Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about "Amylose/amylopective derivative adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

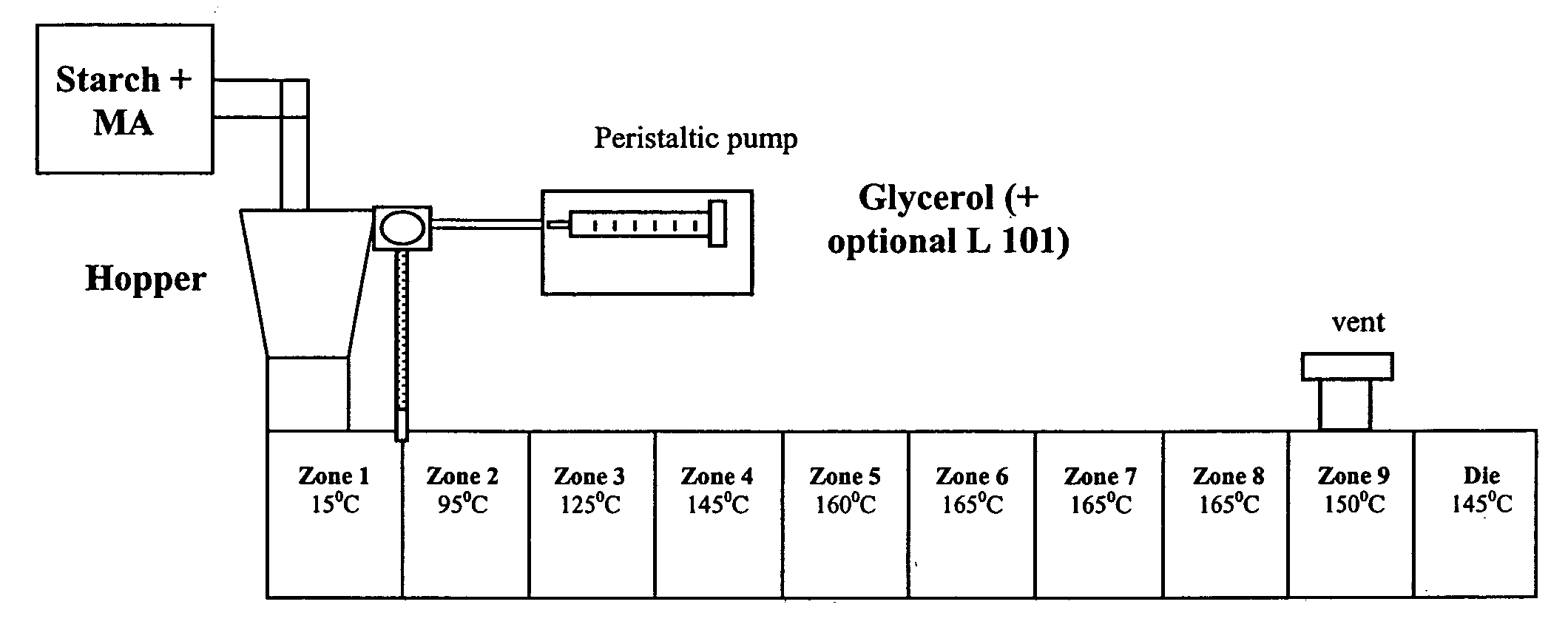

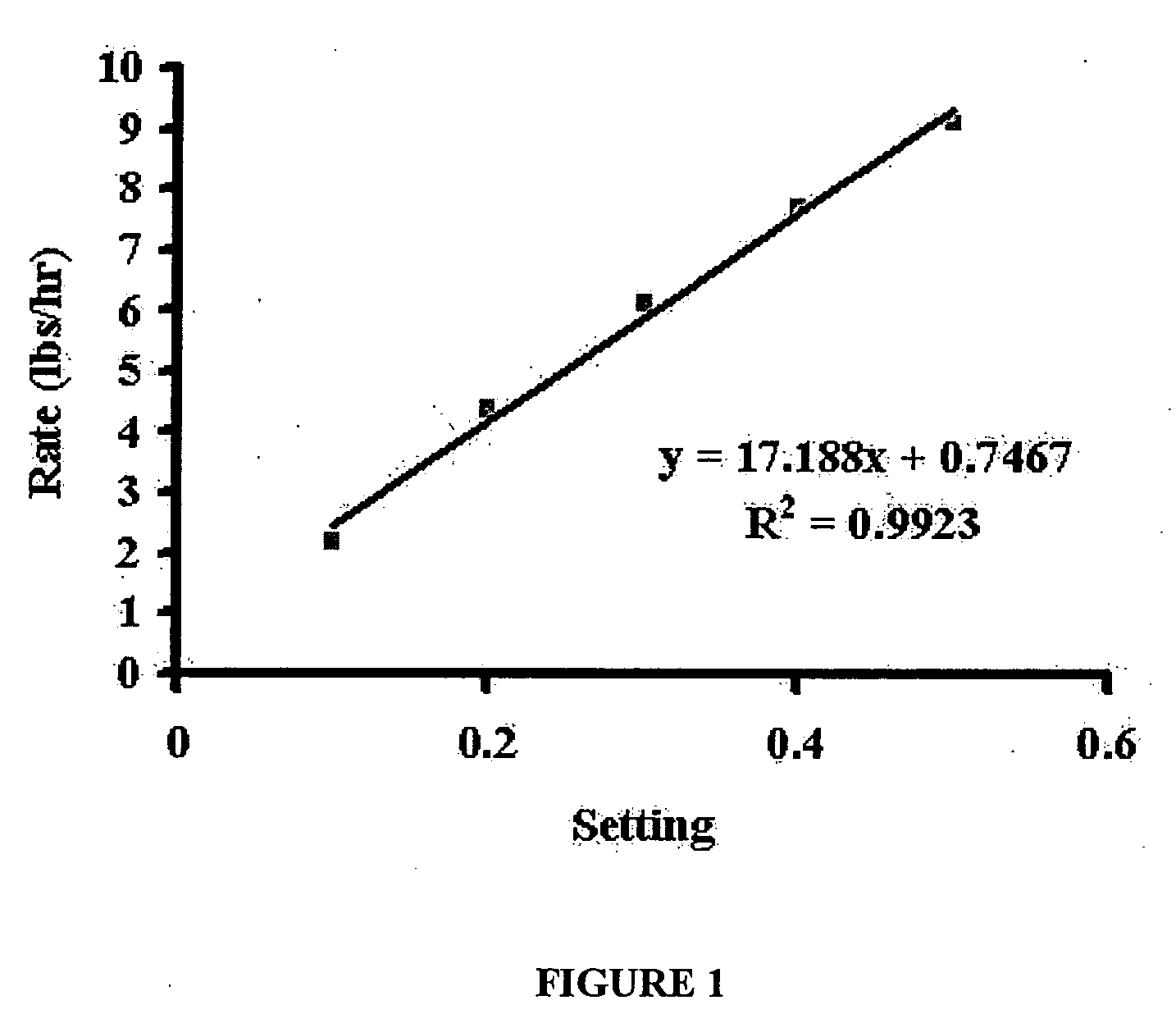

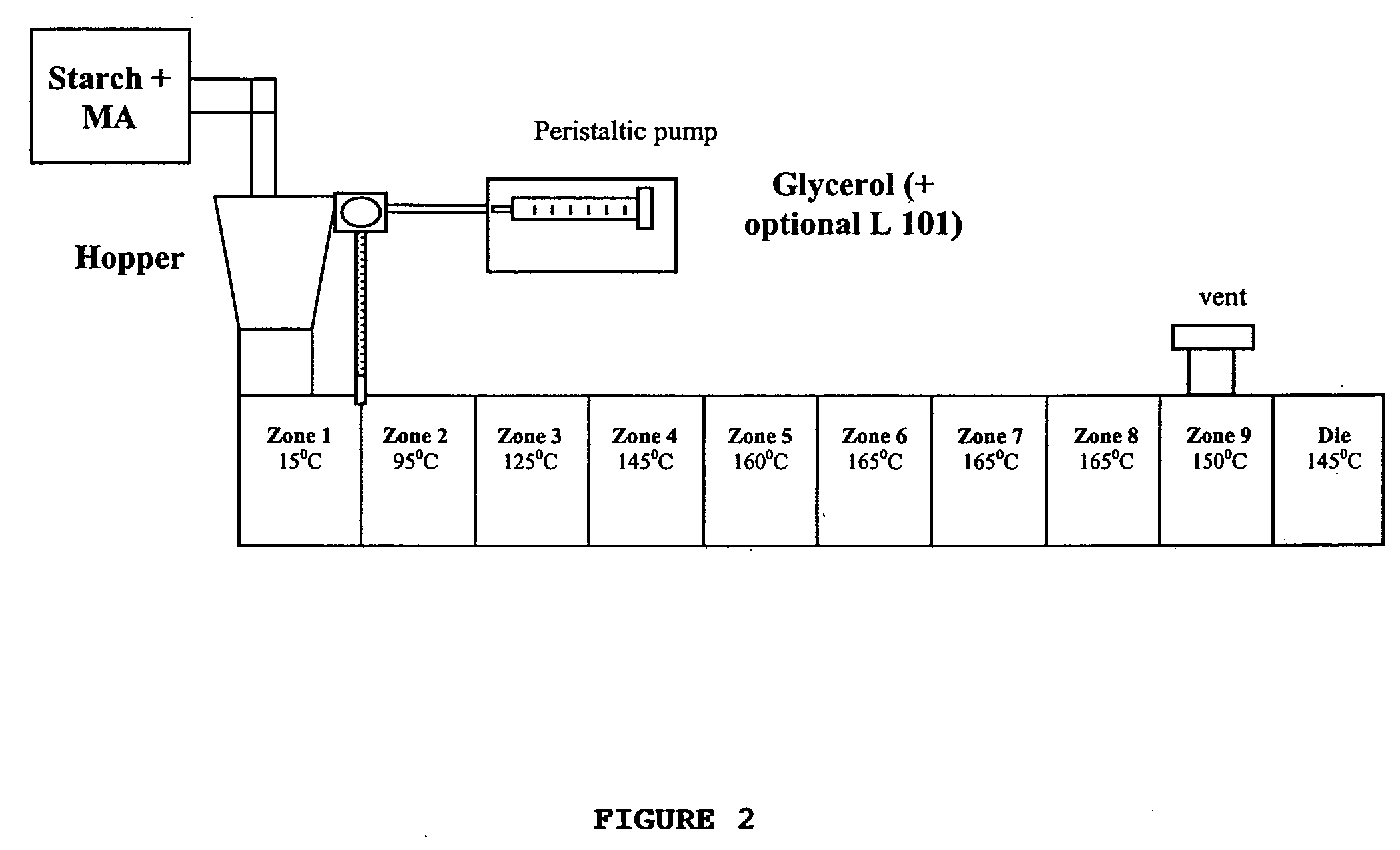

Chemically modified plasticized starch compositions by extrusion processing

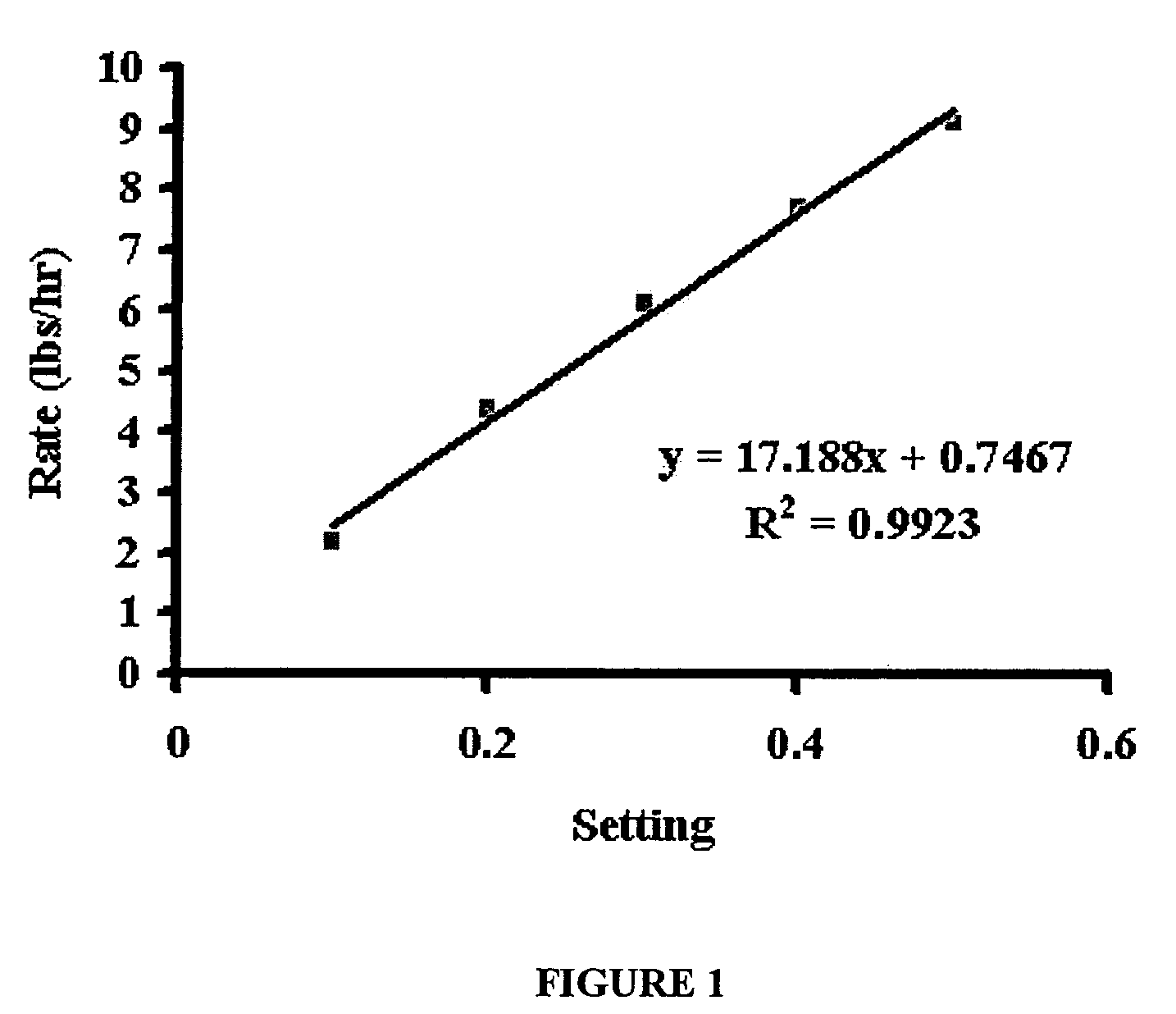

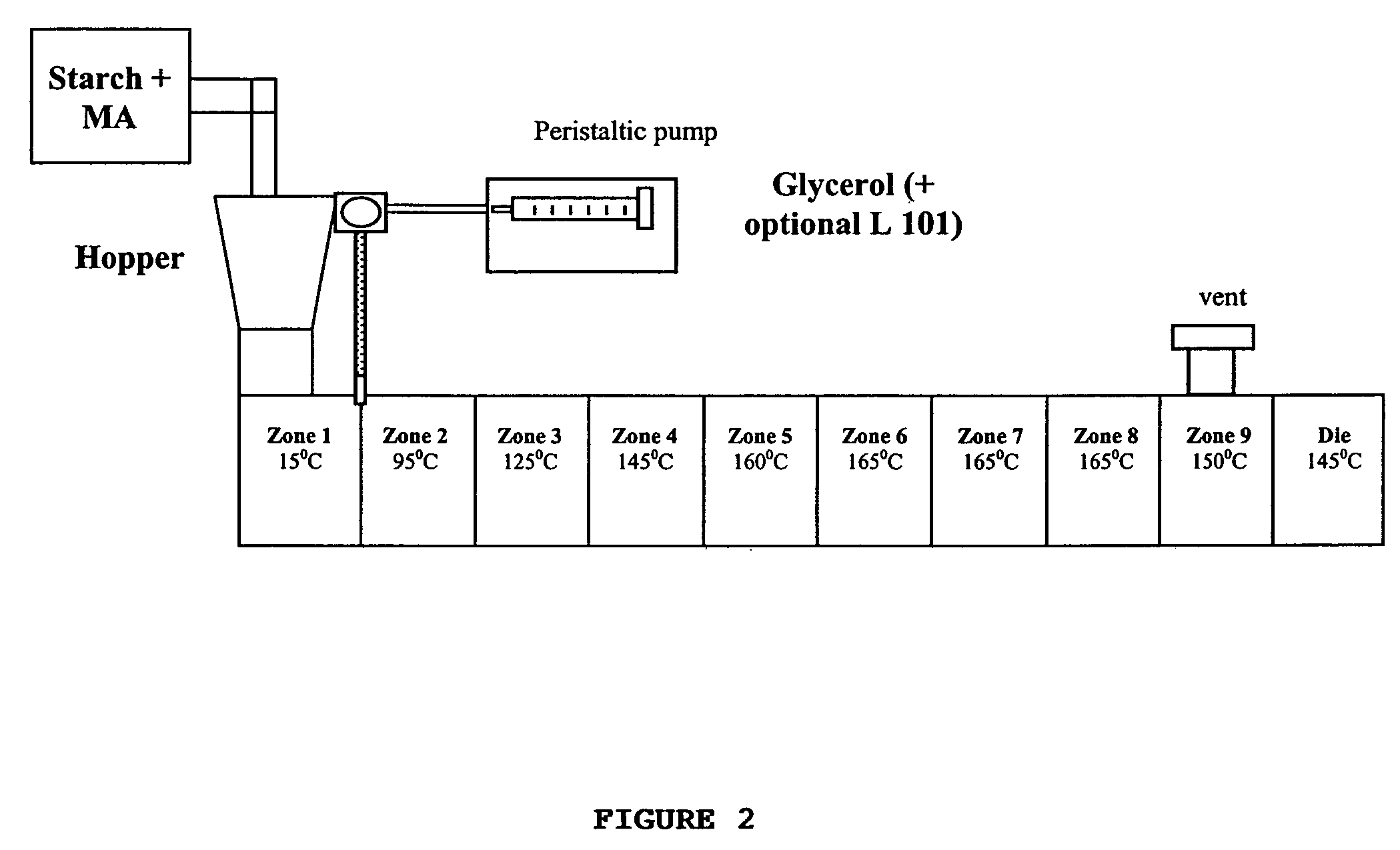

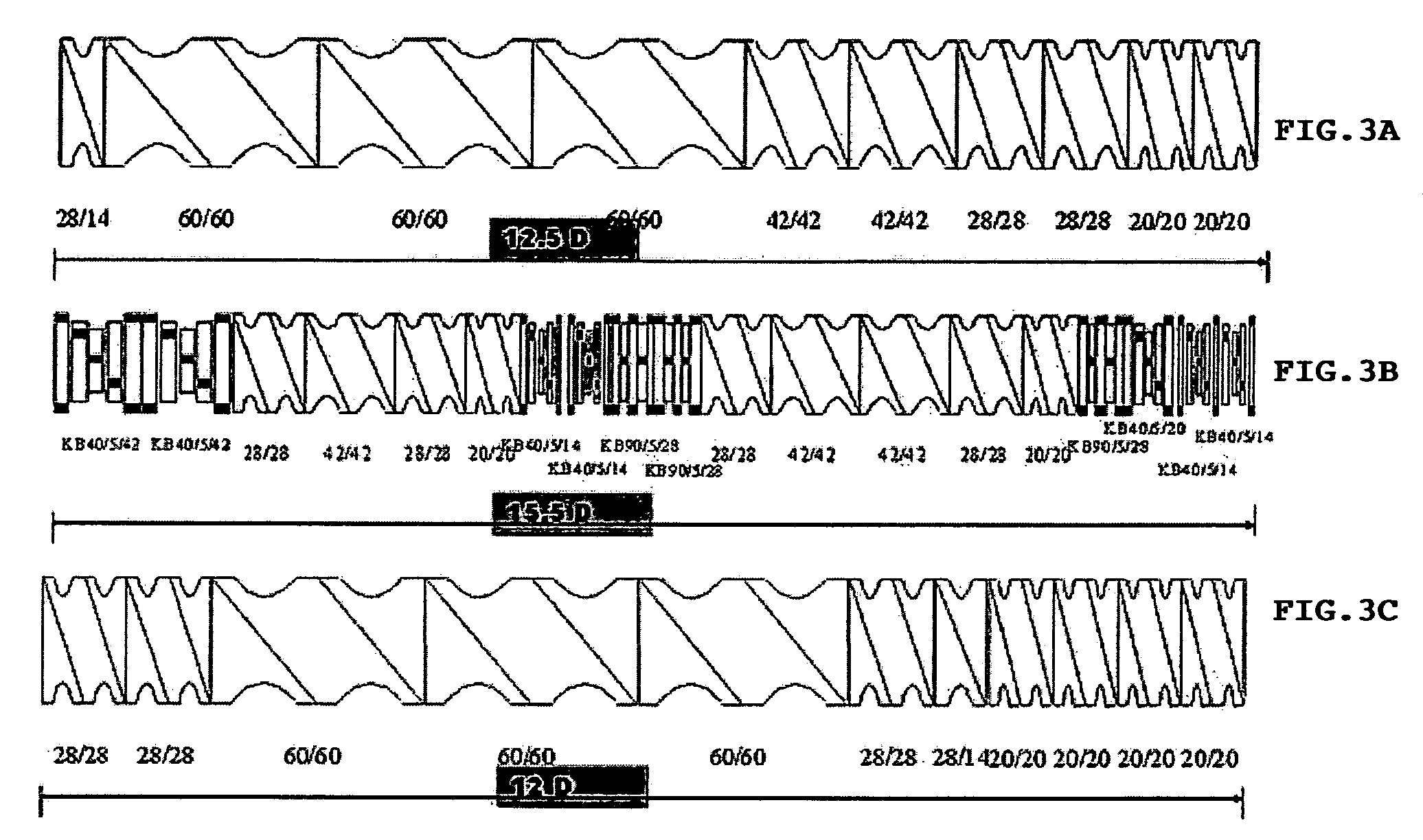

ActiveUS7153354B2Improved propertyEconomical and reproducibleStarch dervative coatingsAmylose/amylopectin derivative coatingsPlasticizerViscosity

A chemically modified plasticized starch (CMPS) is prepared by reacting starch with an organic dibasic acid or an anhydride of the acid in the presence of a plasticizer using optional free radical initiators, and optionally with the incorporation of nano clays in the reactive extrusion process. The starch is thermoplastic and has a lower viscosity than the traditional thermoplastic starch. The CMPS is useful in preparing starch polymer compositions which are at least partially biodegradable.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

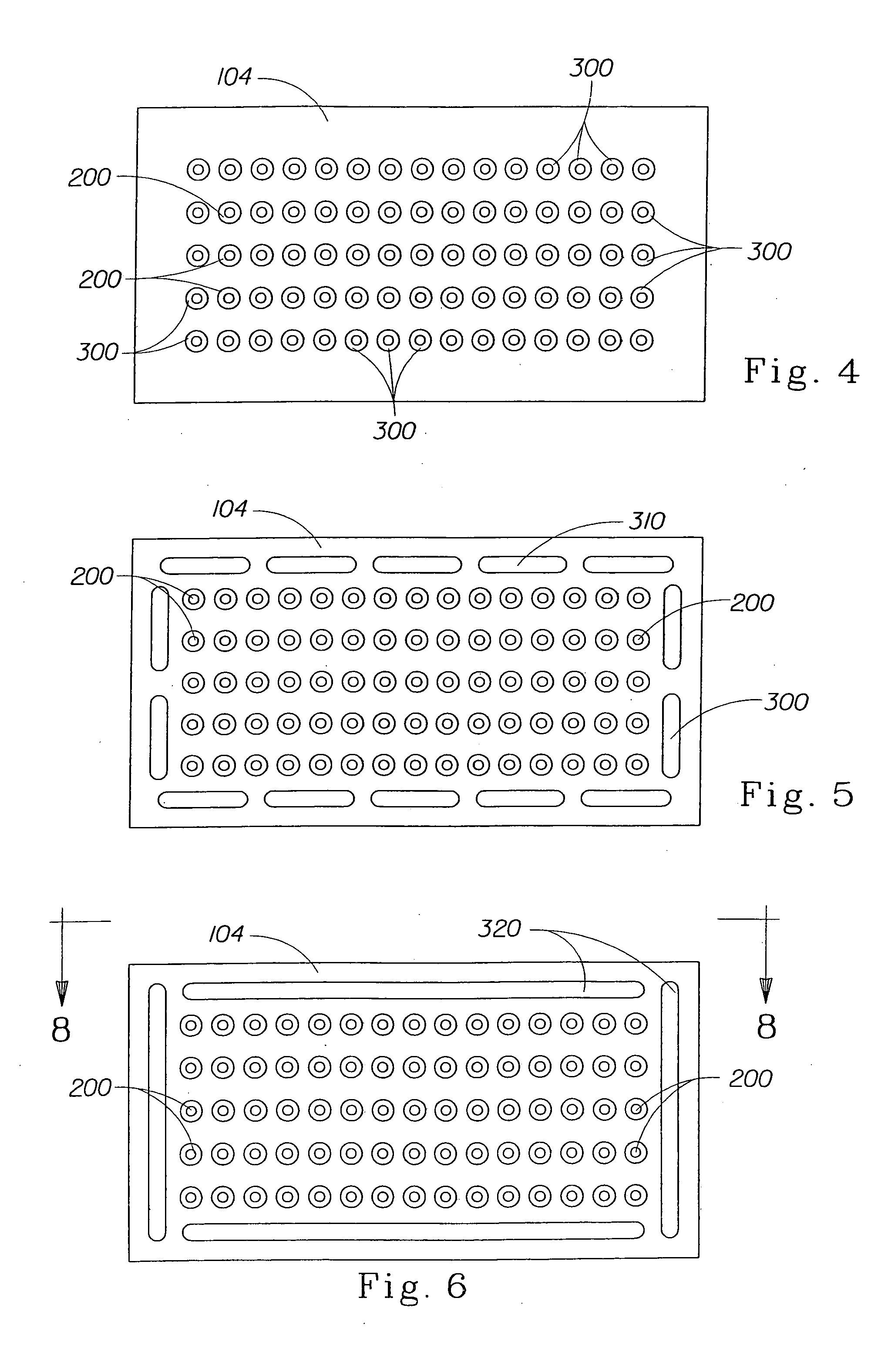

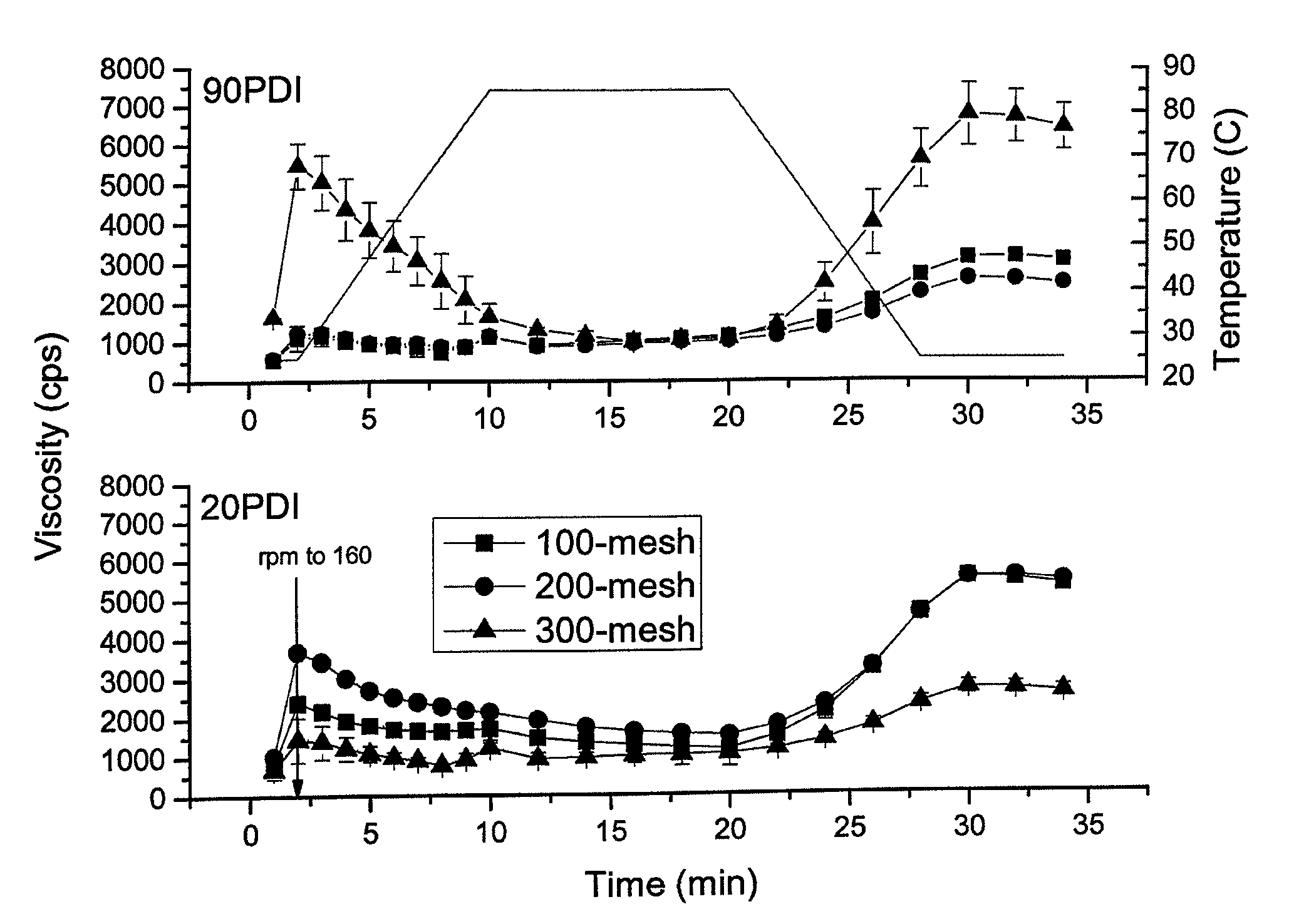

Non-thermoplastic starch fibers and starch composition for making same

InactiveUS7025821B2Starch dervative coatingsAmylose/amylopectin derivative coatingsFiberThermoplastic

Non-thermoplastic starch fibers having no melting point and having apparent peak wet tensile stress greater than about 0.2 MegaPascals (MPa). The fibers can be manufactured from a composition comprising a modified starch and a cross-linking agent. The composition can have a shear viscosity from about 1 Pascal·Seconds to about 80 Pascal·Seconds and an apparent extensional viscosity in the range of from about 150 Pascal·Seconds to about 13,000 Pascal·Seconds. The composition can comprise from about 50% to about 75% by weight of a modified starch; from about 0.1% to about 10% by weight of an aldehyde cross-linking agent; and from about 25% to about 50% by weight of water. Prior to cross-linking, the modified starch can have a weight average molecular weight greater than about 100,000 g / mol.

Owner:PROCTER & GAMBLE CO

Non-thermoplastic starch fibers and starch composition for making same

InactiveUS20050076809A1Starch dervative coatingsAmylose/amylopectin derivative coatingsThermoplasticFiber

Non-thermoplastic starch fibers having no melting point and having apparent peak wet tensile stress greater than about 0.2 MegaPascals (MPa). The fibers can be manufactured from a composition comprising a modified starch and a cross-linking agent. The composition can have a shear viscosity from about 1 Pascal.Seconds to about 80 Pascal.Seconds and an apparent extensional viscosity in the range of from about 150 Pascal.Seconds to about 13,000 Pascal.Seconds. The composition can comprise from about 50% to about 75% by weight of a modified starch; from about 0.1% to about 10% by weight of an aldehyde cross-linking agent; and from about 25% to about 50% by weight of water. Prior to cross-linking, the modified starch can have a weight average molecular weight greater than about 100,000 g / mol.

Owner:THE PROCTER & GAMBLE COMPANY

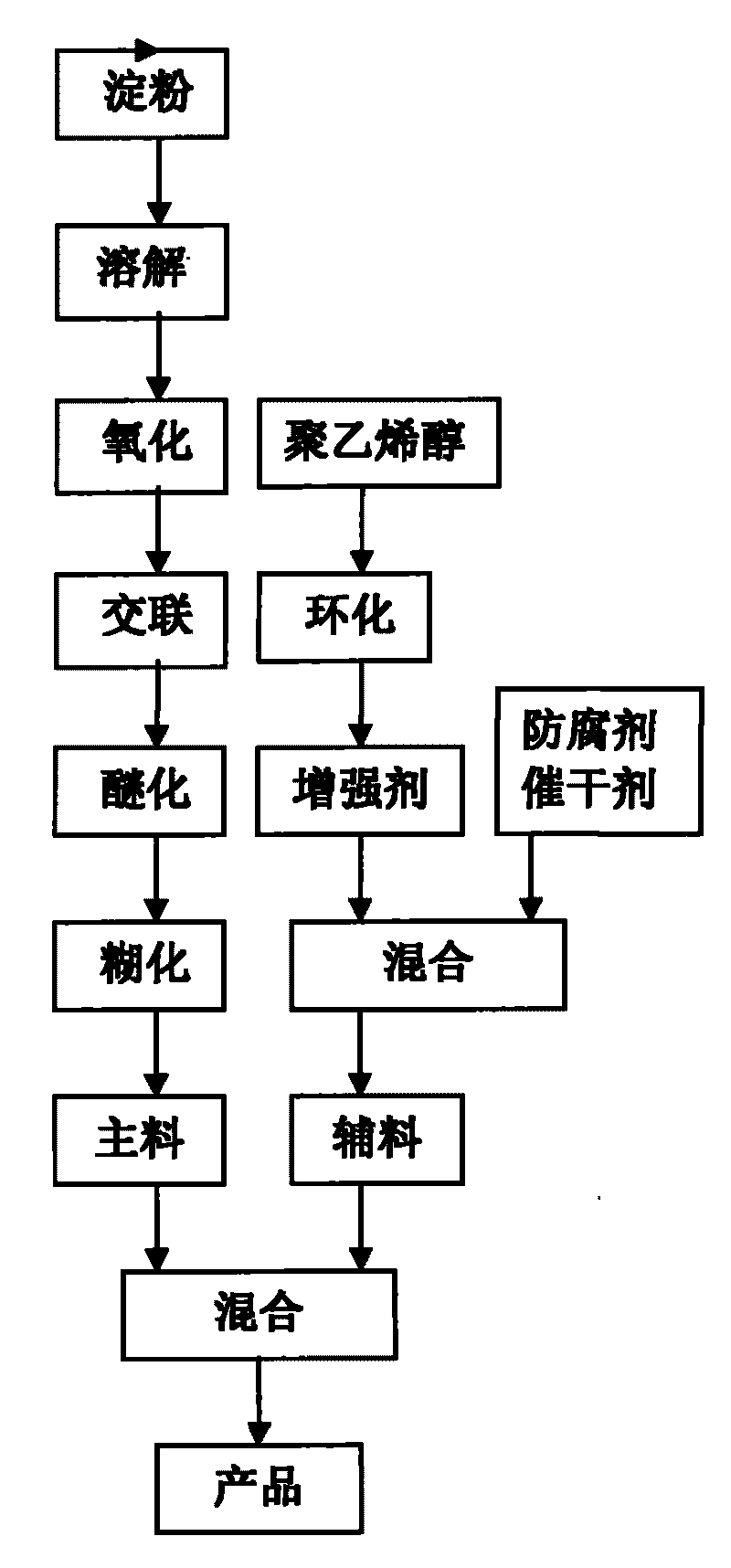

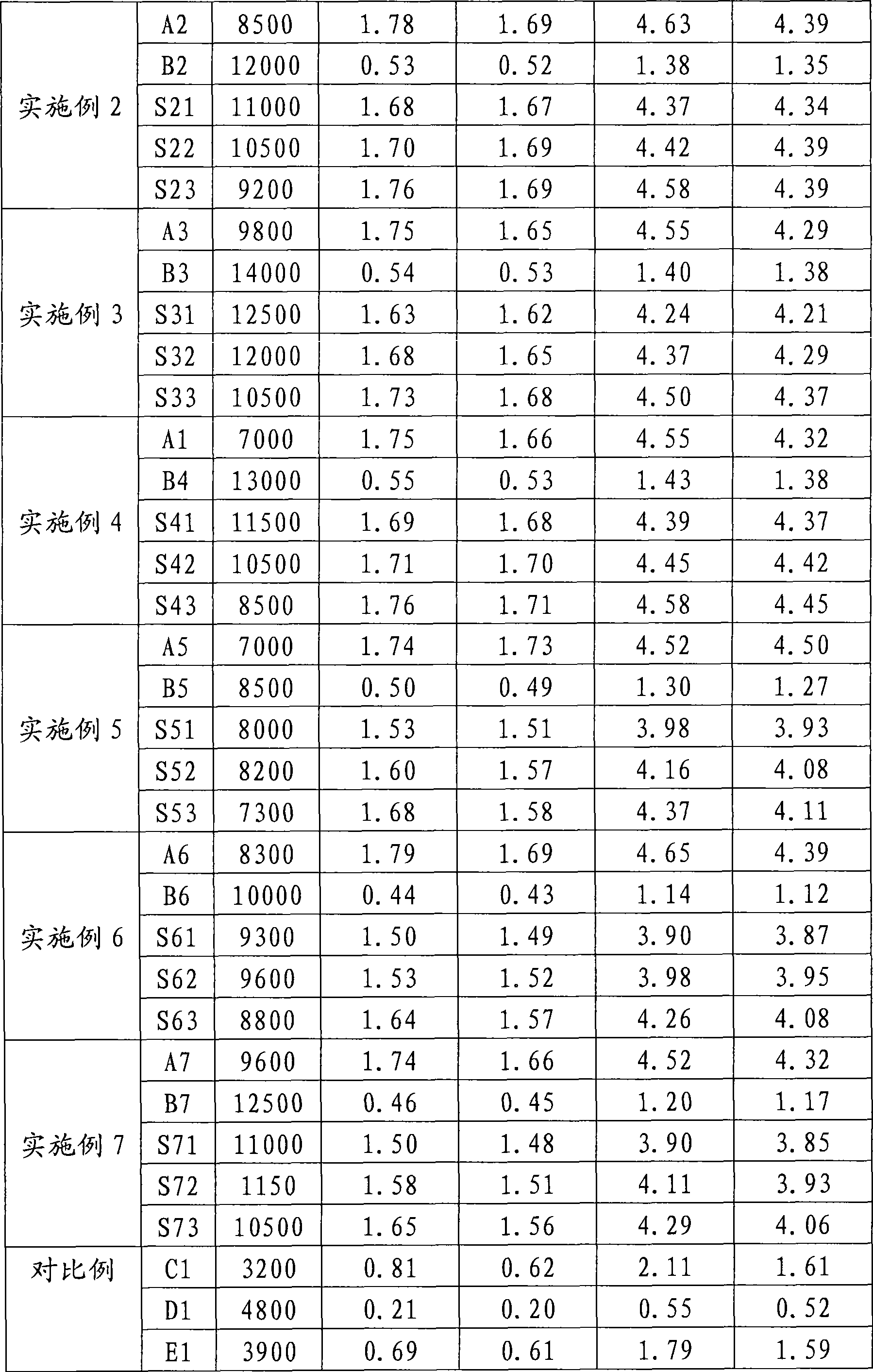

Environmental-friendly amylopectin composite adhesive for paper products and production method thereof

InactiveCN101760149AWell mixedGood adhesionMechanical working/deformationAmylose/amylopective derivative adhesivesCardboardPolyvinyl alcohol

The invention discloses an environmental-friendly amylopectin composite adhesive for paper products and a production method thereof. The composite adhesive is prepared by oxidizing, cross-linking, etherifying and pasting starch to generate a modified starch adhesive, modifying polyvinyl alcohol to be used as a reinforcing agent, adding a preserving agent and a drier, and compounding. The environmental-friendly amylopectin composite adhesive for the paper product has strong initial adhesion and adhesive force, high-speed drying, fast natural air-drying without the phenomenon of wire drawing, corrugation deviation, corrugation-collapse, and the like, favorable cardboard hardness and stiffness, and has no efforescence, and does not absorb moisture. The invention is applied to the glue for producing three domestic corrugated boards and applied to the glue for various paper barrels, paper tubes, cement bag papers, furniture and interior decorations.

Owner:莫元烈

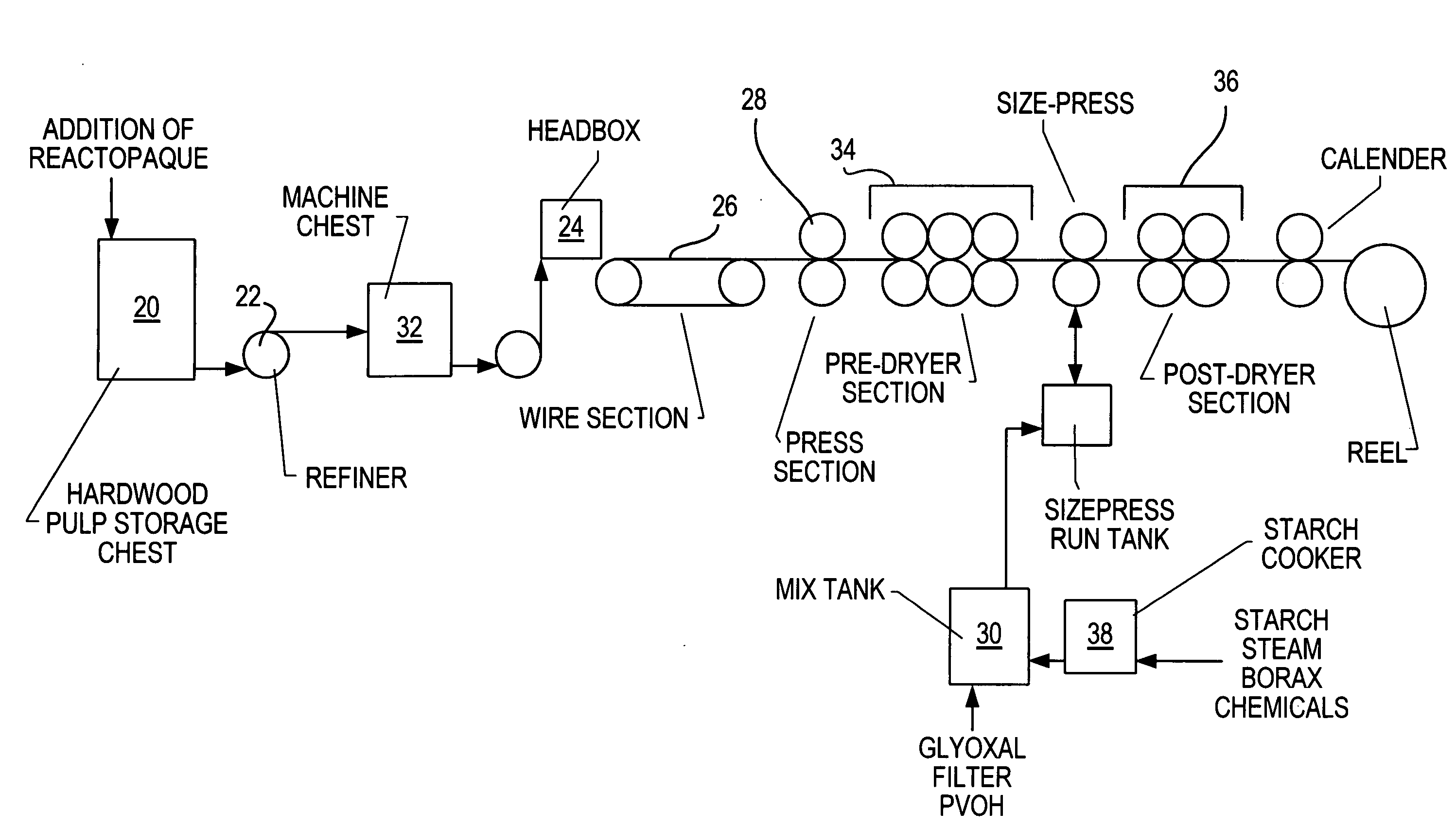

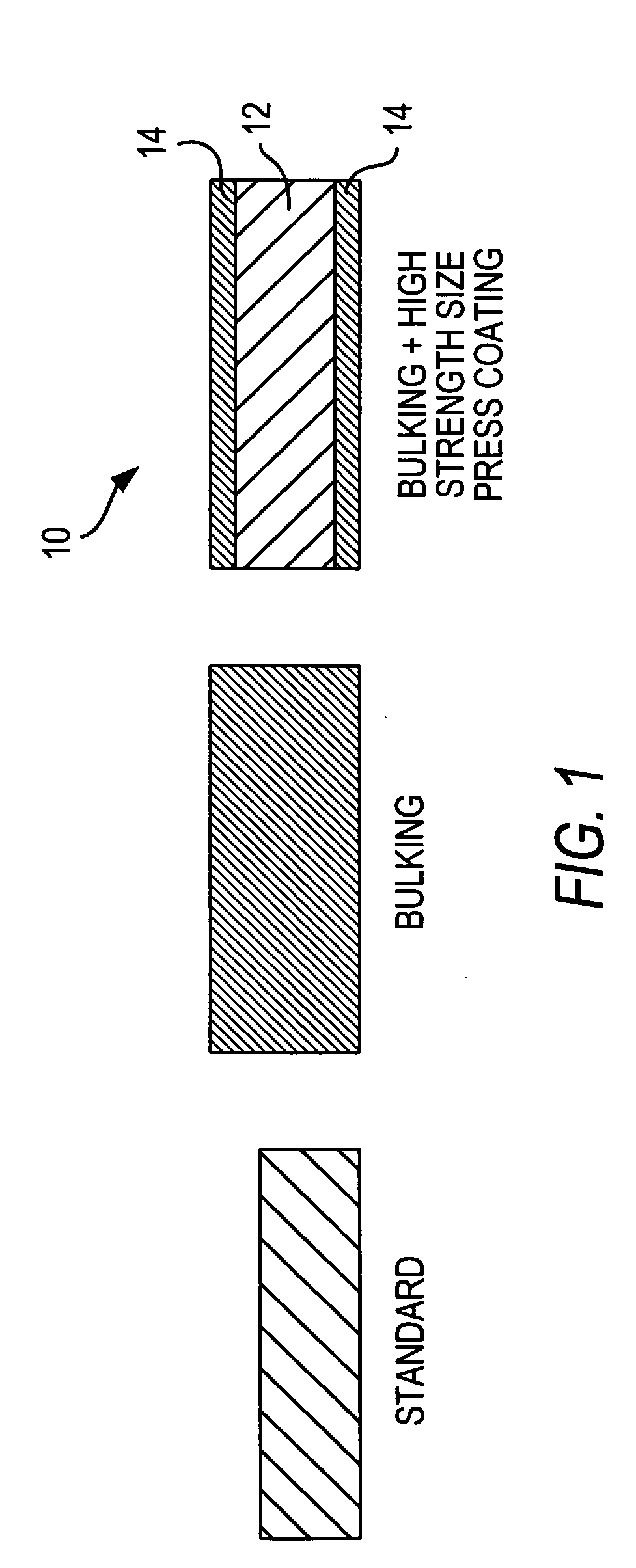

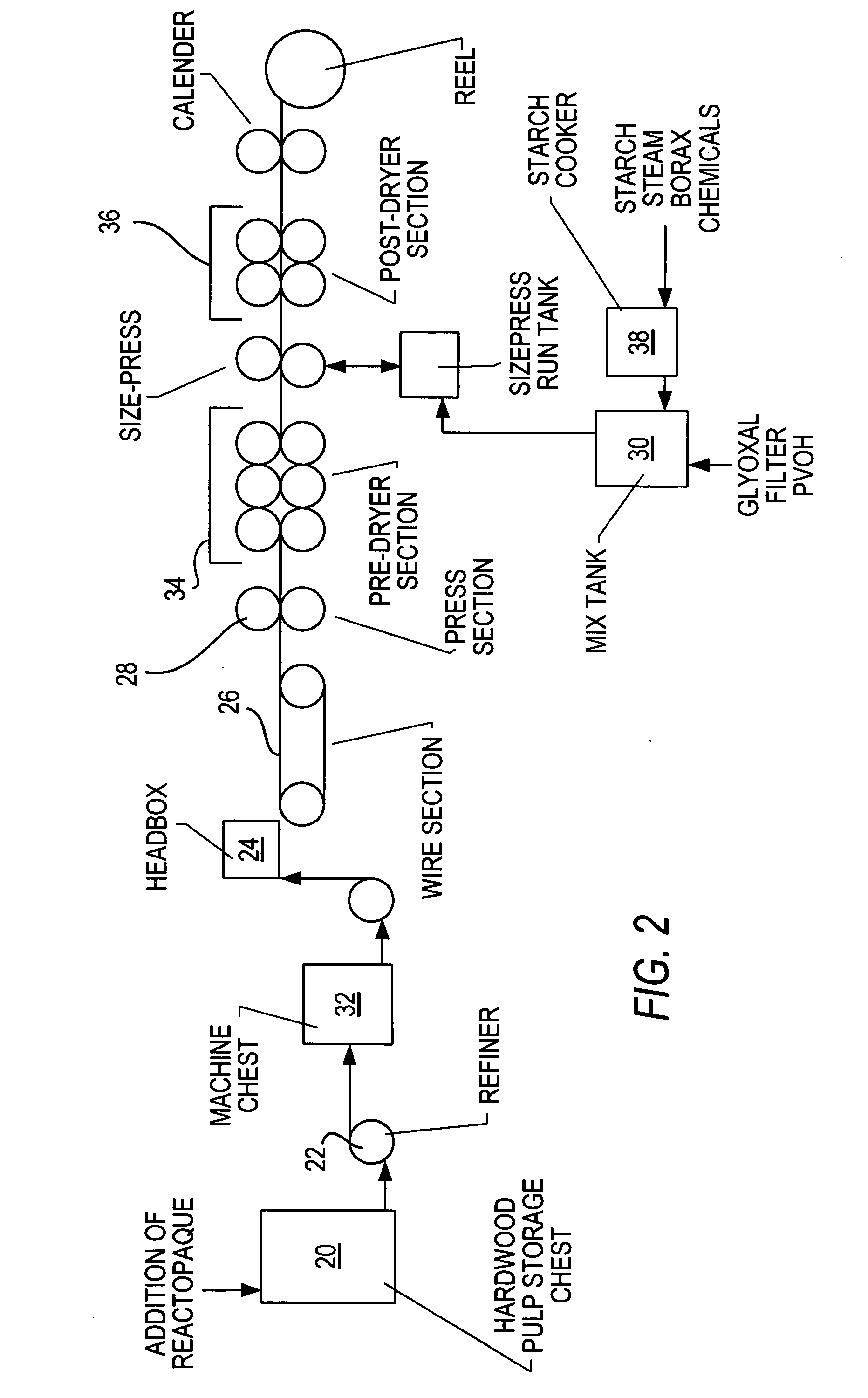

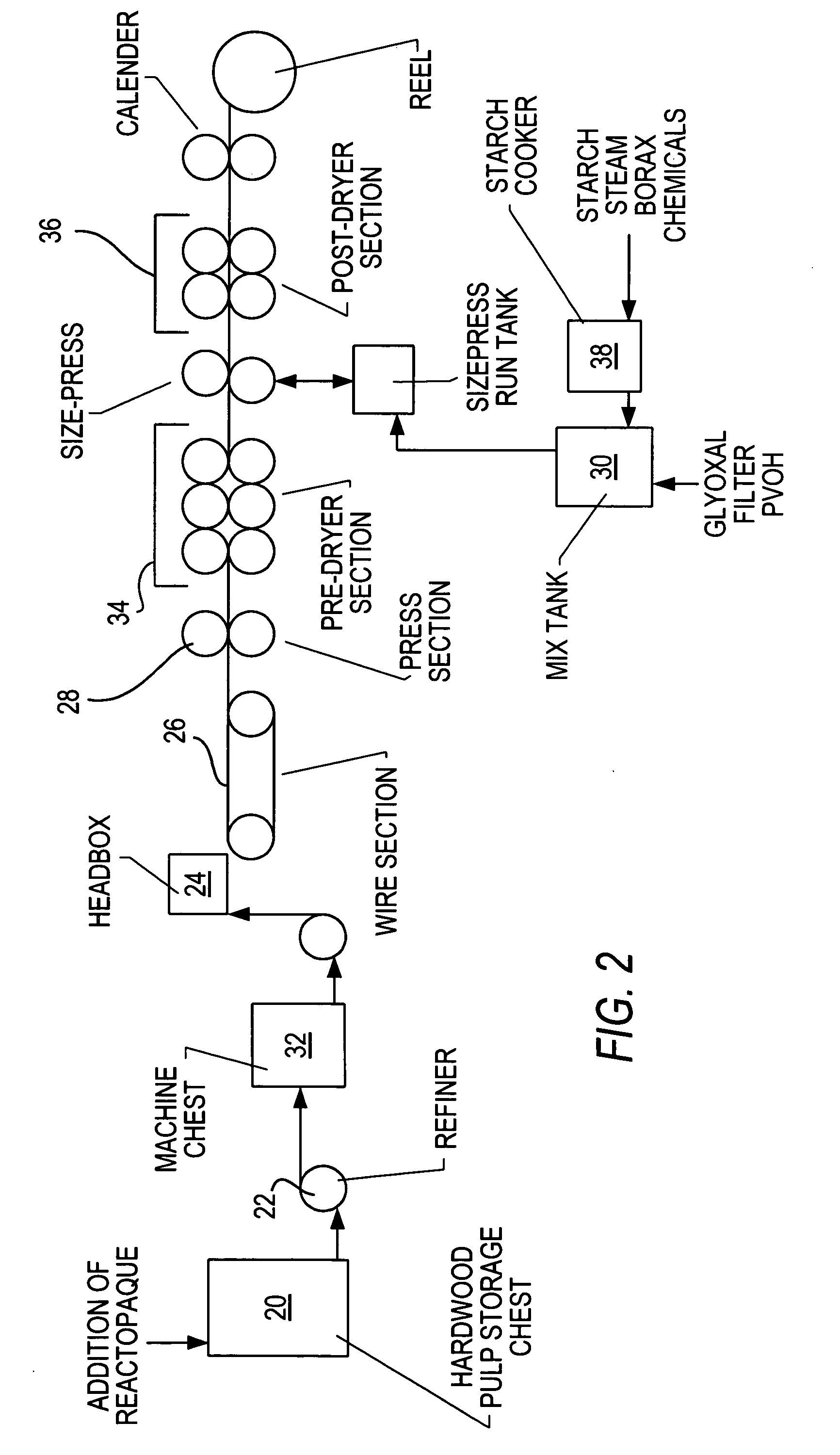

Paper with improved stiffness and bulk and method for making same

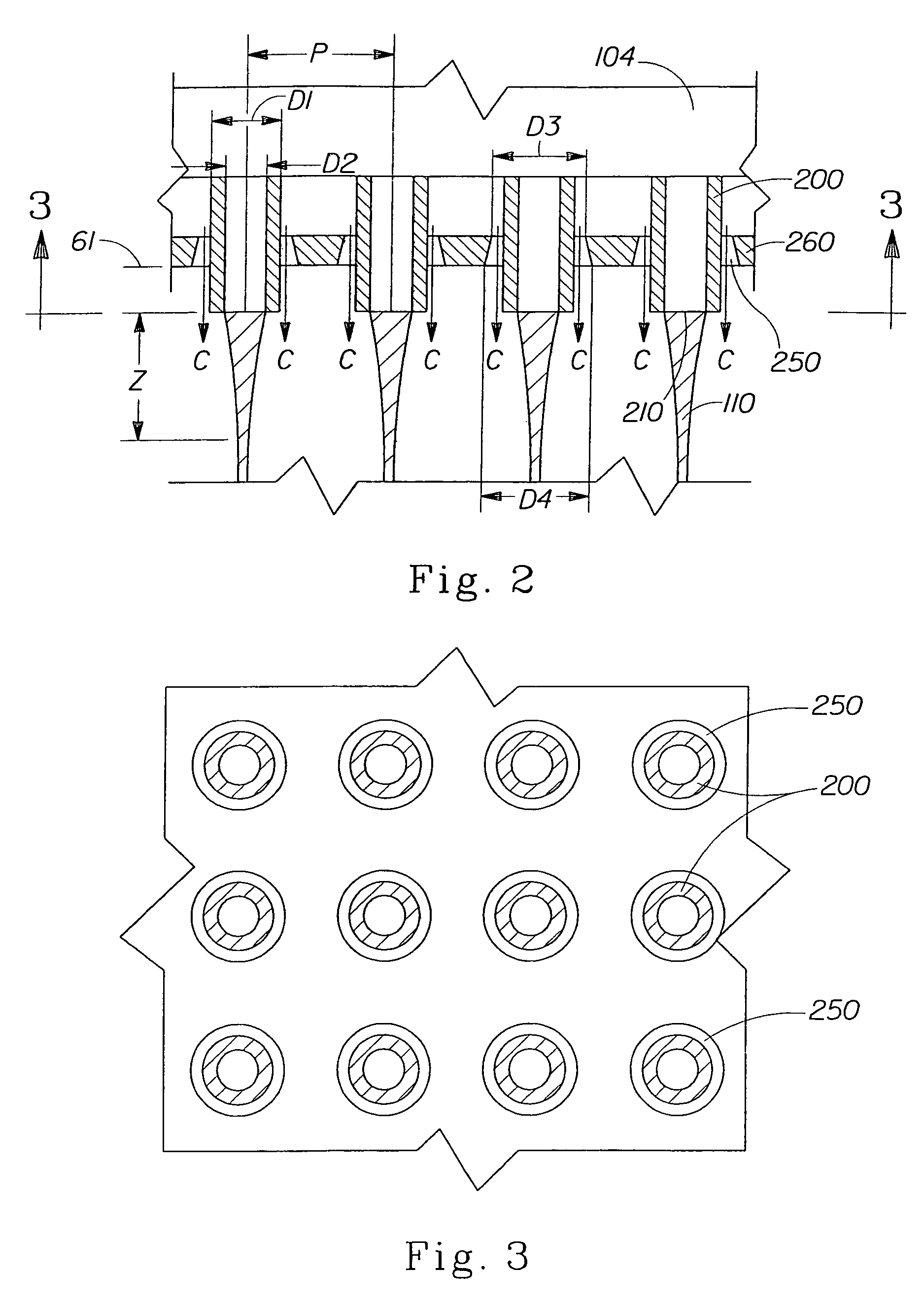

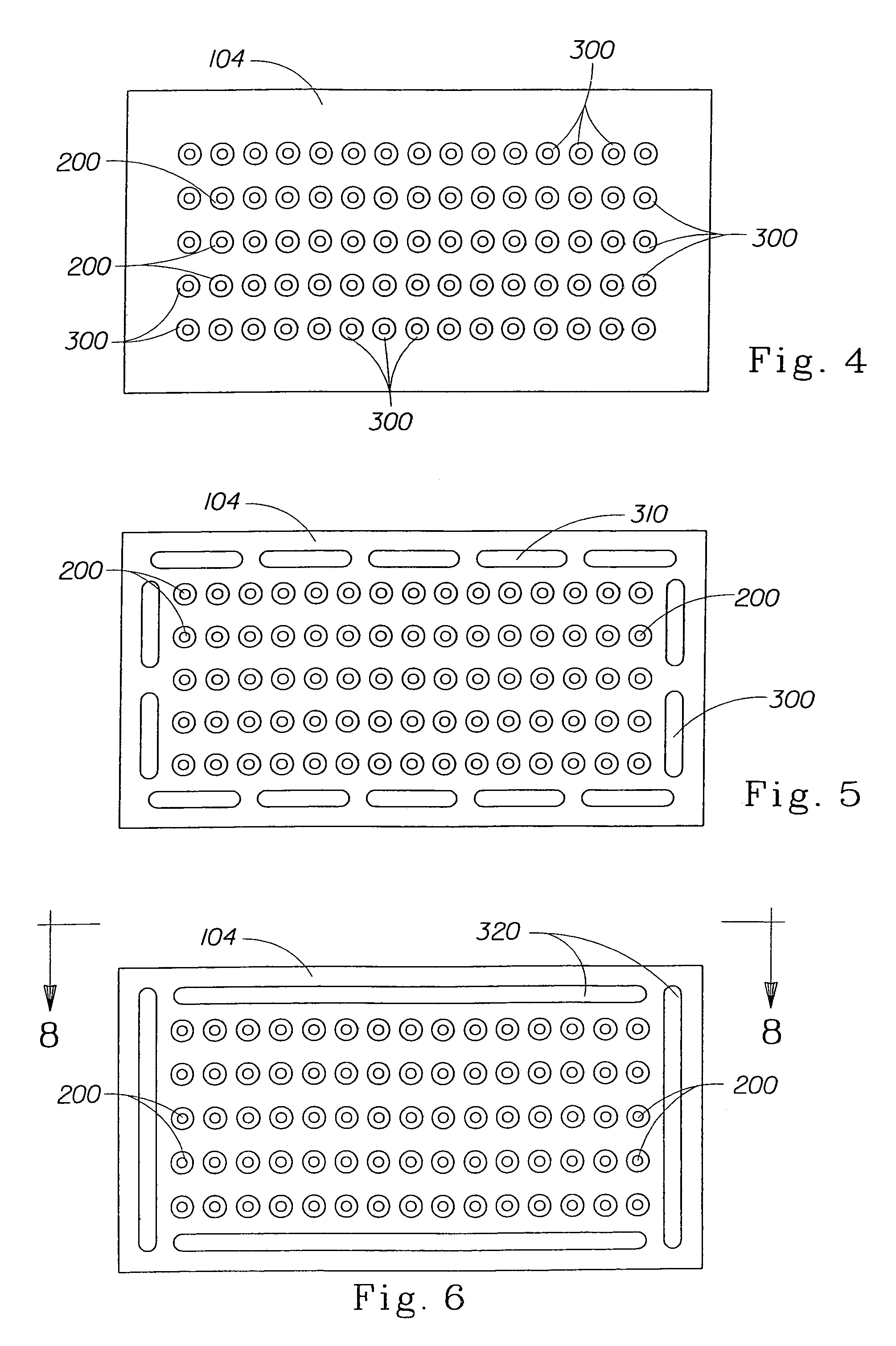

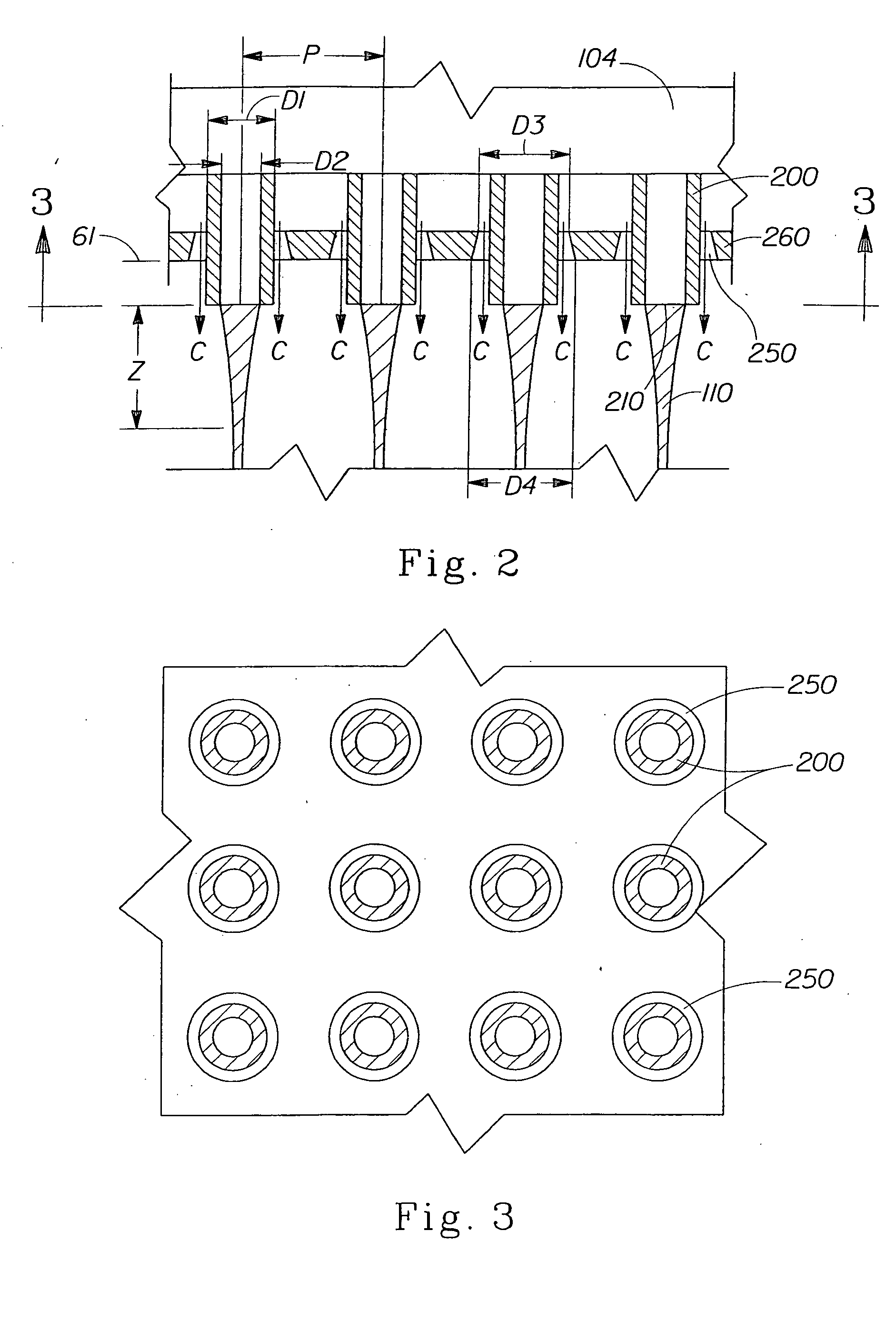

InactiveUS20090020247A1Improve bulkIncrease stiffnessSpecial paperWater-repelling agents additionCellulosePulp and paper industry

The invention provides a three layered reprographic paper having improved strength, stiffness and curl resistance properties, and a method for making same. The paper has a central core layer made largely of cellulose and bulked with a bulking agent such as a diamide salt. A starch-based metered size press coating is pressed on both sides of the core layer, wherein the starch has a high solid content. The coating forms a three layered paper having an I-beam arrangement with high strength outer layers surrounding a low density core.

Owner:INT PAPER CO

Chemically modified plasticized starch compositions by extrusion processing

ActiveUS20060107945A1Low viscosityEasy to processStarch dervative coatingsAmylose/amylopectin derivative coatingsPlasticizerViscosity

A chemically modified plasticized starch (CMPS) is prepared by reacting starch with an organic dibasic acid or an anhydride of the acid in the presence of a plasticizer using optional free radical initiators, and optionally with the incorporation of nano clays in the reactive extrusion process. The starch is thermoplastic and has a lower viscosity than the traditional thermoplastic starch. The CMPS is useful in preparing starch polymer compositions which are at least partially biodegradable.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Esterified-starch-modified waxy corn wet glue and preparation method thereof

ActiveCN102757745AIncrease paste areaReduce decoration costsMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesBiotechnologyWaxy corn

The invention belongs to the field of auxiliary binders in the wallpaper industry and particularly relates to an esterified-starch-modified waxy corn wet glue. The esterified-starch-modified waxy corn wet glue is mainly prepared from the following raw materials in parts by weight through gelatinization, cross-linking and complexation: 76-77 parts of de-ionized water, 5-7 parts of esterified starch A, 3-5 parts of esterified starch B, 4-6 parts of oxidized starch, 4-6 parts of modified waxy corn starch, 0.5-0.8 part of acrylamide, 0.1-0.15 part of nonferrous aluminum sulfate, 0.4 part of sodium benzoate, 0.1-0.15 part of a defoaming agent, 2 parts of urea, 1-1.2 parts of ethylene glycol, 0.2-0.4 part of a bactericide and 2-4 parts of white latex. The invention also provides a preparation method of the modified waxy corn wet glue. The esterified-starch-modified waxy corn wet glue, disclosed by the invention, is extracted and purified from natural waxy corns, belongs to circular plant products and is a renewable resource, so that the policy of saving energy in China is performed better; and meanwhile, the esterified-starch-modified waxy corn wet glue has the advantages of strong bonding power and capabilities of being mixed with water for 100%, improving the bonding area of wallpaper and reducing decoration cost for a user.

Owner:GAREFU TECH CO LTD

Foaming material composite, foamed material, and method of reproducing foamed material

InactiveUS20060272548A1Starch dervative coatingsAmylose/amylopectin derivative coatingsFoaming agentWater soluble polysaccharides

Disclosed is a foaming material composite including a water-soluble polysaccharide having ester linkage or amide linkage, a foaming agent, and a plasticizing agent.

Owner:KK TOSHIBA

Hydrophobic starch derivatives

InactiveUS7157573B2Maintain good propertiesHigh viscosityEsterified saccharide compoundsSugar derivativesPolymer scienceHydrophobe

The invention relates to a process for preparing a hydrophobic starch, comprising etherification, esterification or amidation of a root or tuber starch comprising at least 95 wt. % of amylopectin, based on dry substance of the starch, or a derivative thereof, with a substituent comprising an alkyl chain having from 4–24 carbon atoms. The invention further relates to a hydrophobic starch obtainable by said process.

Owner:COOP AVEBE U A

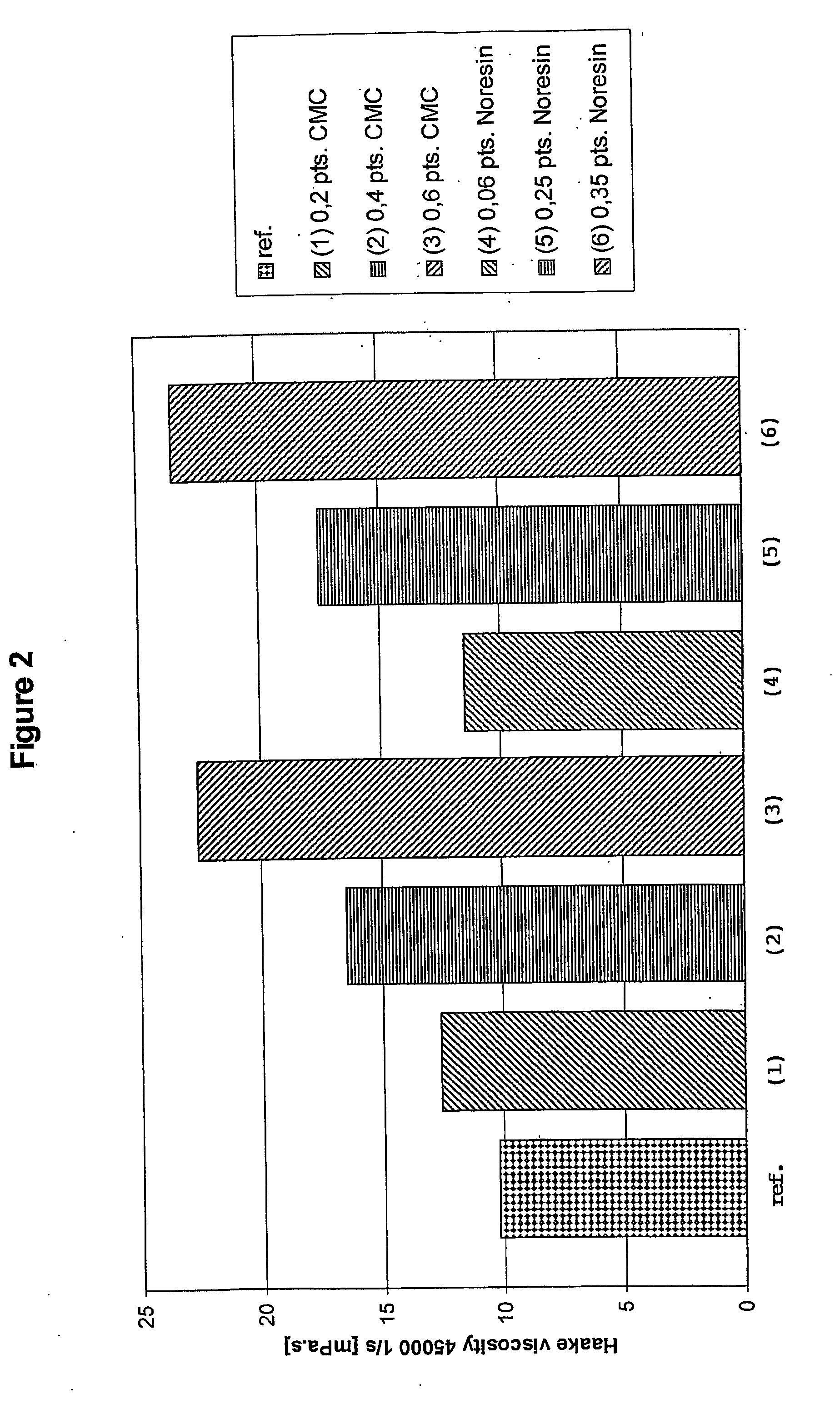

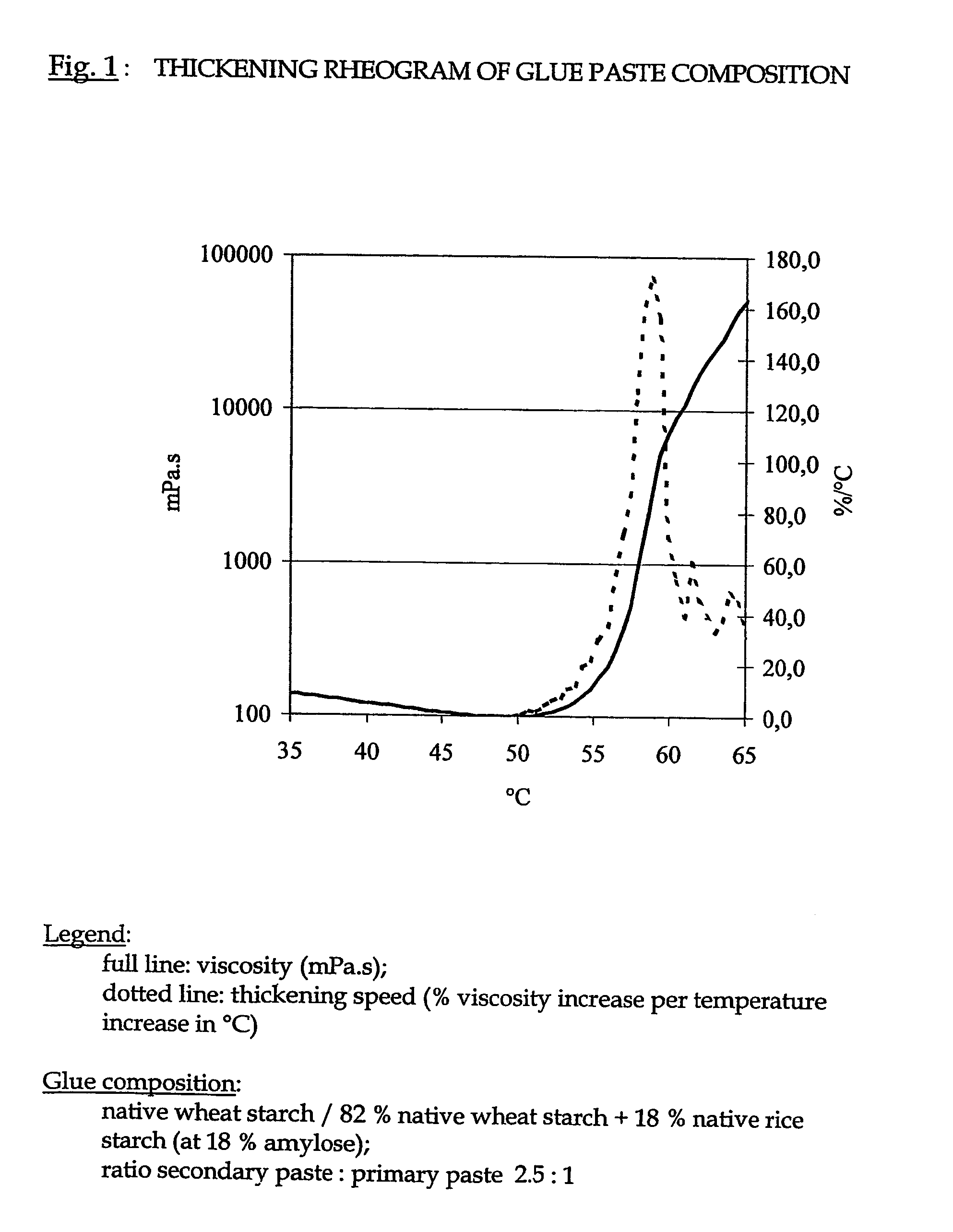

Starch-based glue paste compositions

InactiveUS6964703B2Low costStarch dervative coatingsMechanical working/deformationPotato starchWheat starch

Novel starch-based glue paste compositions are disclosed composed of (i) a carrier paste containing 5 to 16 wt % of a starch selected from the group consisting of corn starch, wheat starch, rye starch, oat starch, barley starch, potato starch, tapioca starch and pea starch, each being native starch or chemically modified starch, or any mixture thereof and (ii) a main paste with a total starch content of 25 to 50 wt % composed of a mixture of 10 to 30 wt % native rice starch or an acetylated version thereof having an amylose content of 12 to 20 wt %, 1 wt % other compounds and a complementary amylopectin content of 87 to 79 wt %, and 90 to 70 wt % of a starch or mixture of starches selected from the above defined group. Processes for the manufacture of the novel glue paste compositions based on the Stein-Hall method are disclosed, as well as a premix of starches for said manufacture. The glue paste compositions present excellent film forming and glueing properties and are particularly suitable for the manufacture of laminated corrugated board.

Owner:REMY IND

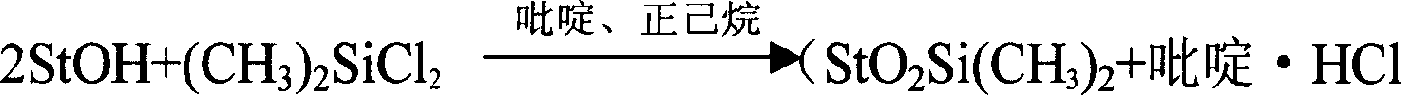

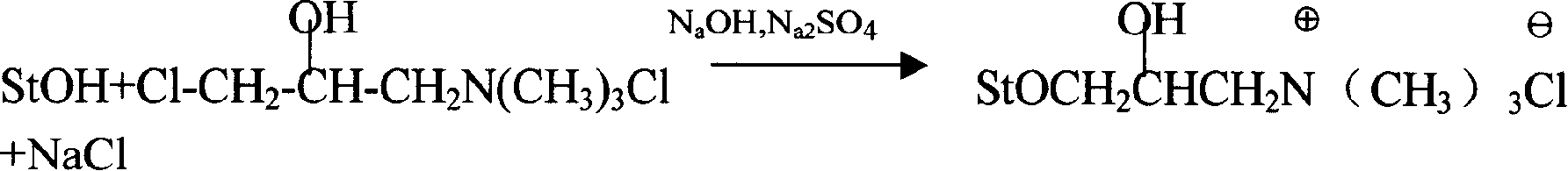

Cation branched-chain starch wood binder and its production

InactiveCN1982395AImprove stabilityImprove water resistanceAmylose/amylopective derivative adhesivesCross-linkAdhesive

A cationic branched-chain starch wood adhesive and its production are disclosed. The process is carried out by adding cross-linking agent, etherifying agent and oxidant into branched-chain starch, cross-linking reacting, etherification reacting and low-degree oxidation reacting. Its advantages include excellent adhesion, water-resistance, fluidity and anticoagulant performance, long storage period and fast dry speed.

Owner:莫元烈

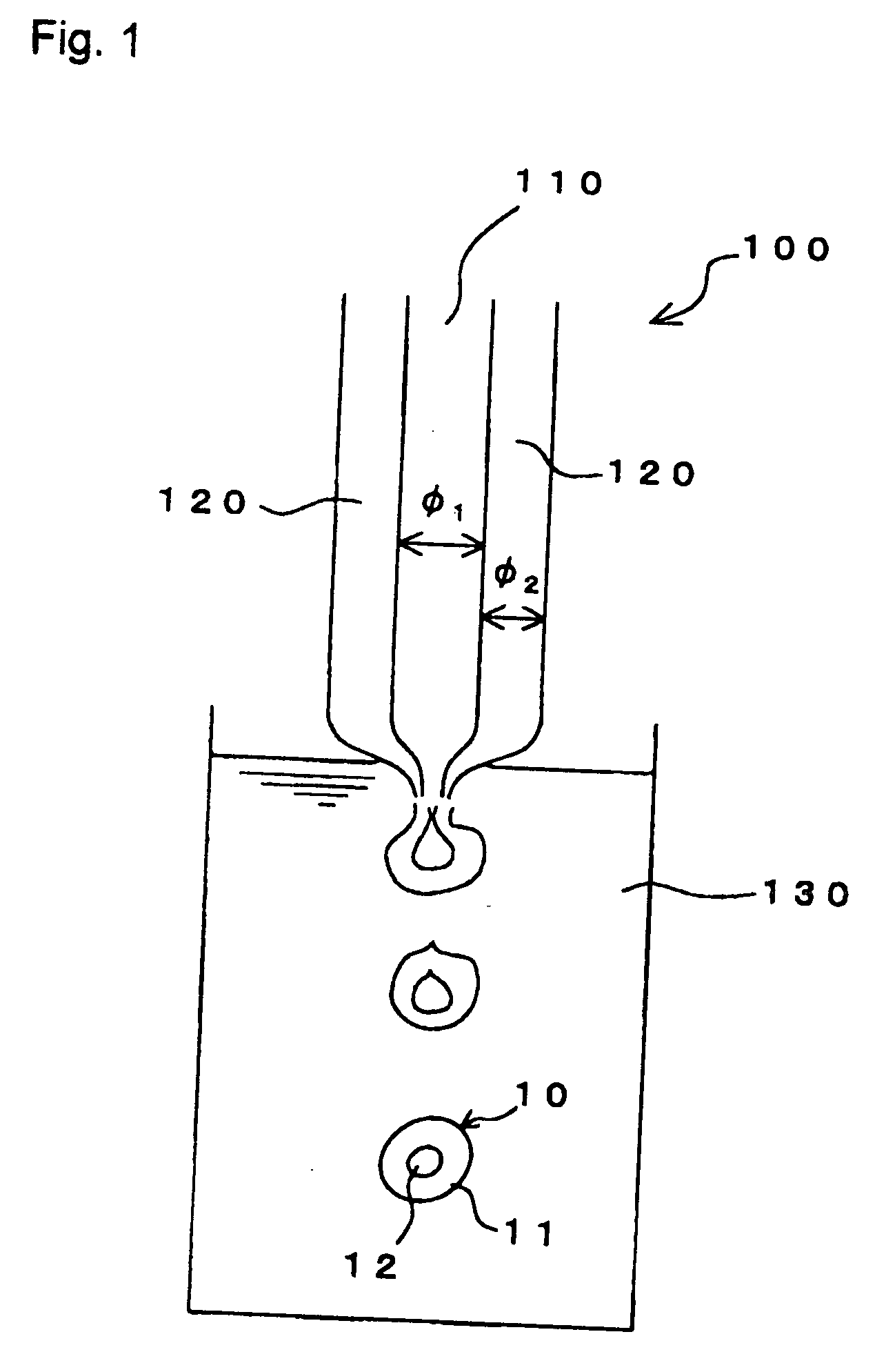

Biodegradable articles obtained from enzymatically synthesized amylose

InactiveUS20040009218A1Defects of natural amyloseAmylose/amylopectin coatingsPowder deliveryEnzymatic synthesisPolymer science

The present invention provides a biodegradable article formed from enzyme-synthesized amylose using phosphorylase, wherein the enzyme-synthesized amylose is composed of glucose monomers exclusively bonded by alpha-1,4-glucosidic likage and has a weight average molecular weight of not less than 100 kDa, preferable not less than 600 kDa. The enzyme-synthesized amylose employed in the present invention has a molecular weight distribution (Mw / Mn) of not more than 1.25 and can be chemically modified if desired. The biodegradable article of the present invention can be produced by (a) the enzyme-synthesized amylose and / or its modified one, or a combination of the amylose (a) and another polymer material (b).

Owner:EZAKI GLICO CO LTD +1

Adhesive

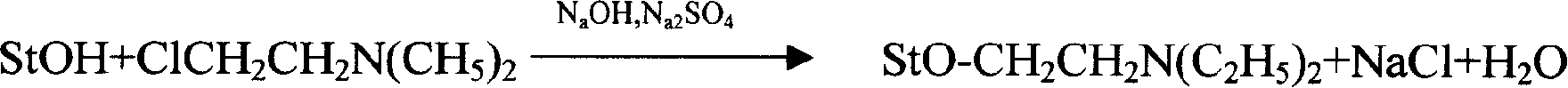

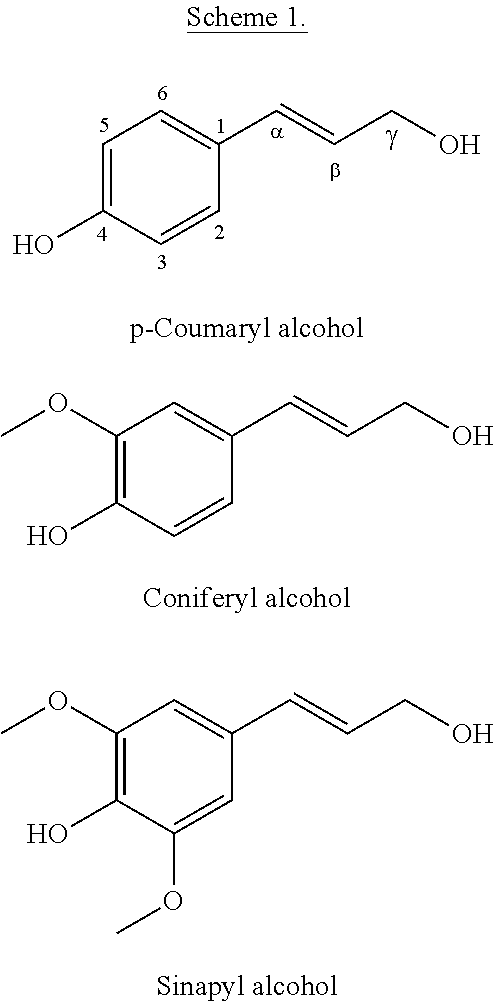

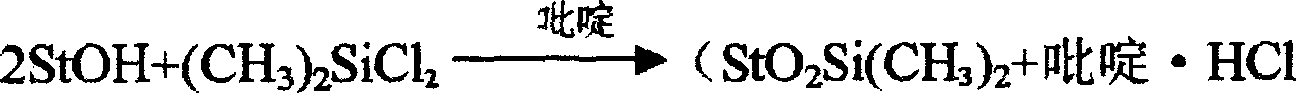

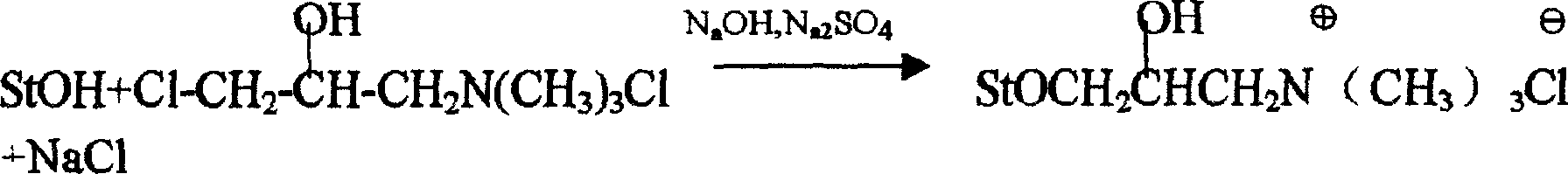

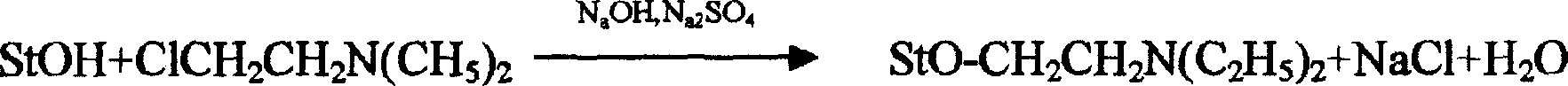

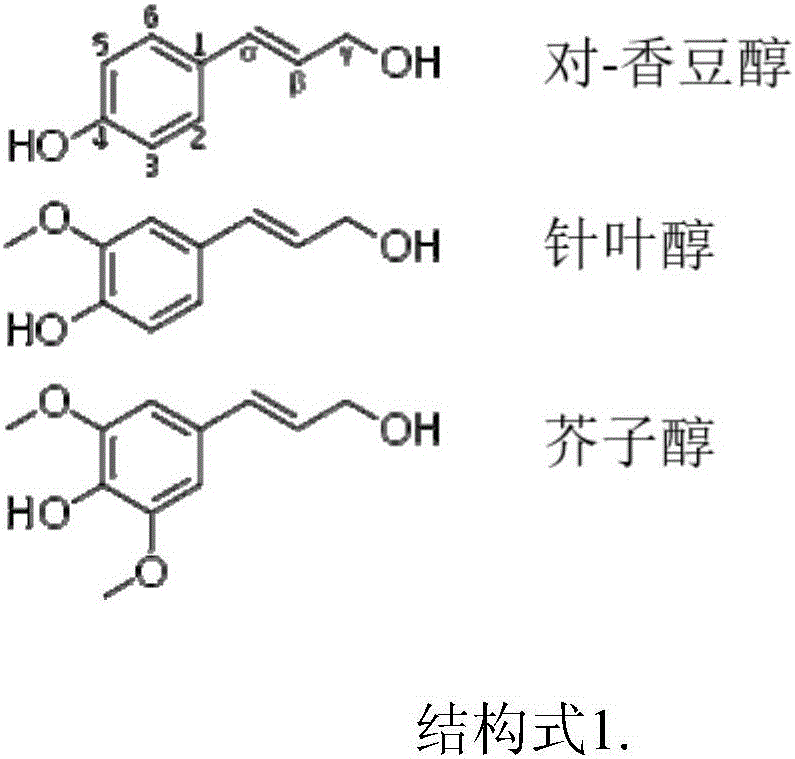

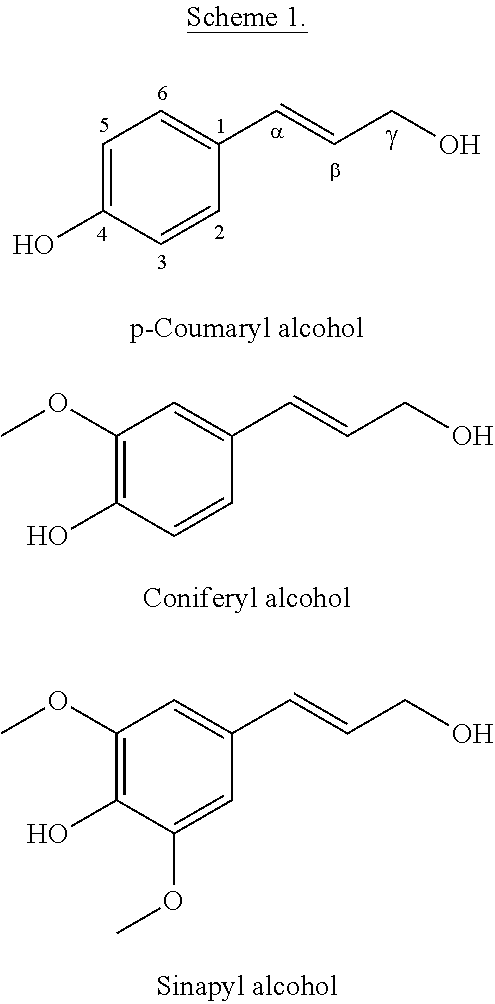

ActiveUS20160333240A1Promote denaturisationPromote solubilisationAgar-agar adhesivesStarch adhesivesLignanPolyphenol

An aqueous adhesive composition and a process for preparing such compositions are disclosed. The composition comprises macromolecular complex comprising (A) a first component comprising (i) a framework element and (ii) a polyphenol, and (B) second component comprising a polypeptide, oligopeptide, amino acid, or polyamine. The framework element comprises (a) a polypeptide, oligopeptide, amino acid, or polyamine, (b) a polysaccharide, oligosaccharide, or monosaccharide, or a saccharide conjugate, or (c) a lignin, a lignan or a lignin conjugate. The polyphenol comprises a tannin, a tannic acid, a flavonoid, or a poly-resorcinol. An adhesive precursor composition comprising the first component is also disclosed.

Owner:NEW ZEALAND FOREST RES INST

Cationic branched-chain starch wood adhesive and its preparing method

InactiveCN1775885AImprove stabilityImprove water resistanceAmylose/amylopective derivative adhesivesAdhesiveWater soluble

The invention discloses a positive ion branched chain starch wood adhesive and the method to manufacture. It adopts low oxidation to increase the starch aldehyde group after reaction to solve the strong cementing force of the adhesive. It adds cross linking agent etherifying agent, and oxidizing agent to branched chain to make the invention has strong cementing force, good water resistance, fluidity, and stability.

Owner:莫元烈

Adhesive

An aqueous adhesive composition and a process for preparing such compositions are disclosed. The composition comprises macromolecular complex comprising (A) a first component comprising (i) a framework element and (ii) a polyphenol, and (B) second component comprising a polypeptide, oligopeptide, amino acid, or polyamine. The 5 framework element comprises (a) a polypeptide, oligopeptide, amino acid, or polyamine, (b) a polysaccharide, oligosaccharide, or monosaccharide, or a saccharide conjugate, or (c) a lignin, a lignan or a lignin conjugate. The polyphenol comprises a tannin, a tannic acid, a flavonoid, or a poly-resorcinol. An adhesive precursor composition comprising the first component is also disclosed.

Owner:NEW ZEALAND FOREST RES INST

Paper with improved stiffness and bulk and method for making same

InactiveUS8460512B2Improved bulk and stiffnessSpecial paperWater-repelling agents additionCellulosePulp and paper industry

The invention provides a three layered reprographic paper having improved strength, stiffness and curl resistance properties, and a method for making same. The paper has a central core layer made largely of cellulose and bulked with a bulking agent such as a diamide salt. A starch-based metered size press coating is pressed on both sides of the core layer, wherein the starch has a high solid content. The coating forms a three layered paper having an I-beam arrangement with high strength outer layers surrounding a low density core.

Owner:INT PAPER CO

Composition and method of forming sand sculptures

InactiveUS6899755B2Sufficient amountCost-effectiveStarch dervative coatingsAmylose/amylopectin derivative coatingsDry weightWater soluble

A sand sculpting composition including approximately 100 parts by dry weight of sand, between 0.1 part and 5 parts by dry weight of at least one non-toxic cold water-soluble adhesive agent selected from the group consisting of pre-gelatinized starches, chemically modified starches and chemically modified celluloses, and between 6 and 25 parts by weight water. The adhesive agent has been combined with the sand and an amount of water sufficient to both dissolve the adhesive agent and allow the adhesive agent to coat the particles of sand. A coloring agent may be added to the adhesive agent.

Owner:SANDSMART

Starch-based glue paste compositions

InactiveUS20050163974A1Reduce alkalinityReduce the temperatureStarch dervative coatingsMechanical working/deformationPotato starchWheat starch

Novel starch-based glue paste compositions are disclosed composed of (i) a carrier paste containing 5 to 16 wt % of a starch selected from the group consisting of corn starch, wheat starch, rye starch, oat starch, barley starch, potato starch, tapioca starch and pea starch, each being native starch or chemically modified starch, or any mixture thereof and (ii) a main paste with a total starch content of 25 to 50 wt % composed of a mixture of 10 to 30 wt % native rice starch or an acetylated version thereof having an amylose content of 12 to 20 wt %, 1 wt % other compounds and a complementary amylopectin content of 87 to 79 wt %, and 90 to 70 wt % of a starch or mixture of starches selected from the above defined group. Processes for the manufacture of the novel glue paste compositions based on the Stein-Hall method are disclosed, as well as a premix of starches for said manufacture. The glue paste compositions present excellent film forming and glueing properties and are particularly suitable for the manufacture of laminated corrugated board.

Owner:REMY IND

Corrugating adhesive and use thereof

InactiveUS20100043968A1Reduce energy costsStarch dervative coatingsAmylose/amylopectin derivative coatingsAdhesiveGram

Owner:HENKEL KGAA

Biodegradable articles obtained from enzymatically synthesized amylose

InactiveUS7759316B2Defects of natural amylosePowder deliveryAmylose/amylopectin coatingsEnzymatic synthesisPolymer science

The present invention provides a biodegradable article formed from enzyme-synthesized amylose using phosphorylase, wherein the enzyme-synthesized amylose is composed of glucose monomers exclusively bonded by α-1,4-glucosidic likage and has a weight average molecular weight of not less than 100 kDa, preferable not less than 600 kDa. The enzyme-synthesized amylose employed in the present invention has a molecular weight distribution (Mw / Mn) of not more than 1.25 and can be chemically modified if desired.The biodegradable article of the present invention can be produced by (a) the enzyme-synthesized amylose and / or its modified one, or a combination of the amylose (a) and another polymer material (b).

Owner:EZAKI GLICO CO LTD +1

Process for producing low viscosity phosphate ester starch by new dry method

InactiveCN1781948AImprove reaction efficiencyGood viscosity stabilityWater-repelling agents additionPaper/cardboardPhosphoric Acid EstersPolymer science

The present invention relates to dry process of producing low viscosity phosphate ester starch, and features that starch, NaHPO4.12H2O, NaHPO2.2H2O, urea, hydrochloric acid, caustic soda and other material are produced into low viscosity phosphate ester starch through the technological process including pre-drying, temperature raising and lowering, regulating pH value and other steps. The low viscosity phosphate ester starch has the features of low viscosity, high stability, good filming performance, high water maintaining property, etc. and may be widely used in starch processing.

Owner:诸城兴贸玉米开发有限公司

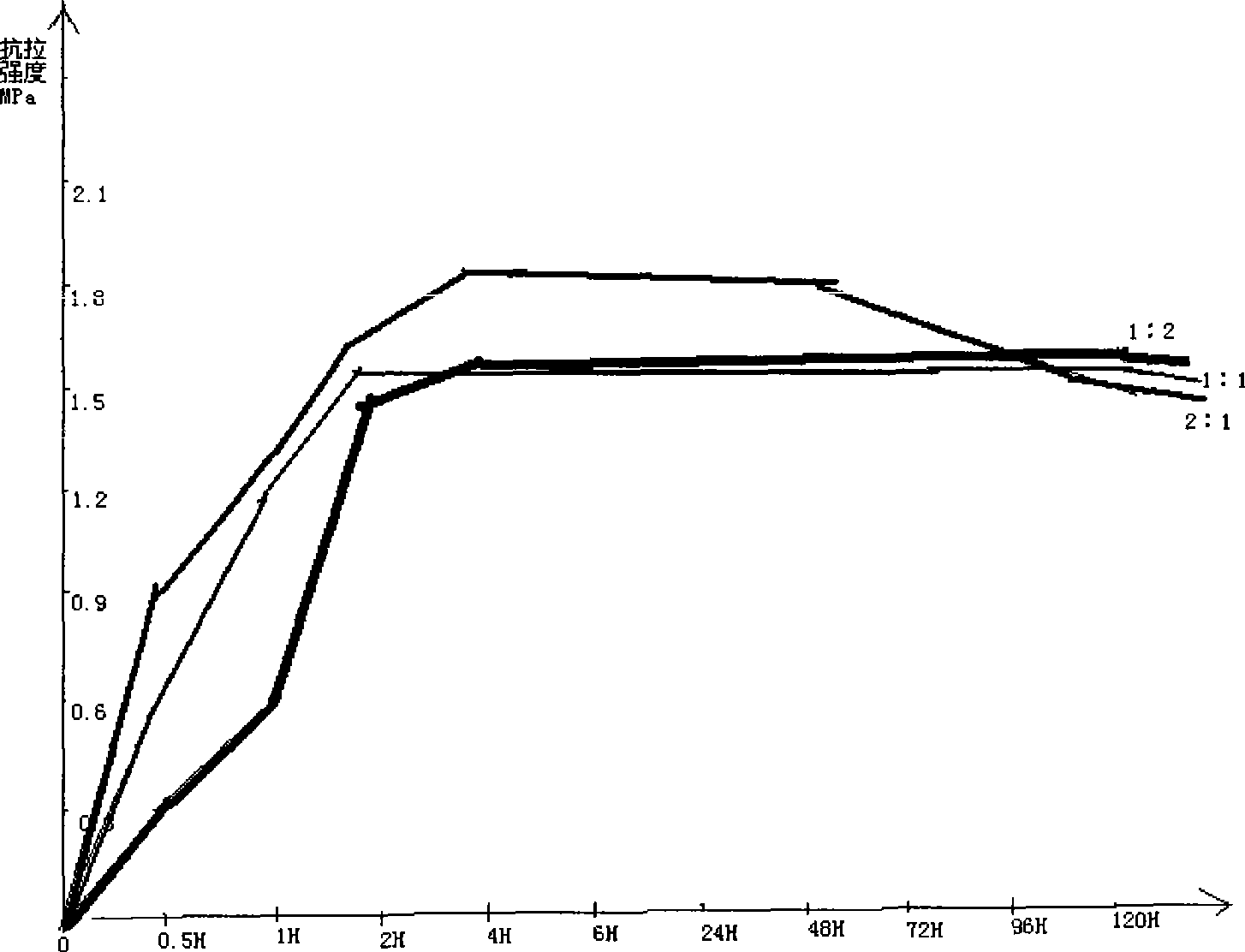

Dual-component binder and preparation thereof

ActiveCN101475784AHigh bonding strengthSlow curingMonocarboxylic acid ester polymer adhesivesAmylose/amylopective derivative adhesivesPolyvinyl acetateAdhesive

The invention relates to a bicomponent adhesive, which comprises a first component with the viscosity of between 800 and 2,000 centipoises and a second component with the viscosity of between 6,000 and 15,000 centipoises; the weight portion ratio of the first component to the second component is between 0.5-1 and 10-1, wherein the first component mainly comprises polyvinyl acetate latex and refractory powder; the first component is taken as a whole; the weight portion of the polyvinyl acetate latex is between 35 and 65; the weight portion of the refractory powder is between 40 and 70; vinyl acetate and carboxylic ester in an alcoholic solvent are subjected to evocation and polymerization through a chemical evocating agent to form the polyvinyl acetate latex; and the second component is formed through the mixing of amylopectin, the alcoholic solvent and an emulsifier. The invention also provides a method for preparing the bicomponent adhesive. The prepared bicomponent adhesive has the advantages of high strength, hydrolytic resistance, rapid curing speed, and the like.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Pressure sensitive adhesive composition

A pressure sensitive adhesive composition suitable for medical purposes comprising a rubbery elastomeric base and two or more water soluble or water swellable hydrocolloids, said adhesive composition comprising a substantially homogeneous mixture of 15-60 % of one or more rubbery components, 10-60 % of a mixture of hydrocolloids comprising one or more hydrocolloids selected from the group of amidated pectins and potato starch, 0-50 % of one or more tackifier resins, 0-15 % cohesive strengthening agent, 0-10 % of a plasticizer and 0-5 % pigment, shows at least as good properties with respect to resistance to biological fluids as well as adhesion to the skin and coherence as state of the art adhesives comprising gelatine.

Owner:COLOPLAST AS

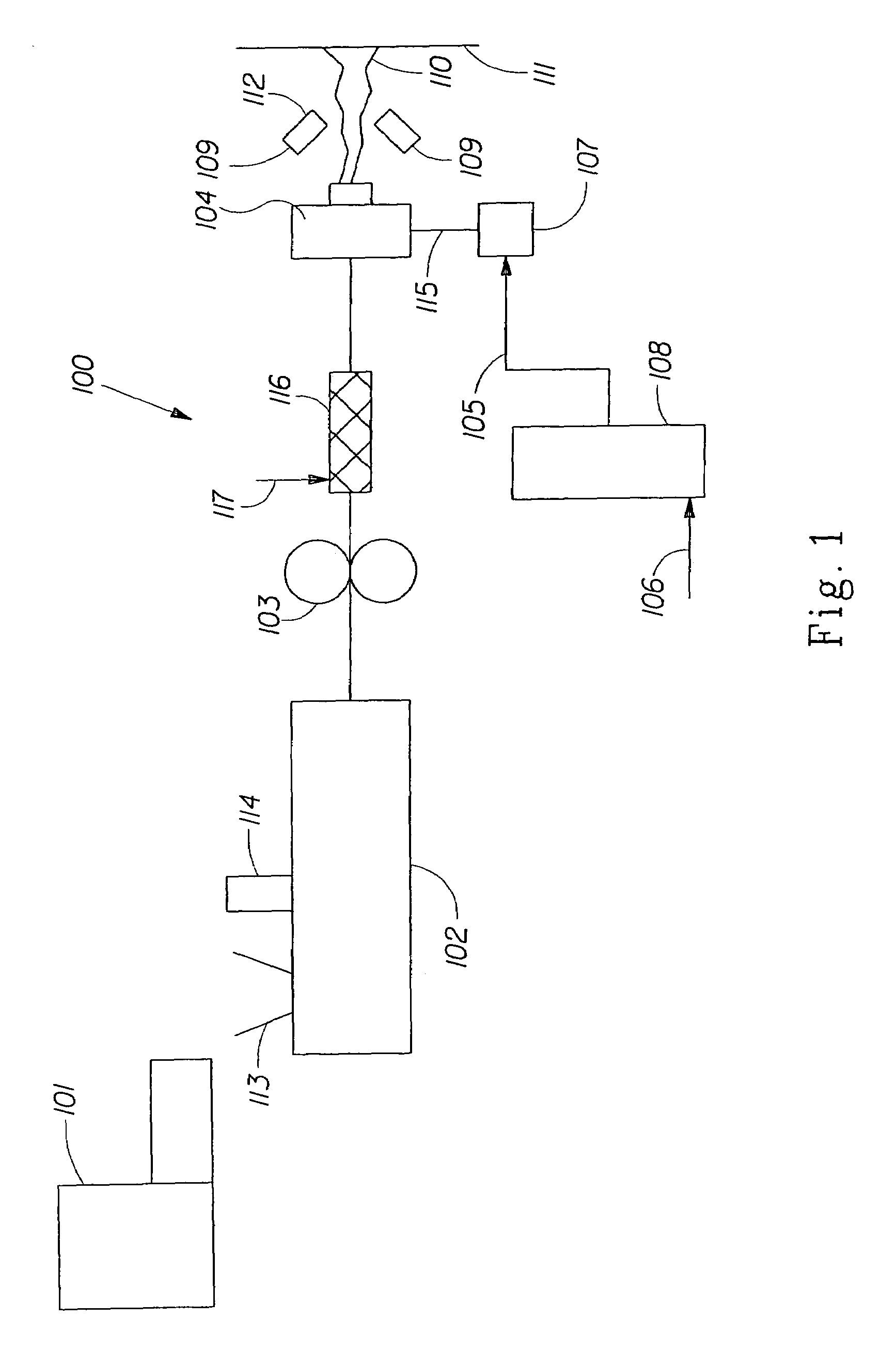

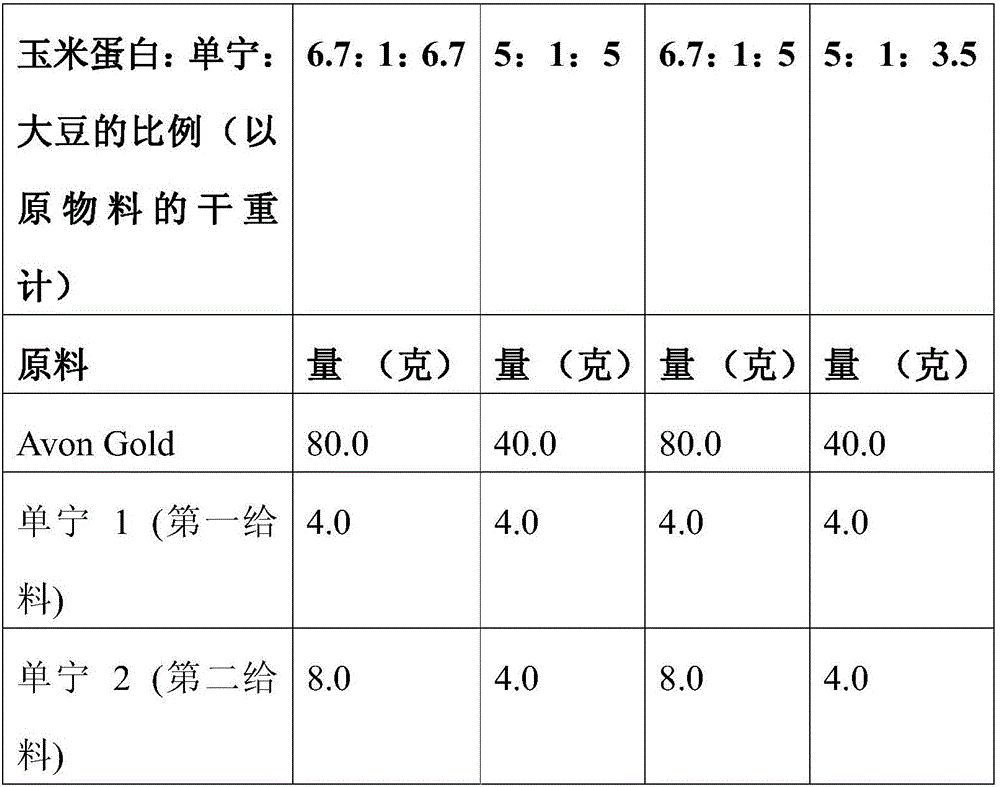

Protein and starch compositions, methods for making and uses thereof

The present disclosure relates to protein-starch compositions. The disclosure also relates to processes for preparing the protein-starch compositions. Further, the disclosure relates to uses of the protein-starch compositions in the preparation of adhesives or binders. Further, the disclosure relates to adhesive formulations that include protein-starch containing compositions and to paper products resulting from the processes herein.

Owner:CARGILL INC

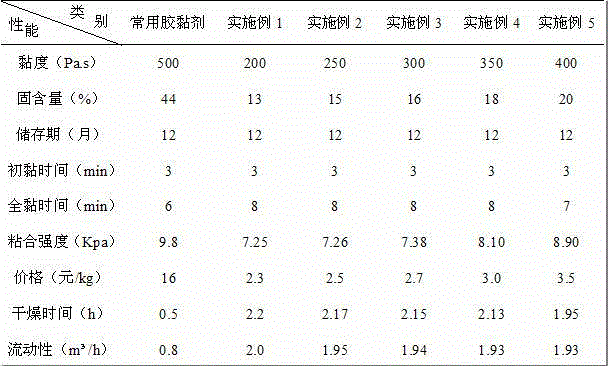

Adhesive for combining aluminum-foil papers and preparation method thereof

InactiveCN104910831ALow raw material costSimple processAmylose/amylopective derivative adhesivesAdhesiveSolid content

The invention discloses an adhesive for combining aluminum-foil papers and a preparation method thereof, and belongs to the technical field of adhesives. The adhesive consists of the following components: 100-140 parts by weight of oxidized starch, 4-6 parts by weight of borax, 20-30 parts by weight of sodium hydroxide, 4-8 parts by weight of hydrogen peroxide, 0.8-1.2 parts by weight of tributyl phosphate, and 90-110 parts by weight of water. Due to the fact that the adhesive employs the oxidized starch as the main raw material, the cost on raw materials of the adhesive is reduced, and the adhesive is environment-friendly and non-toxic; due to the fact that the hydrogen peroxide, the borax, the sodium hydroxide and the tributyl phosphate are mixed with certain amount of water under the normal temperature according to specific procedures, not only the technology is simple, but also the prepared adhesive can be stored for 12 months without influencing the character of service; therefore, the adhesive is good in stability; moreover, the adhesive contains 13-20% of solid, therefore, the adhesive is good in fluidity and is able to meet the requirements of different combining speeds.

Owner:SHANDONG JINJIAN LOGISTICS CO LTD

Adhesive

ActiveUS10696882B2Improve water resistanceProvides water resistanceAgar-agar adhesivesStarch adhesivesPolymer scienceLignan

Owner:NEW ZEALAND FOREST RES INST

Modified starch-based adhesive for high-speed cigarette making machine

ActiveCN104946163AEasy to dryImprove adhesionAmylose/amylopectin adhesivesAmylose/amylopective derivative adhesivesAdhesivePreservative

The invention relates to a modified starch-based adhesive for a high-speed cigarette making machine. The modified starch-based adhesive comprises, by weight, 10%-80% of urea modification waxiness corn starch and / or a derivative of the urea modification waxiness corn starch, 10%-80% of degraded waxiness corn starch and / or a derivative of the degraded waxiness corn starch, 2%-20% of modified tamarindus powder and a corrosion remover.

Owner:钟博文

Coating agent

ActiveUS20100126381A1Amylose/amylopectin coatingsStarch dervative coatingsHigh concentrationFilm-forming agent

The invention relates to pharmaceutical, cosmetic, nutraceutical and food areas, in particular to compositions for coating tablets, capsules and other solid- or semisolid-form substances currently used in different application fields. More specifically, said invention relates to solid ready-for-use compositions for producing laminating solutions or dispersions for solid- or semisolid-form substances and is characterised in that the viscosity of said cold-regenerated solutions or dispersions is less than 1000 centipoises at a solid matter concentration greater than 20%, wherein said viscosity is obtainable by using natural film-forming agents which are cold-soluble and exhibit a low viscosity in an aqueous medium at high concentrations.

Owner:STEARINERIE DUBOIS FILS

Use of an acetylated pre-gelled starch with a high content of amylose

A starch with a high content in amylose, obtained through a process comprising acetylation and pre-gellation, can provide useful coatings in food, drug, cosmetic and dietetic fields, both for humans and animals, and also in agriculture.

Owner:F T HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com