Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Prevent abnormal noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

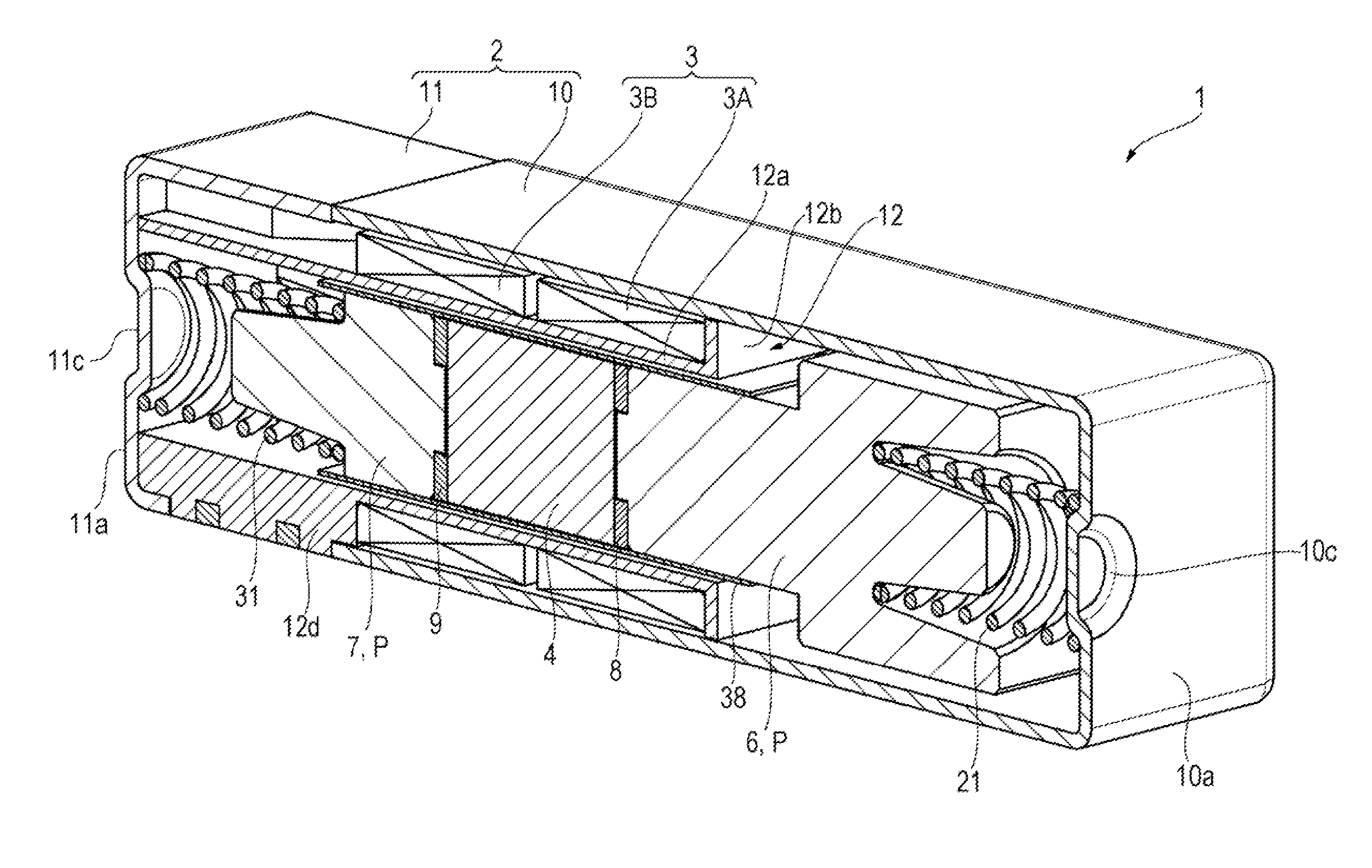

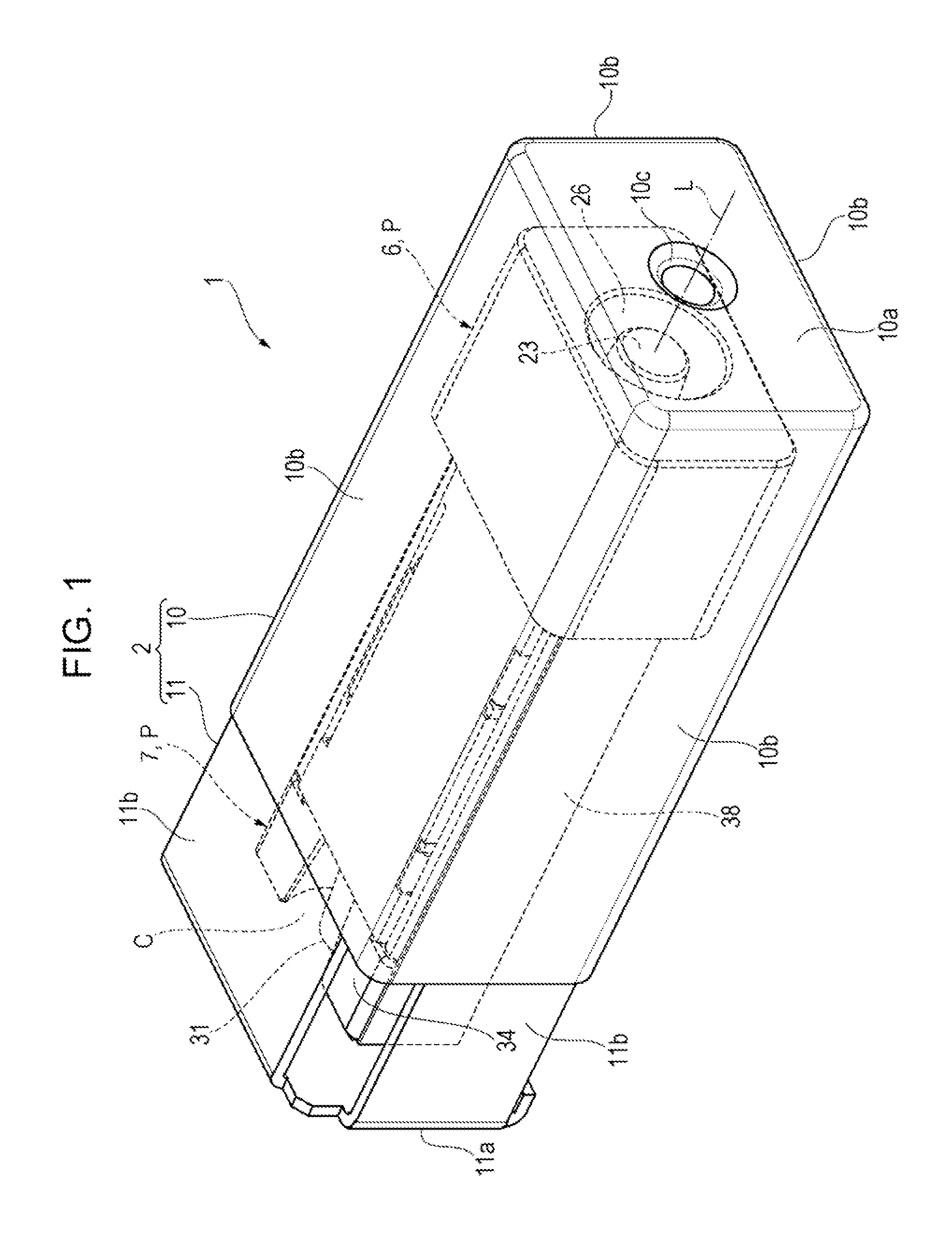

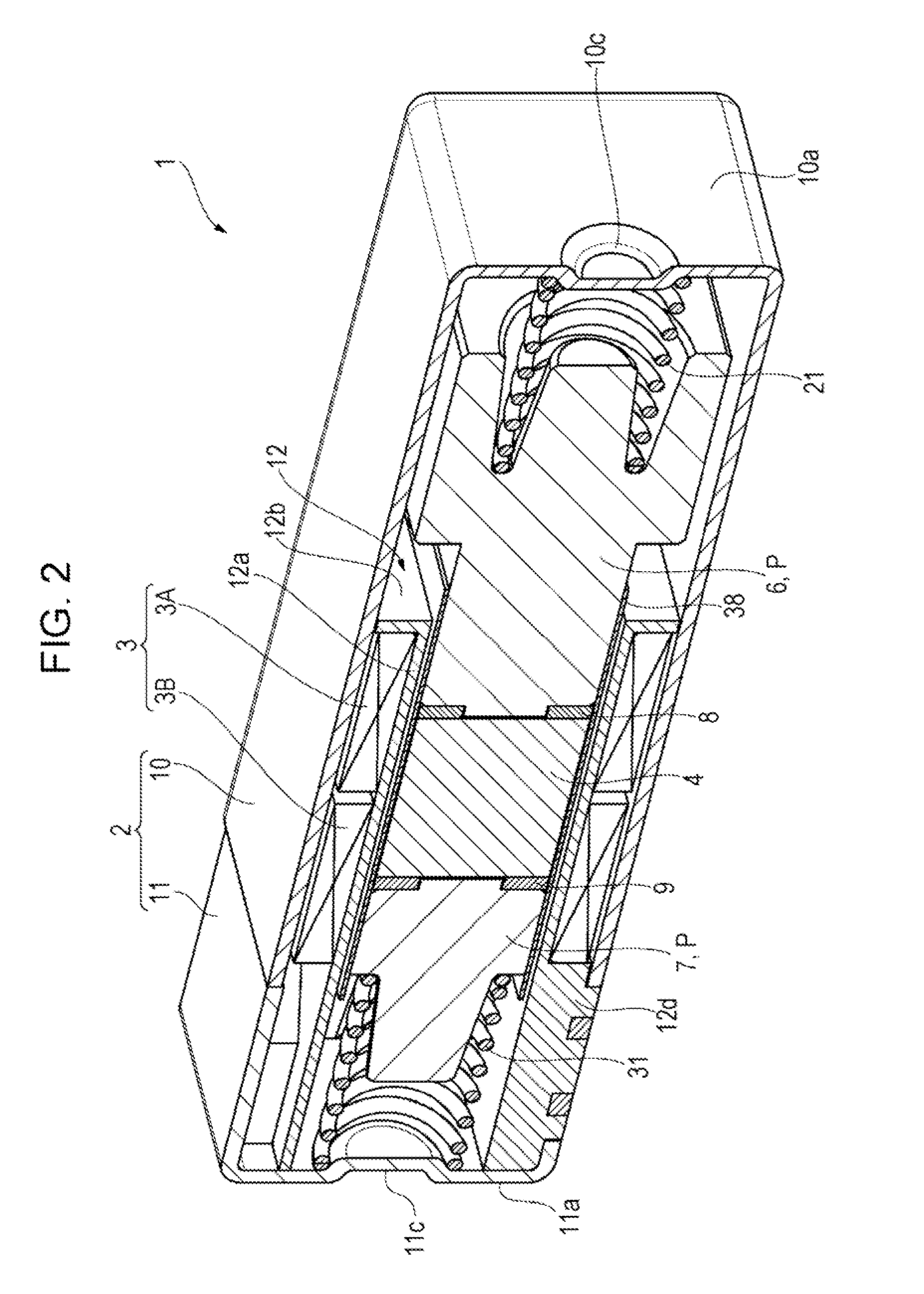

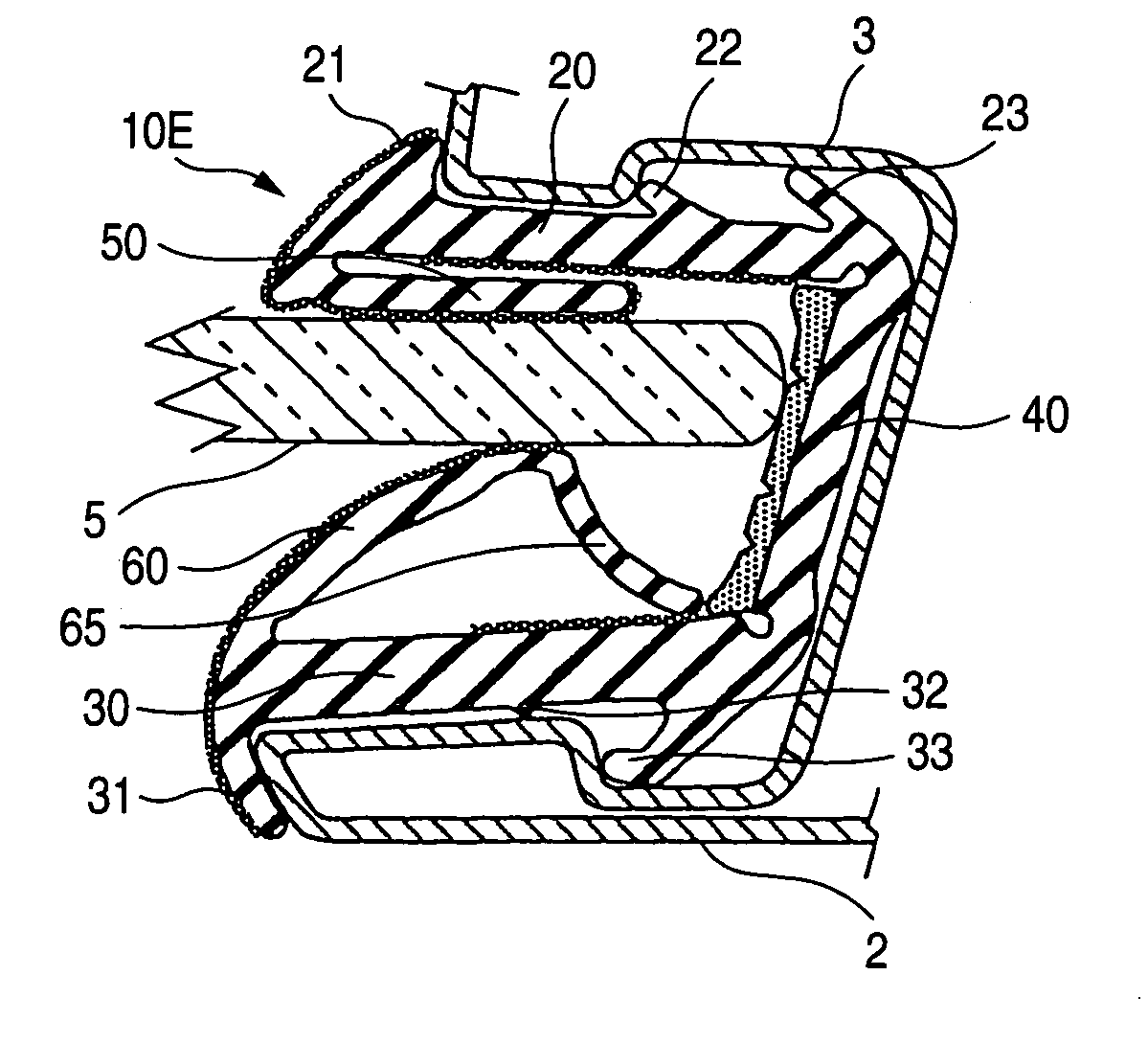

Vibration actuator

ActiveUS20140035397A1Prevent abnormal noiseStable vibrationDynamo-electric machinesEngineeringCoil spring

A first weight portion of a vibration actuator includes an inner-side enlarged portion that protrudes from an end portion of a solid head in a direction of a vibration axis and that is inserted into an opening portion extending within a first compression coil spring along the direction of the vibration axis. An outer peripheral surface of the inner-side enlarged portion becomes continuously smaller in diameter from a base end towards a free end, with the vibration axis being the center of the diameter. That is, the inner-side enlarged portion has the shape of a truncated cone. The inner-side enlarged portion is inserted into the opening portion of the first compression coil spring and the opening portion is utilized to change the length of the inner-side enlarged portion in the direction of the vibration axis, thereby changing the mass of the first weight portion.

Owner:NIDEC COPAL CORPORATION

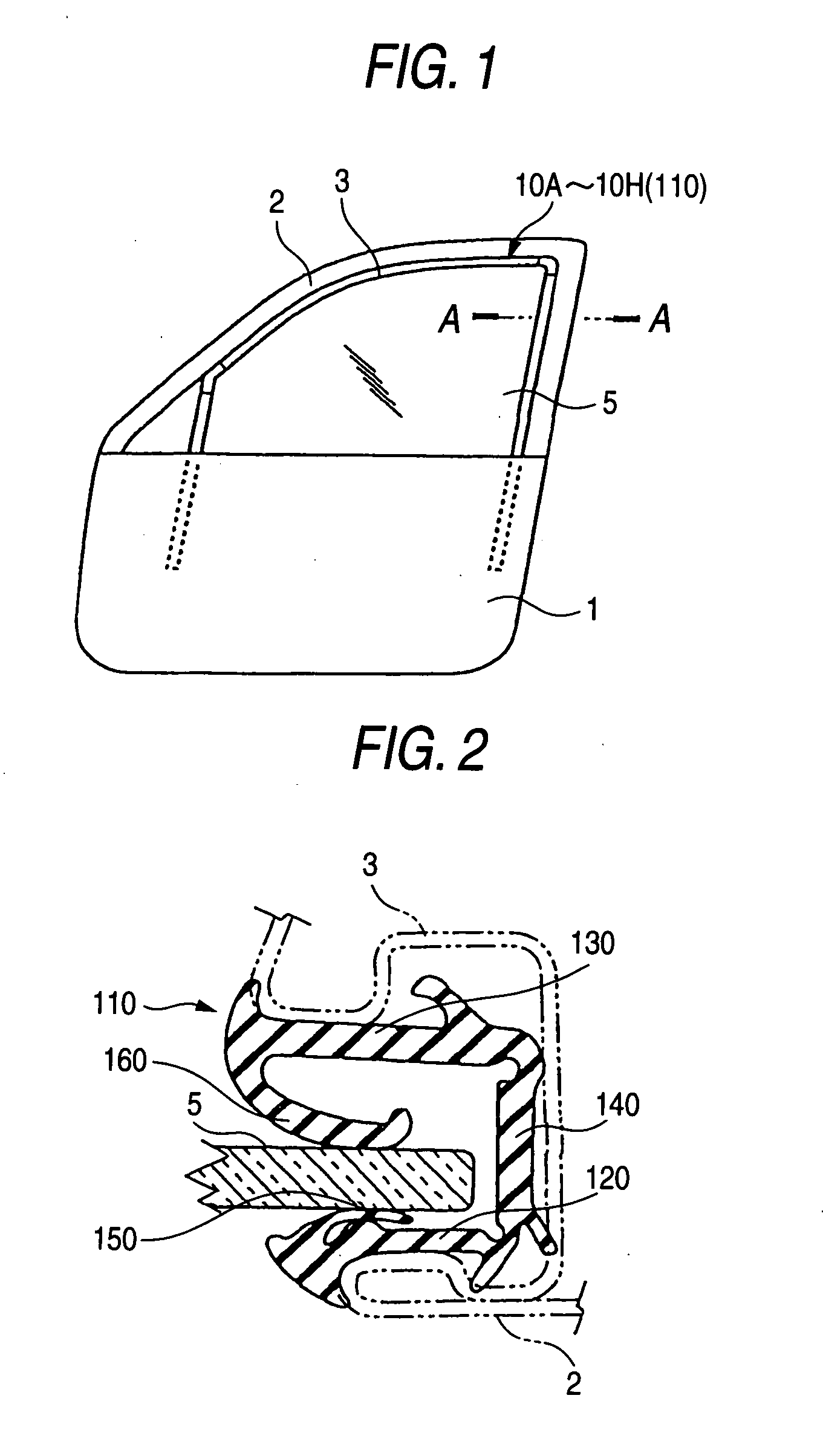

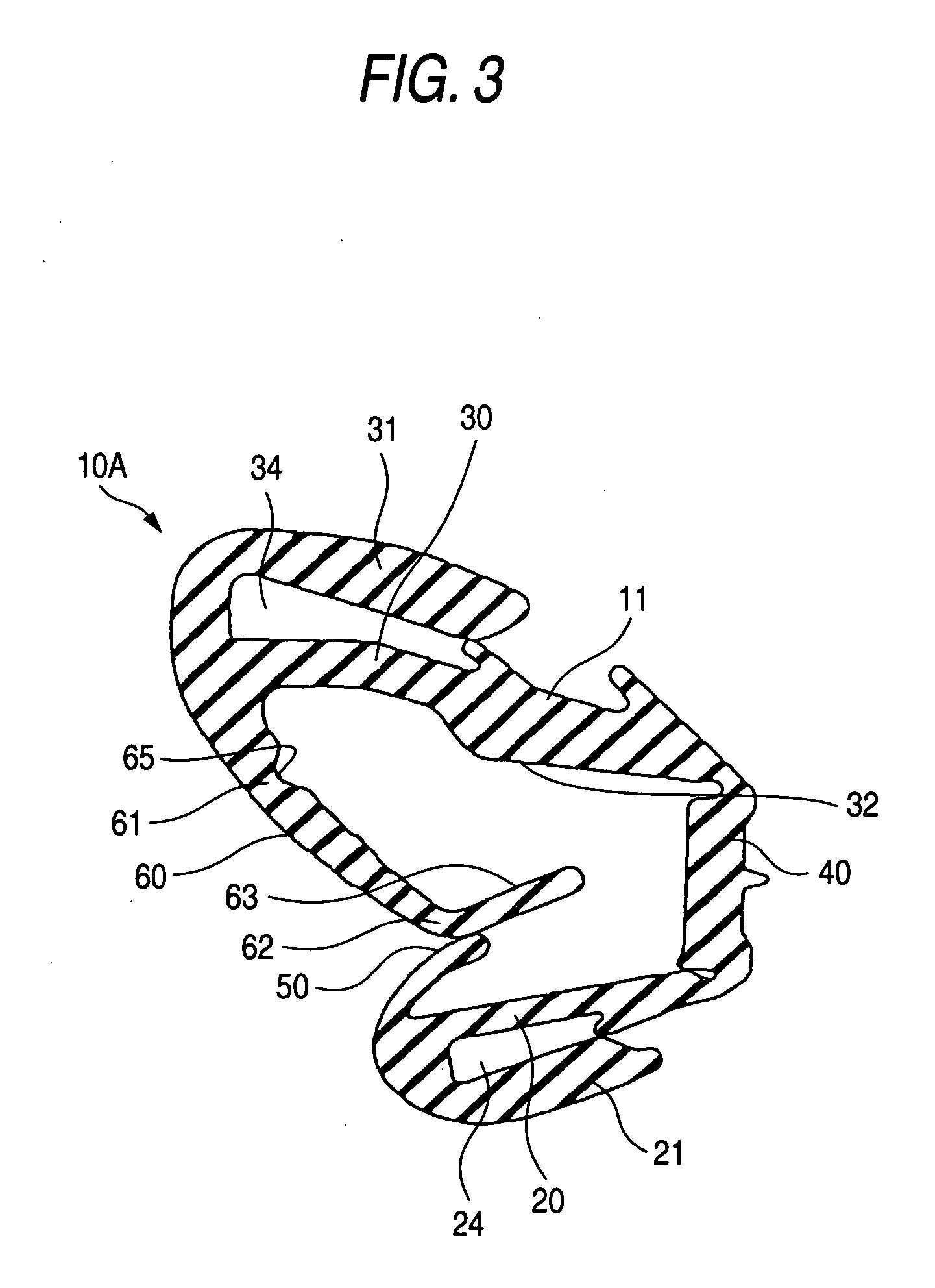

Glass run for vehicle

InactiveUS20050120633A1Reduce difference in levelReduced sliding resistanceEngine sealsSealing arrangementsEngineeringCar door

Owner:TOYODA GOSEI CO LTD

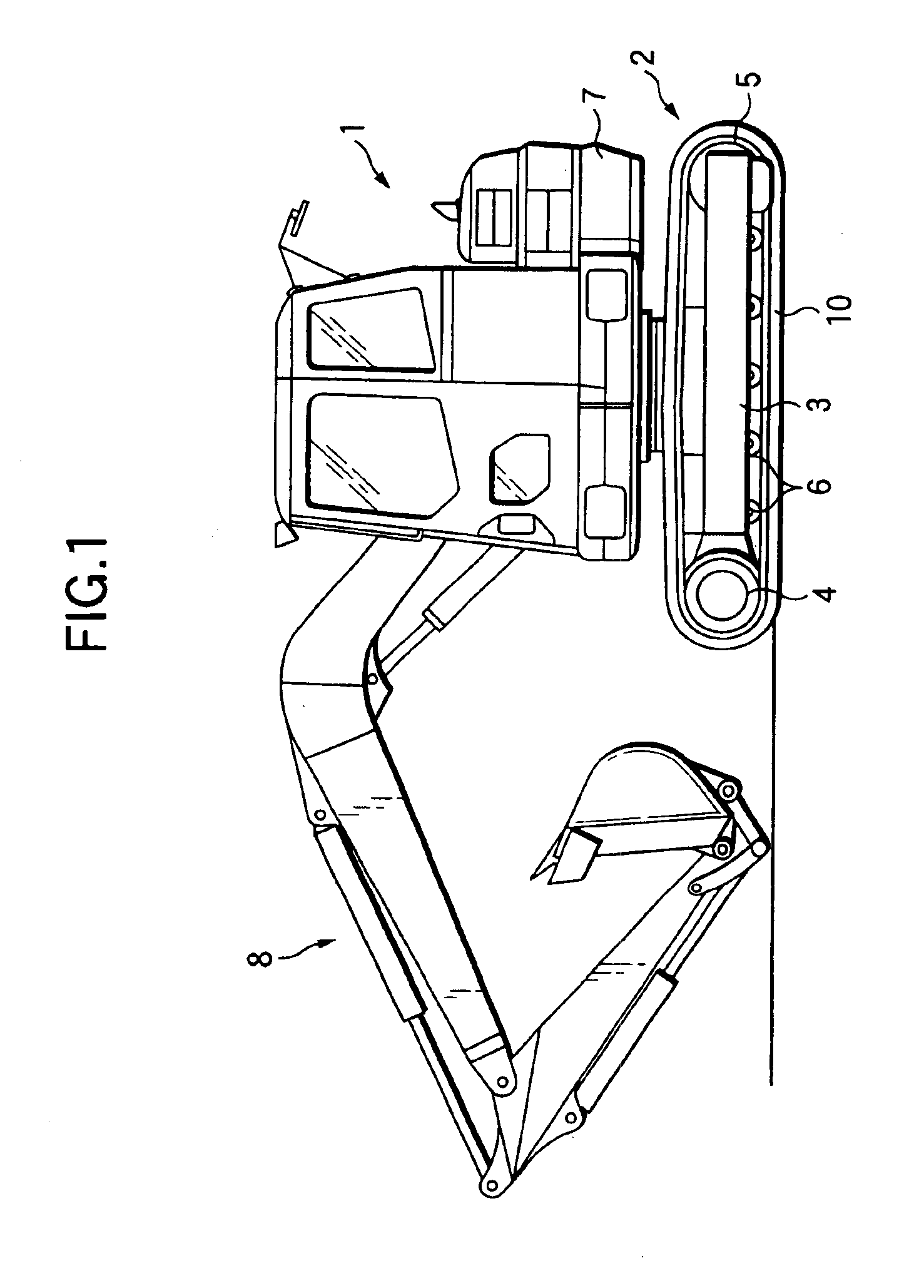

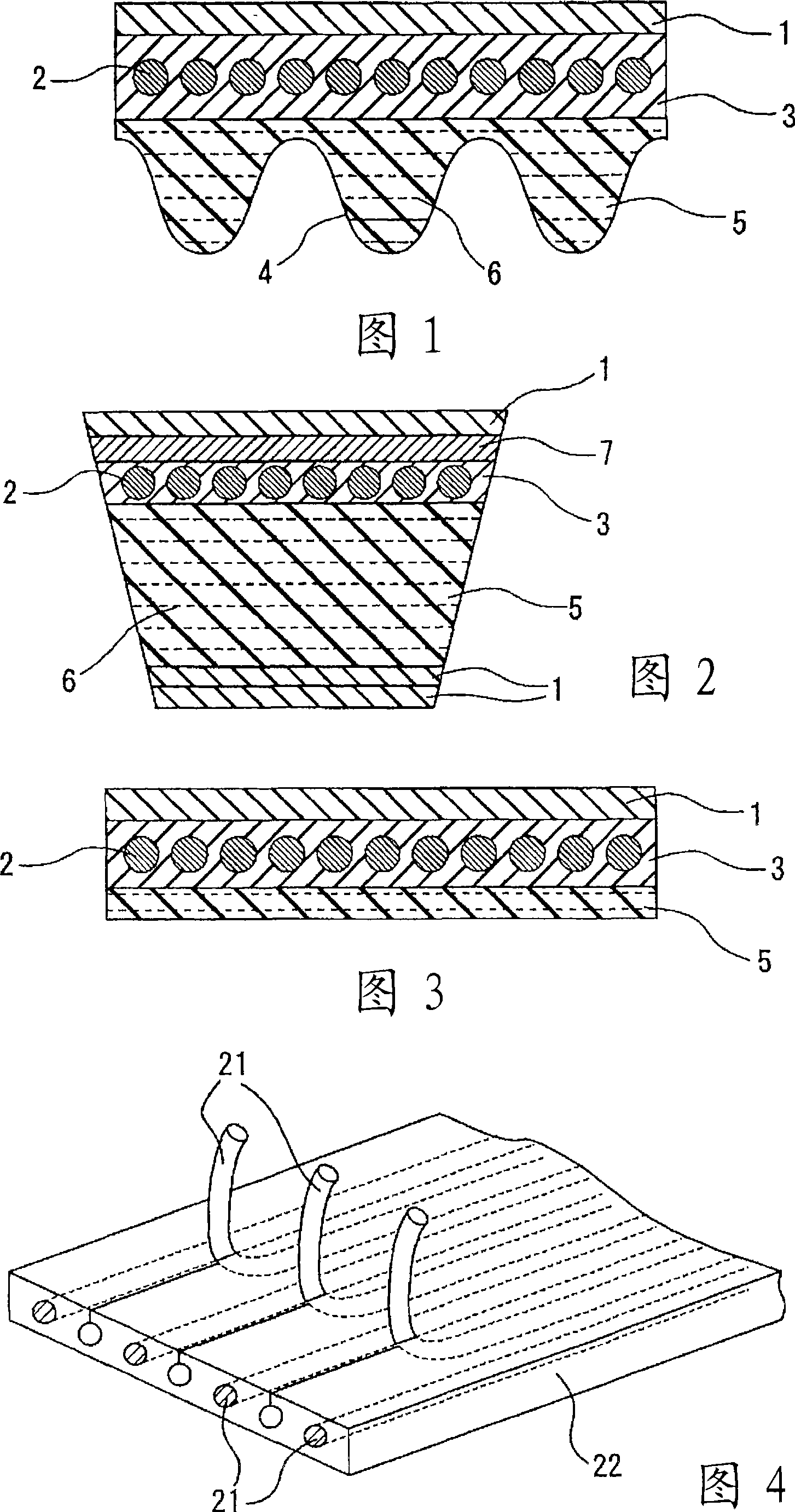

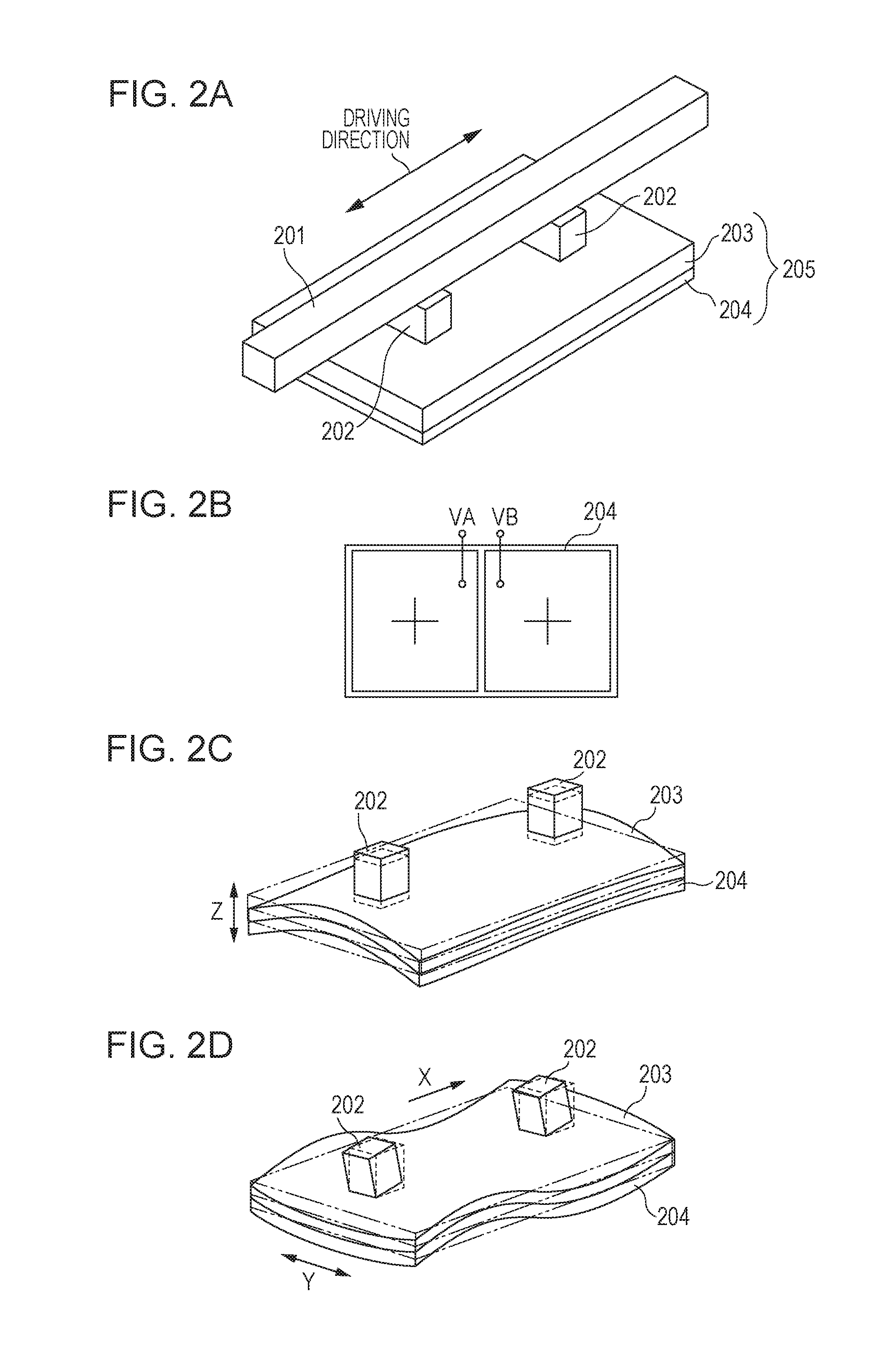

Elastic-bodied crawler

InactiveUS6932442B2Increased durabilityDriven projectionDriving beltsEndless track vehiclesElastomerEngineering

An elastic-bodied crawler, in which damages, such as local wear, coming-off of driven projections and the like in use, are prevented from being brought about, and frictional resistance is decreased at engaging portions to provide for durability, comprises a body with a reinforcement layer of reinforcement cables embedded therein circumferentially, driven projections provided in a predetermined pitch on an inner peripheral surface of the body, lug portions formed on an outer surface of the body, and reinforcement members (driven projection reinforcement cables) embedded to bridge the driven projections and the body.

Owner:KOMATSU LTD

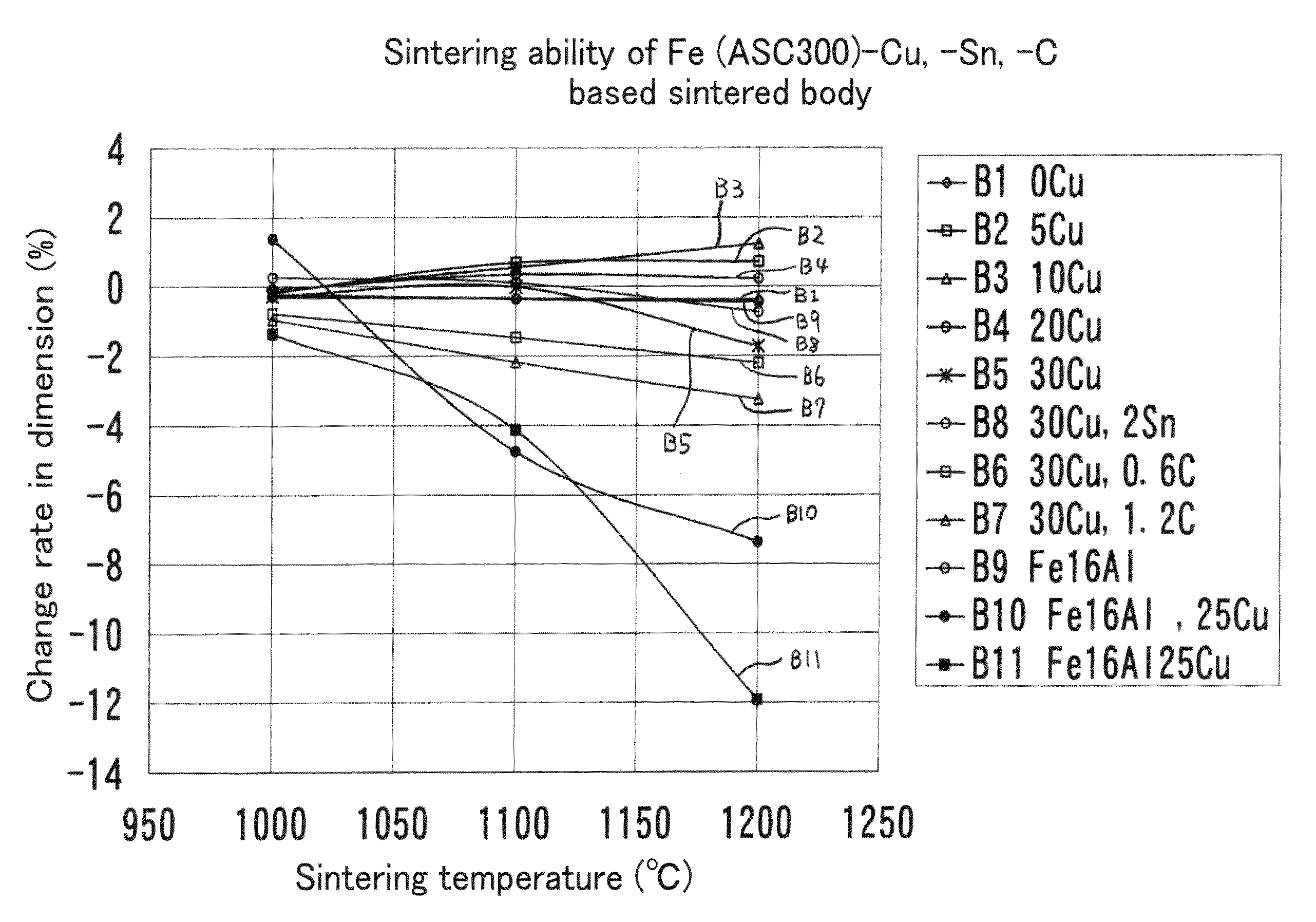

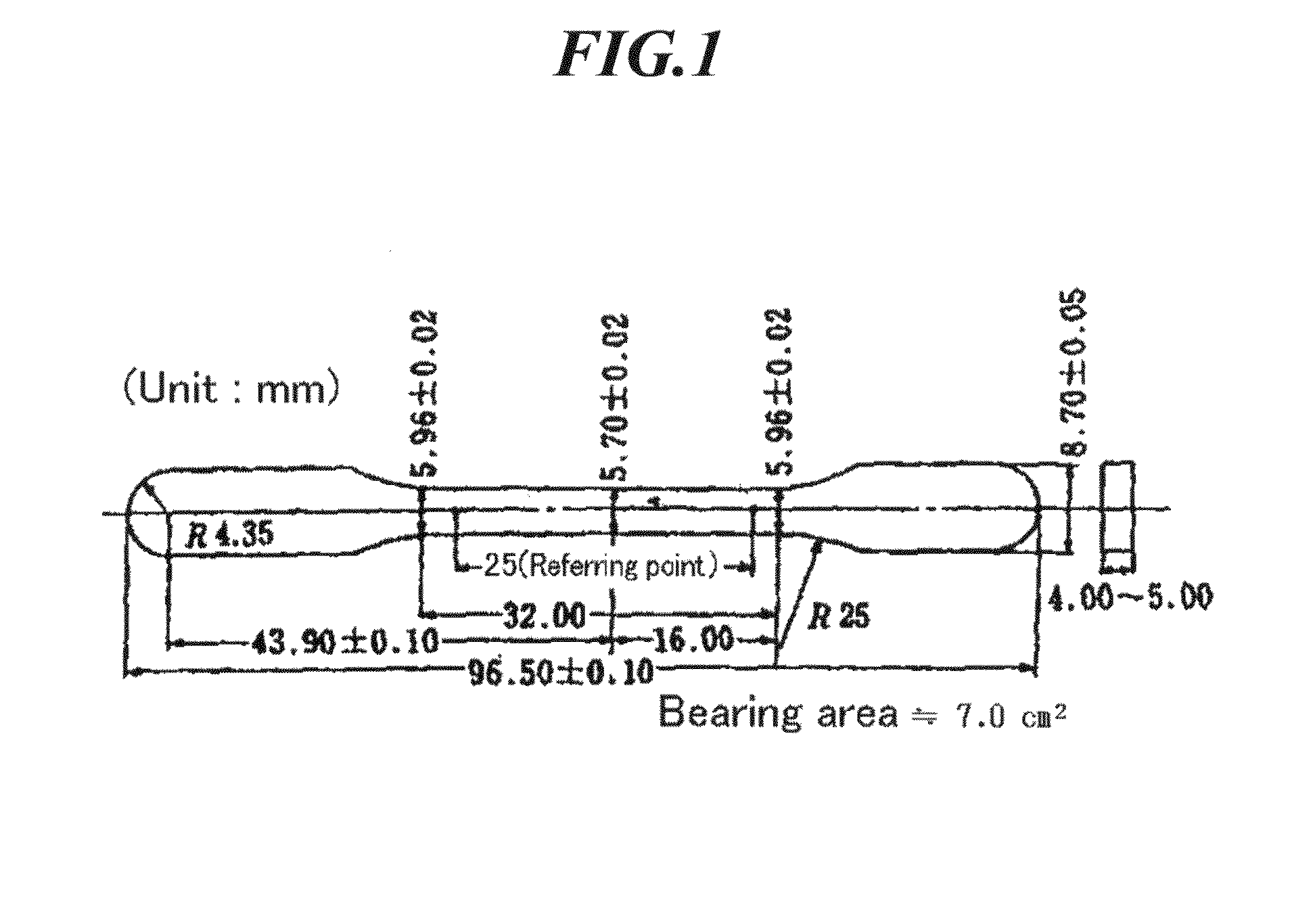

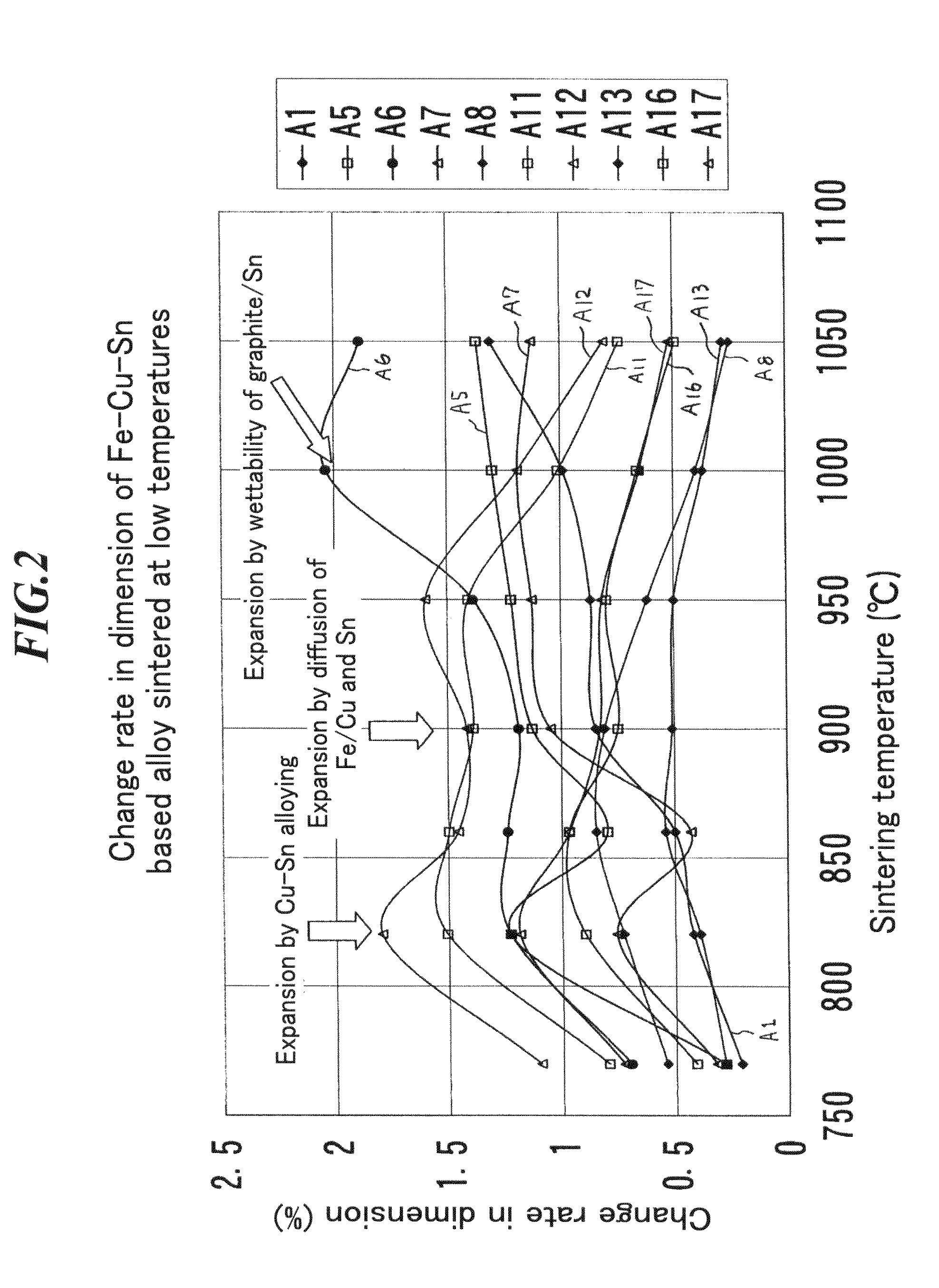

Ferrous Sintered Multilayer Roll-Formed Bushing, Producing Method of the Same and Connecting Device

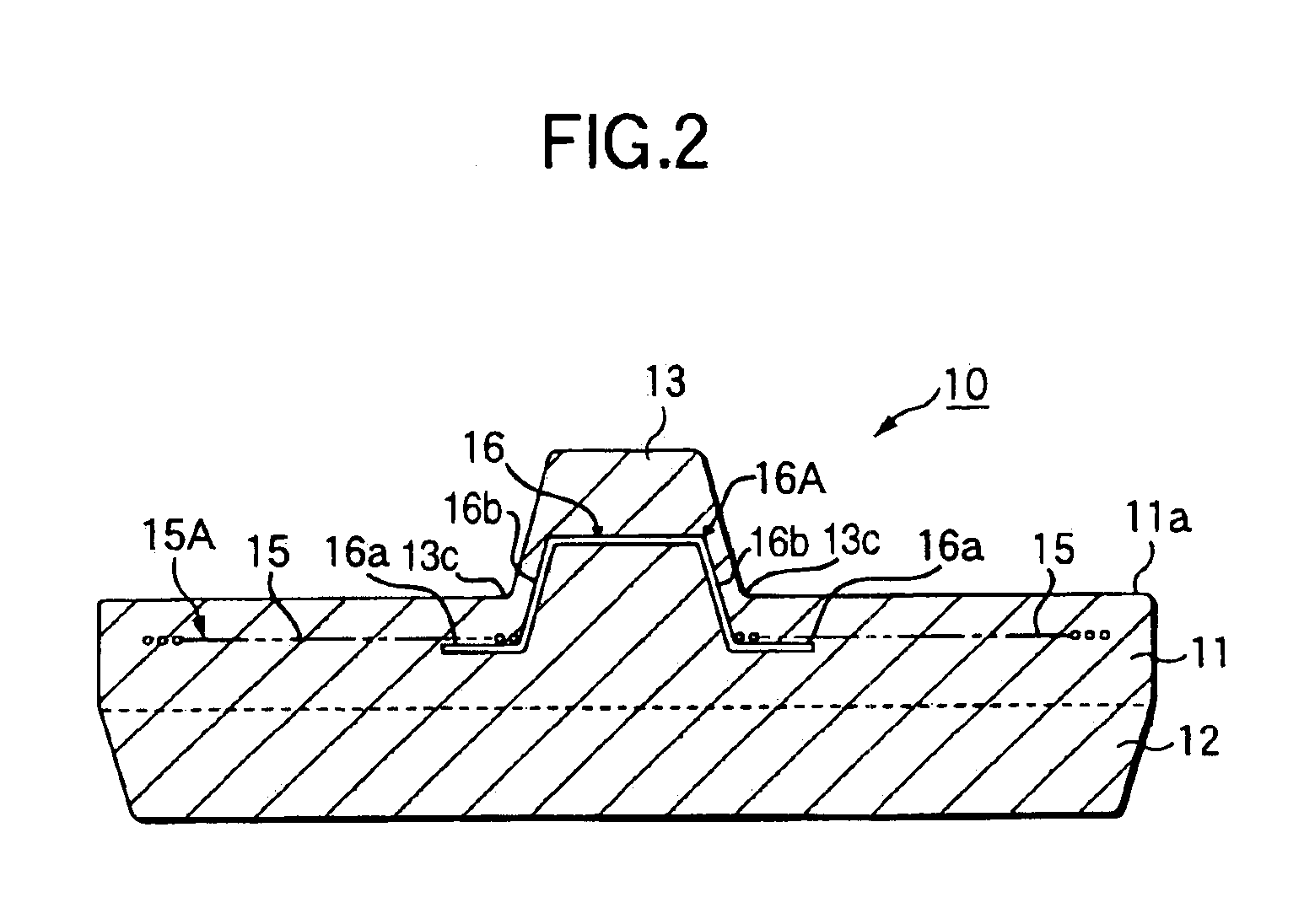

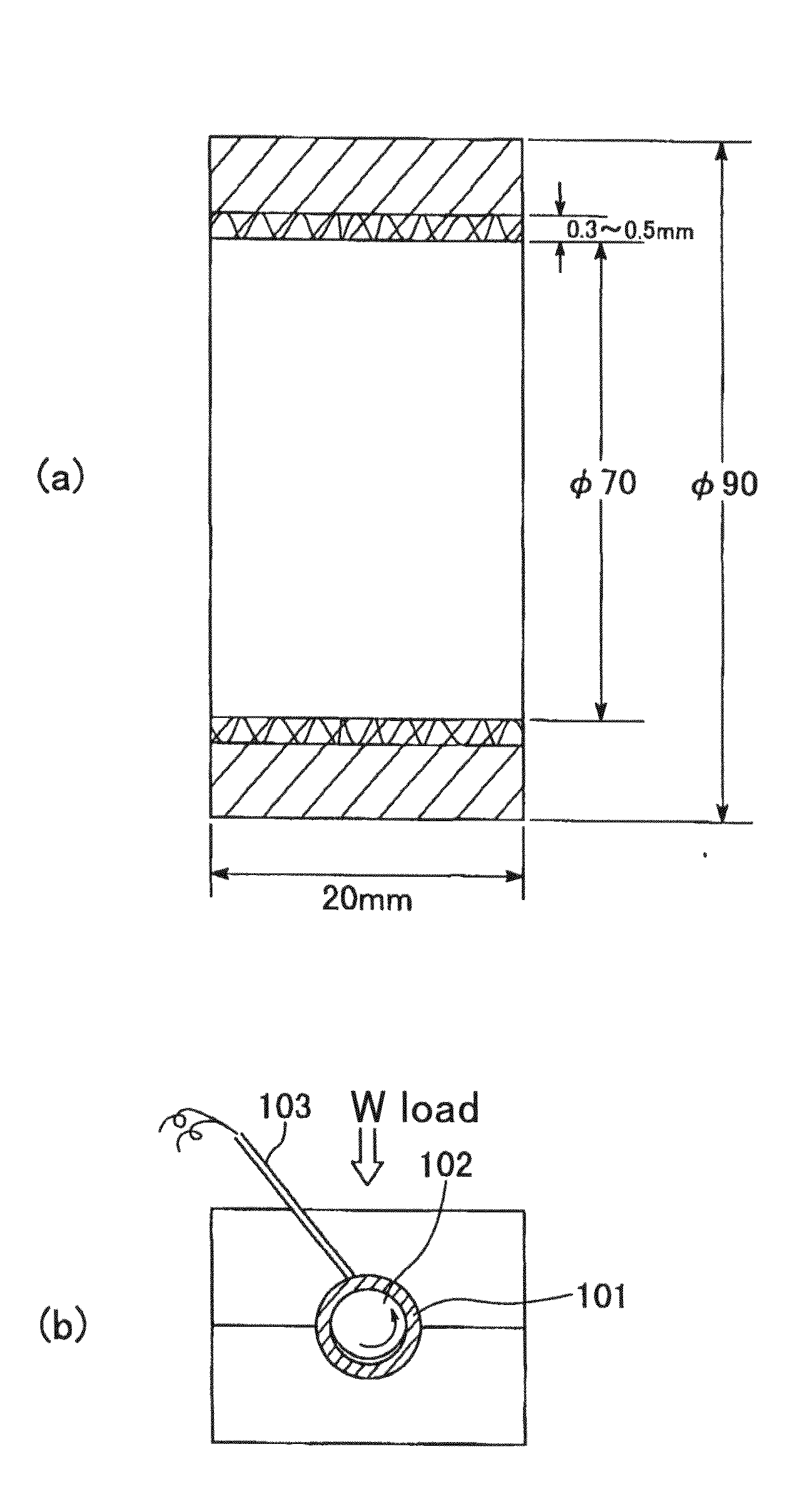

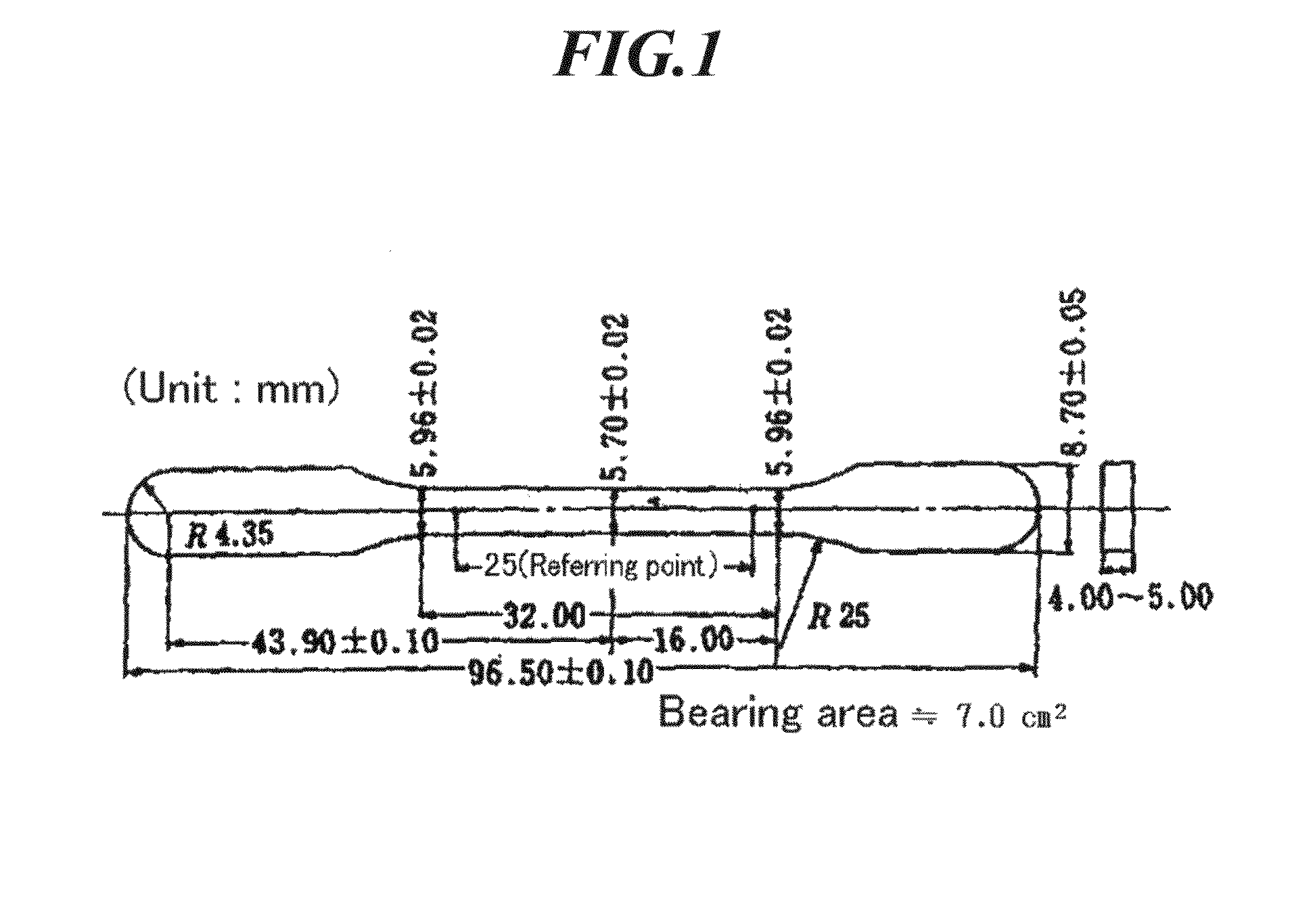

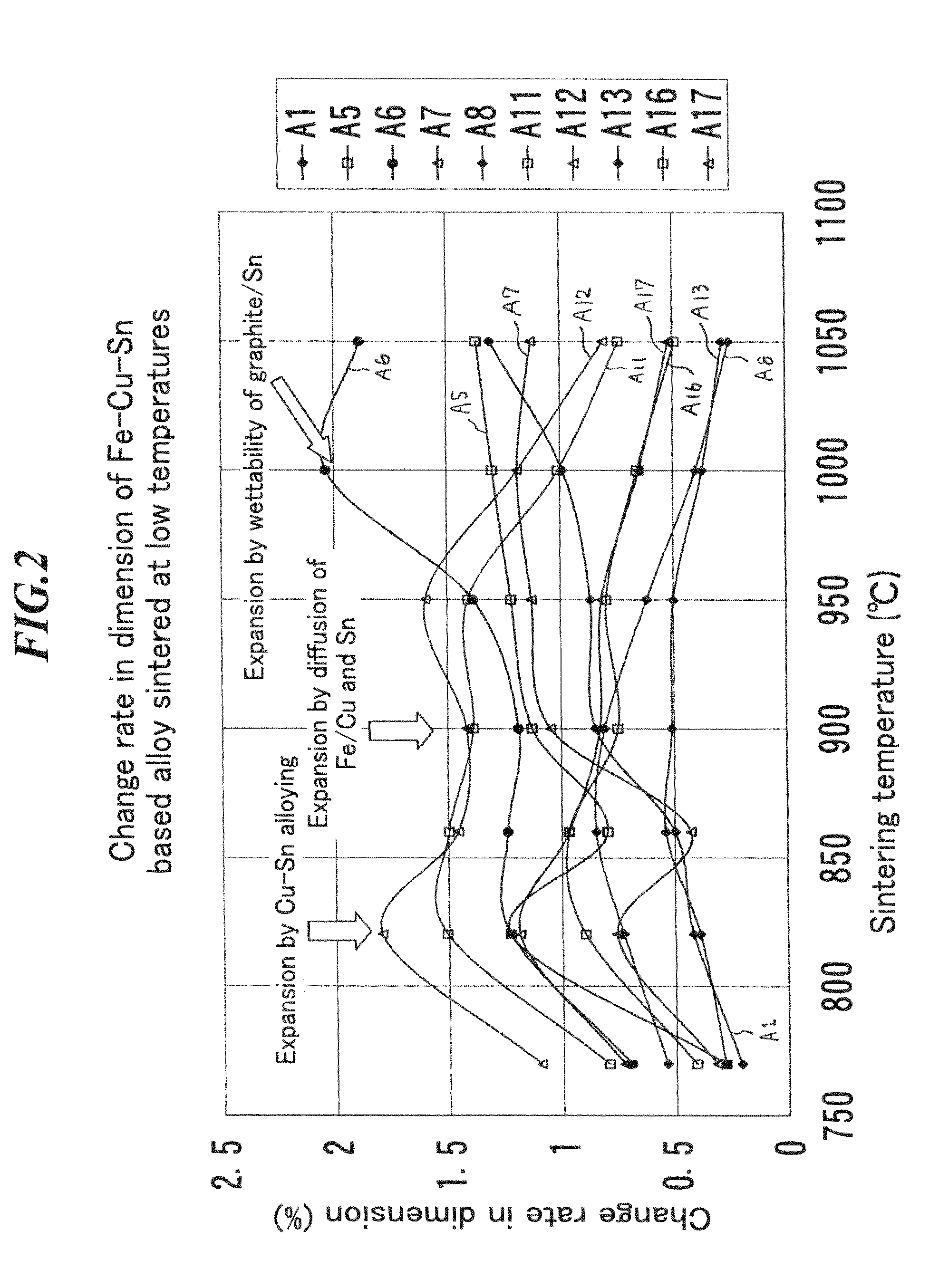

InactiveUS20100227188A1Low coefficient of frictionExcellent seize resistance and abrasion resistanceBearing assemblyMetal-working apparatusLubricationDiffusion layer

An economic ferrous sintered multilayer roll-formed bushing, a producing method of the same and a connecting device are provided, in which a ferrous sintered sliding material layer is tightly sintered-bonded to a back metal steel, the ferrous sintered sliding material layer being intended to have low coefficient of friction, having excellent seizing resistance and abrasion resistance and providing self-lubricating property so as to prolong a lubrication interval or eliminate the necessity of lubricating.The ferrous sintered multilayer roll-formed bushing according to the present invention comprises: a back metal steel; a ferrous sintered sliding material layer sinter-bonded to the back metal steel; a diffusion layer of ferrous alloy particle formed at the vicinity of the bonding boundary between the ferrous sintered sliding material layer and the back metal steel; and a Cu alloy phase formed at the vicinity of the bonding boundary and extending in the direction of the bonding boundary.

Owner:KOMATSU LTD

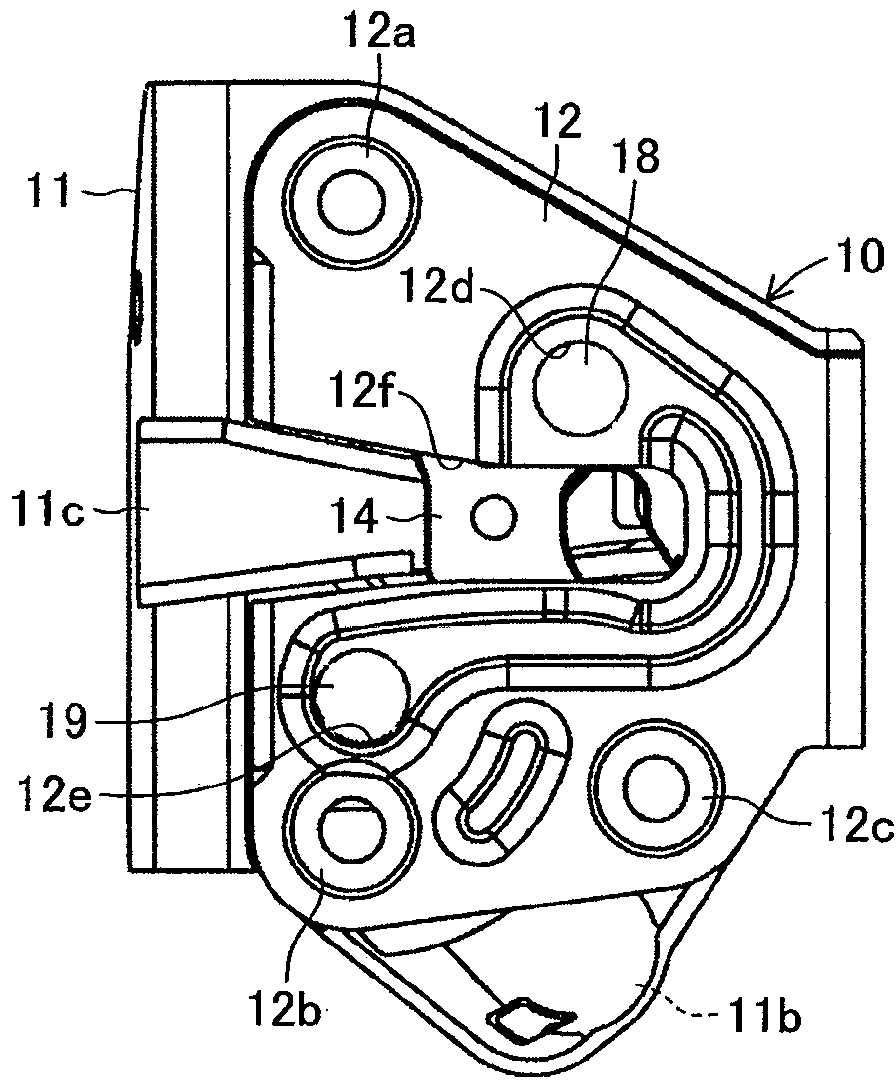

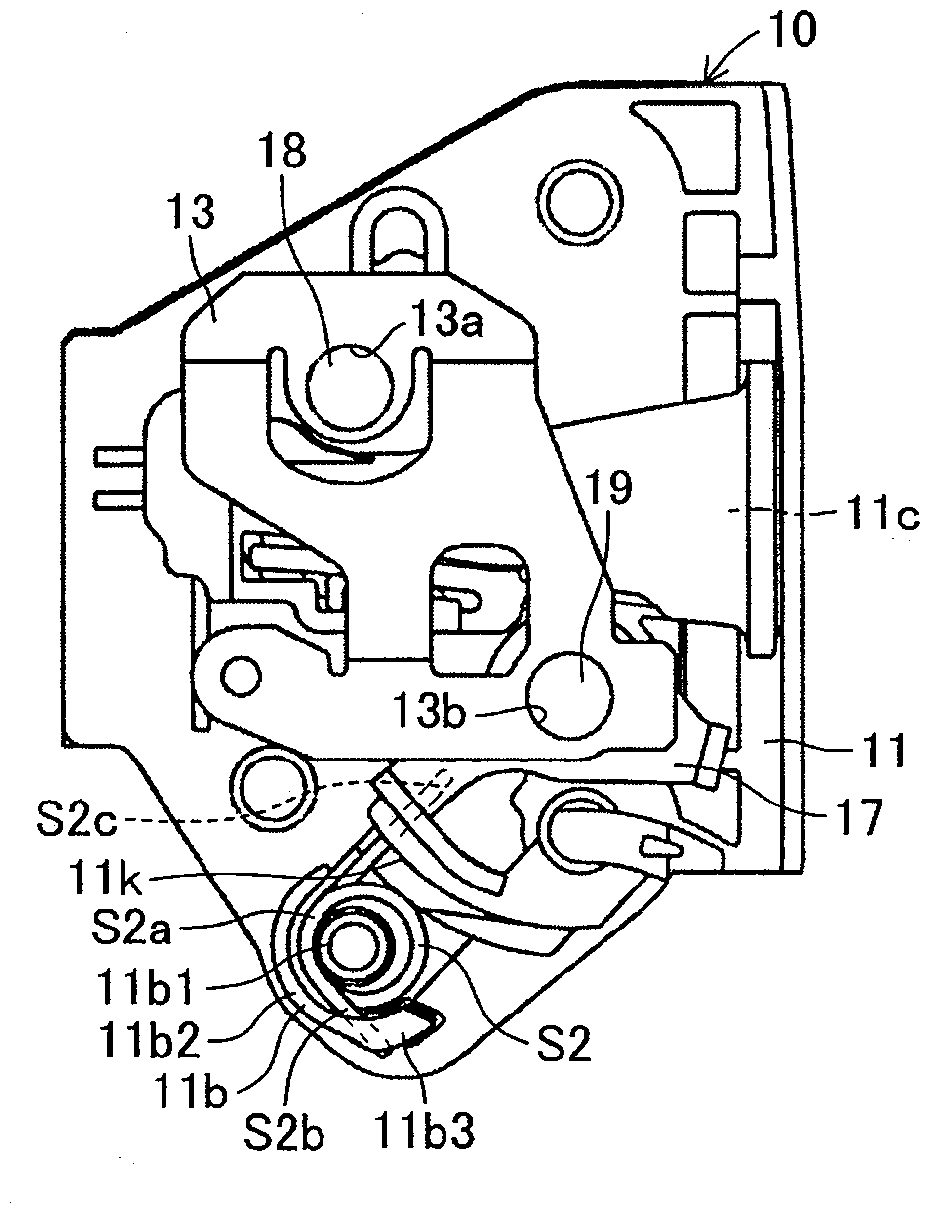

Automotive door latch device

ActiveCN102762807AImprove discharge efficiencyInhibition of undesired accumulationFastening meansDoorsEngineeringCar door

An automotive door latch device is provided with a latch which rotates by being pushed into motion by a striker; a latch return spring which applies force to the latch in the direction of the return position; a pawl which engages with the latch and prevents the same from rotating in the door opening direction (in the direction of the return position); and a pawl return spring which applies force to the pawl in the direction of the return position. A housing section, which belongs to the body and houses the latch and the pawl, opens downward at a location which is at one side of the body and is below the pawl. A pawl return spring is mounted on a spring mounting section formed at a location which is at the other side of the body and is away and downward from the rotation support section of the pawl. The pawl side end of the pawl return spring engages with the pawl via a through hole provided in the body. Due to the above, it is possible to enhance the discharging of powder dust or the like intruding inside the housing section, which belongs to the body and houses the latch and the pawl, outside the body.

Owner:AISIN SEIKI KK

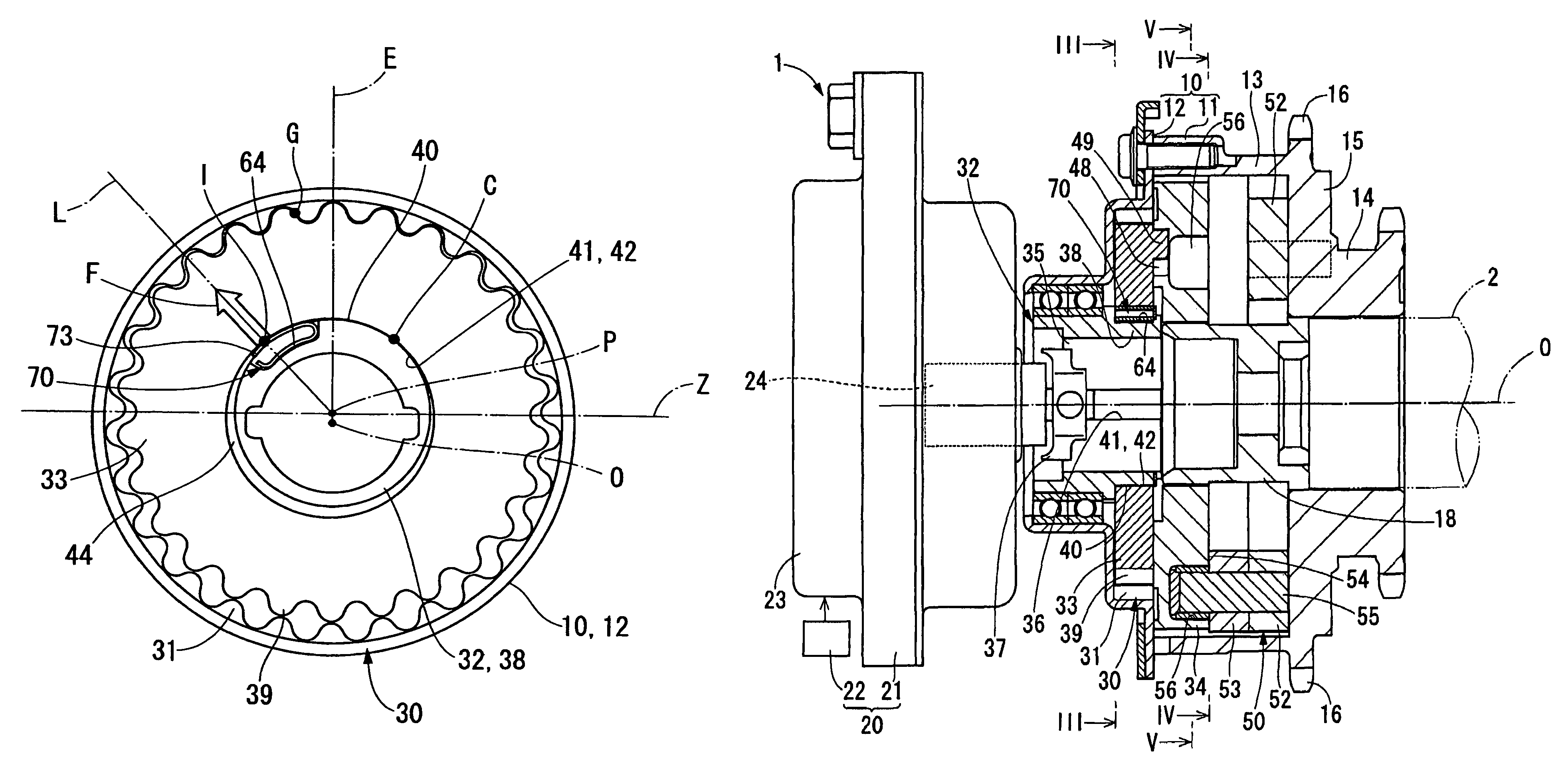

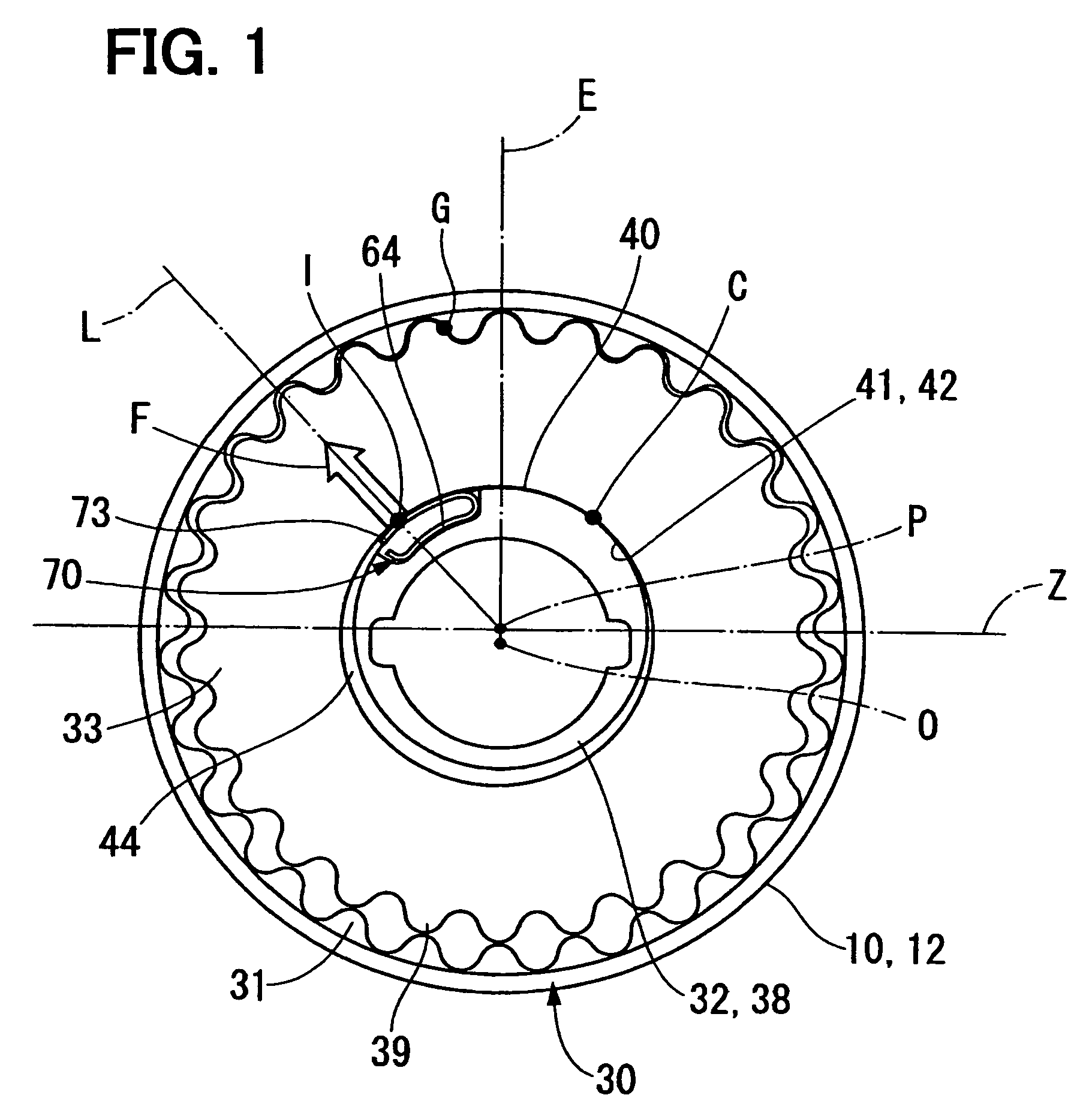

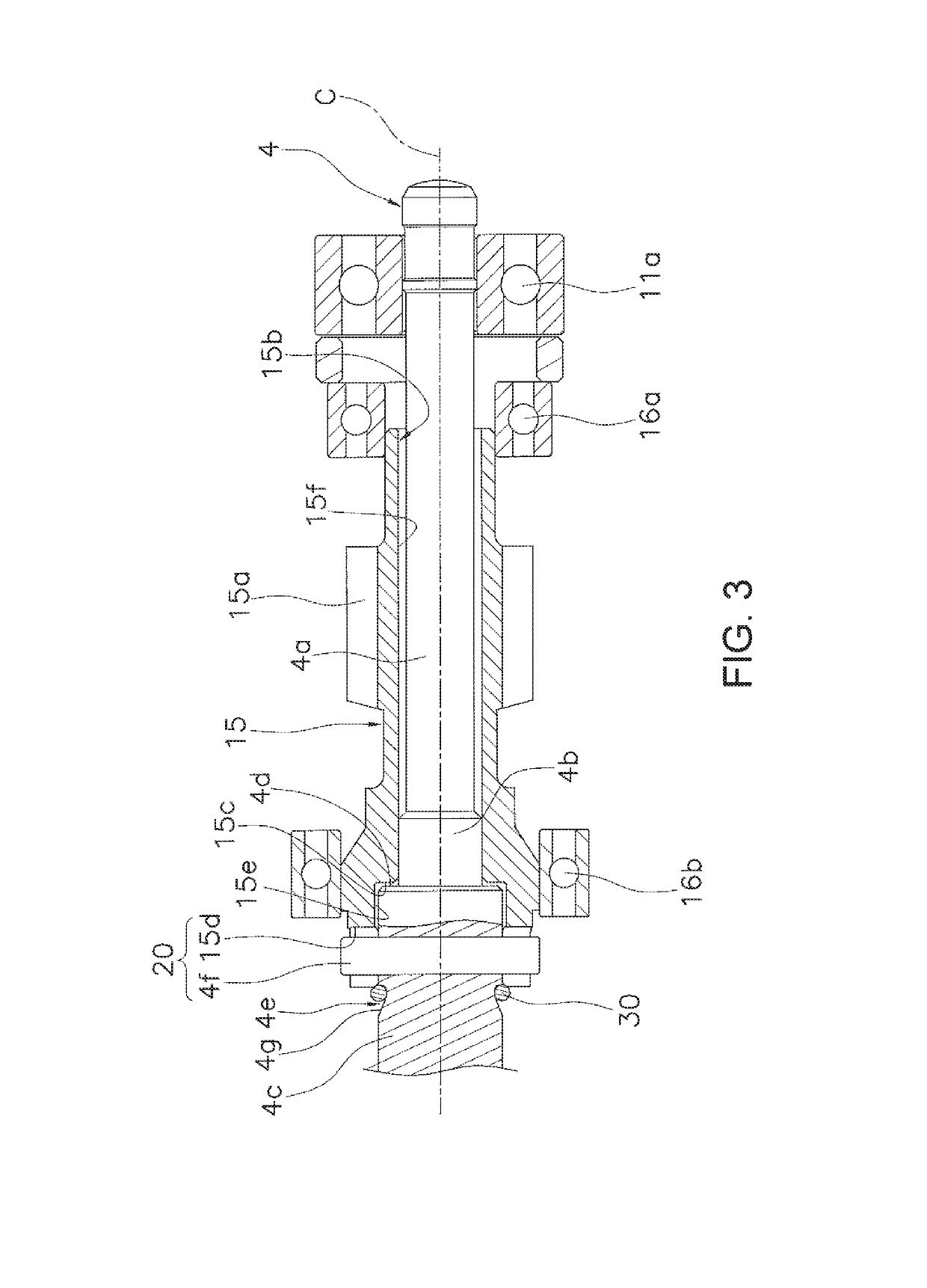

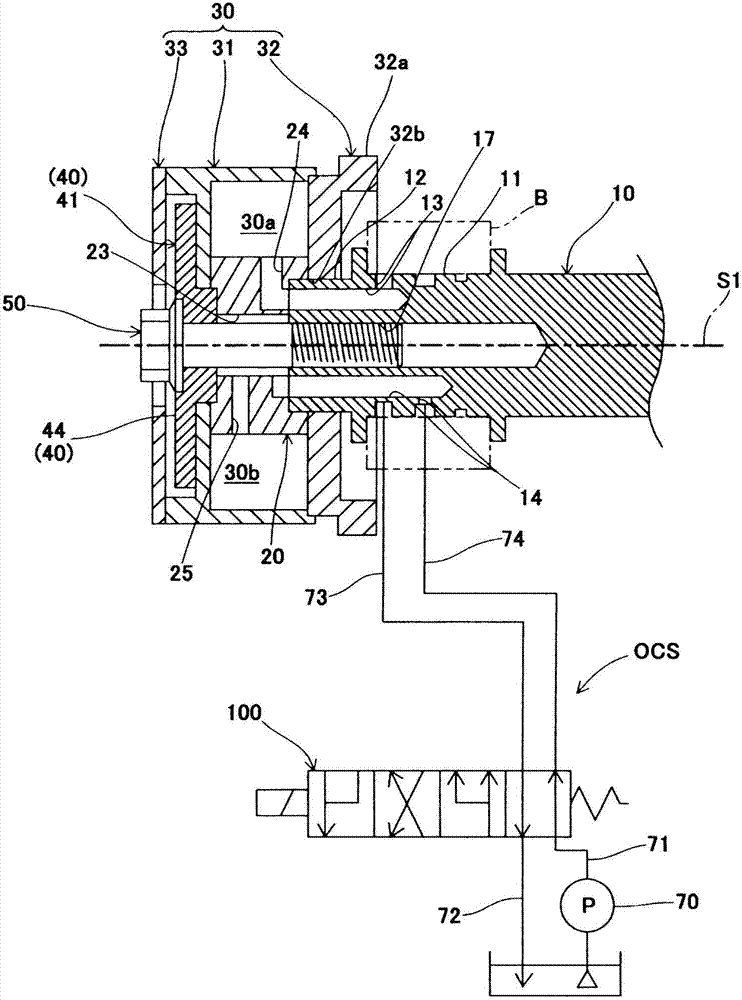

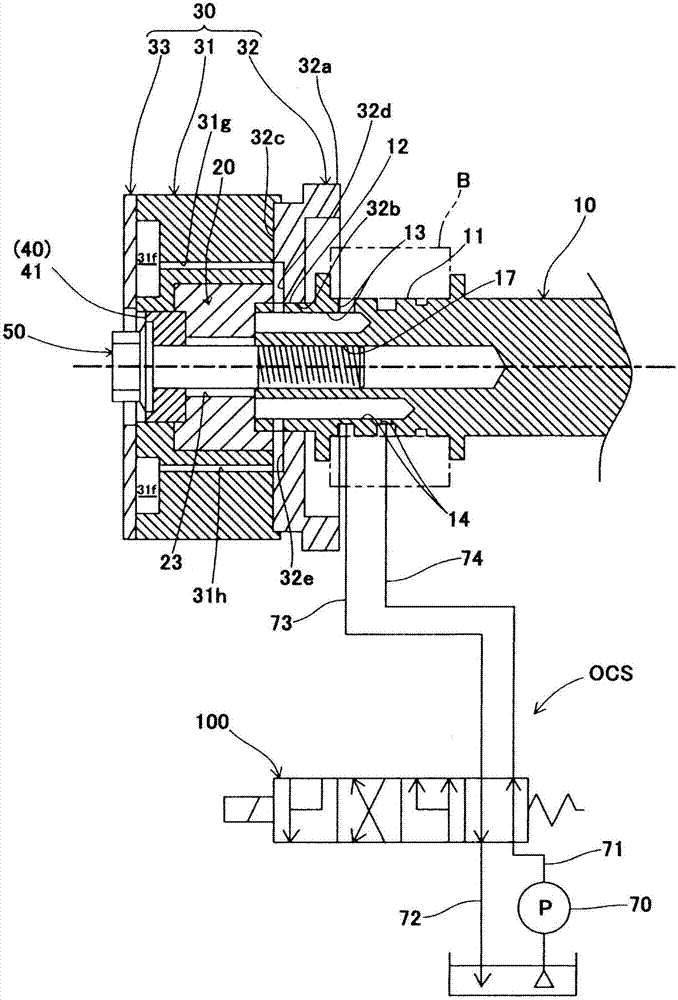

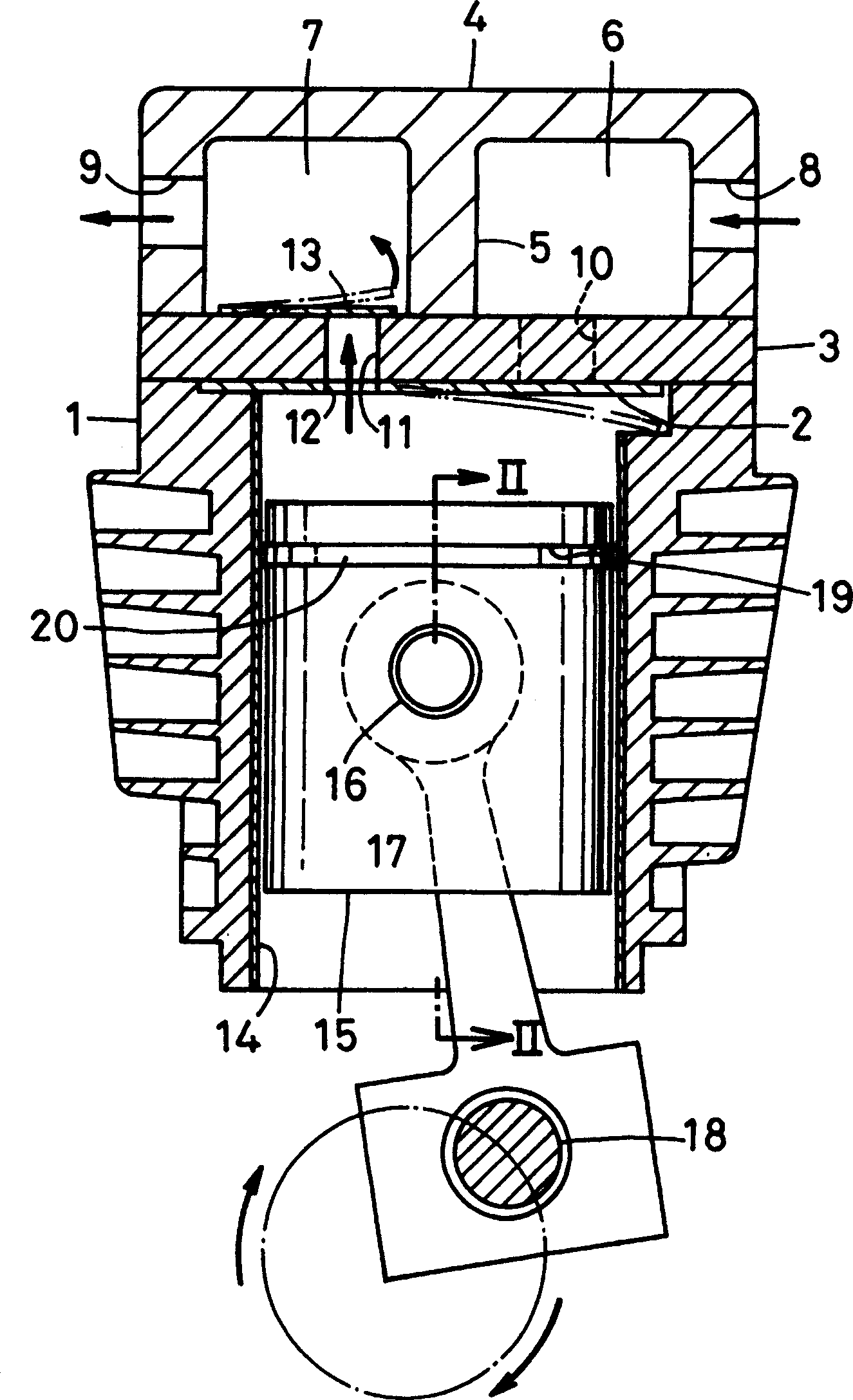

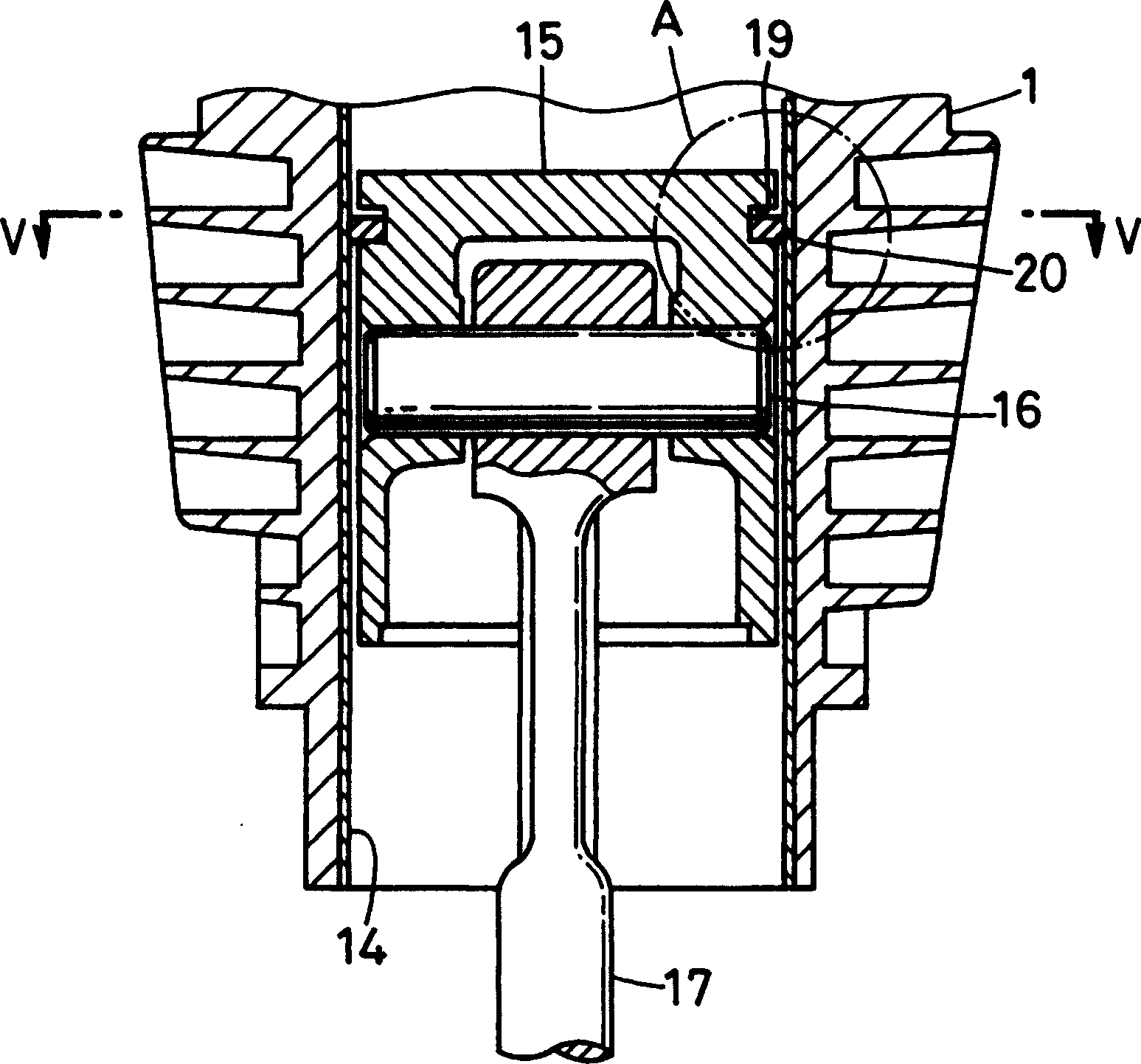

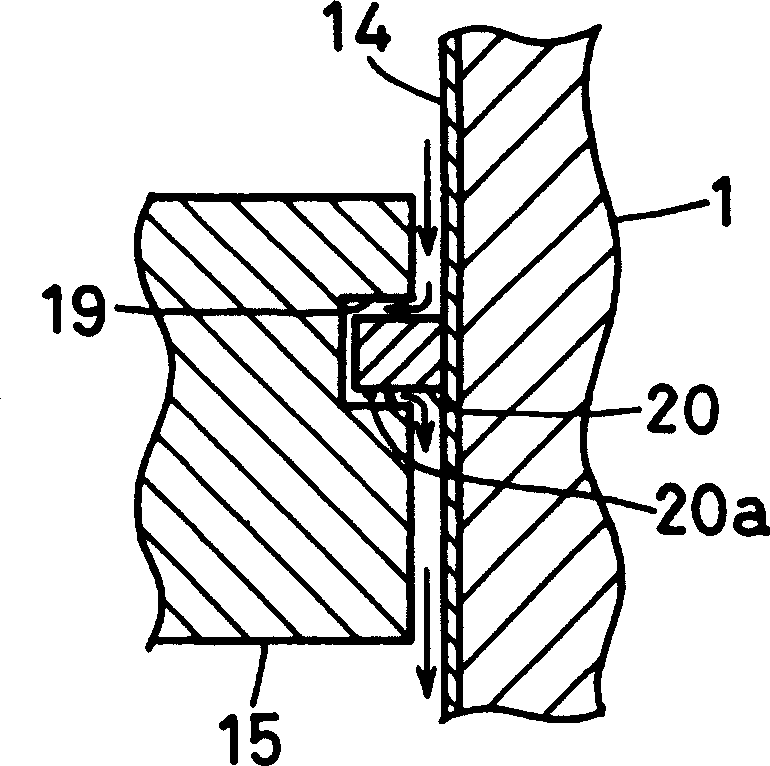

Valve timing controller

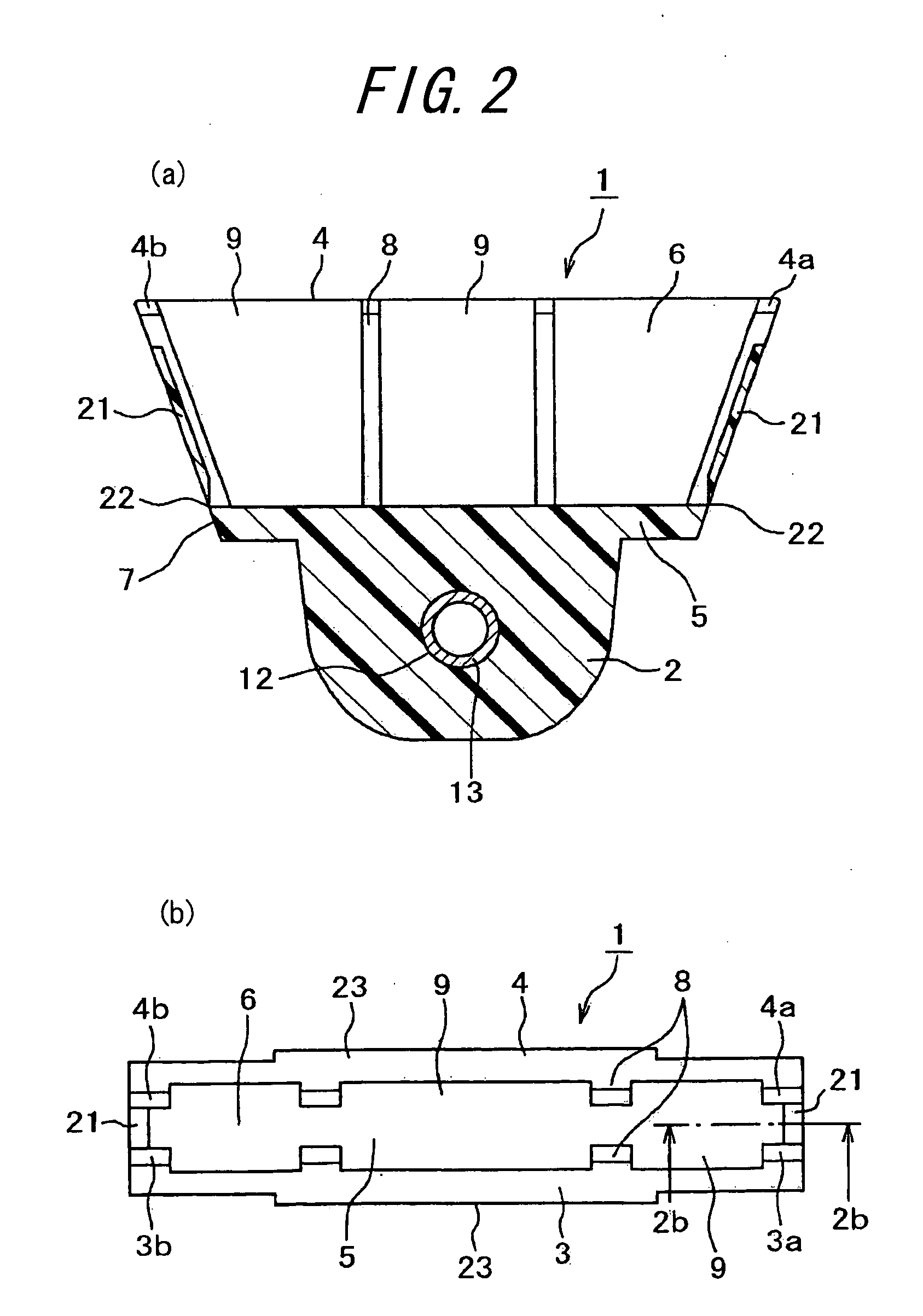

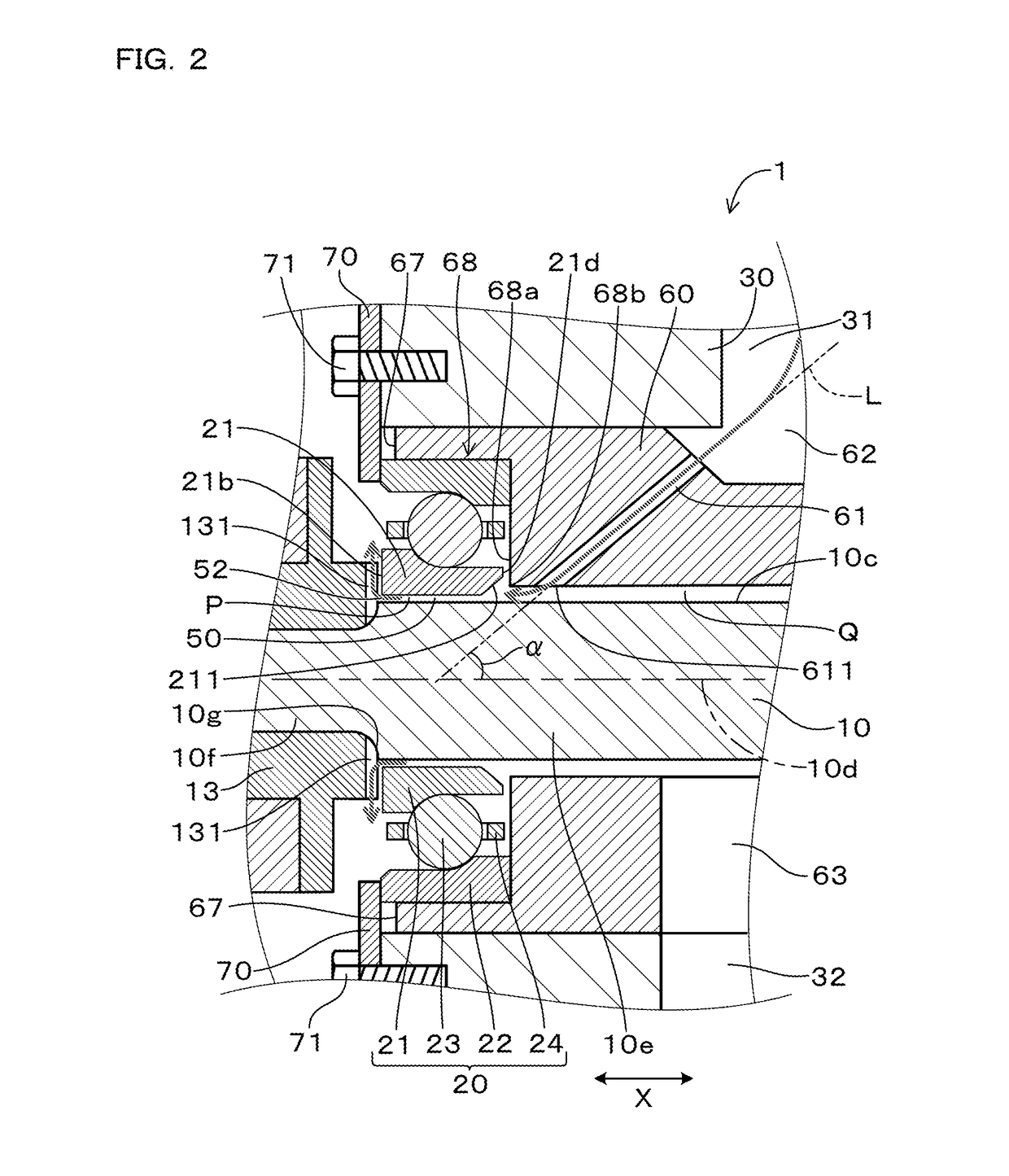

ActiveUS7603975B2Restricts abnormal noisePrevent abnormal noiseValve arrangementsYielding couplingGear wheelEngineering

A valve timing controller includes a first gear rotating together with a crankshaft, a planetary carrier eccentric to the first gear, a second gear engaging with the planetary carrier. The second gear performs a planetary motion while engaging with the first gear. The planetary motion is converted into a rotational motion of the camshaft to change a relative rotational phase between the crankshaft and the camshaft. A pressing element is provided between the planetary carrier and the second gear for pressing the second gear by the elastic force. An action line of the elastic force is inclined to the eccentric direction line of the planetary carrier in the circumferential direction.

Owner:DENSO CORP

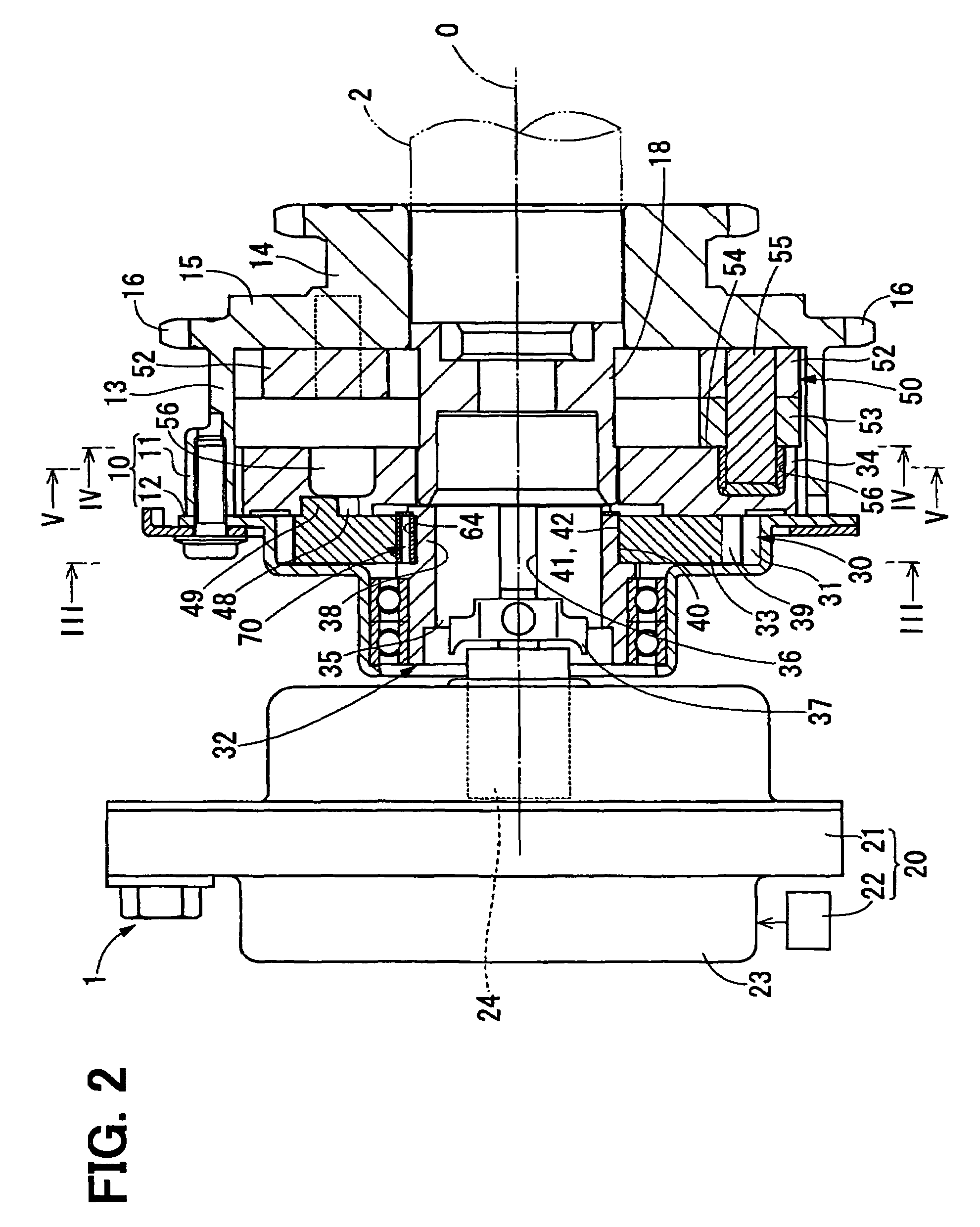

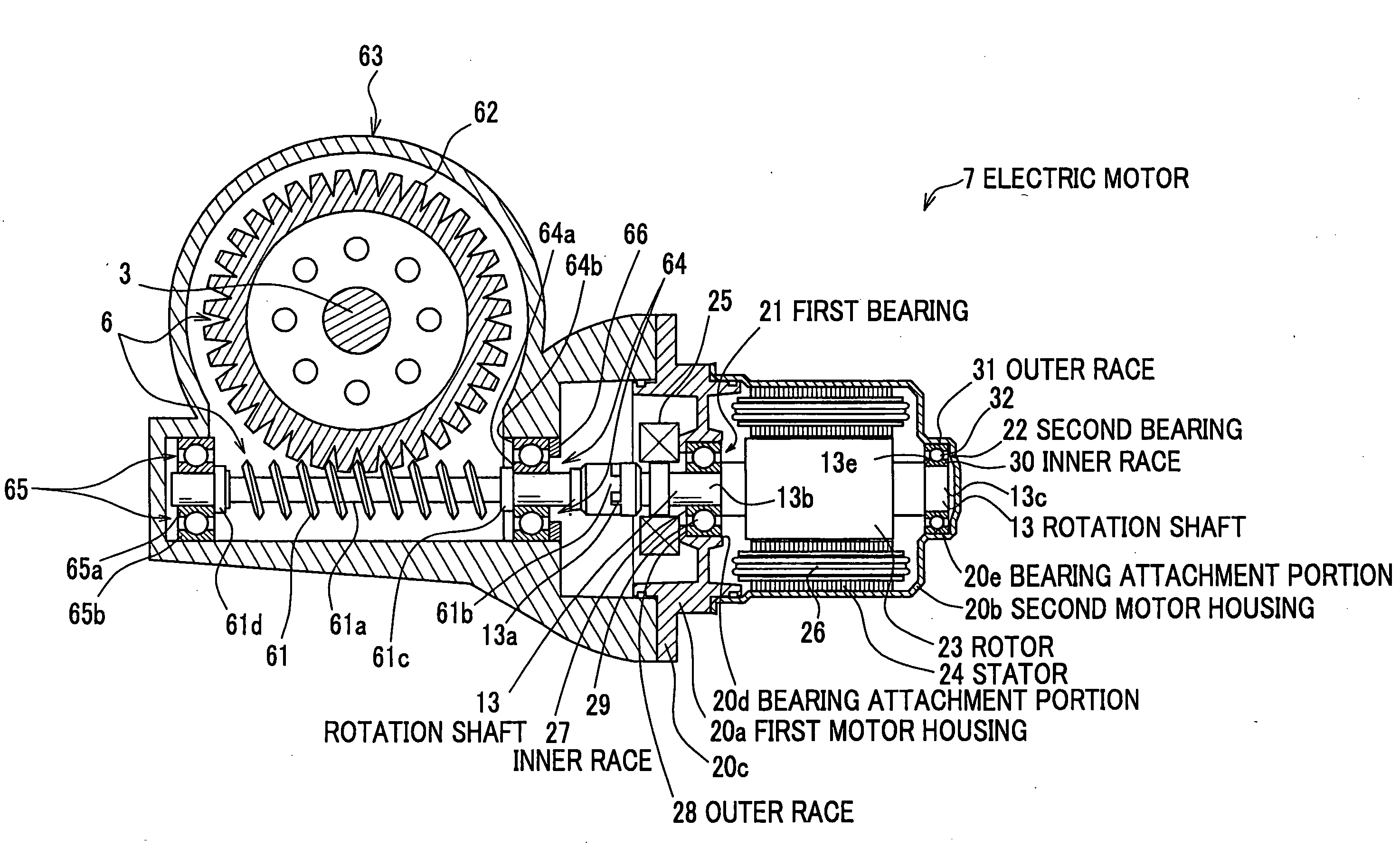

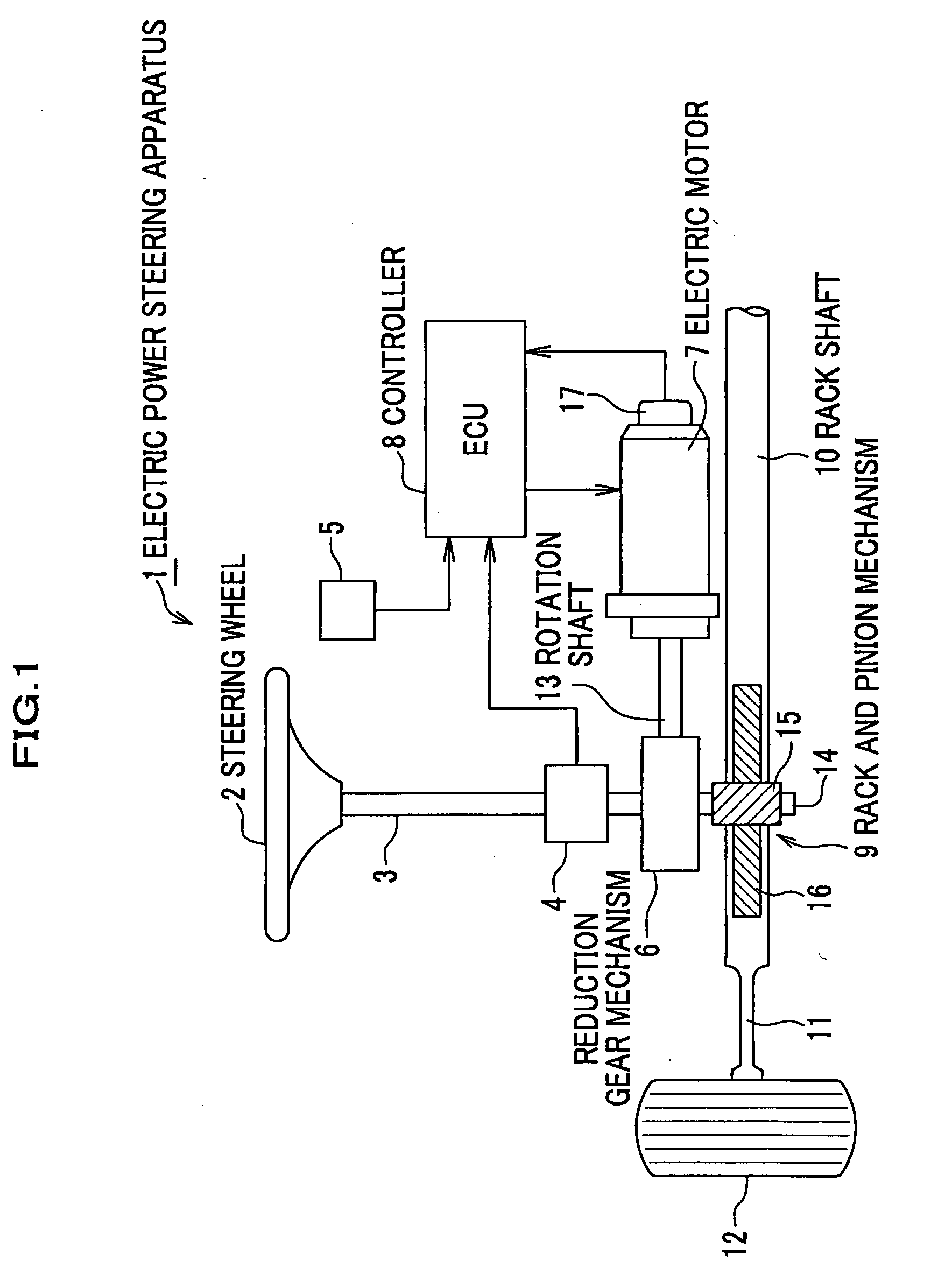

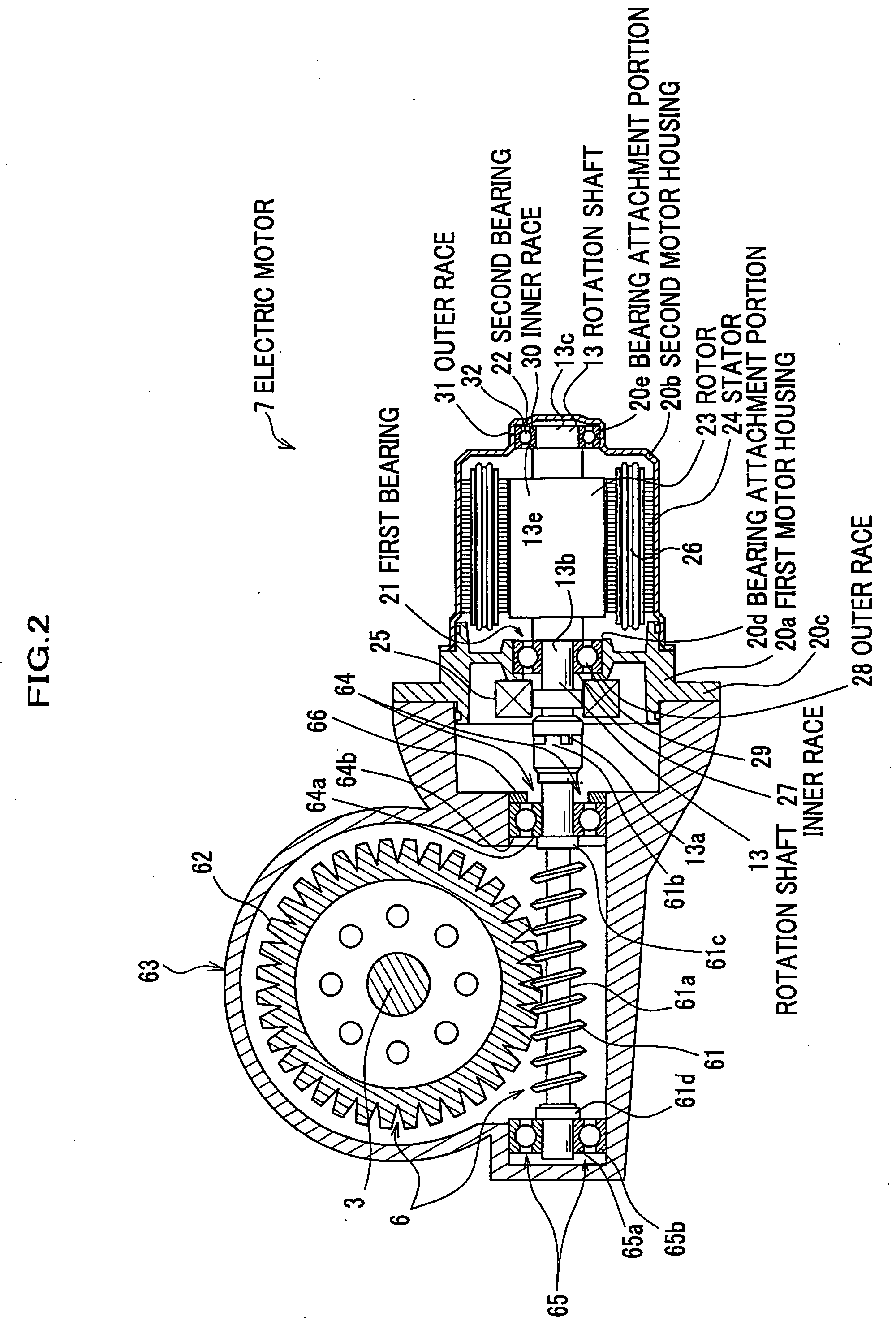

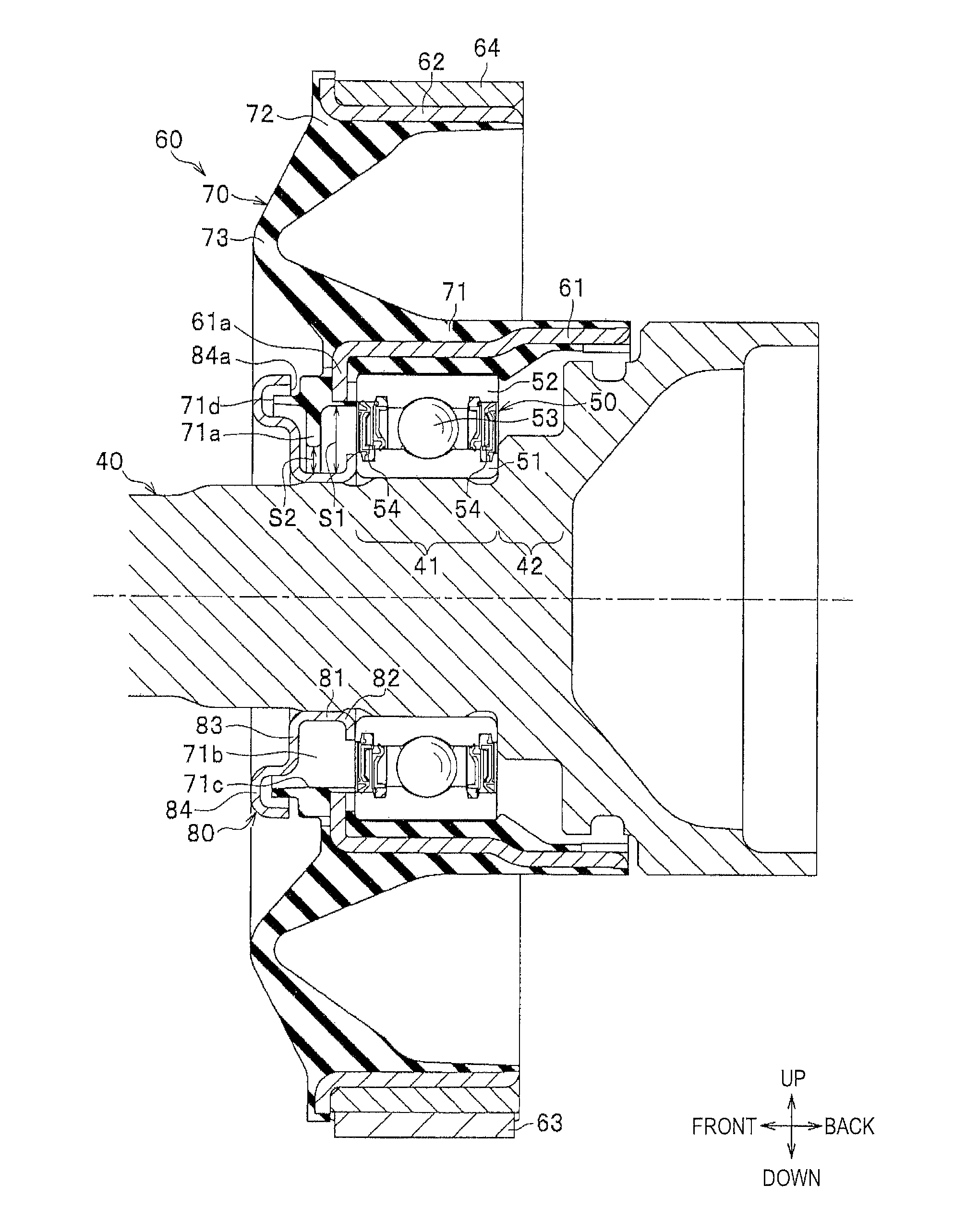

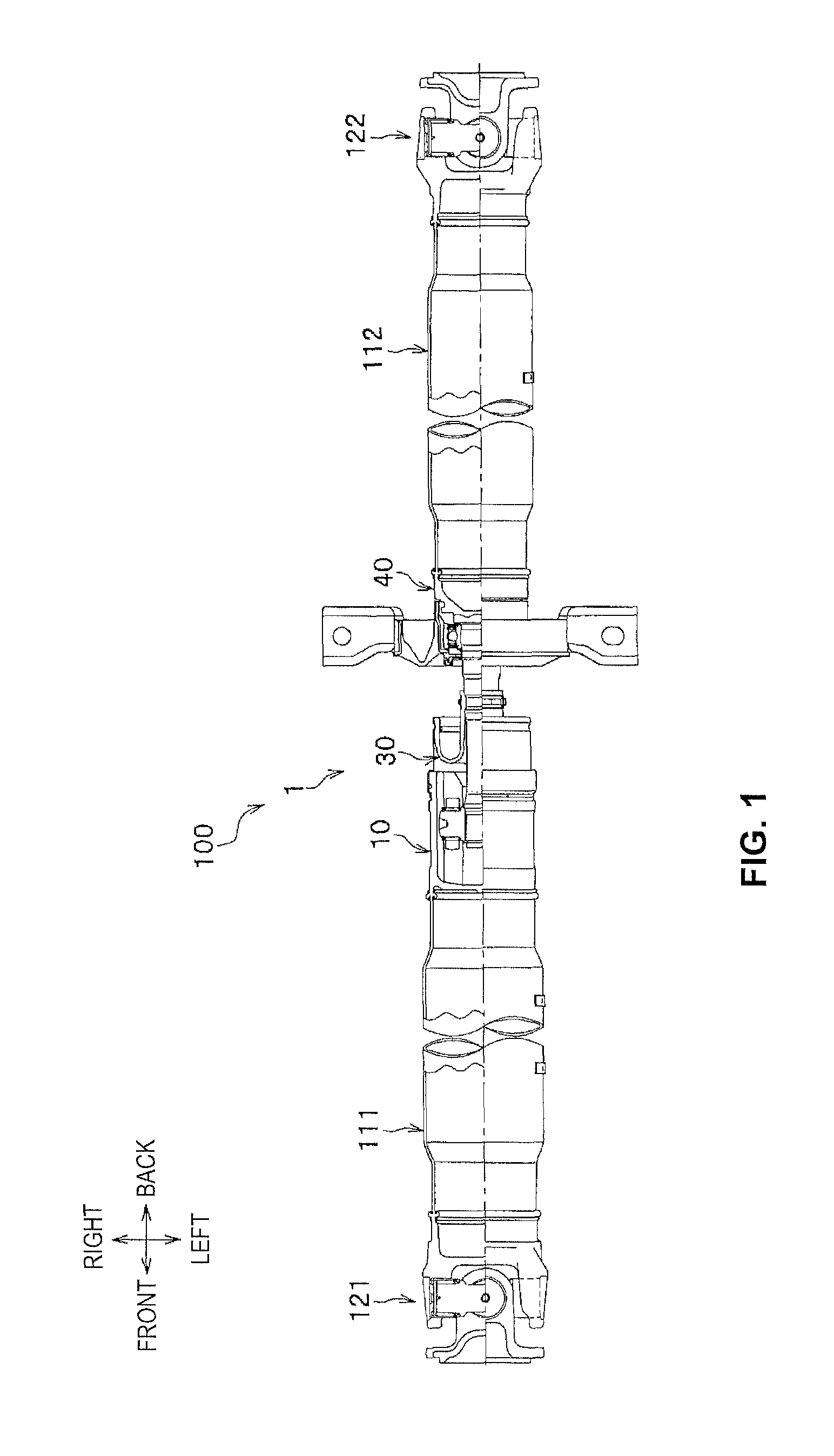

Electric motor and electric power steering apparatus

InactiveUS20070205680A1Prevent vibrationExcellent steer feelingShaftsToothed gearingsEngineeringRolling-element bearing

An electric motor having a rotation shaft includes a motor housing into which the electric motor is accommodated, at least one pair of rolling bearings positioned in the motor housing and rotatably supporting both ends of the rotation shaft, and a displacement restriction member provided inside the motor housing and restricting a displacement of the rolling bearing in an axial direction of the rolling bearing. Each rolling bearing includes an inner race, an outer race, and rolling elements rotatably supported between the inner race and the outer race. The inner race is press fitted without any gaps onto an outer peripheral surface of the rotation shaft, and the outer race is press fitted without any gaps into a bearing attachment portion provided inside the motor housing.

Owner:HONDA MOTOR CO LTD

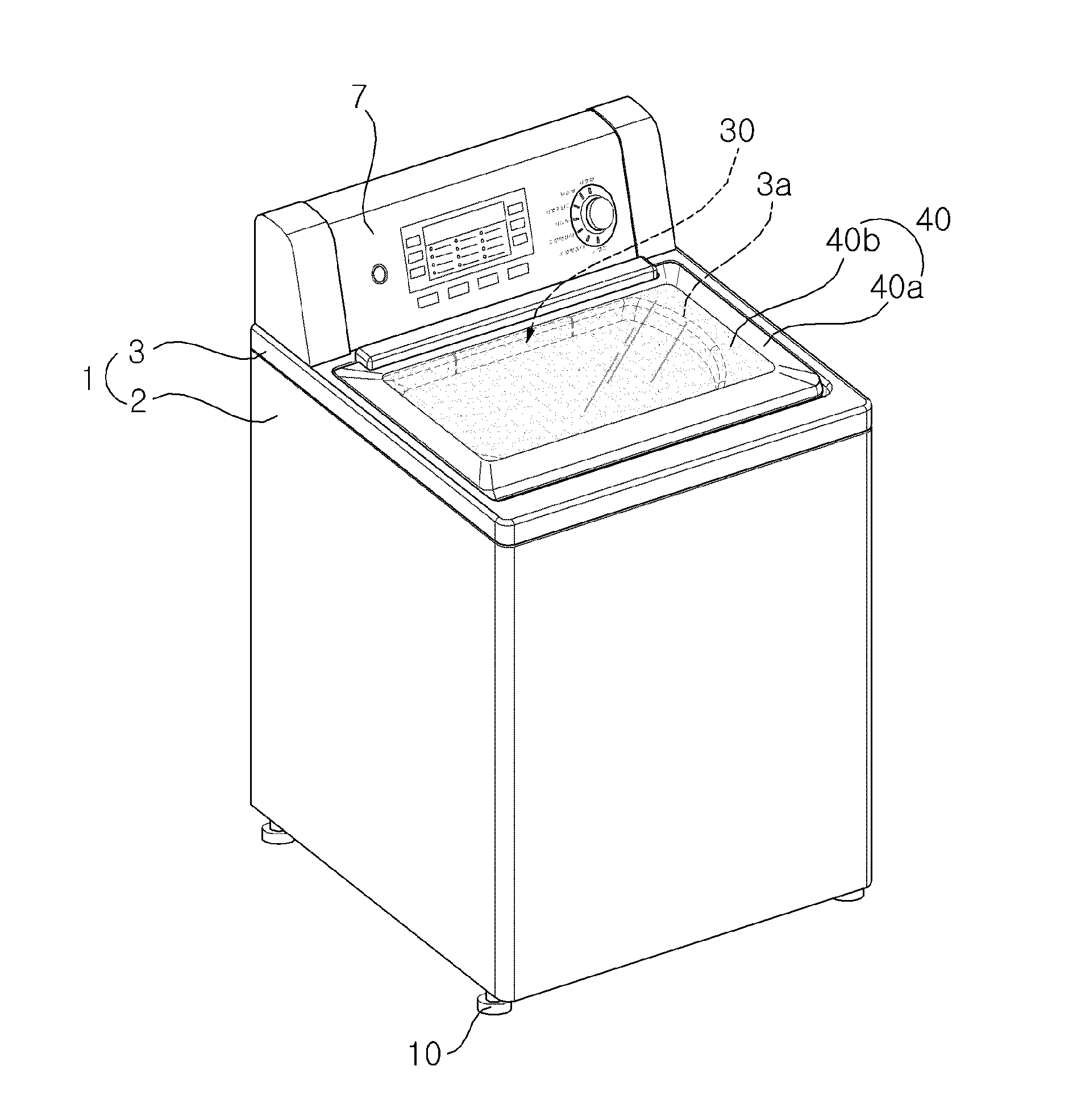

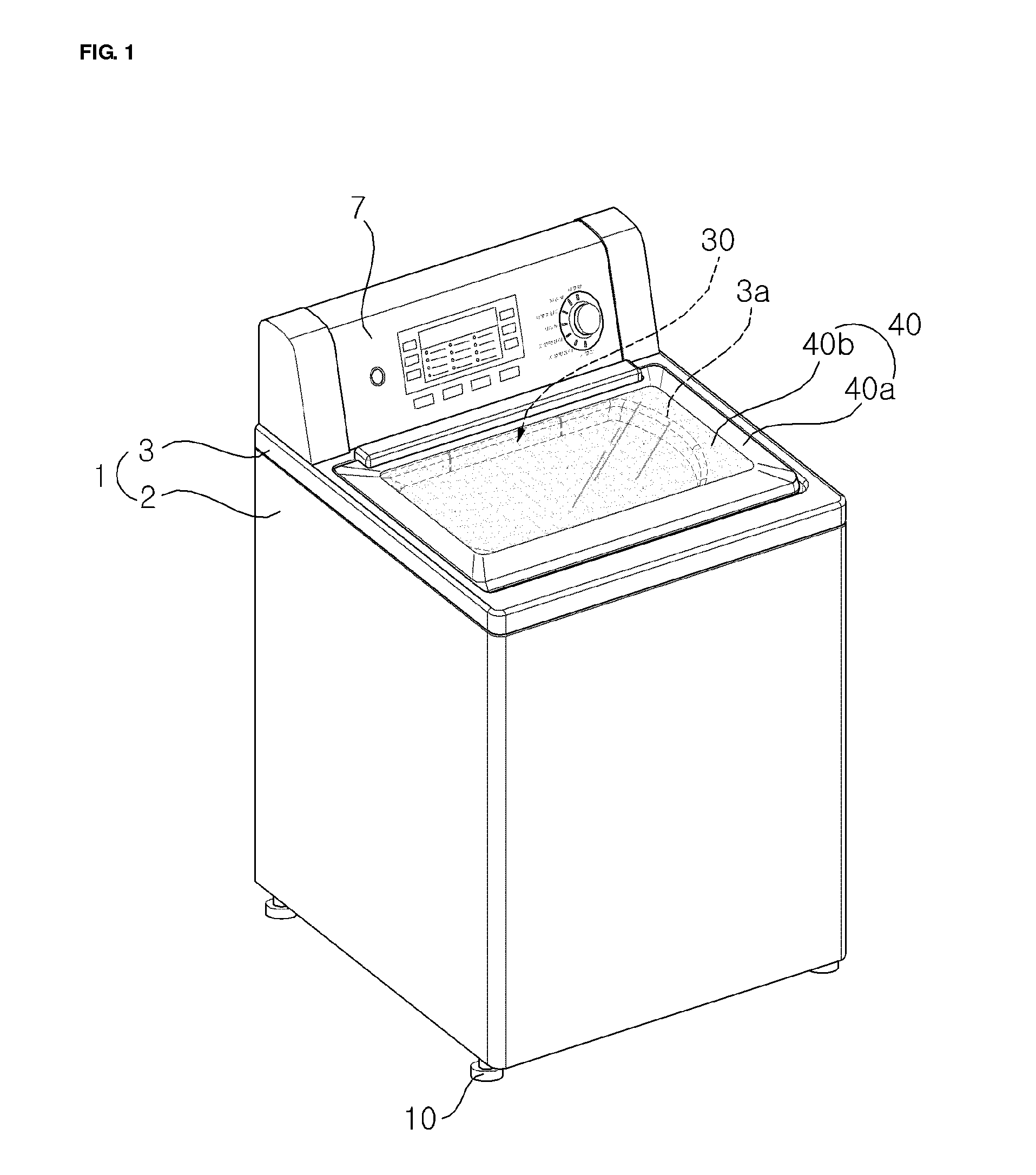

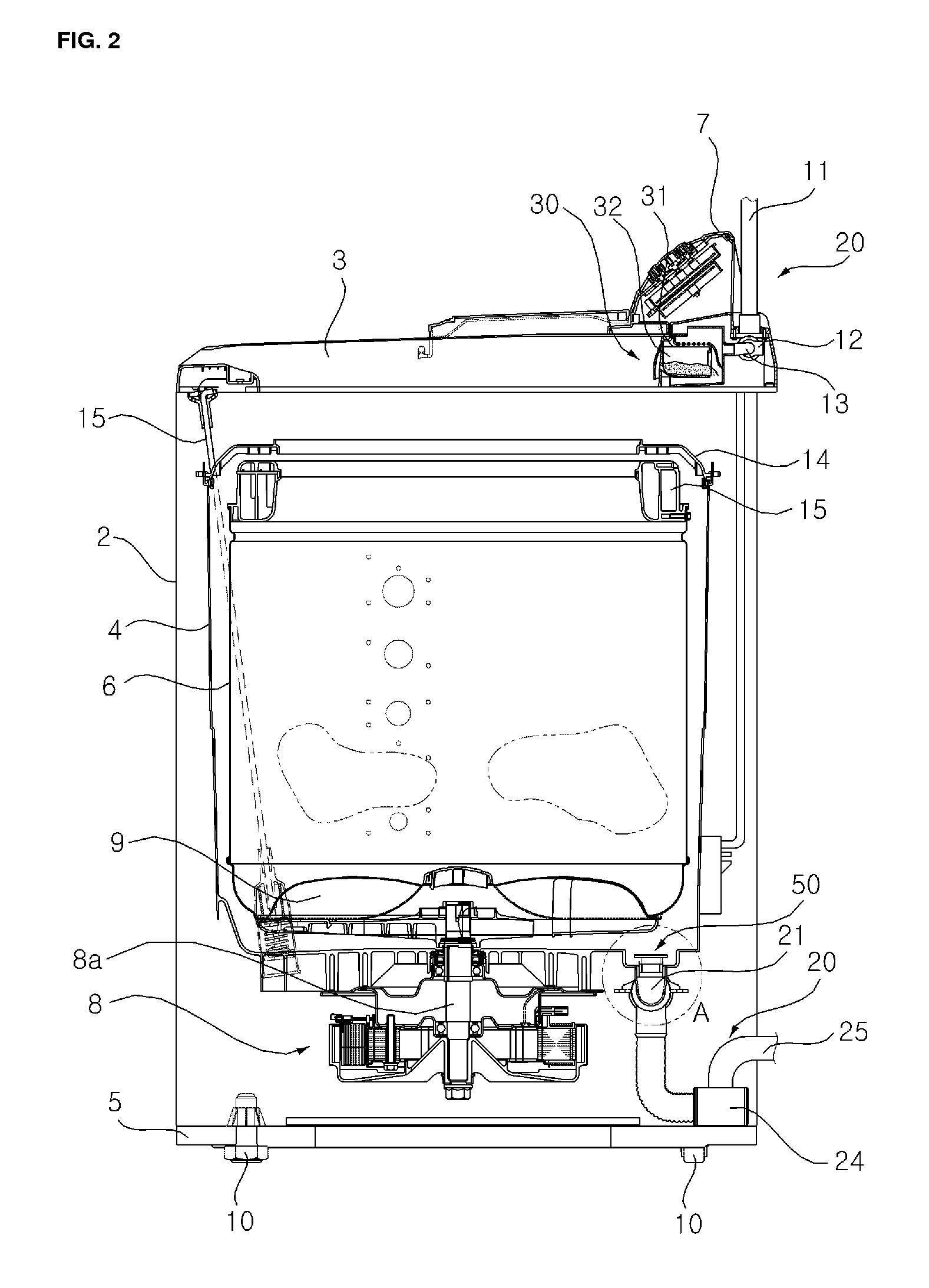

Laundry treating machine

InactiveUS20110016927A1Quiet operationImproving consumer trustOther washing machinesTextiles and paperProcess engineeringLaundry

The laundry treating machine includes a silencer for covering the upper space over the drain hole, whereby the upper space over the drain hole is always filled with washing water and the generation of a vortex is prevented. Thus, abnormal noise during drainage is prevented, thereby contributing to a quiet operation of the washing machine and improving consumer trust.

Owner:LG ELECTRONICS INC

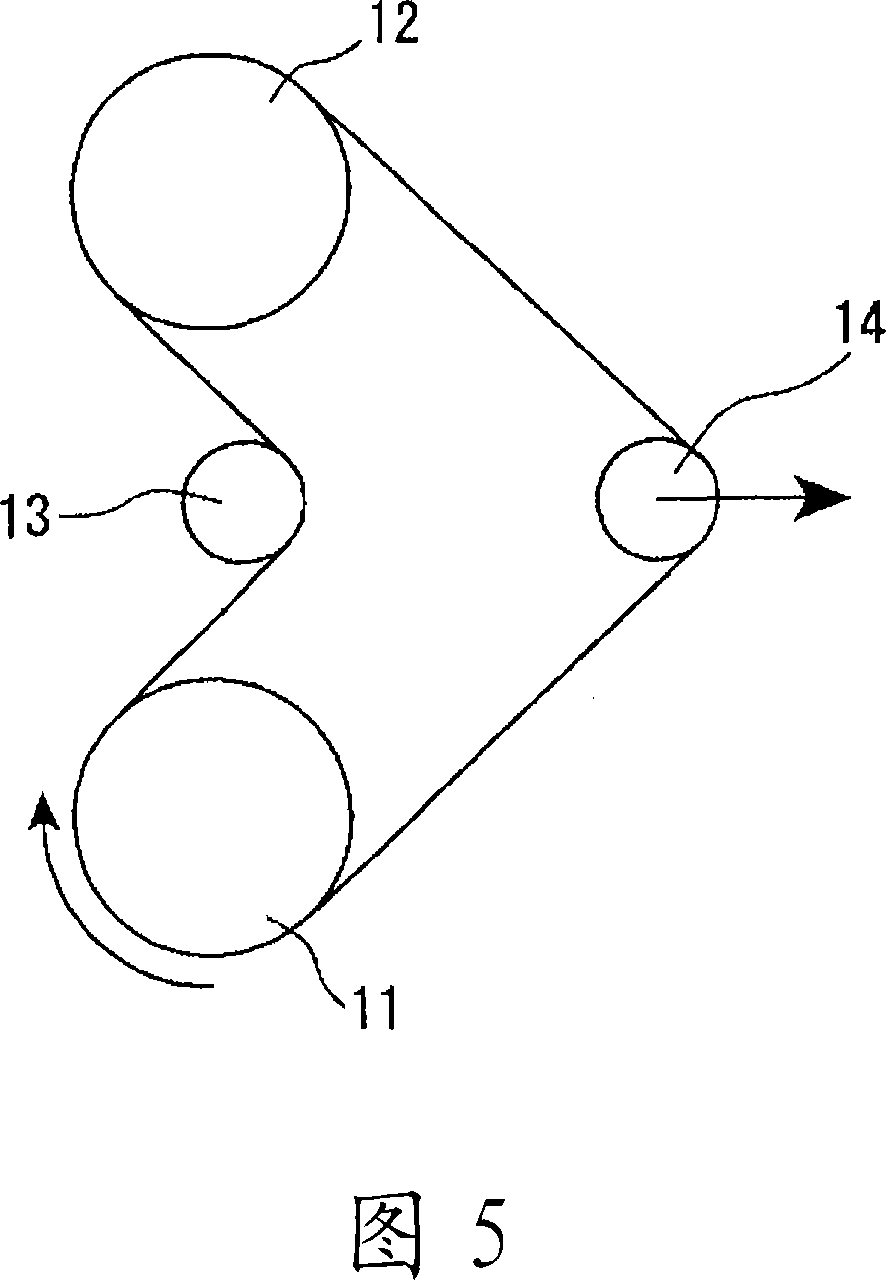

Friction transmission belt and process for producing the same

InactiveCN101160478AExcellent heat resistance adhesionExcellent dynamic adhesionV-beltsDriving beltsElastomerHeat resistance

A friction transmission belt that excels in not only repeated flexures of friction transmission belt and adhesion performance, such as heat resisting adhesion and dynamic adhesion, in run under heating conditions around engine but also desirable performance, such as heat resistance, abrasion resistance or abnormal noise prevention. There is provided a friction transmission belt comprising an adhesive rubber layer having core wires buried therein along the longitudinal direction of the belt and, piled thereon, a compression rubber layer, wherein the adhesive rubber layer is one formed by crosslinking an ethylene-a-olefin elastomer composition in the presence of an organic peroxide, and wherein the compression rubber layer is one formed by crosslinking an ethylene-a-olefin elastomer composition, and wherein the core wires are those having undergone adhesion treatment with the use of a resorcin-formaldehyde-latex adhesive composition containing a 2,3-dichlorobutadiene containing polymer latex.

Owner:BANDO CHEM IND LTD

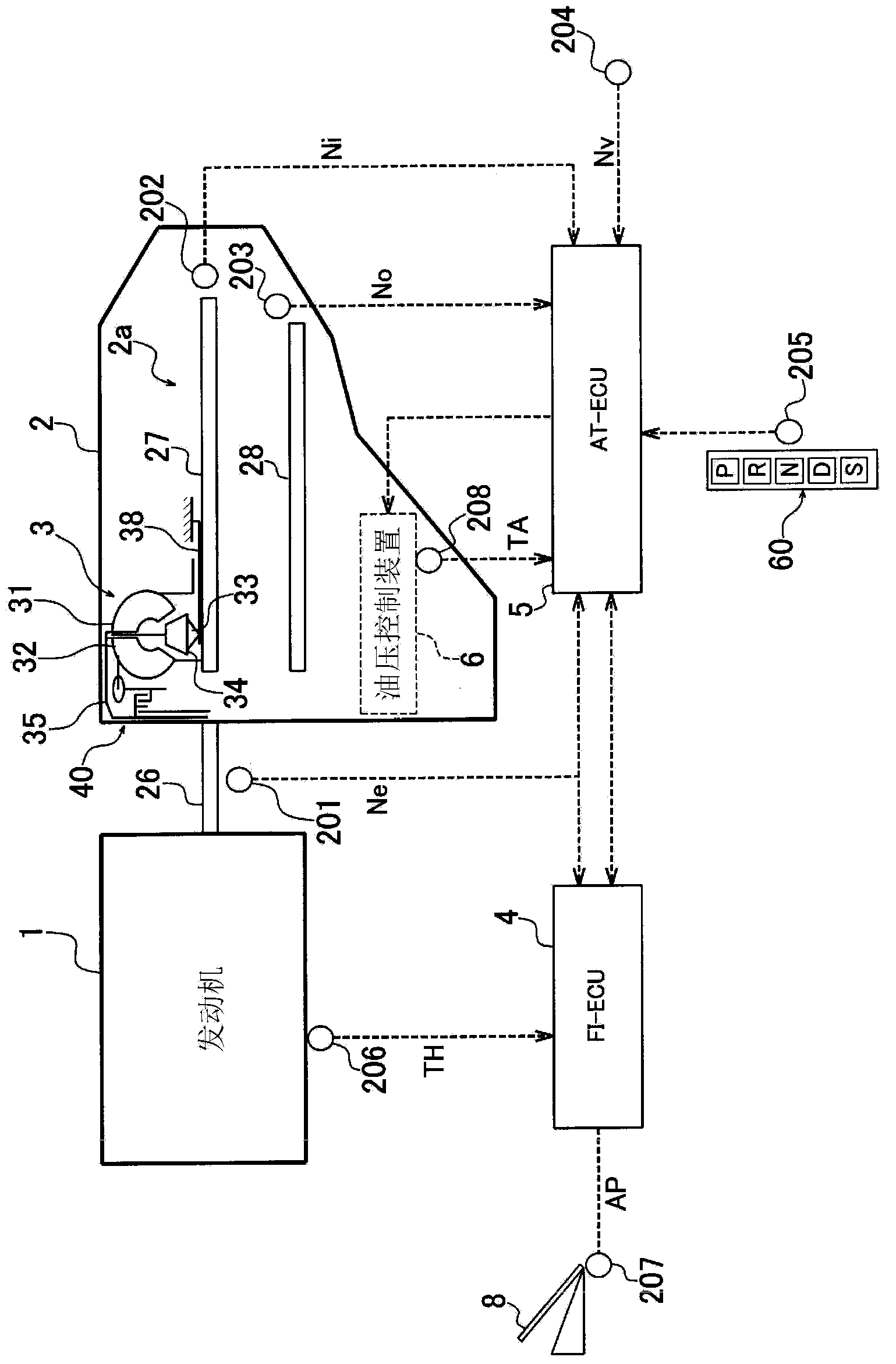

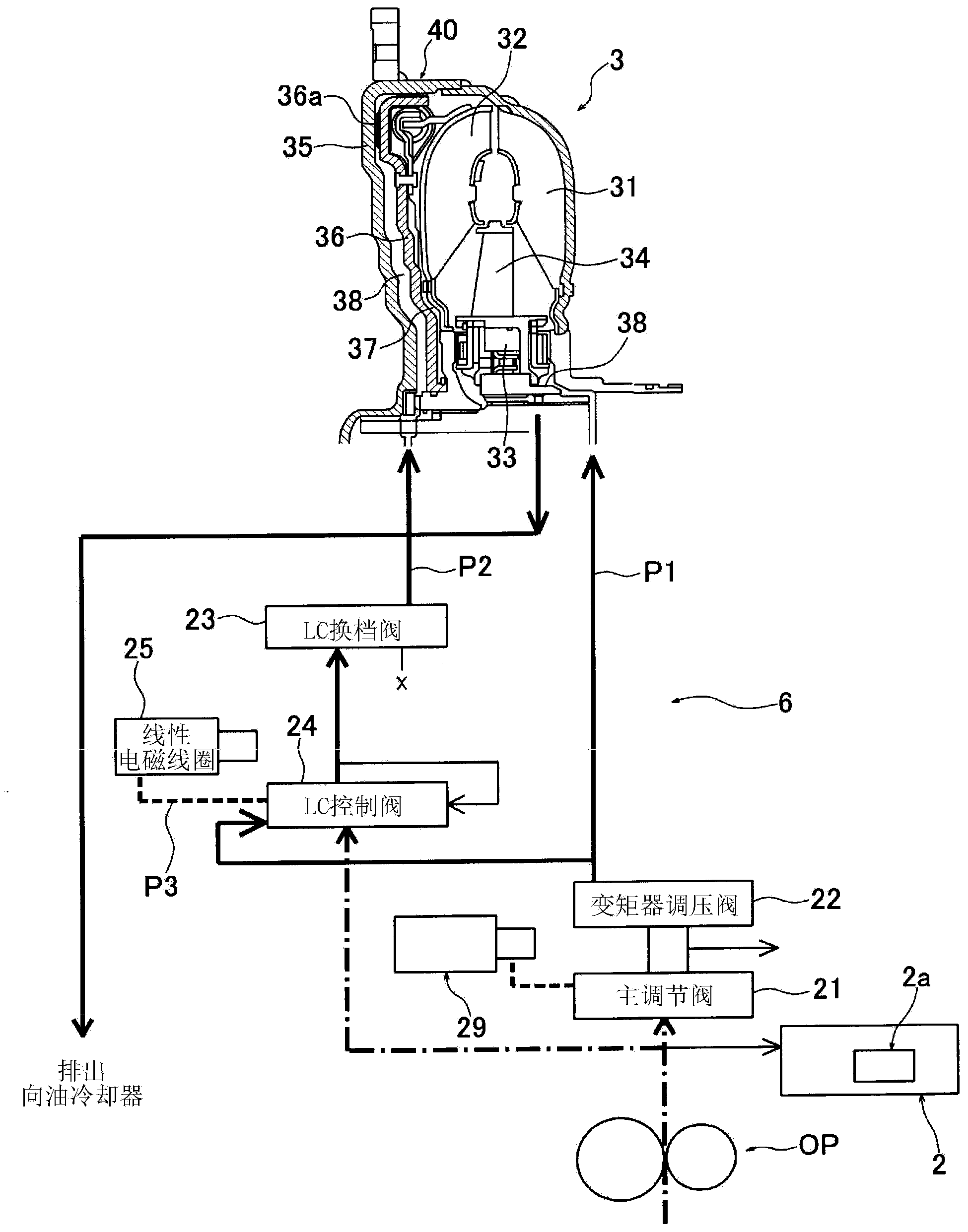

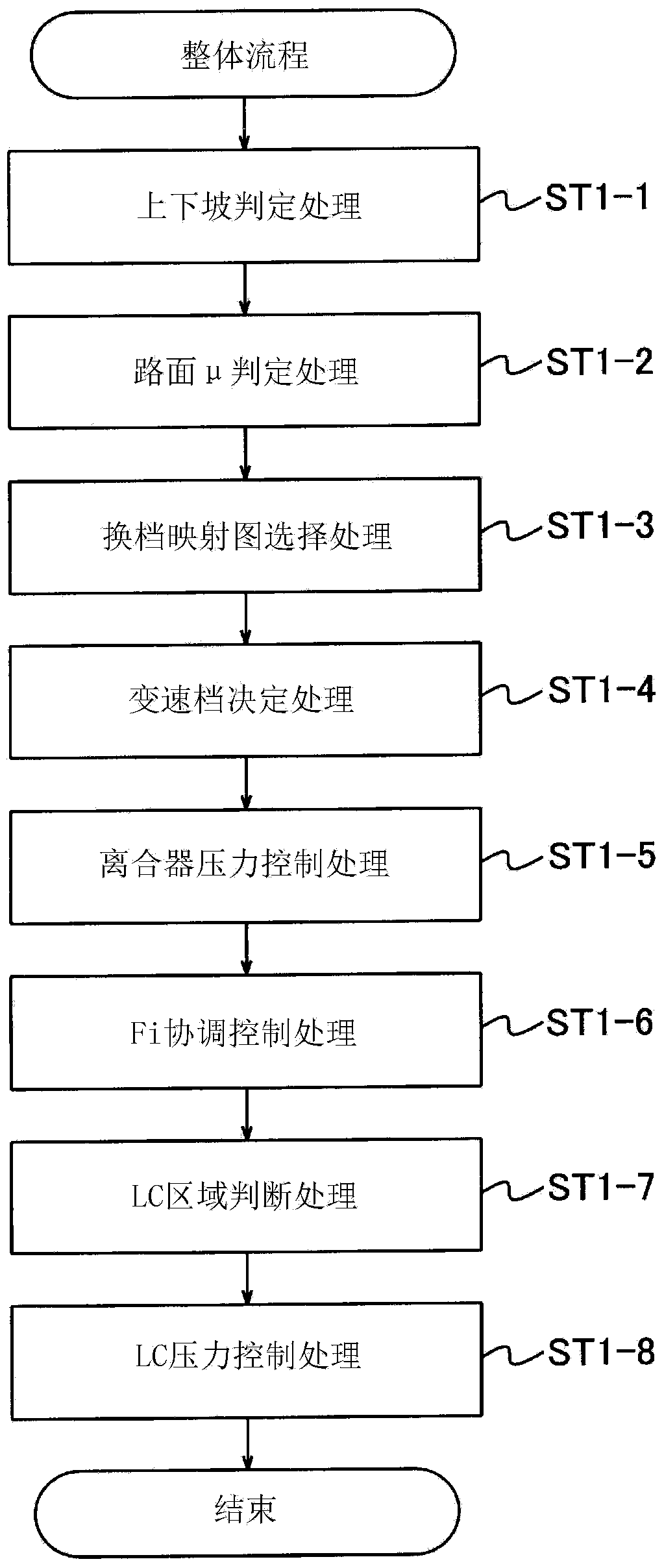

Control gear of automatic gearbox

ActiveCN103542086APrevent slippingLarge amount of bondingGearing controlFluid gearingsAutomatic transmissionTimer

The invention provides a control device of automatic gearbox, which can be used in an oil pressure control of lock-up clutch during speed change, thereby preventing oil pressure reduction caused by speed change prepration pressure, and appropriately adjusting oil pressure in required area for the lock-up clutch, and not only inhibiting slipping of the lock-up clutch, but also preventing generation of abnormal noise. When the oil pressure instruction of the lock-up clutch is sent, whether the speed change instruction for a speed change mechanism is sent is judged; if the speed change instruction is sent, summing of adjusting oil pressures (PA) for the control oil pressure (P) for the lock-up mechanism is carried out. Moreover, a timer (TM) is set used from summing the adjusting oil pressures (PA) to the end. The timer (TM) is set as that the adjusting oil pressures (PA) are summed after the speed change signals are connected and the ending is before the speed change mechanism begins to change speed.

Owner:HONDA MOTOR CO LTD

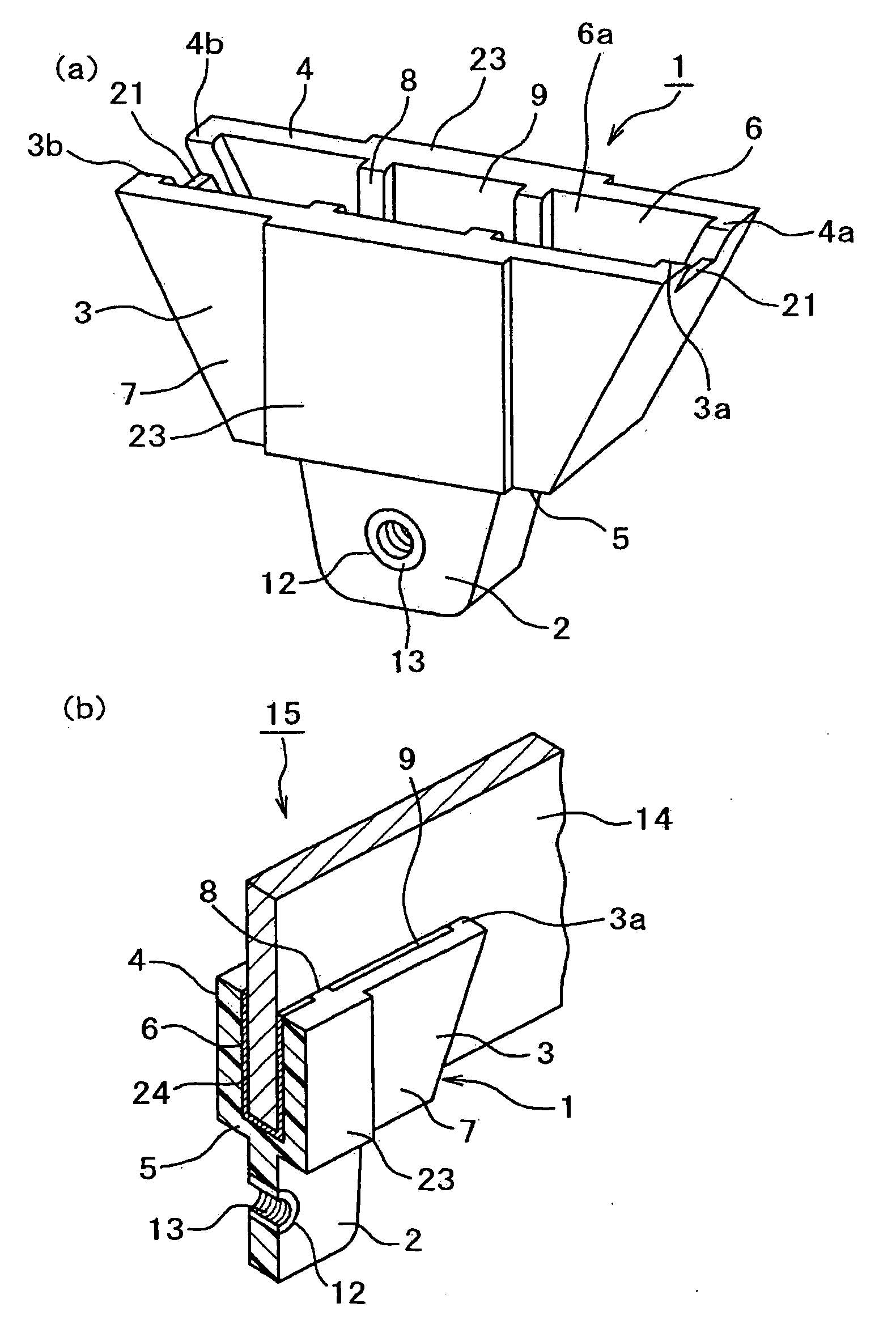

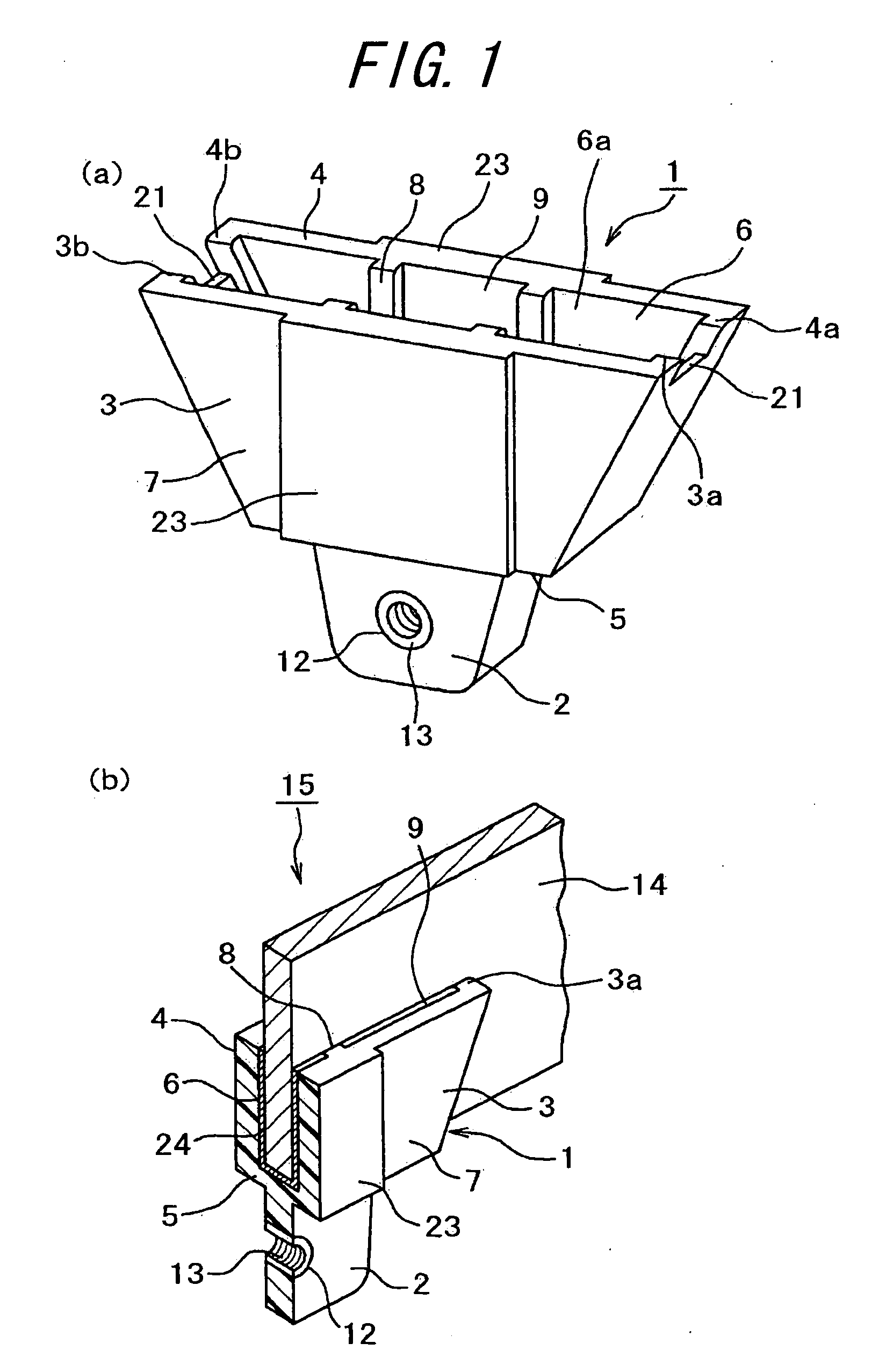

Vehicle Windowpane Holder and Method of Producing Vehicle Window Assembly Using the Same

InactiveUS20090072579A1Prevent abnormal noiseIncrease widthWindowsDoors/windowsEngineeringMechanical engineering

A vehicle windowpane holder (1) includes a glass holding section (7) extending from a leg portion (2), in which a windowpane receiving groove (6) is defined by gradually broadening opposed surface portions (3, 4) and a bottom surface portion (5). Weir portions (21) are formed at both side edges of the opposed surface portions-(3, 4) so as to close both ends of the windowpane receiving groove (6). The weir portions (21) are gradually inclined outwards and removed, upon insertion of the windowpane. When the windowpane holder (1) is to be assembled to the windowpane (14), an adhesive agent (24) is injected into the windowpane receiving groove (6), and the windowpane (14) is inserted into the windowpane receiving groove (6) from its opening side. By this, the weir portions (21) are caused to be gradually inclined outwards and removed, and the windowpane holder (1) and the windowpane (14) are adhered to each other by the adhesive agent, to produce a vehicle window assembly (15).

Owner:FALTEC CO LTD

Damper device

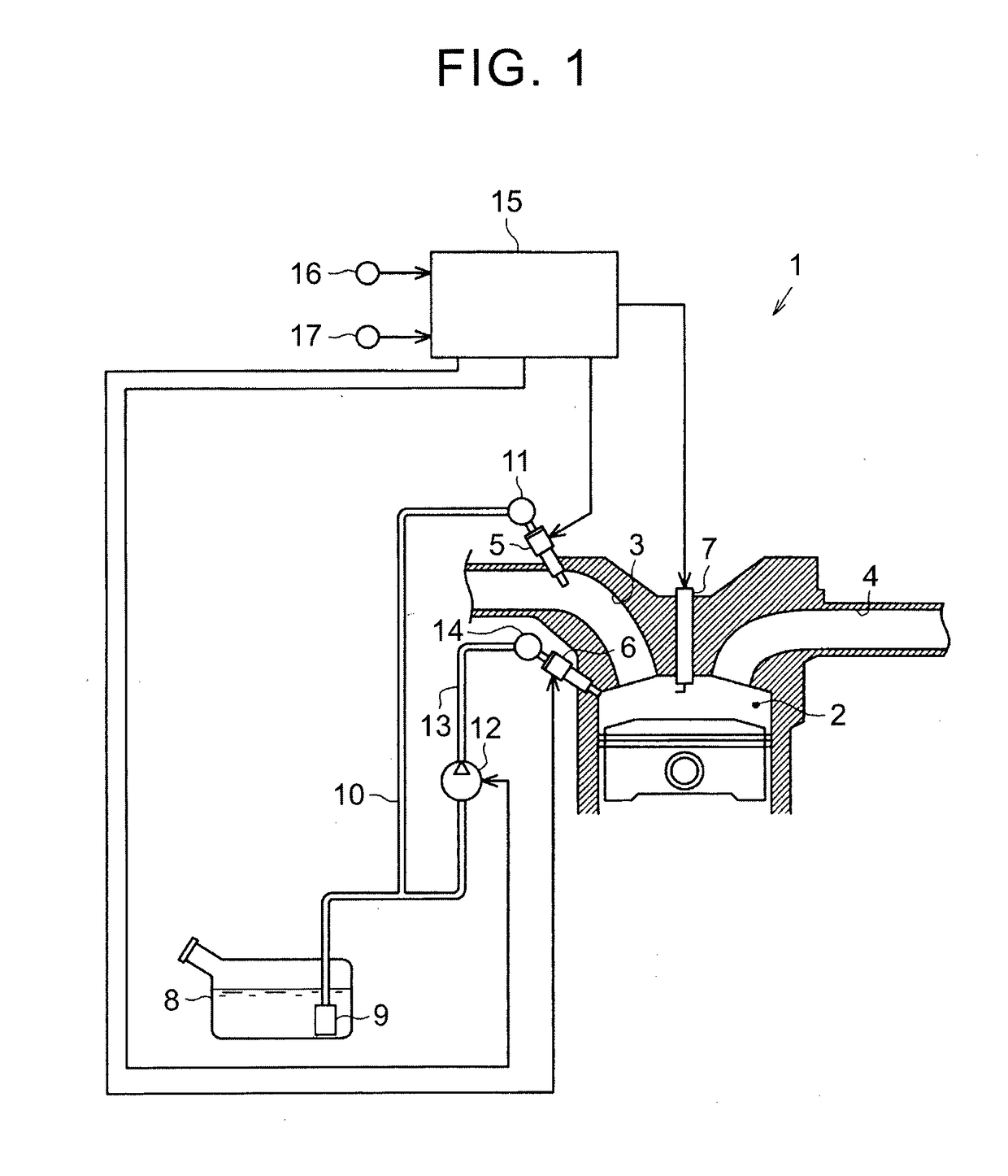

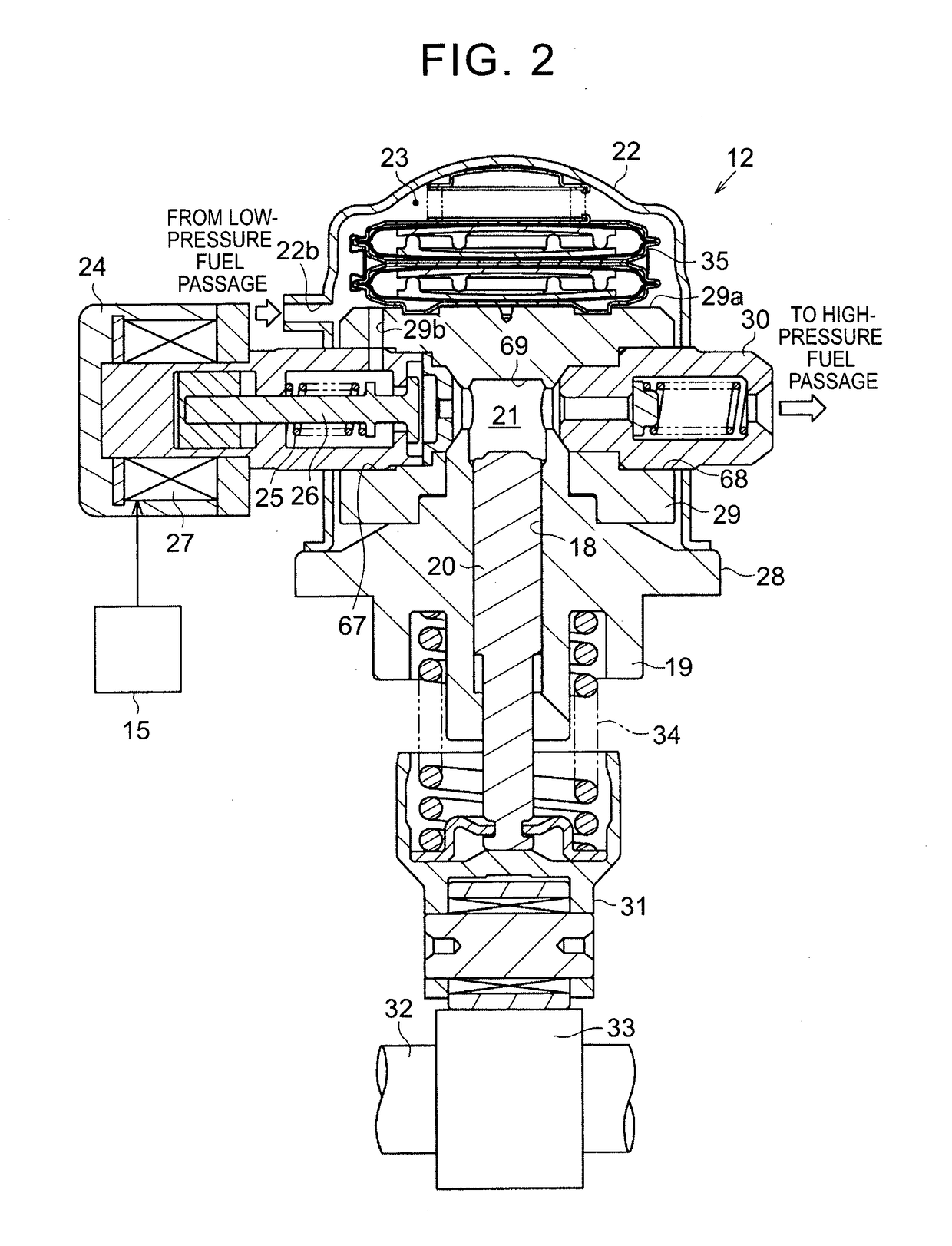

ActiveUS20180223782A1Easily avoidedPrevent abnormal noiseSpecial fuel injection apparatusLiquid fuel feedersEngineeringShock absorber

A damper device is provided in a flow passage of a fluid. The damper device includes a plurality of diaphragm dampers that are stacked together. Each of the plurality of diaphragm dampers includes a first flexible portion, a second flexible portion, and a rim including a welded portion. A peripheral edge of the first flexible portion and a peripheral edge of the second flexible portion are welded together in the welded portion. Each of the plurality of diaphragm dampers is configured to seal a gas in an inner region between the first flexible portion and the second flexible portion. A coupler that couples the plurality of diaphragm dampers together includes holders that hold the rims of the plurality of diaphragm dampers. A gap is provided between the holder of the coupler and the welded portion of each of the plurality of diaphragm dampers.

Owner:TOYOTA JIDOSHA KK +2

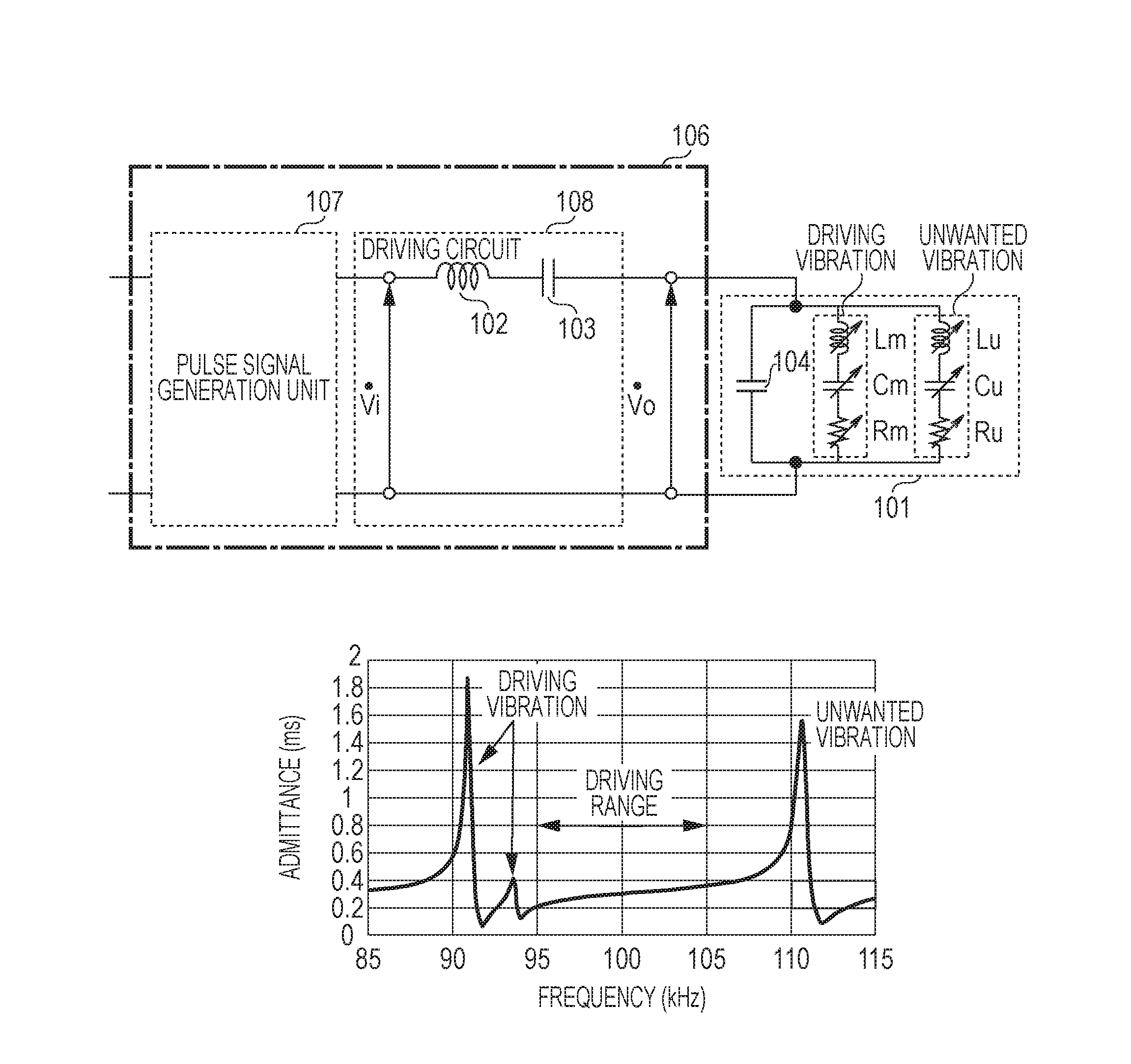

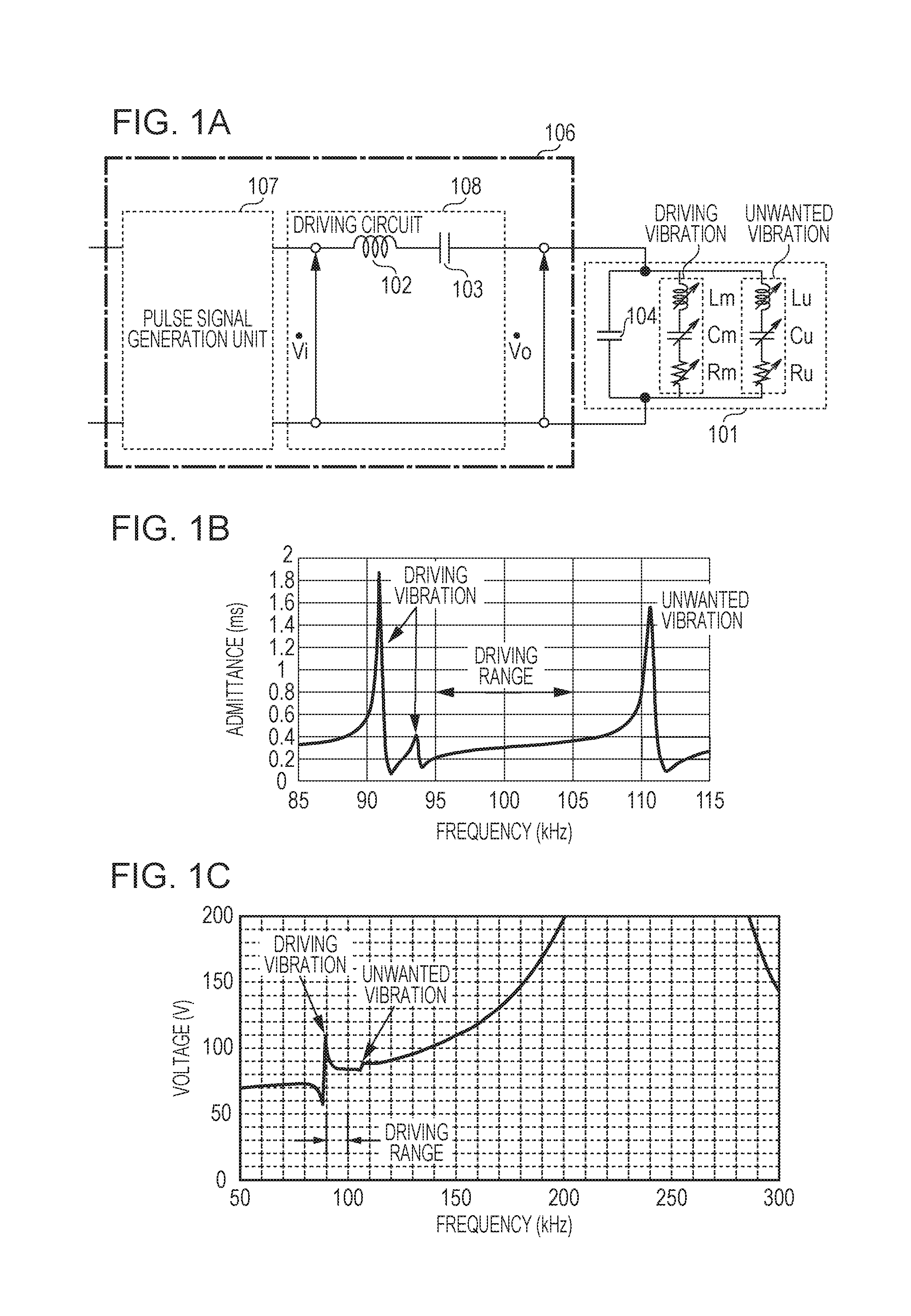

Driving circuit for a vibration type actuator, vibration device, image blur correction apparatus, replacement lens, image pickup apparatus, and automatic stage

ActiveUS20170054387A1Prevent abnormal noiseTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesInductorEngineering

A driving circuit for a vibration type actuator includes an inductor and a capacitor which are connected in series to an electric-mechanical energy conversion element, in which, in a case where a series resonance frequency based on the inductor and the capacitor is set as fs, and a resonance frequency in a vibration mode other than vibration used for driving of the vibrator is set as fu, 0.73·fu<fs<1.2·fu is satisfied.

Owner:CANON KK

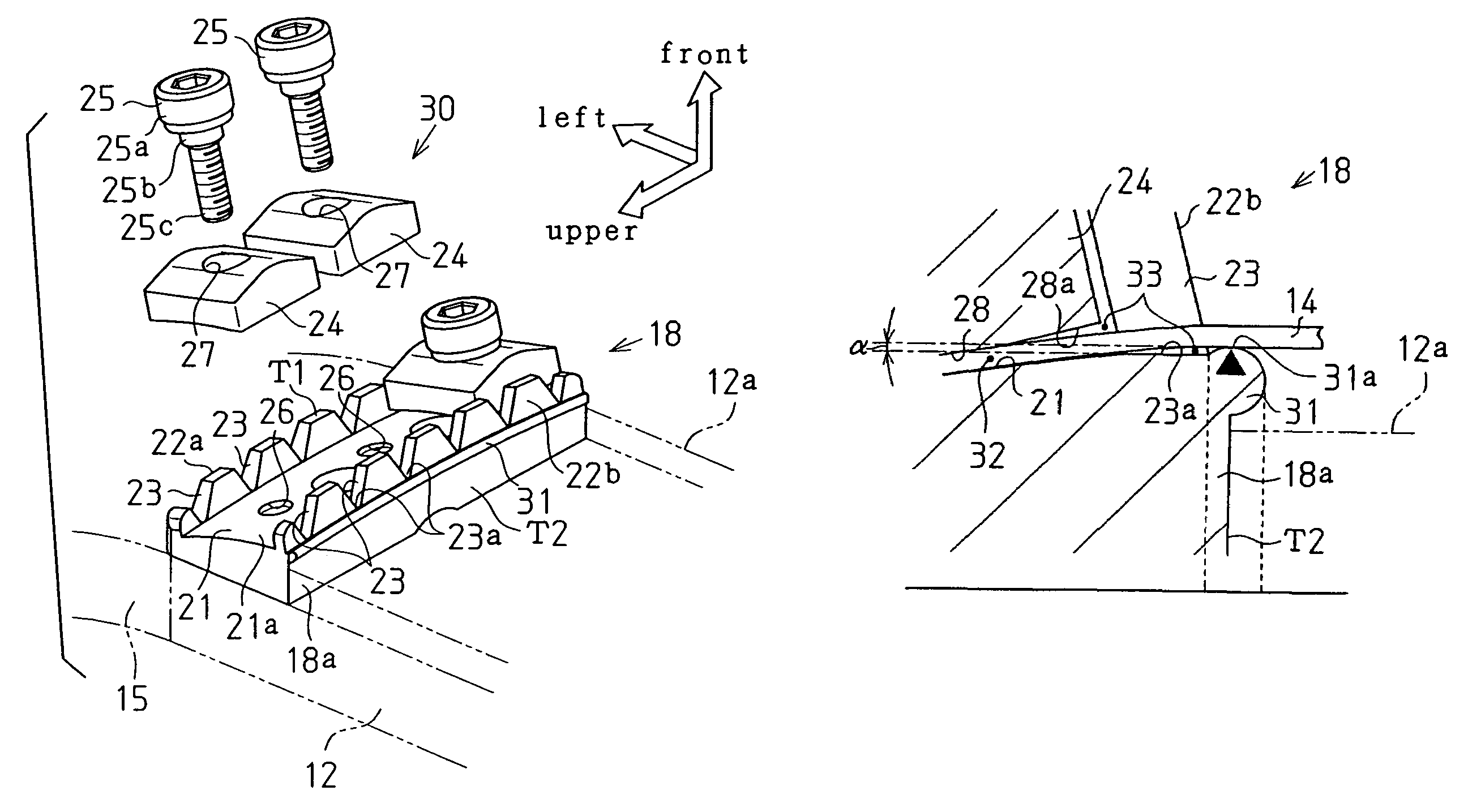

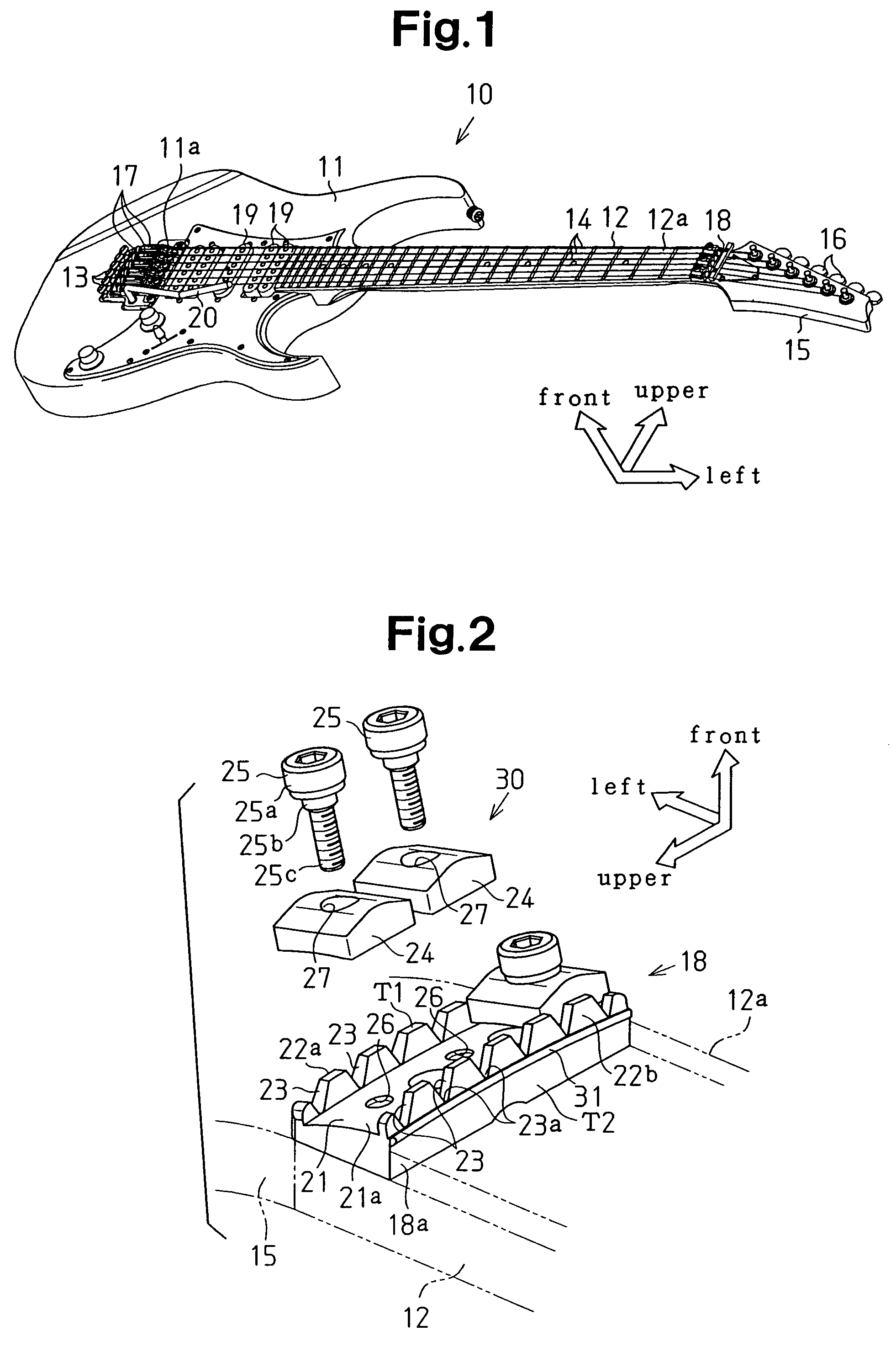

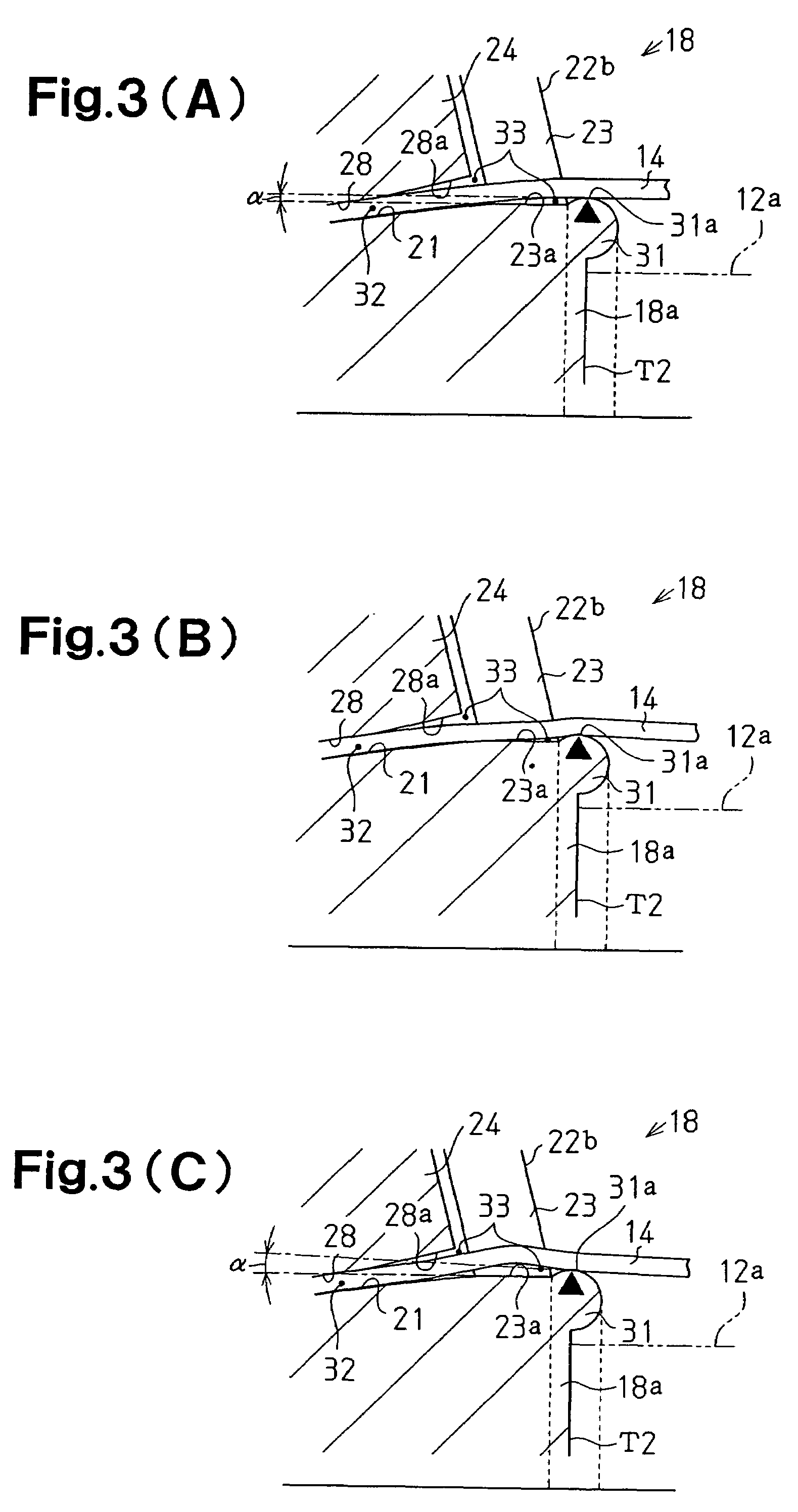

Stringed instrument nut and stringed instrument

A stringed instrument including strings supported by bridges, which are fixed to a body, and a nut fixed to a neck. The strings are supported in a manner enabling vibration of each string. The nut includes a nut body and a fastener. The fastener is formed by pressing members and adjustment screws. The pressing members press the strings against the nut surface so that the strings are fixed to the nut surface. A projection projecting toward the strings is formed on an end portion of the nut. The strings are supported by the nut so as to contact the top surface of the projection. This enables each string to vibrate while being in constant contact with the projection and prevents each string from coming into contact with the nut or fastener. Thus, abnormal noise is not generated.

Owner:HOSHINO GAKKI COMPANY LIMITED

Ferrous sintered multilayer roll-formed bushing, producing method of the same and connecting device

InactiveUS8283046B2Prevent abnormal noiseImprove the lubrication effectBearing assemblyMetal-working apparatusMaterials scienceMetal

Owner:KOMATSU LTD

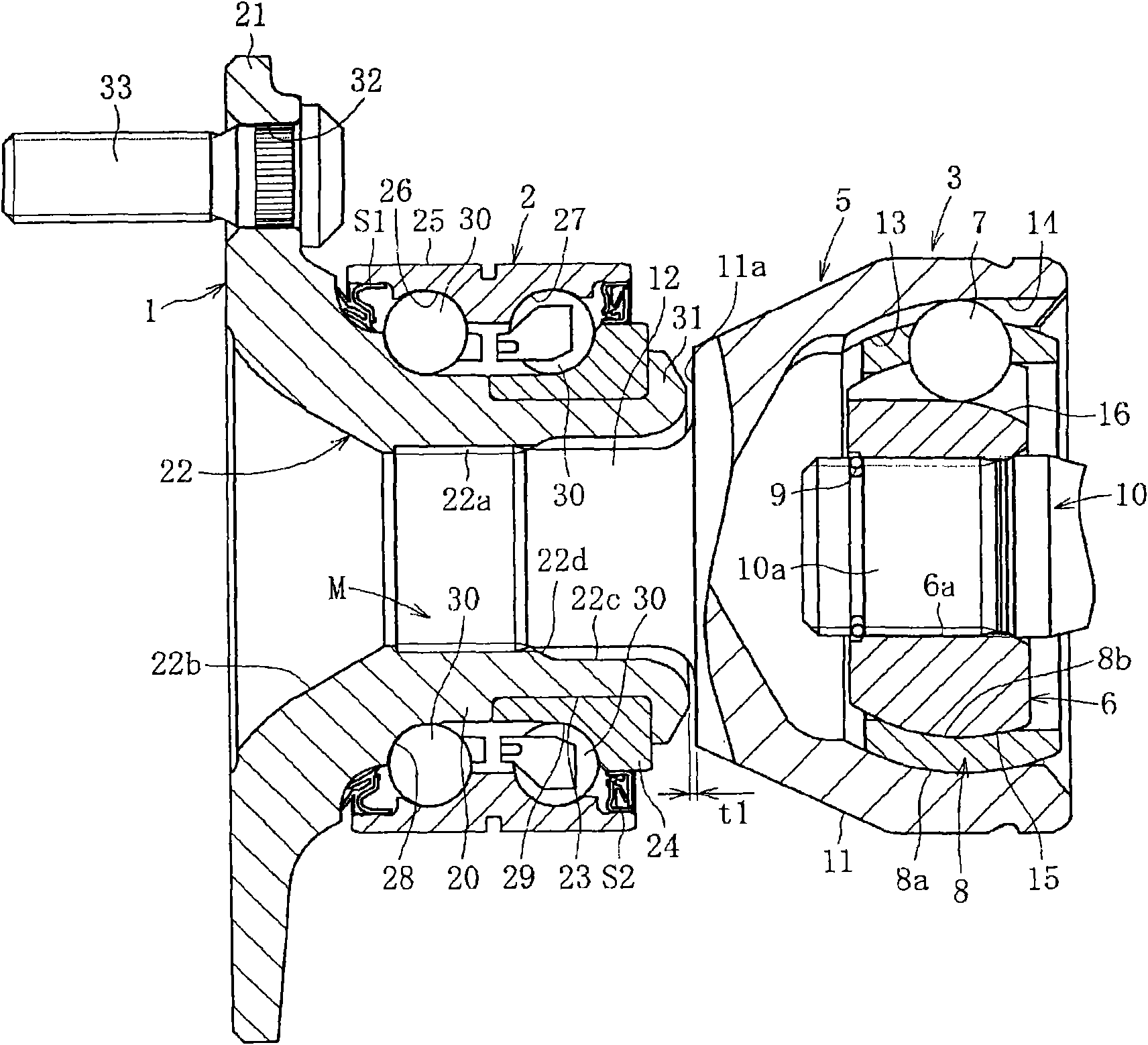

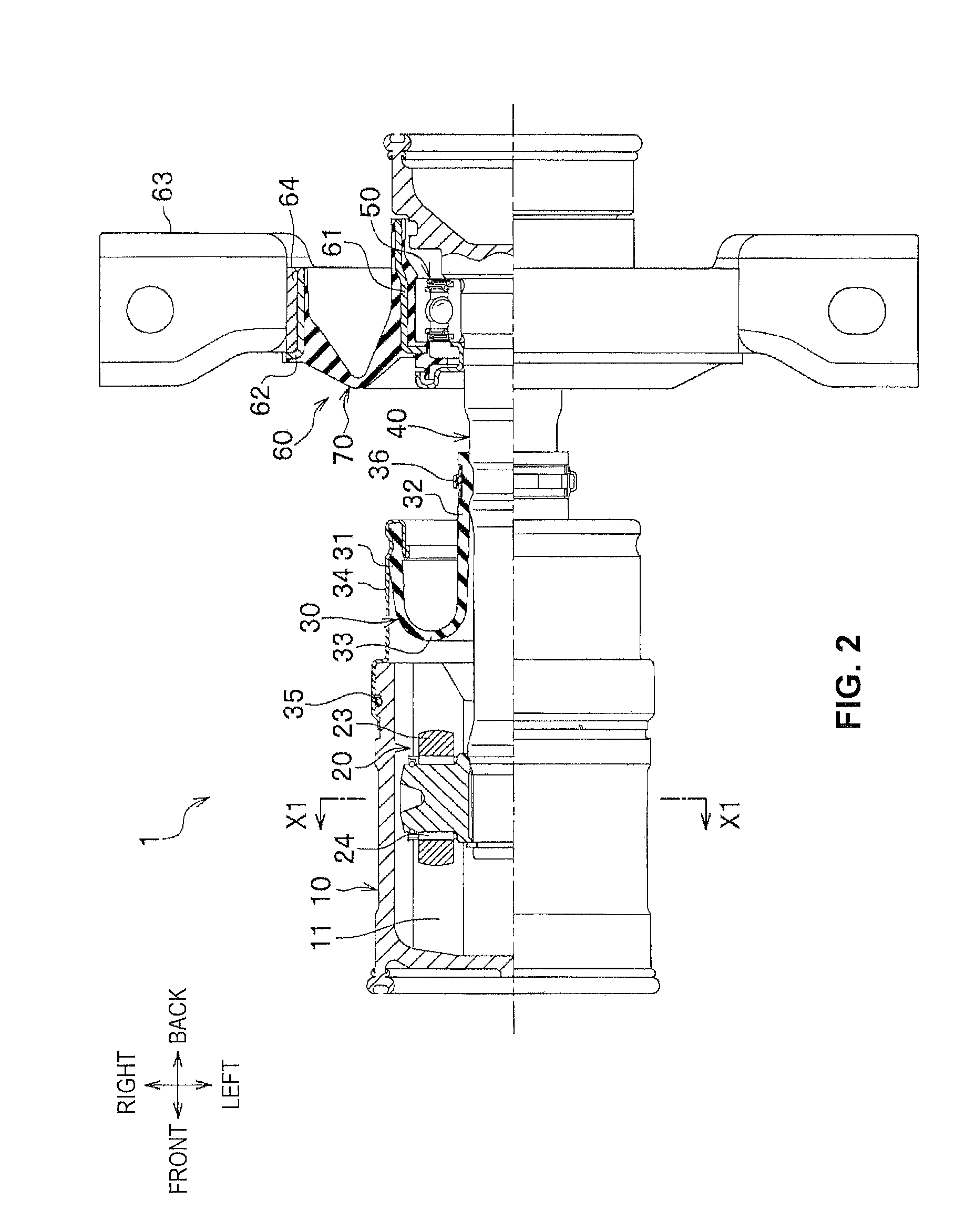

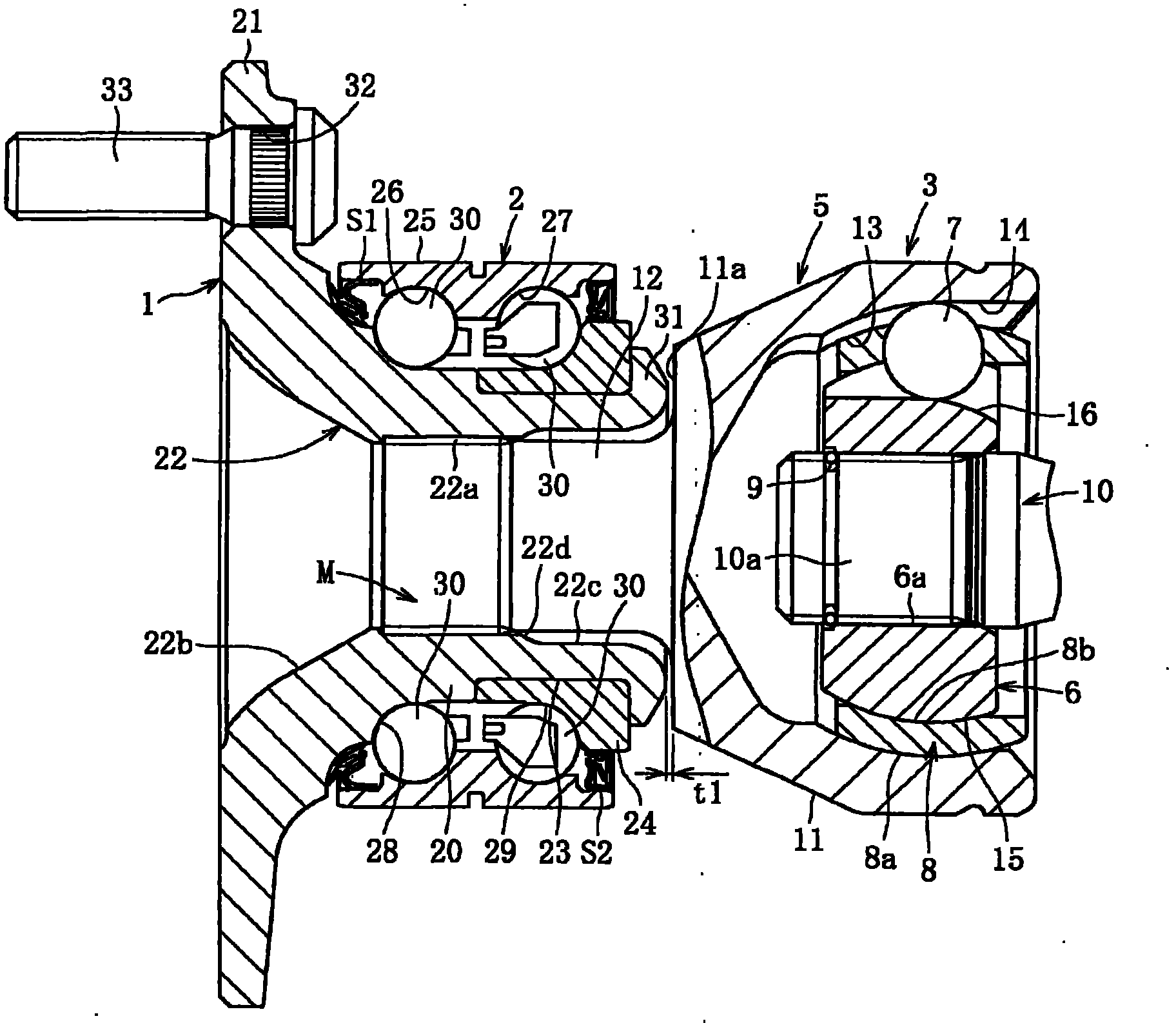

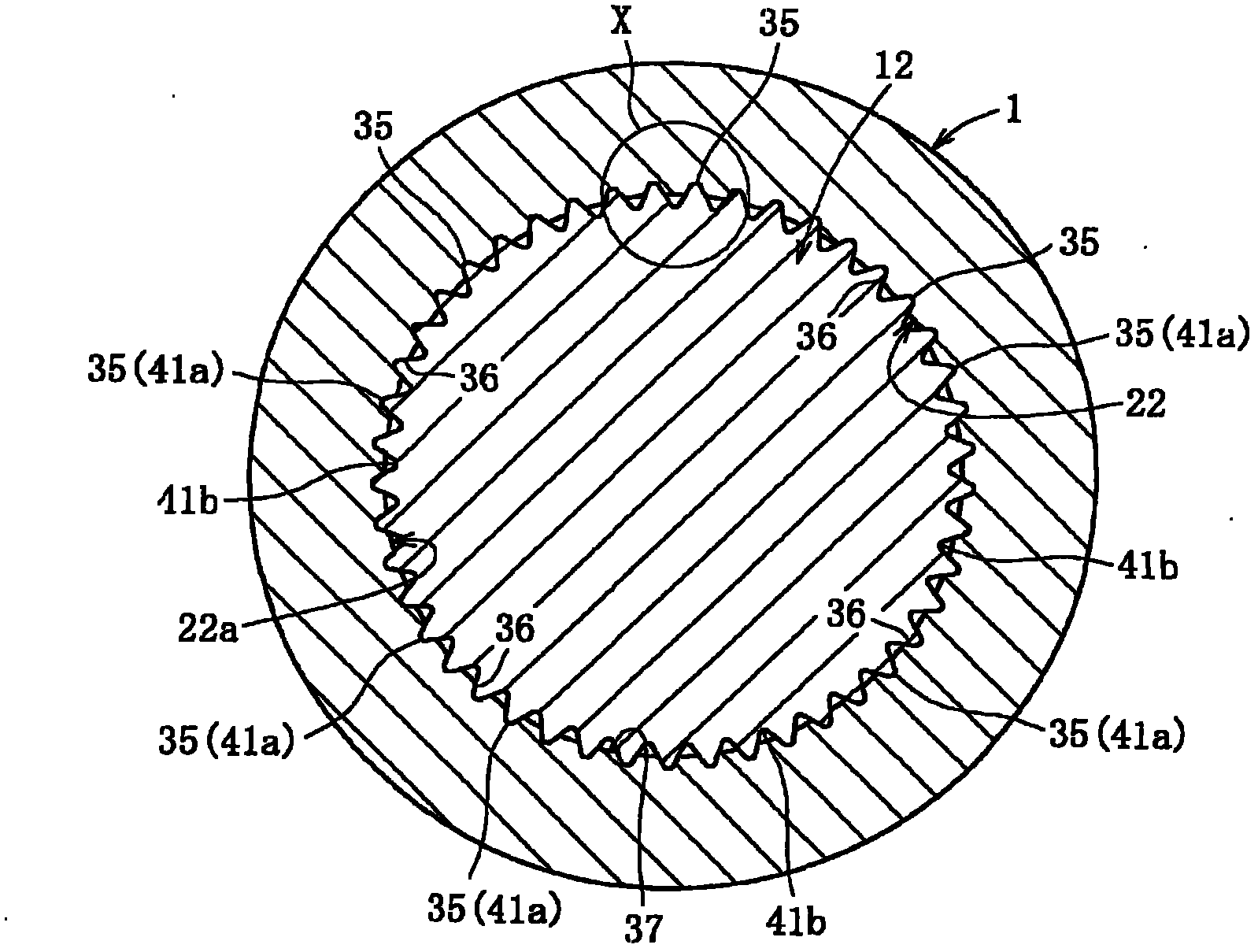

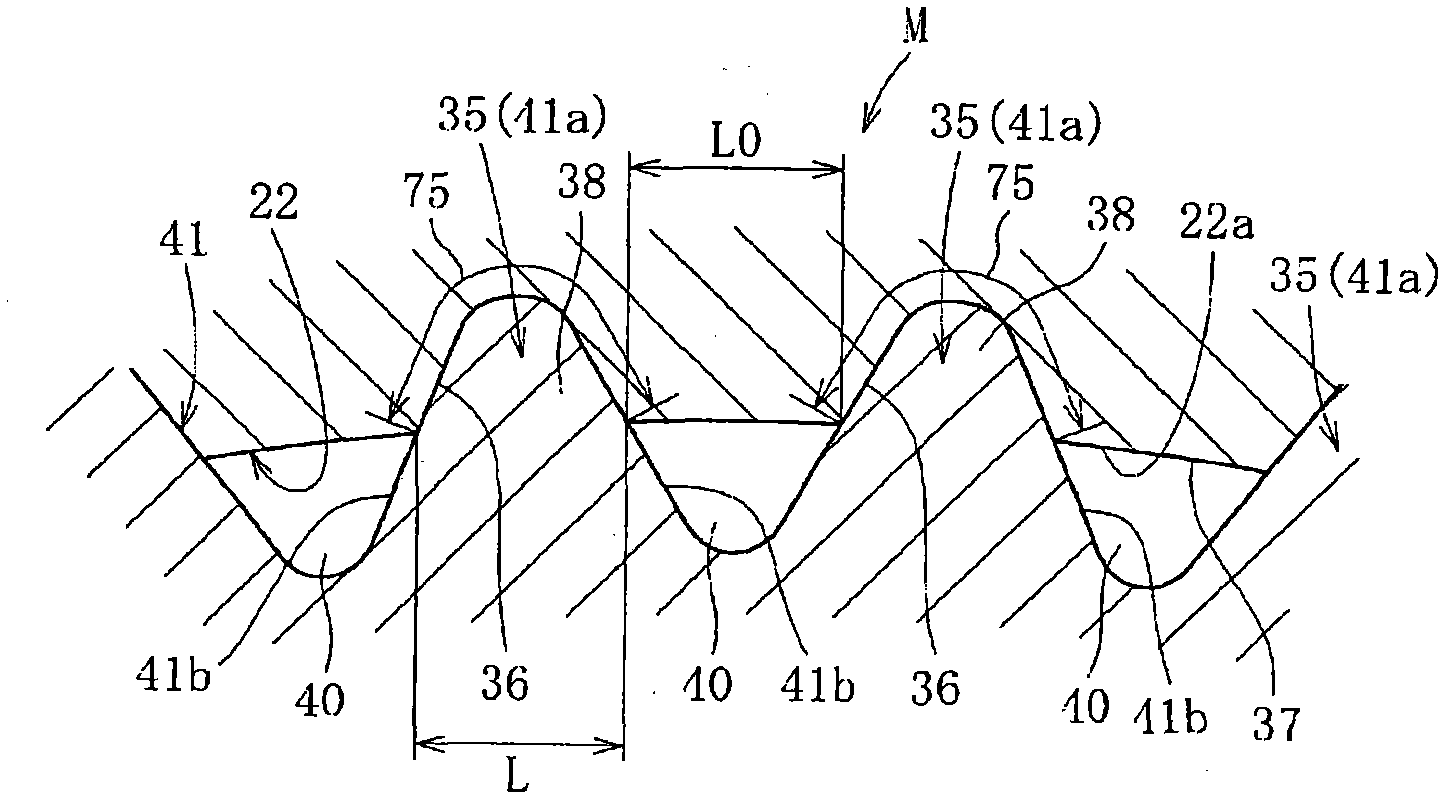

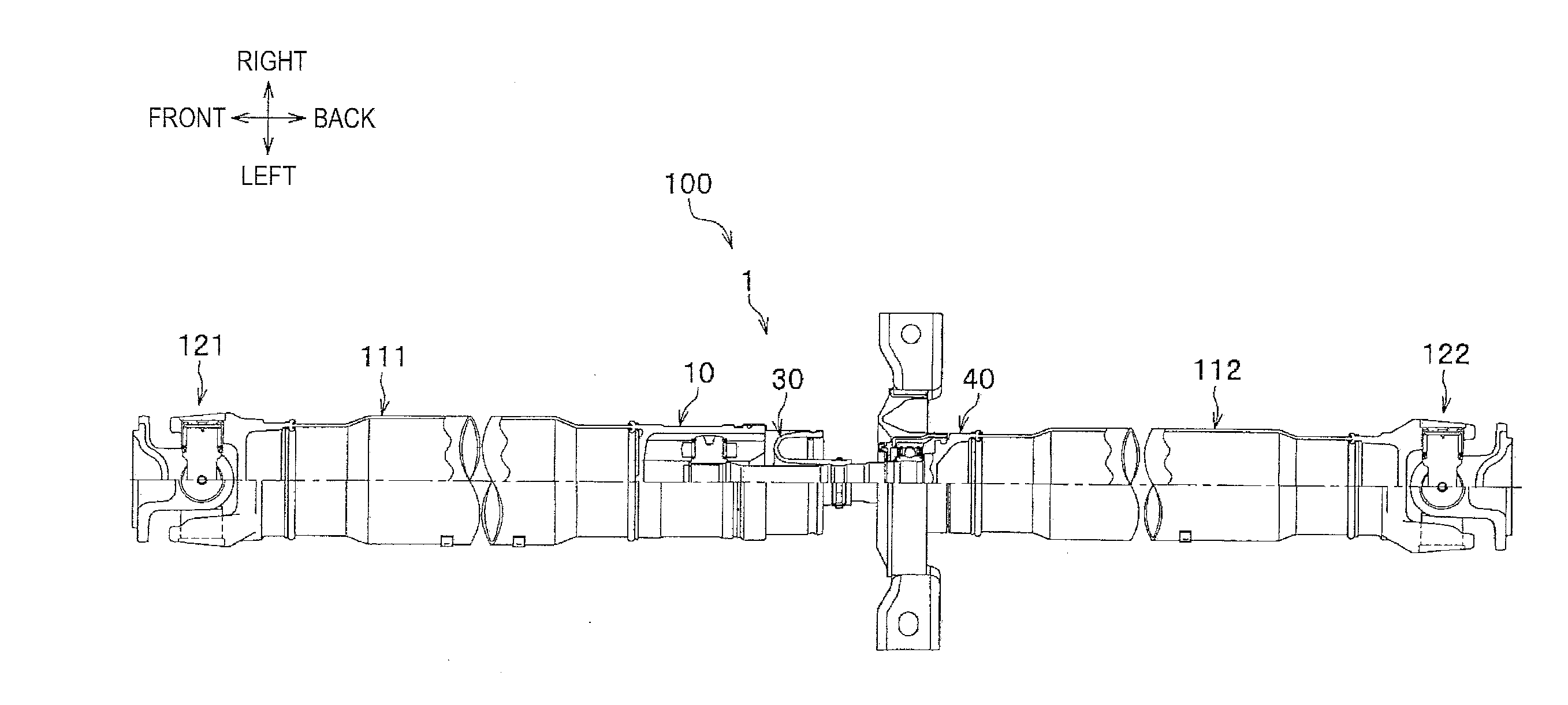

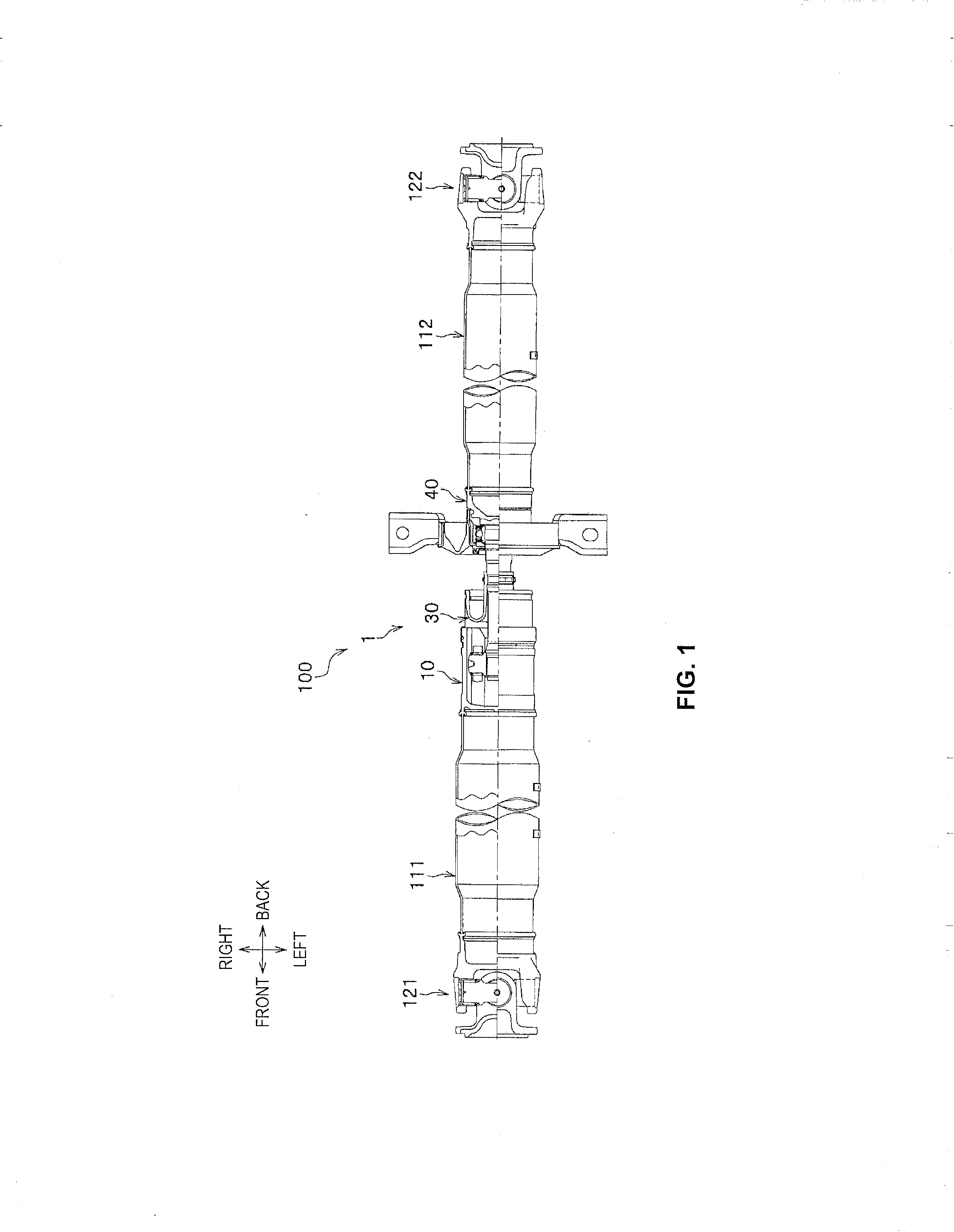

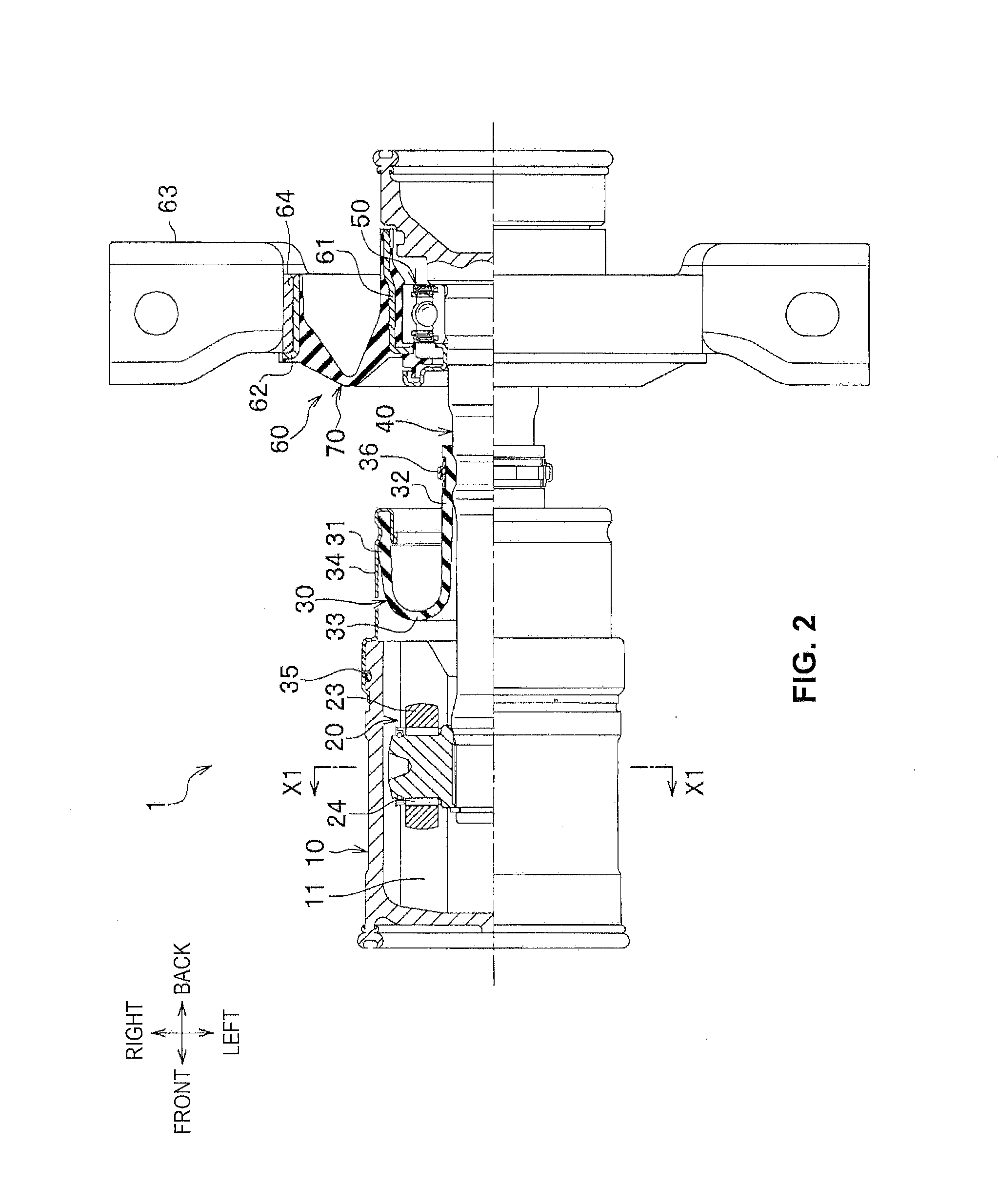

Bearing device for wheel

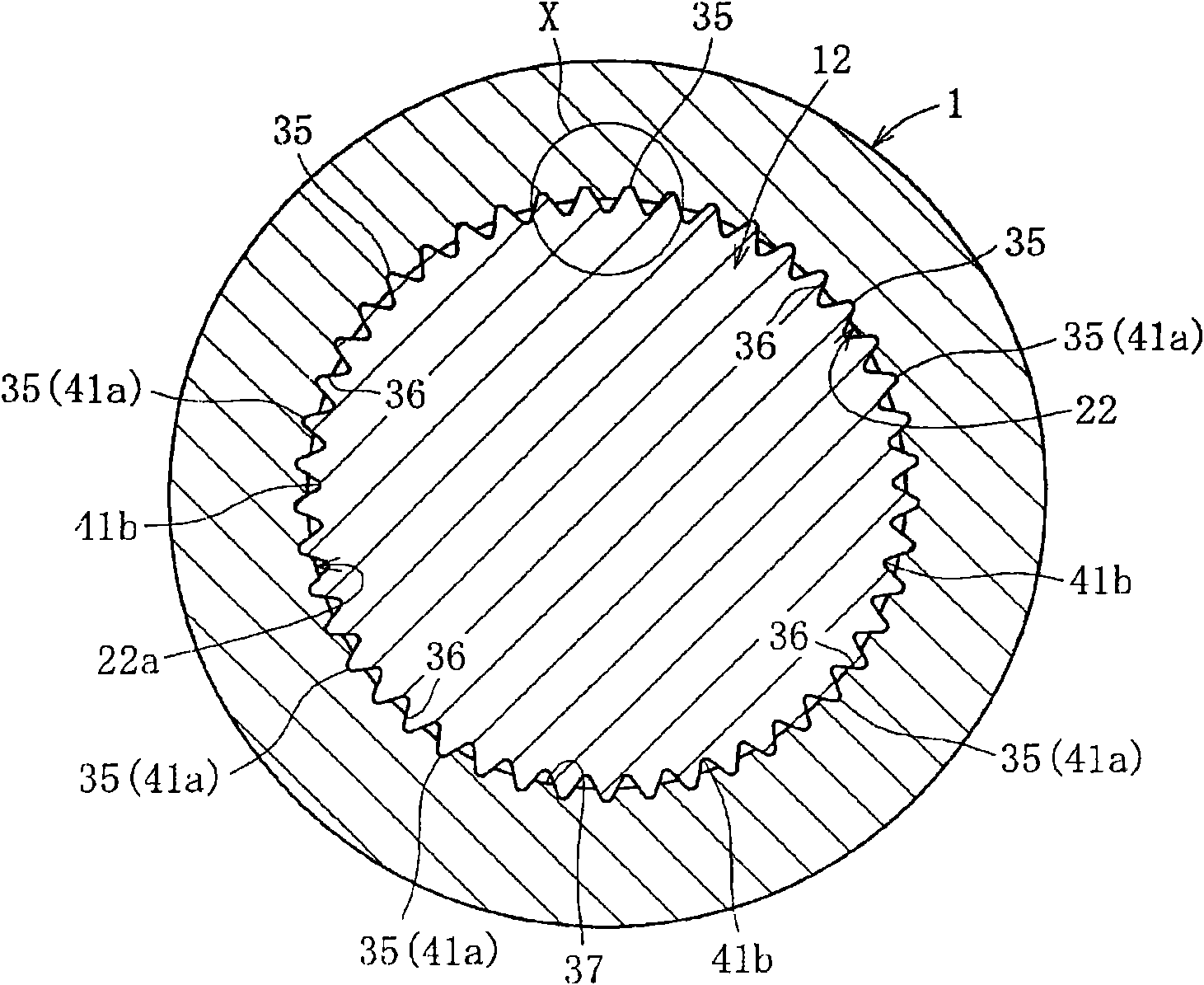

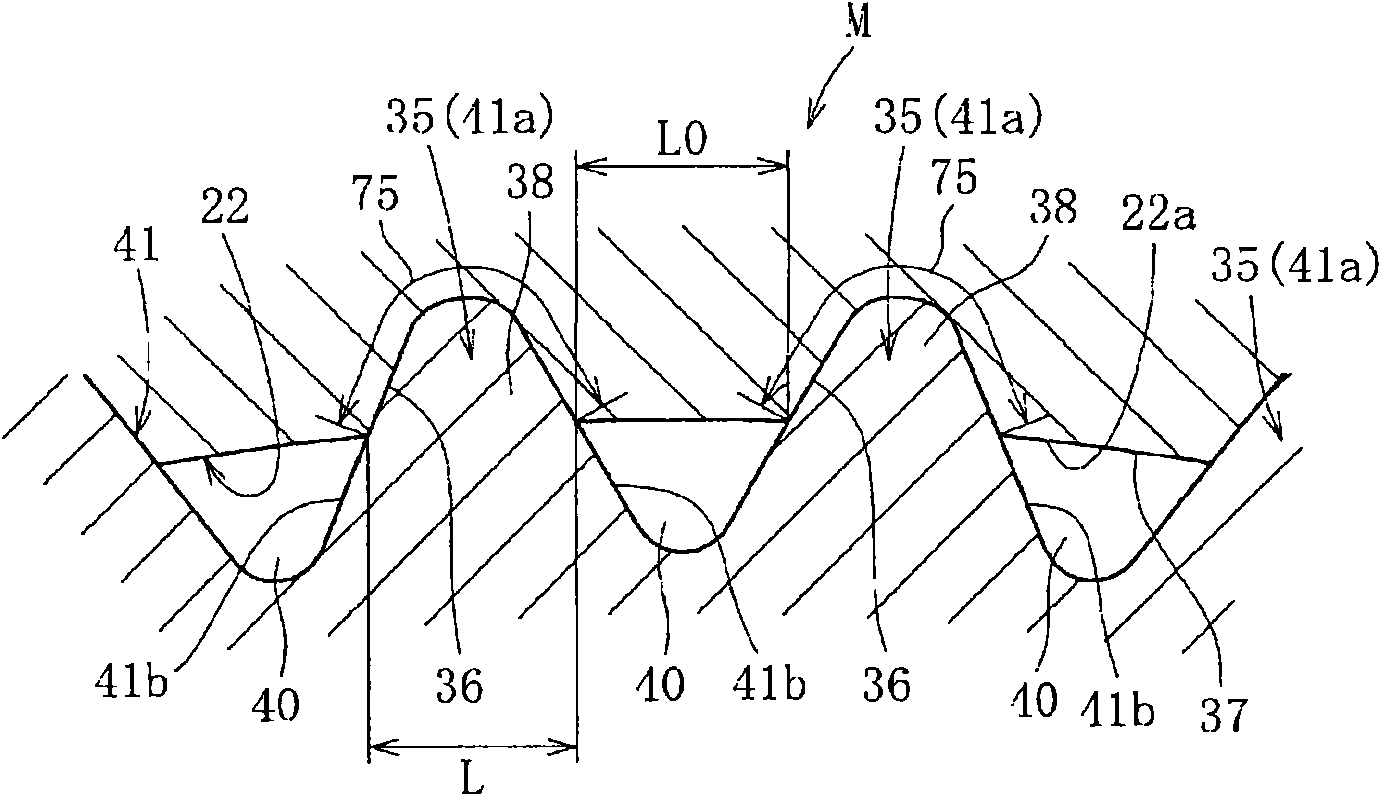

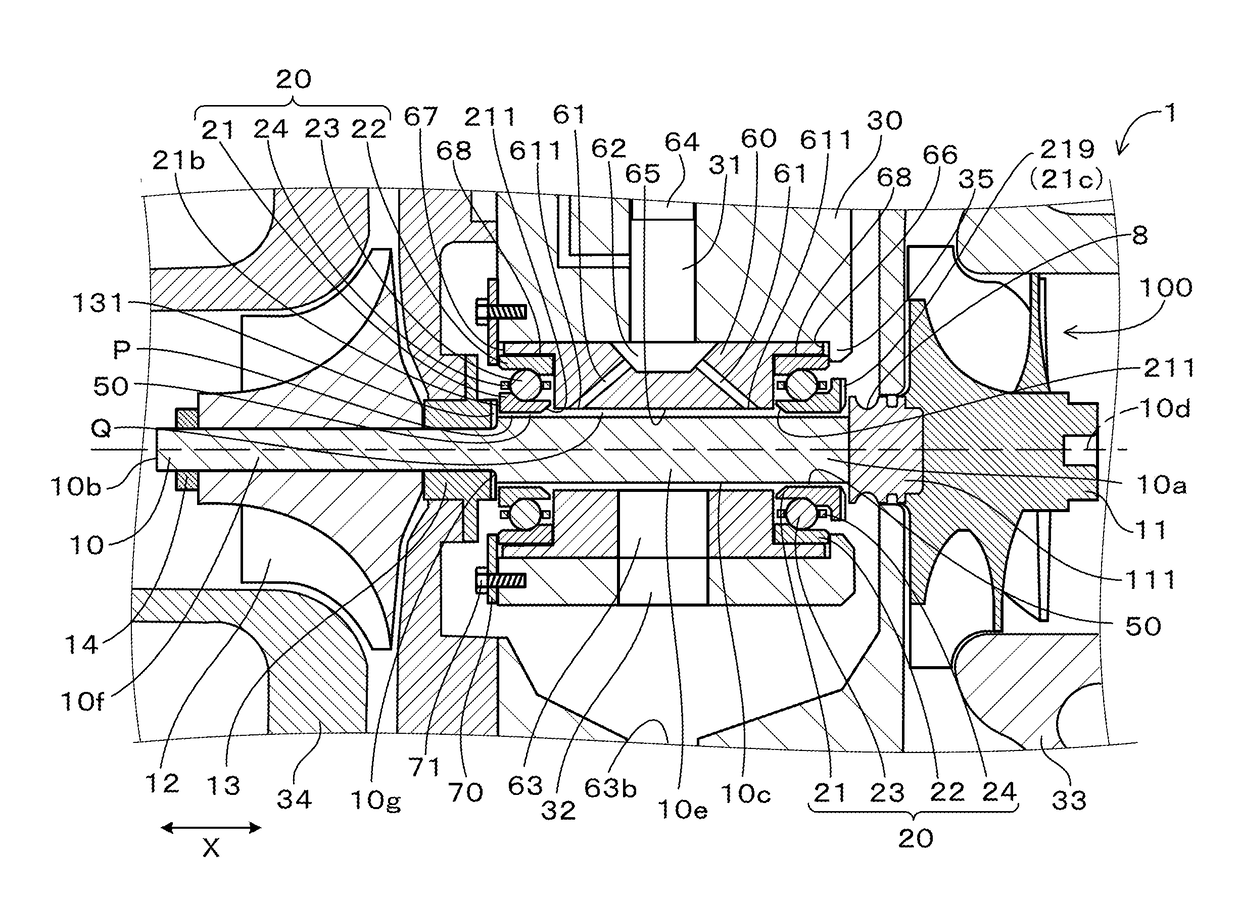

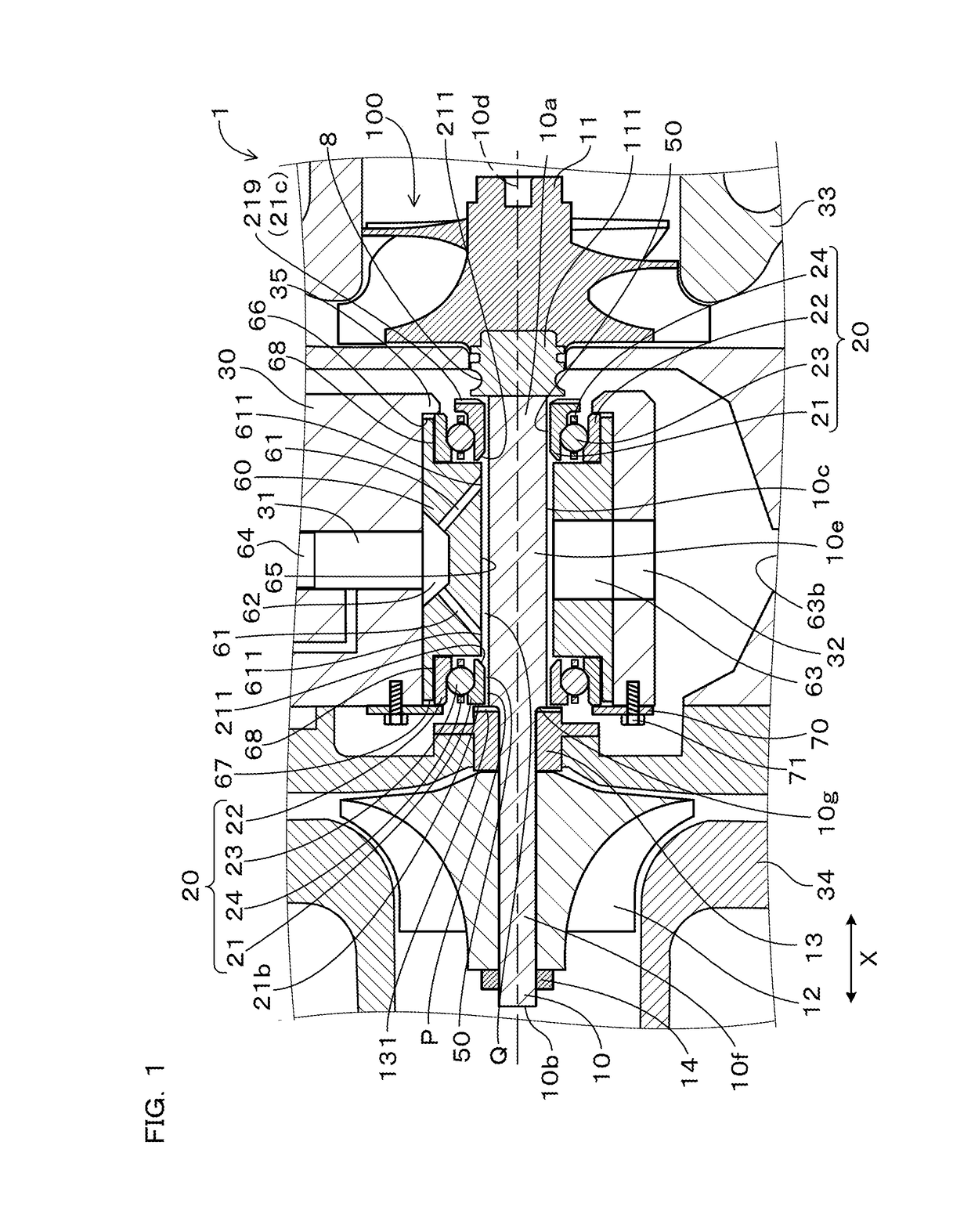

InactiveCN101641225ADoes not generate abnormal noiseHigh strengthRolling contact bearingsAxle unitsKnuckleEngineering

A bearing device for a wheel, in which circumferential play is suppressed, which facilitates connection between a hub ring and an outer coupling member, in which a reduction in NVH characteristics due to play at a joint between the hub ring and the constant velocity universal joint and by play between a bearing outer member and a knuckle is prevented, and which performs highly accurate transmission of rotational torque. The bearing device has a groove-ridge fitting structure (M) by which the hub ring (1) and a shaft section (12) of the outer coupling member of the constant velocity universal joint (3) are integrated together, and the shaft section (12) is fitted in a hole (22) of the hub ring (1). In the groove-ridge fitting structure (M), ridges (35) on the outer diameter surface of the shaft section (12) and grooves (36) in the inner diameter surface (37) of the hub ring (1) are fitted to each other in a fitting contact portion (38), and the ridges (35) and the grooves (36) are in intimate contact with each other in the entire fitting contact portion (38).

Owner:NTN CORP

Bearing structure

A bearing structure comprises a shaft member, a bearing, an inner ring, a ring-shaped mount which is made of an elastic material, is fixed to a vehicle body and encloses the inner ring, and a dust cover which is fixed to the bearing member and rotates in unison with the bearing member, the bearing member being supported rotatably on the vehicle body via the bearing. The mount includes, on a front side, a rib facing inward in a radial direction and extending in a circumferential direction so as to seal off a first gap formed between the shaft member and the inner ring. A second gap is formed between an inner radial end of the rib and the shaft member. The dust cover covers the rib and the second gap on the front side of the rib. A cutout is formed in a lower vertical portion of the rib.

Owner:SHOWA CORP

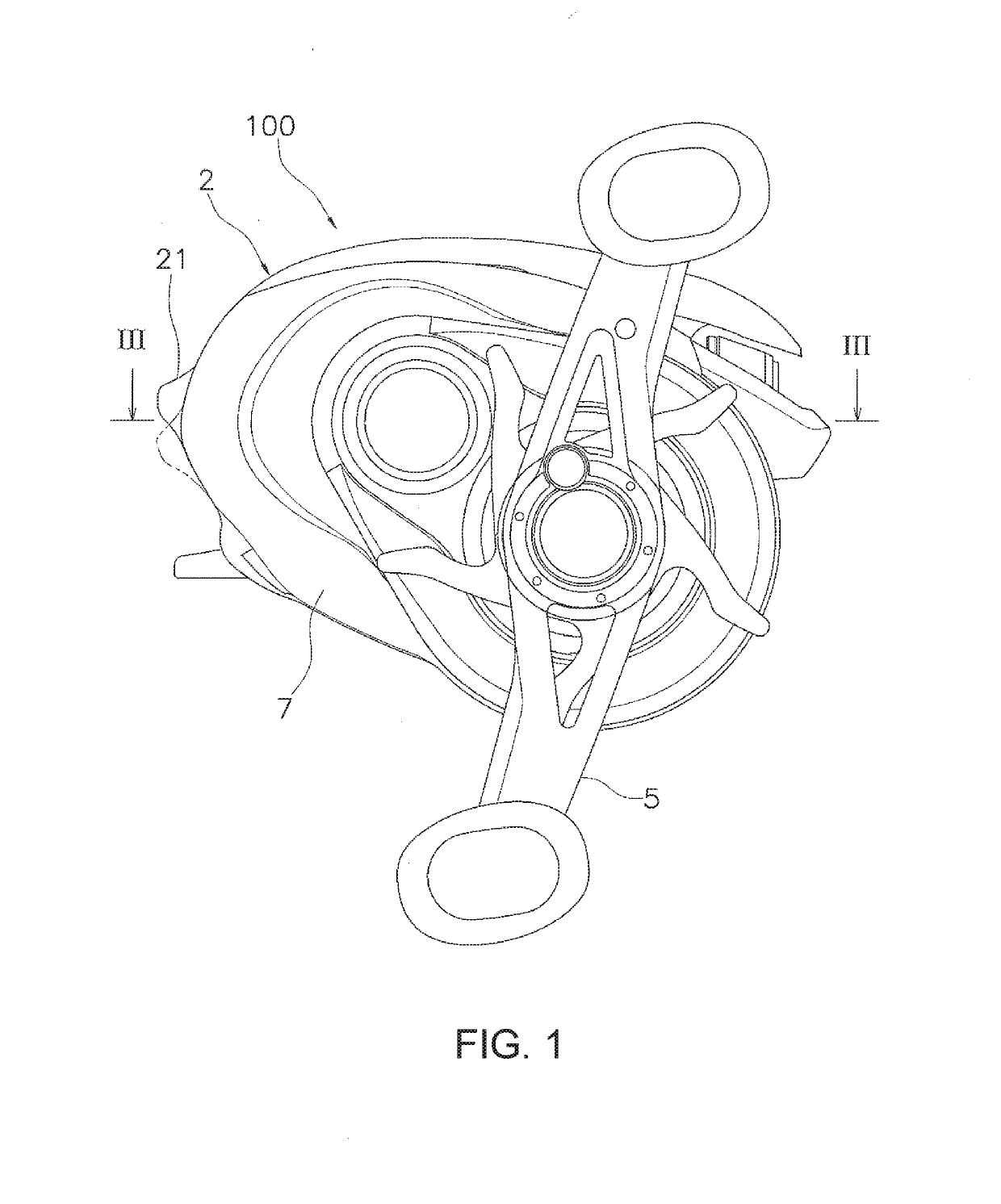

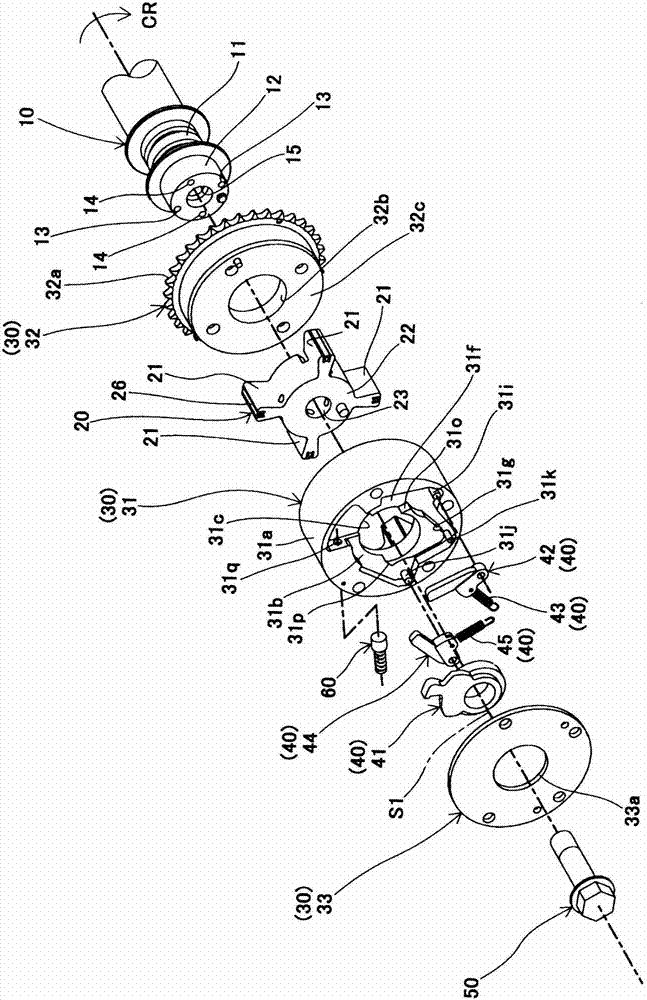

Dual-brering reel

A dual-bearing reel includes a handle, a spool, a spool shaft, a clutch mechanism, a pinion gear, and an elastic member. The spool shaft is connected to the spool to be integrally rotatable and has a first abutting portion. The pinion gear has a second abutting portion to abut the first abutting portion in the axial direction in the inner circumferential portion thereof, and can move in the axial direction between a coupled position, in which the pinion gear is connected to the spool shaft so as to be integrally rotatable, and a decoupled position, in which the connection is disconnected. When the pinion gear is in the coupled position, the elastic member contacts the distal end of the pinion gear and biases the first abutting portion and the second abutting portion in directions away from each other.

Owner:SHIMANO INC

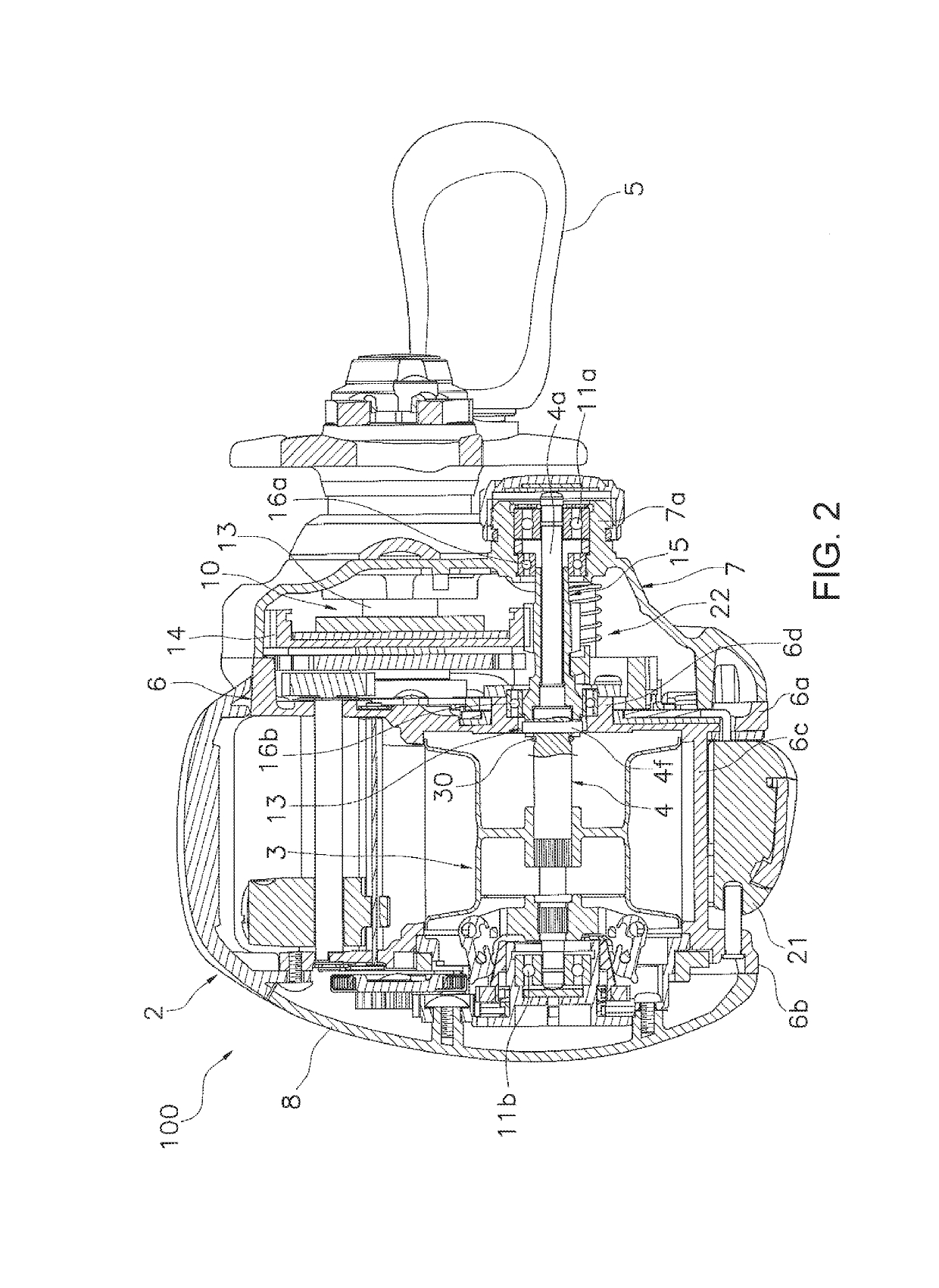

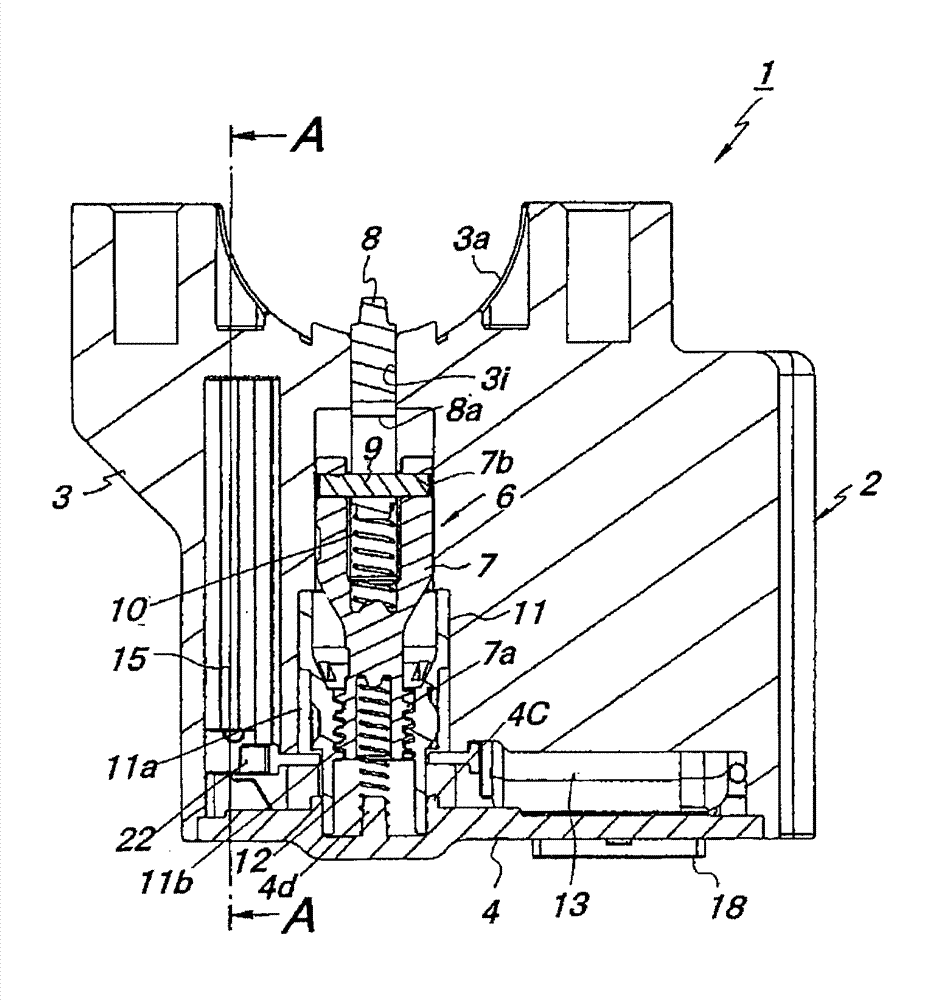

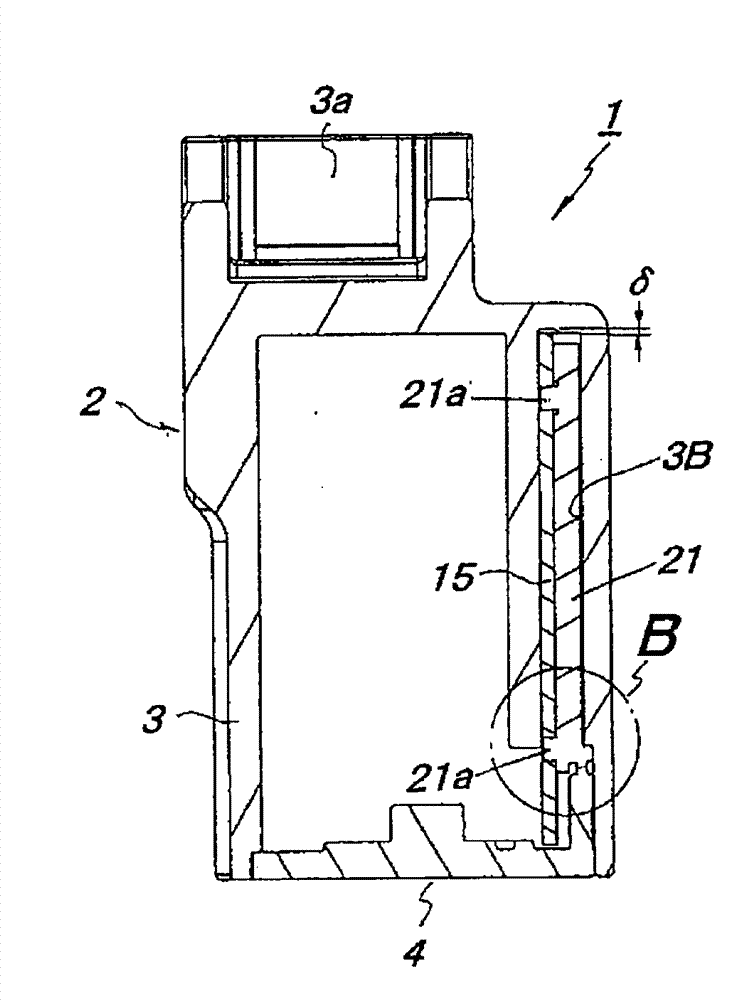

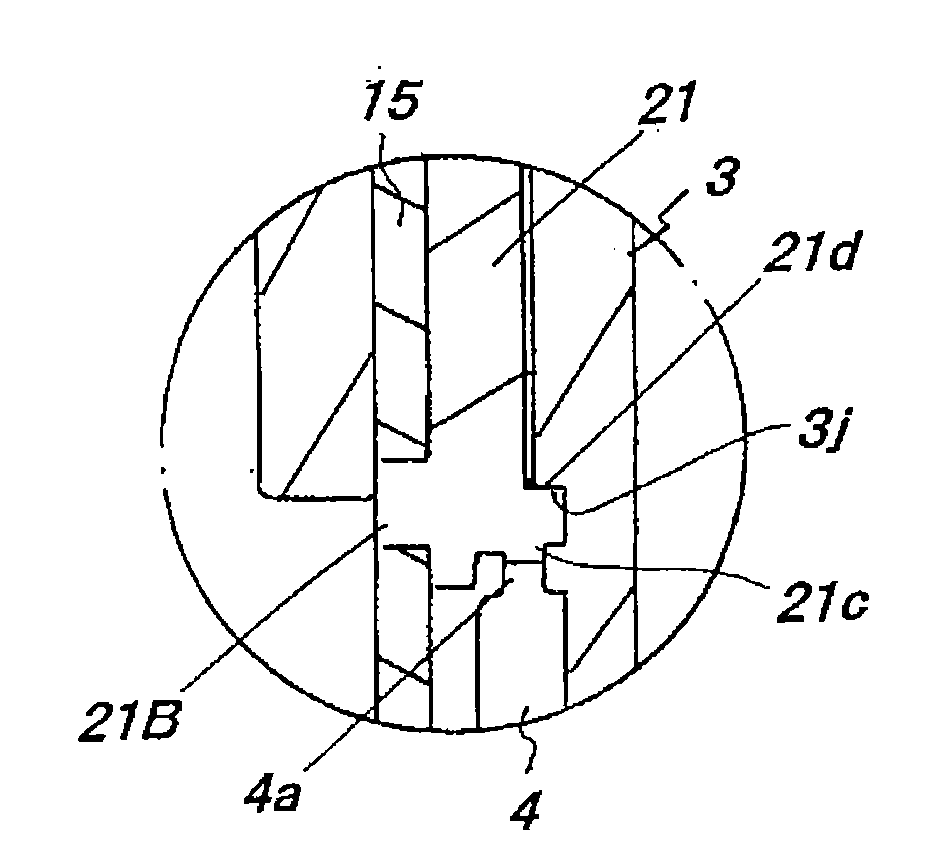

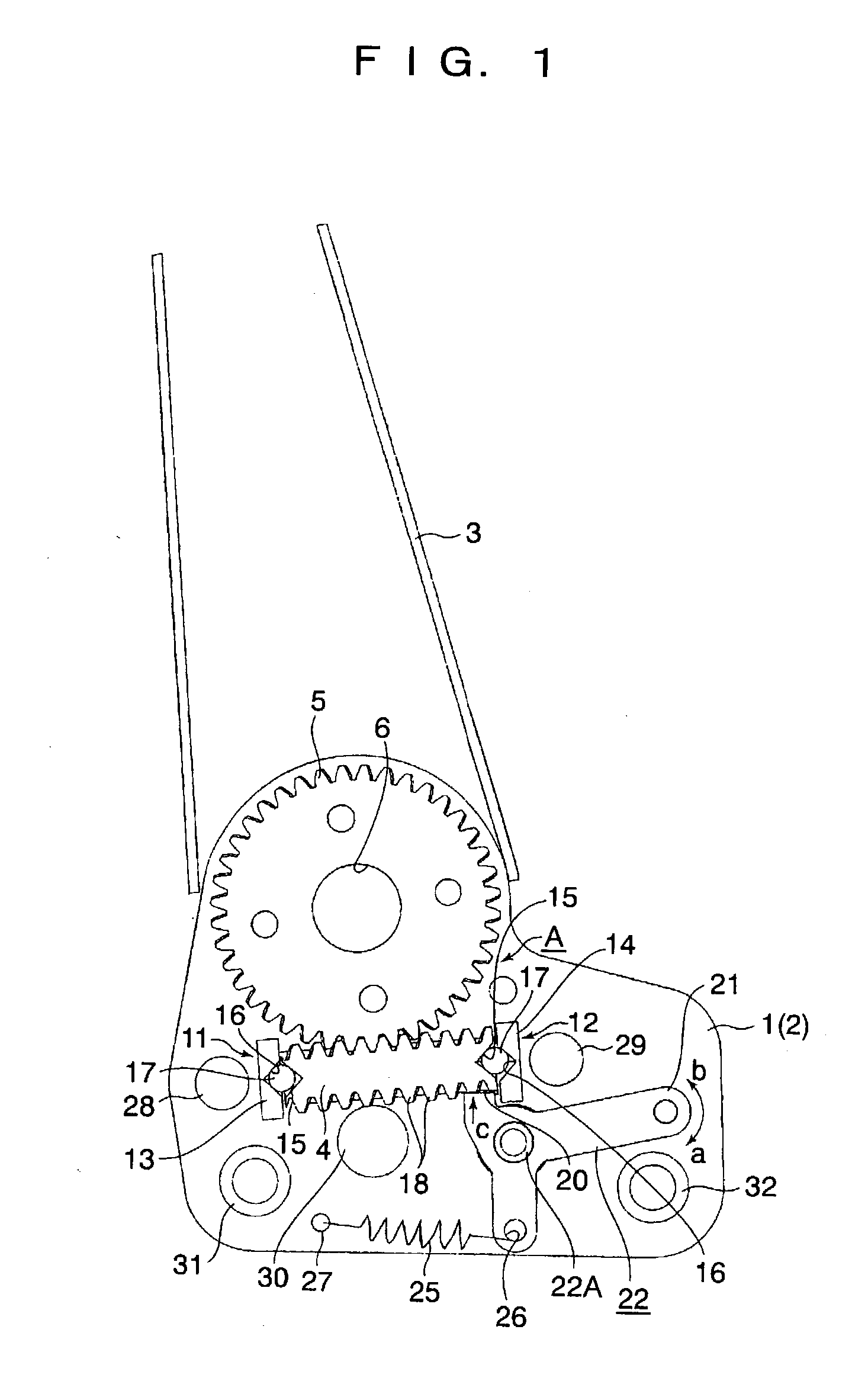

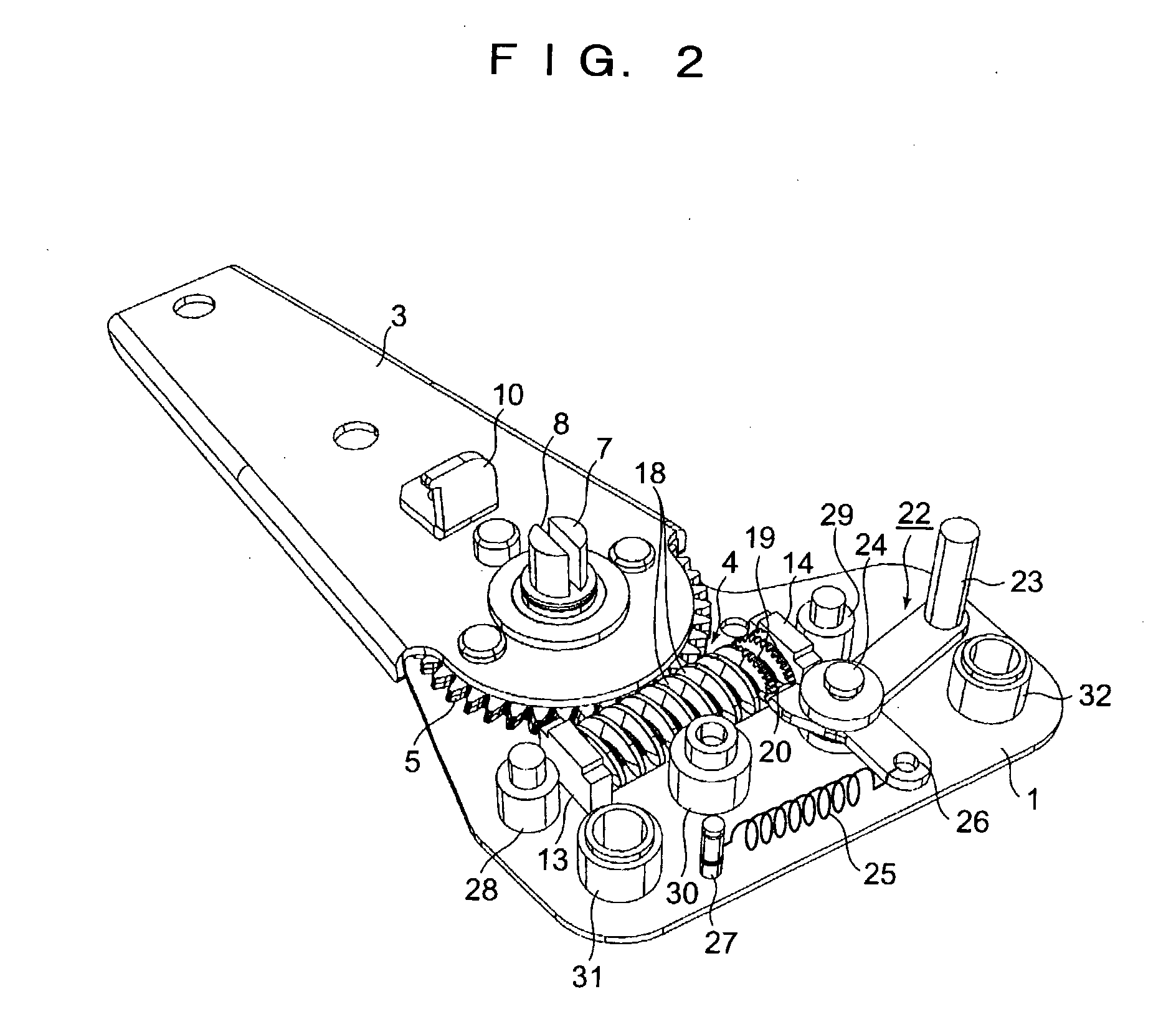

Electrically actuated steering lock device

The invention provides an electrically actuated steering lock device which can realizes assembly of a substrate with fewer parts and good workability and without looseness. The electrically actuated steering lock device (1) comprises a locking member, an electric motor driving the locking member to work, a driving mechanism converting a rotation force of an output shaft of the electric motor to an advancing and retreating force of the locking member, a magnet fixed to the locking member, a substrate (15) provided with a magnetic force detection element capable of detecting a magnetic force of the magnet and disposed opposite to the magnetic, and a housing (2) formed by a shell (3) receiving the locking member, the electric motor, the magnet and the substrate (15) and a cover plate (4) sealing an open part of the shell (3). The inside of the shell (3) is provided with a substrate receiving part (3B) for receiving the substrate (15); a locating member (21) disposed on the substrate (15) is provided with a snug (21c) capable of being pressed flat; and the cover plate (4) is provided with a substrate pressing part (4a) capable of pressing the snug (21c) of the locating member (21) flat.

Owner:U SHIN LTD

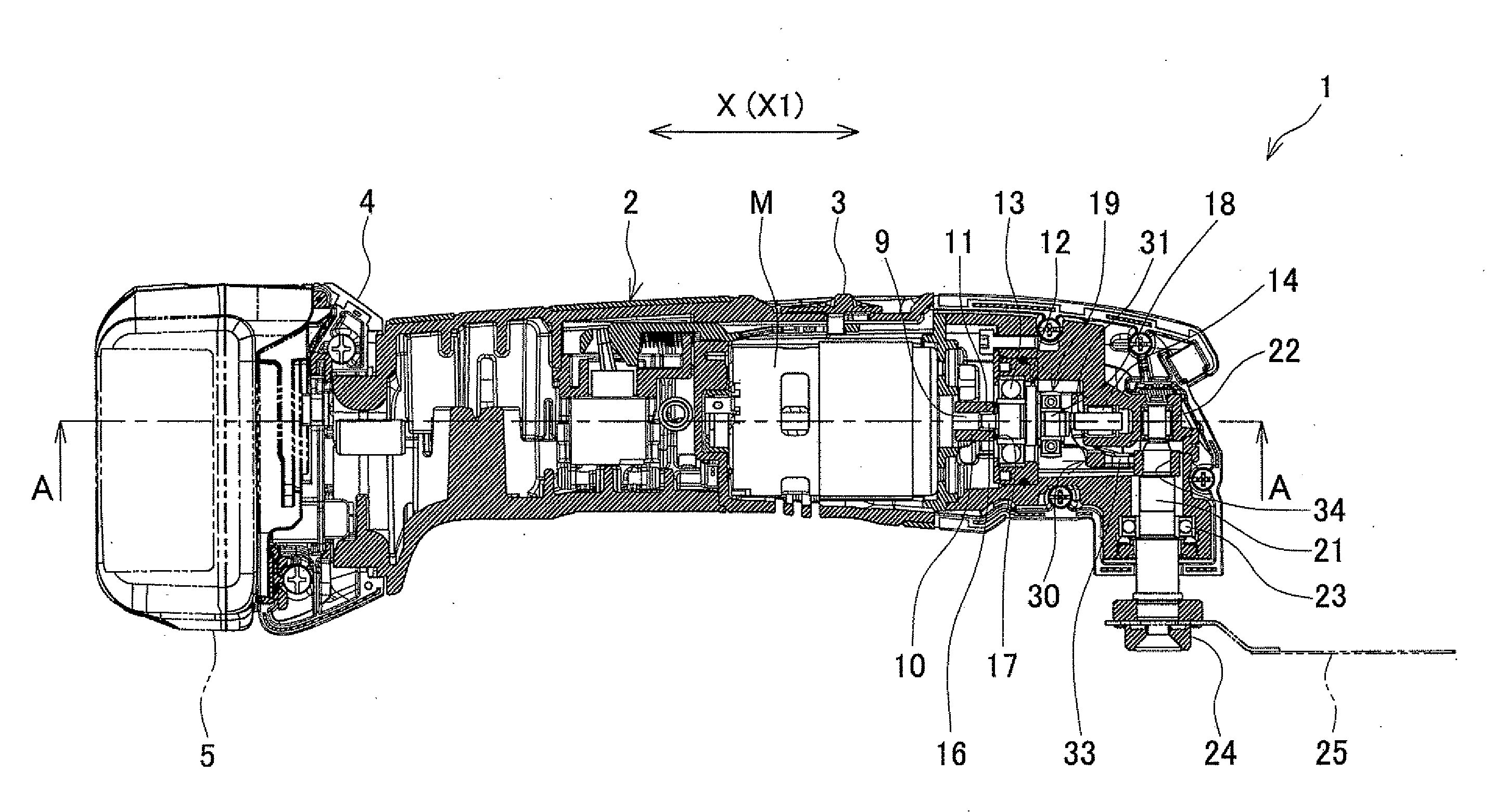

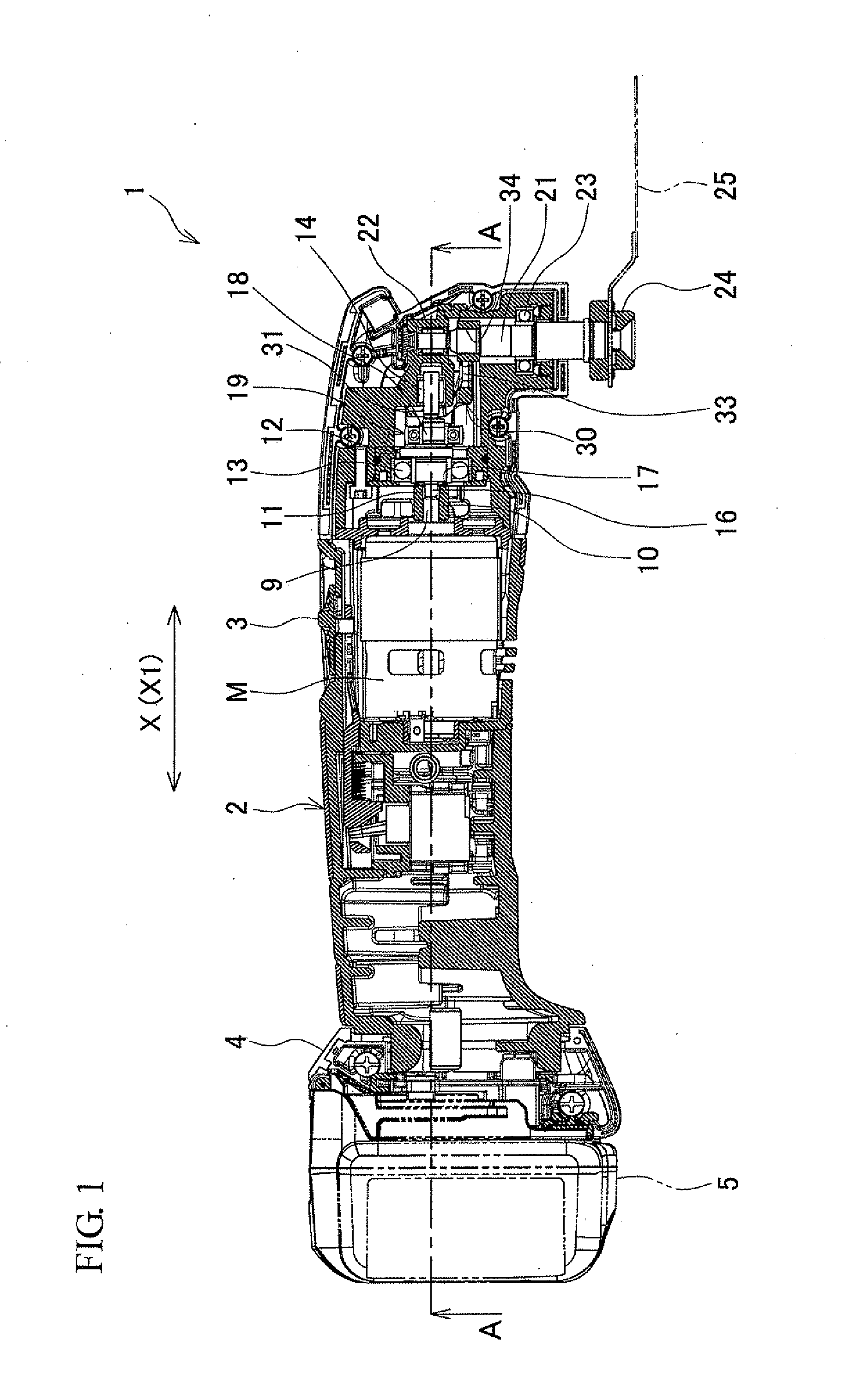

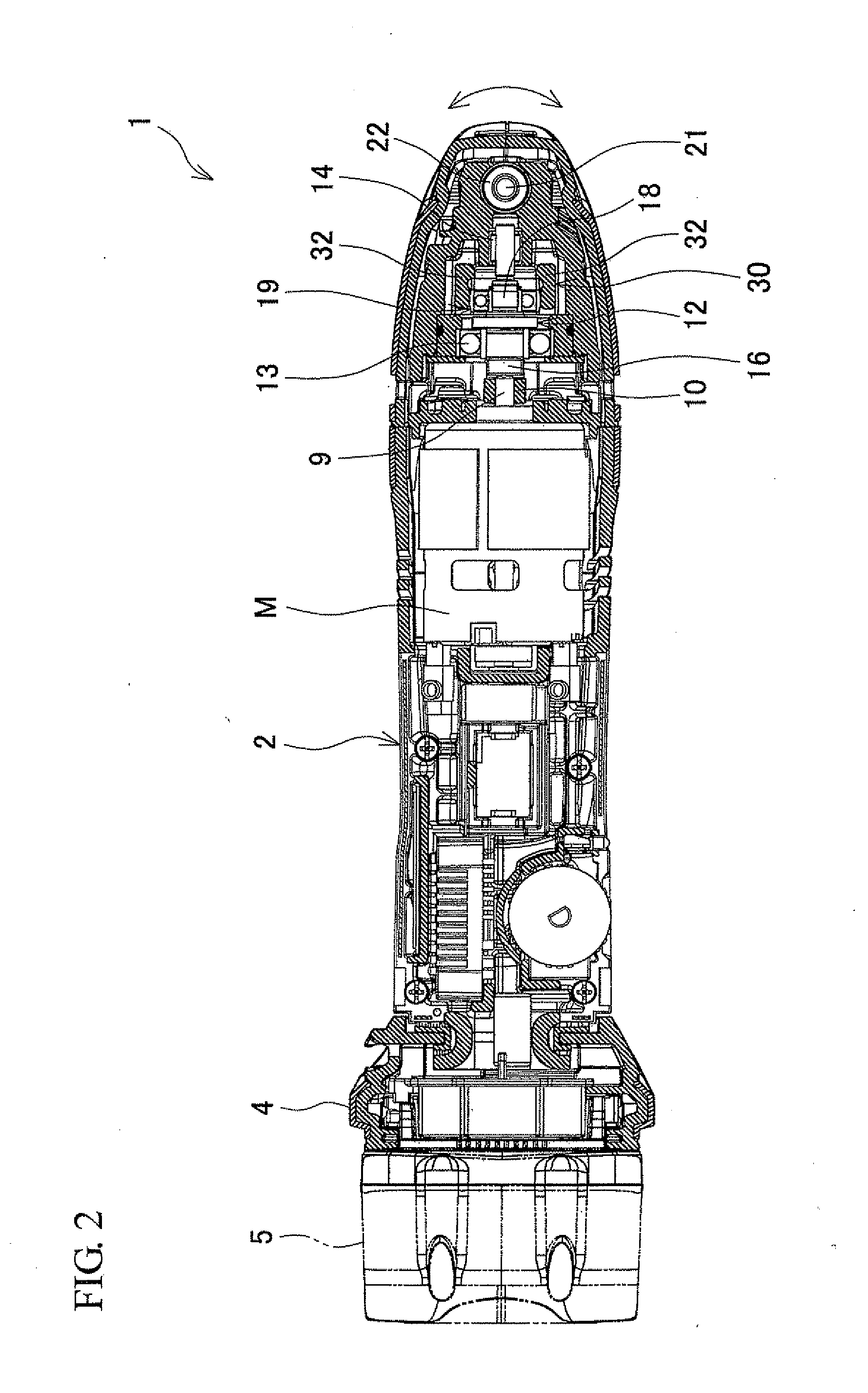

Oscillating rotary electric power tool

ActiveUS20130220659A1Prevent abnormal noiseIncrease resistanceYielding couplingDrilling rodsPower toolEngineering

An oscillating rotary electric power tool, in which a spindle with a distal end tool attached thereto is projected downward from a front end portion of a housing accommodating a motor, and the housing also accommodates a coupling member rotatable integrally with an output shaft of the motor, a crankshaft fitted with the coupling member in a depression and projection fitting structure, and a link member to which the spindle is fixed and power is transmitted from the crankshaft to rotate clockwise and counterclockwise in an oscillating manner so that the link member will be driven by the motor to rotate the spindle clockwise and counterclockwise in the oscillating manner, wherein an elastic body is interposed between the coupling member and the crankshaft in the same axial direction as the output shaft.

Owner:MAKITA CORP

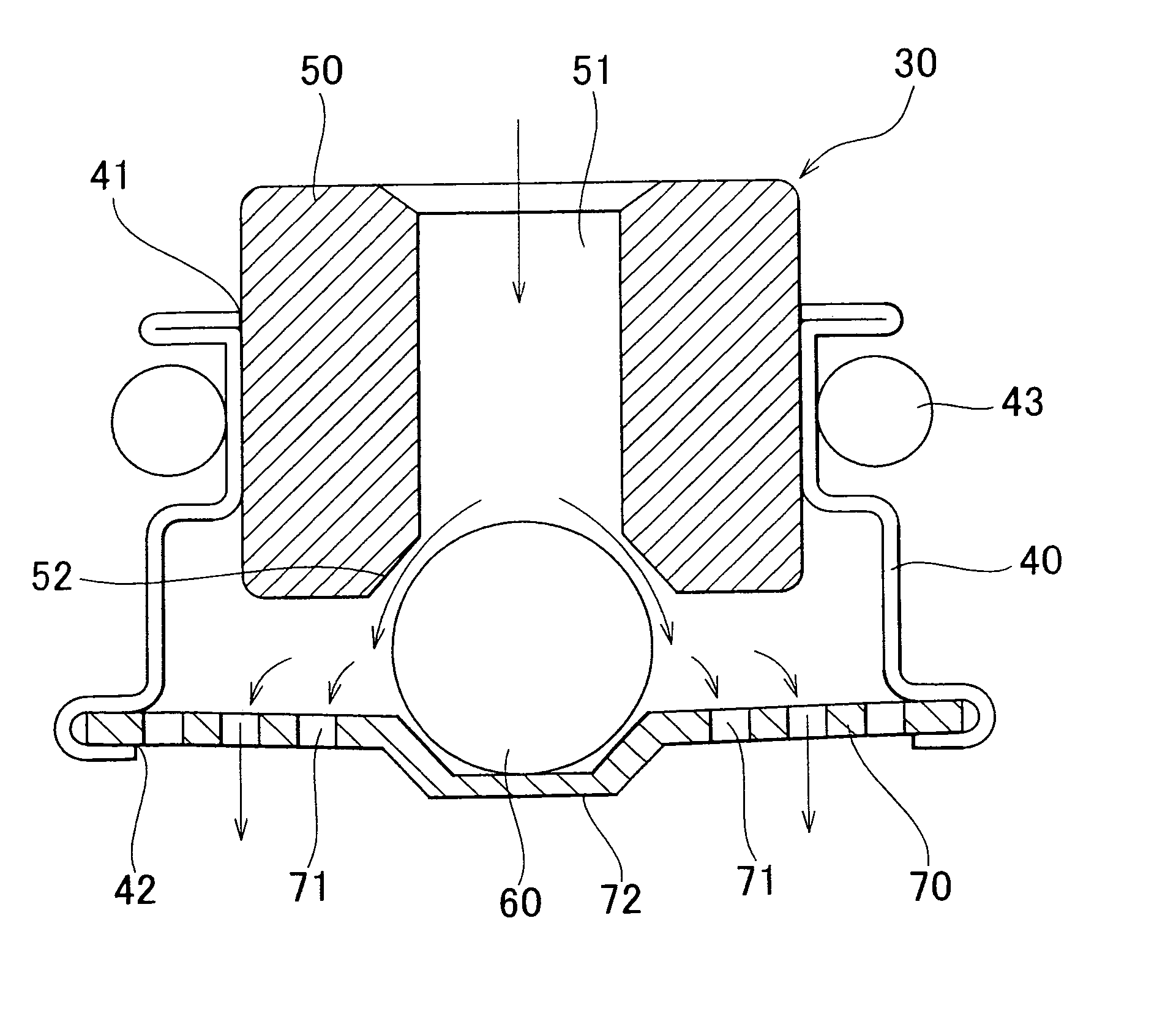

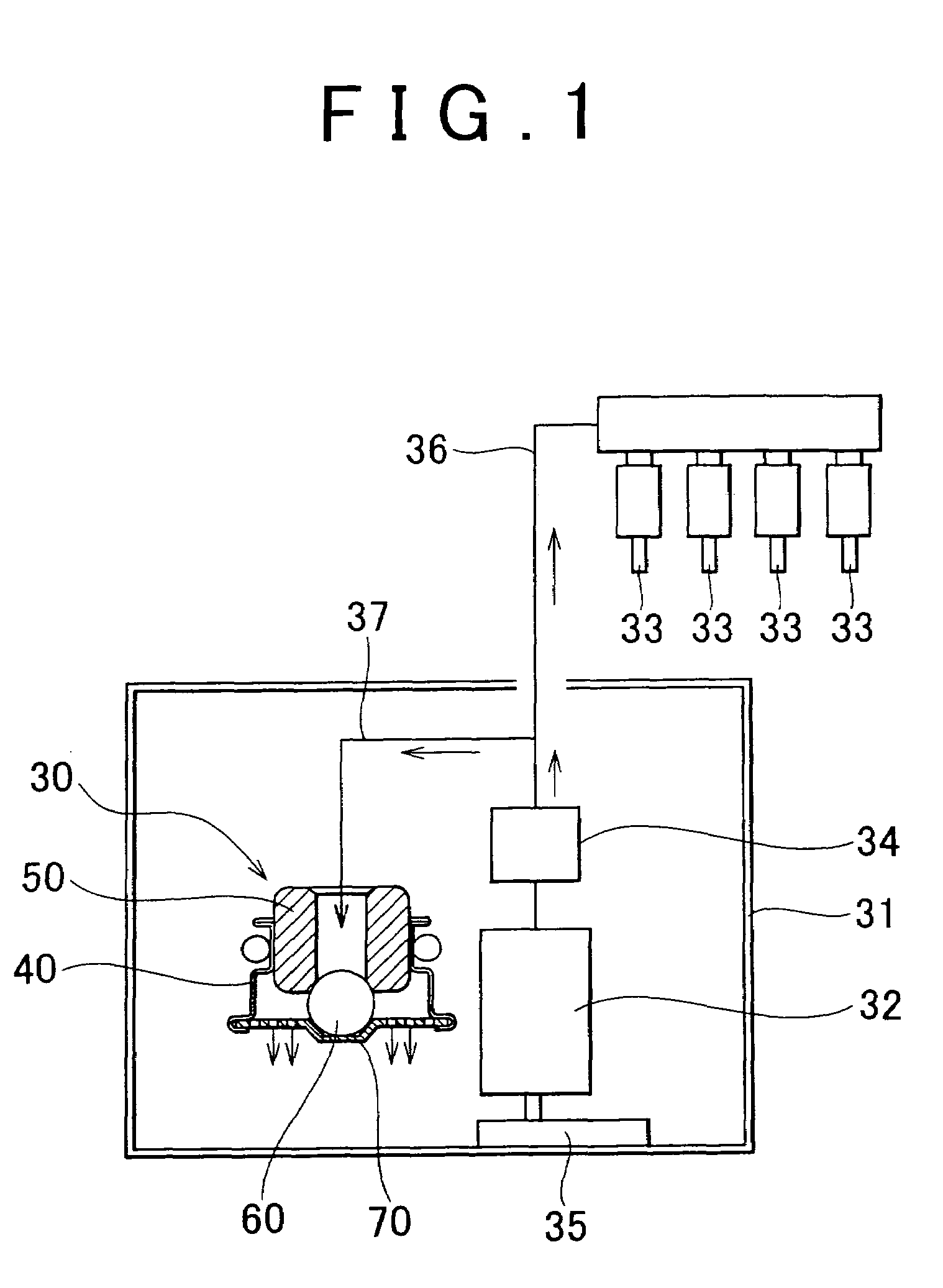

Fuel pressure adjusting apparatus

ActiveUS7124739B2Avoid local wearPrevent abnormal noiseLow pressure fuel injectionMachines/enginesEngineeringValve seat

A fuel pressure adjusting apparatus which includes a casing which includes a fuel introduction port, and a fuel discharge port; and a cylindrical member which is housed in the casing, and which includes a valve seat at an end portion thereof, and a communication passage therein, the communication passage connecting the fuel introduction port to the fuel discharge port; a valve element which is provided on a fuel discharge port-side of the valve element in the casing, and which closes the communication passage when the valve element is seated on the valve seat; and a leaf spring which is provided at the fuel discharge port, and which applies force to the valve element in a direction toward the valve seat. The leaf spring includes a concave portion which supports the valve element, and which is formed such that there is a gap between the concave portion and the valve element.

Owner:AISAN IND CO LTD

Bearing structure of turbocharger

InactiveUS20170292405A1Improve internal performanceReductionRolling contact bearingsPump componentsBall bearingTurbocharger

A bearing structure of a turbocharger includes a rotor shaft, two angular ball bearings, a retainer, a housing, and an oil film damper. Each of the angular ball bearings includes an inner ring and an outer ring that are supported in relatively rotatable manner. The rotor shaft is inserted into the inner ring. The retainer holds the outer ring. The housing houses therein the rotor shaft, the angular ball bearings, and the retainer to constitute a bearing housing. The oil film damper is formed of oil in a film state and is interposed between the inner ring and an outer peripheral surface of the rotor shaft. The inner ring is configured to rotate with rotation of the rotor shaft via the oil film damper.

Owner:OTICS CORP

Bearing device for wheel

InactiveCN102152711AStable deliveryHigh strengthYielding couplingRolling contact bearingsUniversal jointTorque transmission

Provided is a bearing device for a wheel that can realize prevention of a backlash in a circumferential direction and is excellent in workability of connection of a hub wheel and an outer joint member of a constant velocity universal joint. Further, provided is a bearing device for a wheel that can prevent deterioration in NVH characteristics, which is caused by the backlash occurring in a joint section between the hub wheel and the constant velocity universal joint or between an outer member and a knuckle, and can perform rotation torque transmission with high accuracy. The bearing device includes a recess-projection fitting structure (M) in which the hub wheel (1) and a shaft section (12), which is fitted in a hole (22) of the hub wheel (1) of the outer joint member of the constant velocity universal joint (3) are unitized together. In the recess-projection fitting structure (M), entire fitting regions among projections (35) on the outer surface of the shaft section (12) of the outer joint member and recesses (36), which fit on the projections, are brought into intimate contact with each other.

Owner:NTN CORP

Valve timing changing device

InactiveCN102808669ASmooth startAvoid knockingInternal combustion piston enginesOutput powerLocking mechanismEngineering

The invention provides a valve timing changing device, by which a vane rotor is kept at a central position when the engine is started to prevent sloshing, knocking noise and wearing. The device includes a housing rotor (30), a vane rotor (2), an advance angle passageway (13) communicated with an advance angle chamber for operating oil to pass through, a lag angle passageway (14) communicated with a lag angle chamber for the operating oil to pass through, and a lock mechanism (40) which locks the vane rotor at a center position relative to the housing rotor and unlocks the lock by means of the hydraulic pressure of the operating oil. The lock mechanism includes an advance angle lock bar (42) and a lag angle lock bar (44). The advance angle passageway (13) guides the hydraulic pressure to unlock the lock of the advance angle lock bar and the lag angle lock bar, and the lag angle passageway (14) guides the hydraulic pressure to maintain the unlocking of the lock of the lag angle lock bar. The vane rotor is kept at the central position when the engine is started so as to ensure the stable starting performance of the engine.

Owner:MIKUNI CORP

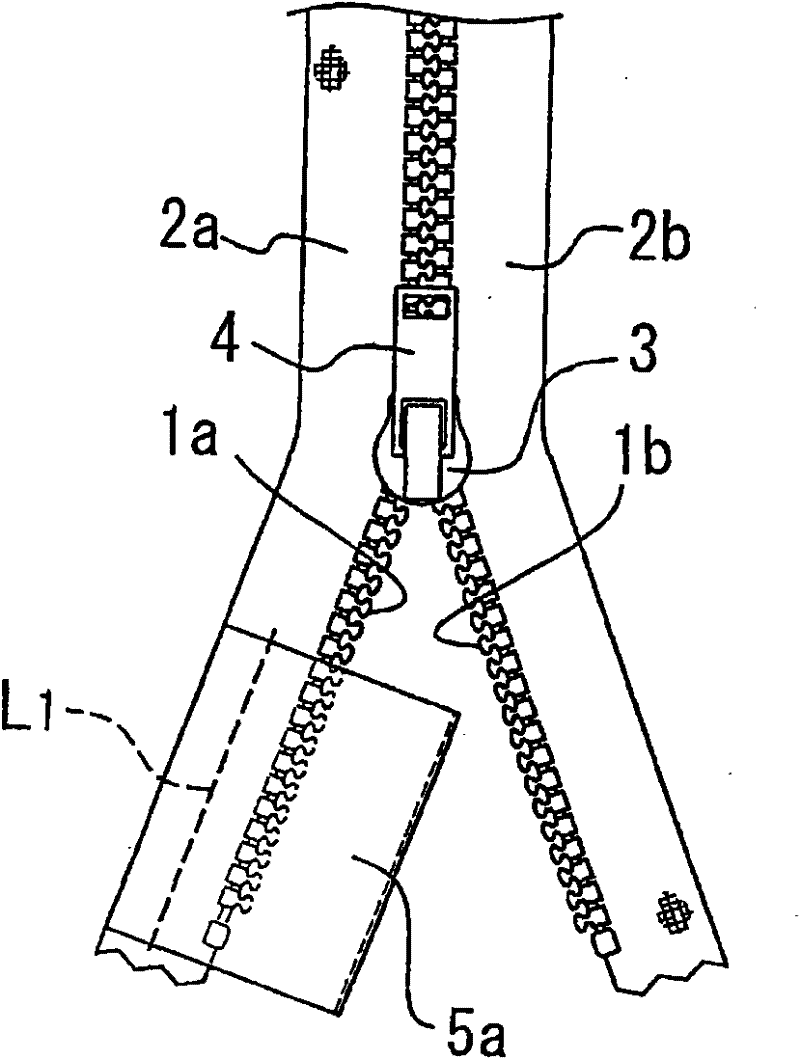

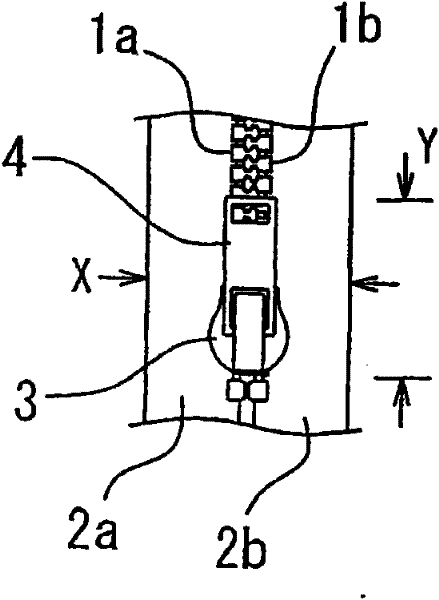

Closed-end treatment structure of slide fastener for vehicle seat

InactiveCN102197906APrevent abnormal noiseShorten the lengthVehicle seatsSlide fastenersFastenerEngineering

According to embodiments of the present invention, there is provided a closed-end treatment structure for a slide fastener of a vehicle seat, the structure including: a pair of cloth tapes to be attached to a seat skin of the vehicle seat; a pair of teeth lines respectively attached to the pair of cloth tapes; a slider configured to move from a top stop side to a bottom stop side while detachably meshing the teeth lines; a pull-tab connected to the slider through a connection portion; and a storing portion configured to store the slider, the pull-tab and end portions of the cloth tapes, in a state where the slider is moved to the bottom stop side, thereby storing the closed-end of the slide fastener.

Owner:TS TECH CO LTD

Oilless reciprocating air compressor

InactiveCN1664365AAvoid it happening againGuaranteed tightnessPiston ringsPositive displacement pump componentsPiston ringReciprocating motion

Owner:ANEST IWATA CORP

Bearing structure

InactiveUS20130178298A1Not readily infiltratePrevent abnormal noiseShaftsBall bearingsEngineeringRib cage

A bearing structure comprises a shaft member, a bearing, an inner ring, a ring-shaped mount which is made of an elastic material, is fixed to a vehicle body and encloses the inner ring, and a dust cover which is fixed to the bearing member and rotates in unison with the bearing member, the bearing member being supported rotatably on the vehicle body via the bearing. The mount includes, on a front side, a rib facing inward in a radial direction and extending in a circumferential direction so as to seal off a first gap formed between the shaft member and the inner ring. A second gap is formed between an inner radial end of the rib and the shaft member. The dust cover covers the rib and the second gap on the front side of the rib. A cutout is formed in a lower vertical portion of the rib.

Owner:SHOWA CORP

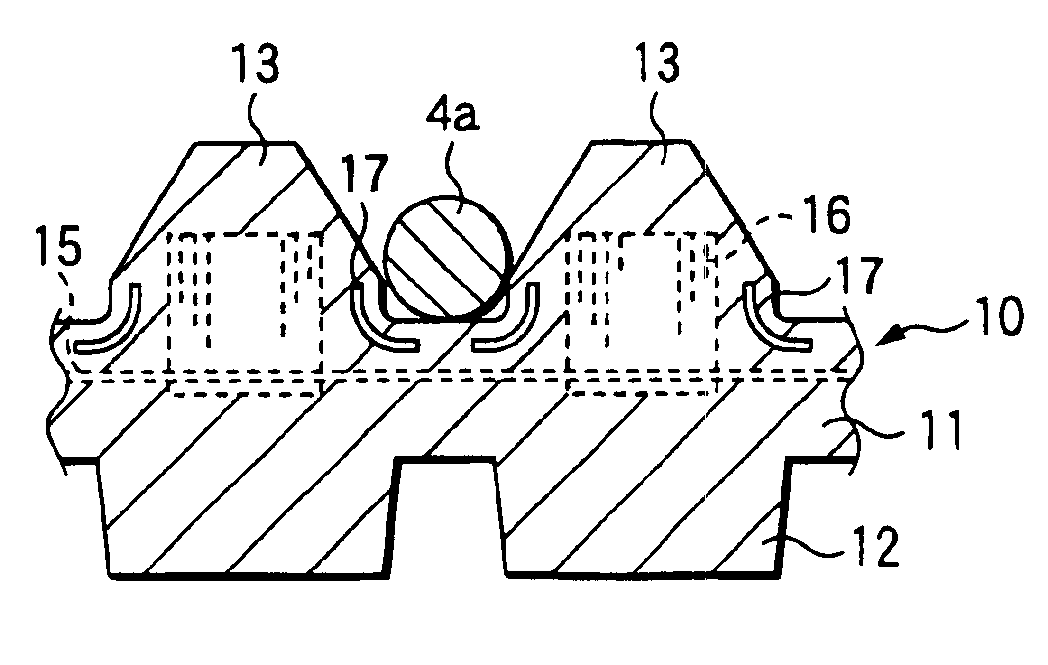

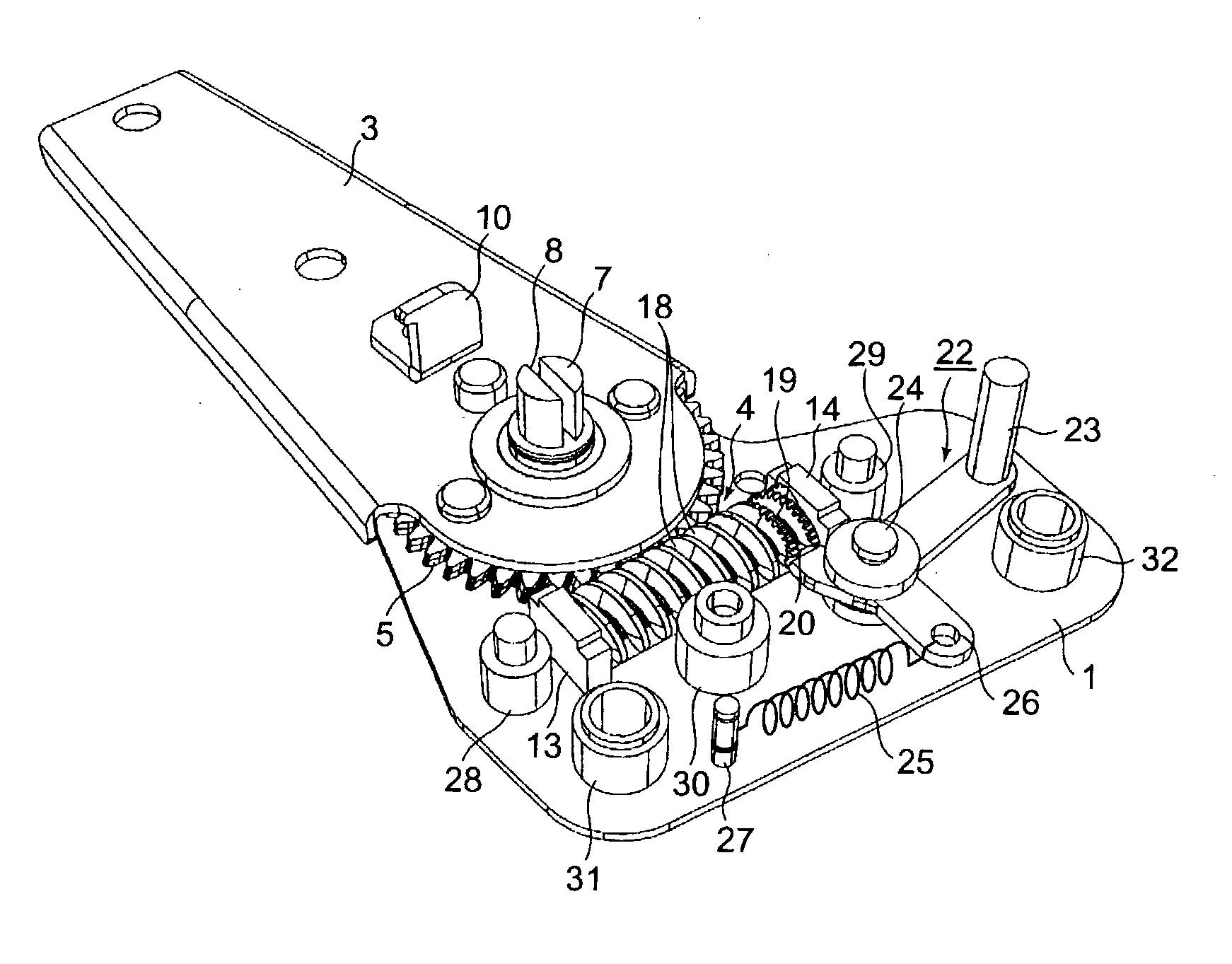

Reclining adjuster

InactiveUS20030160489A1Simple structureReduces not only a backlashMovable seatsLocking mechanismCoil spring

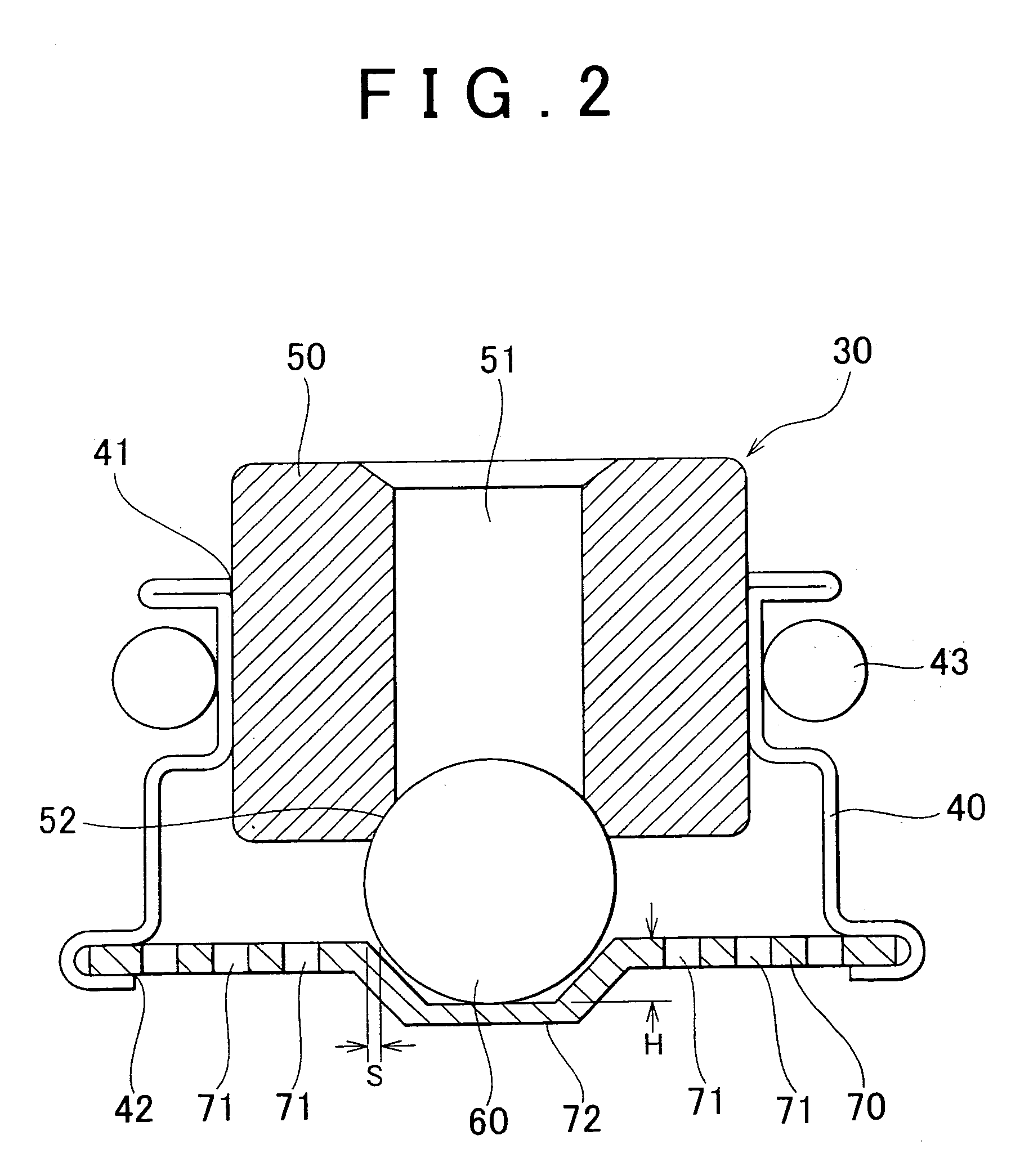

The objects of the present invention is to reduce a backlash at the time of locking of a seat back and to reduce clearance in the thrust direction of a worm so as to prevent generation of an abnormal noise with a simple structure suitable for mass production. Substantially cone-shaped recesses 15 and 16 are provided respectively on both end faces of the worm 4 pivotably attached on a seat cushion, and inside end faces of a pair of holders 13 and 14 to support these two end portions, and at the same time balls 17 are rotatably housed respectively in a pair of spaces formed in the recesses 15 and 16 facing each other to form a pair of bearings 11 and 12 which rotatably support the worm 4. A press means composed of a coil spring 25 and the like which presses the worm 4 to the worm wheel 5 is provided in a locking mechanism.

Owner:DELTA TOOLING CO LTD

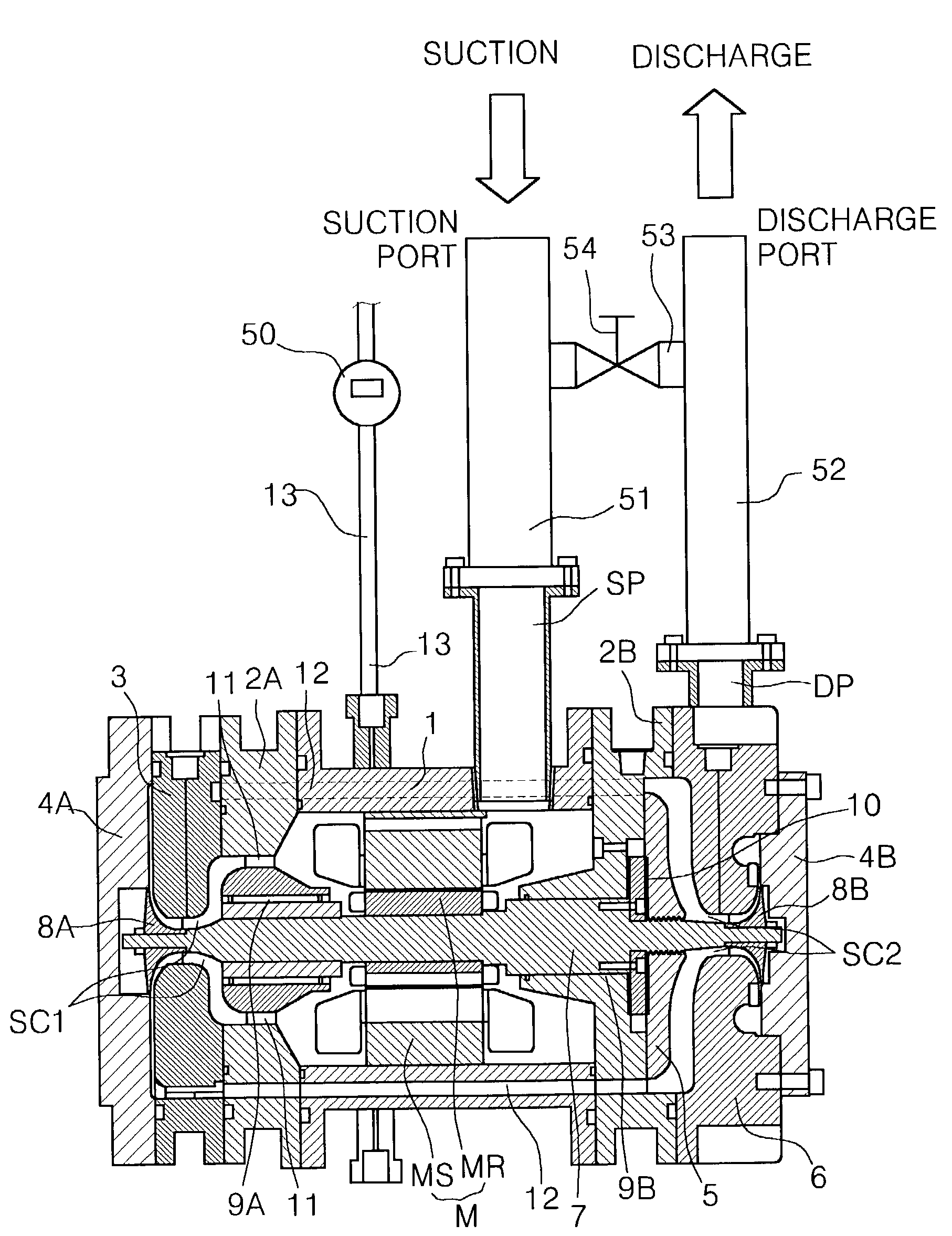

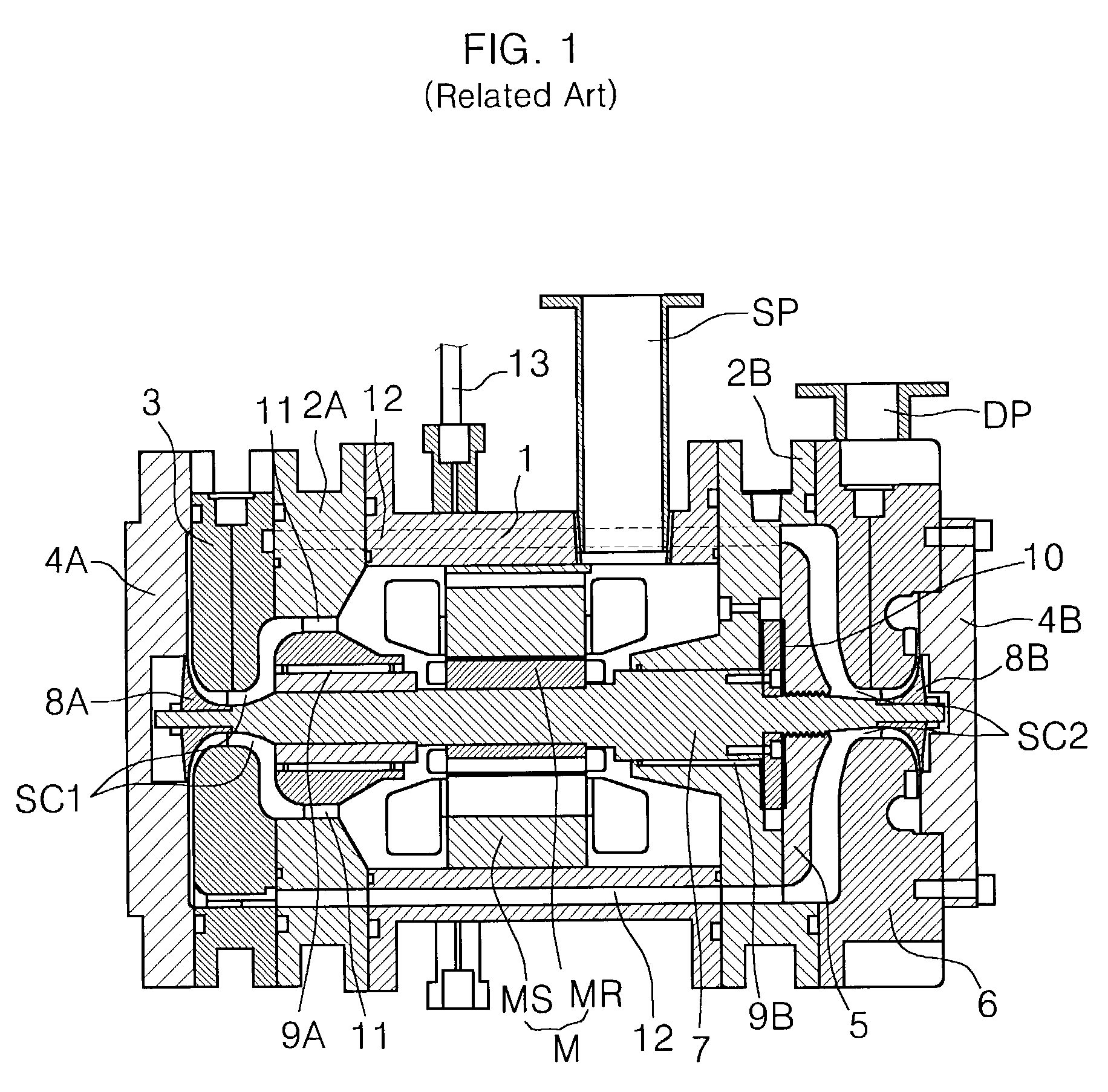

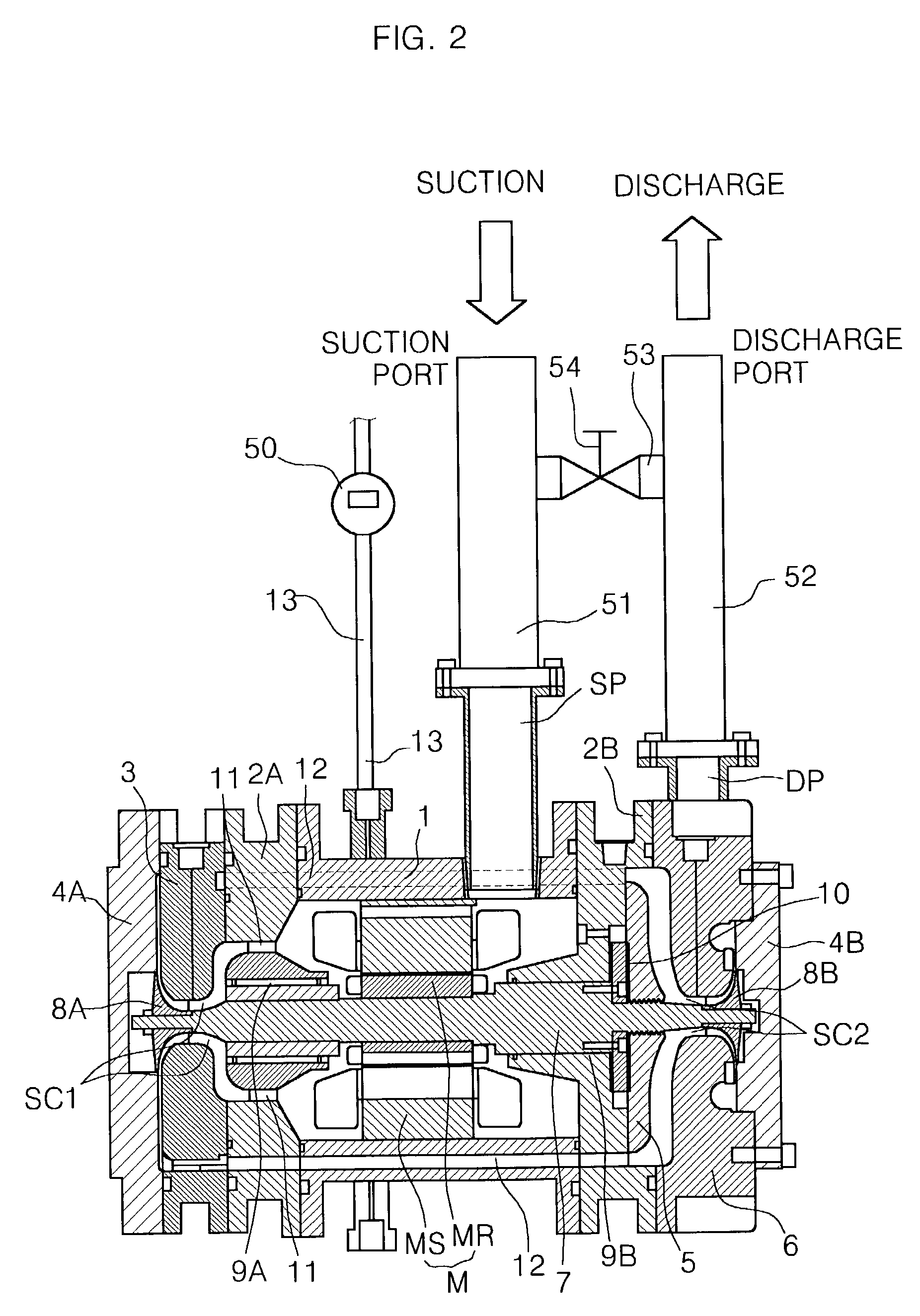

Reverse rotation preventing structure of centrifugal compressor

InactiveUS7121813B2Avoid structurePrevent abnormal noisePump controlPositive-displacement liquid enginesCentrifugal compressorEngineering

The invention relates to a reverse rotation preventing structure of a centrifugal compressor. The reverse rotation preventing structure of the centrifugal compressor comprises: a discharge pipeline of the centrifugal compressor; a suction pipeline of the centrifugal compressor; a bypass pipeline for connecting the discharge pipeline and the suction pipeline, wherein a predetermined valve is formed thereon; a control means for controlling an operation of the centrifugal compressor; and a detecting means for generating a predetermined signal to the control means if the operation of the centrifugal compressor is suddenly stopped, thereby opening the bypass pipeline.

Owner:LG ELECTRONICS INC

Drum type washing machine

InactiveCN1749469AAvoid abnormal vibrationPrevent abnormal noiseOther washing machinesControl devices for washing apparatusVibration controlControl theory

The invention provides a drum type washing machine equipped with a displacement detecting means for detecting the displacement of a water tub with accuracy so as to cause neither abnormal vibration nor abnormal noise by the vibration of the water tub holding a rotating drum, due to the unbalance or the like of a washing. A water tub unit 7 is supported in a position closer to the front face side than the center-of-gravity position by a vibration control damper. The water tub unit 7 is disposed in a swingable manner in a washing machine casing 6, and a displacement sensor 36 is disposed on the back face side rather than the vibration control damper 70 and on or near a hanging line from the center-of-gravity position of the water tub unit 7. Since the displacement of the water tub unit 7 is accurately detected by the displacement sensor 36, operation control causing neither abnormal vibration nor abnormal noise can be performed.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com