A structure and the manufacturing method for friction parts on concrete pump

A friction component, concrete pump technology, applied in the direction of pumps, piston pumps, liquid variable capacity machinery, etc., can solve the problems of waste, low wear rate, high maintenance cost and resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Through the following description of the embodiments with reference to the drawings, other objects and aspects of the present invention will be clearly understood.

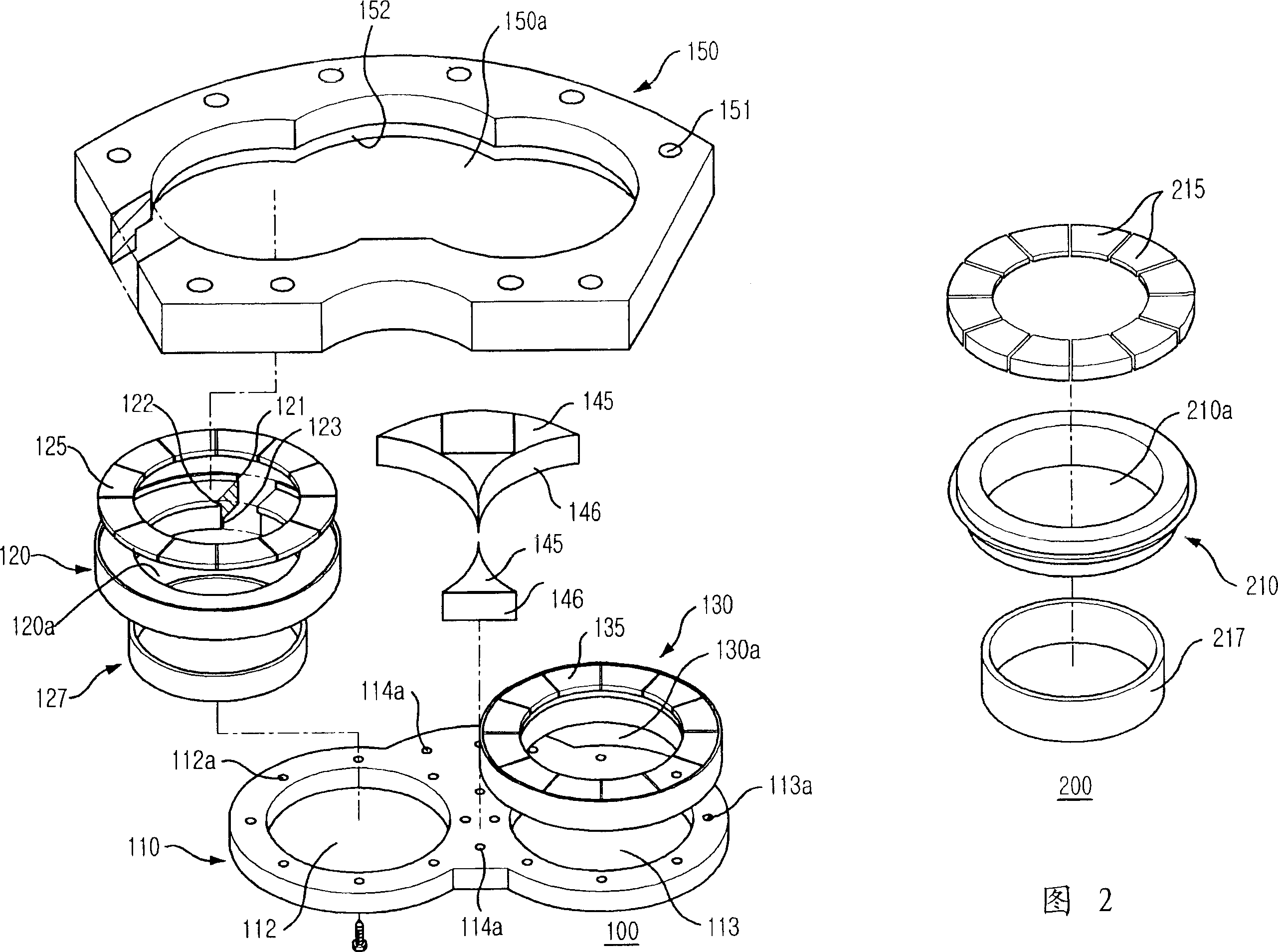

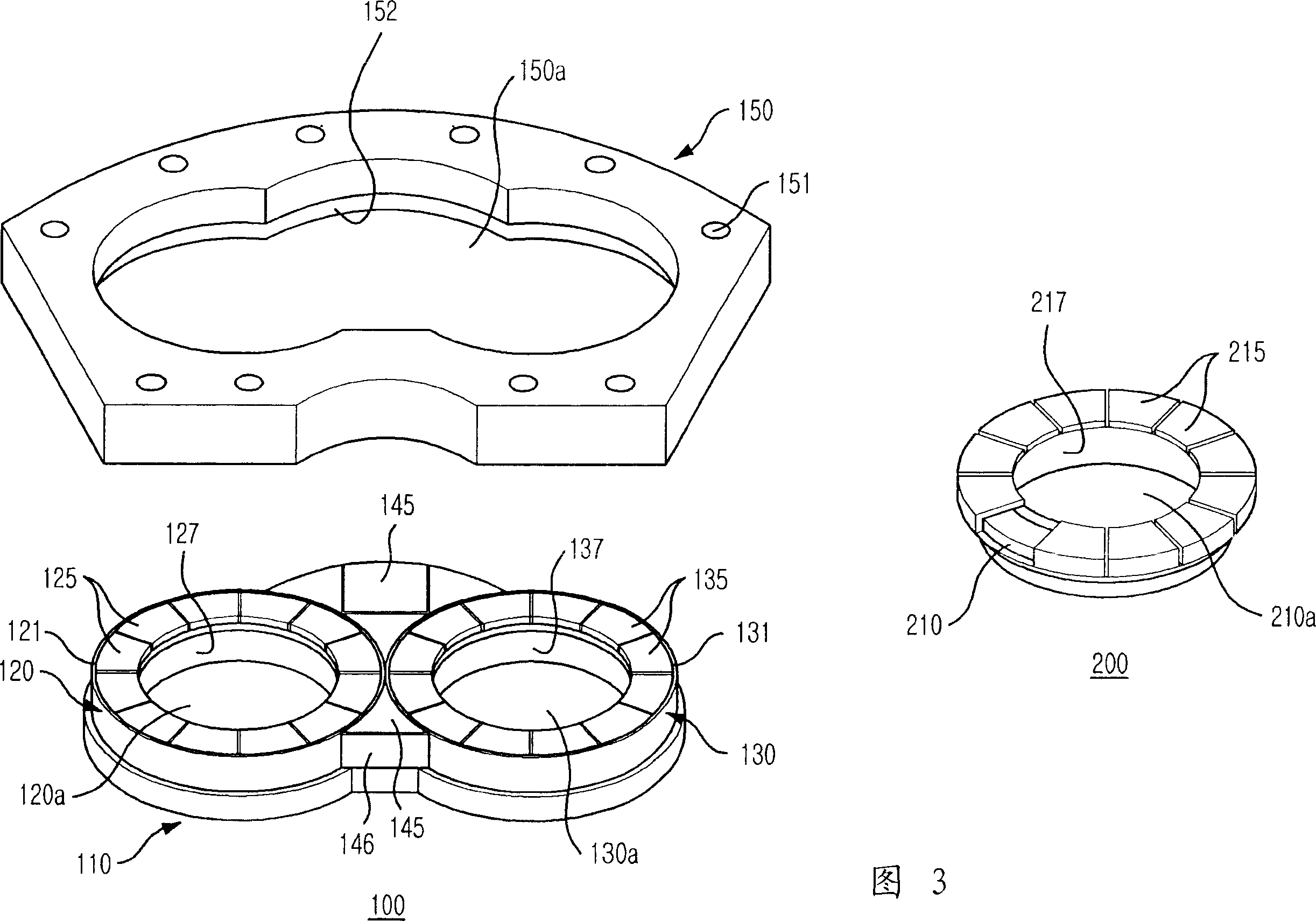

[0031] Fig. 2 is an exploded perspective view showing the sliding structure of the embodiment of the present invention. Fig. 3 is a perspective view showing the sliding structure of Fig. 2, Figure 4 It is a cross-sectional view showing a side part of the sliding structure of FIG. 3. The sliding structure for a concrete pump includes: a flat fixed part 100 with a pair of inlet holes 120a and 120b; and an annular movable part 200 with an outlet hole 210a.

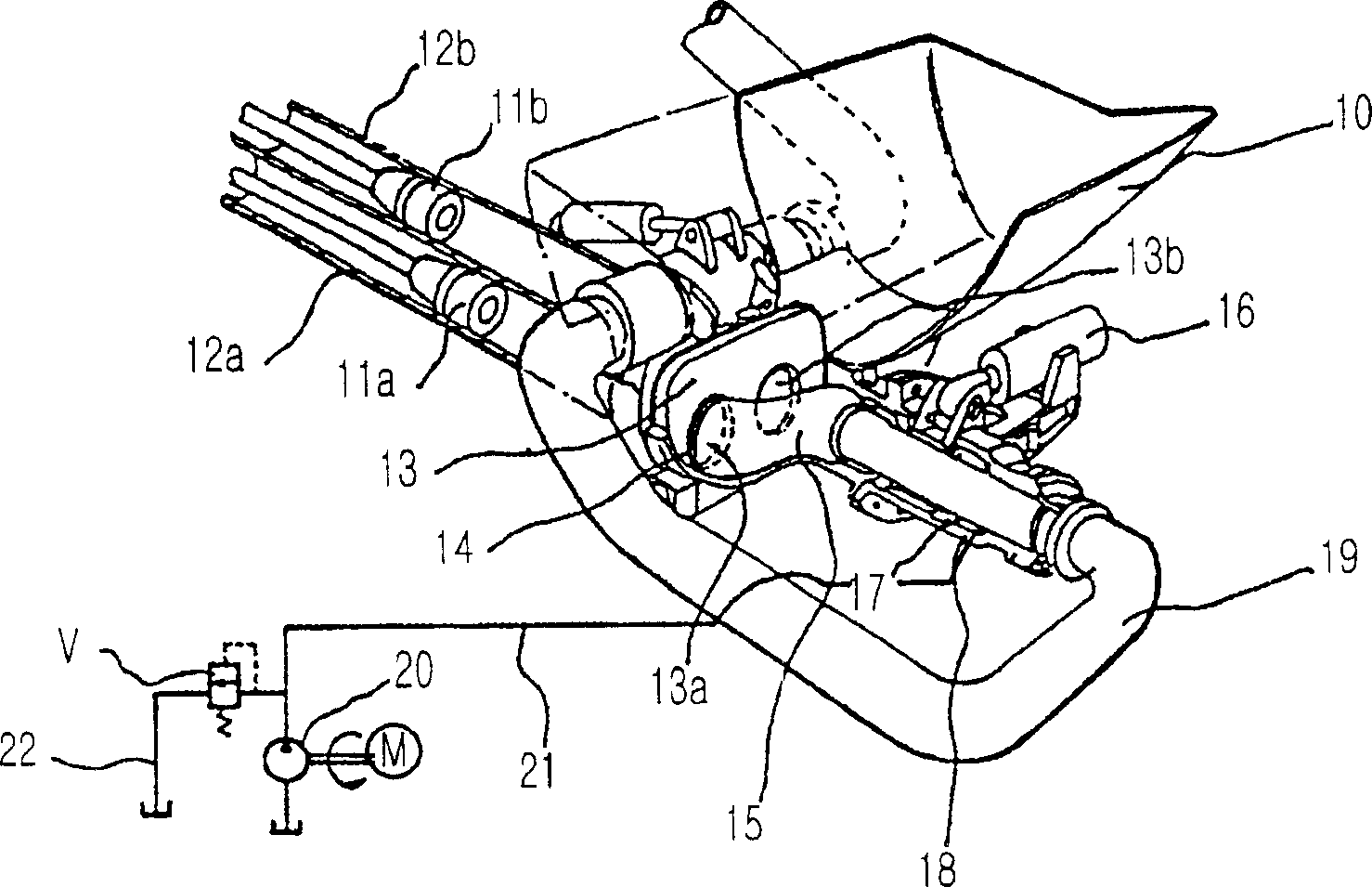

[0032] The concrete pump extrudes concrete by using concrete pistons that alternately move back and forth in a pair of concrete cylinders, and discharges the concrete through an S-shaped gate valve. The extruded concrete is shaken in the S-shaped gate valve, and the fixed part 100 and the movable part 200 are firmly fixed. At the end of the concrete cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com