Environmental-friendly amylopectin composite adhesive for paper products and production method thereof

A composite adhesive and amylopectin technology, which is applied in the directions of amylose/amylopectin derivative adhesives, adhesive types, mechanical processing/deformation, etc. Stability, large amount of starch and other problems, to achieve the effect of low production cost, strong initial adhesion and adhesion, and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

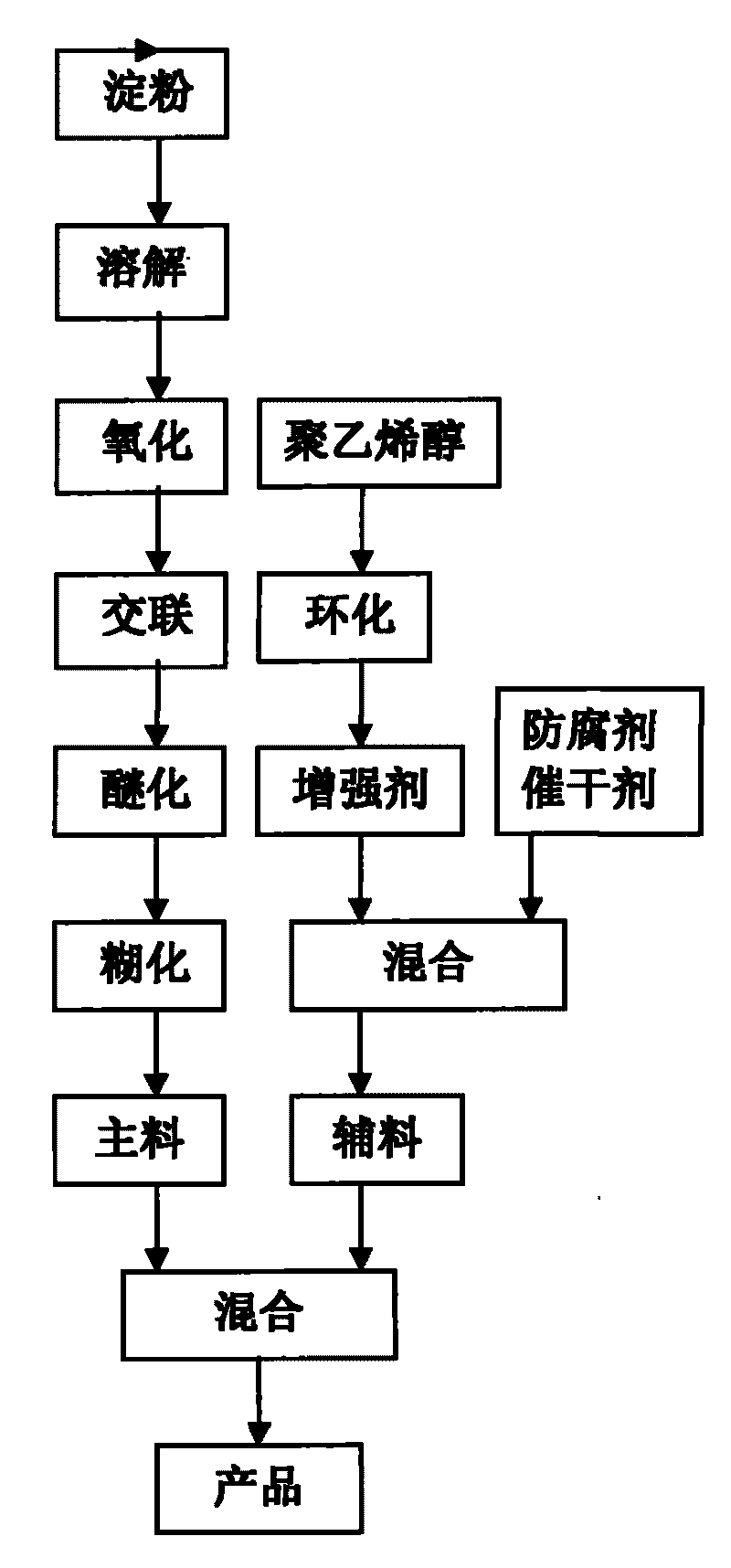

Method used

Image

Examples

Embodiment 1

[0034] 1. Formula:

[0035] 100 parts of tapioca starch, 6 parts of oxidizing agent hydrogen peroxide, 3 parts of oxidation terminator sodium sulfite, 4 parts of crosslinking agent formaldehyde, 8 parts of complexing aldehyde removing agent and cyclizing agent urea, 5 parts of etherifying agent monochloroacetic acid, pasting agent hydrogen 3.5 parts of sodium oxide, 6 parts of polyvinyl alcohol as a reinforcing agent, 2 parts of zinc sulfate as an antiseptic, 10 parts of bentonite as a drier, PH regulator sulfuric acid and sodium hydroxide according to the pH value requirements of the process, and 700 parts of water.

[0036] 2. Preparation process:

[0037] Put 230 parts of water in the reaction kettle, start the agitator, add 100 parts of tapioca starch into the reaction kettle, and stir to make a 30% starch suspension.

[0038] Add 6 parts of oxidant hydrogen peroxide to the starch suspension to oxidize the starch to obtain the expected oxidized starch, then add 3 parts of...

Embodiment 2

[0045] 1. Formula:

[0046] 110 parts of corn starch, 3 parts of oxidizing agent sodium hypochlorite, 2.5 parts of oxidation terminator sodium sulfite, 6 parts of crosslinking agent formaldehyde, 9 parts of complexing aldehyde removing agent and cyclizing agent urea, 7 parts of etherifying agent monochloroacetic acid, pasting agent hydrogen 4 parts of sodium oxide, 10 parts of polyvinyl alcohol as a strengthening agent, 2.5 parts of zinc sulfate as an antiseptic, 15 parts of bentonite as a drier, PH regulator hydrochloric acid and sodium hydroxide according to the pH value requirements of the process, and 750 parts of water.

[0047] 2. Preparation process:

[0048] First, put 250 parts of water in the reactor, start the agitator, add 110 parts of cornstarch into the reactor, and stir to make a 30% starch suspension.

[0049] Add 3 parts of oxidant sodium hypochlorite to the starch suspension to oxidize the starch. After obtaining the expected oxidized starch, add 2.5 parts of ...

Embodiment 3

[0056] 1. Formula:

[0057] 70 parts of corn flour starch, 40 parts of sorghum starch, 8 parts of oxidizing agent sodium hypochlorite, 6 parts of oxidation terminator sodium thiosulfate, 5 parts of crosslinking agent epichlorohydrin, 4 parts of etherifying agent monochloroacetic acid, pasting agent hydrogen oxidation 5 parts of sodium, 7 parts of polyvinyl alcohol as a strengthening agent, 2.5 parts of cyclizing agent urea, 3 parts of zinc sulfate as a preservative, 10 parts of bentonite as a stabilizer, 10 parts of bentonite, PH regulator sulfuric acid and sodium hydroxide according to the pH requirements of the process Quantity, 750 parts of water.

[0058] 2. Preparation process:

[0059] First put 250 parts of water in the reactor, start the mixer, add 70 parts of corn flour starch and 40 parts of high-grain starch into the reactor, and mix to form a 30% starch suspension.

[0060] Add 8 parts of oxidant sodium hypochlorite to the starch suspension to oxidize the starch....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com