Pork carcass atomized spraying cooling system and atomized spraying cooling method

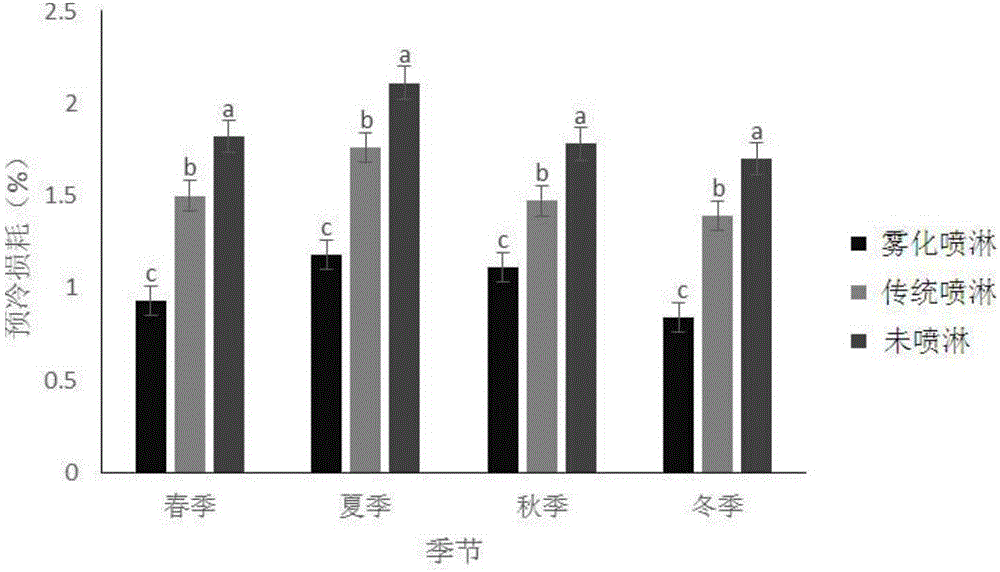

A technology of atomization spraying and cooling system, which is applied in the direction of carcass cooling, slaughtering accessories, slaughtering, etc. It can solve the problems of large water marks on the surface of the carcass, uneven spraying, and no atomization spraying, etc., so as to improve the sensory properties , Improve the uniformity, reduce the effect of pre-cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] Materials: 1440 pig halves, each weighing about 40kg.

[0044]Method: Adjust the water pressure, air pressure and flow rate of the spray. The values are: the spray water pressure is 0.35Mpa, the air pressure is 0.2Mpa, and the flow rate is 13L / h.

[0045] Set up the program of the intelligent control system, select the carcass placement track (select the spray track according to the actual production situation), spray time, and the spray frequency of each time period. Before the sample enters the warehouse, pre-spray for 30 minutes, humidify and cool down. After the pig carcass enters the warehouse, intermittent spraying is carried out, and the anti-drip nozzle is used for atomization spraying treatment, and the spraying is carried out according to the previously set parameters.

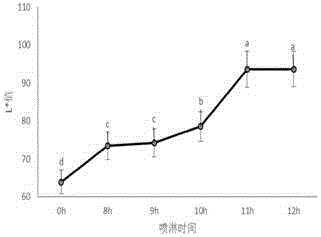

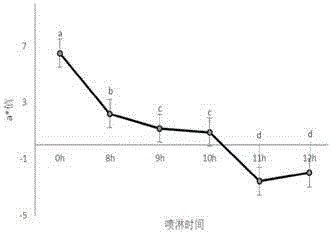

[0046] Different treatment groups were tested for 6 consecutive days, and 240 pig half-carcasses were placed in each batch of treatment groups, and put into the same pre-cooling room. The t...

example 2

[0063] Materials: 19,200 pig halves, each weighing about 40kg.

[0064] method:

[0065] 1. In the four seasons (January, March, July, November), 4800 pig half-carcasses were selected and divided into three treatment groups (atomized spray, no spray, traditional spray in enterprises) ).

[0066] 2. Pre-spray for 30 minutes before entering the warehouse in treatment group 1, humidify and cool down. After the pig carcass enters the warehouse, the pig carcass is intermittently sprayed, and the anti-drip nozzle is used for atomized spraying treatment. The spray water is 0°C-5°C, and the first 4h is sprayed every 5min for 30s, and the subsequent spraying 6h is spraying for 30s every 30min. The spray water pressure is 0.35Mpa, the air pressure is 0.2Mpa, and the flow rate is 13L / h; After the treatment group 2 enters the pre-cooling room, no spray treatment is performed on the carcass; after the treatment group 3 enters the pre-cooling room, the artificial method currently used by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com