Diesel engine

A diesel engine and piston technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of reduced fuel spray and air mixing, increased cooling loss, increased NOx, black smoke production, etc., to achieve Achieve cooling loss and improved mixing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

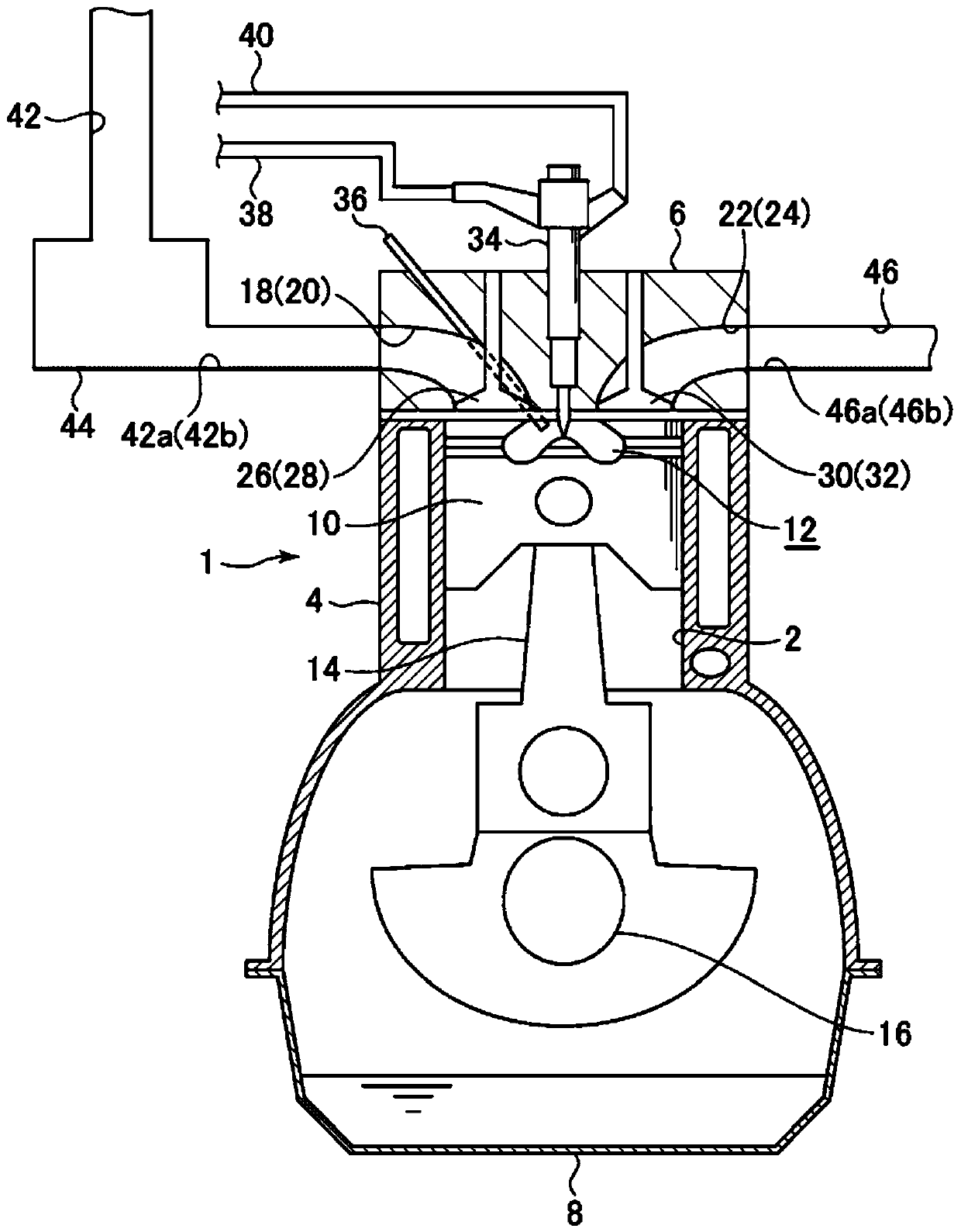

[0040] Hereinafter, a diesel engine according to an embodiment of the present invention will be described with reference to the drawings.

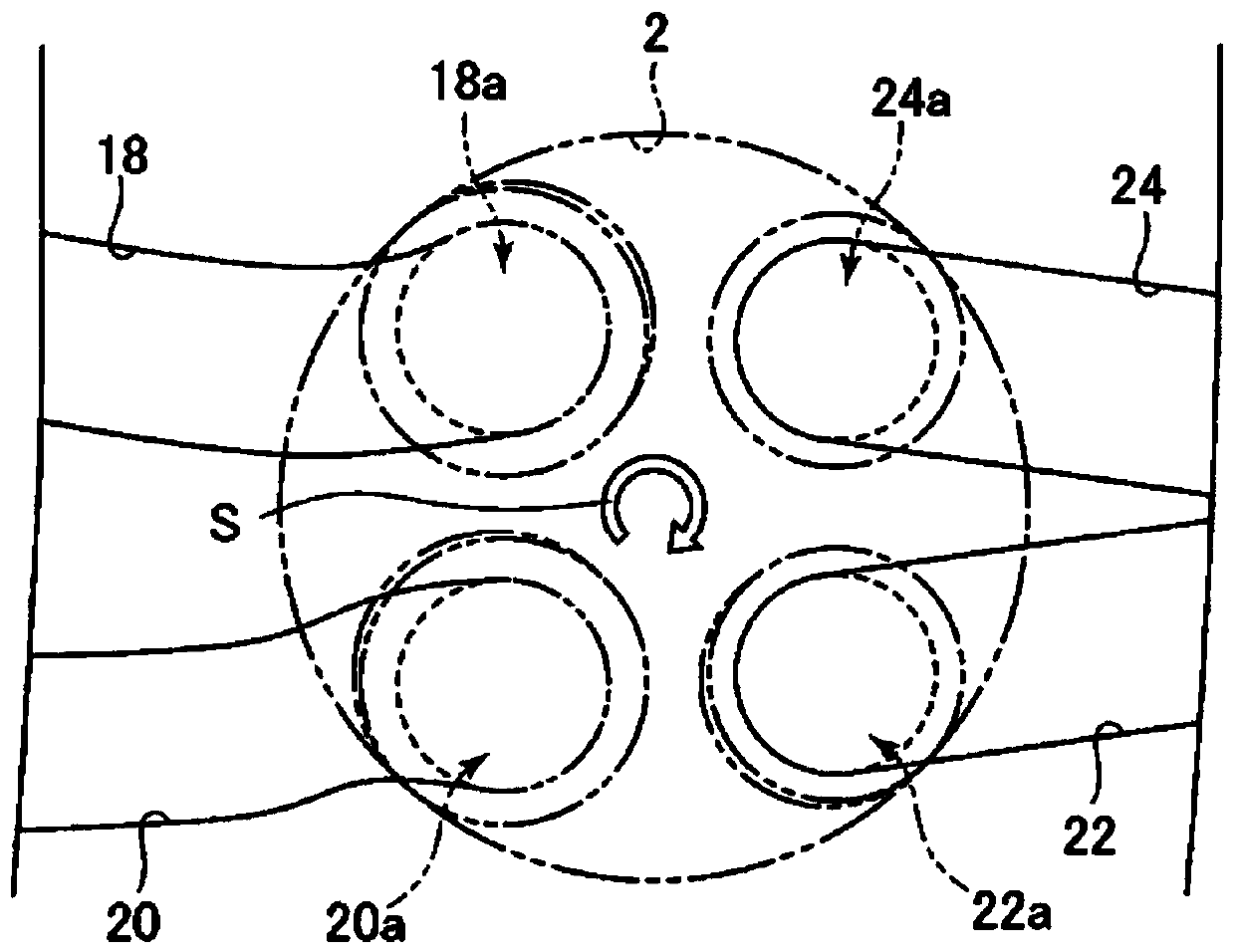

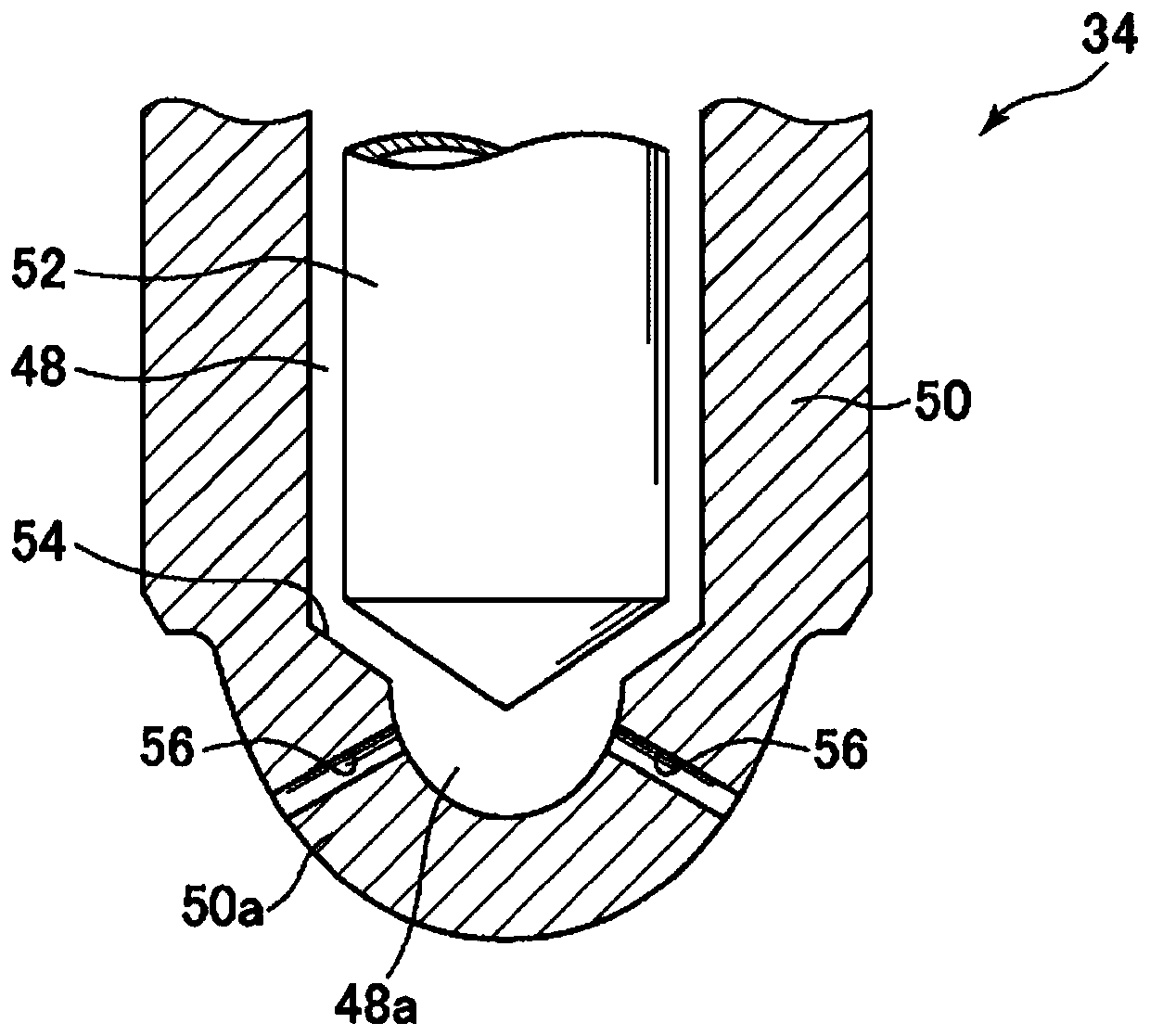

[0041] First, refer to Figure 1 to Figure 4 The structure of a diesel engine according to an embodiment of the present invention will be described.

[0042] figure 1 is a schematic diagram showing the structure of a diesel engine according to an embodiment of the present invention, figure 2 It is a top view schematically showing the arrangement of intake ports and exhaust ports in a diesel engine according to an embodiment of the present invention, image 3 is a partial cross-sectional view of a tip portion of a fuel injection valve according to an embodiment of the present invention, Figure 4 It is a diagram showing an example of a fuel injection method that is set differently depending on the operating state of the diesel engine according to the embodiment of the present invention.

[0043] exist figure 1 Among them, symbol 1 rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com