Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Avoid local wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

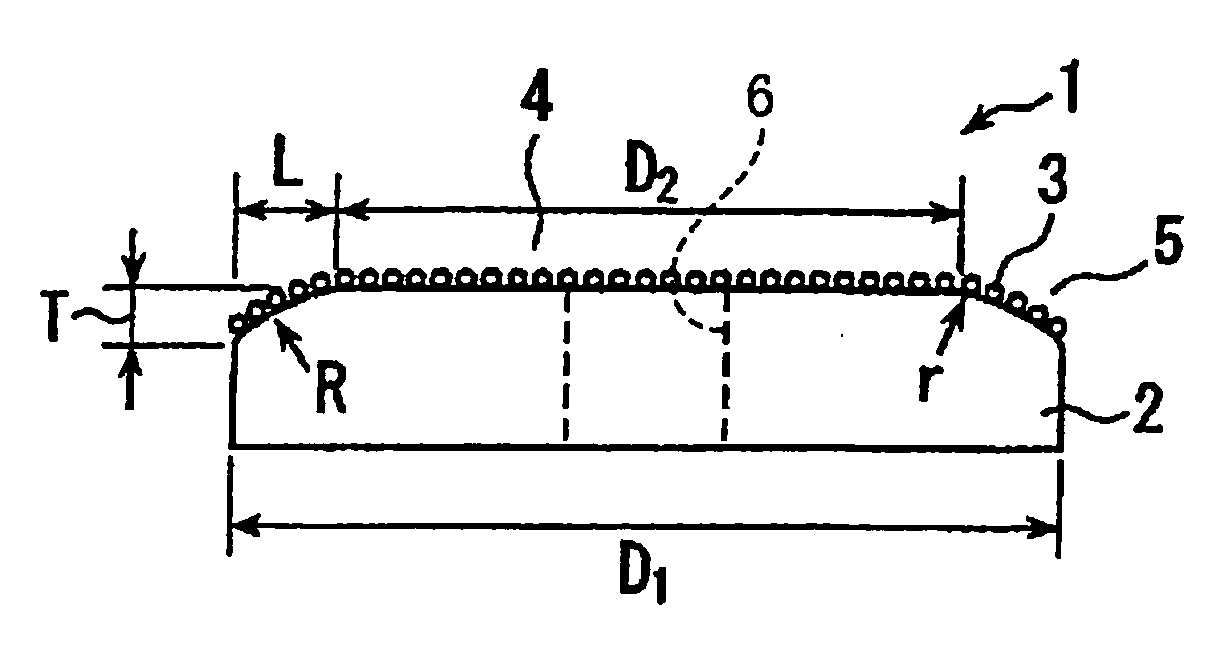

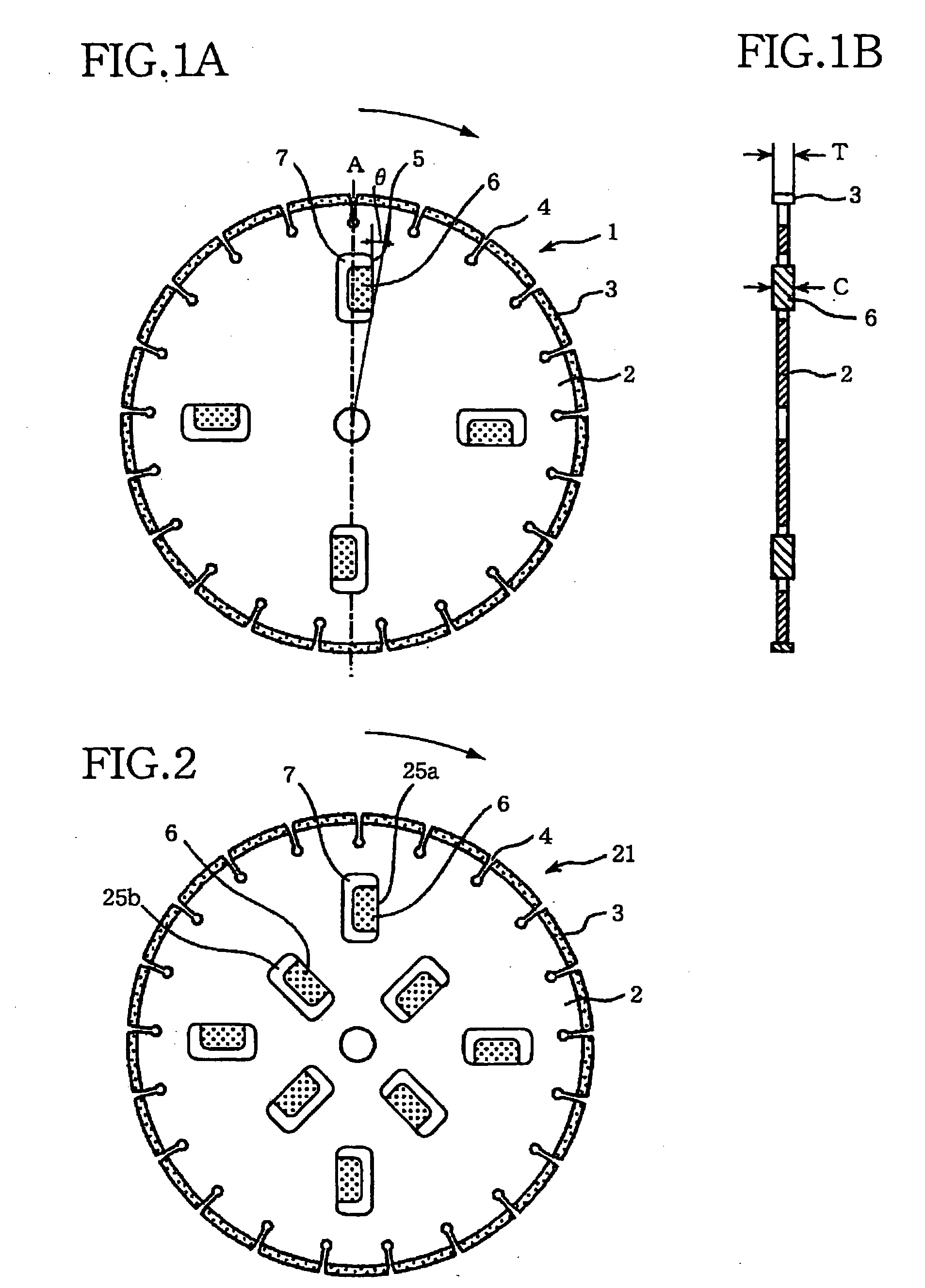

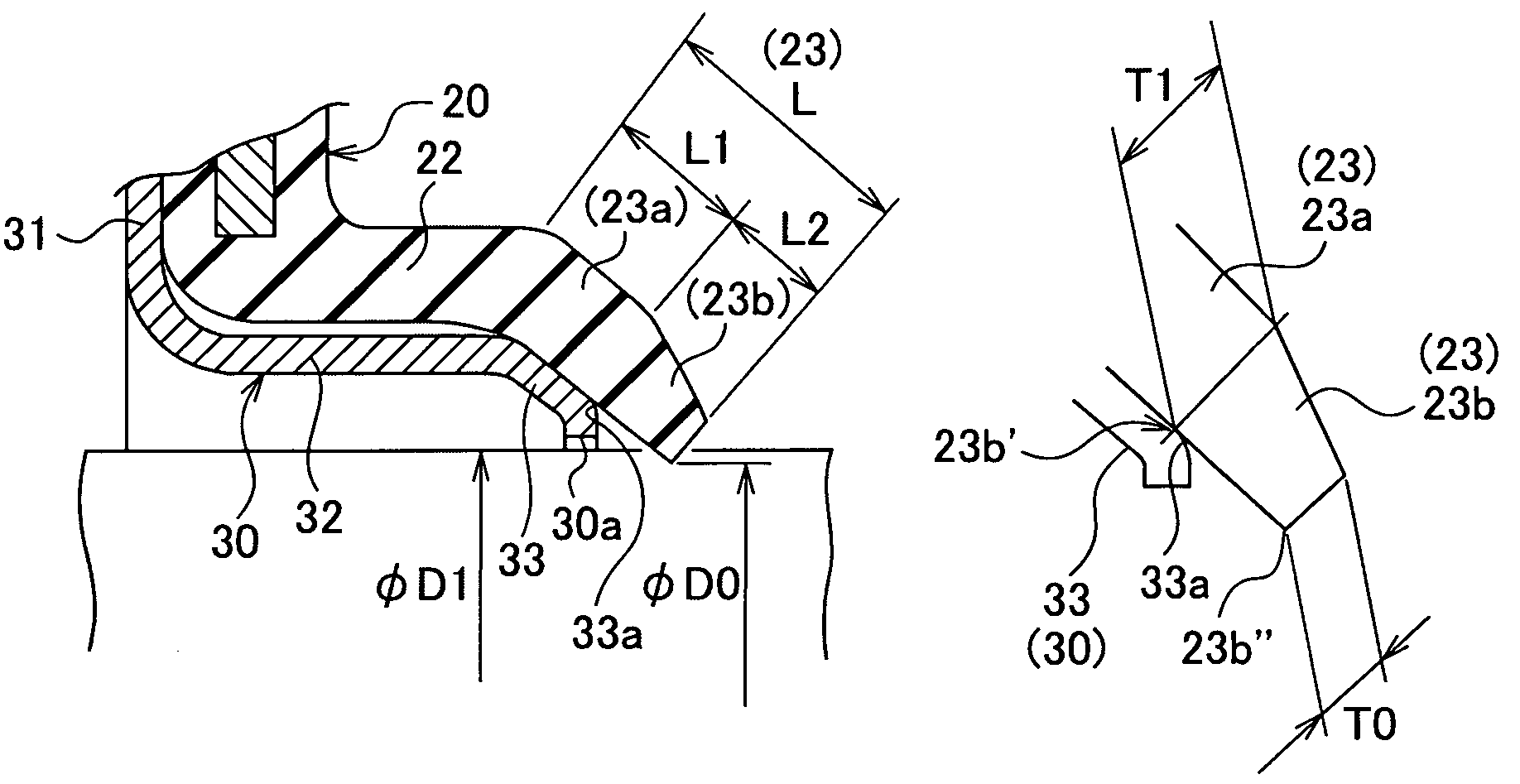

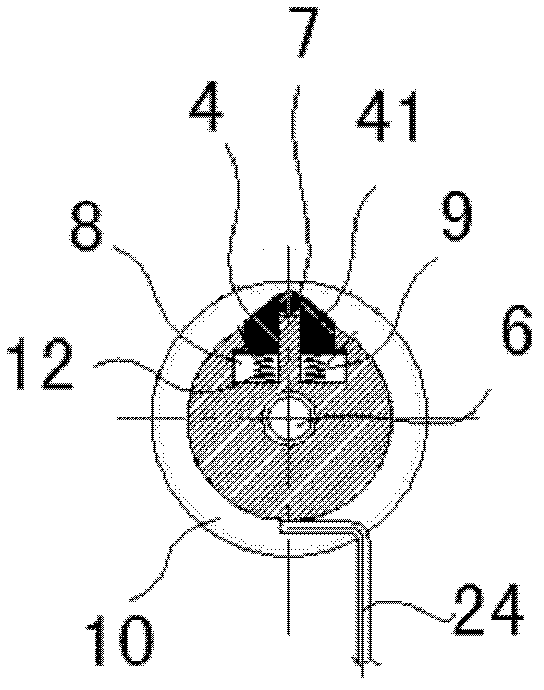

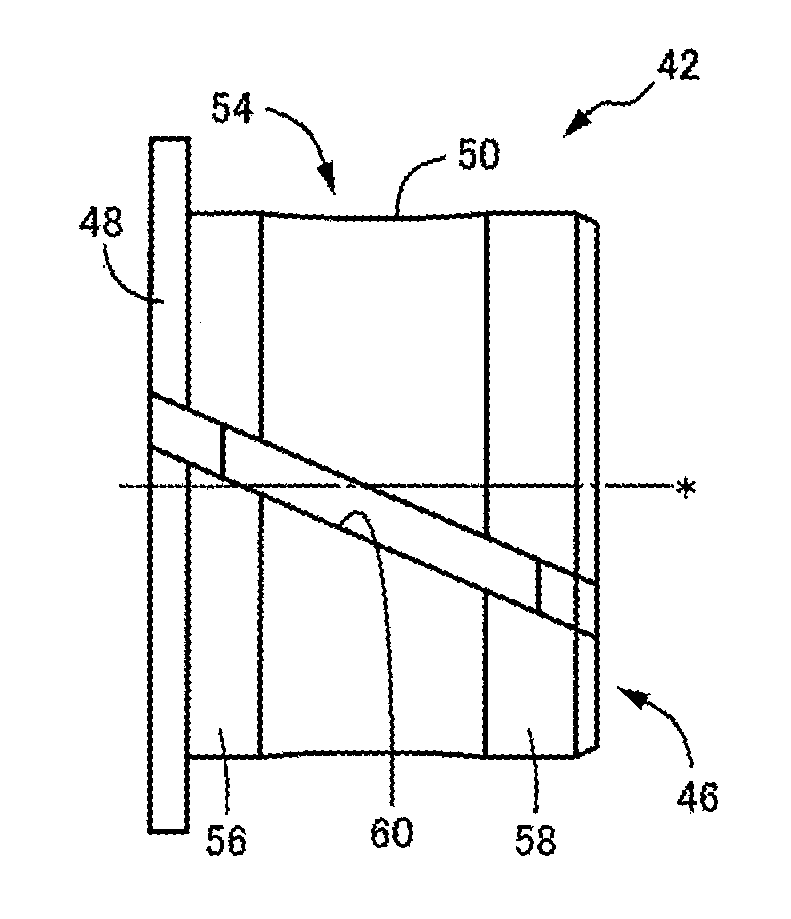

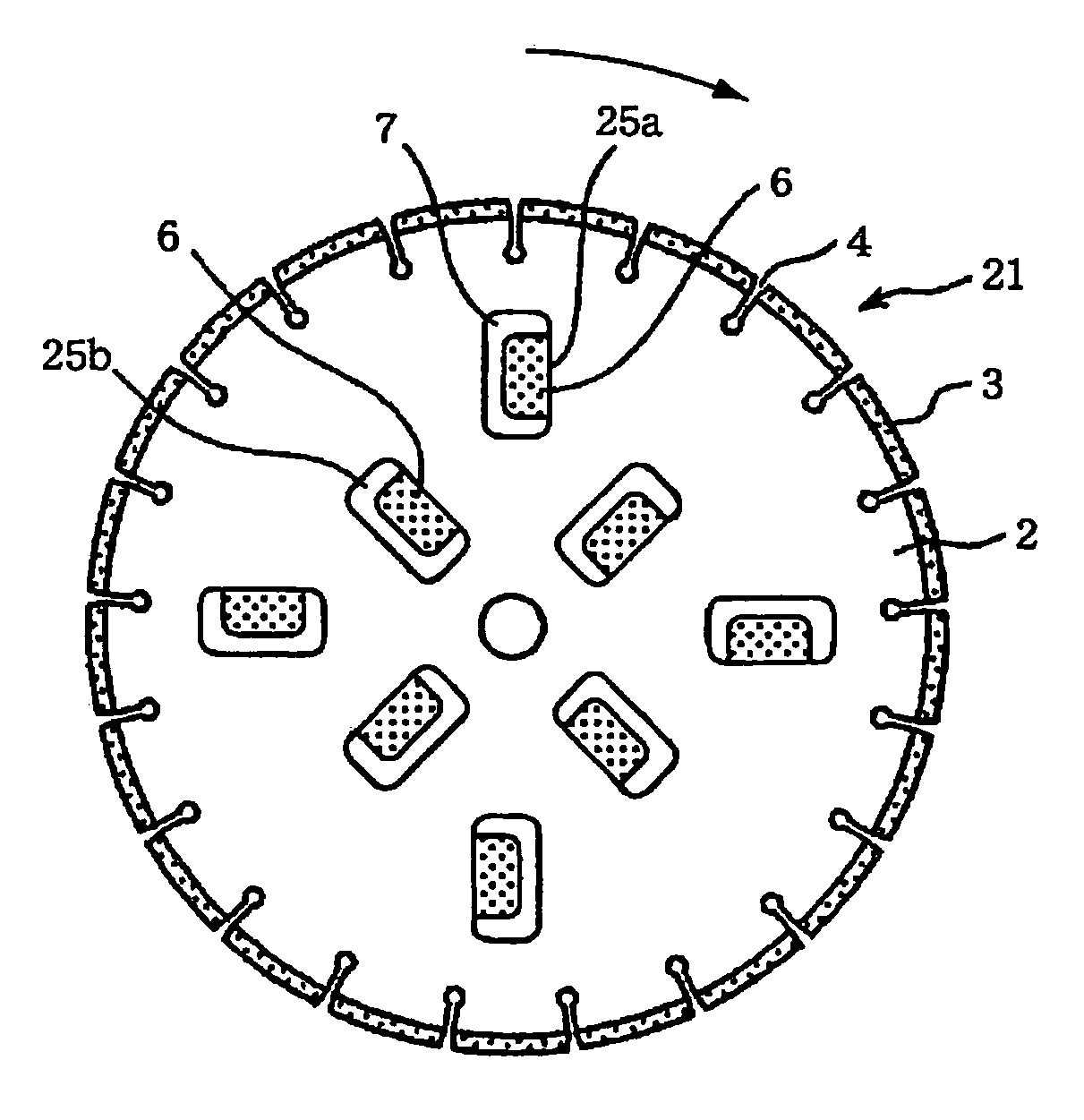

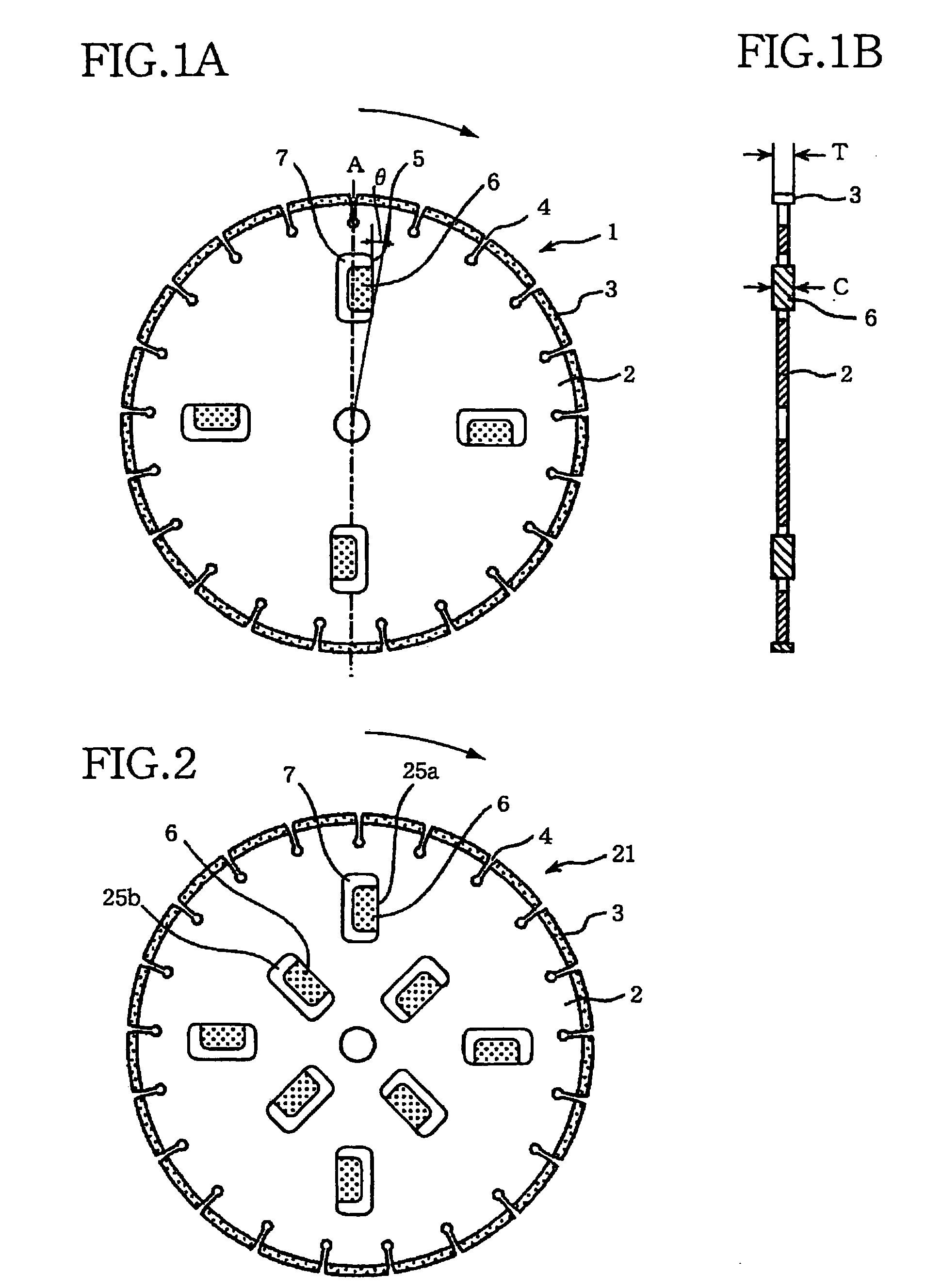

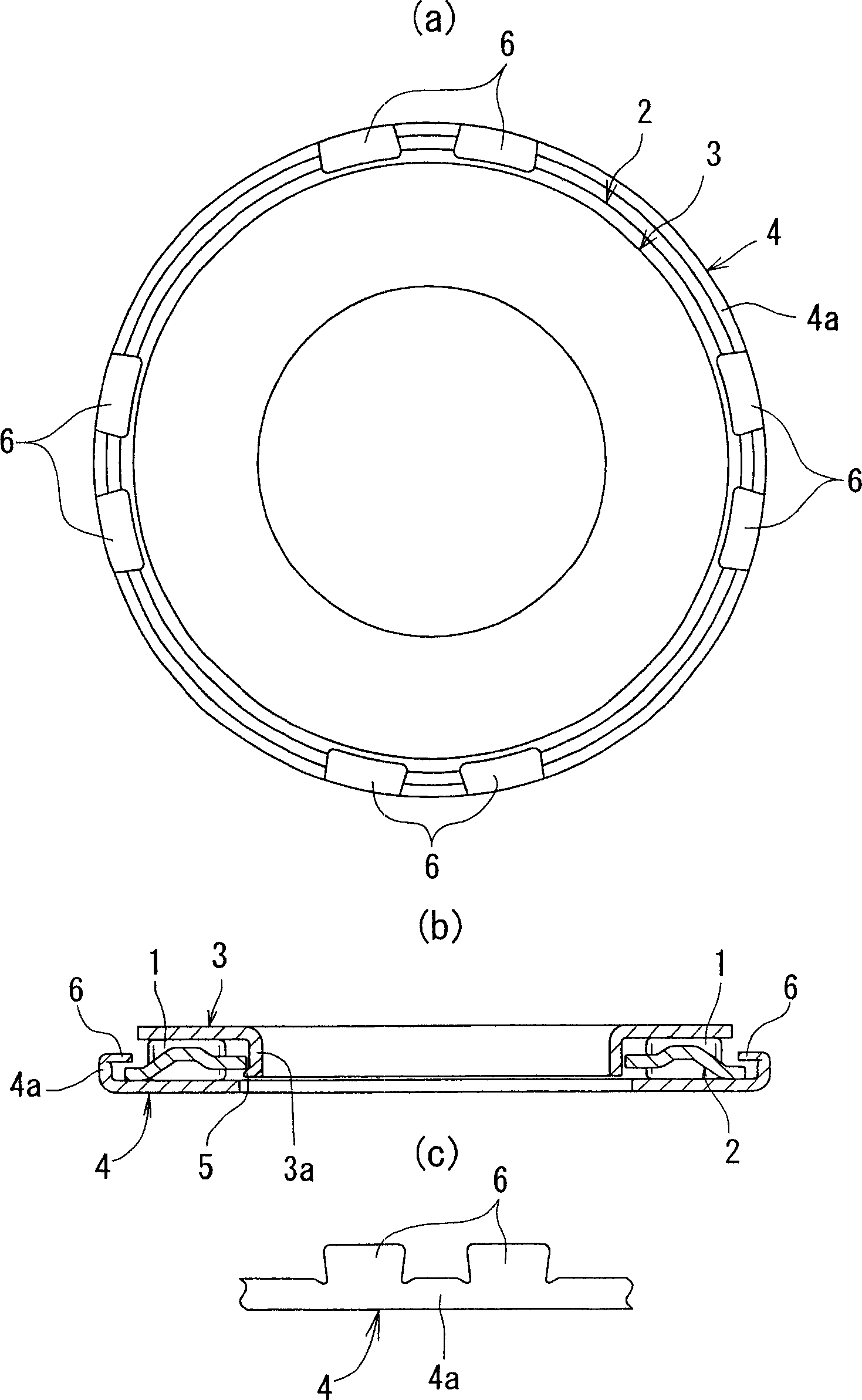

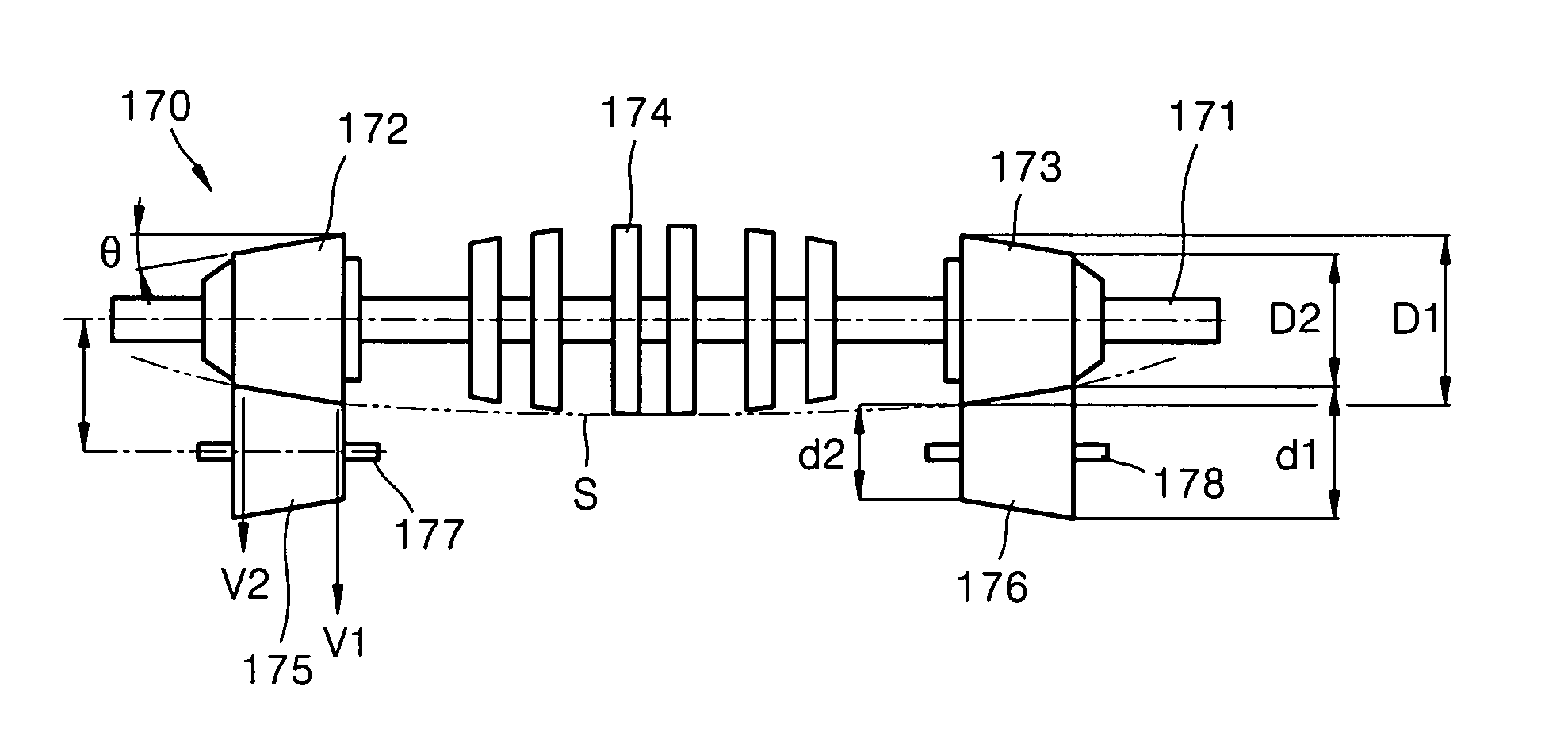

CMP pad conditioner having working surface inclined in radially outer portion

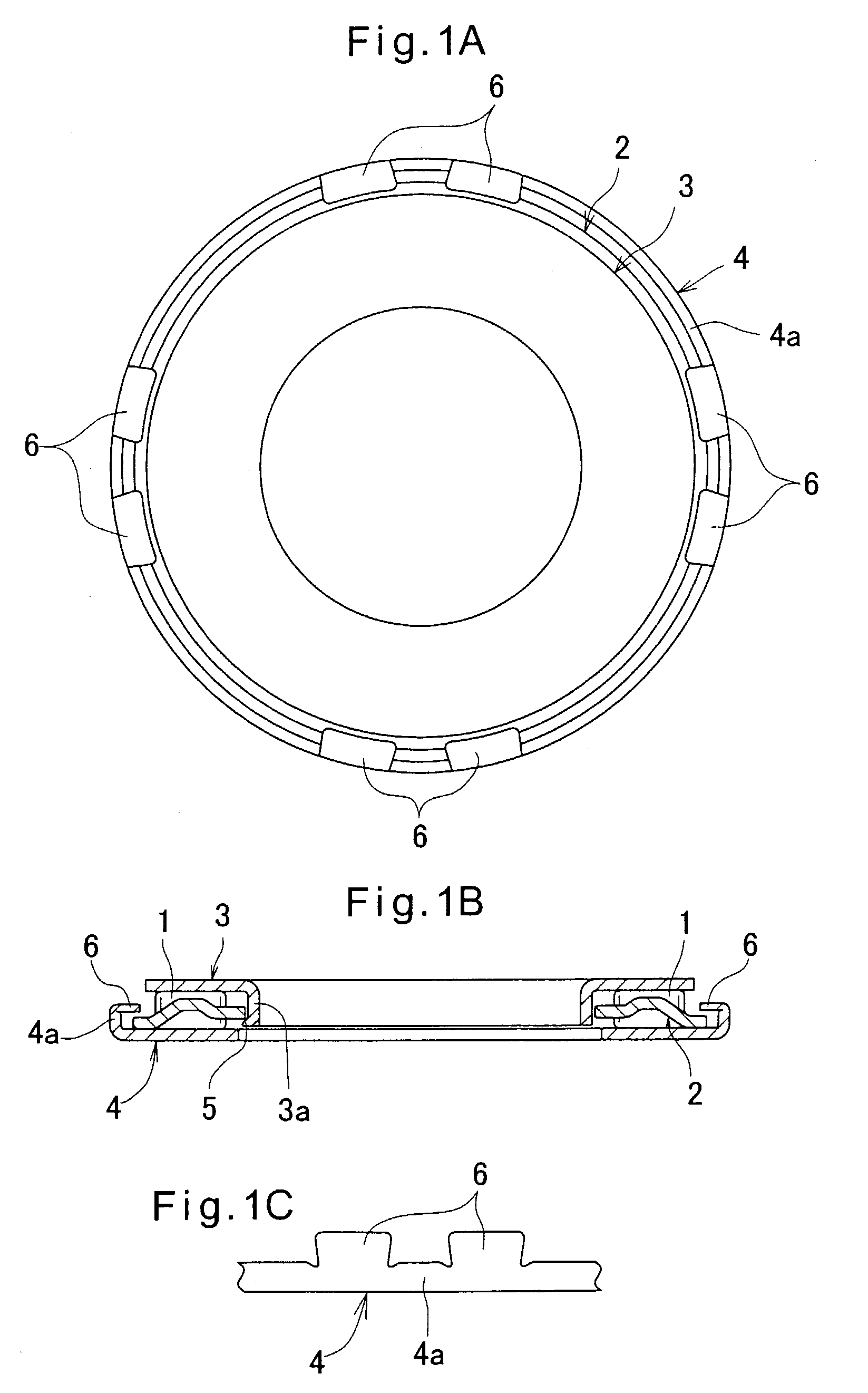

ActiveUS7021995B2Avoiding considerable damageExtended service lifeRevolution surface grinding machinesGrinding drivesMechanical engineeringEngineering

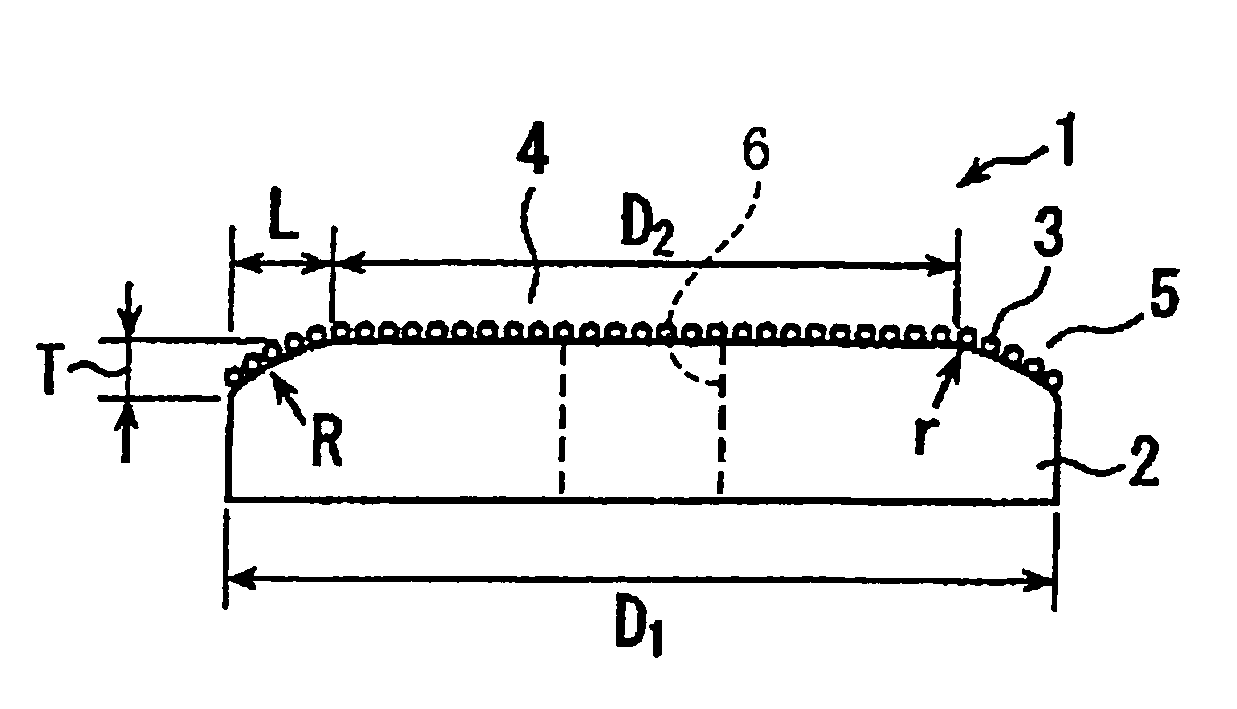

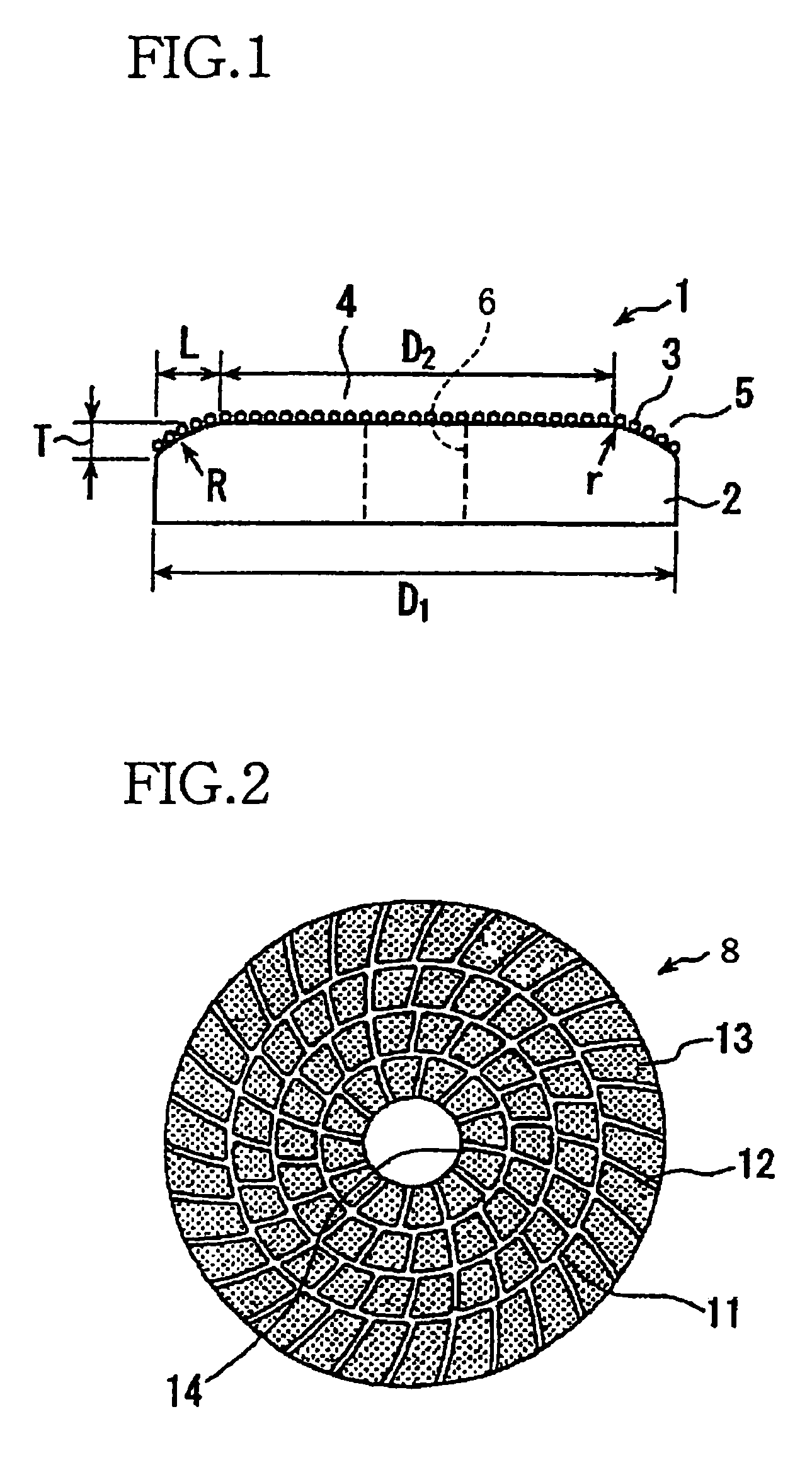

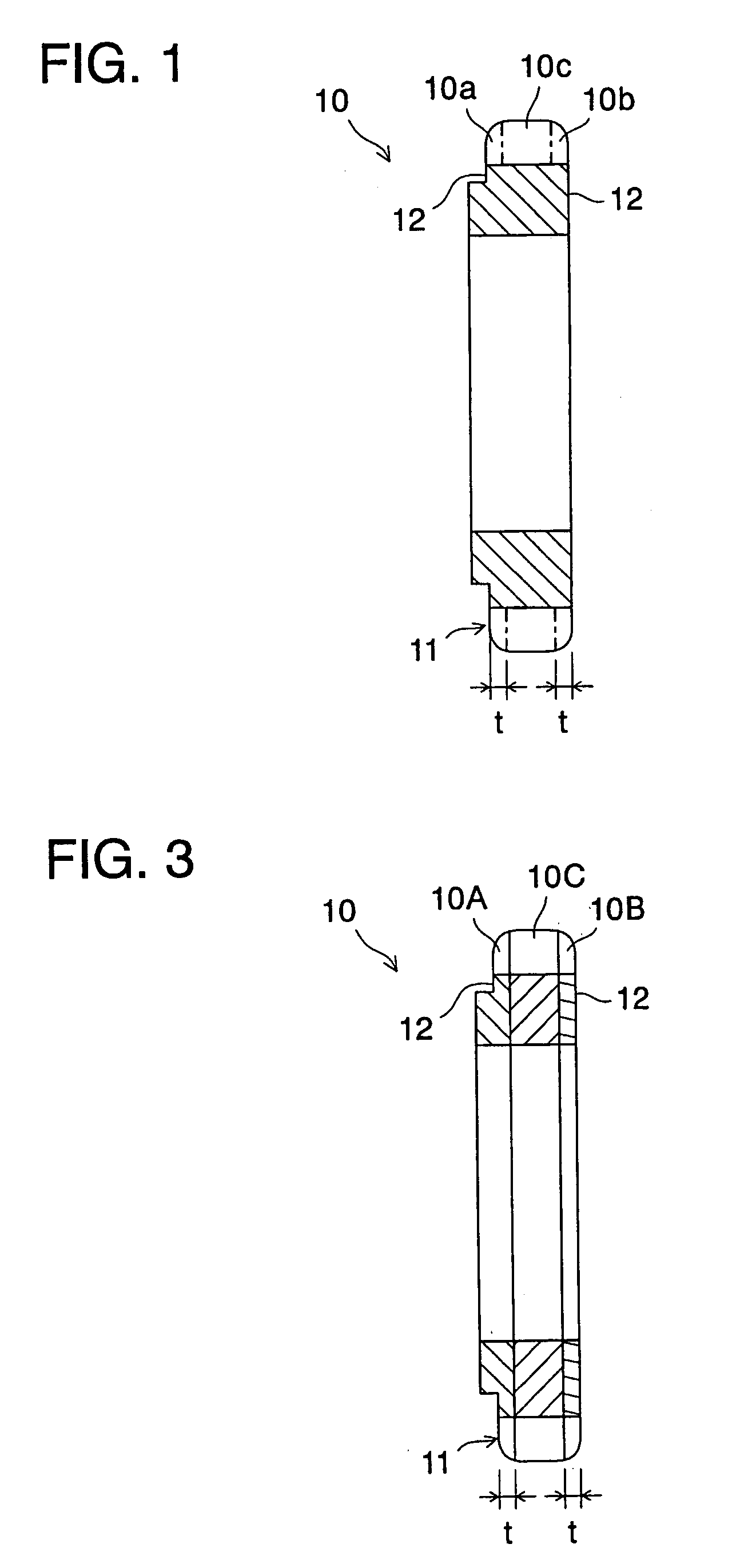

A CMP pad conditioner including: (a) a disk-shaped substrate having a working surface which is provided by one of its axially opposite end surfaces and which is to be brought into contact with the CMP pad; and (b) abrasive grains which are fixed to the working surface. The substrate includes a radially inner portion and a radially outer portion which is located radially outwardly of the radially inner portion. The working surface in the radially outer portion is inclined with respect to the working surface in the radially inner portion, such that a thickness of the radially outer portion as measured in an axial direction of the substrate is reduced as viewed in a direction away from an axis of the substrate toward a periphery of the substrate. A ratio of an outside diameter of the radially inner portion to an outside diameter of the substrate is 60–85%.

Owner:NORITAKE CO LTD +1

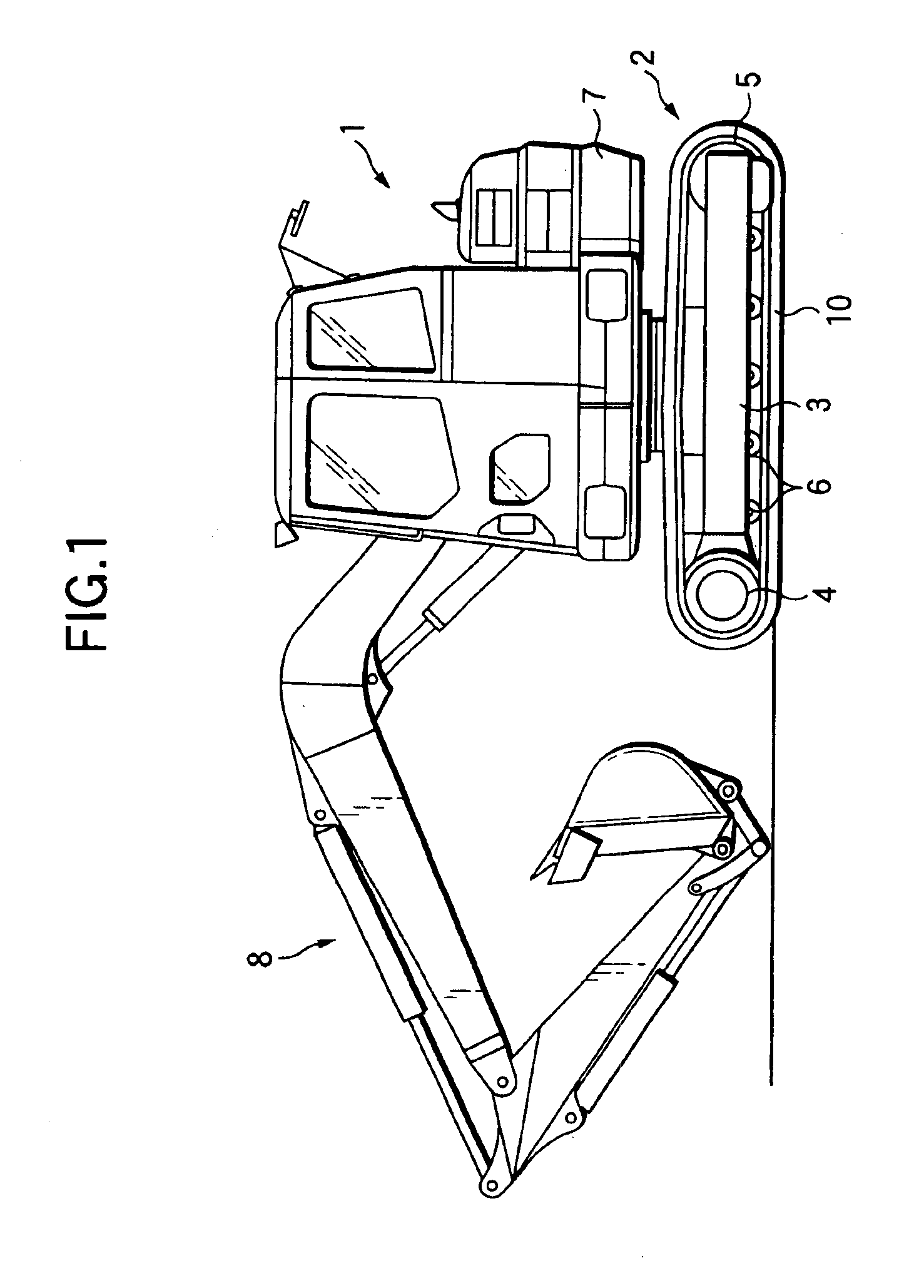

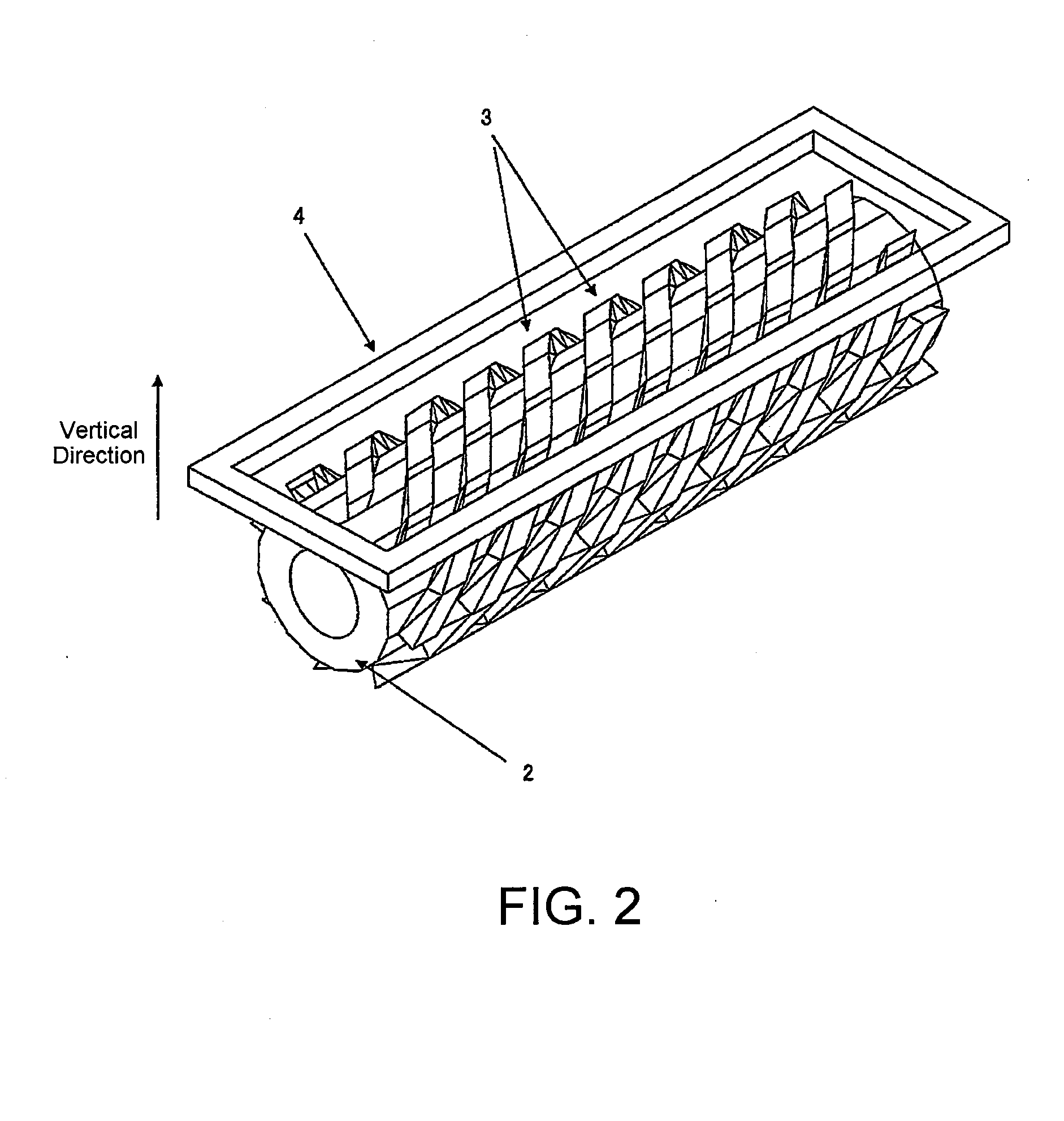

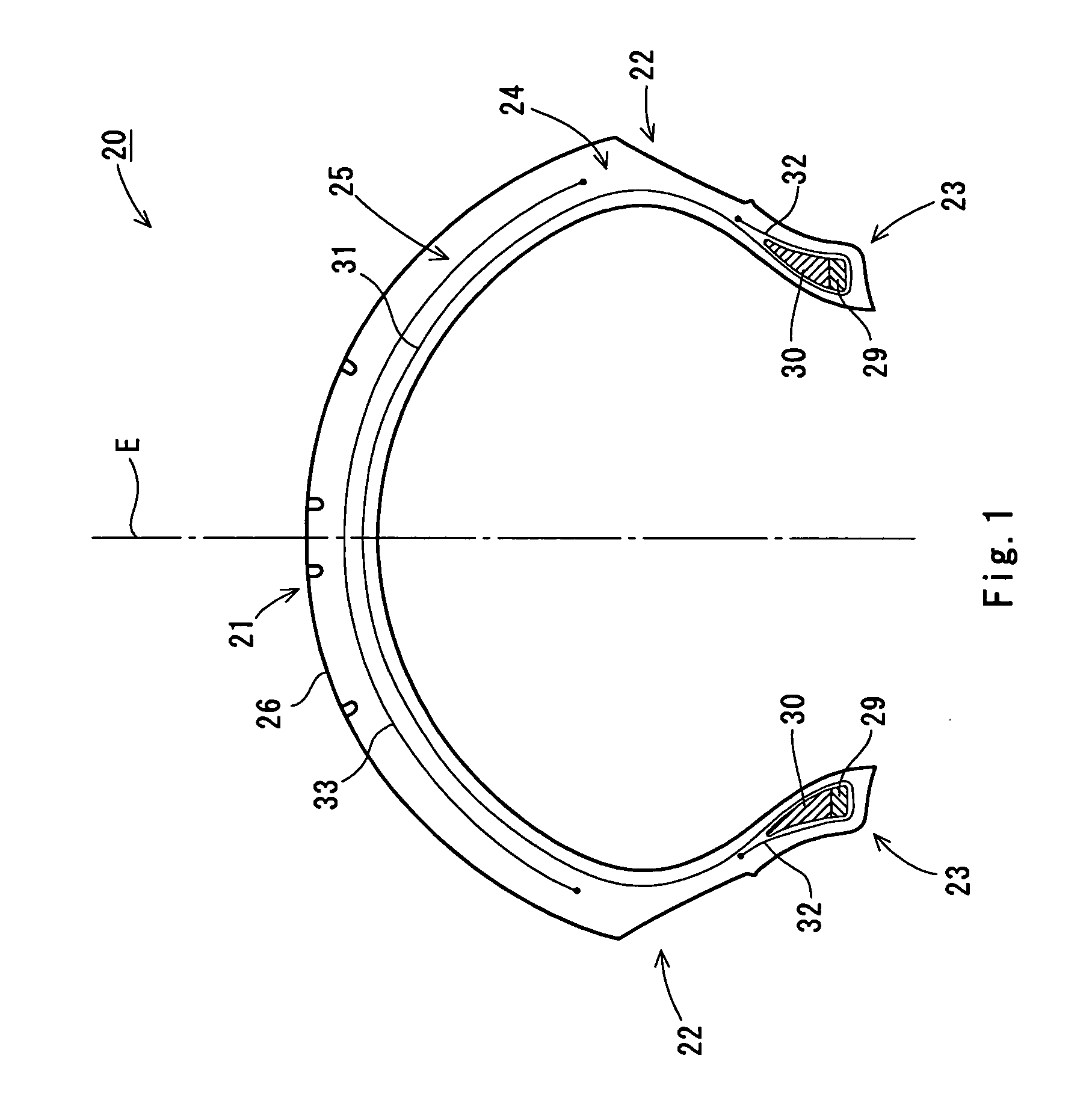

Elastic-bodied crawler

InactiveUS6932442B2Increased durabilityDriven projectionDriving beltsEndless track vehiclesElastomerEngineering

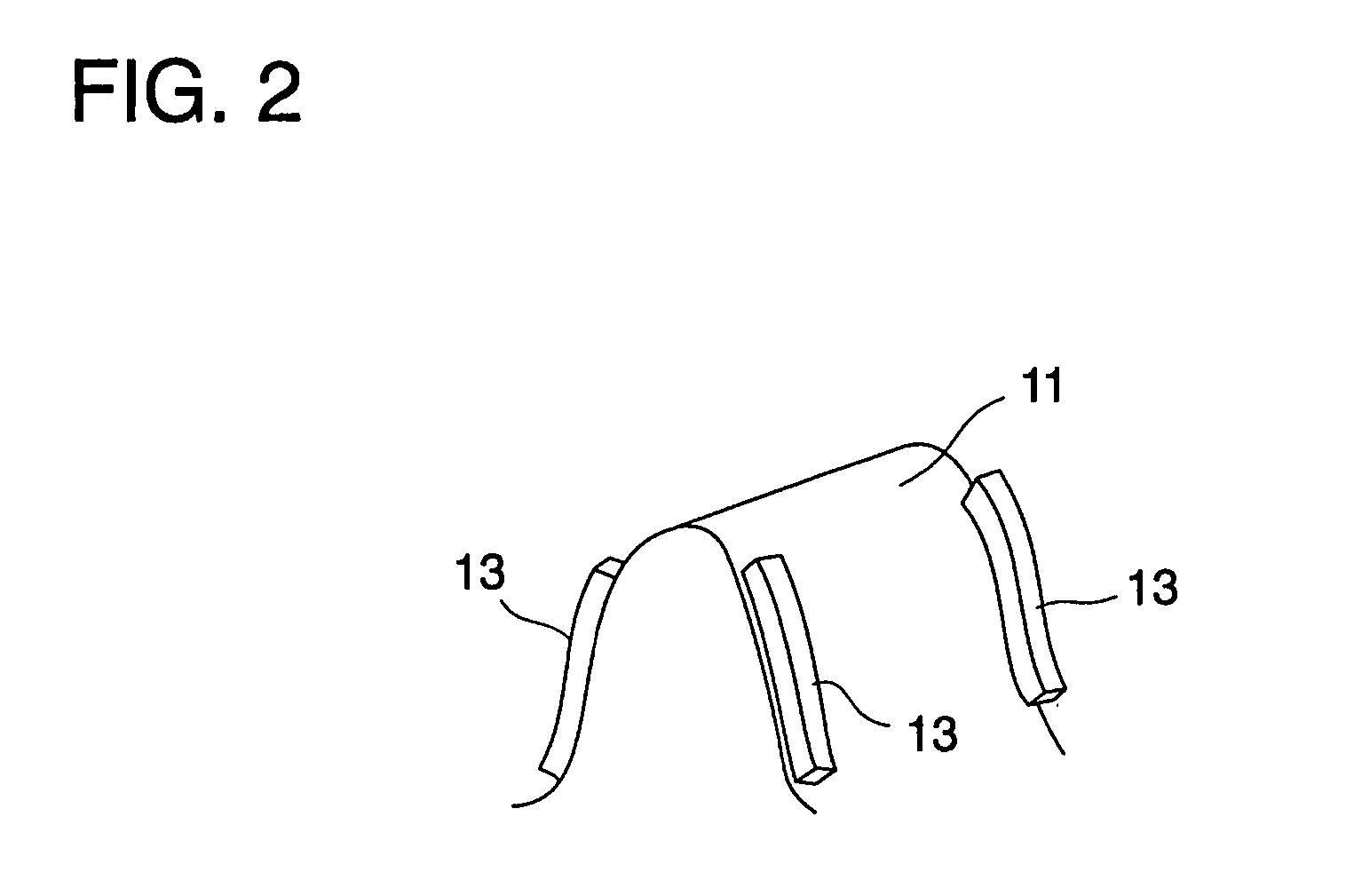

An elastic-bodied crawler, in which damages, such as local wear, coming-off of driven projections and the like in use, are prevented from being brought about, and frictional resistance is decreased at engaging portions to provide for durability, comprises a body with a reinforcement layer of reinforcement cables embedded therein circumferentially, driven projections provided in a predetermined pitch on an inner peripheral surface of the body, lug portions formed on an outer surface of the body, and reinforcement members (driven projection reinforcement cables) embedded to bridge the driven projections and the body.

Owner:KOMATSU LTD

CMP pad conditioner having working surface inclined in radially outer portion

ActiveUS20050215188A1Facilitates evacuationEfficient evacuationRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

A CMP pad conditioner including: (a) a disk-shaped substrate having a working surface which is provided by one of its axially opposite end surfaces and which is to be brought into contact with the CMP pad; and (b) abrasive grains which are fixed to the working surface. The substrate includes a radially inner portion and a radially outer portion which is located radially outwardly of the radially inner portion. The working surface in the radially outer portion is inclined with respect to the working surface in the radially inner portion, such that a thickness of the radially outer portion as measured in an axial direction of the substrate is reduced as viewed in a direction away from an axis of the substrate toward a periphery of the substrate. A ratio of an outside diameter of the radially inner portion to an outside diameter of the substrate is 60-85%.

Owner:NORITAKE CO LTD +1

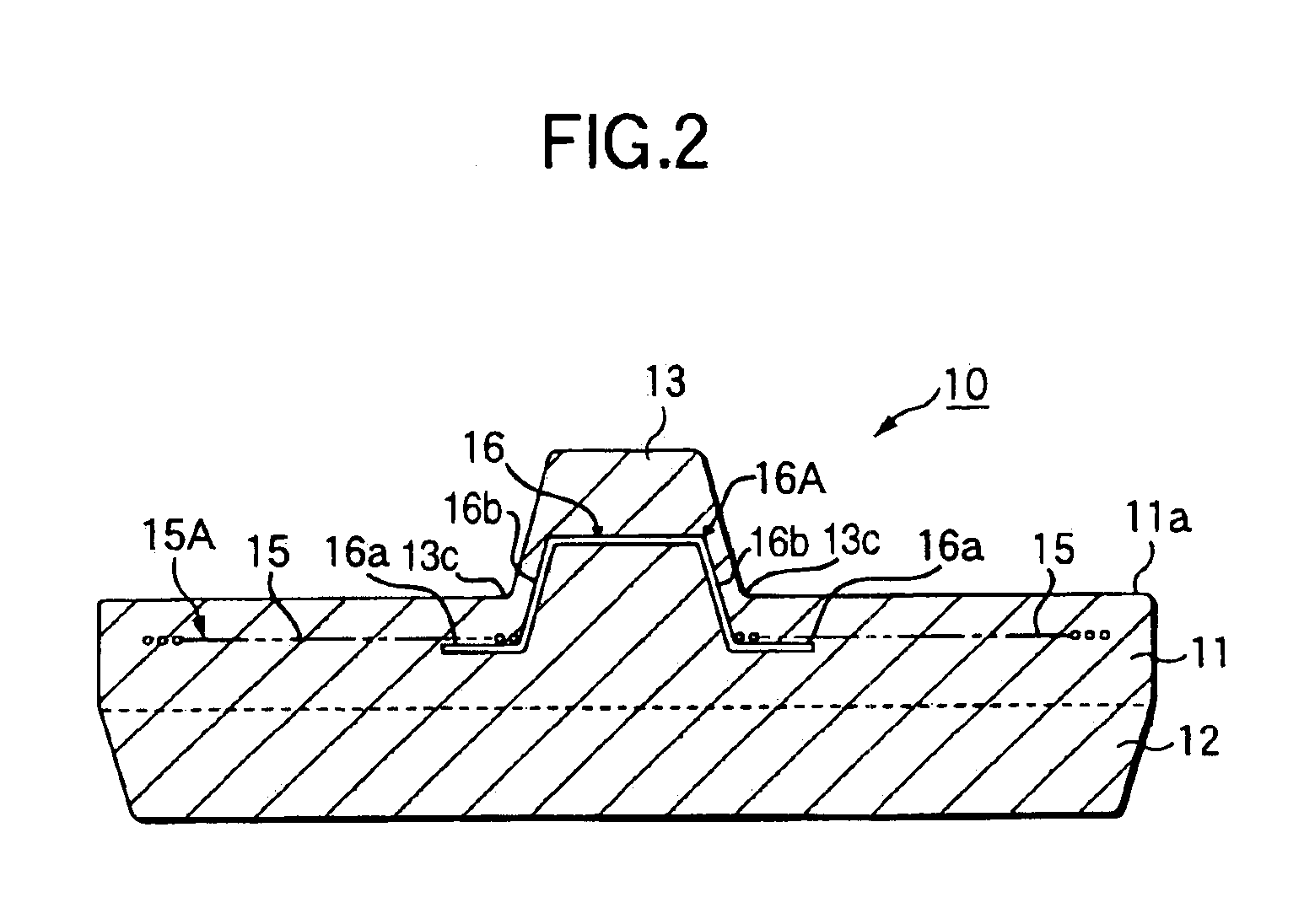

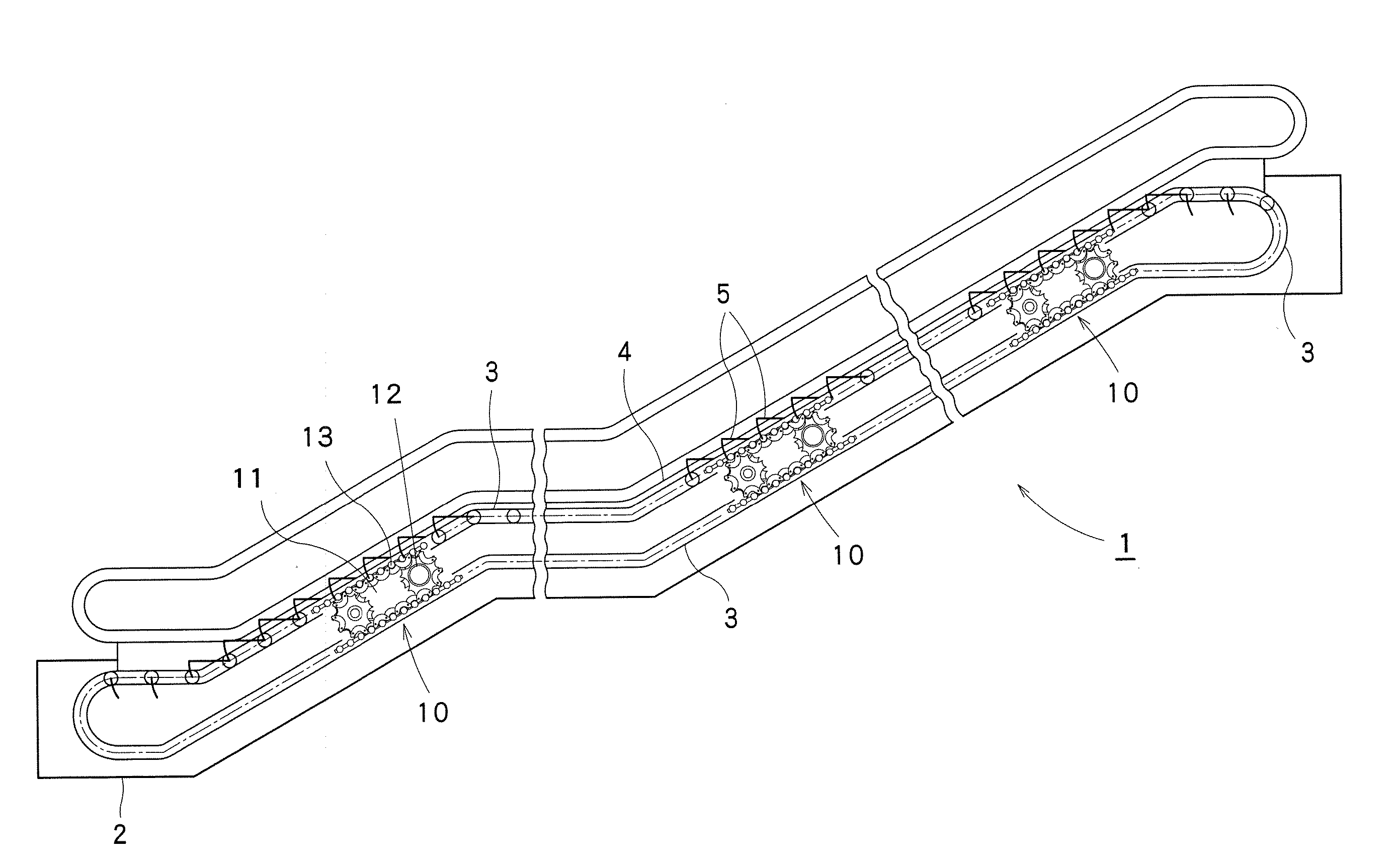

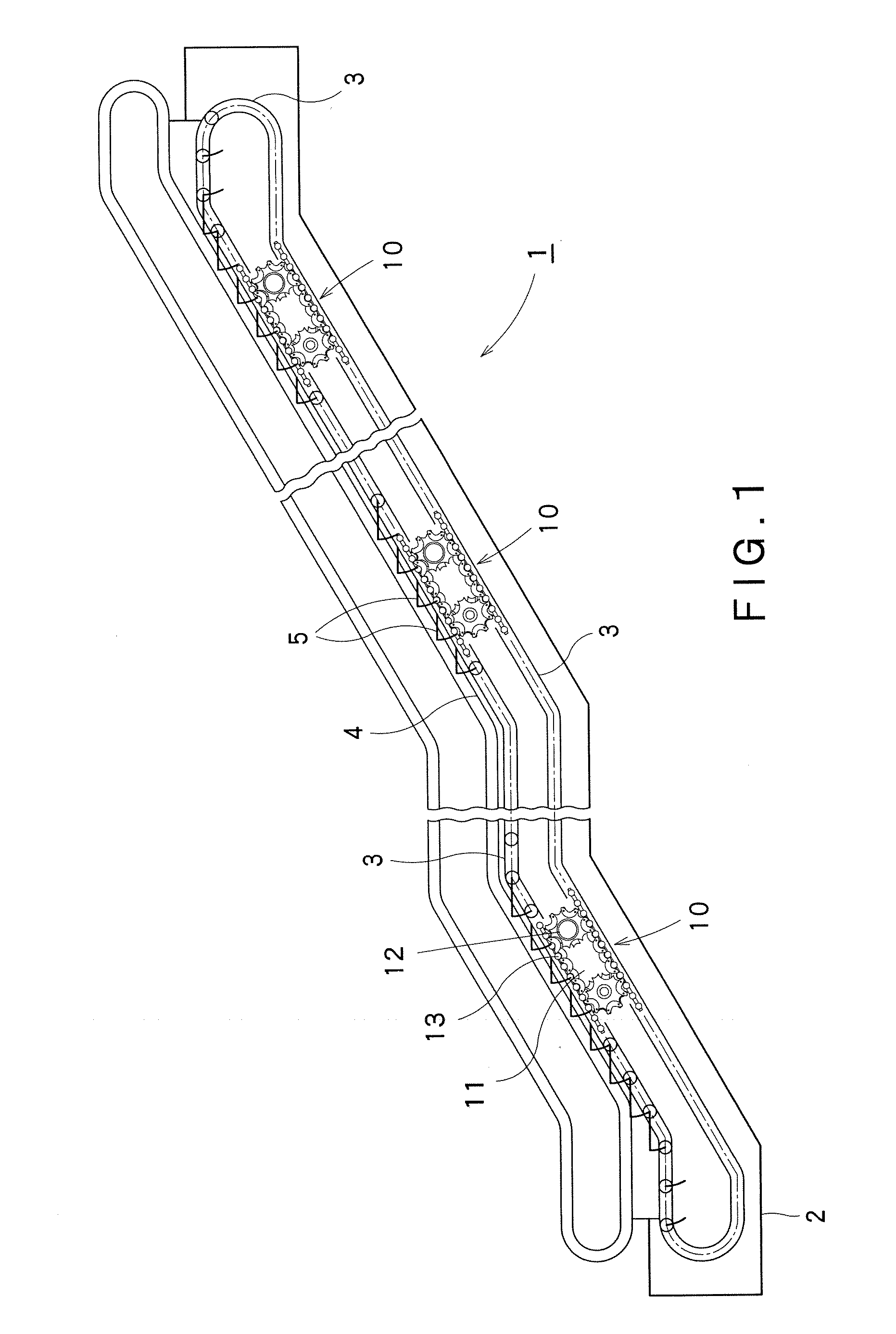

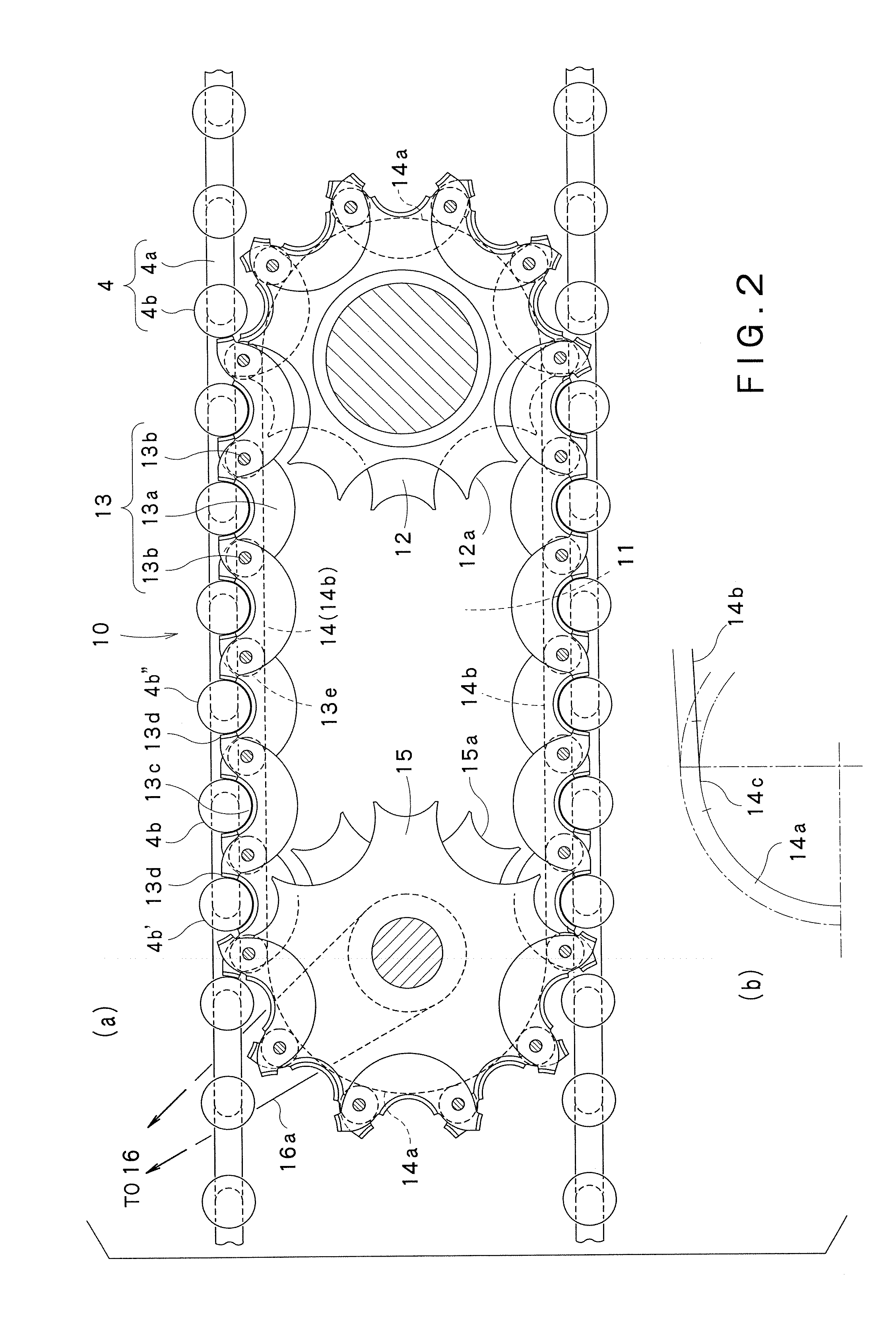

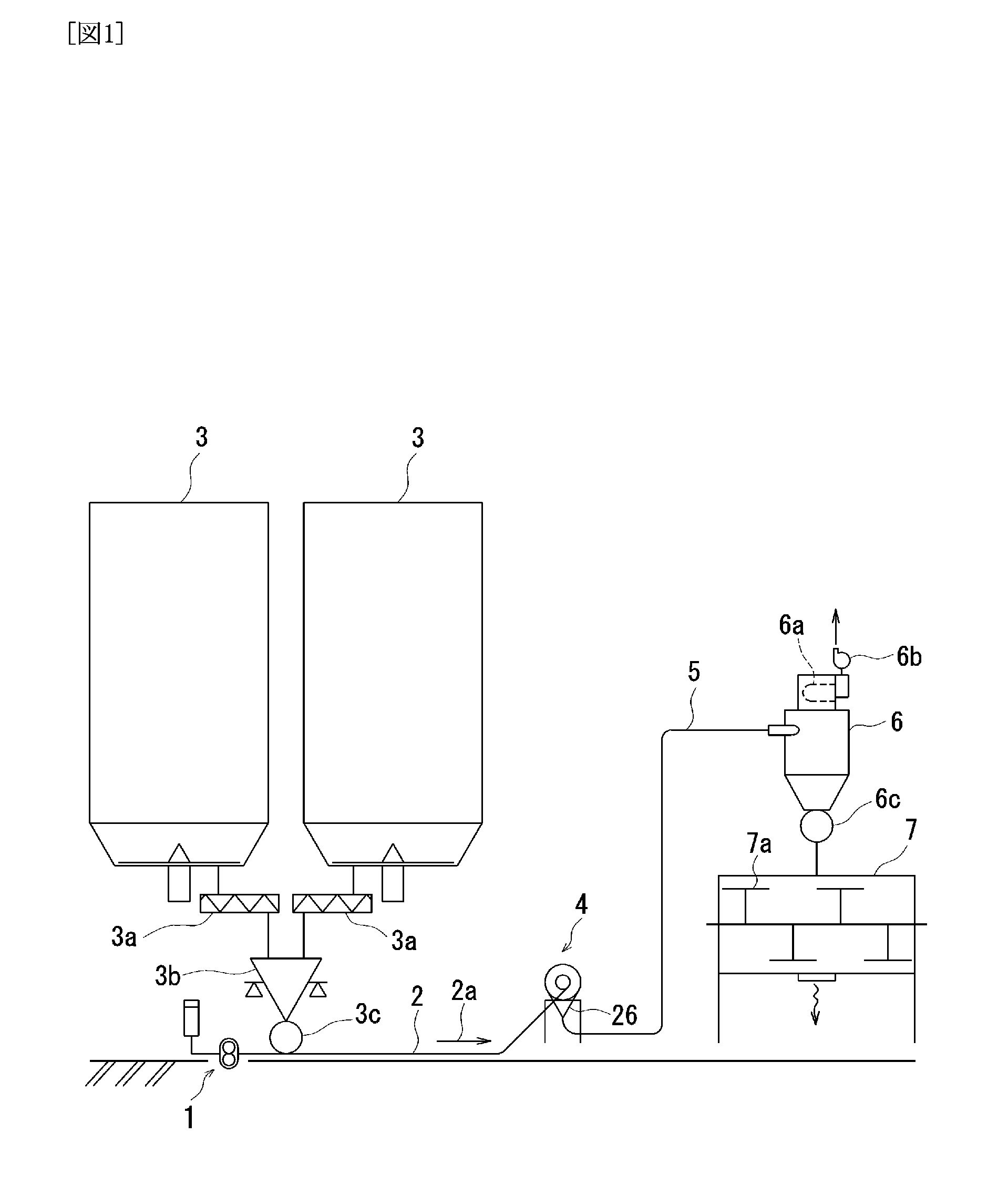

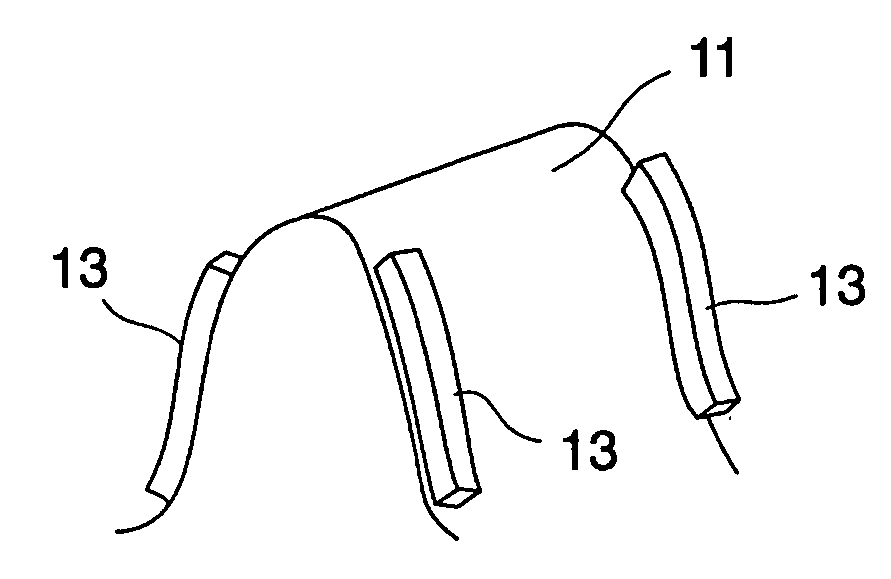

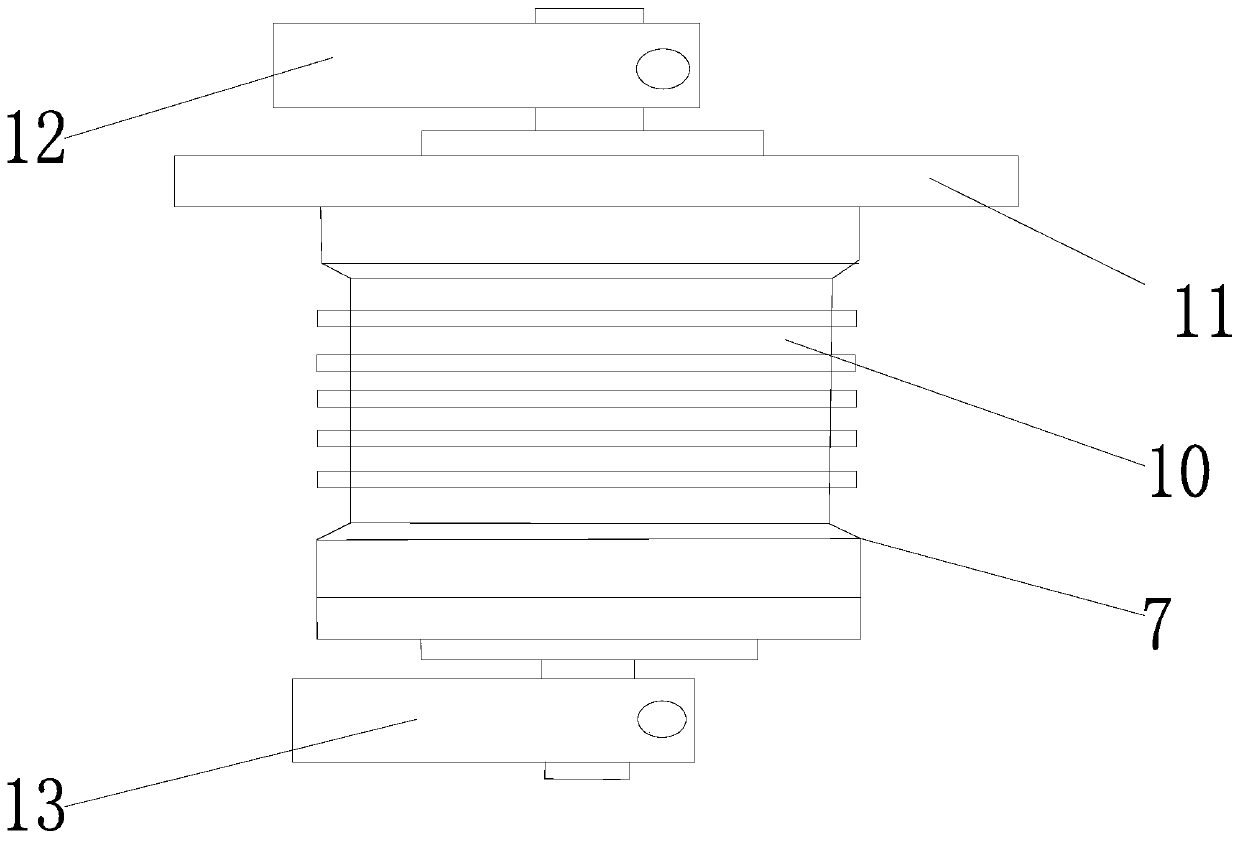

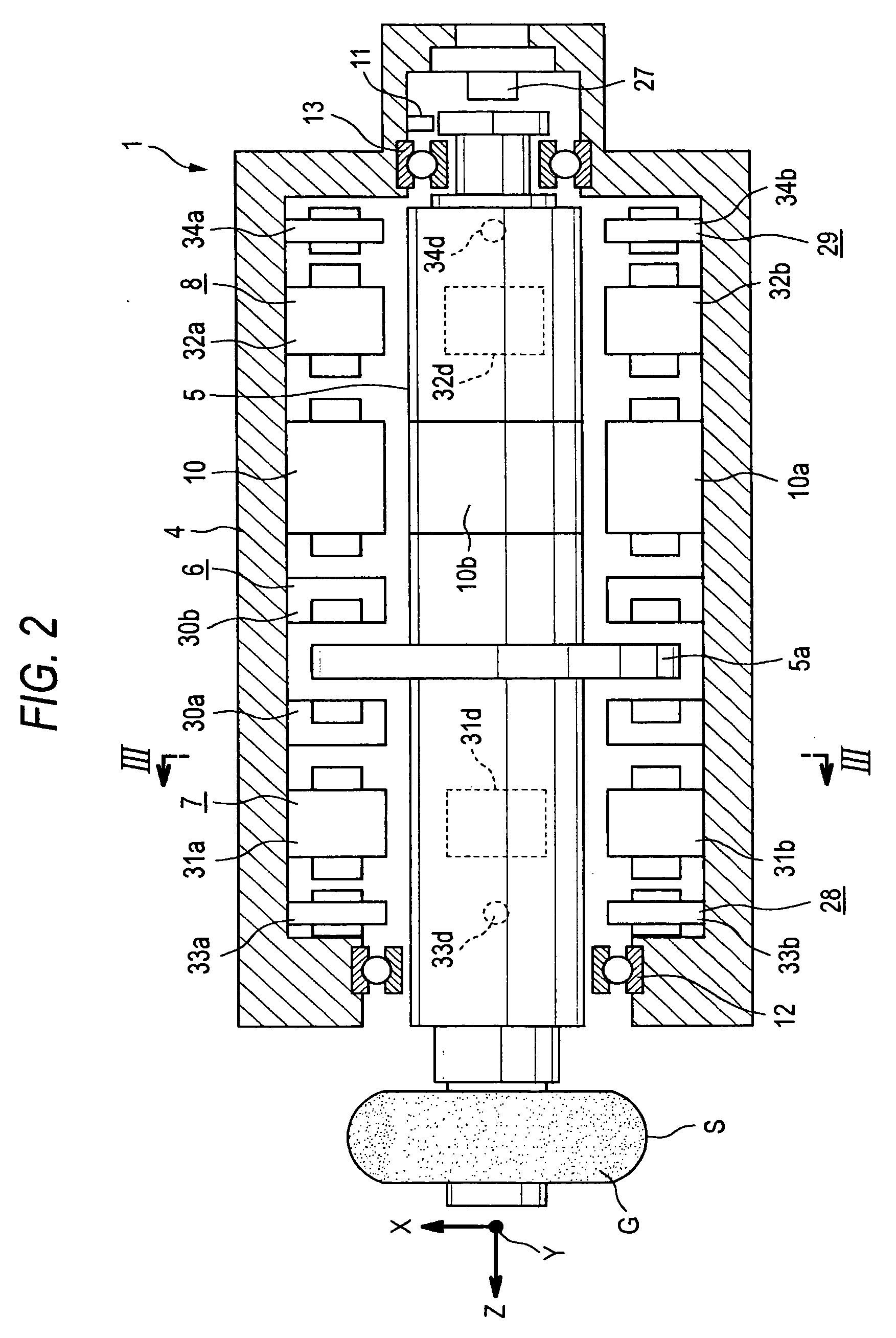

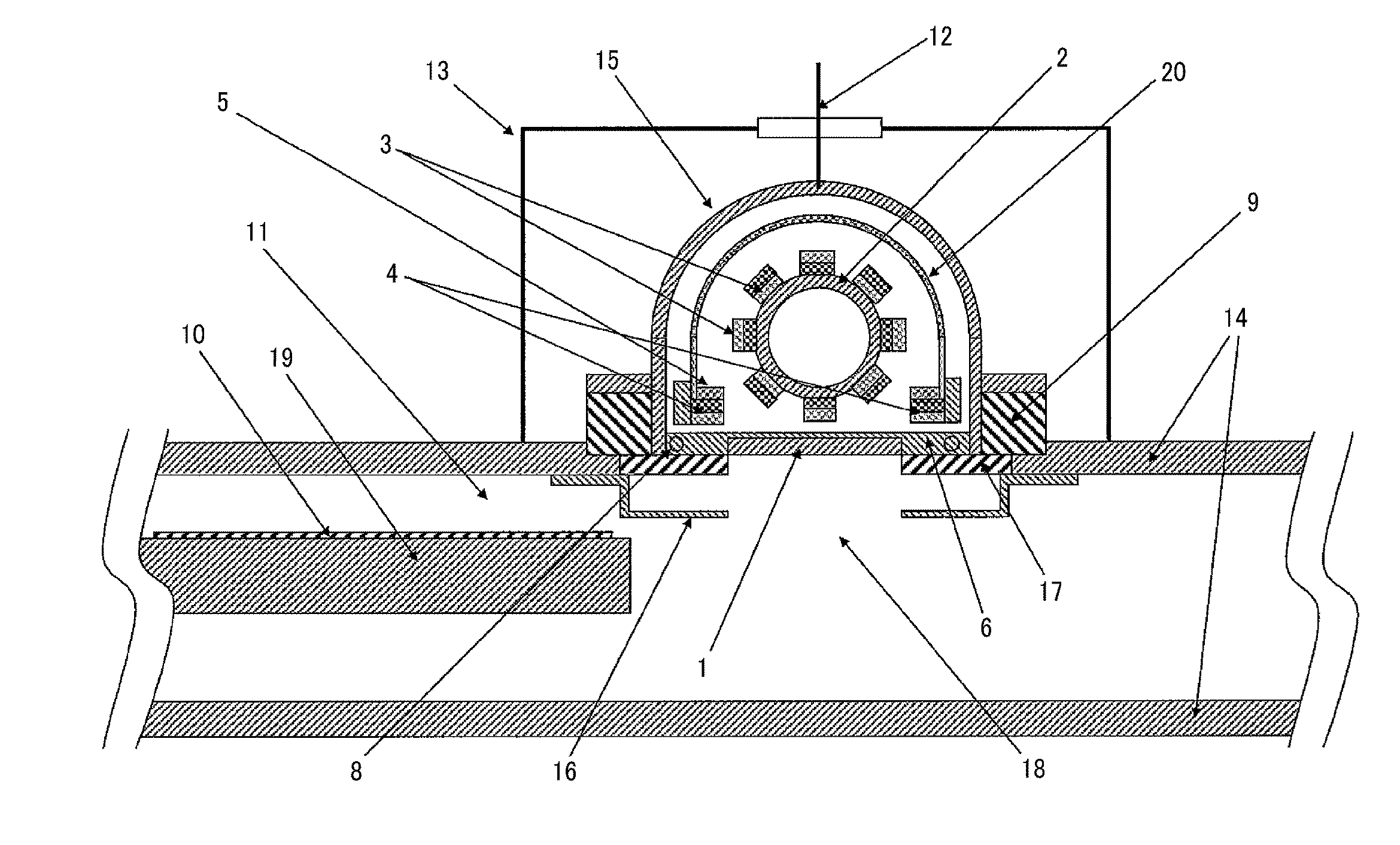

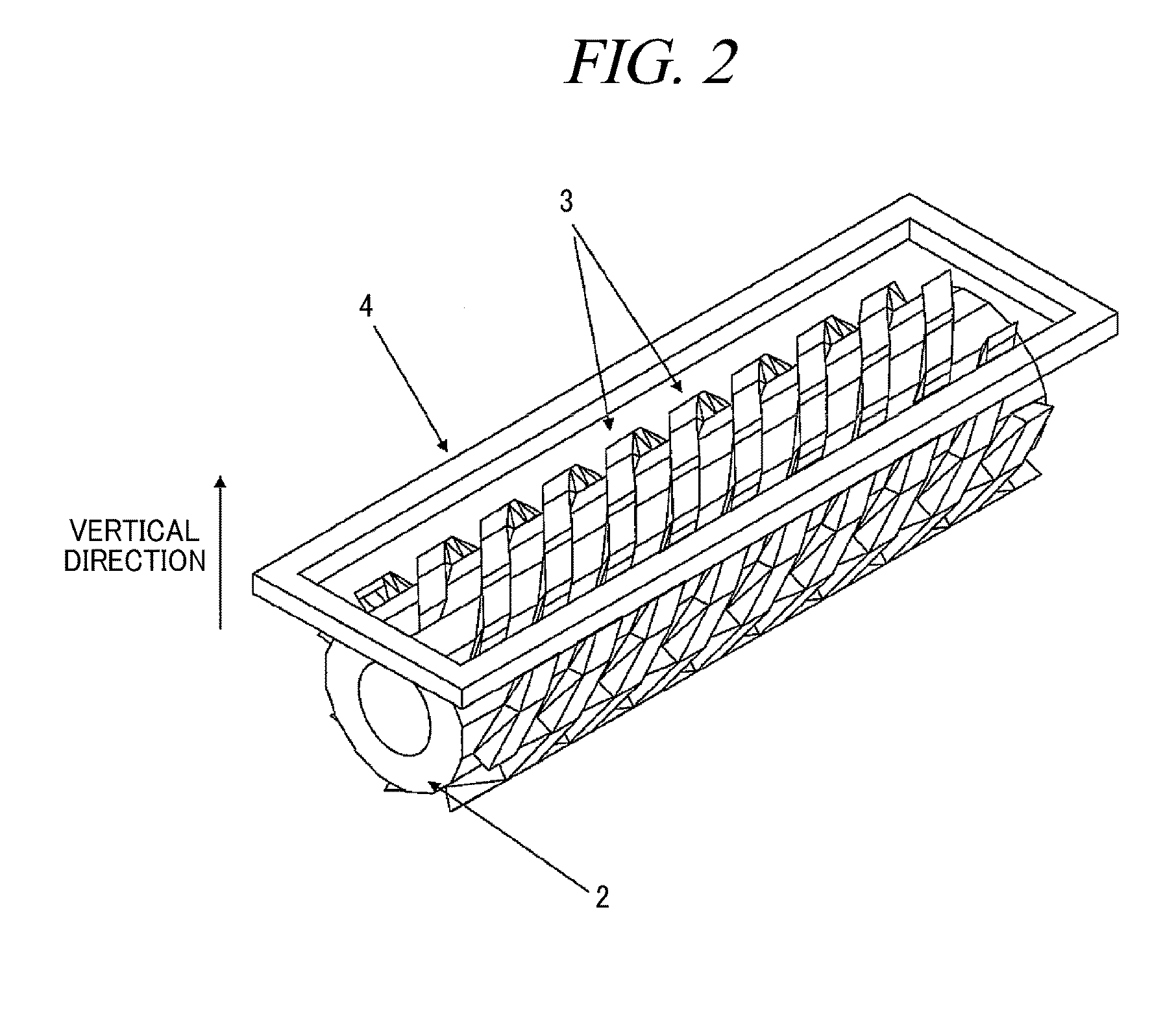

Conveyor apparatus

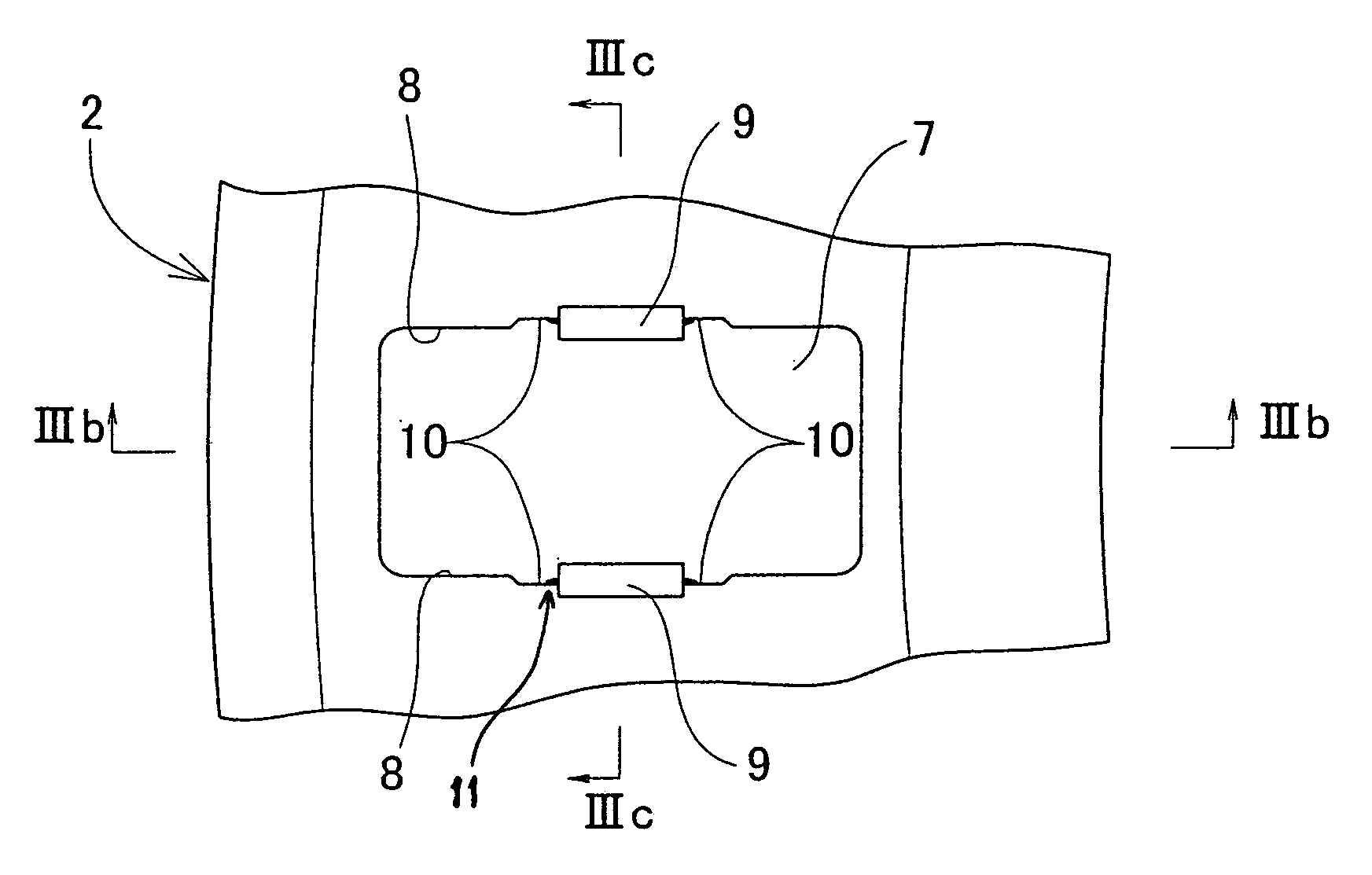

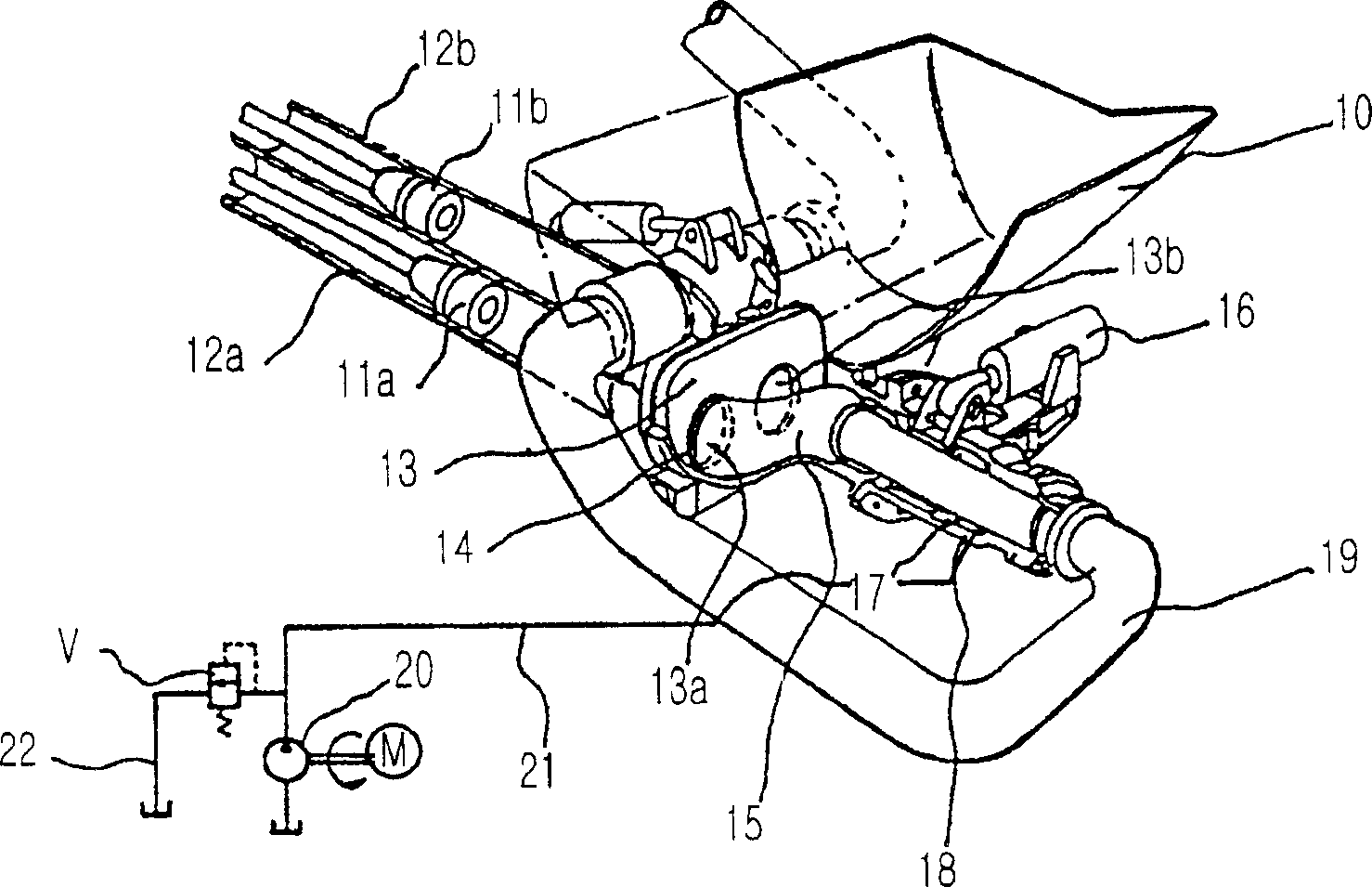

InactiveUS20080053788A1Comfortable ride qualityAvoid local wearConveyorsEscalatorsEngineeringChain link

There is provided a conveyor apparatus free of pulsing motion in circulating chains to provide a comfortable ride quality on steps. A conveyor apparatus 1 includes a step guide rail 3, a plurality of steps 5, a step chain 4, and a chain driving mechanism 10 for driving the step chain 4. The chain driving mechanism 10 includes a rotating and driving unit 11, a driving sprocket 12 which is rotated by a driving force given by the rotating and driving unit 11, and circulating chain 13 for giving a thrust to the step chain 4. The circulating chain 13 has chain links 13a and hinges 13b to be connected to the adjacent chain links 13a. The chain link 13a includes a placing surface 13c on which the step roller 4b is placed, and pressing surfaces 13d and 13d that are in contact with step rollers 4b.

Owner:TOSHIBA ELEVATOR KK

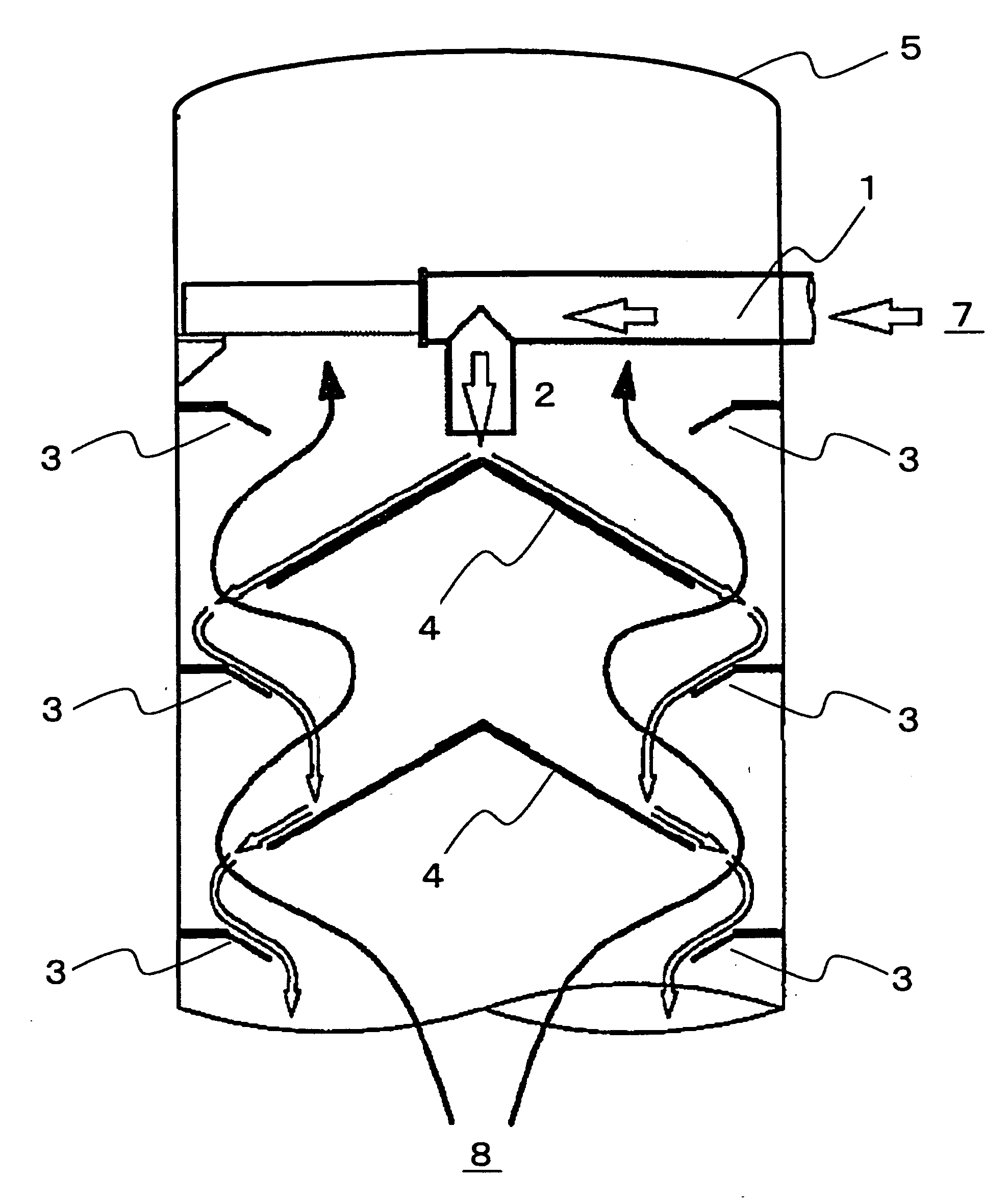

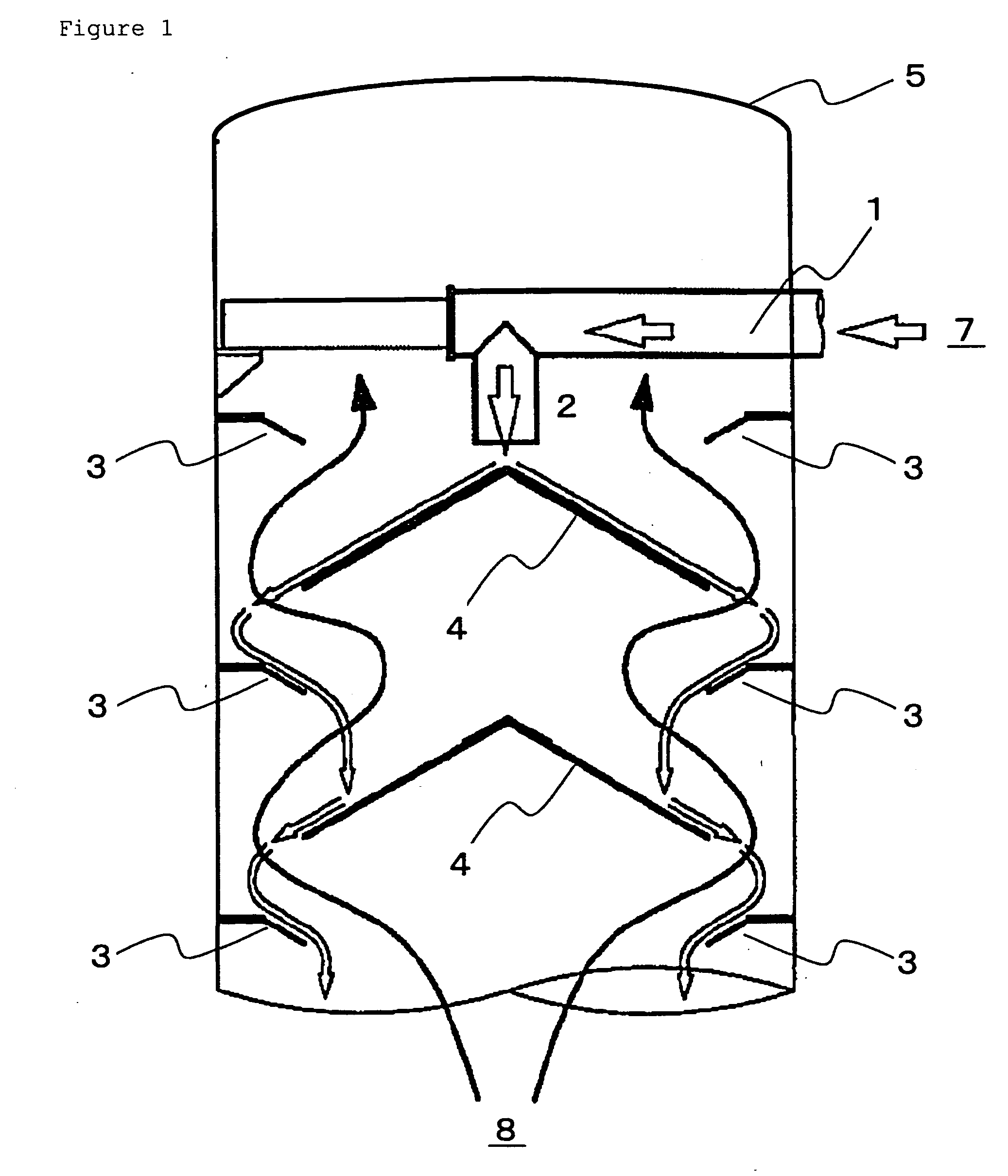

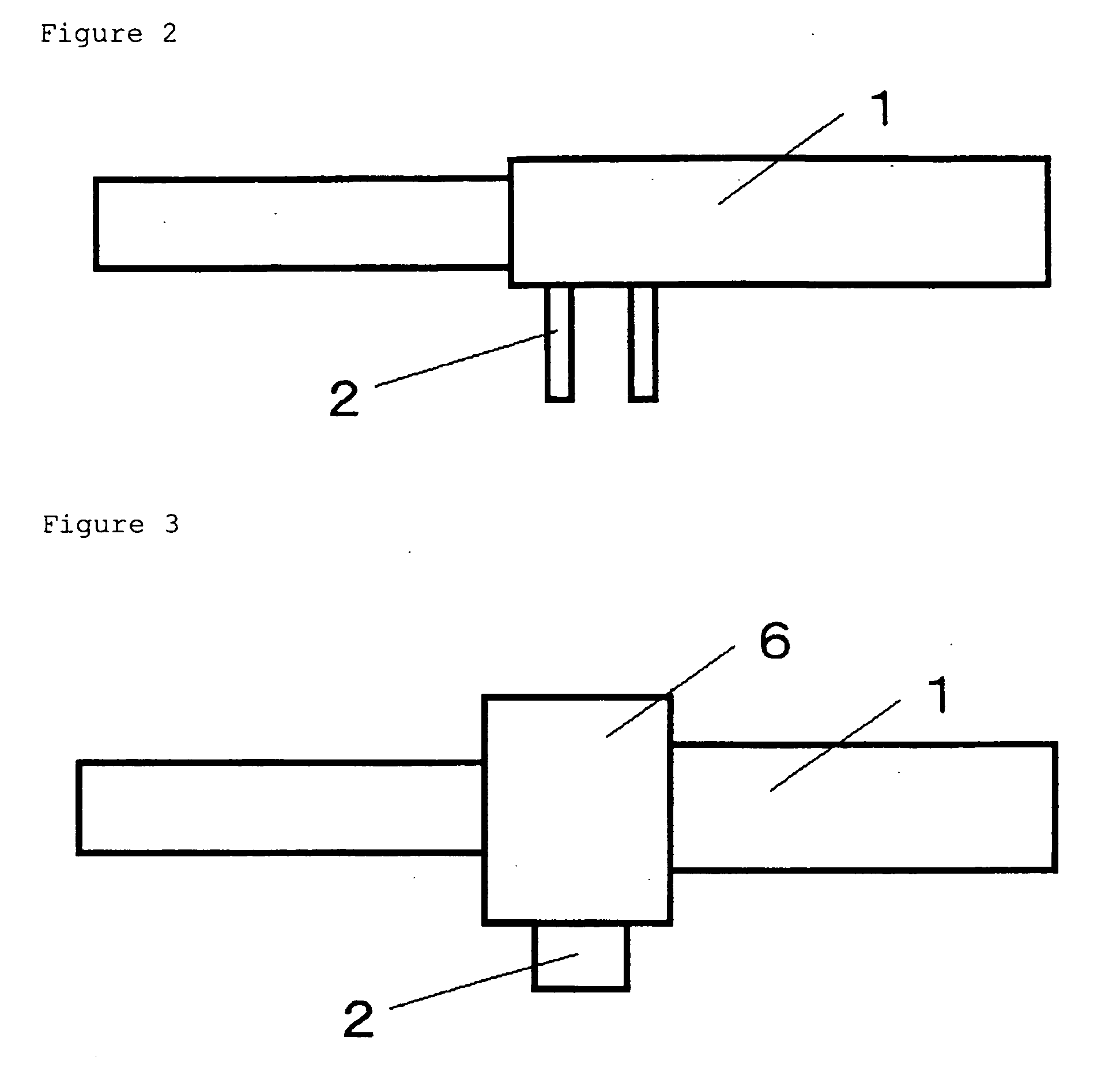

Countercurrent direct-heating-type heat exchanger

ActiveUS20100019422A1Drift suppressionAvoid local wearBlast furnace componentsBlast furnace detailsPlate heat exchangerEngineering

The countercurrent direct-heating-type heat exchanger that is able to suppress drift in the case when a fluid to be heated is supplied, to prevent local abrasion of the members and also to carry out efficient heat exchange.The countercurrent direct-heating-type heat exchanger equipped with a feed pipe, a feed nozzle, ring-like straightening plates and umbrella-type dispersing plates of the above fluid to be heated, characterized in that the above feed nozzle has the shape of a pipe having a circular cross section and the dimension satisfying the following formula (1) and formula (2):Ln / Dn≧1 Formula (1)(wherein, Ln indicates the length of the feed nozzle; and Dn indicates the inside diameter of the feed nozzle)1.5≦Sp / Sn≦2.0 Formula (2)(wherein, Sp indicates the inner cross-sectional area of the feed pipe; and Sn indicates the inner cross-sectional area of the feed nozzle).

Owner:SUMITOMO METAL MINING CO LTD

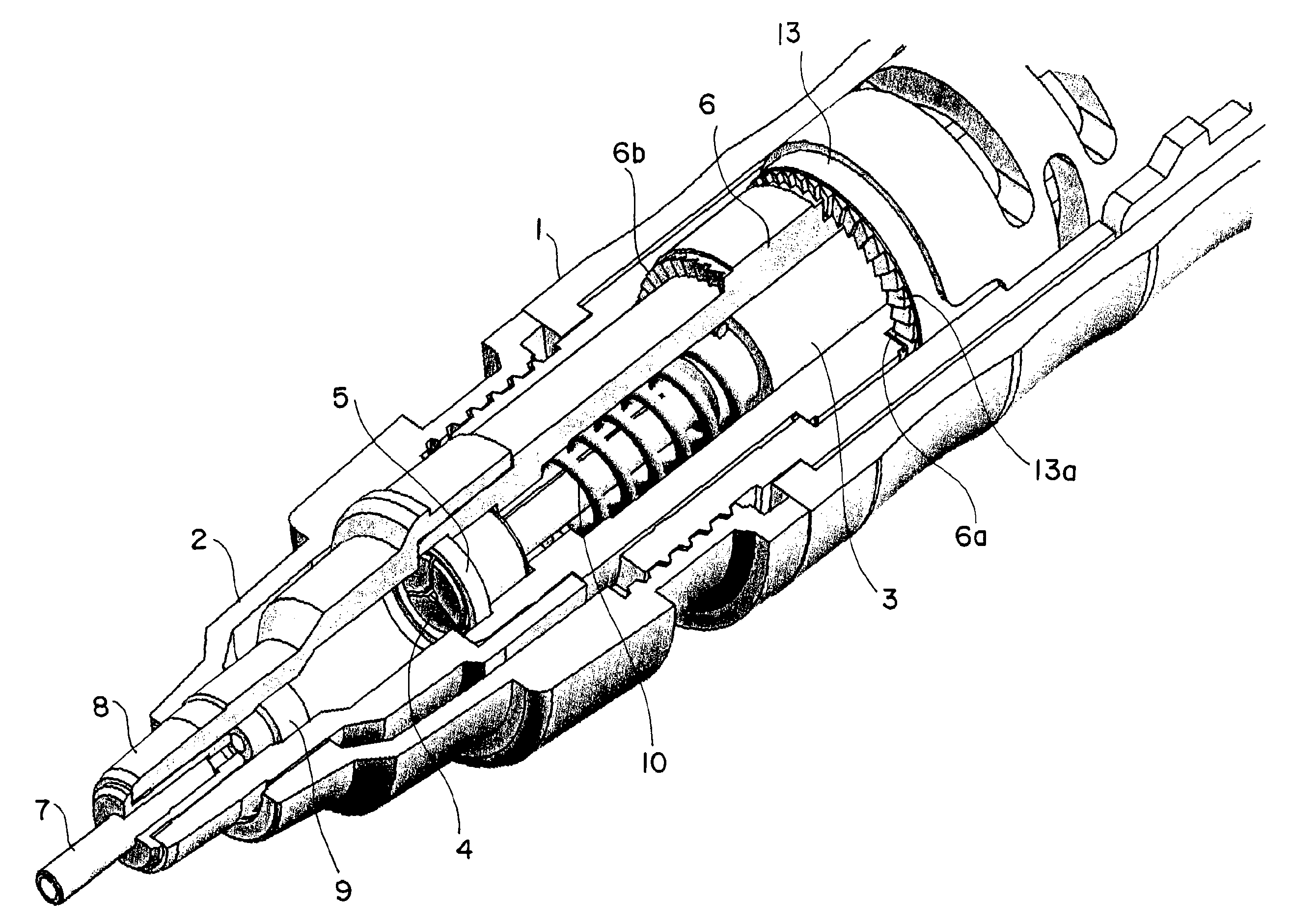

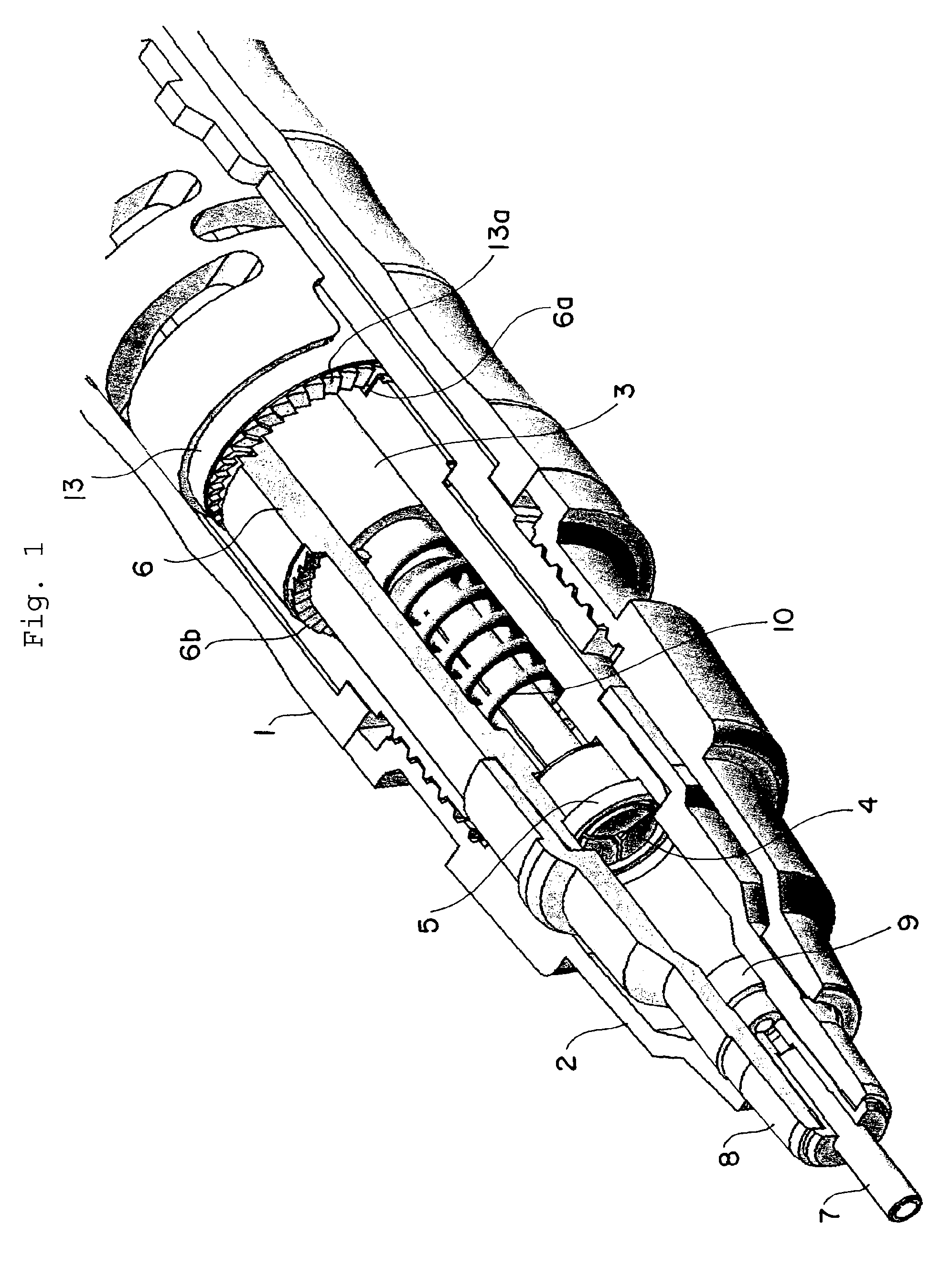

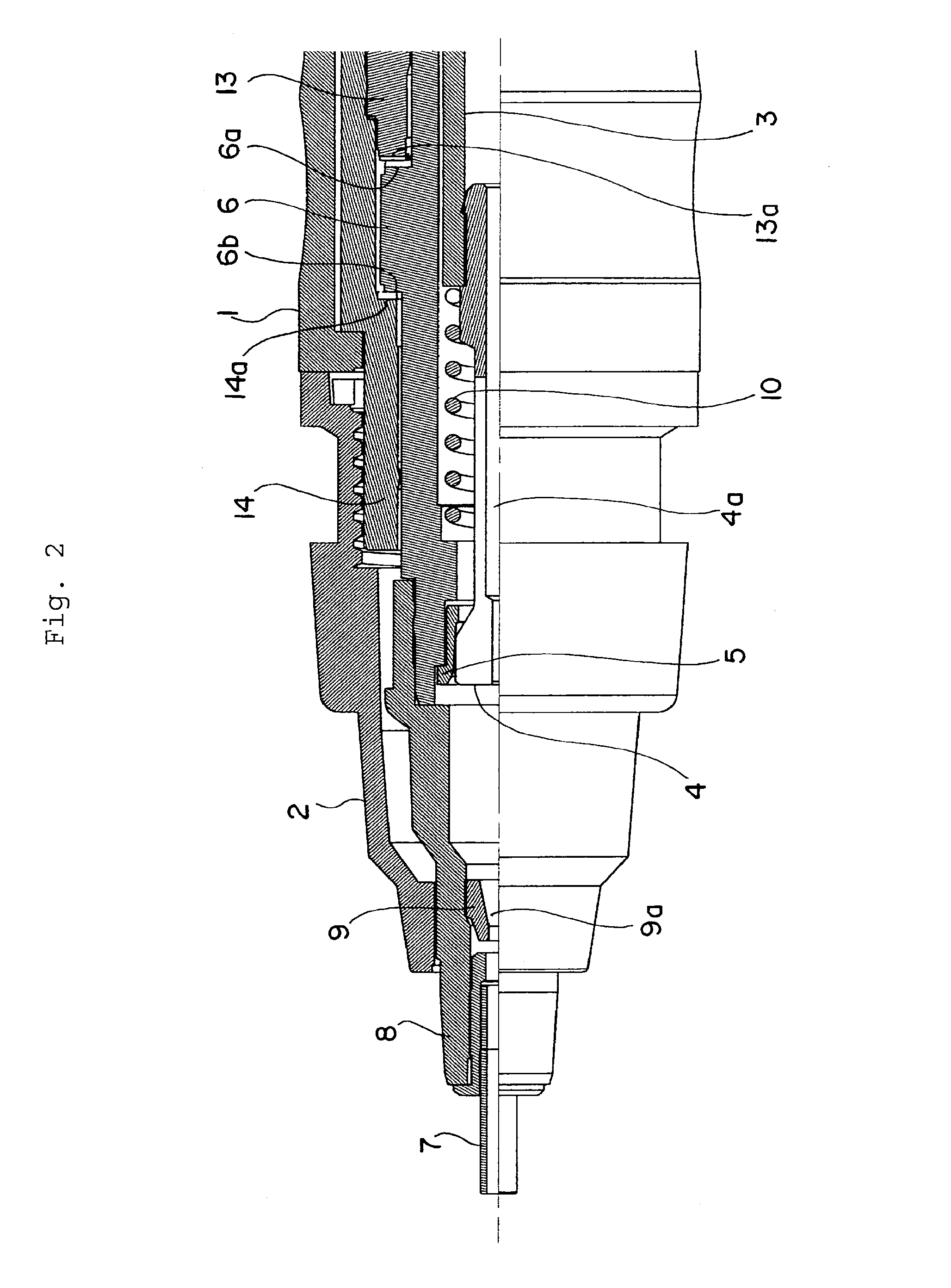

Mechanical pencil

ActiveUS7802936B1Avoid local wearQuality improvementPropelling pencilsBall-point pensEngineeringMechanical engineering

A chuck (4) for grasping a writing lead and a rotor (6) arranged to be movable in a direction of rotation and an axial direction within a body cylinder (1). A rotational drive mechanism for the writing lead is formed such that first and second cam faces (6a) and (6b) are respectively formed at one end face and another end face of the rotor in the axial direction, and first and second fixed cam faces (13a) and (14a) are arranged on the body cylinder side to face the above-mentioned first and second cam faces respectively. An indicator (6c) of a wedge-shaped notch is formed at a part of the rotor. The indicator can be observed through the body cylinder made of a transparent material. By this structure, a mechanical pencil is provided in which operation of the writing lead that is gradually rotated by way of writing pressure can be known certainly.

Owner:MITSUBISHI PENCIL CO LTD

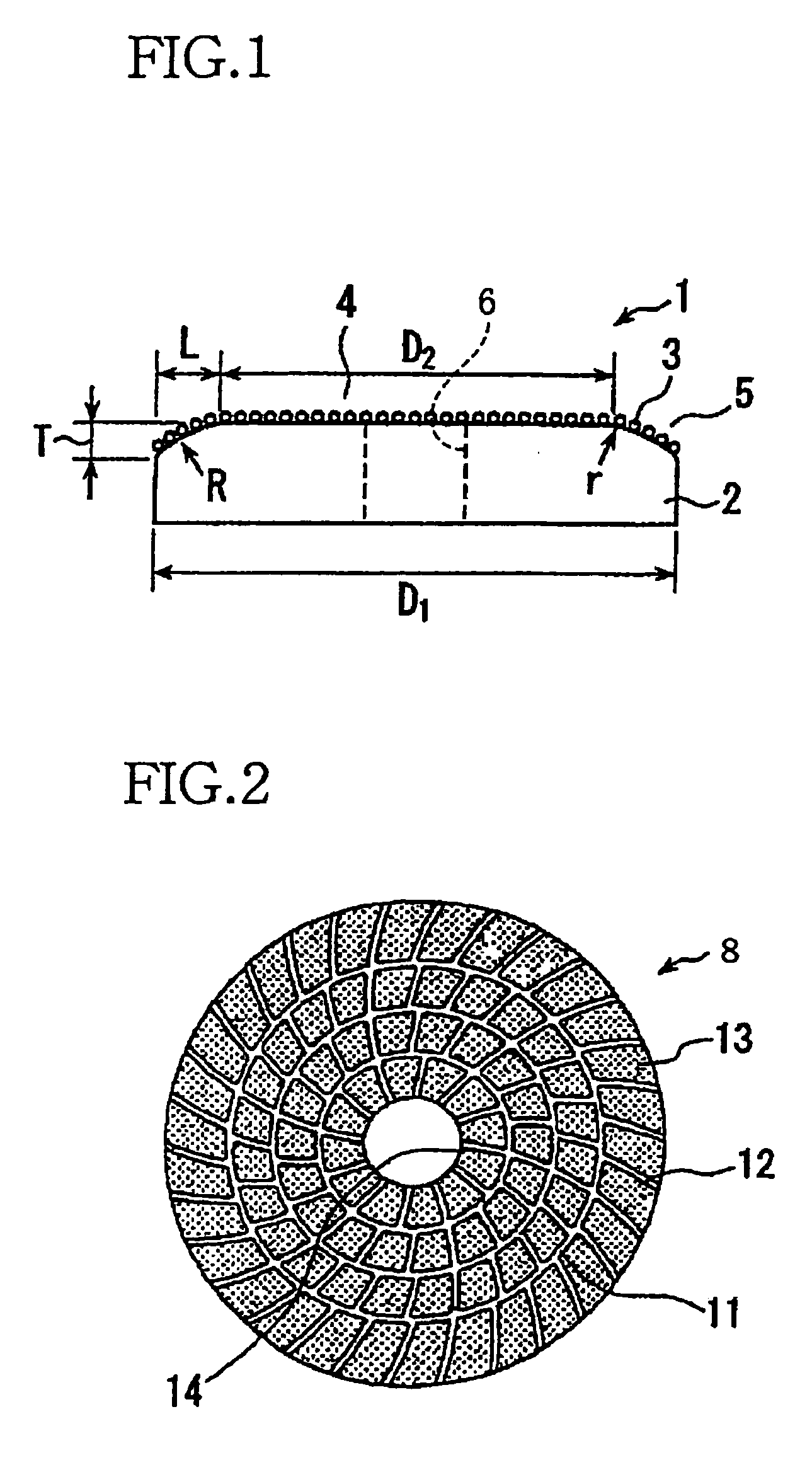

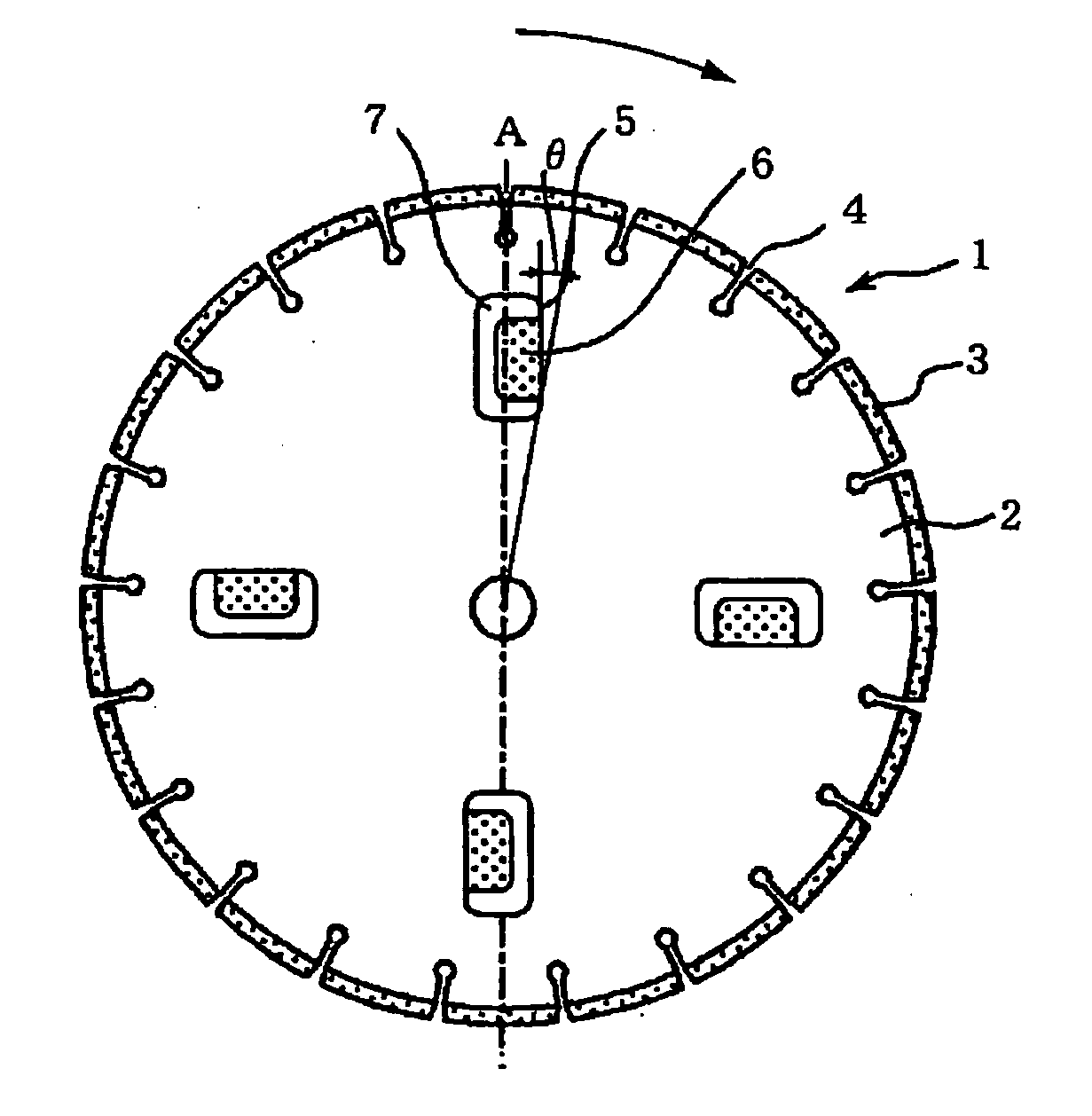

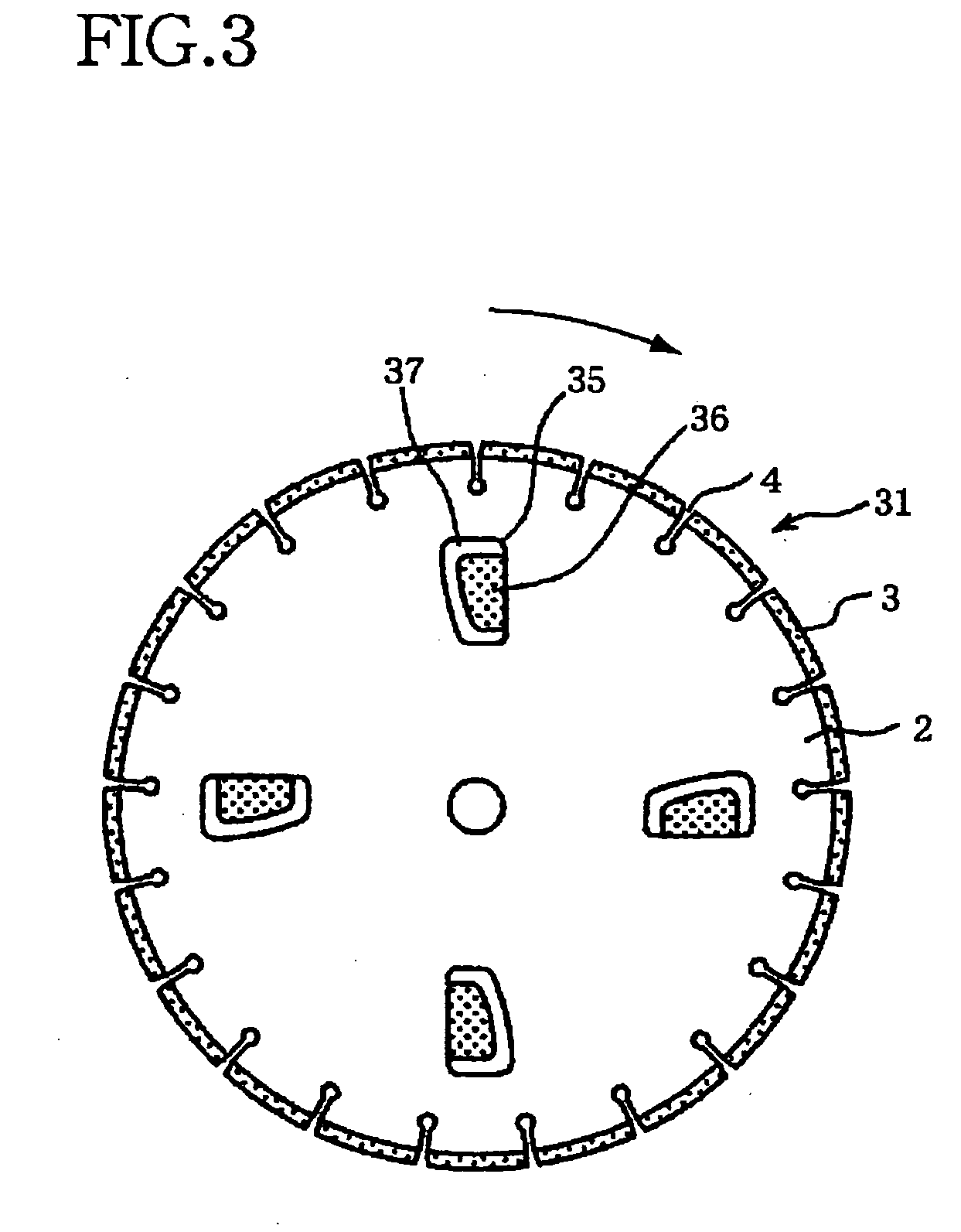

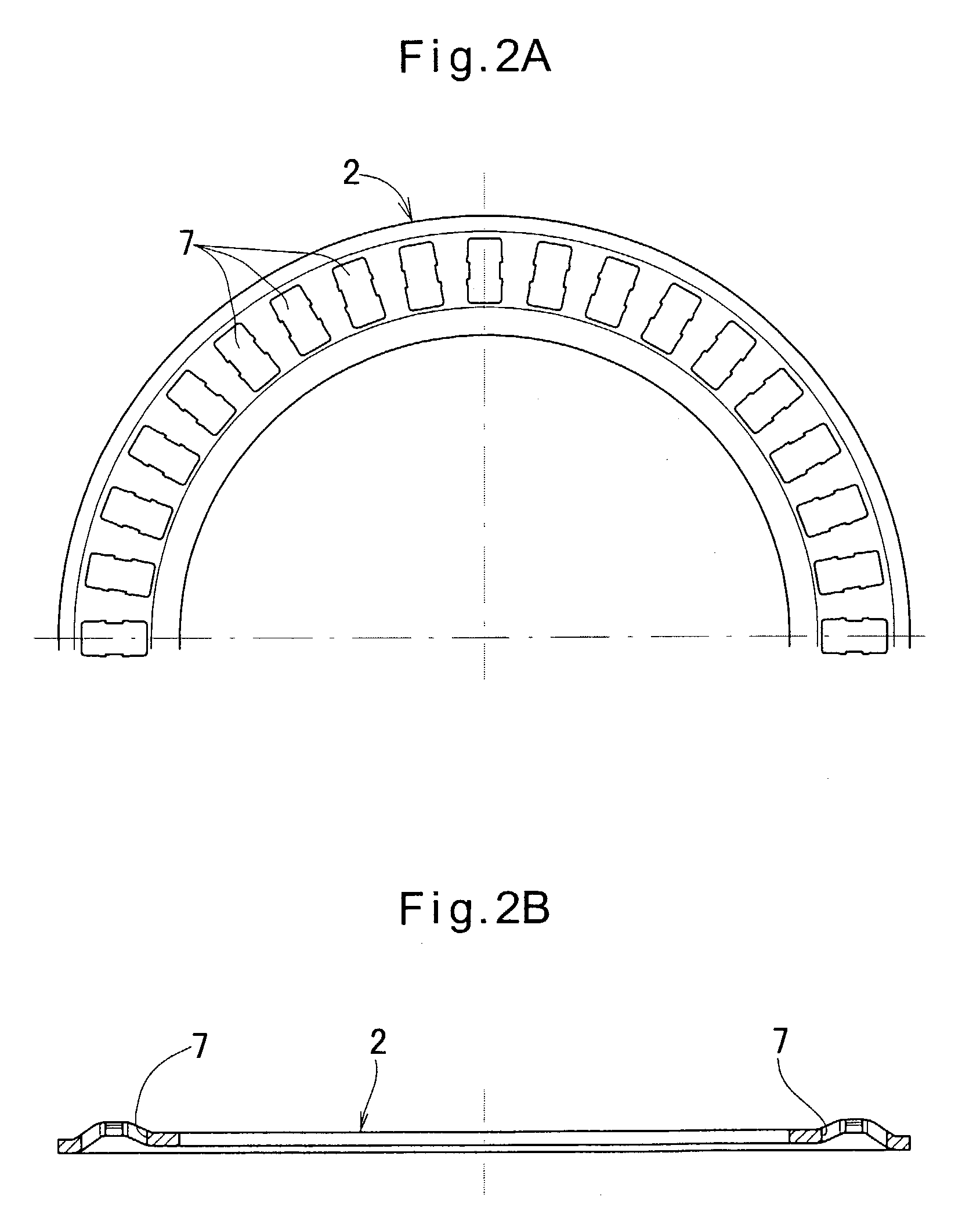

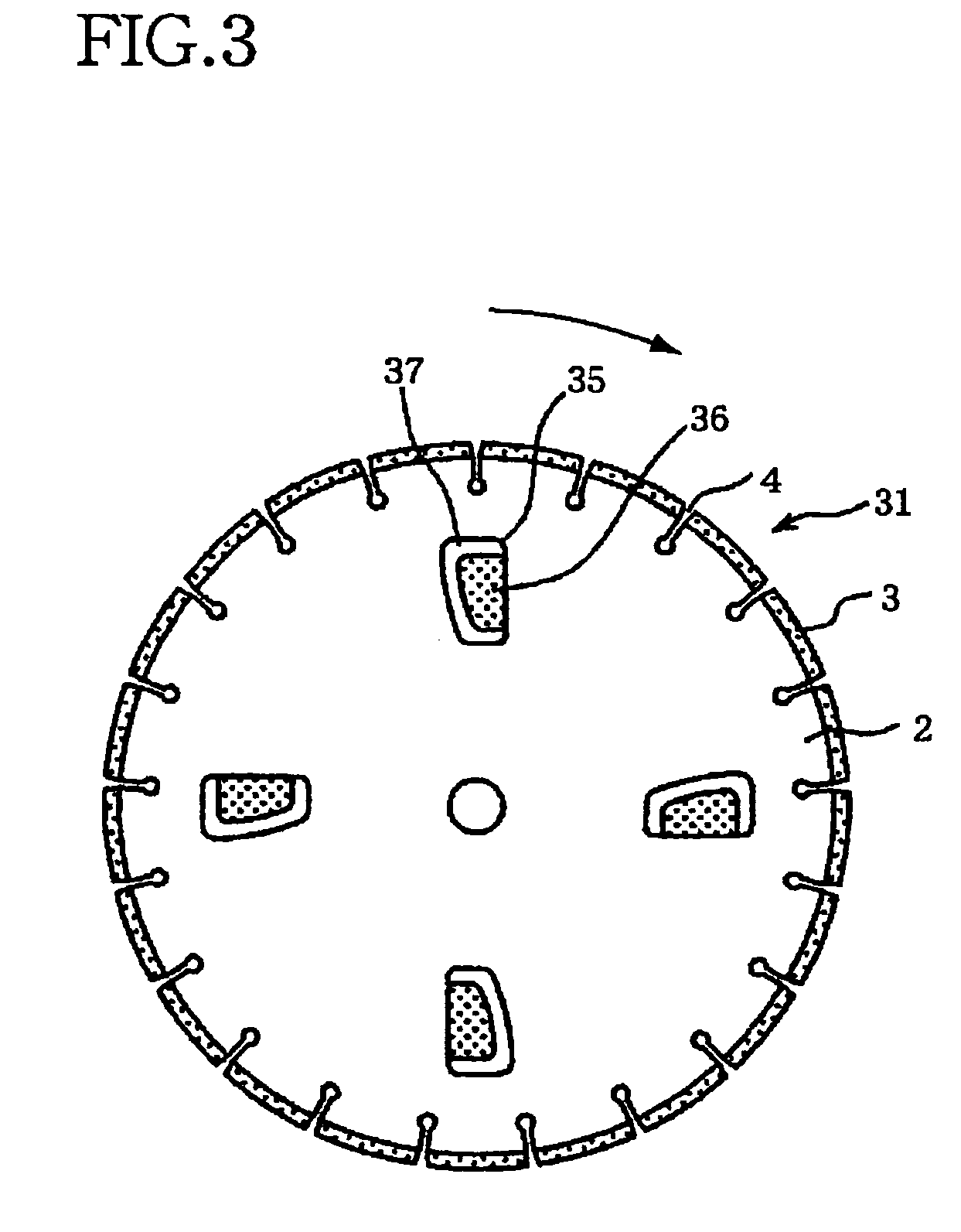

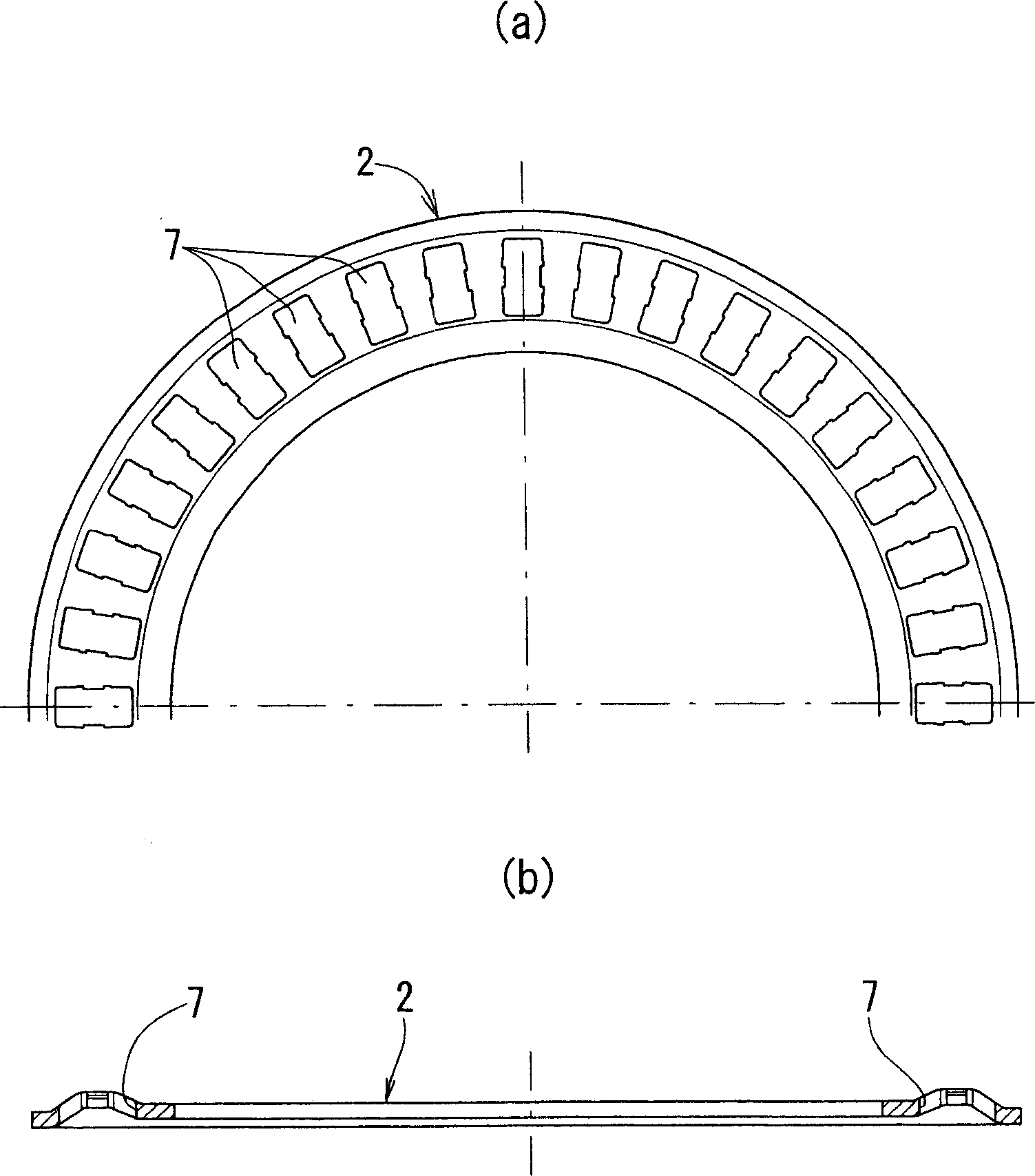

Rotary cutting saw with improved heat dissipation performance

ActiveUS20050224063A1Avoid burnsImprove performanceRevolution surface grinding machinesMetal sawing toolsEngineeringMechanical engineering

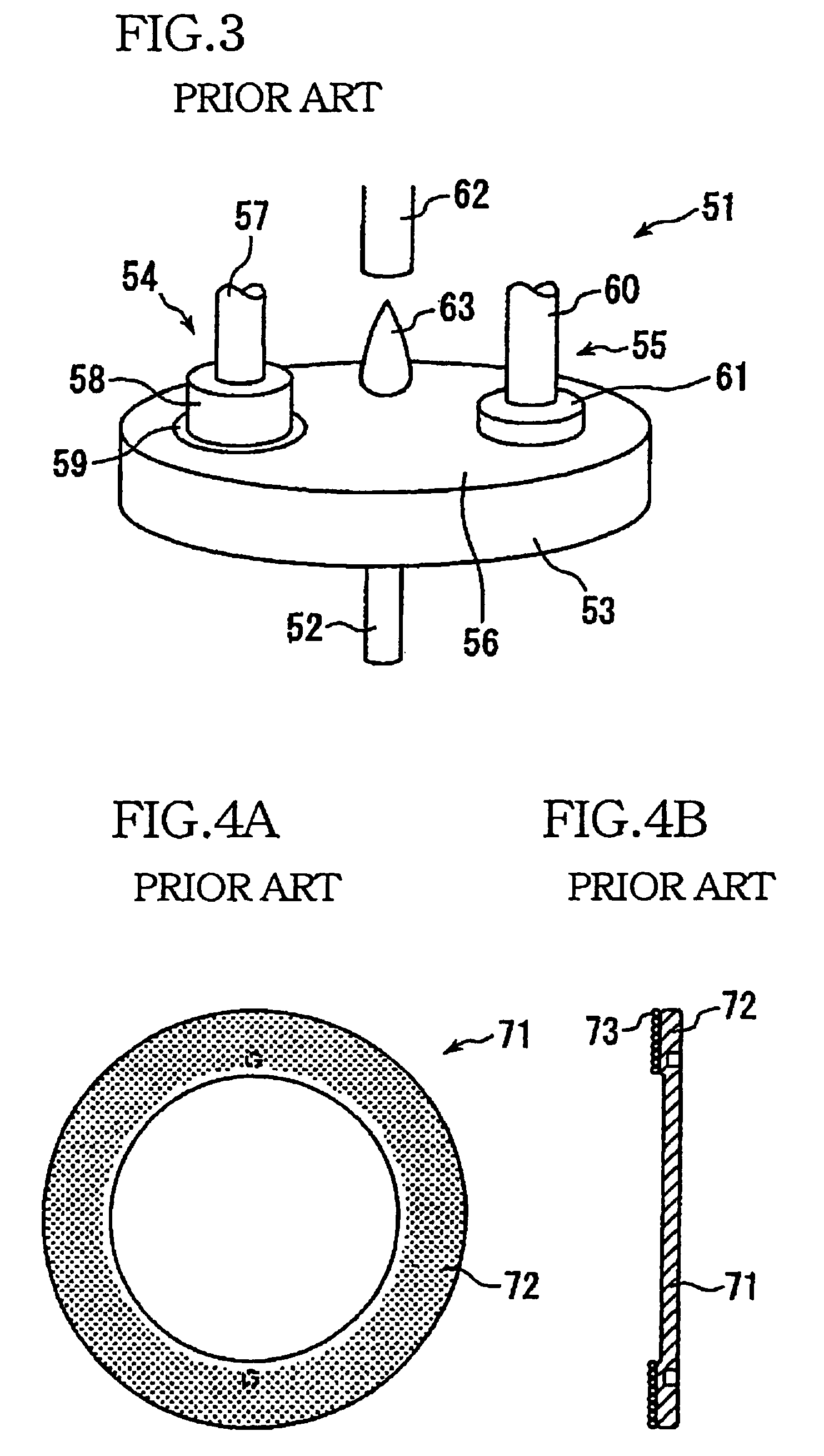

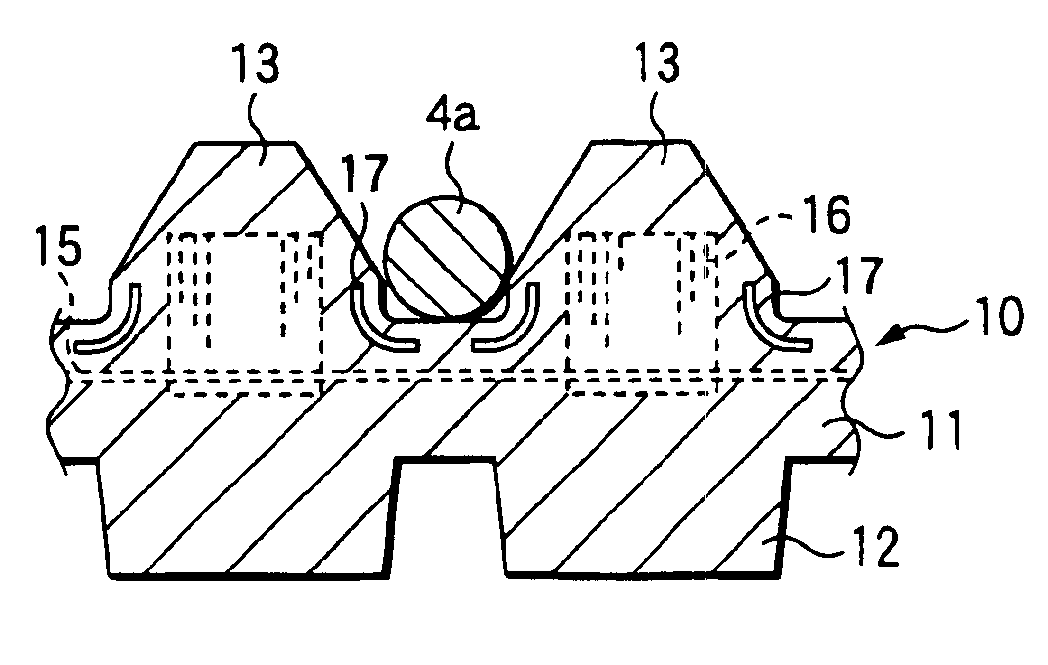

A rotary cutting saw including: (a) a base disk which has a plurality of apertures formed therethrough and opening in axially opposite end surfaces thereof; (b) a plurality of abrasive segments which are fixed to an outer circumferential surface of the base disk; and (c) a plurality of axial-runout restraining members which are received in the apertures. Each of the axial-runout restraining members has a size which is smaller than a size of each of the apertures, such that a clearance is defined between the periphery of each of the apertures and a corresponding one of the axial-runout restraining members which is received in the each of the apertures. A ratio of a size of the clearance to the size of each of the axial-runout restraining members is 5-150%.

Owner:NORITAKE SUPER ABRASIVE CO LTD +1

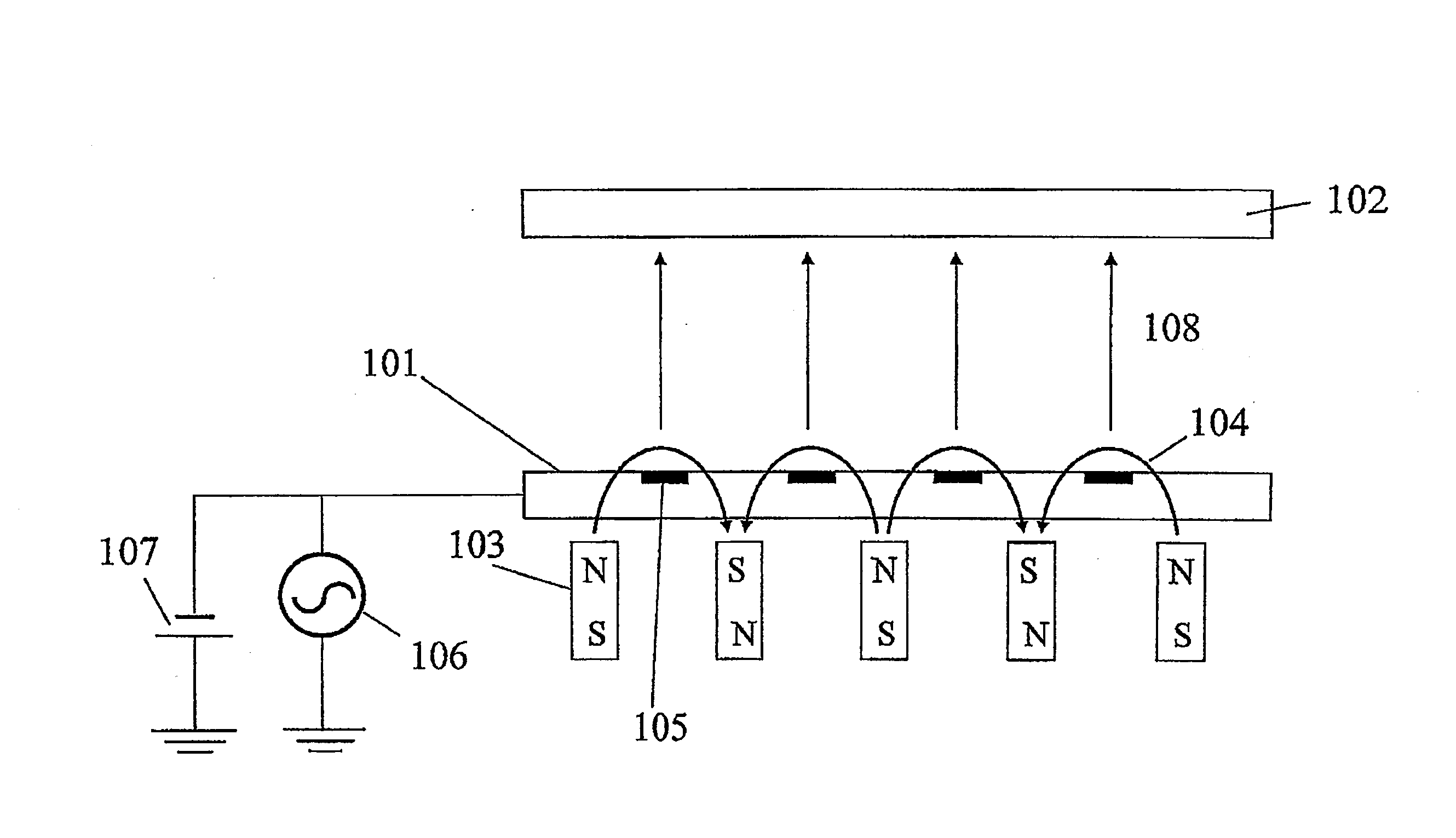

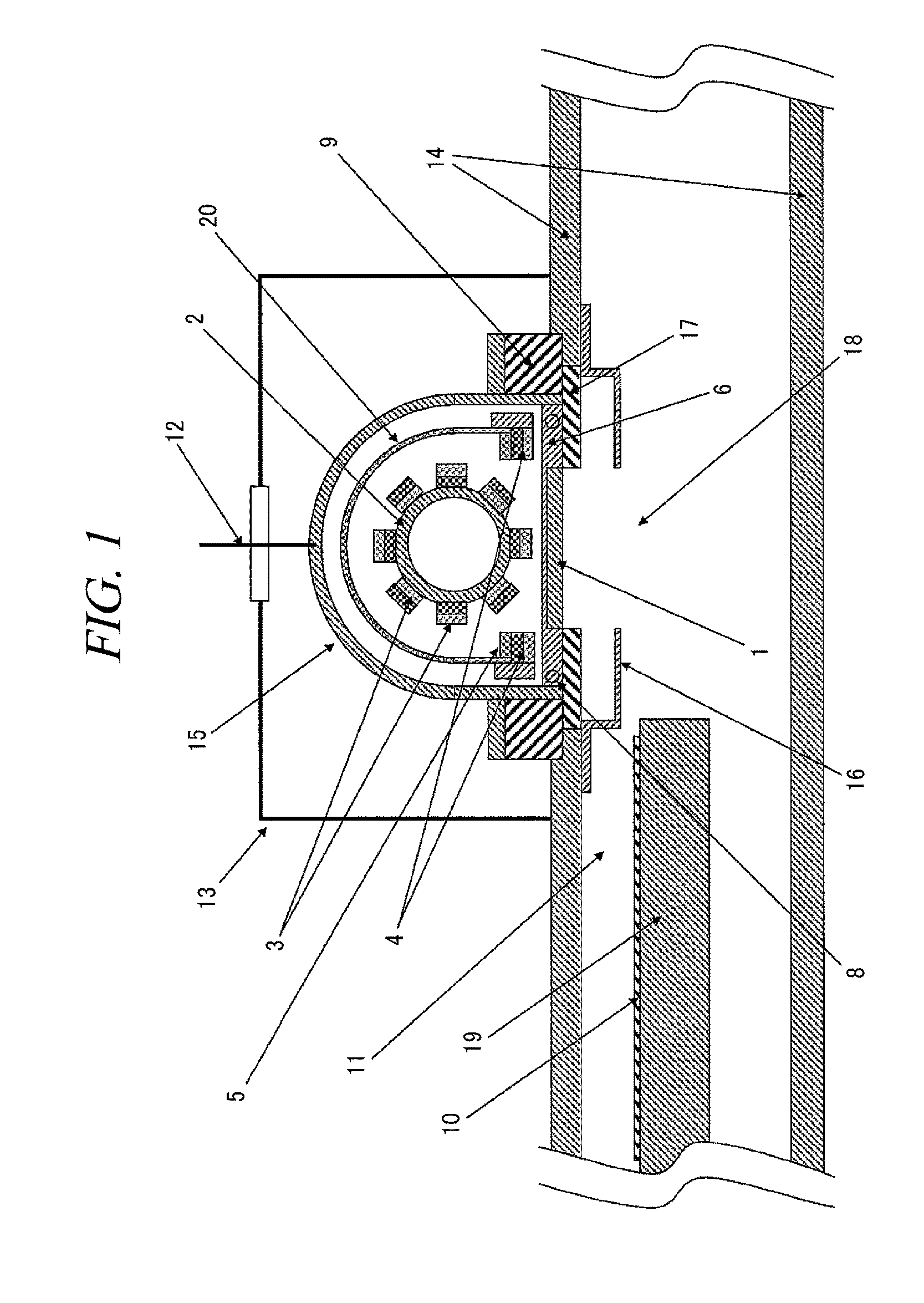

Rotary magnet sputtering apparatus

InactiveUS20100126852A1Improve utilization efficiencyProlong lifeCellsElectric discharge tubesTarget surfaceSputtering

In a rotary magnet sputtering apparatus, a target consumption displacement quantity is measured, and corresponding to the measurement results, a distance between a rotating magnet group and a target is adjusted, and uniform film forming rate is achieved over a long period of time so as to reduce the change of a target surface due to consumption of the target and to reduce the change of the film forming rate with time. An ultrasonic sensor or a laser transmitting / receiving device may be used as a means for measuring the consumption displacement quantity of the target.

Owner:TOHOKU UNIV +1

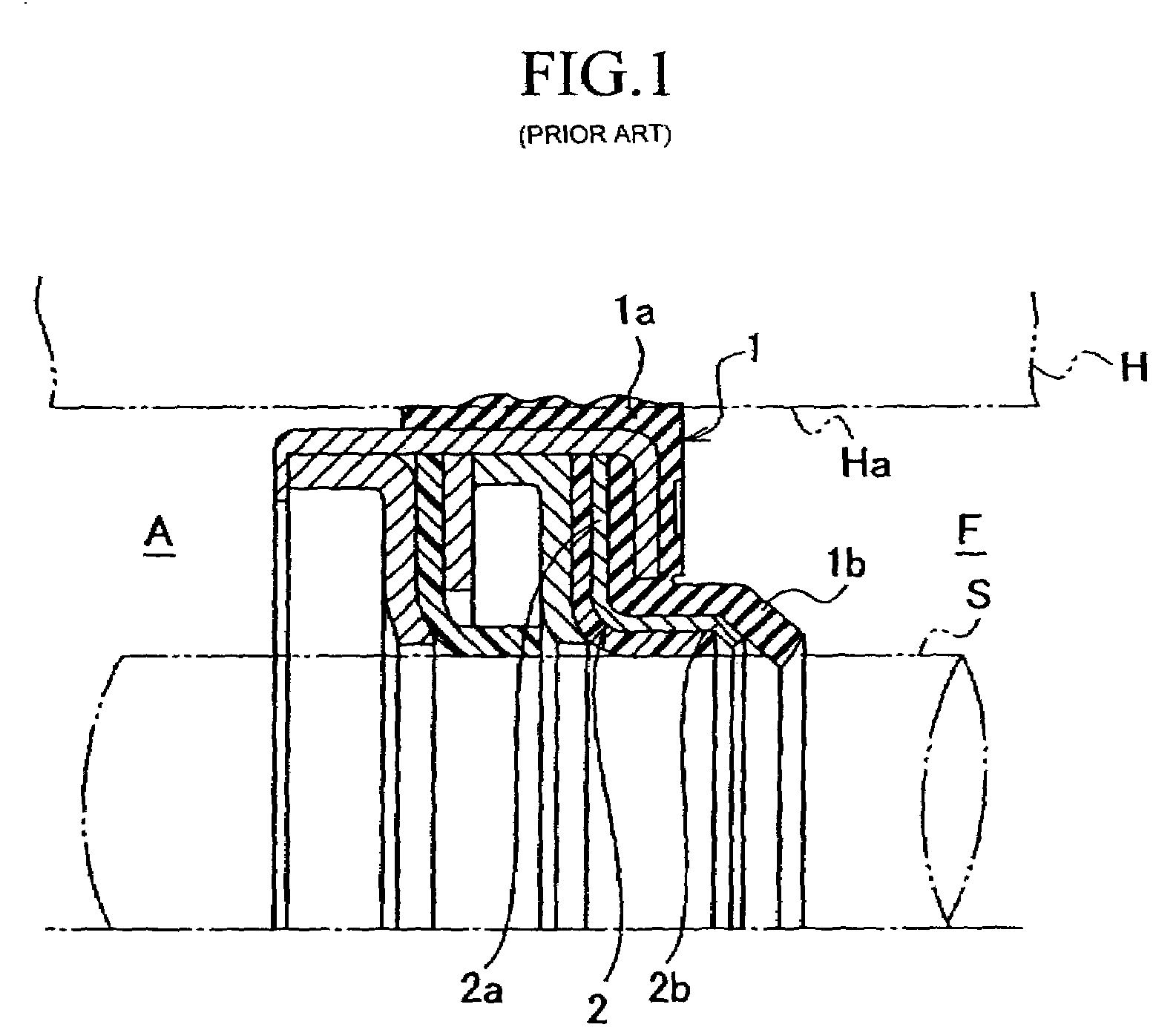

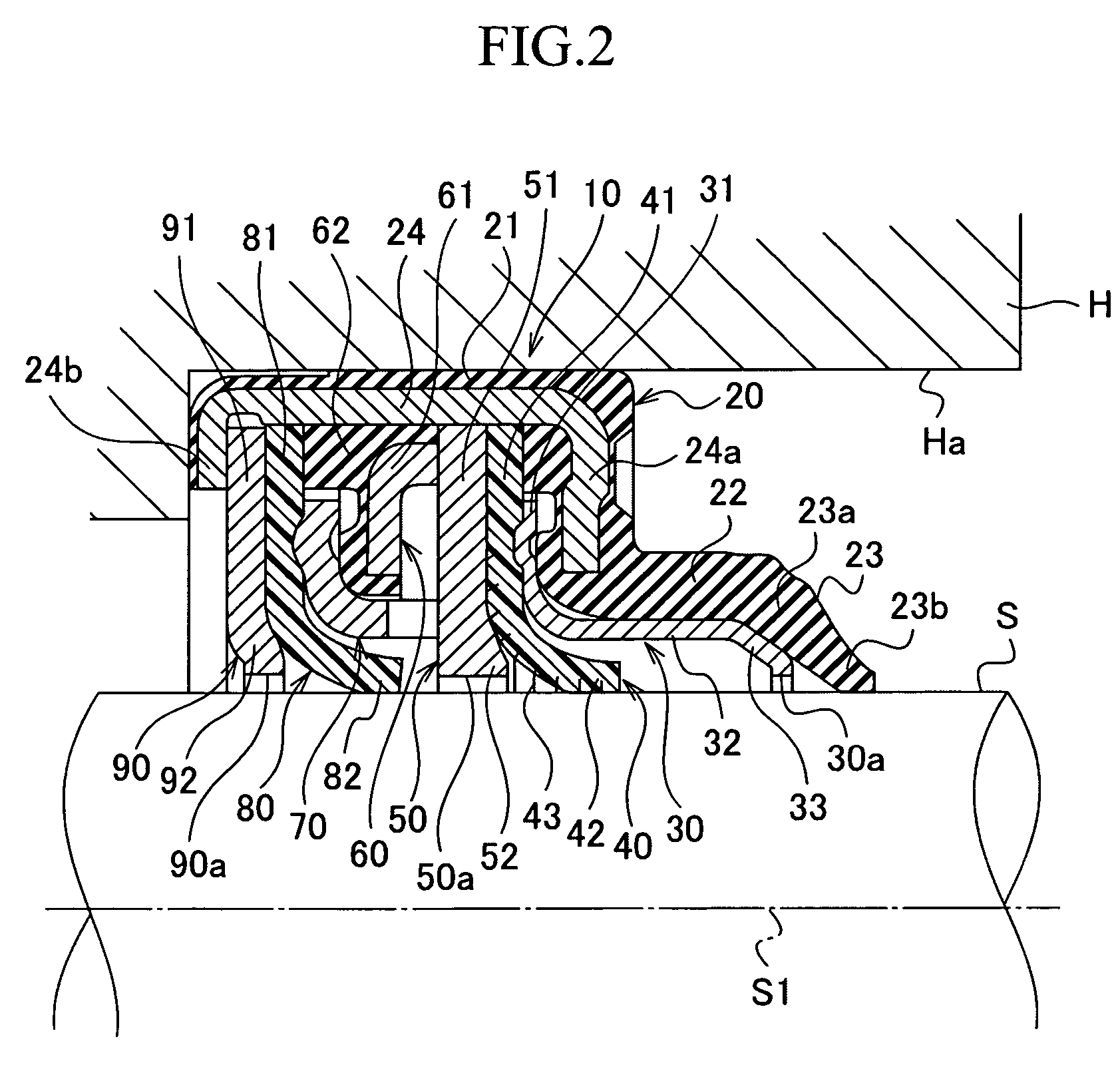

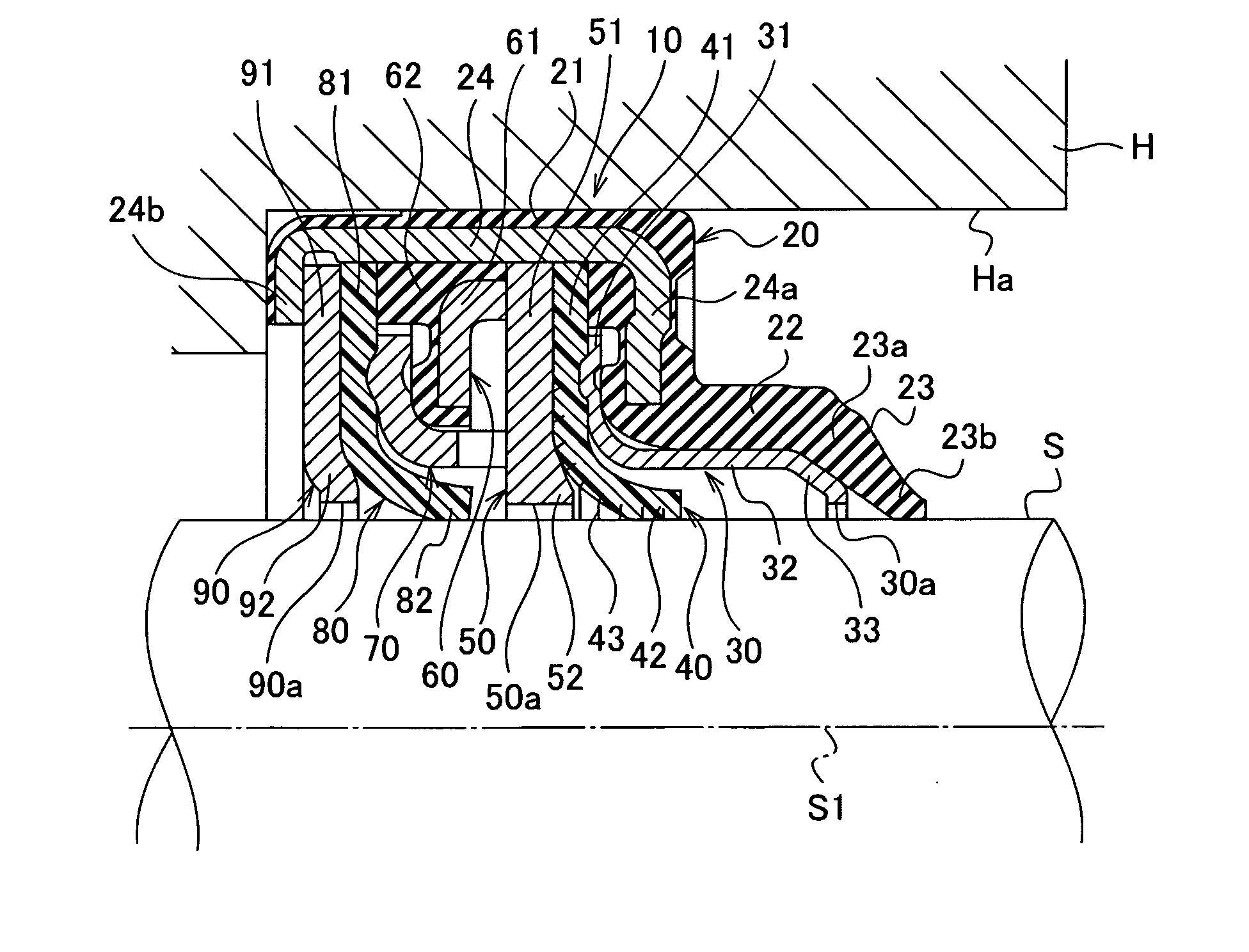

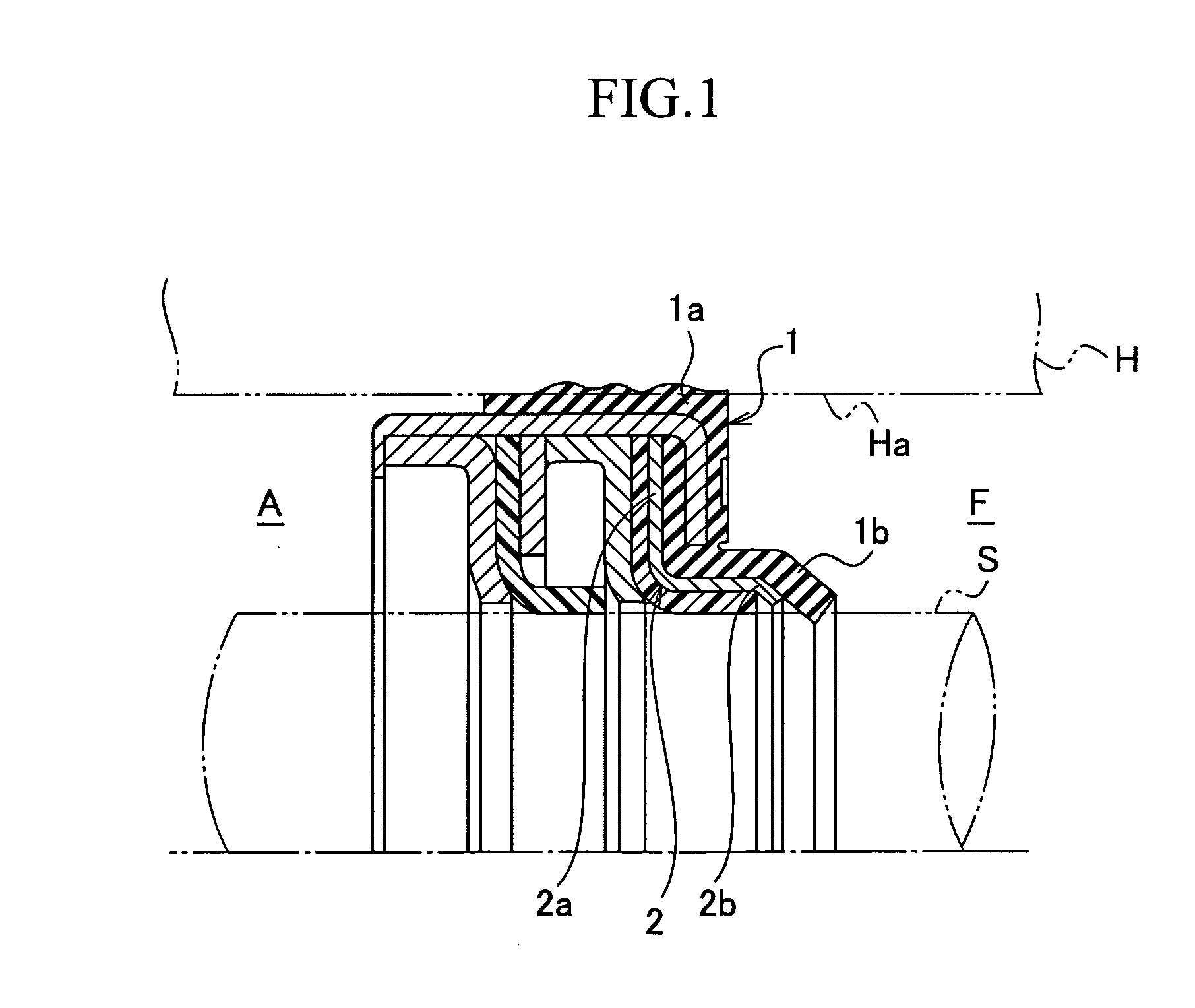

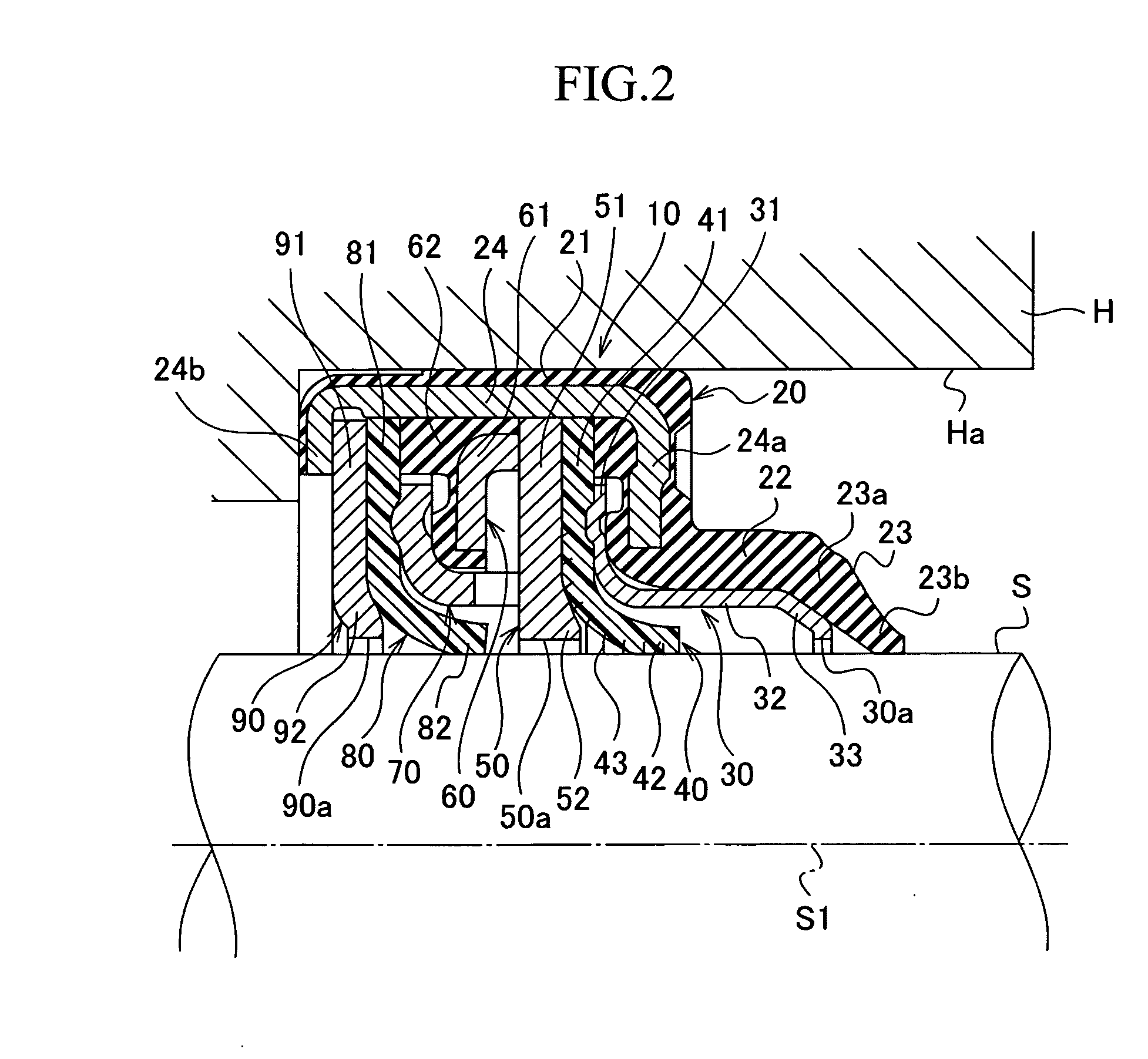

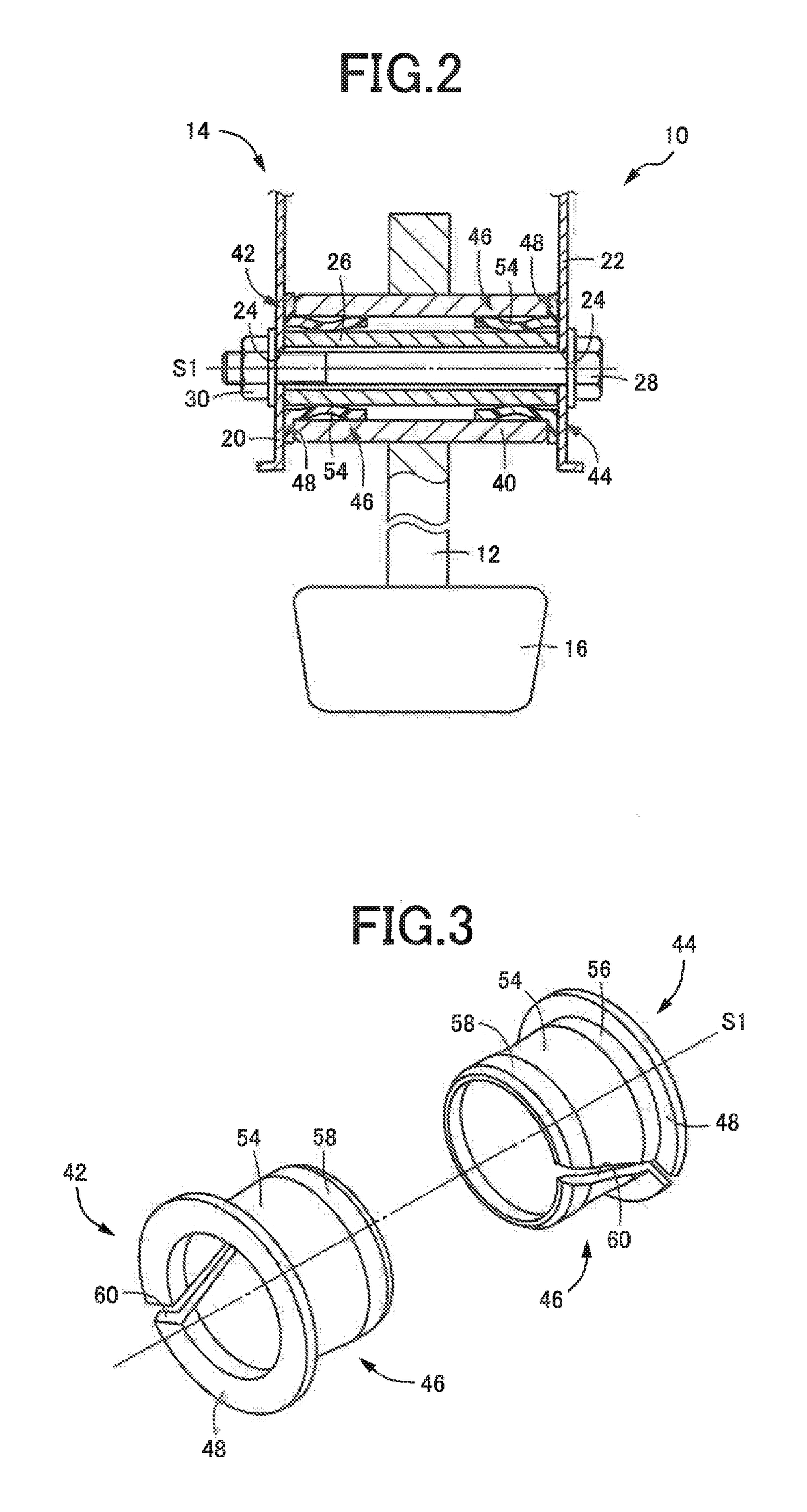

Lip-type seal

Owner:EAGLE INDS +1

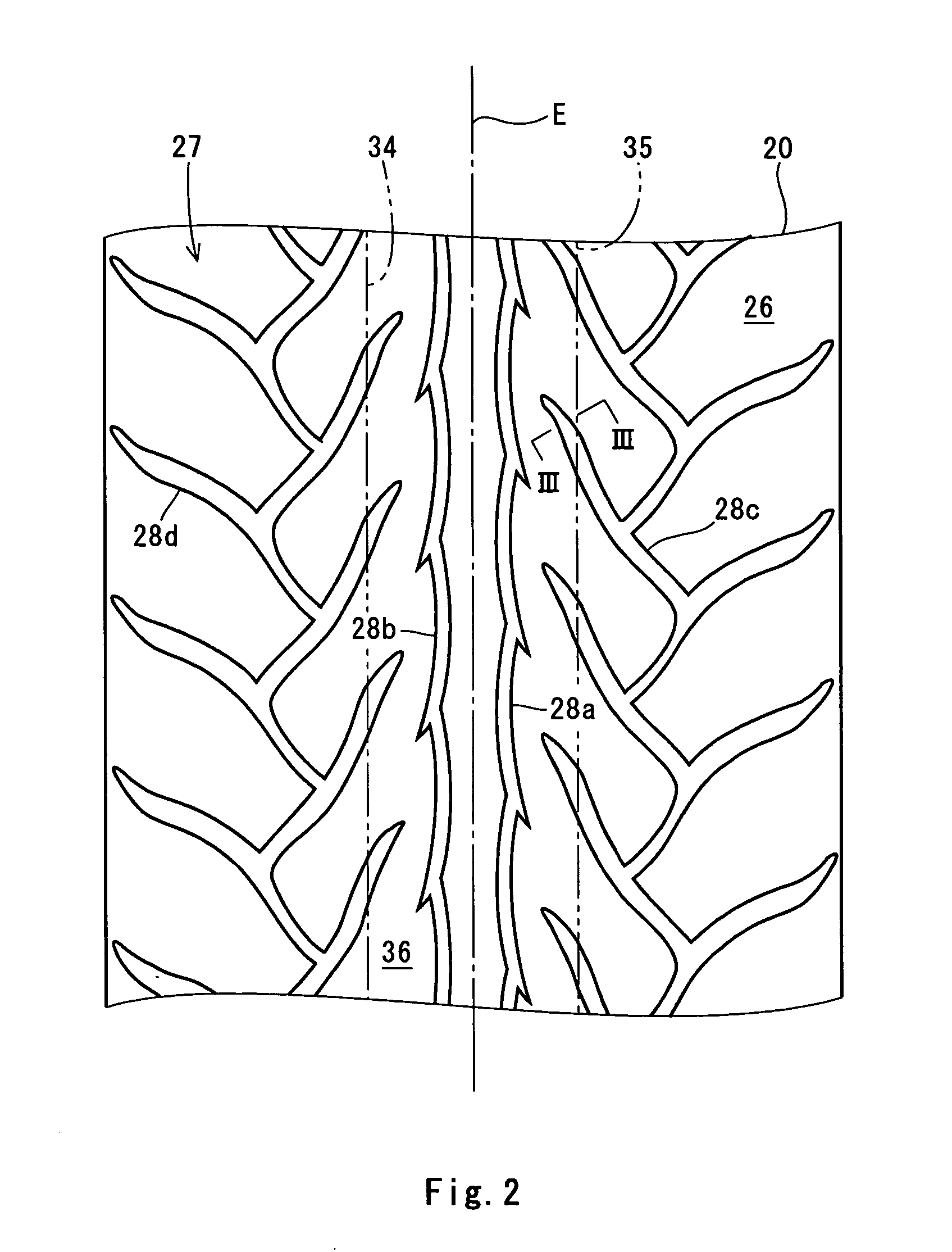

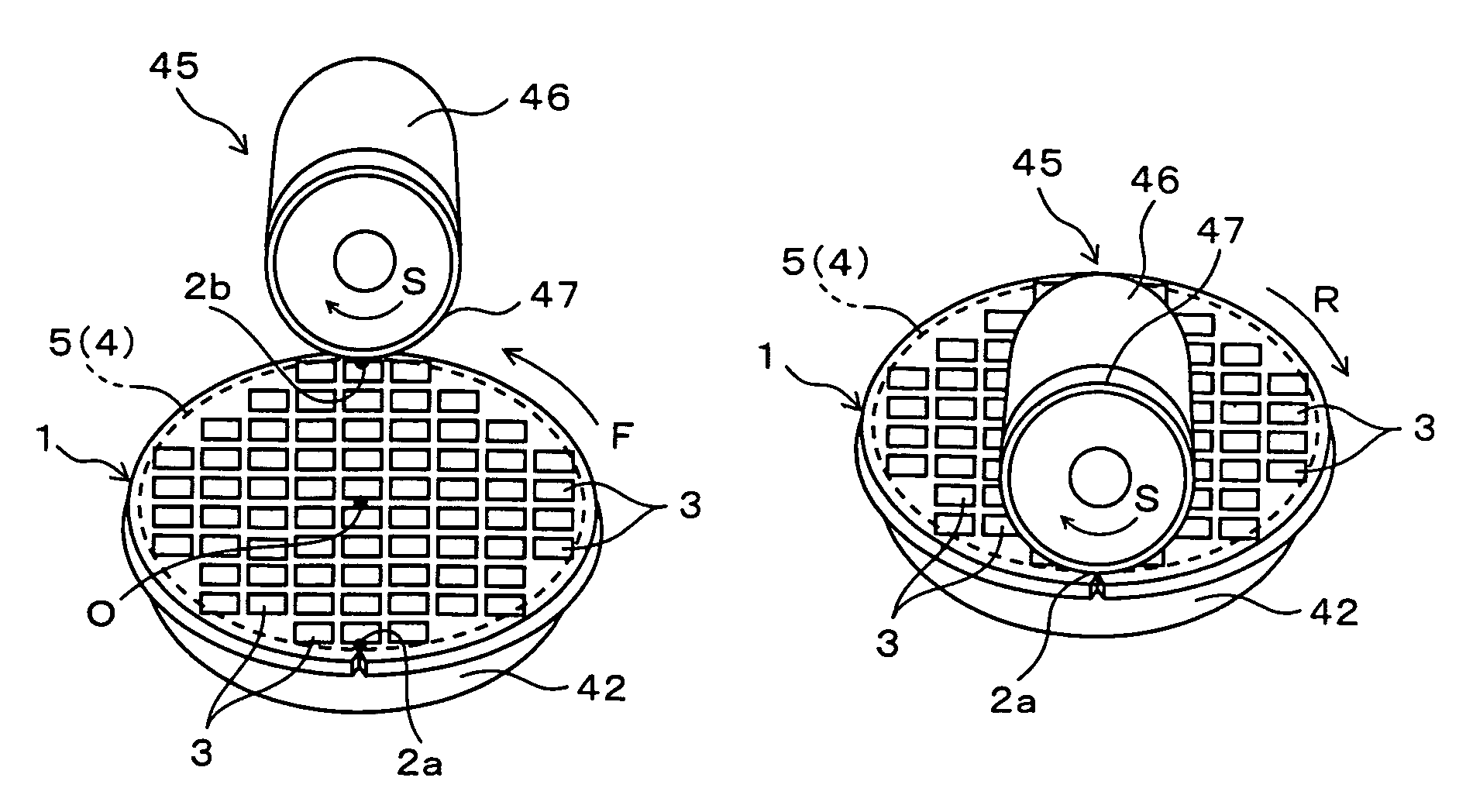

Tyre for motorcycle

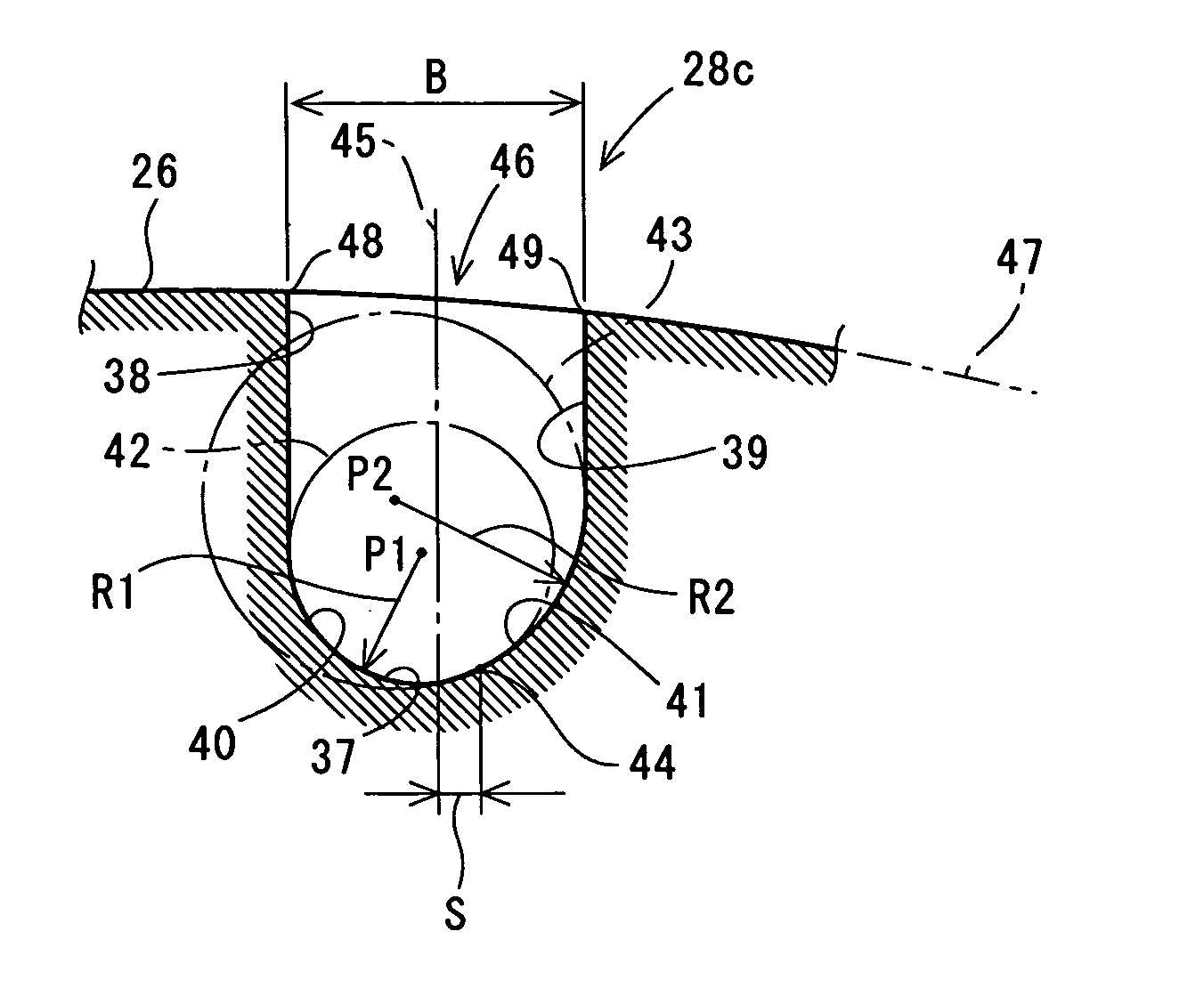

InactiveUS20050039835A1Avoid local wearMaintain performanceMotorcycle tyresTyre tread bands/patternsMotorcycle tyreEngineering

A radius of curvature (R1) of a corner portion (40) on one side (an inside in an axial direction) of a groove of a tyre (20) is smaller than a radius of curvature (R2) of the other corner portion (41). Both of the radii of curvature (R1) and (R2) are set to be 2 mm or more. A first phantom circle (42) for defining the corner portion (40) is inscribed on a second phantom circle (43) for defining the corner portion (41). A point of contact (44) of the first phantom circle (42) and the second phantom circle (43) is positioned on an outside from the center of a groove (28c). A distance between the center of the groove (28c) and the point of contact (44) is equal to or smaller than one fifth of a width (B) of the groove (28c).

Owner:SUMITOMO RUBBER IND LTD

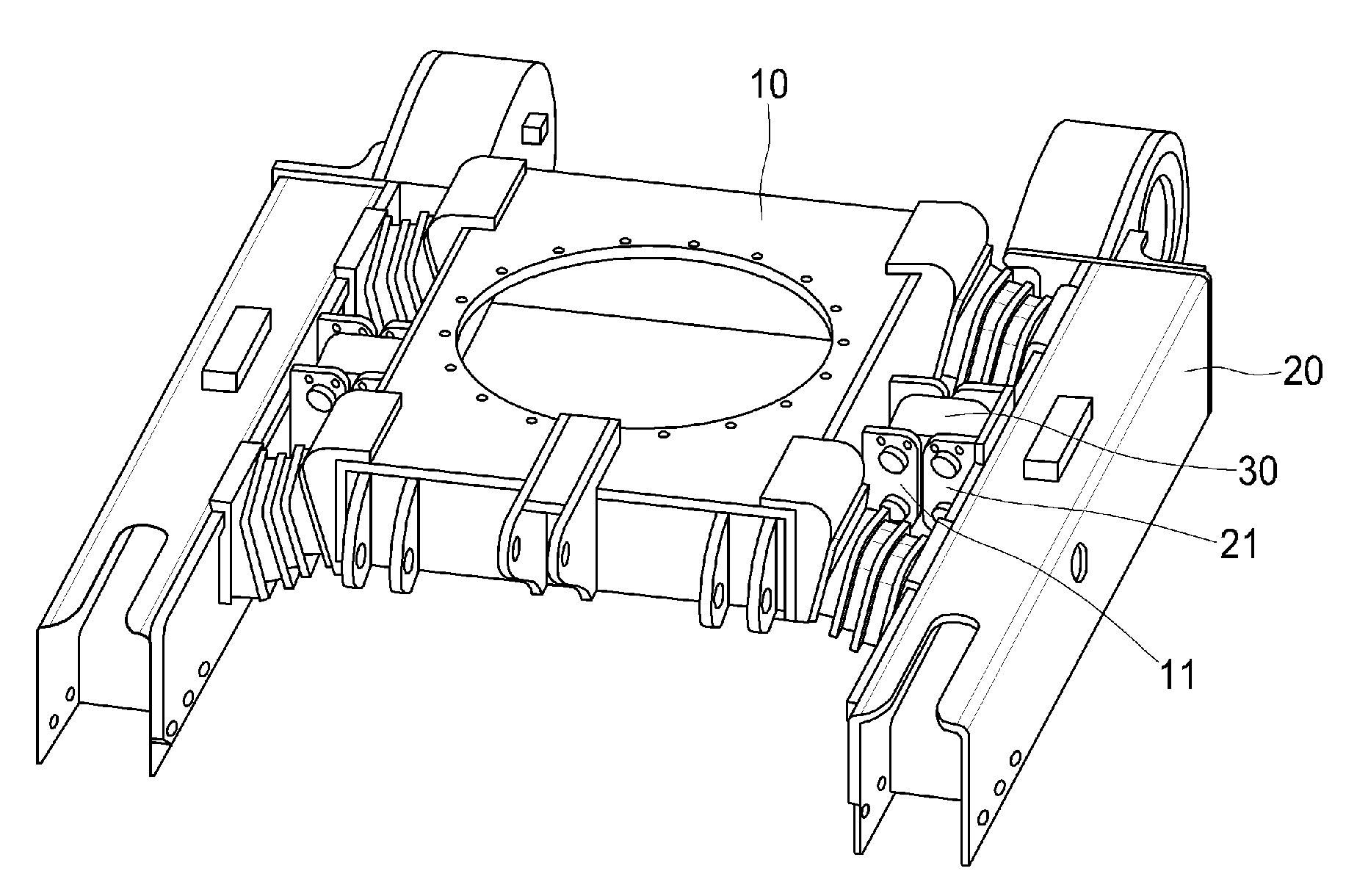

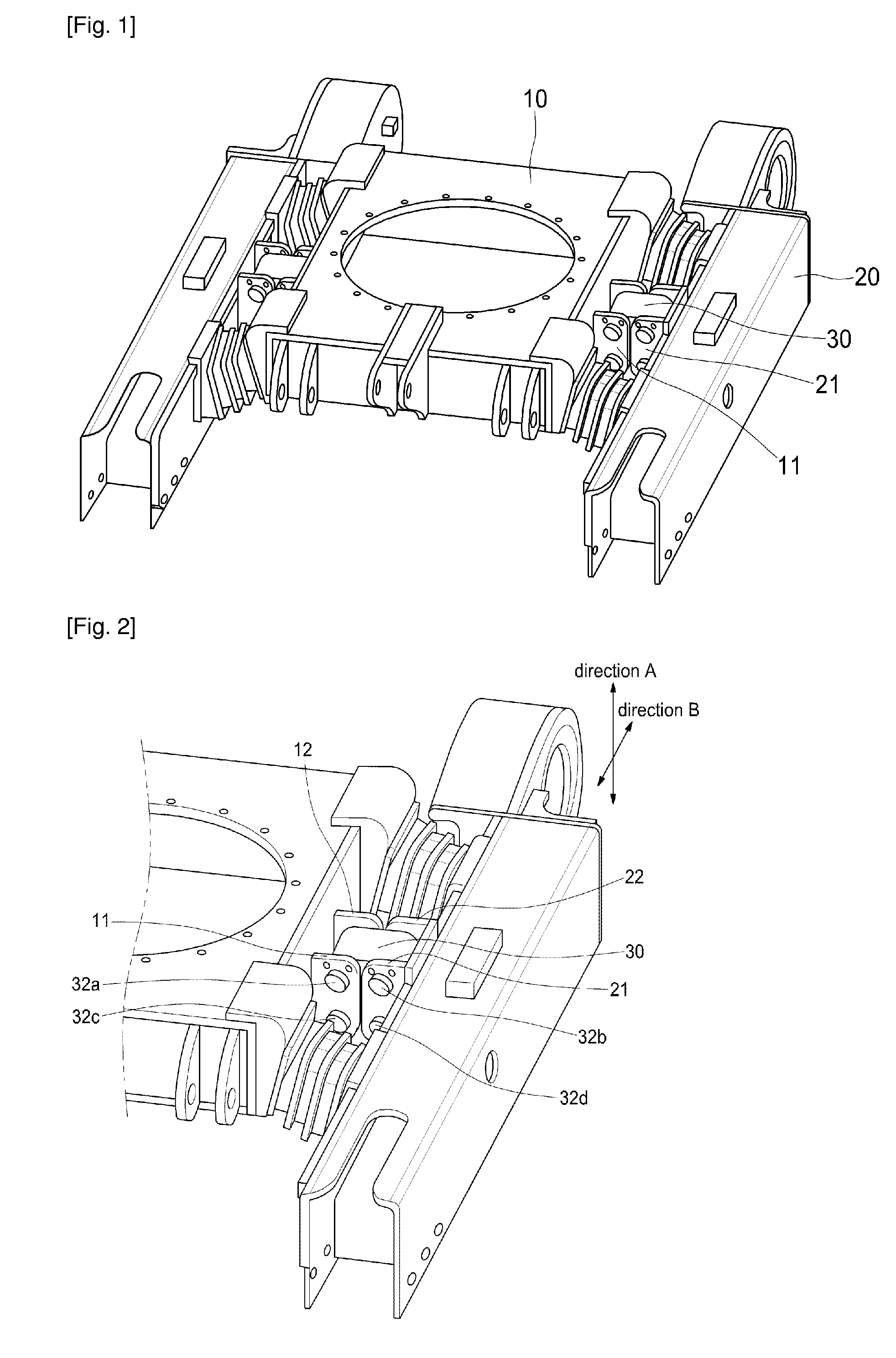

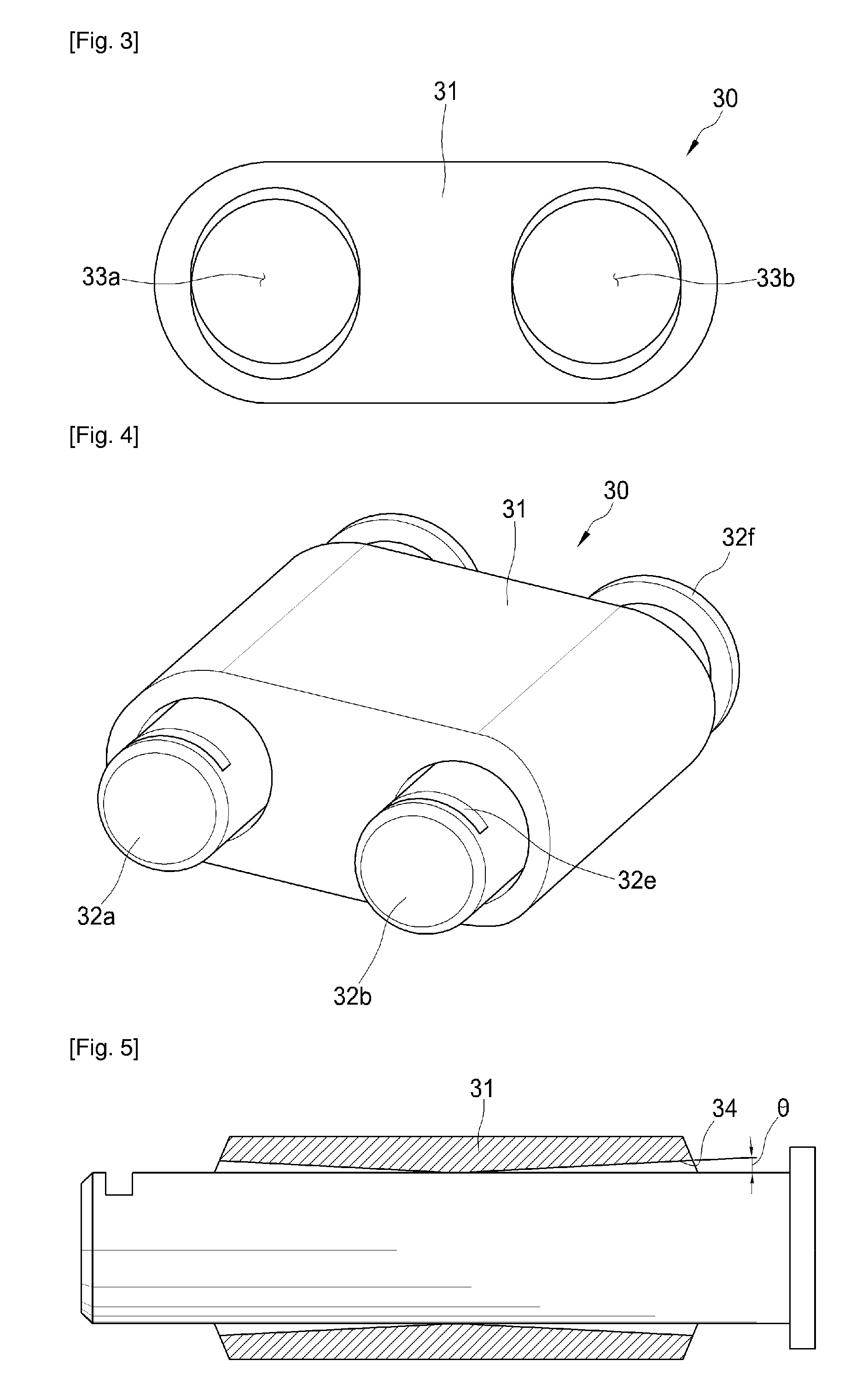

Multi-Link Bridge In Undercarriage System

InactiveUS20110036649A1Avoid local wearPreventing inclinationSemiconductor/solid-state device manufacturingSoil-shifting machines/dredgersMulti linkEngineering

The present invention employs a multi-link to an excavator for the first, and restricts a relative movement of the center frame (10) and the roller frame (20) using a multi-link bridge (30) in relation to an undercarriage system of vehicle body structures of the excavator. According to the present invention, in an undercarriage system in which the center frame 10 and the roller frame 20 are independently from each other, a plurality of links is added to rotate up and down by a predetermined angle in a vertical direction and a longitudinal direction of the roller frame (20) and thus the overturning can be prevented and also operator's feeling of riding can be enhanced by preventing an inclination of the center frame (10) due to condition of an uneven road surface, and a service life of the track can be increased as the partial wear is prevented.

Owner:DONG IL RUBBER BELT CO LTD

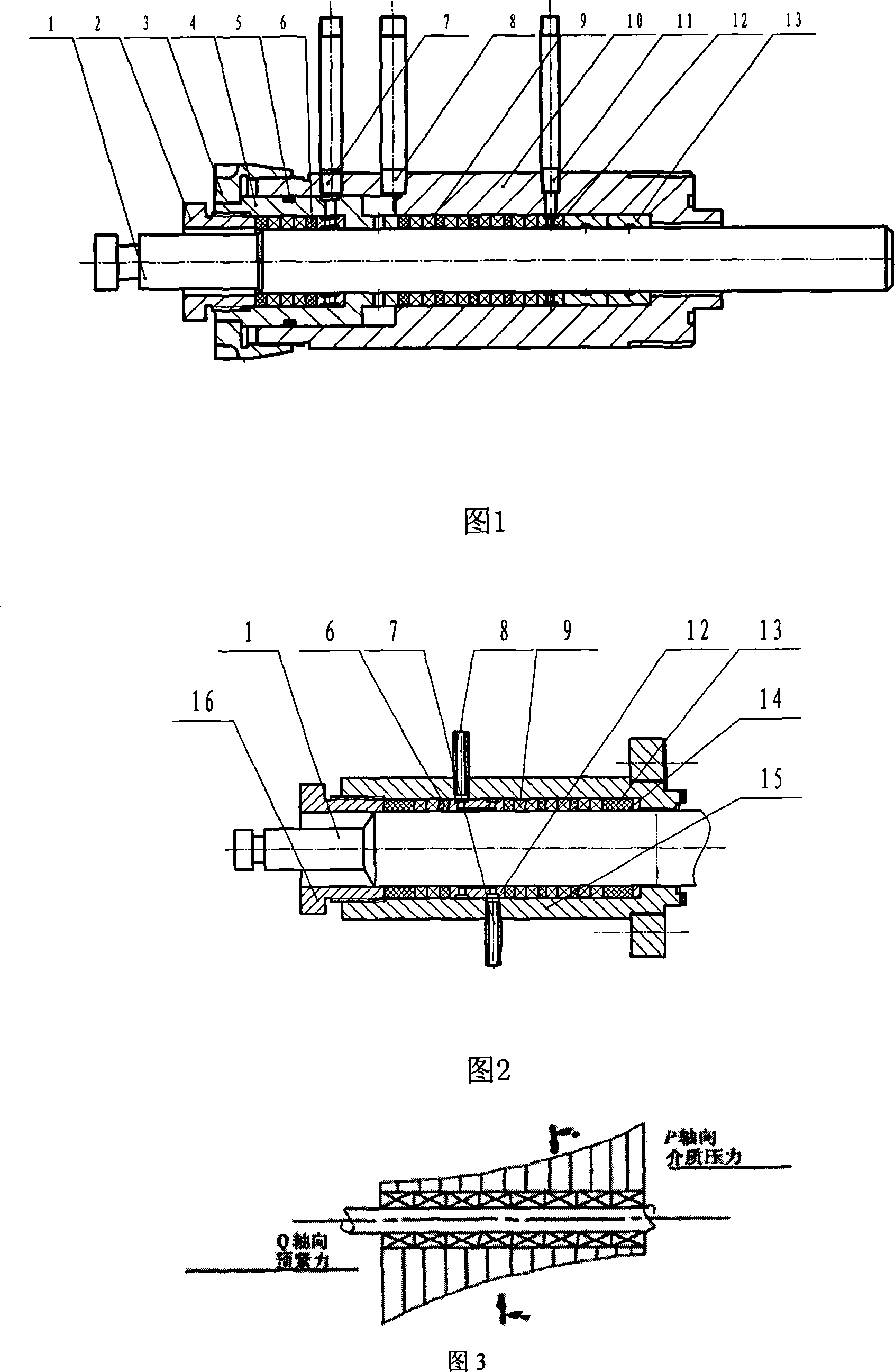

High-pressure-resistant wear-resisting contact type reciprocation sealing with washing ring

InactiveCN101070841AAvoid solid friction and wearExtended service lifePositive displacement pump componentsLiquid fuel engine componentsReciprocating pumpEngineering

A high pressure resistance and anti-abresive reciprocating seal with flushing ring relates to the lunger pistom of reciprocating pump and packing seal, it is characterized in that two set of packing seal combines with a set of muff clearance seal, namely two guide sleeve closing side of cylinder combines with a flushing ring and main packing seal with subsidiary packing seal closing air. The gland of main packing seal is a seal box of subsidiaty one. Injecting flushing lubricating oil into between main and subsidiary packing seal, the front-end of main packing seal has a flushing ring, which adopting synchronized hydraulic oil to be as flush fluid of packing box, the effect of flush fuid is that flushing the particle medium between lunger pistom and main packing seal, at the same tine between filling and lunger pistom formed a fluid film to avoid directing friction between filling and lunger pistom,and takes away heat caused by friction, which can prolong the life of seal. The invention is applicable to all conveyors solid particles media reciprocating pump.

Owner:JIANGSU UNIV

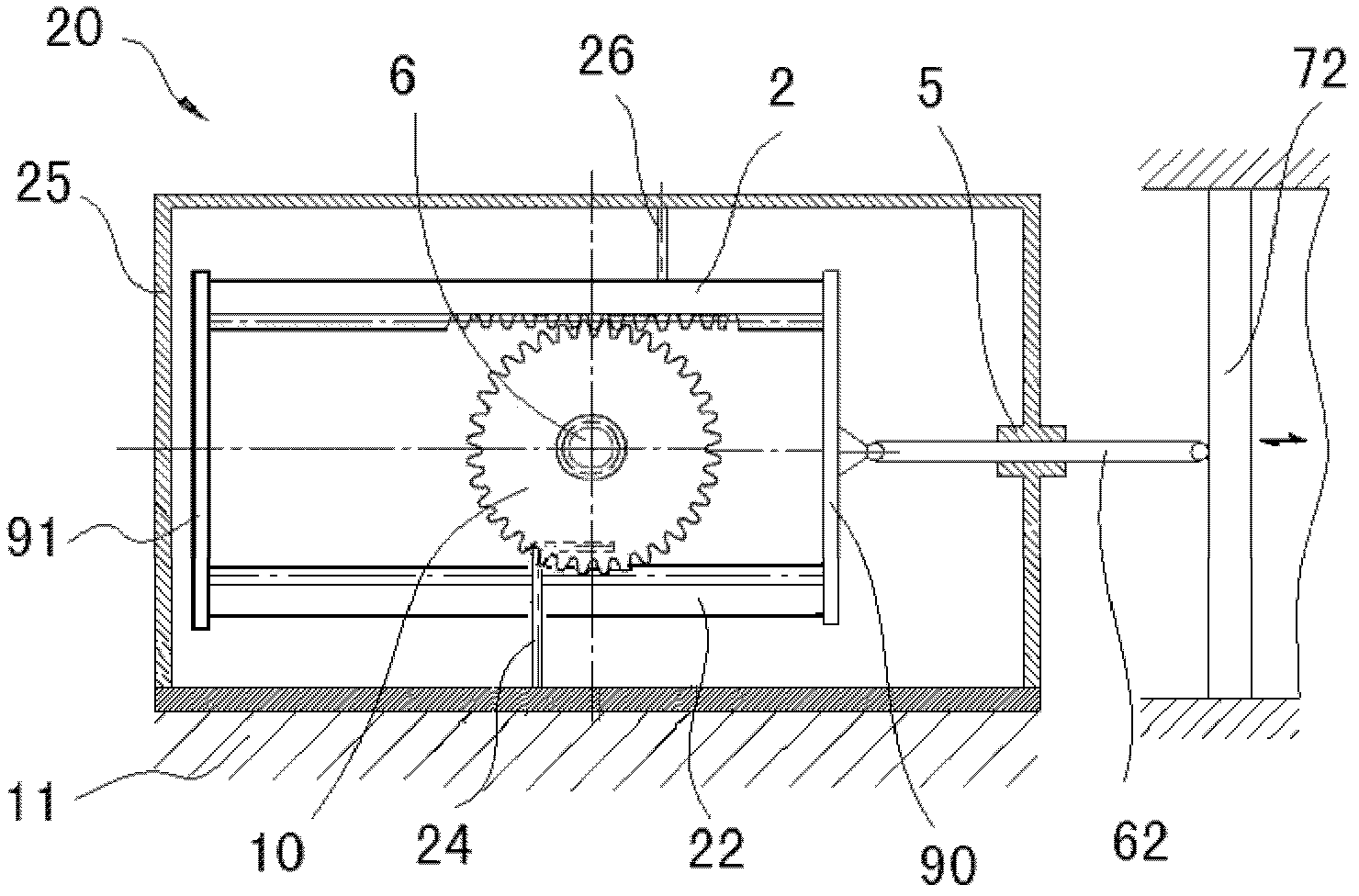

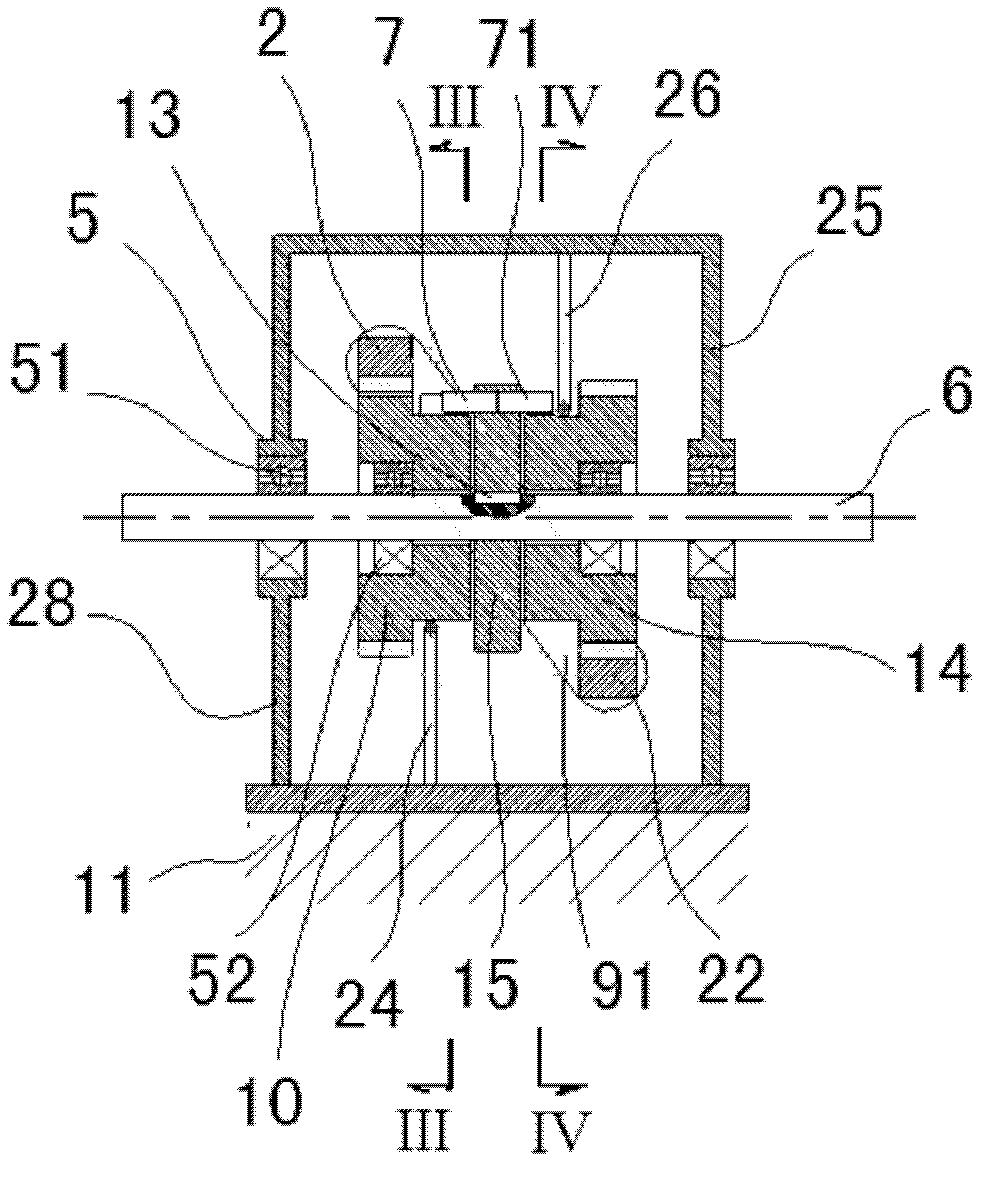

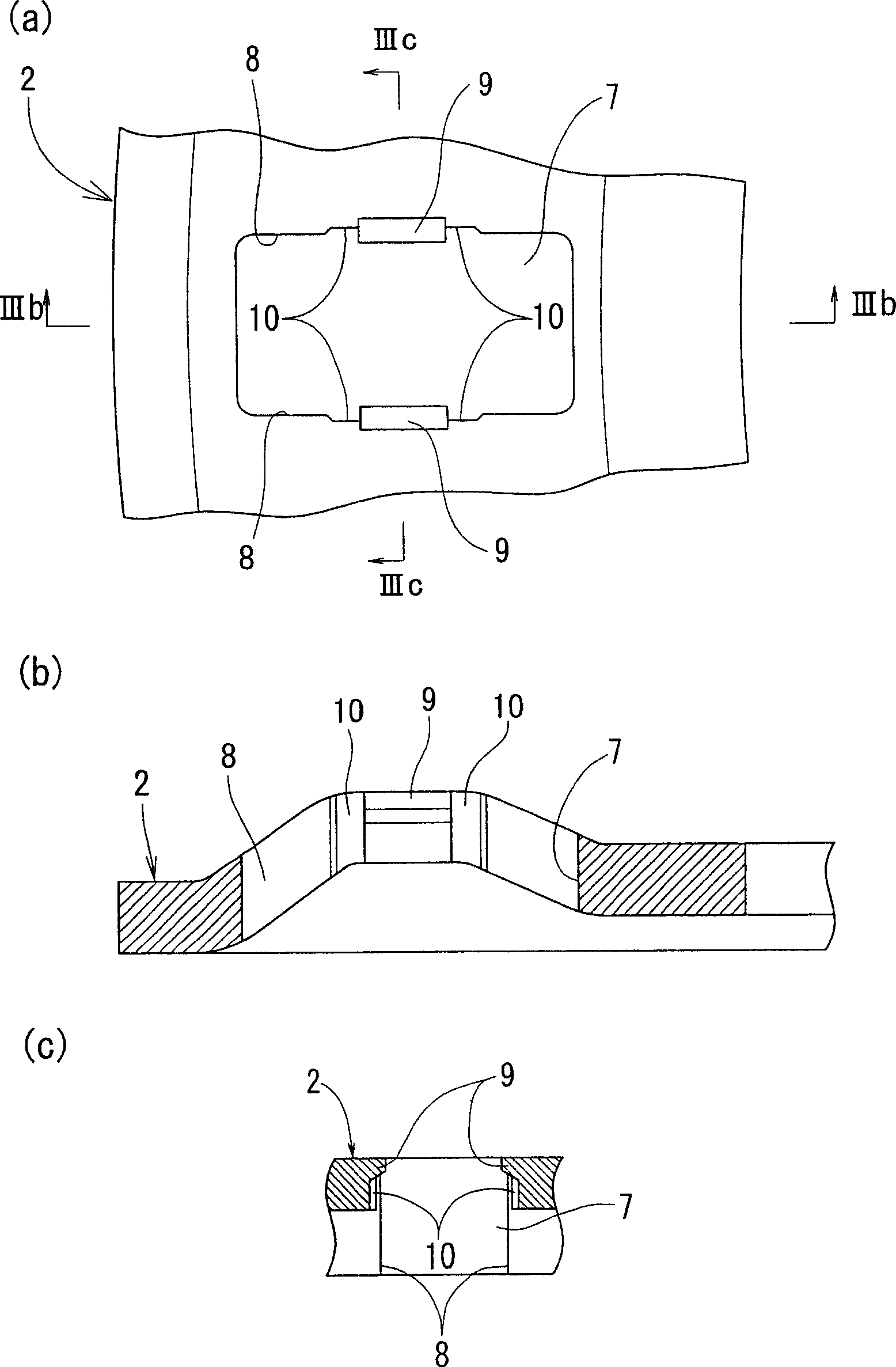

Rotary motion and reciprocating motion converting device

InactiveCN102207179AReasonable power transmission and movement mode conversionIncrease tangential forceFriction gearingsPistonReciprocating motion

The invention relates to a rotary motion and reciprocating motion converting device (20) which comprises pistons (72, 74, 76, 78), wherein one end of each piston rods (62, 64) is connected with the pistons (72, 74, 76, 78); a shell (25) is installed on a base seat (11); a side wall (28) of the shell (25) is provided with a bearing seat (5); a transmission shaft (6) is installed in the bearing seat (5); the transmission shaft (6) is provided with transmission wheels (15, 17); the edge parts of the transmission wheels (15, 17) are provided with column pins (7, 71) extending out axially; a first gear (10) and a second gear (14) which can rotate relative to the transmission shaft (6) are installed close to the transmission wheels (15, 17); the first gear (10) and a first rack (2) are meshed mutually; the second gear (14) and a second rack (22) are meshed mutually; the first rack (2) and the second rack (22) are respectively positioned at two sides of the transmission shaft (6); connecting plates (90, 91) are connected with the end parts of the first rack (2) and the second rack (22); the connecting plates (90,91) are connected with other ends of the piston rods (62, 64); tooth-free parts of the first gear (10) and the second gear (14) are respectively provided with pin grooves (9, 21); the pin grooves (9, 21) are internally provided with sliding blocks (32, 42) which are matched with the column pins (7, 71); and the restoration springs (12, 121) are arranged below the sliding blocks (32, 42). Thus the conversion between the rotary motion and the reciprocating motion is realized.

Owner:安里千

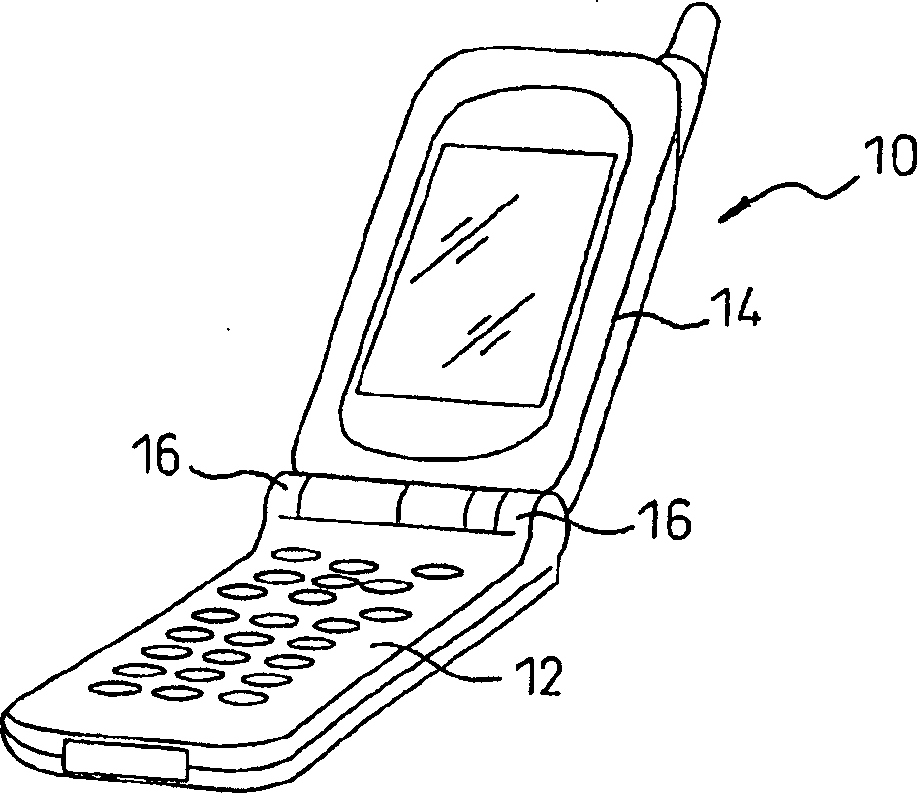

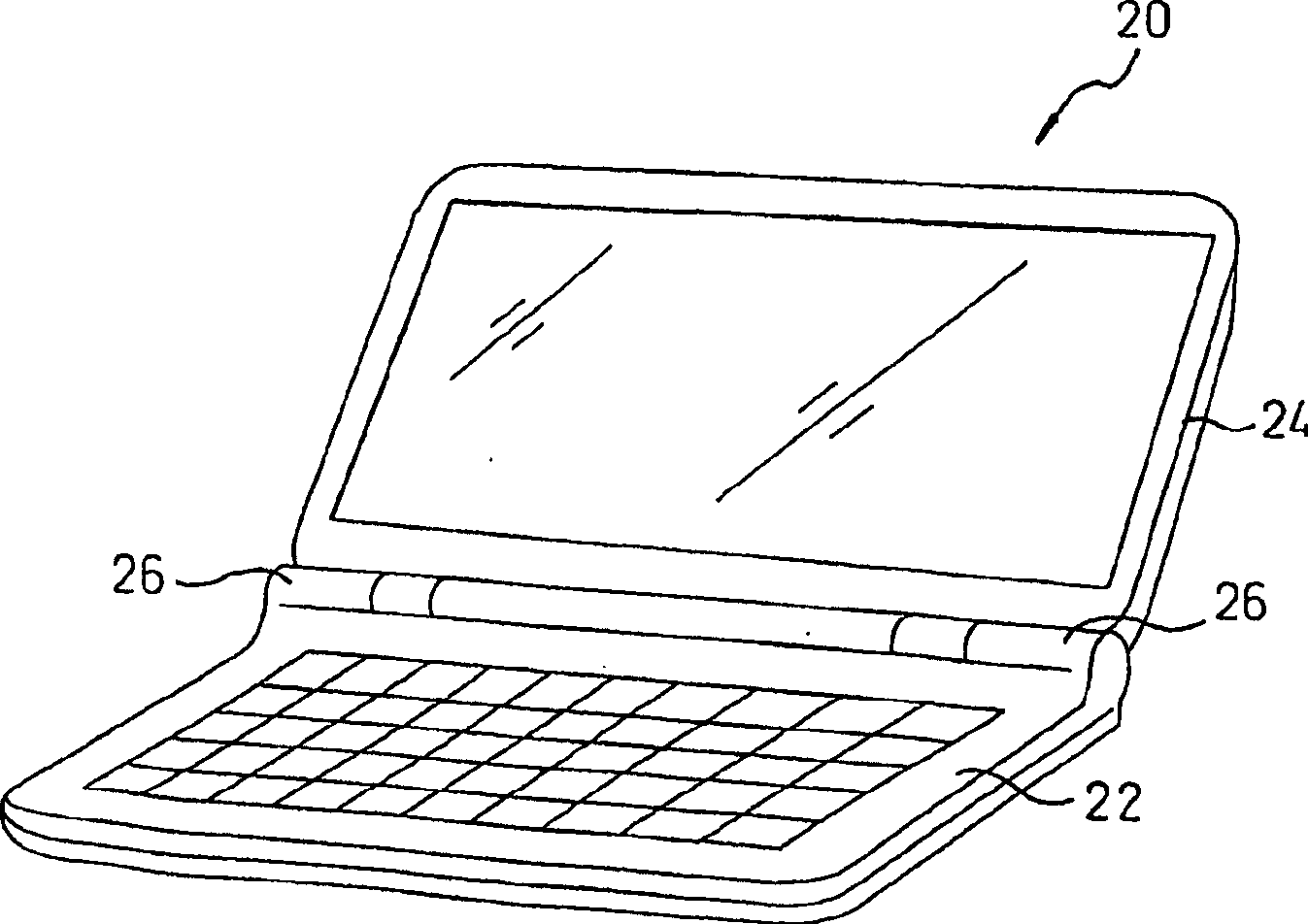

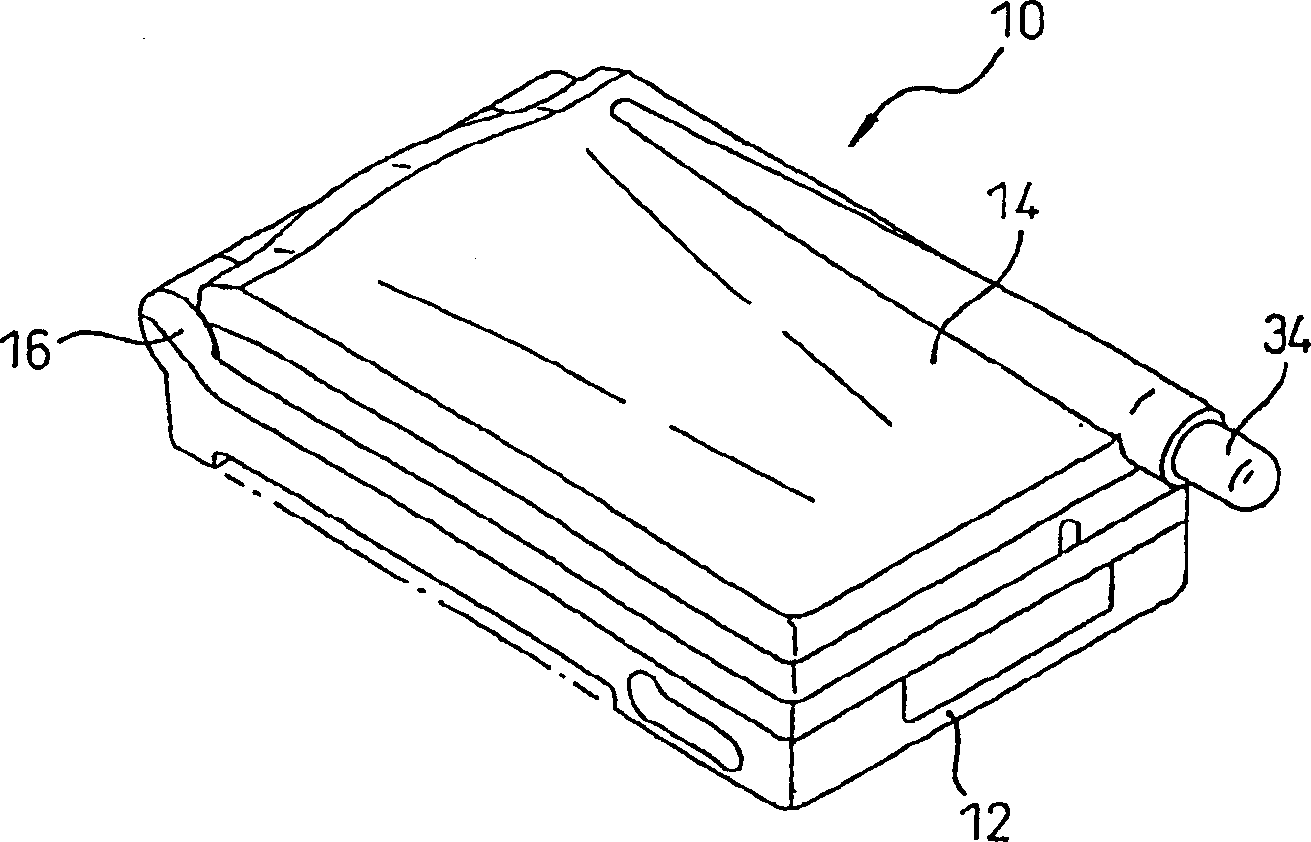

Portable apparatus

InactiveCN1537408AAvoid local wearGuaranteed natural movementCasings/cabinets/drawers detailsPivotal connectionsComputer moduleDegrees of freedom

This portable apparatus includes a first housing having a printed board module, a second housing coupled at one end thereof with the first housing via a hinge mechanism and having a printed board module, a flexible flat cable connected at one end thereof with the printed board module in the first housing and at the other end thereof with the printed board module in the second housing, while being at least once curled at a position corresponding to the hinge mechanism, and an insert member to be inserted into the curled portion of the flexible flat cable. This insert member is not fixed to either the first housing or the second housing but the movement thereof is restricted. The present invention relates to a portable apparatus such as a mobile phone or a notebook type personal computer, an object of which is to improve the durability of a flexible flat cable without lowering the degree of freedom of a curled portion thereof and prevent the same from being locally worn.

Owner:FUJITSU LTD +1

Lip-type seal

InactiveUS20060208428A1Improve durability and abrasion resistanceIncrease widthEngine sealsEngineeringHigh pressure

Owner:EAGLE INDS +1

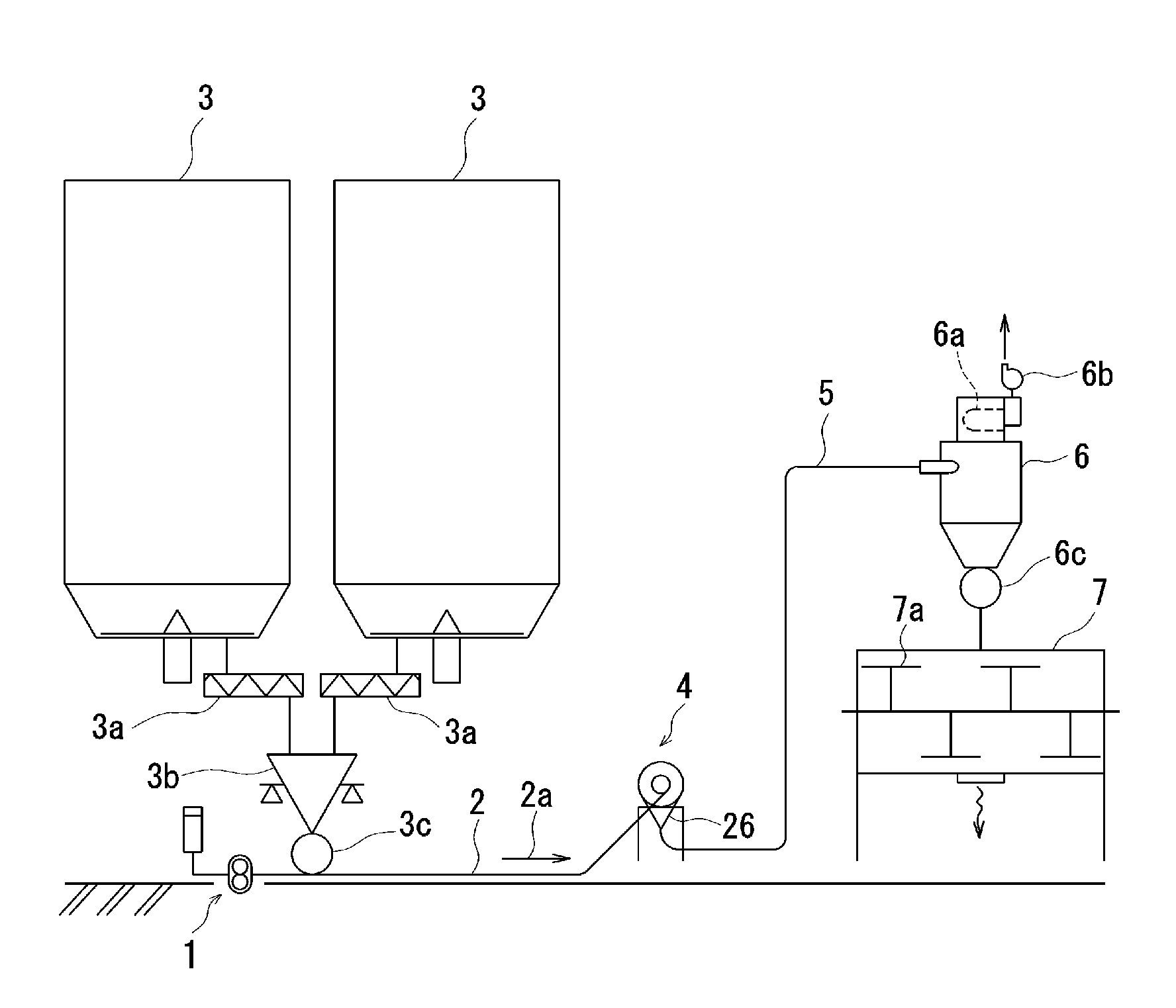

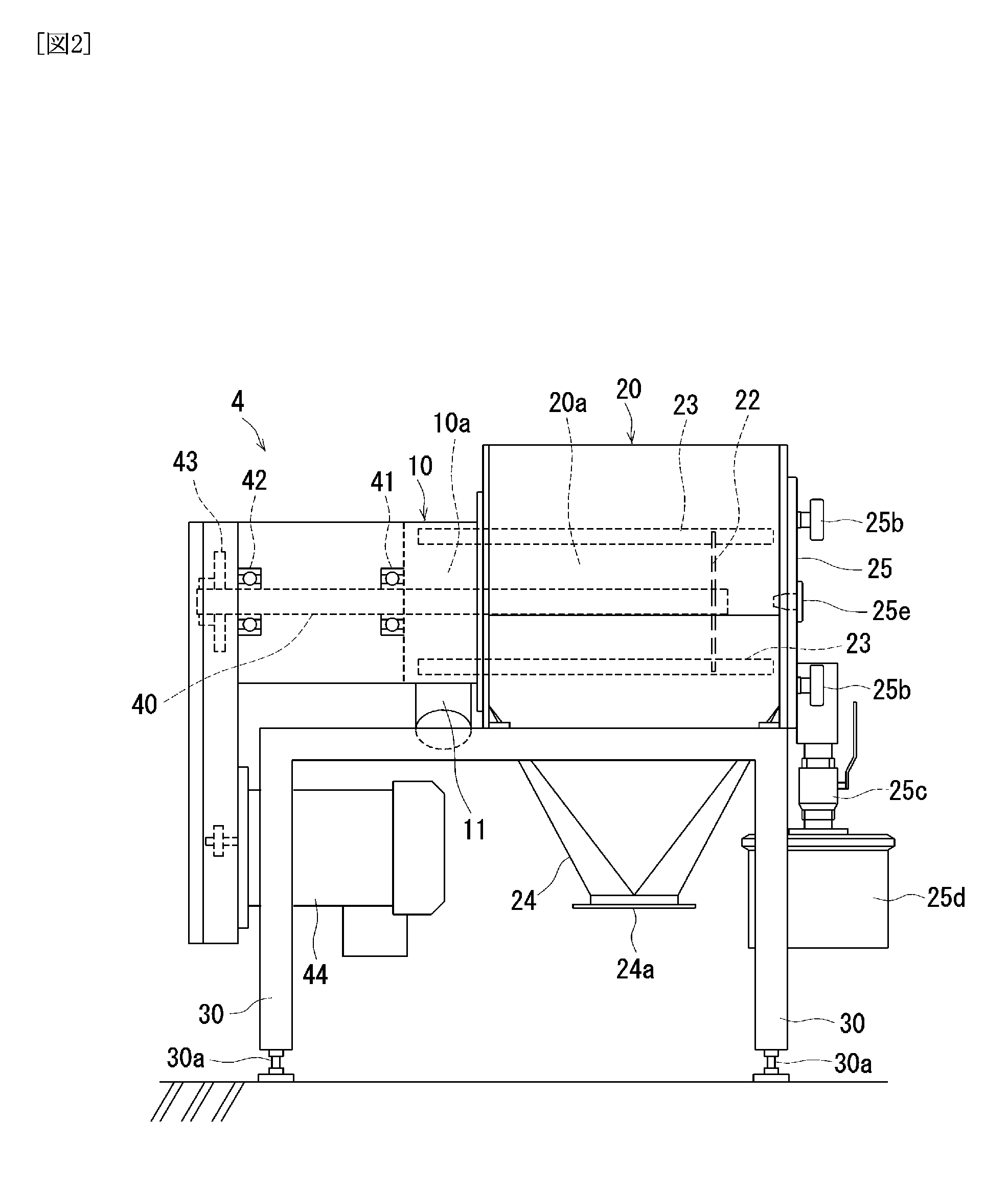

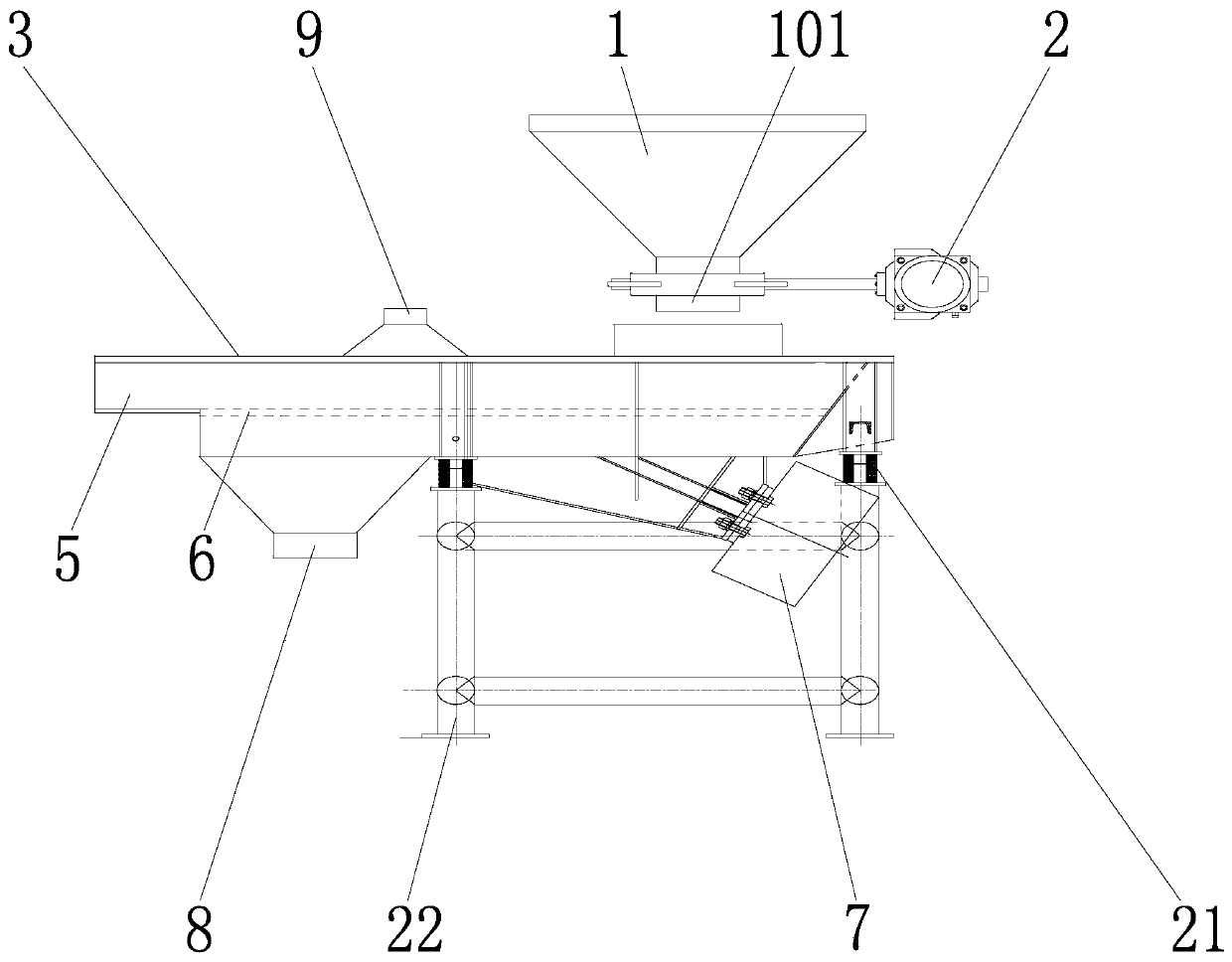

Particulate sifter

ActiveUS20090020460A1Preventing reduced performance of netReduce lossesSievingScreeningParticulatesEngineering

The purpose of the invention is to prevent accumulation of particulates on the outside of a net body of a particulate sifter having a cylindrical net body and to extend the lifetime of the net body. To achieve the purpose, in a particulate sifter which is provided with a sieve 21 having a cylindrical net body 26 extending in a horizontal direction and a booster having rotating blades which rotate along the inner surface of the net body 26 and which separates particulates that pass through the net body 26 from particulates and / or foreign substances that do not pass through the net body 26 while agitating the particulates that have flowed inside the sieve 21 with the booster, the sieve 21 is located rotatably around the central axis of the cylindrical net body 26. The sieve 21 may be rotated forcibly by an electric motor as a driving source or may be rotated by kinetic energy of particulate-air mixture agitated by rotating blades without a driving source.

Owner:TSUKASA KOGYO KK

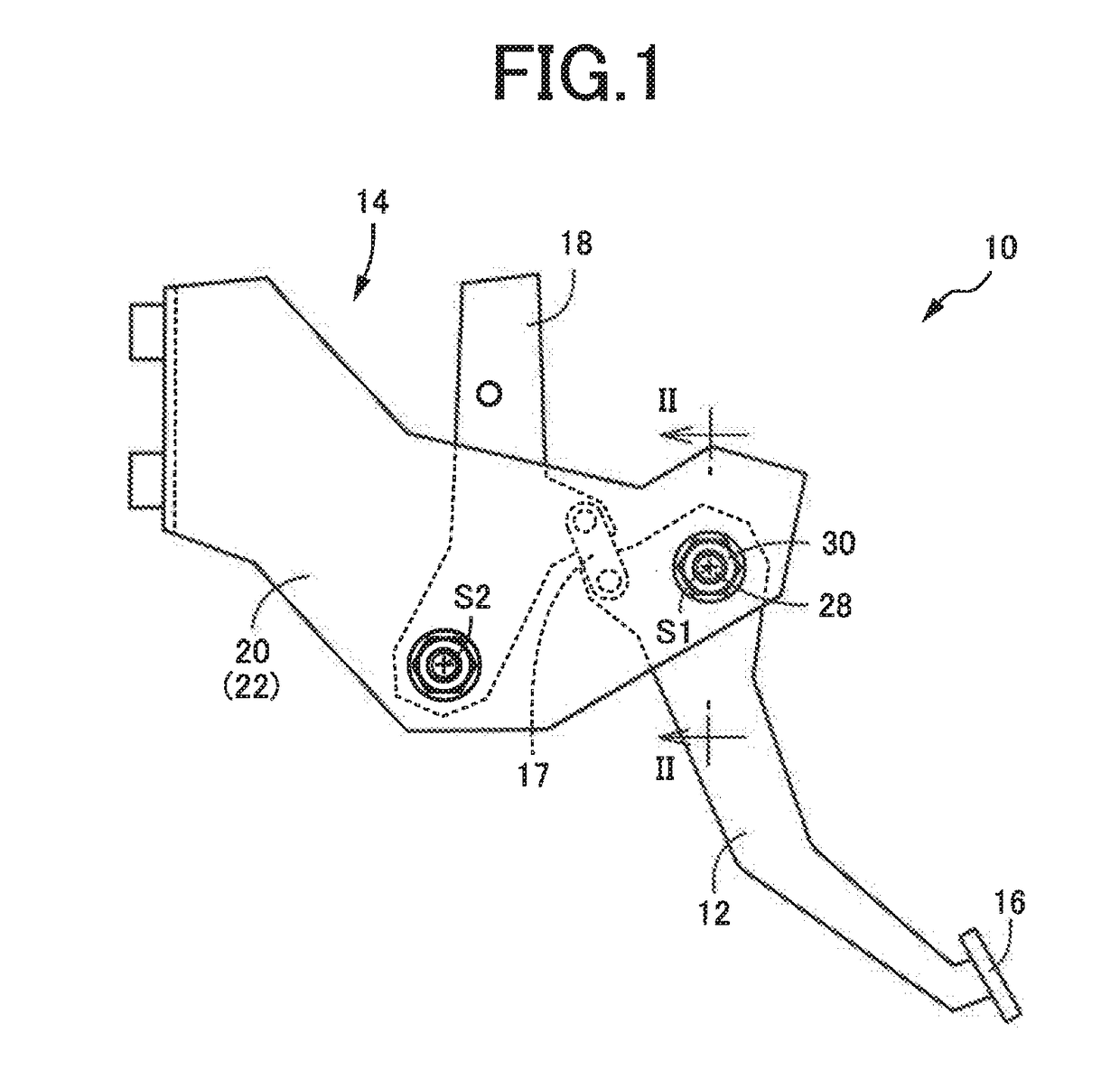

Bearing structure for vehicle pedal device and flanged bushing

InactiveUS20170227047A1Abnormal noise be generateEasily insertControlling membersShaftsEngineeringMechanical engineering

Bearing structure of a pedal device, wherein a support member having a cylindrical outer peripheral surface is fixedly attached to a pedal bracket to be substantially horizontal, a boss of a pivot member radially outside the support member via a pair of flanged bushings each made of resin and having a flange portion at one end of a cylindrical portion so the boss turns about an axis, both axial ends of the flanged bushing cylindrical portion closely contact the boss inner peripheral surface; the flanged bushing cylindrical portion have, in intermediate portion, in an axial direction, a narrow portion having both inner and outer peripheral surfaces reduced in diameter so the narrow portion is curved inward in radial direction; the narrow portion smallest inside diameter being smaller than the support member outside diameter having interference; at least the narrow portion smallest diameter portion of elastically closely contact the support member outer peripheral surface.

Owner:TOYODA IRON WORKS CO LTD

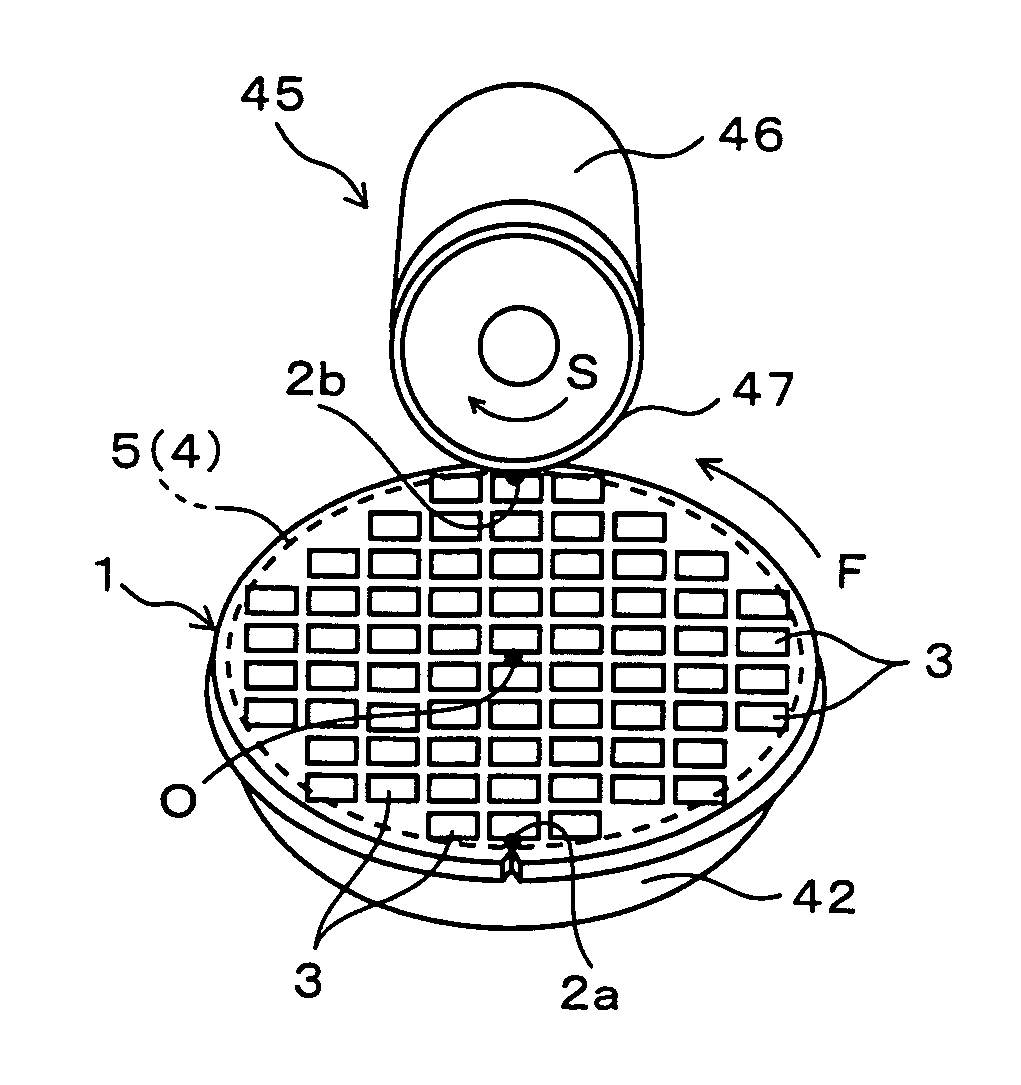

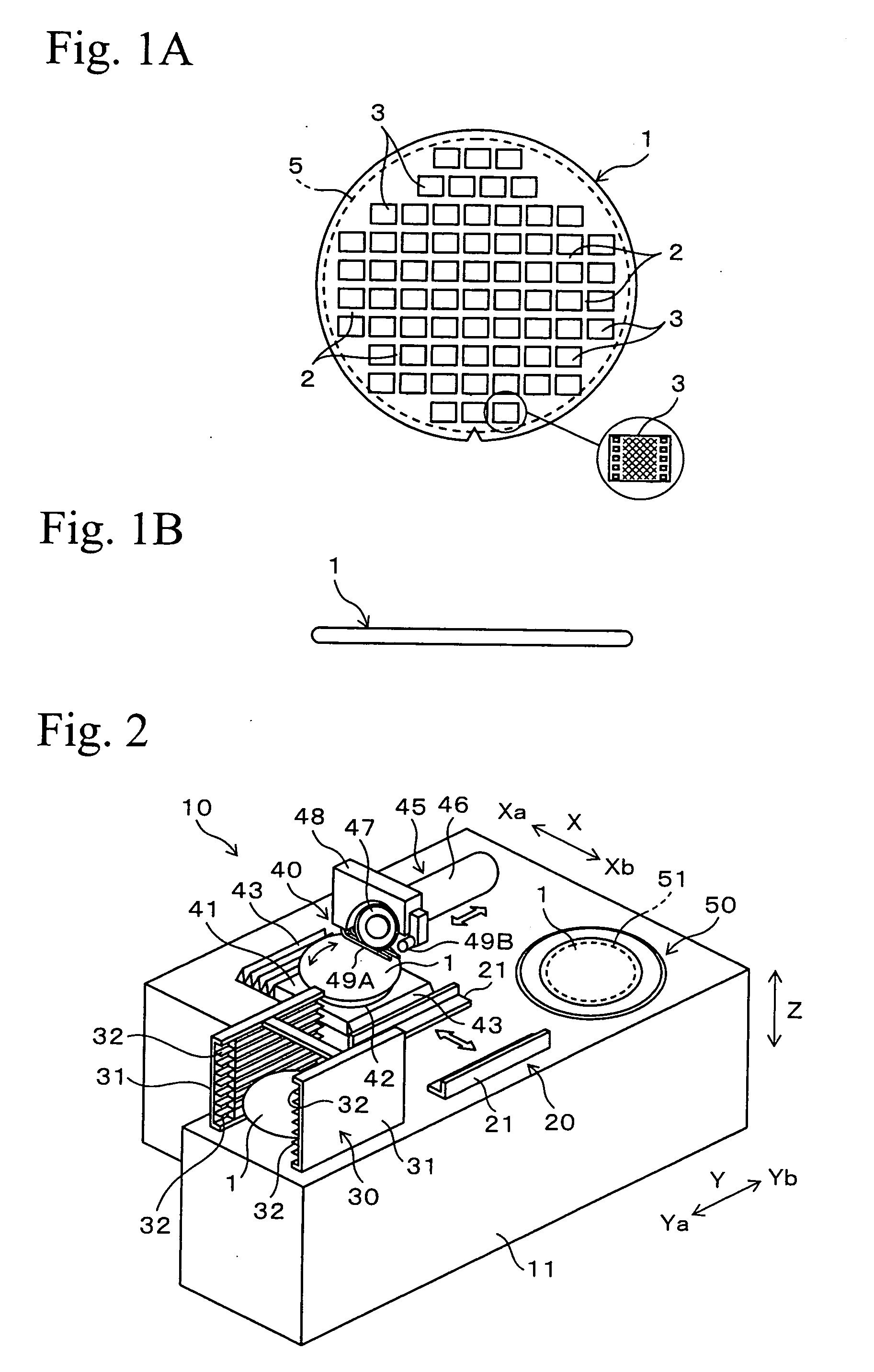

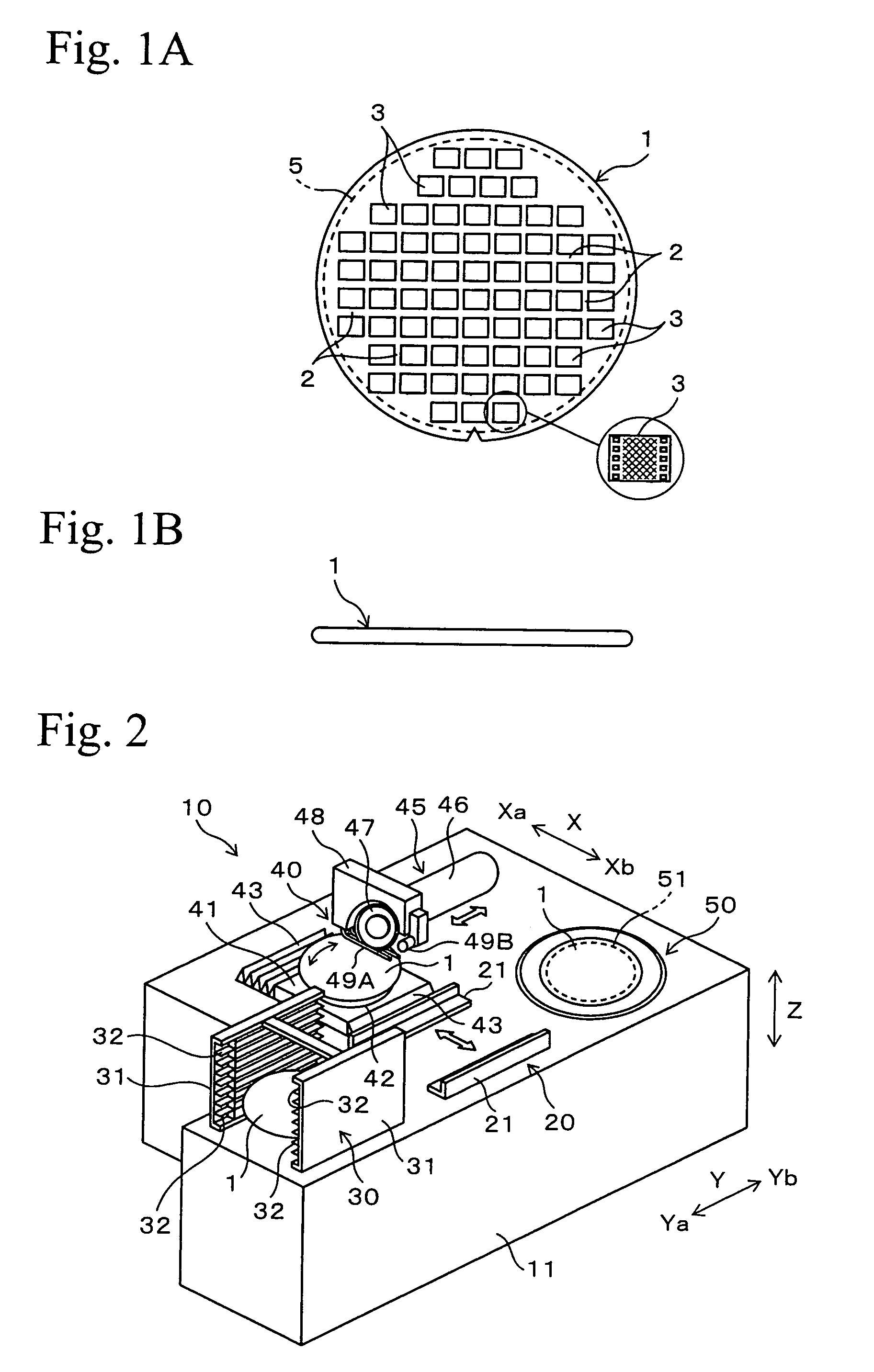

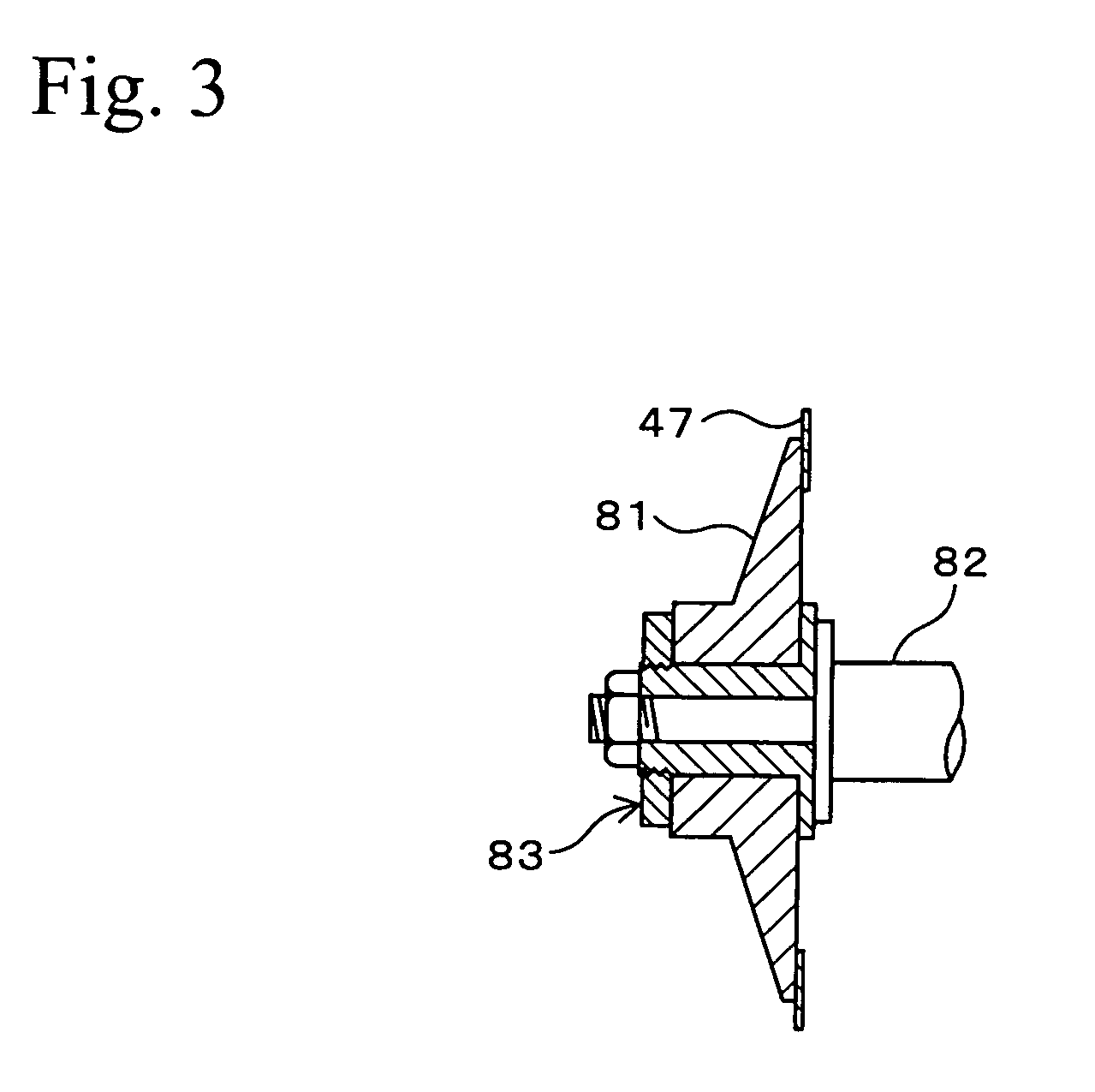

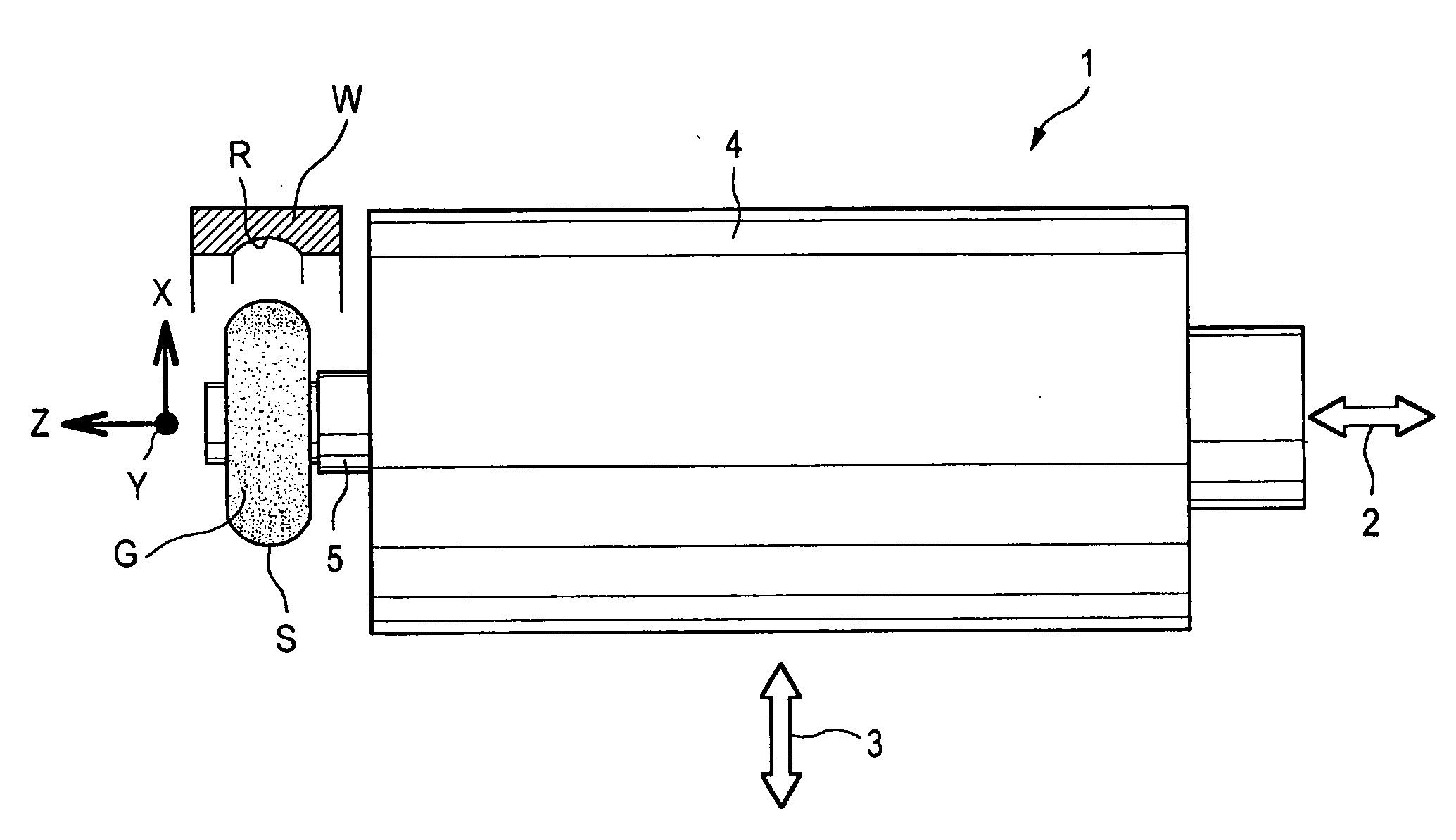

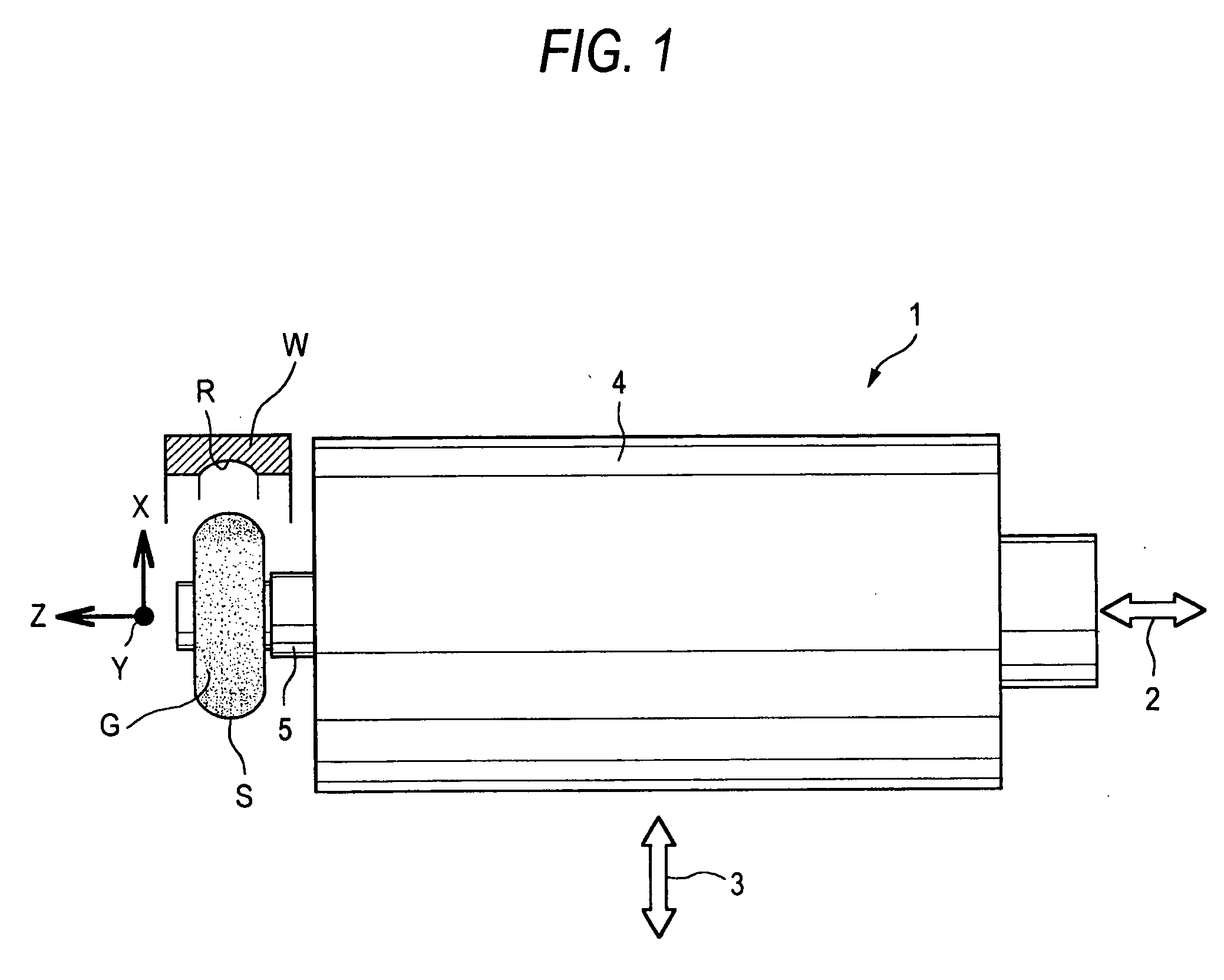

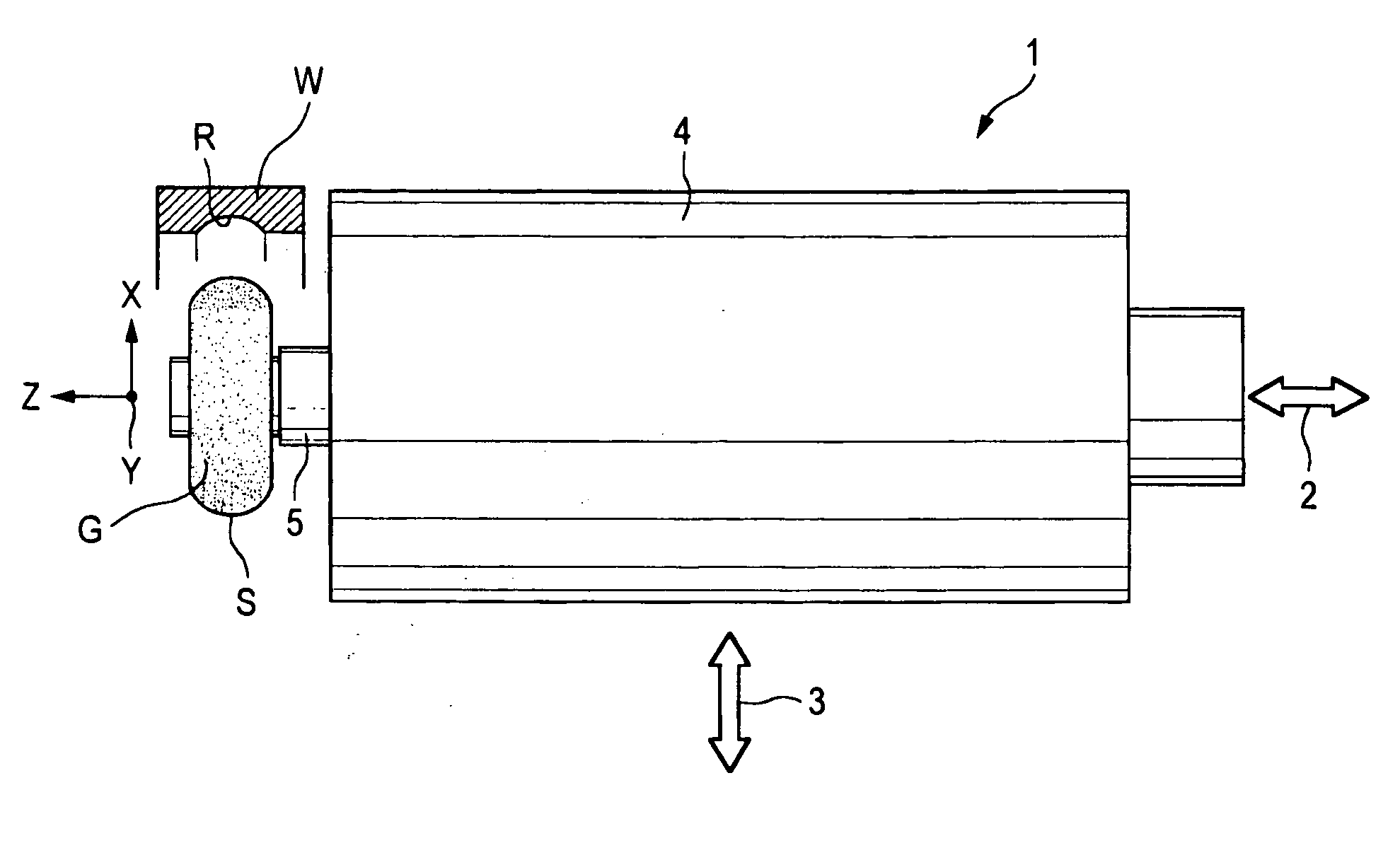

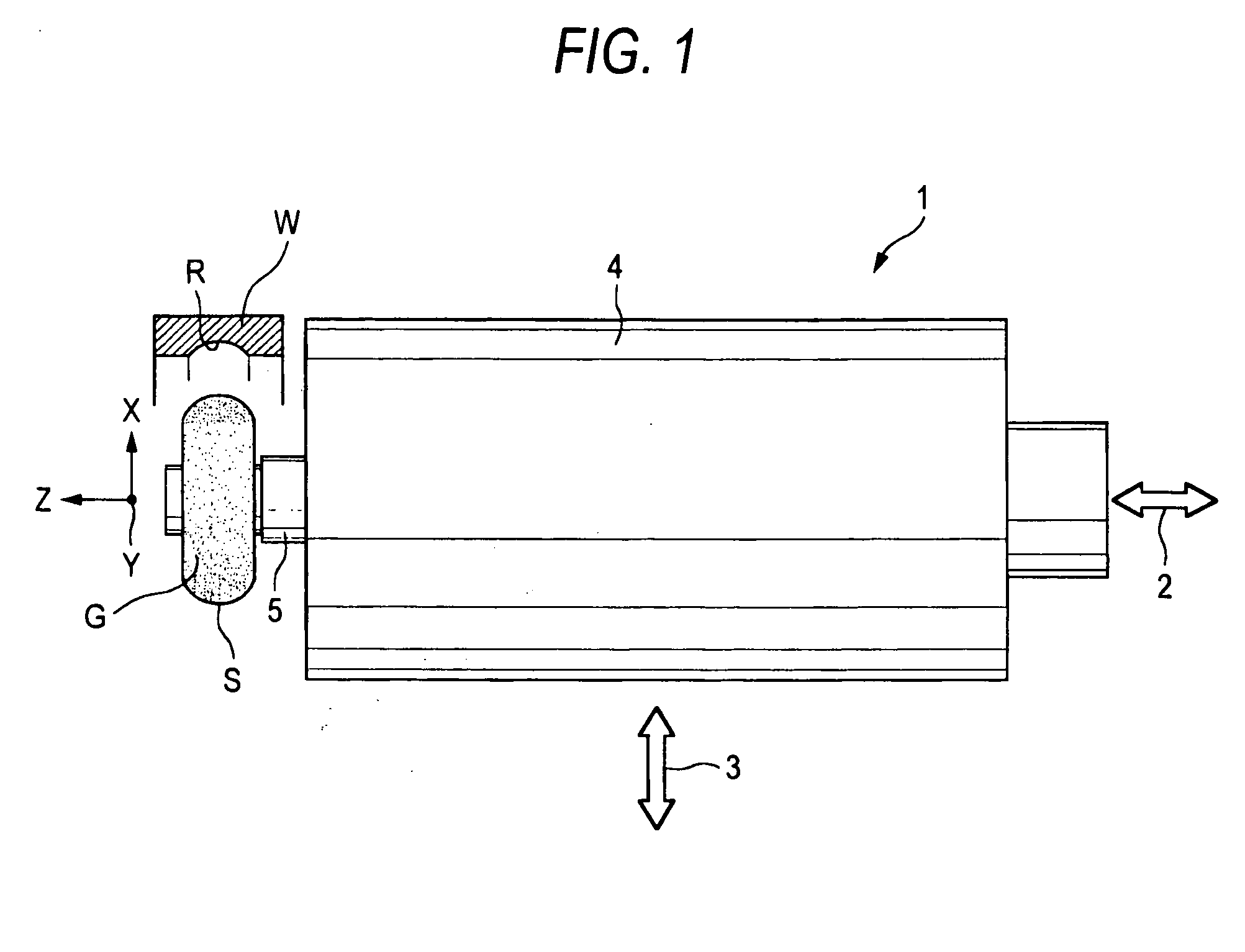

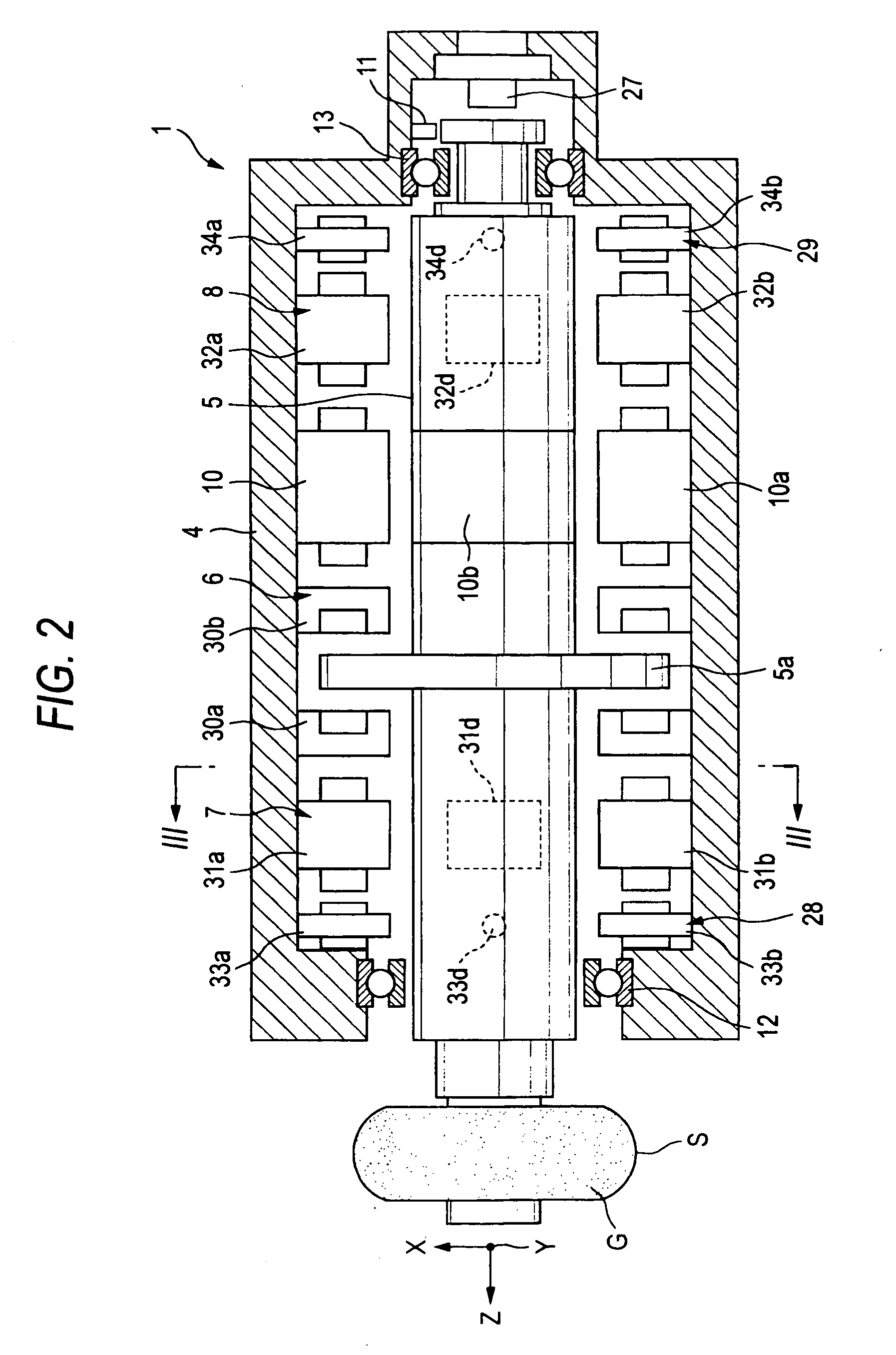

Cutting method for substrate and cutting apparatus therefor

ActiveUS20070134890A1Easy to manufactureLow production costSemiconductor/solid-state device manufacturingReciprocating motionEngineering

A cutting method for substrates includes: preparing a substrate which has a predetermined circular cut line set thereon; chucking the substrate on a surface of a chuck table which is rotatably supported around a rotation axis of the chuck table such that the predetermined circular cut line of the substrate is concentric with the chuck table; disposing a disc-shaped cutting blade having a rotation axis so that the cutting blade faces the substrate; and cutting the substrate along the predetermined circular cut line of the substrate by the cutting blade while rotating the substrate by rotating the chuck table. The substrate has two cut points which are set on one side and the other side of the predetermined circular cut line such that a rotation center of the substrate is positioned between the one side and the other side of the predetermined circular cut line. The cutting blade is disposed so that the rotation axis of the cutting blade perpendicularly crosses the rotation axis of the chuck table. The cutting blade is reciprocatably supported along the rotation axis of the cutting blade, and alternately cuts into the two cut points of the substrate.

Owner:DISCO CORP

Thrust bearing

InactiveUS7066655B2Avoid local wearRemove excess materialRoller bearingsBearing componentsThrust bearingEngineering

An integral type thrust bearing is proposed which can be manufactured with fewer heat treatment steps. The retainer and the inner and outer rollers not hardened are assembled together with rollers into a bearing and thereafter the assembled bearing is carburized, hardened and tempered. This eliminates the need for individual heat treatment of the retainer and the inner and outer rings and decreases heat treatment steps for the production of thrust bearings.

Owner:NTN CORP

Sprocket for a silent chain and method of manufacturing the same

InactiveUS7097580B2Increase surface pressureHigh densityGear vibration/noise dampingPortable liftingSprocketEngineering

A sprocket for preventing the partial wear on the teeth of the sprocket. The teeth of the sprocket comprised of a pair of side portions located on opposite sides of a tooth and a central portion located between the pair of sides. The pair of side portions has a hardness greater than the central portion.

Owner:BORG WARNER MORSE TEC JAPAN KK

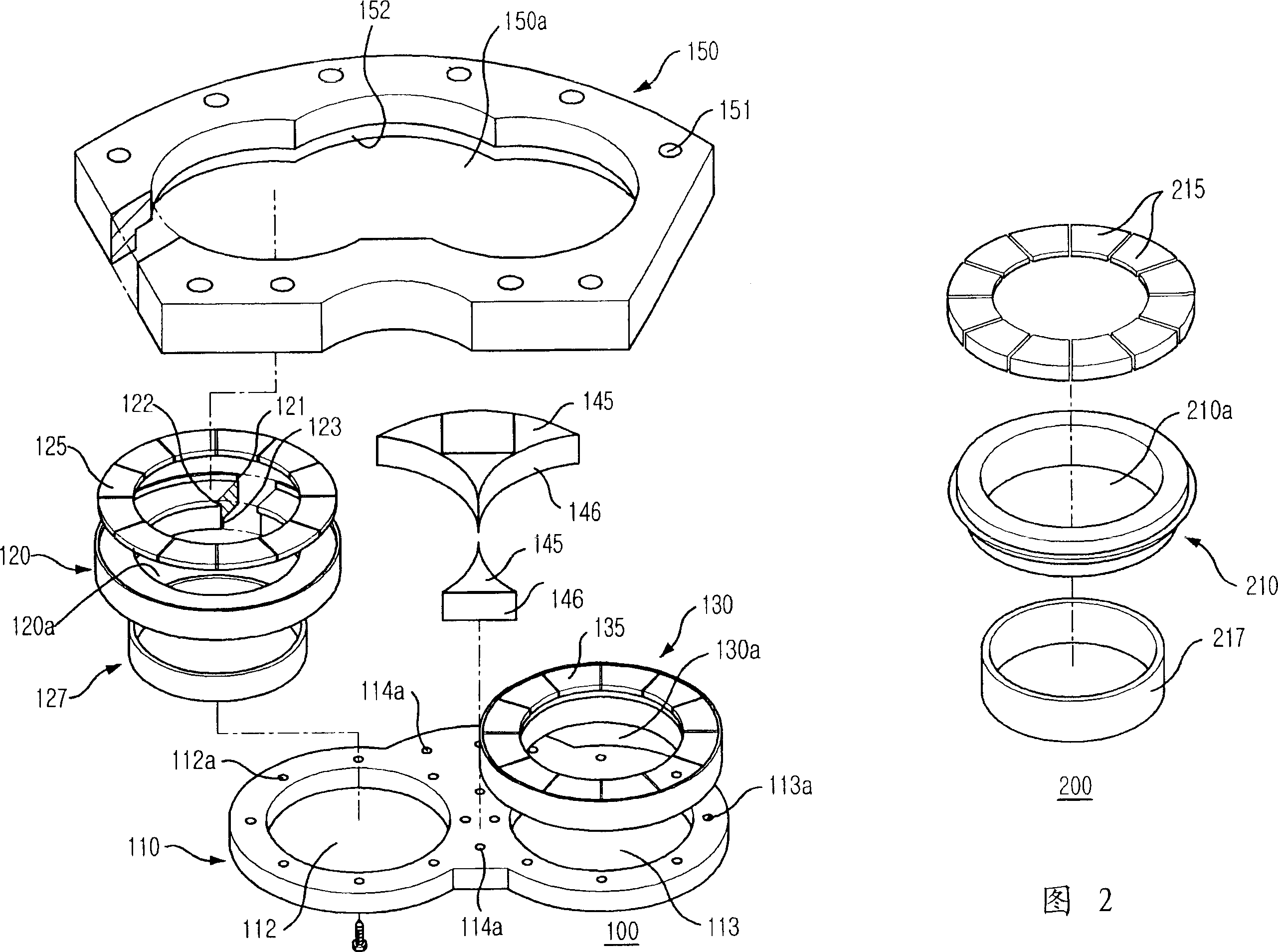

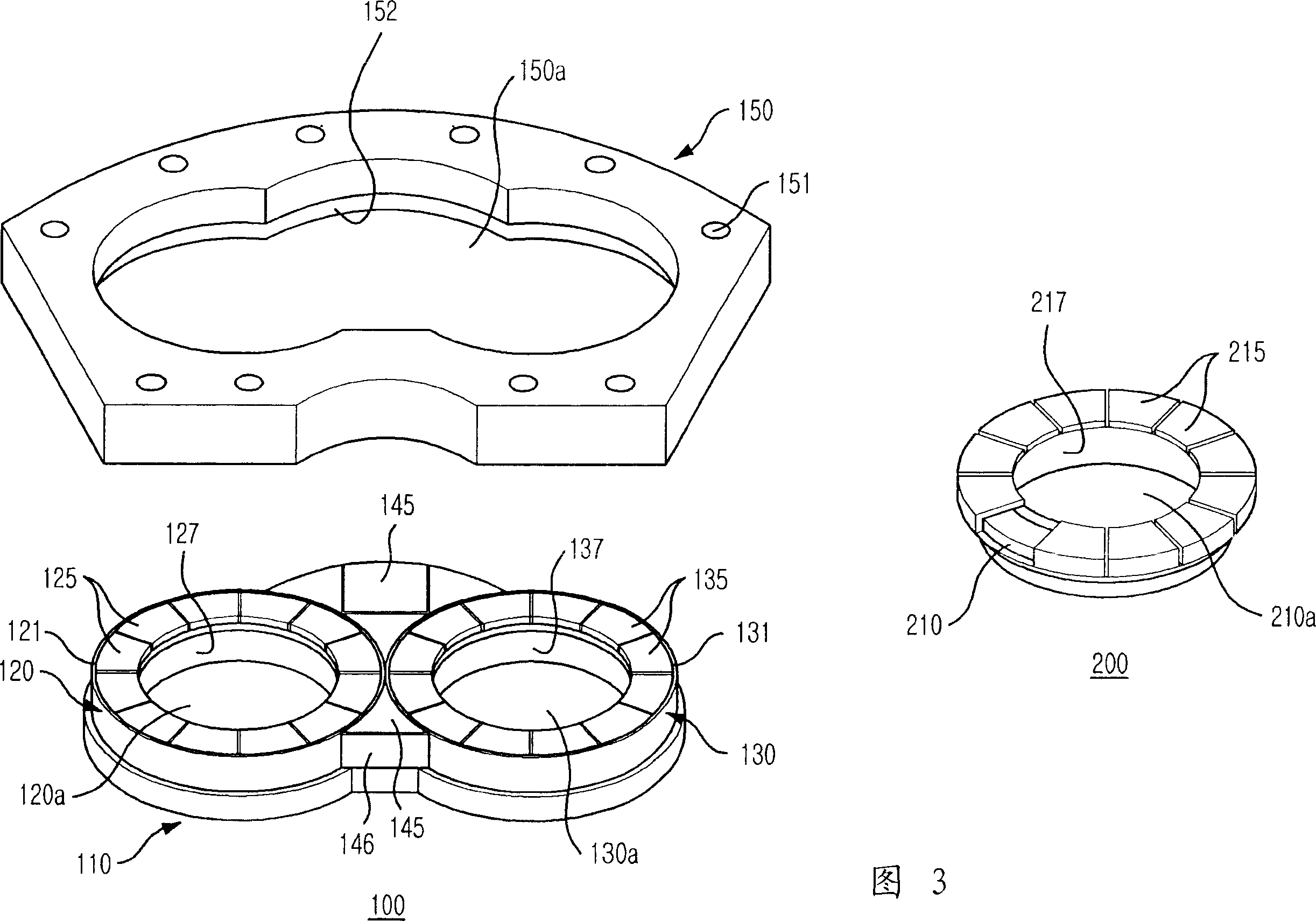

A structure and the manufacturing method for friction parts on concrete pump

InactiveCN1742159AExtended service lifeReduce wear ratePiston pumpsPositive-displacement liquid enginesCouplingWear resistant

The present invention relates to a sliding motion structure for a concrete pump that can reduce the extent of abrasion and solve the problem of high maintenance expenses resulting from frequency replacement of the sliding motion structure by fabricating friction areas with a plurality of wear-resistant friction blocks, and to a manufacturing method thereof. Also, the sliding motion structure and the manufacturing method thereof can also prevent the internal wall surfaces of the inlet ports and outputs, through which concrete is transferred, from being worn out and prevent the external end of the connecting pipe from being worn out partially. The sliding motion structure of the present research includes a plane fixed member having a wear plate, a pair of coupling tubes, first friction members, and a second friction member; and a ring-shaped movable member having a ring-shaped connecting pipe and a third friction member which is formed of tungsten carbide and connected to the first and second friction members tightly along the ends of the connecting pipe in the same length.

Owner:韩乐洙

Cutting method for substrate and cutting apparatus therefor

ActiveUS7384859B2Easy to manufactureLow production costSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A cutting method for substrates includes: preparing a substrate which has a predetermined circular cut line set thereon; chucking the substrate on a surface of a chuck table which is rotatably supported around a rotation axis of the chuck table such that the predetermined circular cut line of the substrate is concentric with the chuck table; disposing a disc-shaped cutting blade having a rotation axis so that the cutting blade faces the substrate; and cutting the substrate along the predetermined circular cut line of the substrate by the cutting blade while rotating the substrate by rotating the chuck table. The substrate has two cut points which are set on one side and the other side of the predetermined circular cut line such that a rotation center of the substrate is positioned between the one side and the other side of the predetermined circular cut line. The cutting blade is disposed so that the rotation axis of the cutting blade perpendicularly crosses the rotation axis of the chuck table. The cutting blade is reciprocatably supported along the rotation axis of the cutting blade, and alternately cuts into the two cut points of the substrate.

Owner:DISCO CORP

Rotary cutting saw with improved heat dissipation performance

ActiveUS7004157B2Avoid burnsImprove performanceRevolution surface grinding machinesMetal sawing toolsEngineeringMechanical engineering

A rotary cutting saw including: (a) a base disk which has a plurality of apertures formed therethrough and opening in axially opposite end surfaces thereof; (b) a plurality of abrasive segments which are fixed to an outer circumferential surface of the base disk; and (c) a plurality of axial-runout restraining members which are received in the apertures. Each of the axial-runout restraining members has a size which is smaller than a size of each of the apertures, such that a clearance is defined between the periphery of each of the apertures and a corresponding one of the axial-runout restraining members which is received in the each of the apertures. A ratio of a size of the clearance to the size of each of the axial-runout restraining members is 5–150%.

Owner:NORITAKE SUPER ABRASIVE CO LTD +1

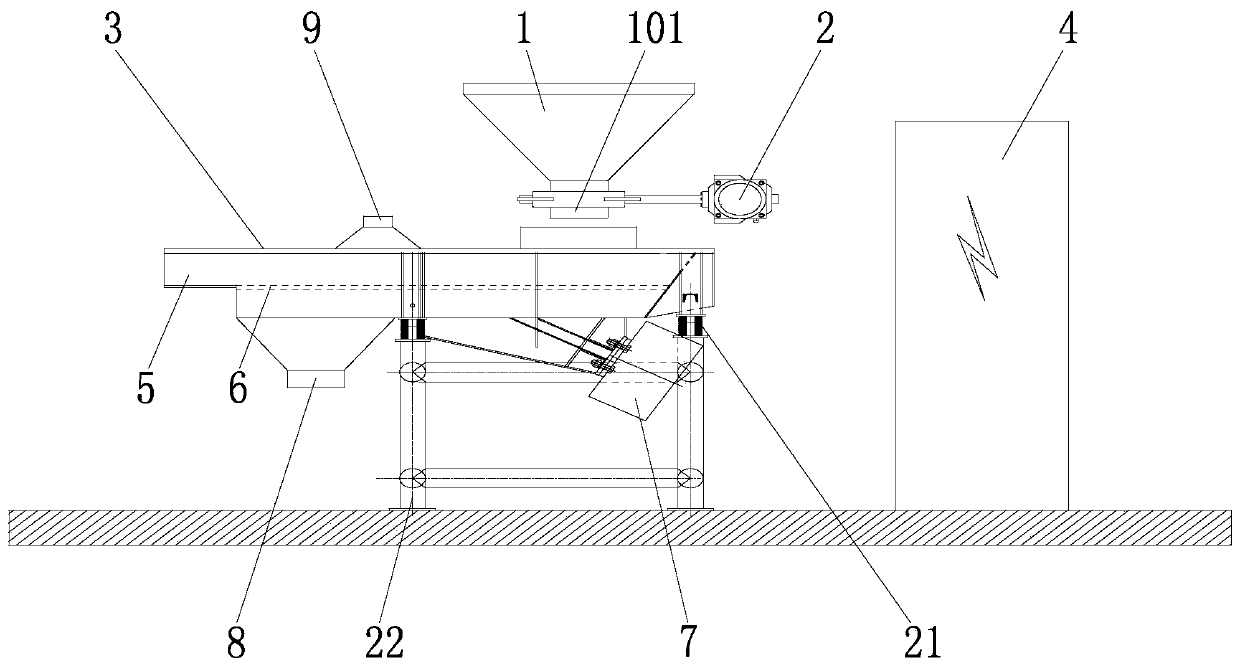

High-efficiency uniform feeding, sieving and crushing system for polysilicon and monocrystalline silicon and method thereof

ActiveCN110918238AAvoid cloggingAvoid secondary crushingSievingScreeningElectric machineryEngineering

The invention discloses a high-efficiency uniform feeding, sieving and crushing system for polysilicon and monocrystalline silicon and a method thereof. The system comprises a material cabin, a feeding machine, a crushing machine, an electronic valve, an accumulation amount detecting device and a control sub-system. The feeding machine comprises a feeding box, a vibrating motor and a screen mesh.The feeding box is provided with a box opening facing an upper discharging hole. One end of the screen mesh is positioned below the box opening; and the other end of the screen mesh faces a discharging end. The vibrating motor is used for moving a silicon material to the other end of the screen mesh in one direction to fall into a lower discharging hole. The accumulation amount detecting device isused for detecting the accumulation amount of the silicon material. The control sub-system is used for reducing the opening / closing frequency or opening / closing amplitude of the electronic valve whenthe accumulation amount is greater than a first preset accumulation amount, and increasing the opening / closing frequency or opening / closing amplitude of the electronic valve when the accumulation amount is smaller than a second preset accumulation amount. According to the high-efficiency uniform feeding, sieving and crushing system for the polysilicon and monocrystalline silicon and the method thereof, the silicon material uniformly falls into the crushing machine for crushing; the overall production efficiency of crushing is improved; the rejection rate of the silicon material is reduced; and the particle size of the finally crushed silicon material is more uniform.

Owner:合肥开比锐精机科技有限公司

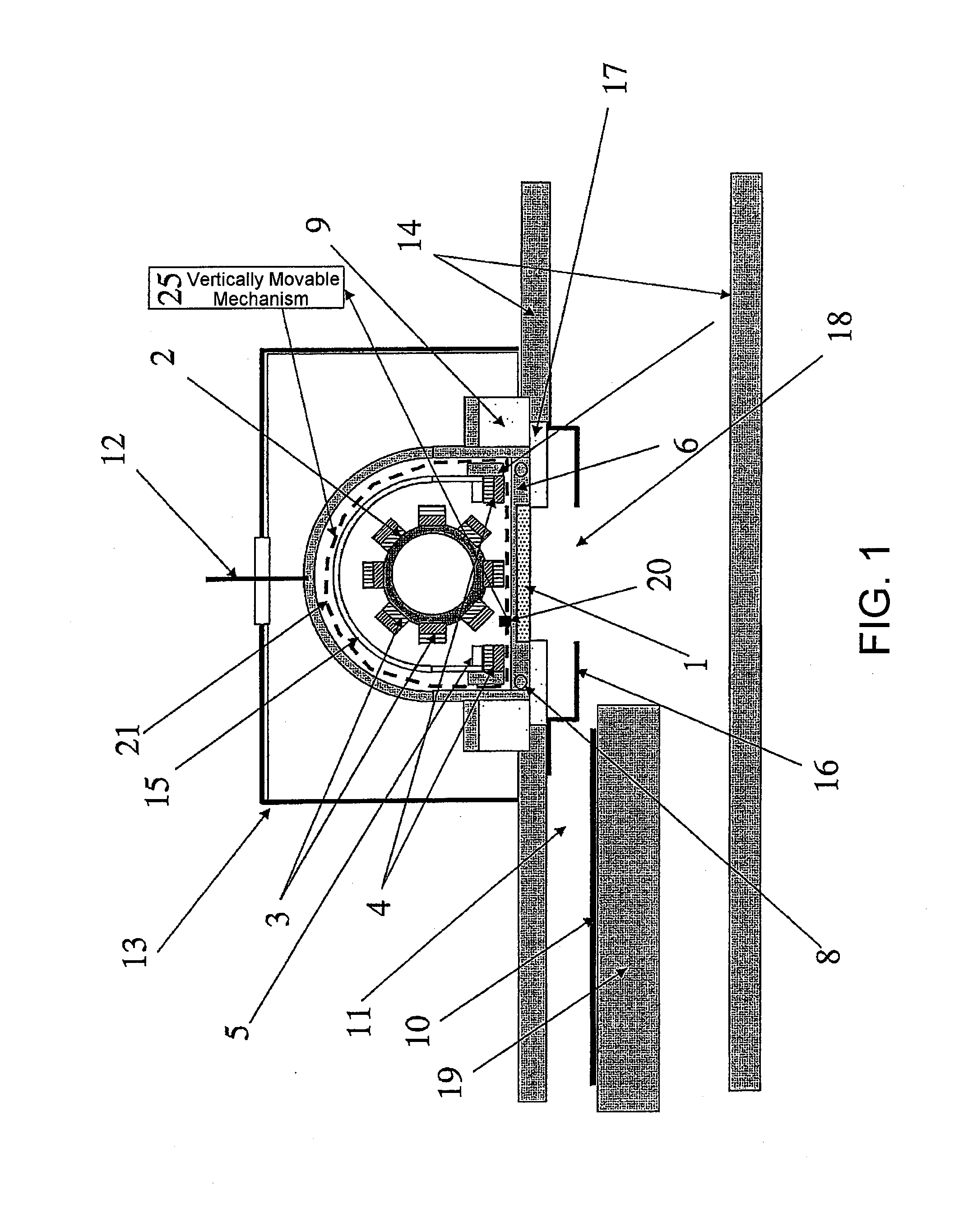

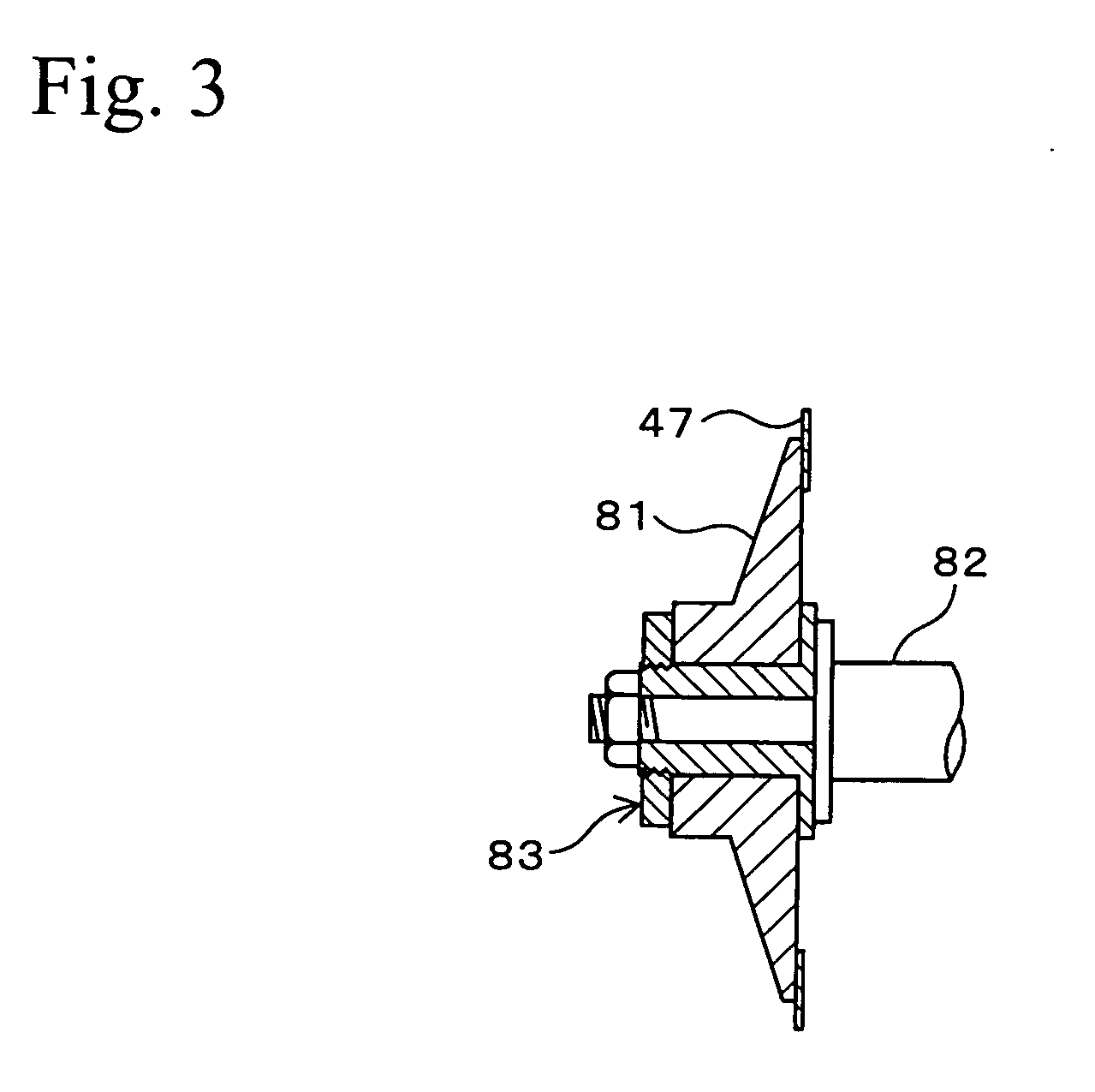

Grinding apparatus

InactiveUS20080233851A1Not easy to wearAvoid local wearRevolution surface grinding machinesShaftsRelative displacementMagnetic bearing

A grinding wheel having a convex grinding surface is attached to a wheel spindle that is contactlessly supported by a casing through a controlled type axial magnetic bearing and controlled type radial magnetic bearings and that is rotated by an electric motor. A groove of a workpiece is ground by causing relative displacement of the casing. After the axial positioning of the casing is performed, the casing is radially displaced. Then, the groove is ground. The stiffness value of the axial magnetic bearing 6 is set to be lower than a normal value before the casing is radially displaced. After it is detected that the grinding surface of the grinding wheel touches the entire groove of the workpiece and that the grinding of the entire surface of the workpiece is started, the stiffness value is set back to the normal value.

Owner:JTEKT CORP

Thrust bearing

InactiveCN1826477APrevent prolapseInhibit sheddingRoller bearingsBearing componentsThrust bearingHeat treating

A thrust bearing, wherein a cage (2) and inner and outer rings (3, 4) in non-quenched state are assembled with each other in the bearing formed integrally with rollers (1), and a carburizing and quenching, and tempering treatments are applied to the assembled bearing, whereby since the individual heat treatment for the cage (2) and the inner and outer rings (3, 4) can be eliminated, the heat treatment steps for the integral thrust bearing can be reduced.

Owner:NTN CORP

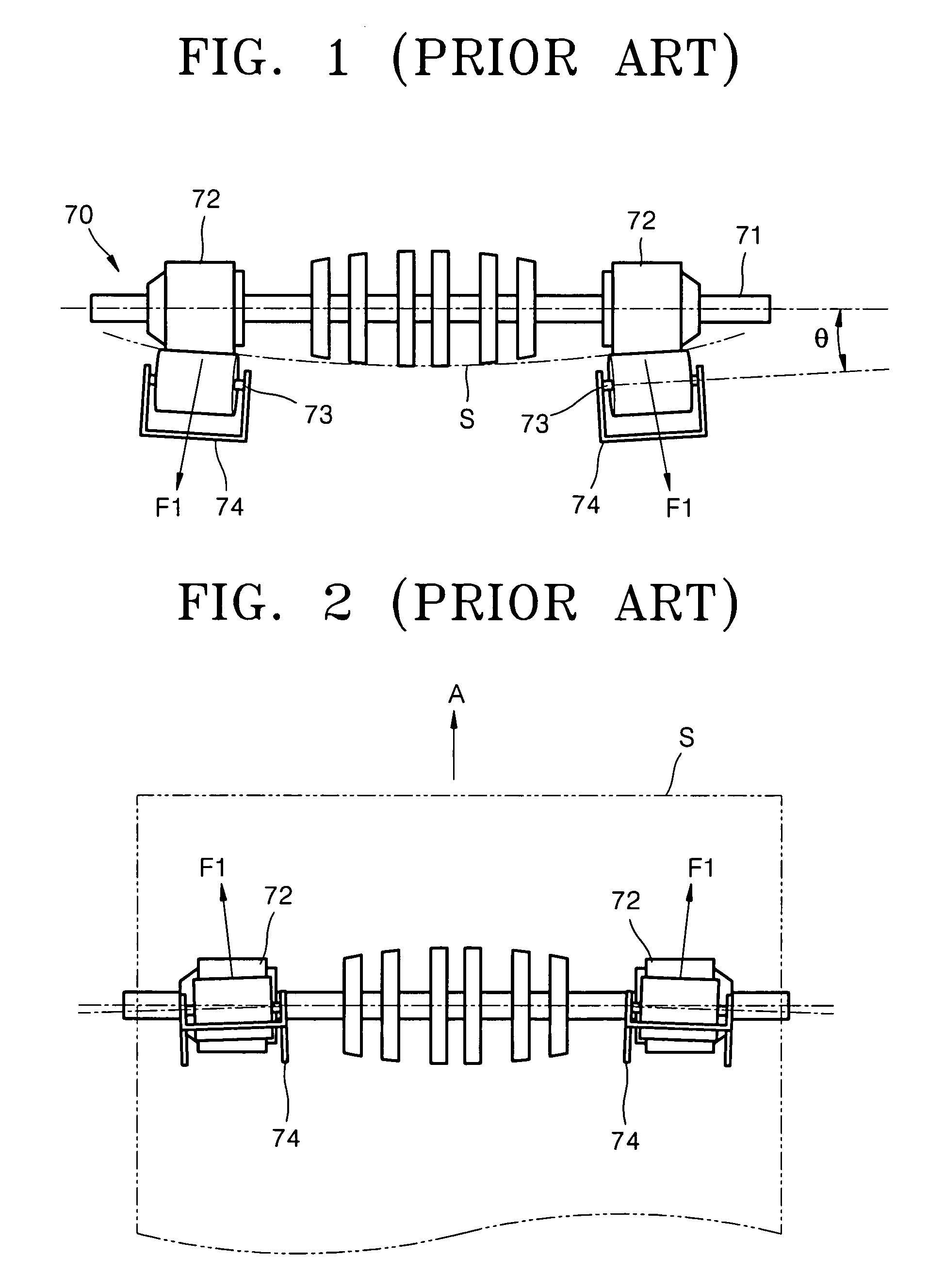

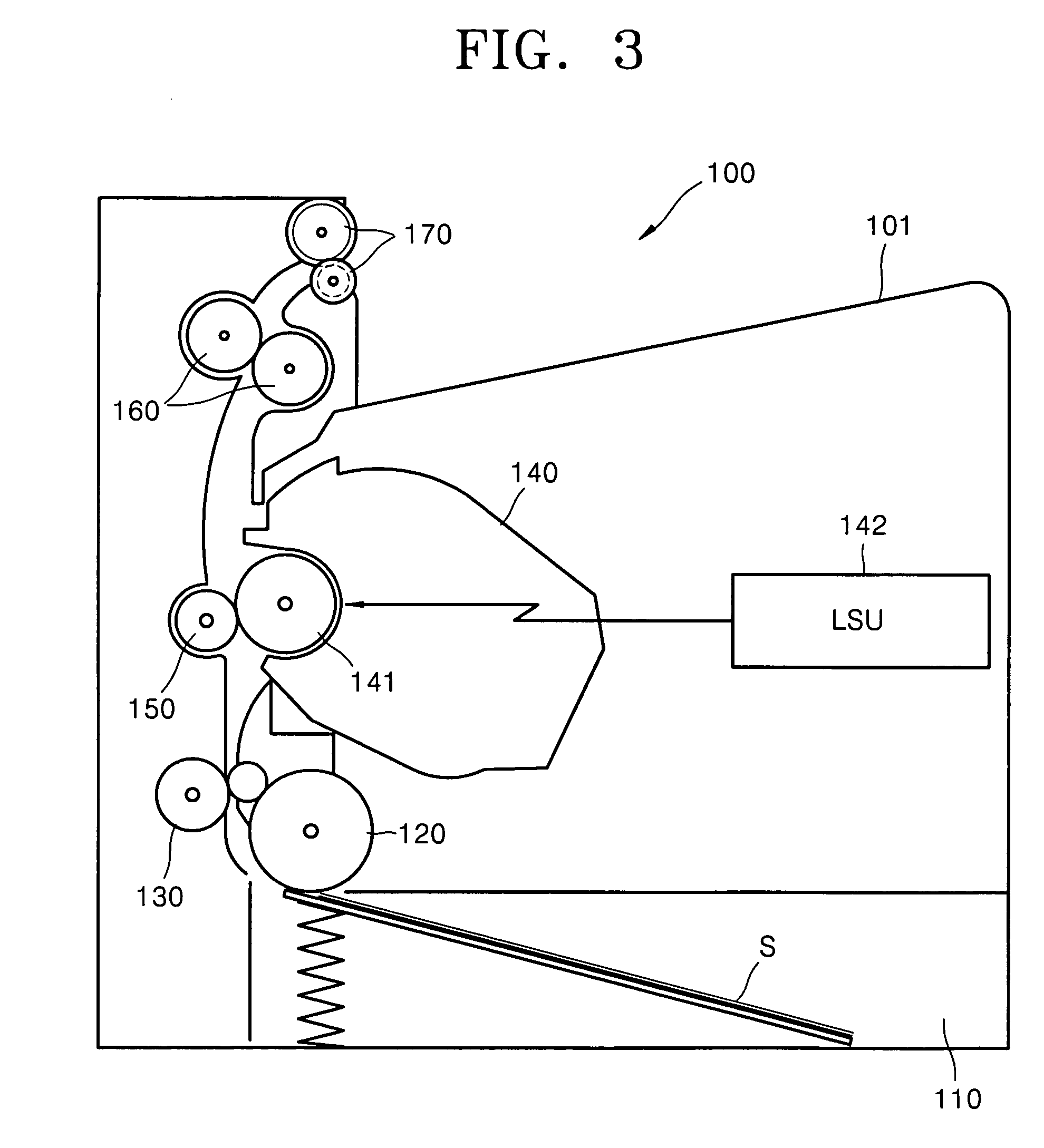

Paper discharge device and image forming apparatus having the same

InactiveUS20050265762A1Avoid partial wearAvoid local wearLighting and heating apparatusDomestic refrigeratorsImage formationPulp and paper industry

A paper discharge device and an image forming apparatus having the same are provided. In the paper discharge device, the paper discharge roller has a non-uniform diameter extending in a longitudinal direction and the idle roller contacts with the paper discharge roller in the longitudinal direction of the paper discharge roller so that the print paper unfolds and discharges utilizing a velocity differential at a nip between the paper discharge roller and the idle roller.

Owner:S PRINTING SOLUTION CO LTD

Magnetron sputtering apparatus

InactiveUS20100059368A1Increase life timeLong life timeCellsElectric discharge tubesMagnetPlasma density

Provided is a magnetron sputtering apparatus that increases an instantaneous plasma density on a target to improve a film forming rate. The magnetron sputtering apparatus includes a substrate to be processed, a target installed to face the substrate and a rotary magnet installed at a side opposite to the substrate across the target. In the magnetron sputtering apparatus, plasma loops are formed on a target surface. The plasma loops are generated, move and disappear in an axis direction of the rotary magnet according to a rotation of the rotary magnet.

Owner:TOHOKU UNIV +1

Grinding apparatus and method of controlling grinding apparatus

InactiveUS20090042479A1Lightening impact forceNot easy to wearEdge grinding machinesGrinding feed controlMagnetic bearingEngineering

A grinding wheel formed on an outer peripheral surface with a grinding surface is attached to a grinding wheel spindle supported by axial active magnetic bearings and radial active magnetic bearings in a noncontact manner axially and radially and rotated by an electric motor. A casing is axially positioned and then is radially moved and a ground part of a workpiece is ground. Before the casing moves radially and the grinding wheel comes in contact with the workpiece, the stiffness value of the radial magnetic bearings is set to an initialization value lower than a value at the usual grinding time and after the grinding surface of the grinding wheel comes in contact with the workpiece, the stiffness value of the radial magnetic bearings is set to a value higher than the initialization value for grinding the workpiece.

Owner:JTEKT CORP

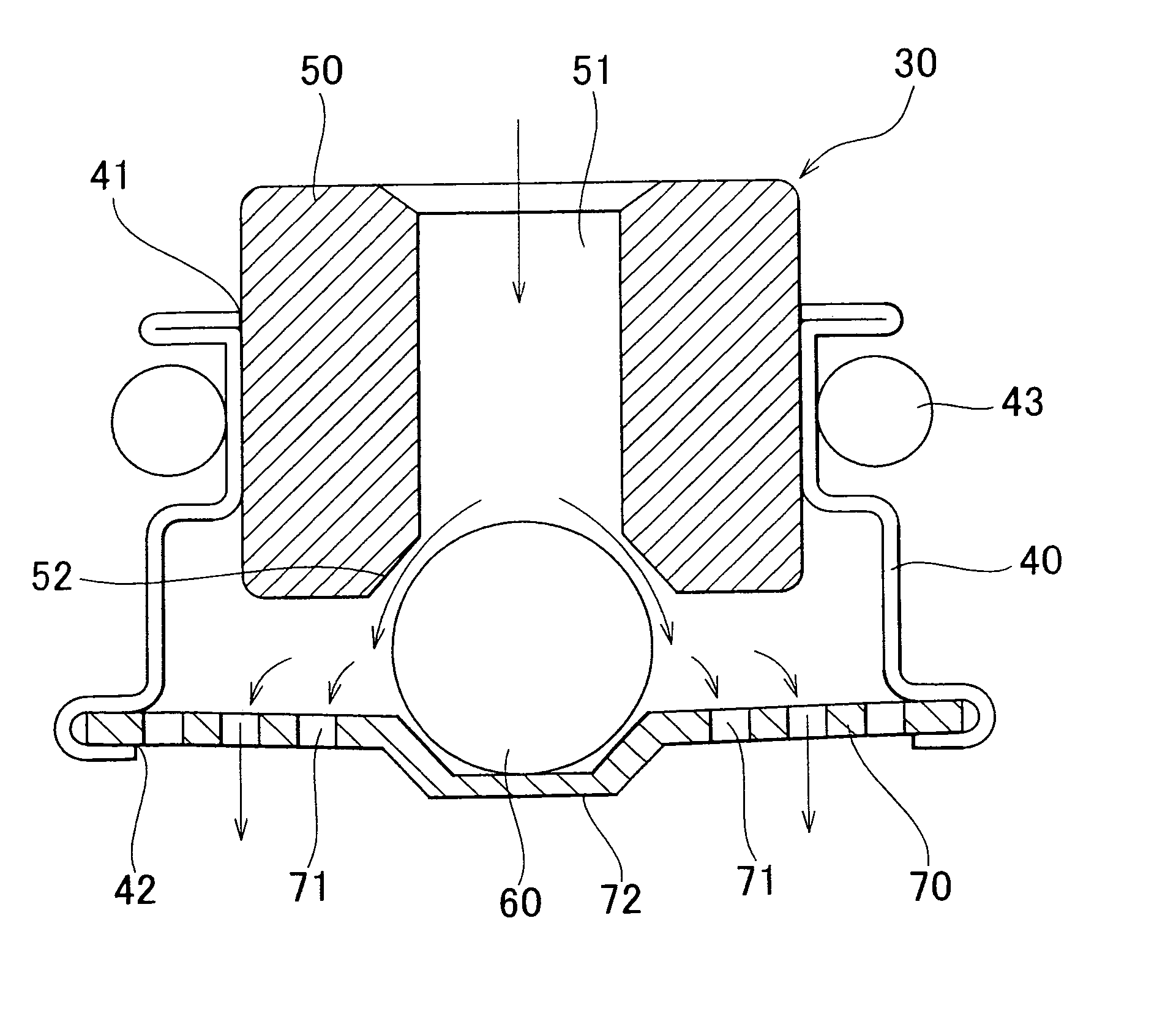

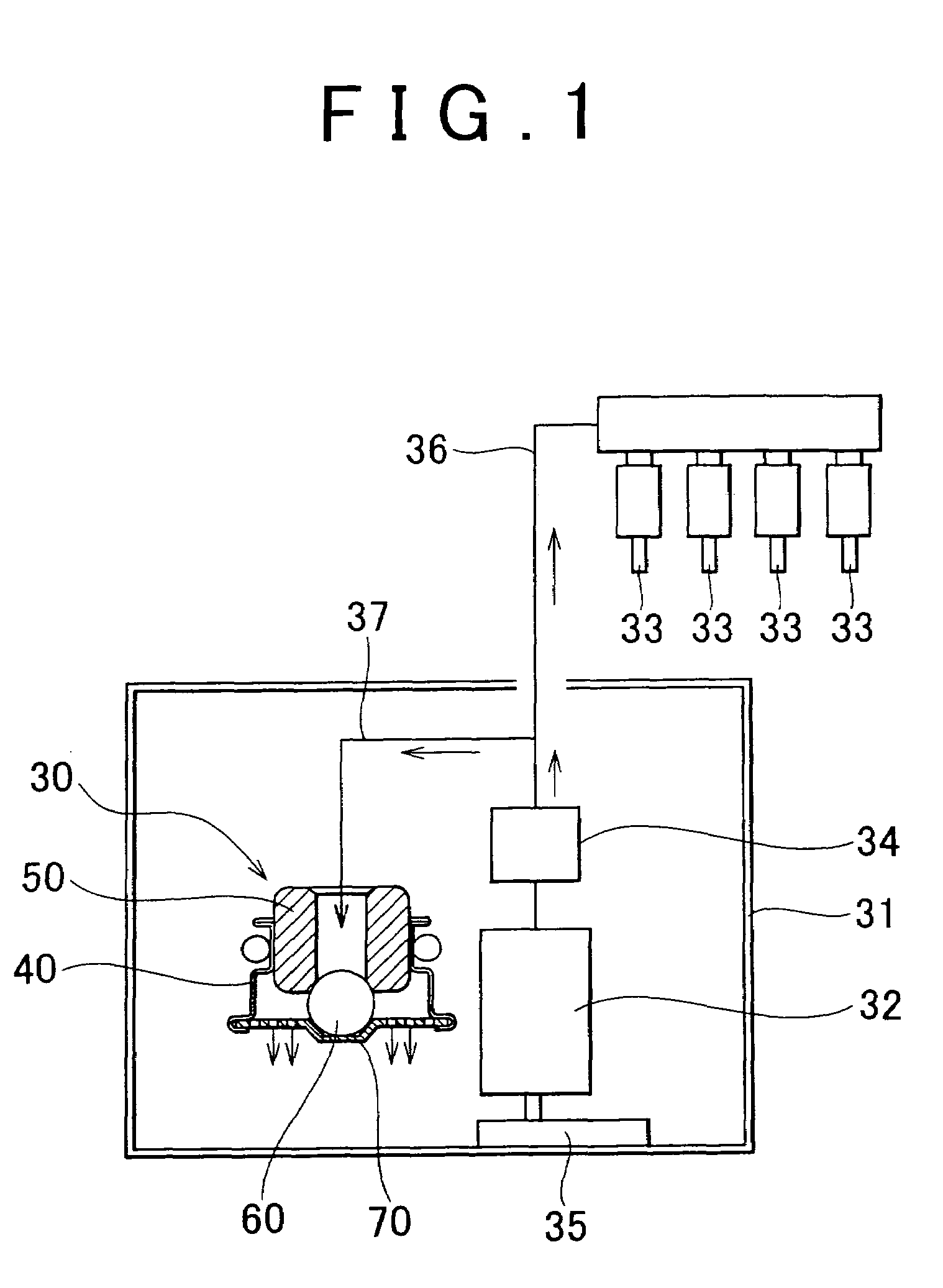

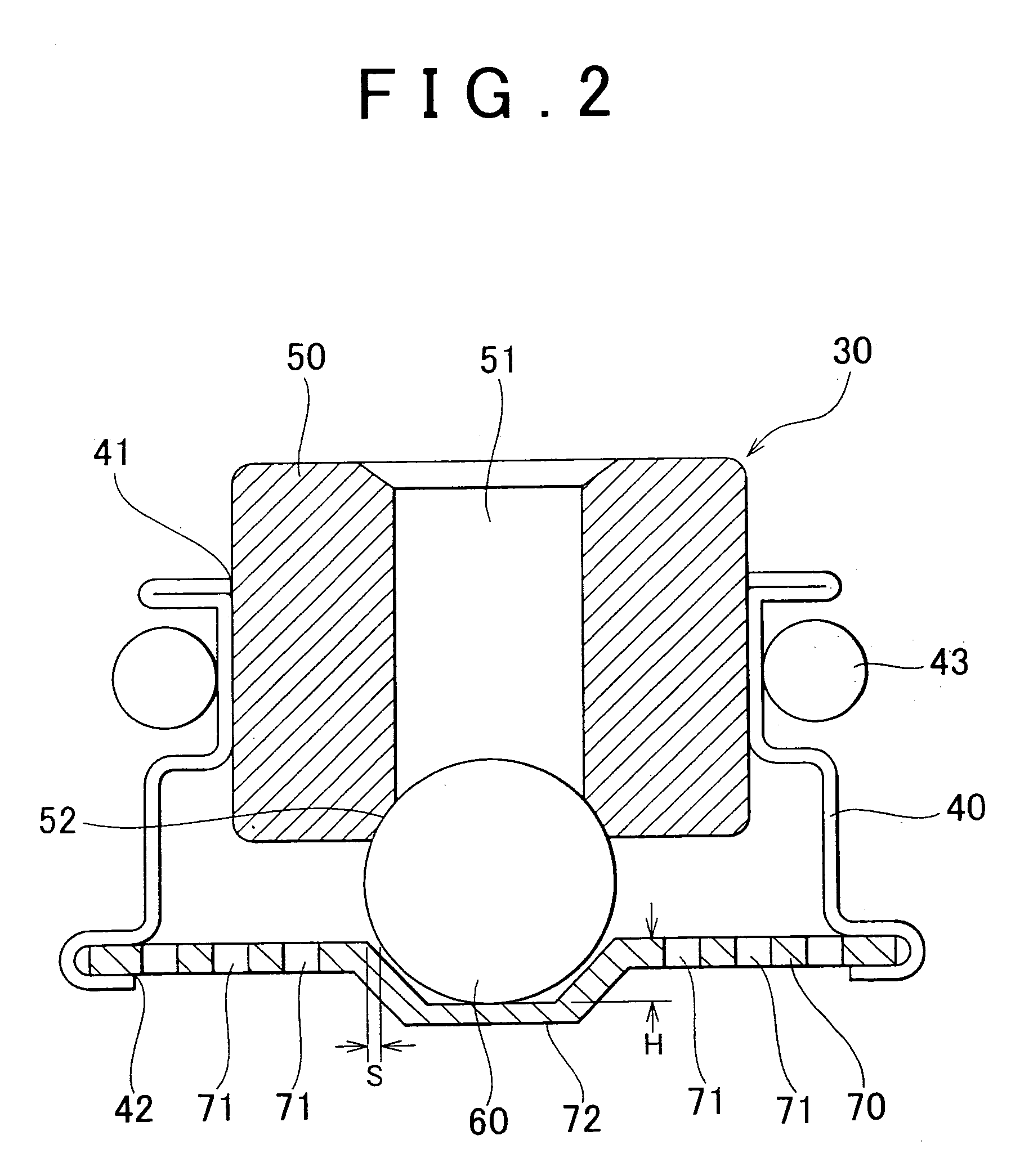

Fuel pressure adjusting apparatus

ActiveUS7124739B2Avoid local wearPrevent abnormal noiseLow pressure fuel injectionMachines/enginesEngineeringValve seat

A fuel pressure adjusting apparatus which includes a casing which includes a fuel introduction port, and a fuel discharge port; and a cylindrical member which is housed in the casing, and which includes a valve seat at an end portion thereof, and a communication passage therein, the communication passage connecting the fuel introduction port to the fuel discharge port; a valve element which is provided on a fuel discharge port-side of the valve element in the casing, and which closes the communication passage when the valve element is seated on the valve seat; and a leaf spring which is provided at the fuel discharge port, and which applies force to the valve element in a direction toward the valve seat. The leaf spring includes a concave portion which supports the valve element, and which is formed such that there is a gap between the concave portion and the valve element.

Owner:AISAN IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com