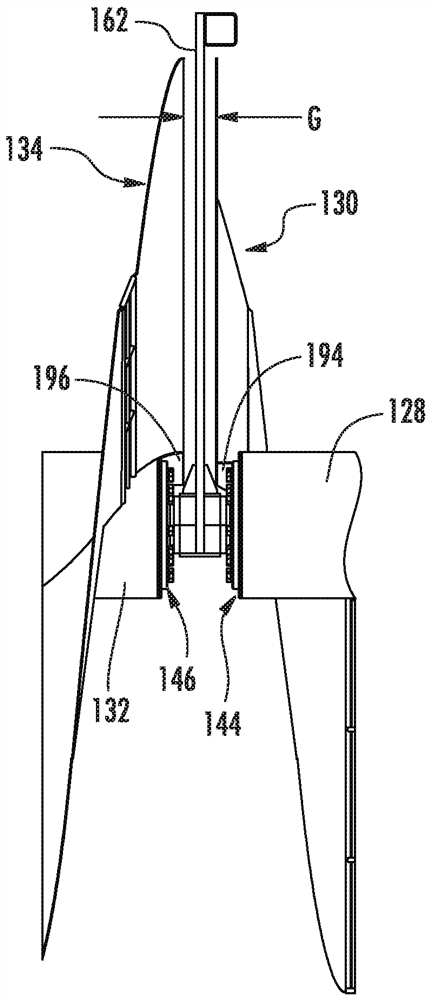

Auger type poultry cooler with enhanced hanger bearing construction and related assemblies

ActiveCN107920539BLarge adjustment rangeMeat/fish preservationStationary refrigeration devicesClassical mechanicsStructural engineering

A poultry cooler includes a tank and an auger rotatably held within the tank. The auger includes a first auger section and a second auger section. The first auger section includes a first auger shaft and a first auger blade. The first auger blade includes a first helical portion on the first auger shaft and a first blade extension extending away from the first helical portion. The second auger section includes a second auger shaft coupled to the first auger shaft and a second auger blade. The second auger blade includes a second helical portion on the second auger shaft and a second blade extension extending away from the second helical portion. The cooler includes a hanger bearing assembly between the first and second auger sections and extending to an upper portion of the tank.

Owner:MORRIS & ASSOCS

Two-section type rapid cooling method after live pig slaughtering

InactiveCN111919870AReduce dry consumptionImprove product qualityMeat/fish preservation by freezing/coolingCarcasses chillingBiotechnologyAnimal science

The invention belongs to the technical field of food processing, and discloses a two-section type rapid cooling method for slaughtered live pigs. The method comprises the following specific steps: (1)pretreatment; (2) primary cooling; (3) second-section cooling; (4) storing. The cooling method has the beneficial effects that the dry consumption of the fresh meat of the live pigs produced by the processing method in the cooling stage can be reduced, the product quality of the cooled meat is improved, and the cooling method is relatively simple in process, can be conveniently adopted in daily life, is low in cost and is a relatively recommended post-slaughter cooling process.

Owner:衡东县吉平食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com