Roller cage cleaning and pre-cooling machine

A technology of pre-cooler and rolling cage, which is applied in carcass cooling, slaughtering, poultry processing, etc. It can solve the problems of inability to install a refrigeration evaporator, poor cleaning effect, and poor cooling effect, achieving good cleaning effect and cooling Good effect and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

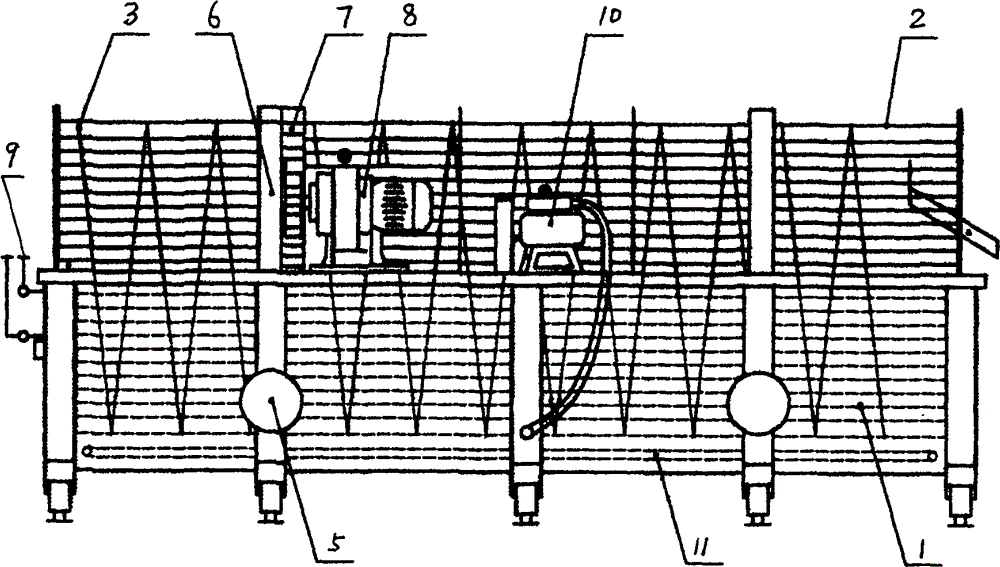

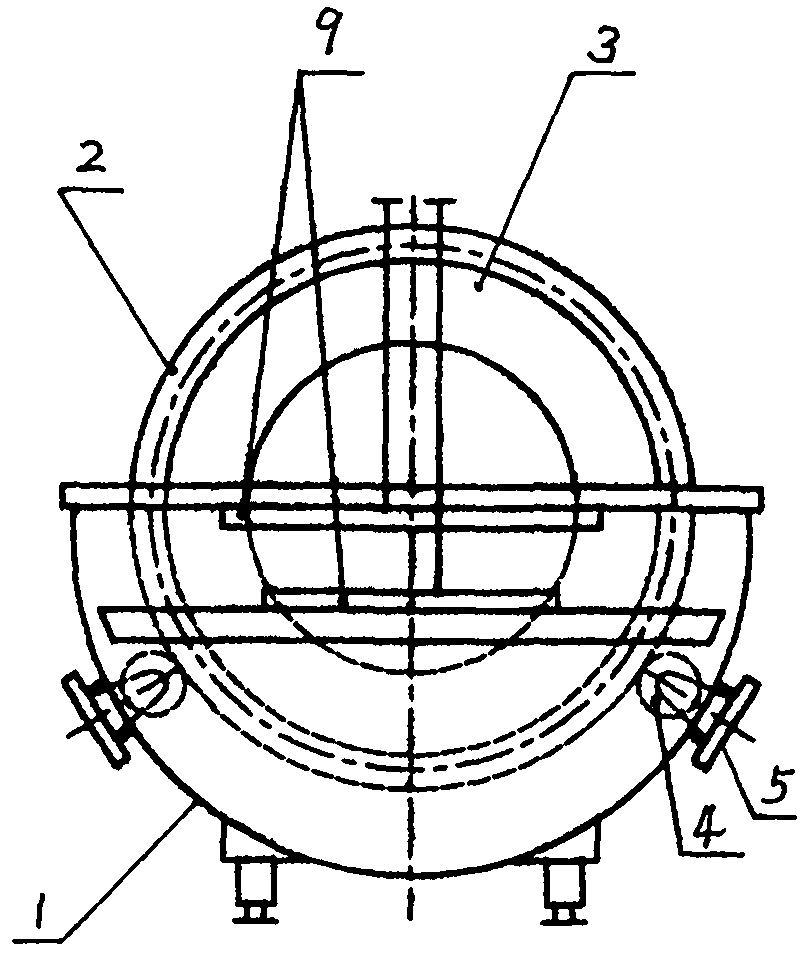

[0011] refer to figure 1 , 2 , it includes a main body 1, a rolling cage 2 is arranged in the main body, a spiral piece 3 is mounted on the inner wall of the rolling cage, and a plurality of rollers 4 are arranged on the main body, and each roller is installed in the main body through a respective roller bracket 5 , the rolling cage has a rolling groove 6 at the position corresponding to the idler roller, the rolling groove is placed on the idler roller, there is a ring gear 7 on the outer circumference of the rolling cage, a motor reducer 8 is fixed on the main body, and the motor reducer power output shaft The gear meshes with the ring gear on the outer circumference of the rolling cage, and the rolling cage has an inlet at one end and an outlet at the other end.

[0012] It includes a main body 1, a rolling cage 2 in the main body, a spiral piece 3 installed on the inner wall of the rolling cage, and several idlers 4 on the main body, each idler is installed in the main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com