Auger Chiller with Sloped Unloader

a chiller and bird technology, applied in the field of poultry chillers, can solve the problem that the birds received in the tank are typically expected to be negatively buoyan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

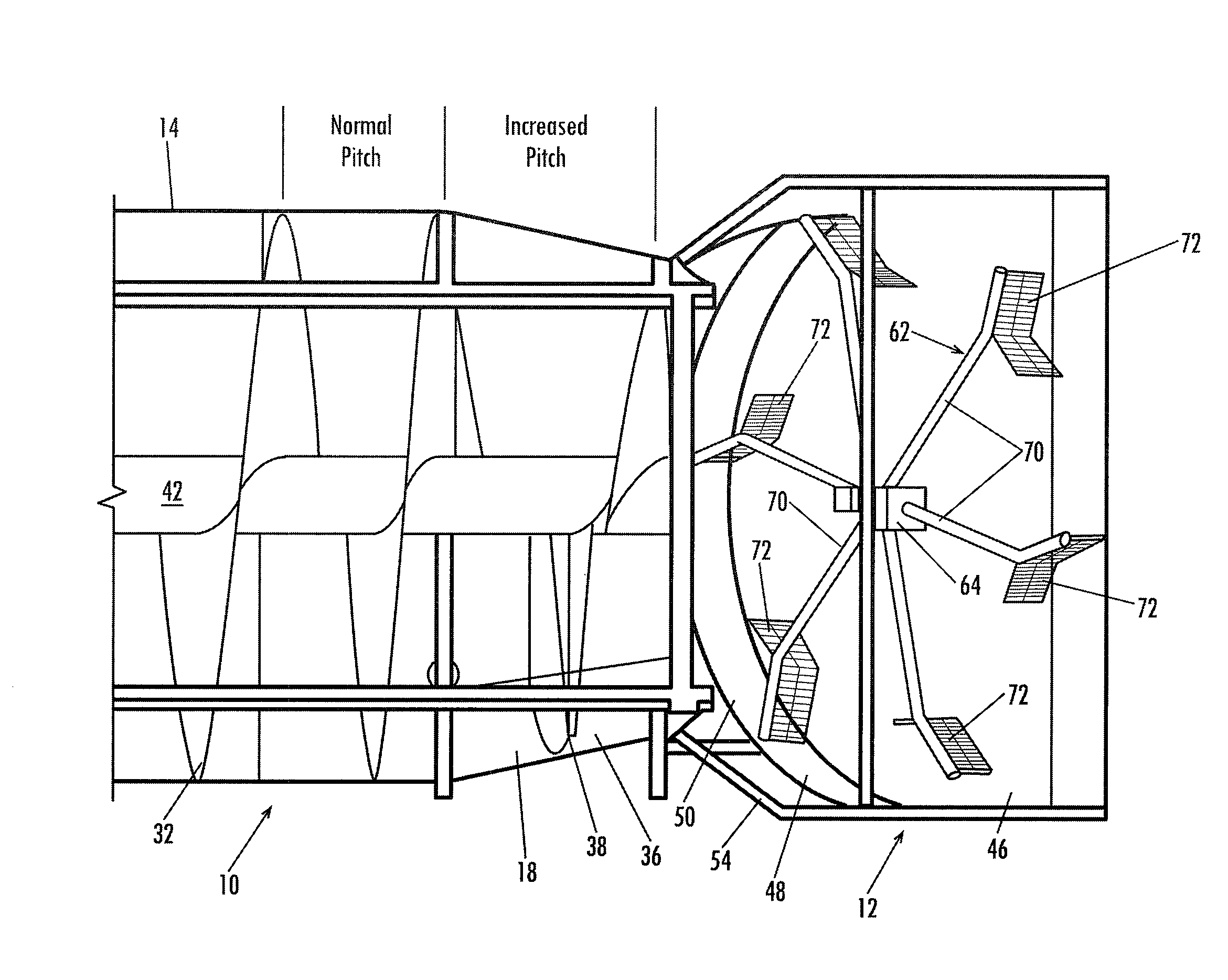

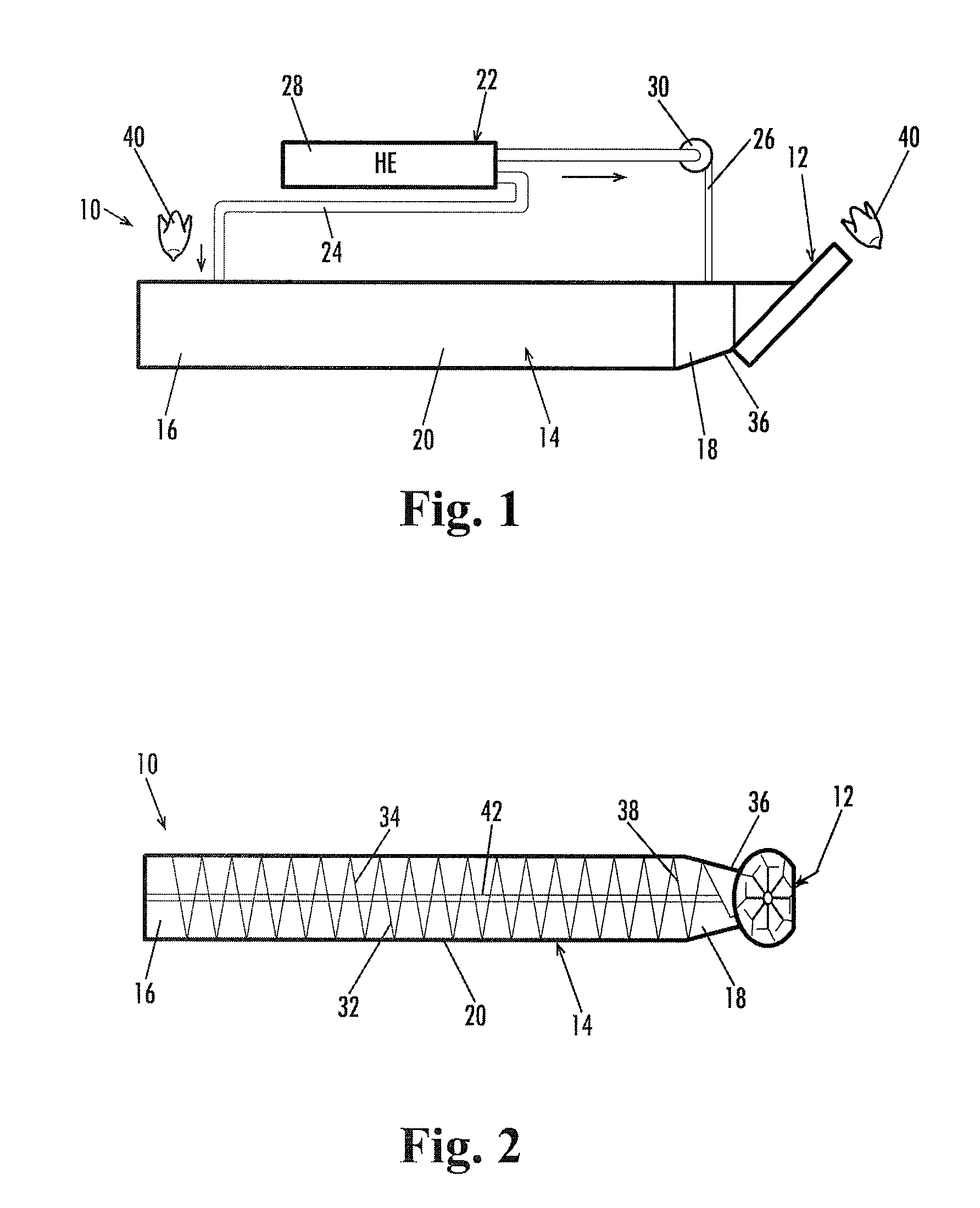

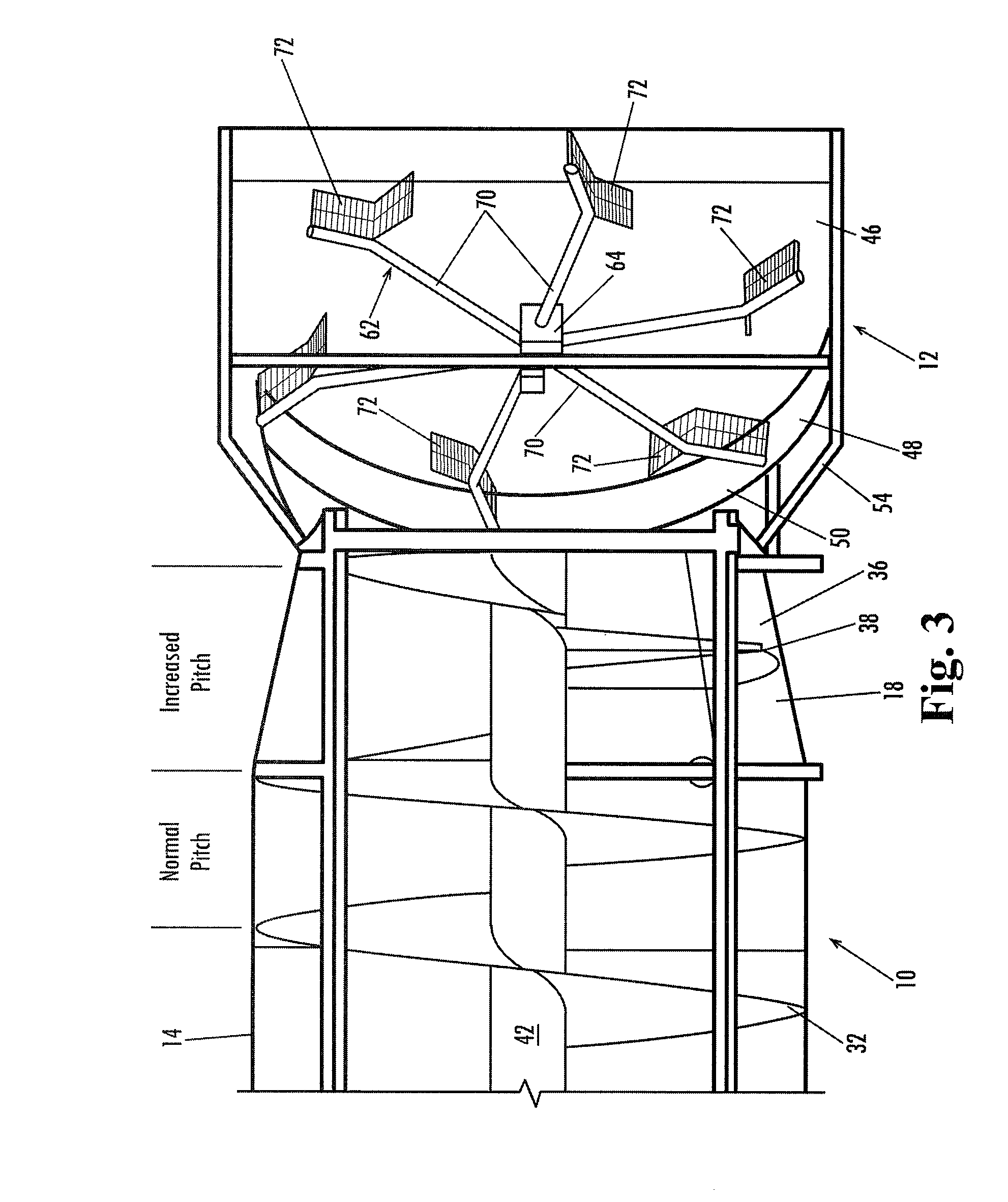

[0023]Referring now in more detail to the drawings, in which like numerals indicate like parts throughout the several views, FIG. 1 illustrates an auger chiller 10 with a sloped bird unloader 12, with the auger chiller including an elongated tank 14 for receiving bird carcasses, with a carcass entrance end 16, a carcass delivery end 18, and a main tank segment 20 extending between the ends.

[0024]As shown in FIG. 1, a chilled water recirculation system 22 is provided for reducing the temperature of the water being recirculated from the carcass entrance end 16 to the carcass delivery end 18, thereby forming a counterflow relationship between the chilled water and the oncoming birds. The recirculation system generally includes conduits 24 and 26, with a heat exchanger 28 therebetween, with a pump 30 moving the liquid from the chiller tank through the heat exchanger.

[0025]As shown in FIG. 2, the auger 32 extends along the bottom wall of the tank and includes its main segment of auger bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com