Adhesive for combining aluminum-foil papers and preparation method thereof

A technology of aluminum foil paper and glue, applied in the direction of adhesive type, amylose / pullulan derivative adhesive, etc., can solve the problems of non-environmental protection and high price, and achieve low raw material cost, good fluidity, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

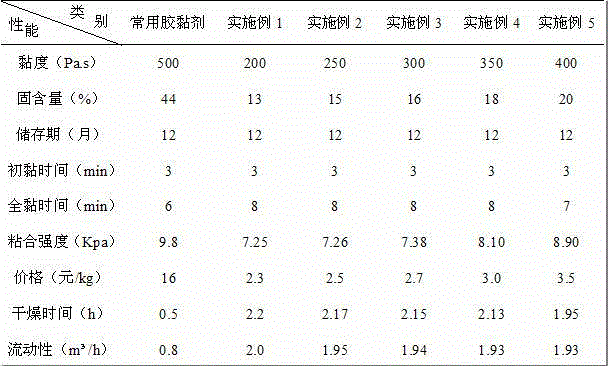

Examples

Embodiment 1

[0050] At room temperature, add 100 parts by weight of oxidized starch to a container containing 110 parts by weight of water, stir evenly so that the oxidized starch is completely dissolved in water to obtain a mixed material liquid; add 4 parts by weight of hydrogen peroxide to the mixed material liquid After that, mix evenly, then add 4 parts by weight of borax and mix evenly, add 20 parts by weight of caustic soda and mix evenly, finally add 0.8 parts by weight of tributyl phosphate and mix evenly, you can get the aluminum foil composite adhesive agent.

Embodiment 2

[0052] The difference between this example and Example 1 is that the amounts of each raw material are different, specifically: 105 parts by weight of water, 120 parts by weight of oxidized starch, 5 parts by weight of hydrogen peroxide, 5 parts by weight of borax, 24 parts by weight of caustic soda and phosphoric acid 0.9 parts by weight of tributyl ester.

Embodiment 3

[0054] The difference between this example and Example 1 is mainly that the amount of each raw material is different, specifically: 100 parts by weight of water, 125 parts by weight of oxidized starch, 6 parts by weight of hydrogen peroxide, 6 parts by weight of borax, 25 parts by weight of caustic soda and phosphoric acid 1 part by weight of tributyl ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com