Dual-component binder and preparation thereof

An adhesive, two-component technology, applied in the direction of monocarboxylate copolymer adhesive, adhesive type, unsaturated alcohol copolymer adhesive, etc., can solve the problem of slow curing speed and high production cost of adhesive problems, to achieve the effect of fast curing speed, cost reduction, and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The preparation process of the two-component adhesive in the present invention includes a preparation step of the first component and a preparation step of the second component.

[0057] The preparation steps of the first component include:

[0058] a) Rectification step: First put 20-50 parts of all vinyl acetate into the stirring tank, heat up to reflux at 60-70 °C, the distilled out is vinyl acetate, and the high-boiler comes out of the kettle, including a large amount of polymerization inhibitor . The reflux time is 2-4 hours, and when the reflux velocity is significantly reduced or the temperature in the kettle is significantly increased and is greater than or equal to 85° C., the rectification process ends.

[0059] b) Polymerization step: at 40-60°C, use methanol to dissolve ammonium persulfate and diacyl peroxide to form an initiator alcohol solution for use, wherein the ratio of ammonium persulfate and diacyl peroxide by weight is 1:1.

[0060] Vinyl acetate...

Embodiment 2

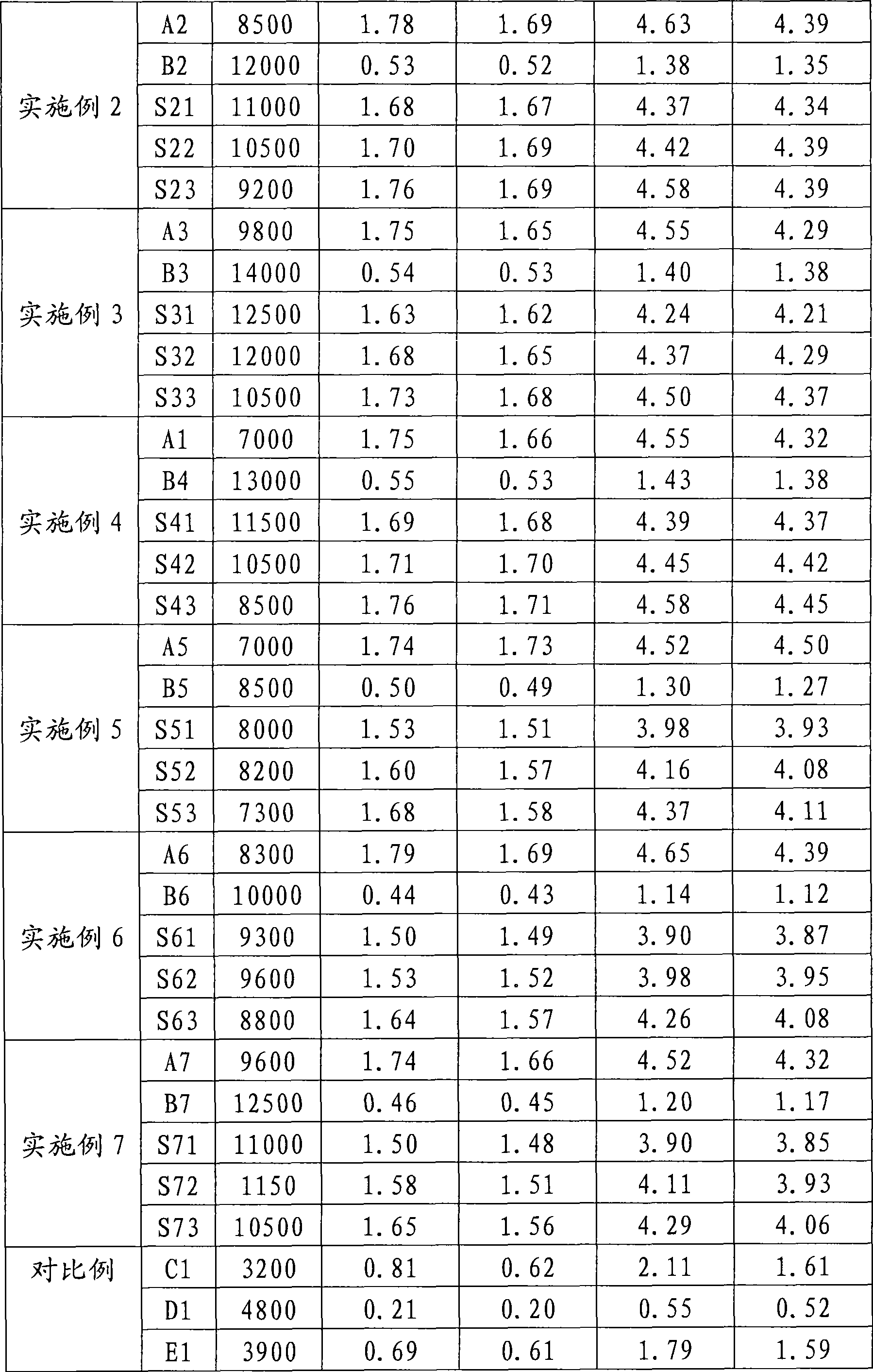

[0095] In this example, the preparation steps of the two-component adhesive are the same as in Example 1, only the parts by weight of the raw materials required for the preparation of the first component and the second component are changed.

[0096] In the first component,

[0097] Taking the polyvinyl acetate latex as a whole, the parts by weight of each raw material required in the preparation process are respectively:

[0098] 50 parts of vinyl acetate;

[0099] 5 parts of ethyl acetate;

[0100] Acrylate 10 parts;

[0101] 5 parts of methacrylate;

[0102] 5 parts of isooctyl acrylate;

[0103] 35 parts of methanol;

[0104] 1.3 parts of ammonium persulfate and diacyl peroxide mixture (ratio by weight and number is 1:1);

[0105] Taking the refractory powder as a whole, among them:

[0106] 30 parts of talcum powder;

[0107] 35 parts of quartz powder;

[0108] Clay 4 parts.

[0109] In the first component, taking the first component as a whole, the polyvinyl ac...

Embodiment 3

[0122] In this example, the preparation steps of the two-component adhesive are the same as in Example 1, only the parts by weight of the raw materials required for the preparation of the first component and the second component are changed.

[0123] In the first component,

[0124] Taking the polyvinyl acetate latex as a whole, the parts by weight of each raw material required in the preparation process are respectively:

[0125] 25 parts of vinyl acetate;

[0126] 3 parts of ethyl acetate;

[0127] Acrylate 2 parts;

[0128] 1 part of methacrylate;

[0129] 1 part of isooctyl acrylate;

[0130] 20 parts of methanol;

[0131] 0.5 parts of ammonium persulfate and diacyl peroxide mixture (ratio by weight and number is 1:1);

[0132] Taking the refractory powder as a whole, among them:

[0133] 30 parts of talcum powder;

[0134] 20 parts of quartz powder;

[0135] Clay 2 parts.

[0136] In the first component, taking the first component as a whole, the polyvinyl aceta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com