Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Visual inspection (procedure)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

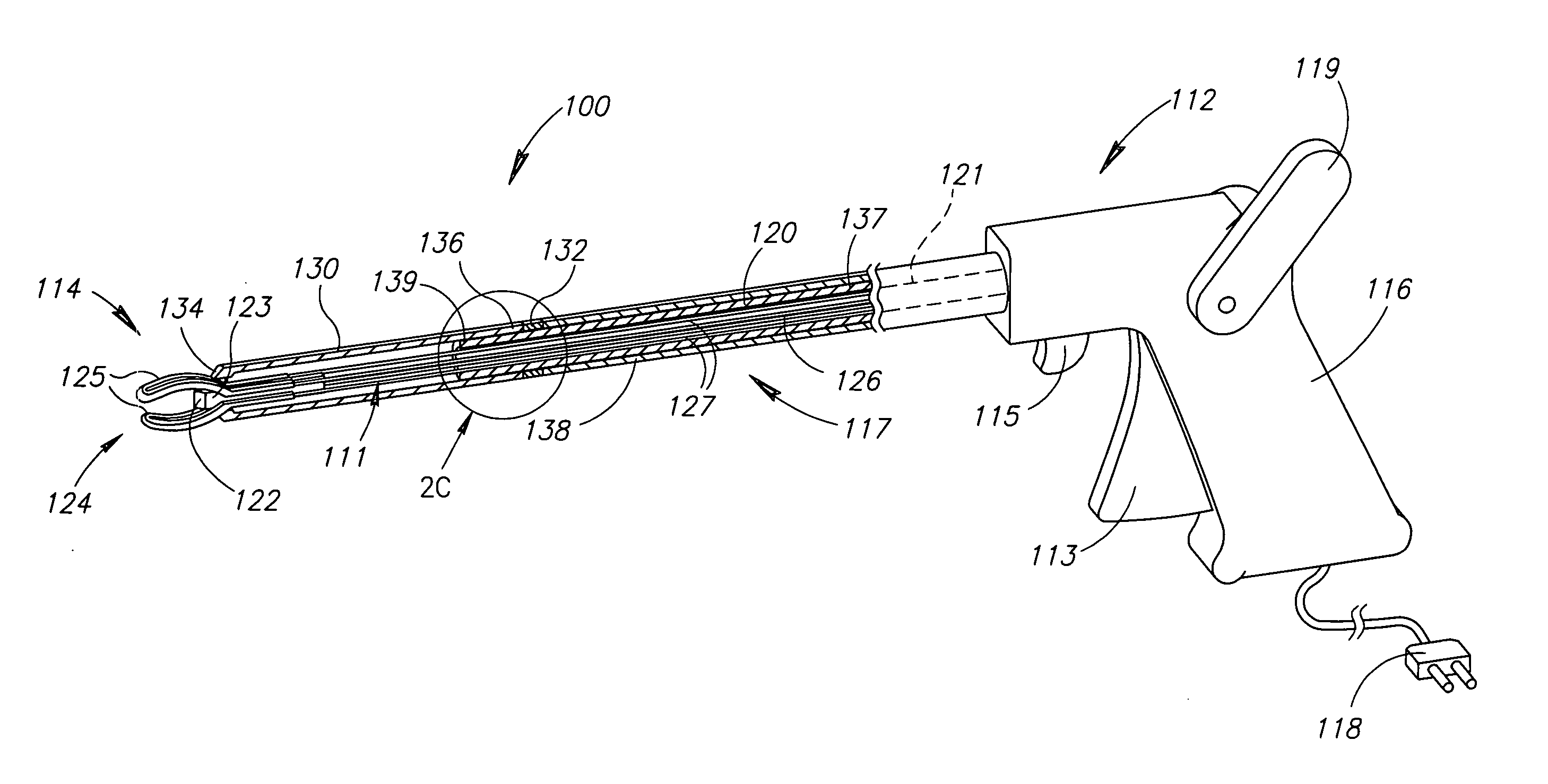

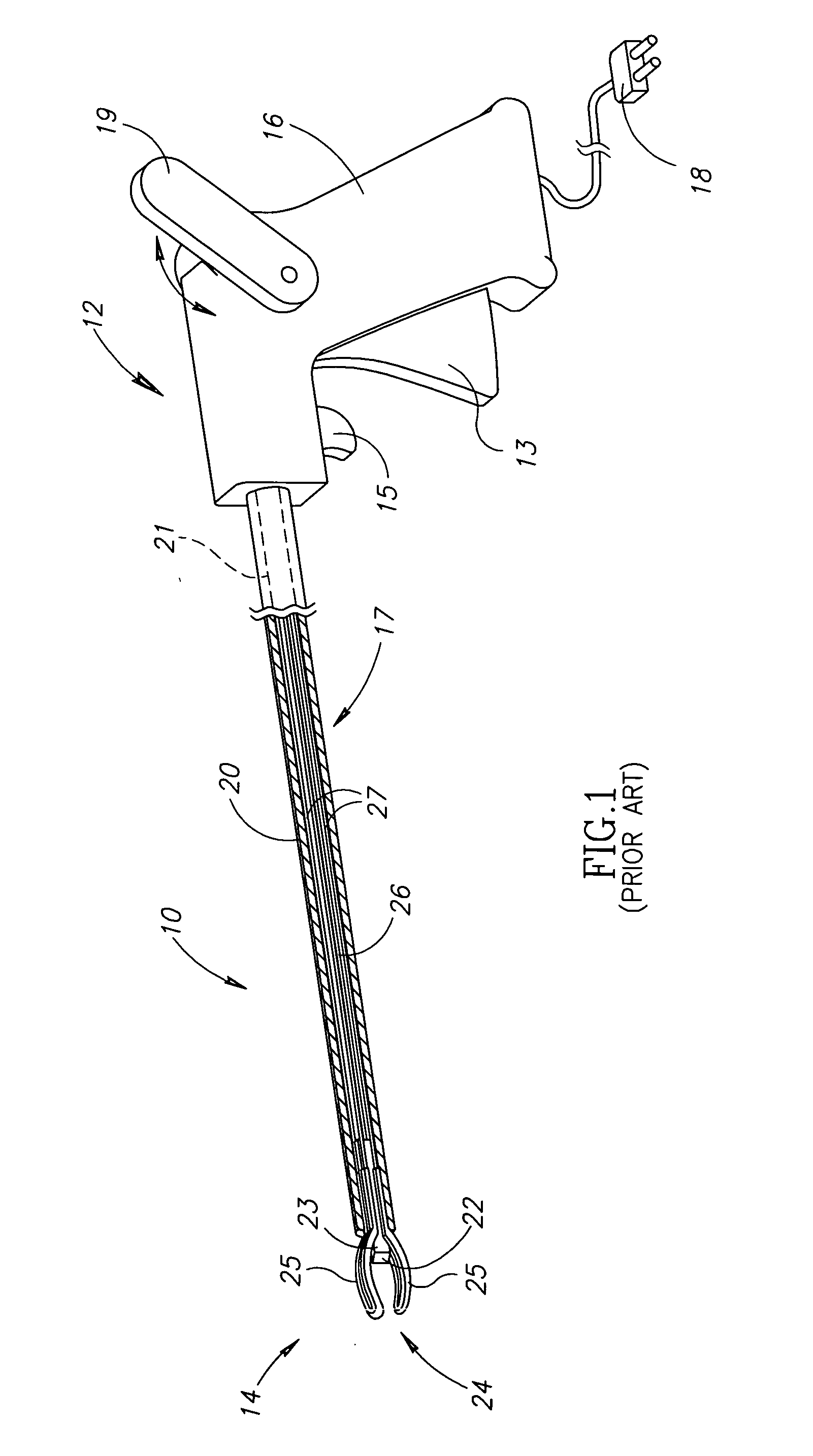

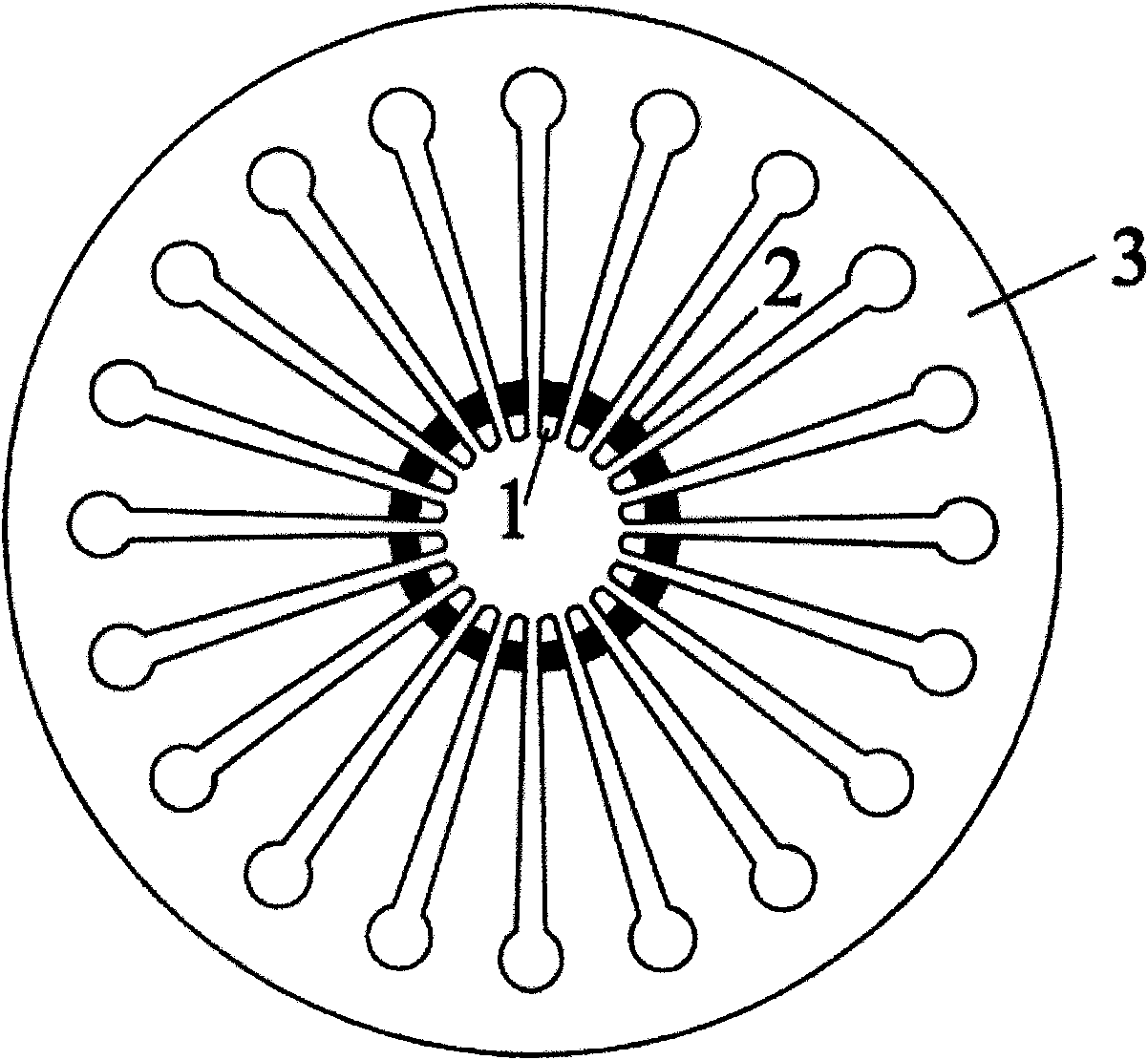

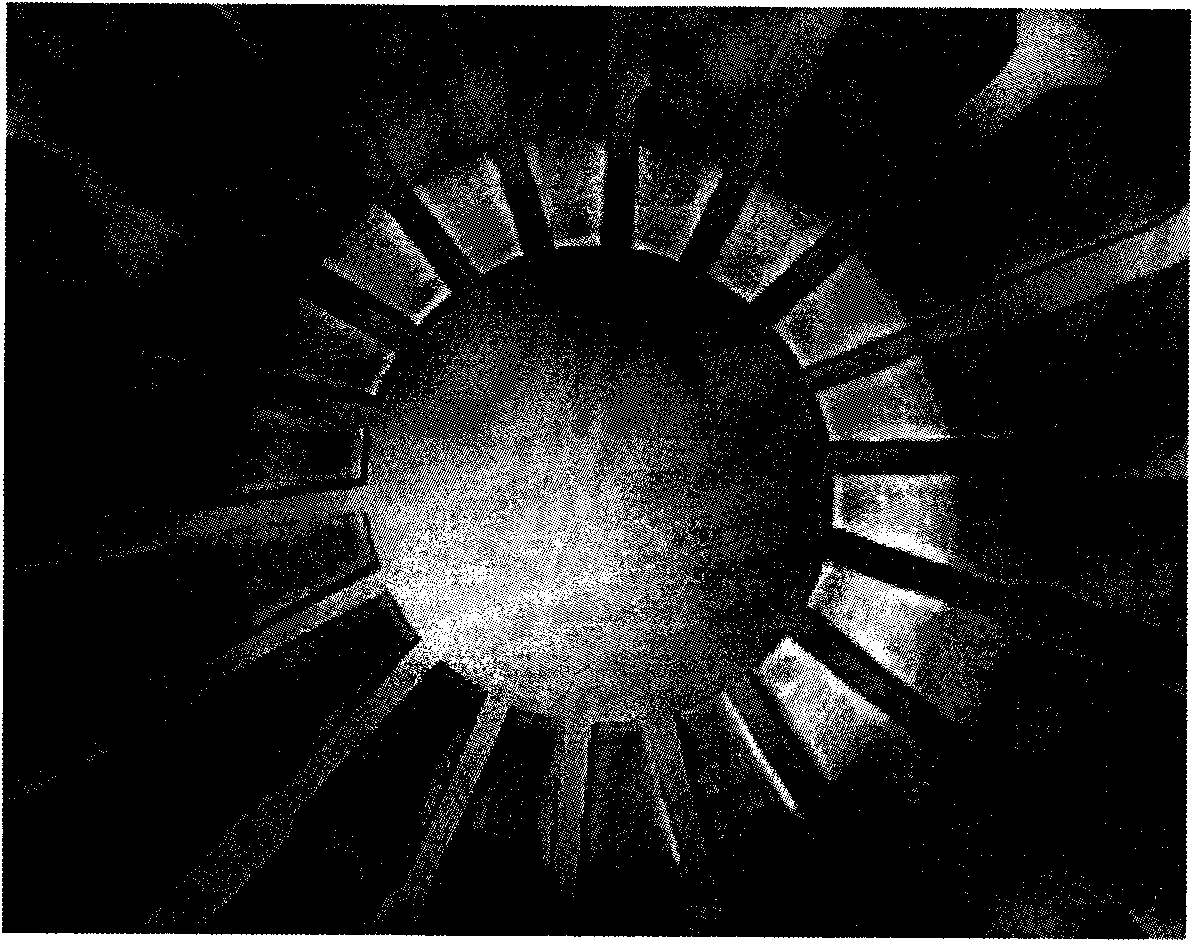

Instrument guard and reusable medical device employing same

InactiveUS20060235382A1DiagnosticsSurgical instrument detailsLess invasive surgeryMegasonic cleaning

An instrument guard for a MIS medical device includes an attachment portion and an instrument holding portion. The attachment portion is removably attachable to a containment tube of a medical device used for minimally invasive surgery. The instrument holding portion is used to contain and insulate surgical instruments used for the procedure. The instrument guard may be removed after use, exposing the surgical instruments and allowing for cleaning thereof, by washing, brushing, ultrasonic cleaning and visual inspection. A clean instrument guard is then placed on the device, enabling the device to be reused in another procedure.

Owner:ASSOC FOR PUBLIC HEALTH

Software based brake shoe wear determination

InactiveUS20040138791A1Reduce amount of friction brake effort suppliedReduce wear rateVehicle testingRegistering/indicating working of vehiclesVisual inspectionEnergy supply

By calculating the energy used by the friction brake equipment, the amount of friction brake shoe / pad wear can be monitored. As the amount of energy supplied reaches a percentage of the friction brake shoe / pad energy design limit, an indication for inspection is provided. If the supplied friction energy continues to increase beyond this point, the brake material must be replaced. The software logic limits are tunable for custom configuring by the transit authority and maintenance personnel. This invention measures the amount of friction effort supplied with respect to time and distance in a software controlled brake system. Furthermore, this invention allows the software to determine when the friction brake material must be replaced based on actual data, which simplifies the maintenance personnel operation procedures, maximizes brake material wear, and avoids costly damage from braking with worn out shoes / pads. The material life remaining for friction brakes is determined currently by a visual inspection followed by a 'best guess' as to whether the material will last until the next scheduled inspection. This invention will annunciate through the software logic program when the friction material requires inspection and replacement. Additionally, the invention provides software logic to indicate the remaining material thickness.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

Diaphragm spring and finger tip thermal processing process thereof

InactiveCN101655129AObvious color differenceReduce labor processFriction clutchesFurnace typesTemperingEngineering

The invention discloses a diaphragm spring and a finger tip thermal processing process thereof. A finger tip high-frequency region of the diaphragm spring is pale and a transition region is blue. Thefinger tip thermal processing process sequentially comprises the following procedures: quenching the diaphragm spring, high-temperature tempering, shot blasting, high-frequency quenching at a finger tip, low-temperature tempering and polishing the finger tip. During the low-temperature tempering, the diaphragm spring is placed in a mesh-belt tempering furnace, and is insulated at a temperature of185-215 DEG C for 2-2.5h under the condition of ensuring that a mesh-belt is not moved. The length of the transition region of the product obtained by thermally processing the finger tip of the diaphragm spring by the method can be distinguished whether accords with the technical requirement or not only through visual inspection by adopting the method of the invention, the product is fully detected without a special hardmeter and is marked without color, thereby reducing the labor procedure and lowering the cost.

Owner:HUBEI DAFAN AUTO PARTS

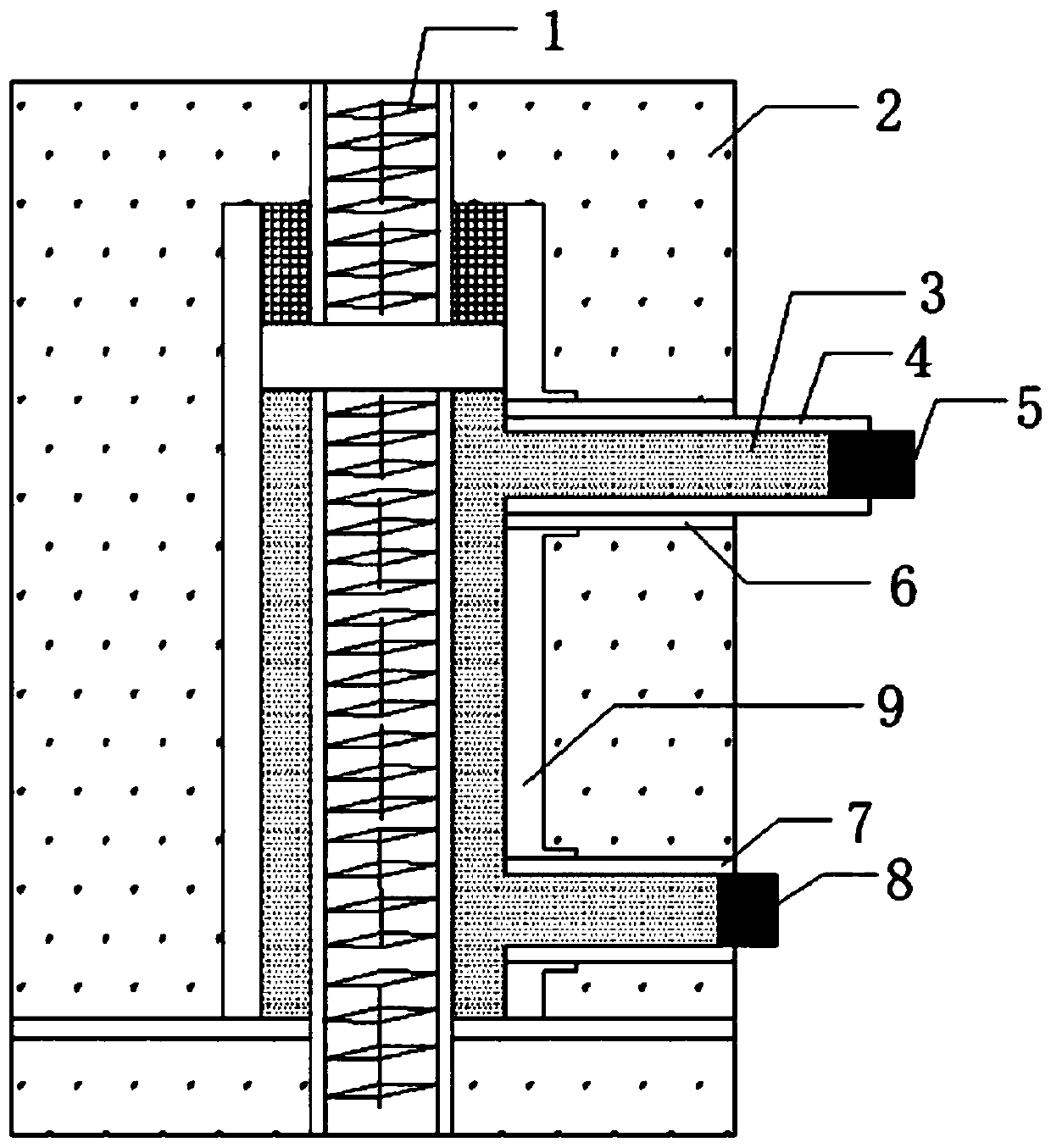

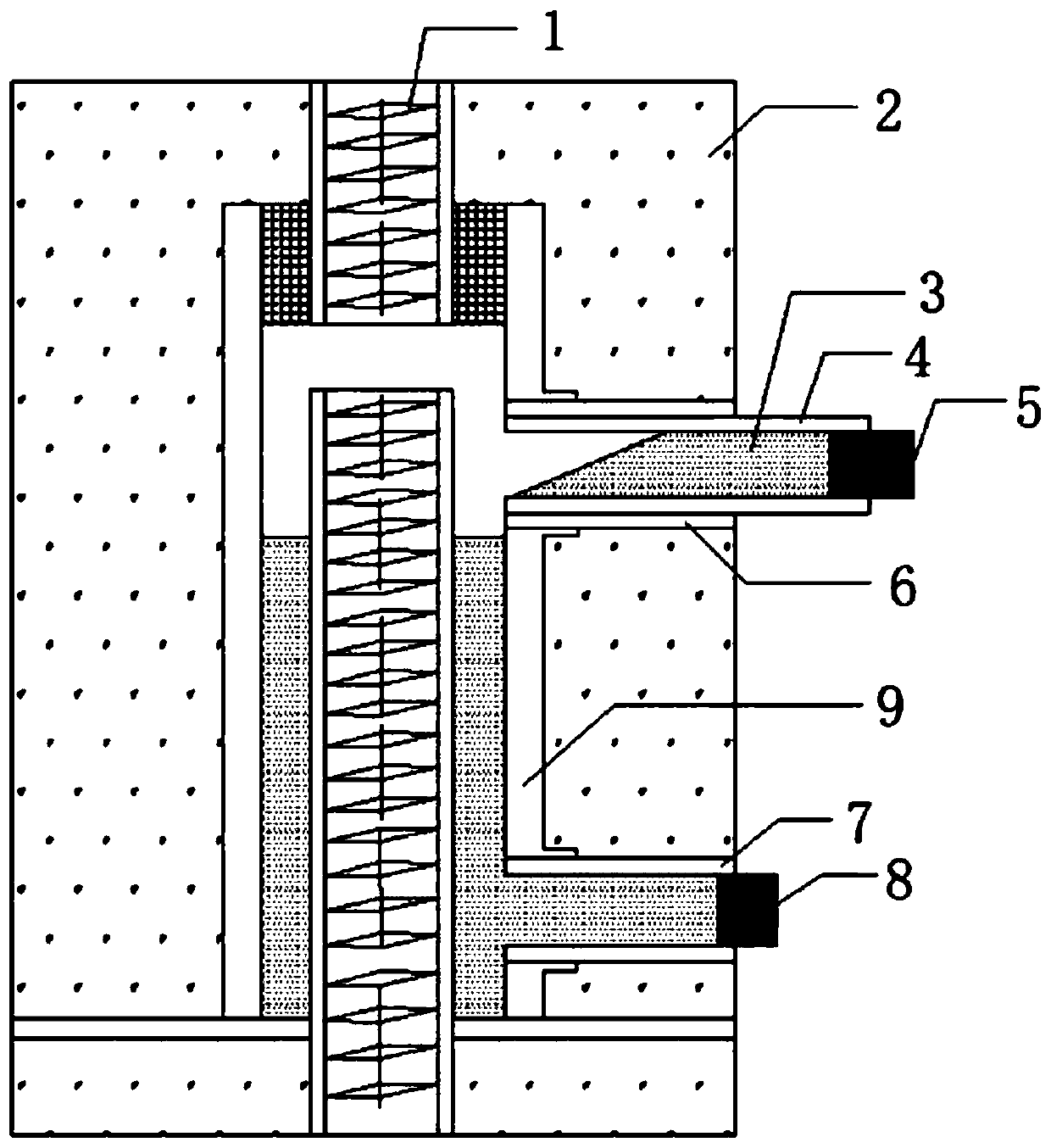

Method for detecting quality of grouting of sleeve of prefabricated concrete structure

ActiveCN109856143ALow costStrong applicability for promotionPreparing sample for investigationMaterial analysis by optical meansShear modulusYoung's modulus

The invention relates to a method for detecting the quality of grouting of a sleeve of a prefabricated concrete structure. The method comprises the steps that before a grouting procedure, a guiding pipe with the depth enabling the guiding pipe to achieve the inner wall of the sleeve is inserted in to a gout outlet pipeline of the sleeve, the guiding pipe is pulled out after a grouting material isfinal set, when the guiding pipe is pulled out, if a hollow cavity is formed in the guiding pipe by visual inspection, that is, the grouting material in the horizontal guiding pipe and the grouting material in the vertical sleeve are discontinuous, and the condition that grouting of the sleeve is not full; and otherwise, if a breaking-off surface of the end part of a horizontal section of the guiding pipe and the grouting material of the inner wall of the sleeve can be seen, the grouting material in the guiding pipe is full; and the solid grouting material in the guiding pipe is taken out to be made into a cylinder test piece, the curl frequency and the distortion frequency of the test piece are measured, a young modulus E<d>, a shear modulus G<d> and a poisson ratio mu are acquired, and dynamic elasticity modulus data is obtained to estimate the strength and material of the grouting material. The method detecting the quality of grouting of the sleeve of the prefabricated concrete structure has randomness, the adaptability is high, the cost is low, population is easy, rapidness and high efficiency are achieved, the connecting part of grouting of the sleeve cannot be damaged, and comprehensive, objective and precise reference is provided for quality detection of actual grouting construction.

Owner:SGS STANDARD TECHNICAL SERVICES SHANGHAI CO LTD

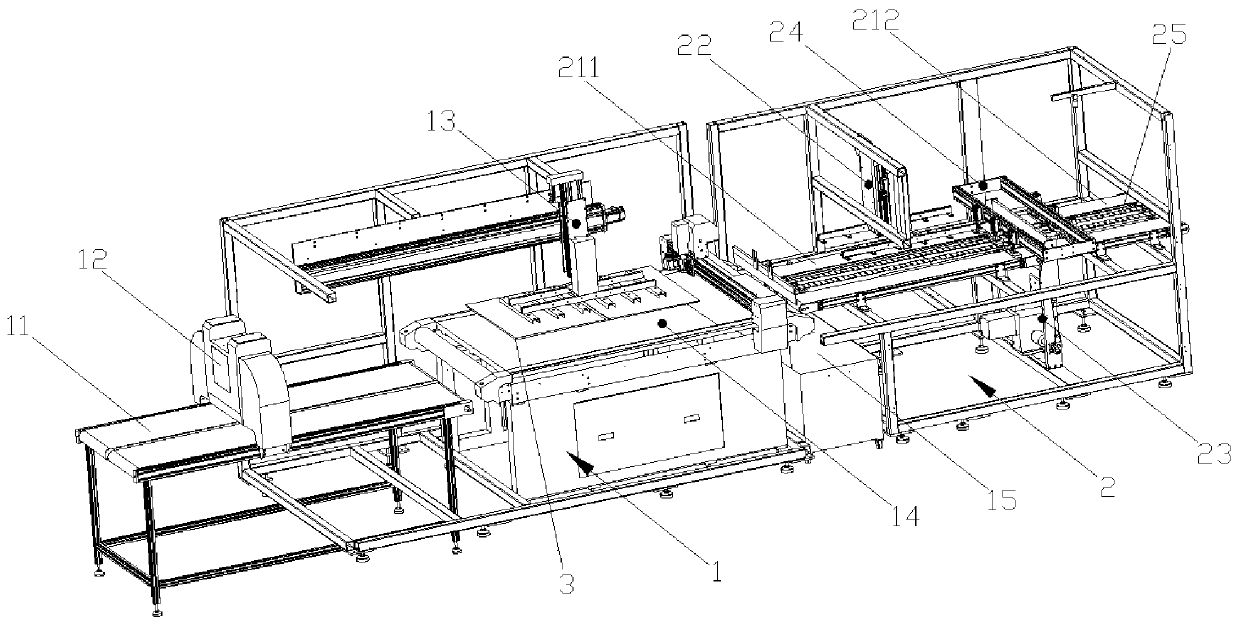

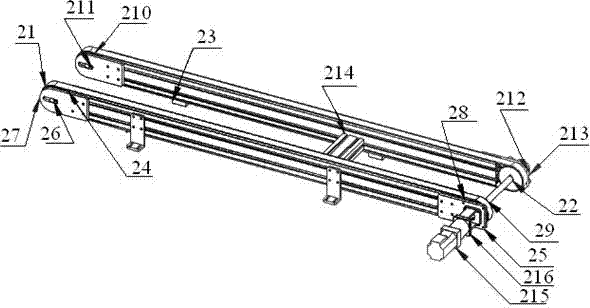

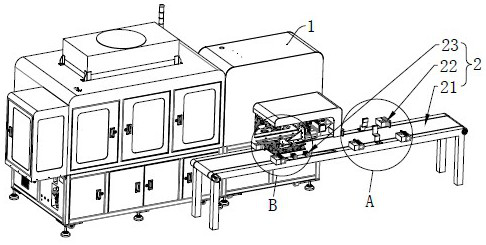

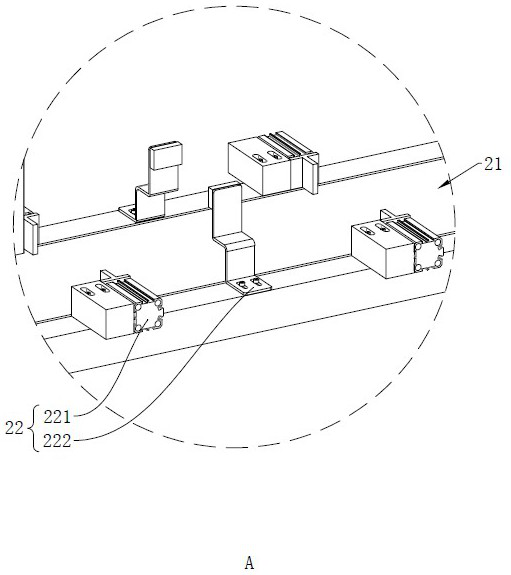

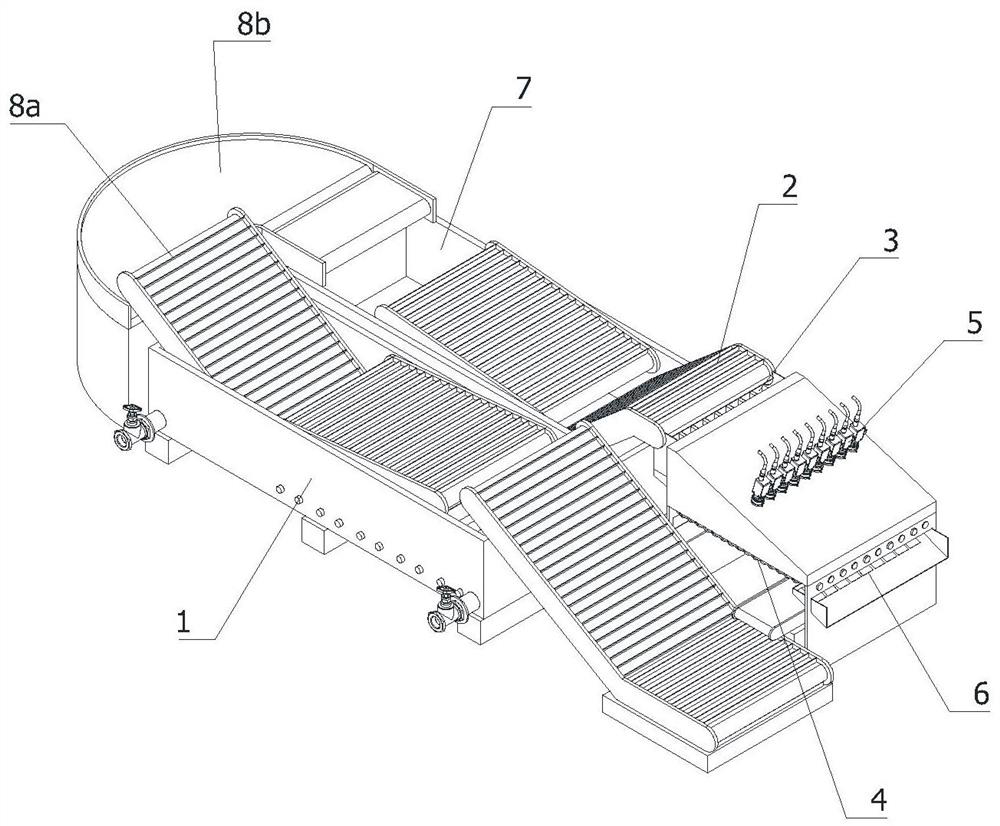

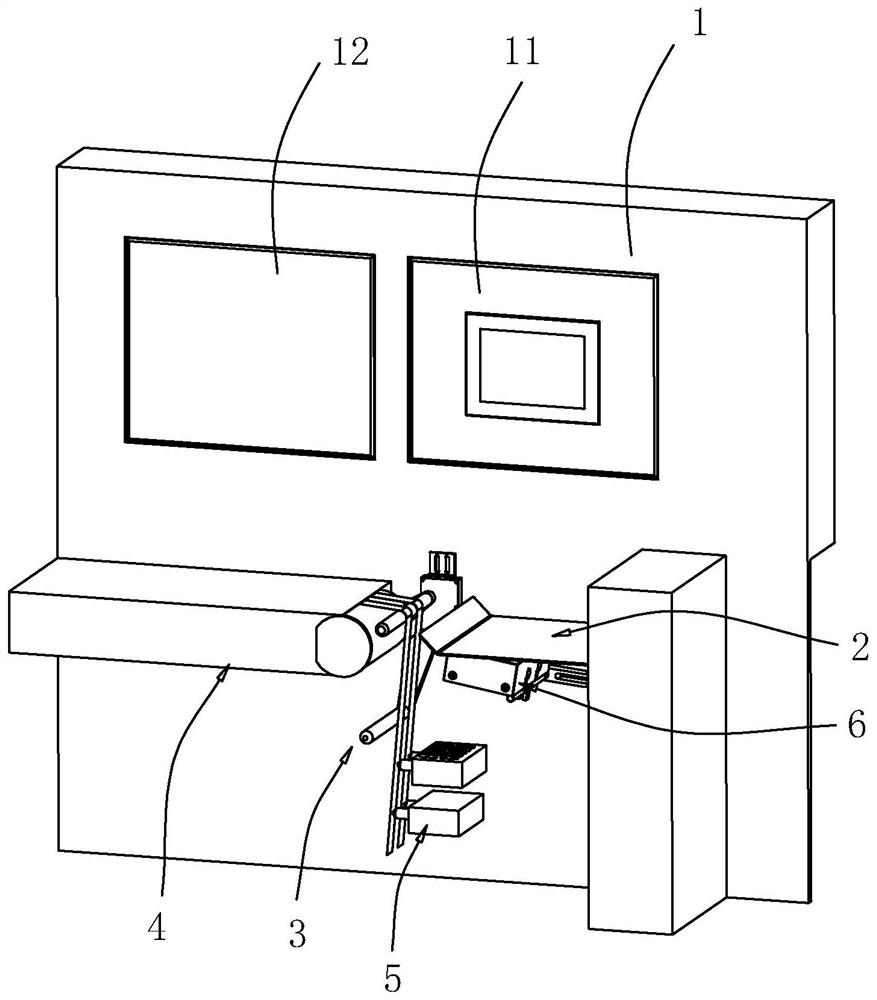

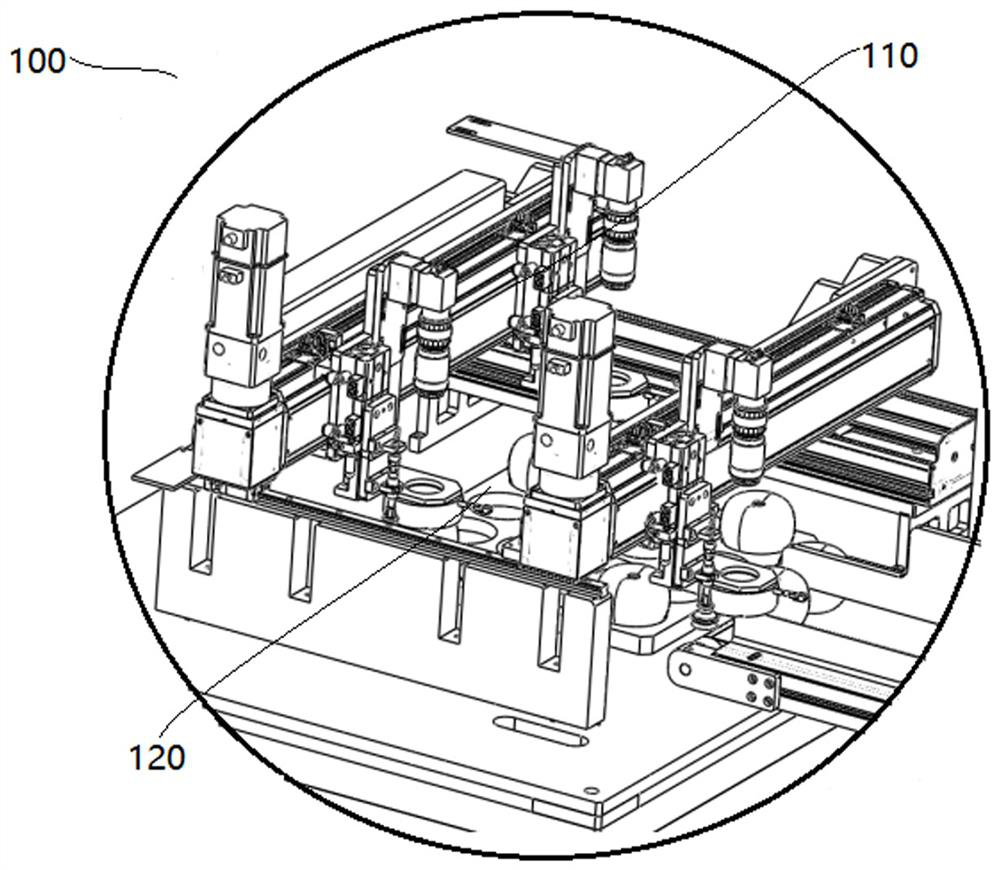

PCB copper foil side cutting and board separating integrated equipment and PCB process line

ActiveCN110815376AAutomated program highEasy constructionMetal working apparatusRobot handProcess engineering

The invention discloses PCB copper foil side cutting and board separating integrated equipment and a PCB process line. The PCB copper foil side cutting and board separating integrated equipment comprises a PCB copper foil side cutting and recovery device and a PCB automatic separation device. The PCB copper foil side cutting and recovery device comprises a feeding conveying belt, a visual inspection device, a feeding mechanical arm, a cutting device and a copper foil recovery box. The PCB automatic separation device comprises a strip conveying belt, a position feedback system, an angle adjusting mechanical arm, a straw hopper board separation assembly, a board pressing assembly and a vacuum adsorption assembly. The PCB copper foil side cutting and recovery device is arranged to achieve PCBcopper foil side cutting, meanwhile, copper foil recovery is achieved, the PCB automatic separation device is used for carrying out automatic and precise board separation on PCBs, production efficiency is improved, the automatic procedure of a plant is improved, the labor intensive degree is reduced, production cost is reduced, and building of the intelligent plant is facilitated.

Owner:深圳恒鼎智能装备有限公司

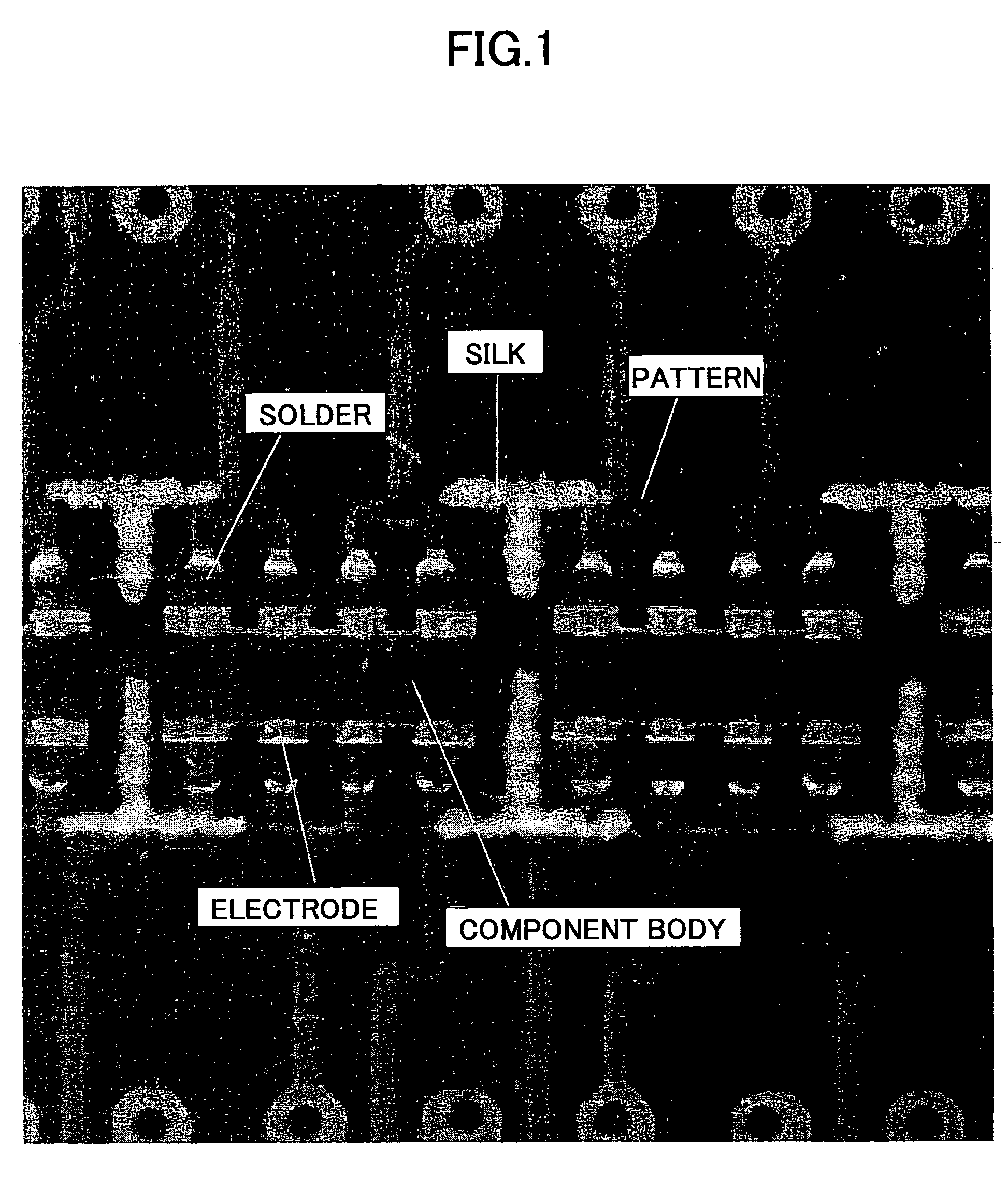

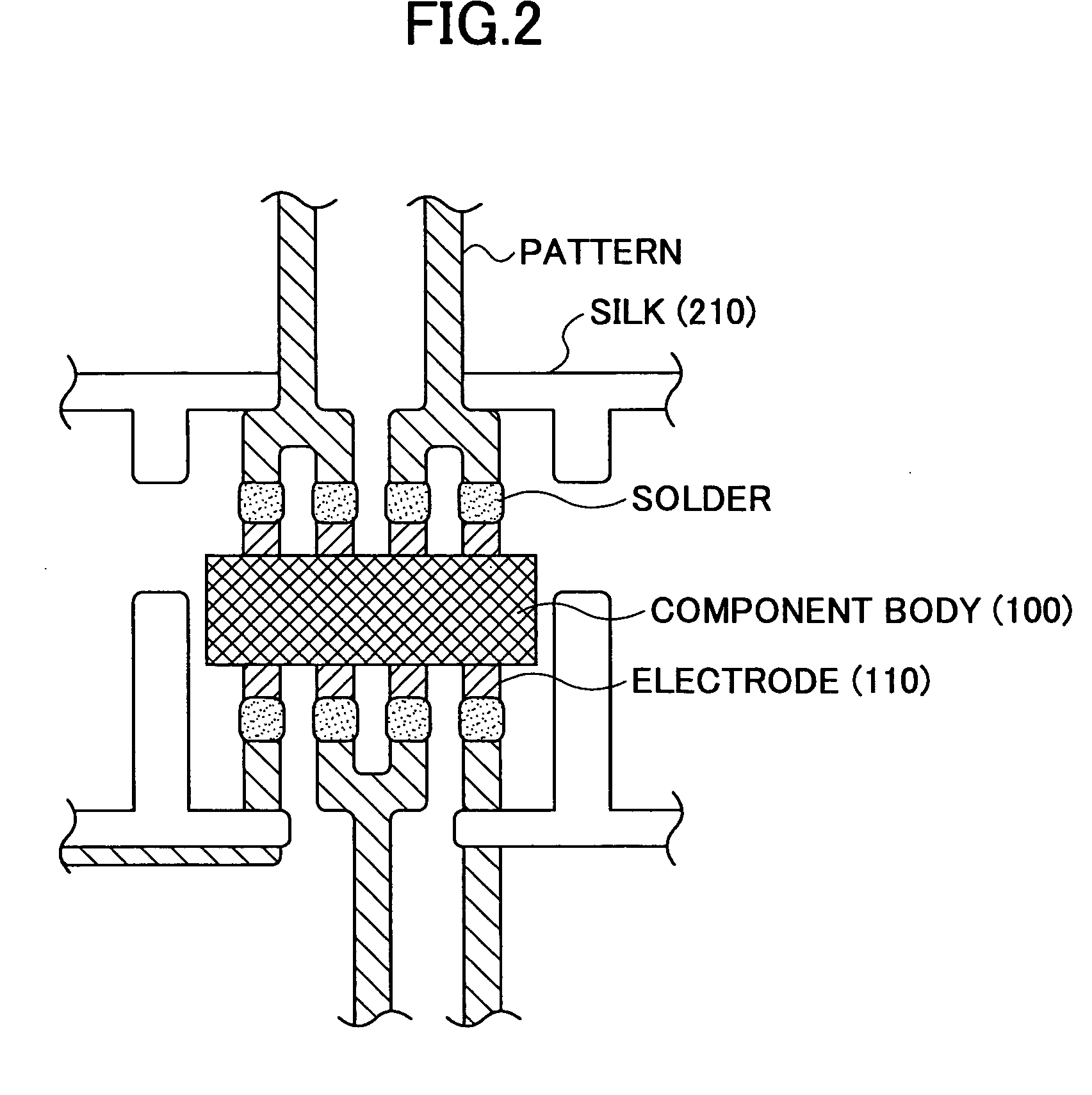

Printed circuit substrate appearance inspection method, printed circuit substrate appearance inspection program and printed circuit substrate appearance inspection apparatus

InactiveUS20060023935A1Degrade appearance inspection accuracyPreventing situationImage enhancementImage analysisVisual inspection (procedure)Imaging data

A printed circuit substrate appearance inspection method comprising: an inspection area defining step defining a predetermined inspection area on an image of a printed circuit substrate including a component mounted on the printed circuit substrate; and an appearance inspection step carrying out appearance inspection of the component by analyzing image data in the thus-defined inspection area, wherein: the inspection area defining step comprises the steps of; detecting a printed substrate pattern part around the component on the printed circuit substrate; and defining the predetermined inspection without overlapping with the thus-detected printed substrate pattern part.

Owner:FUJITSU LTD

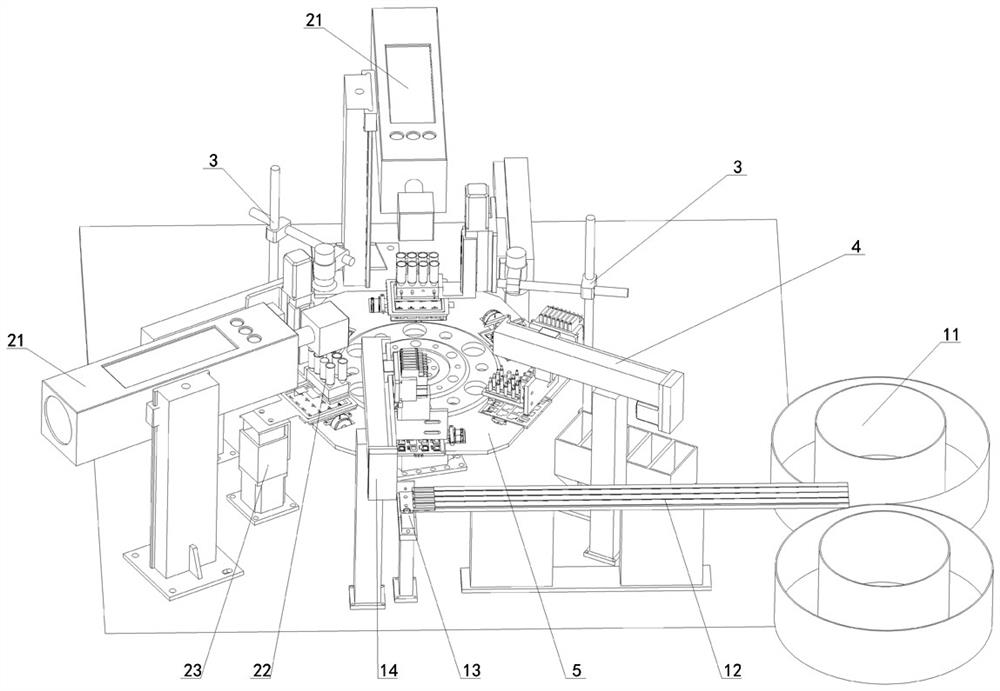

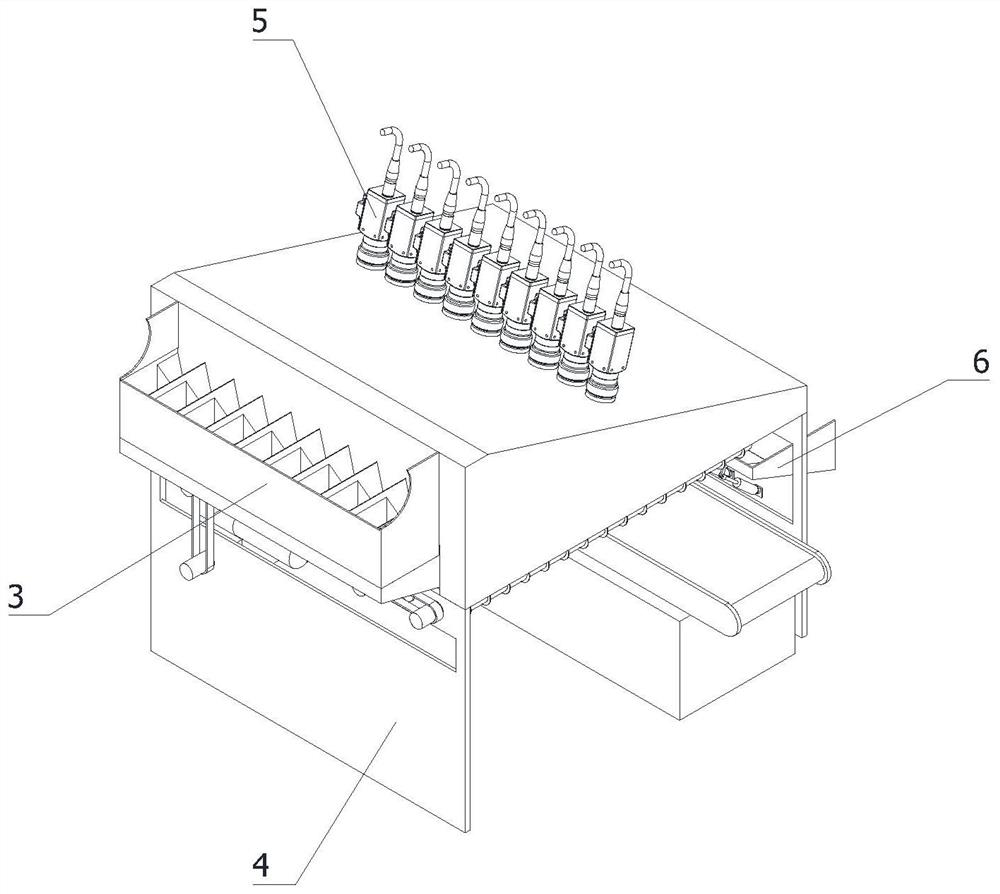

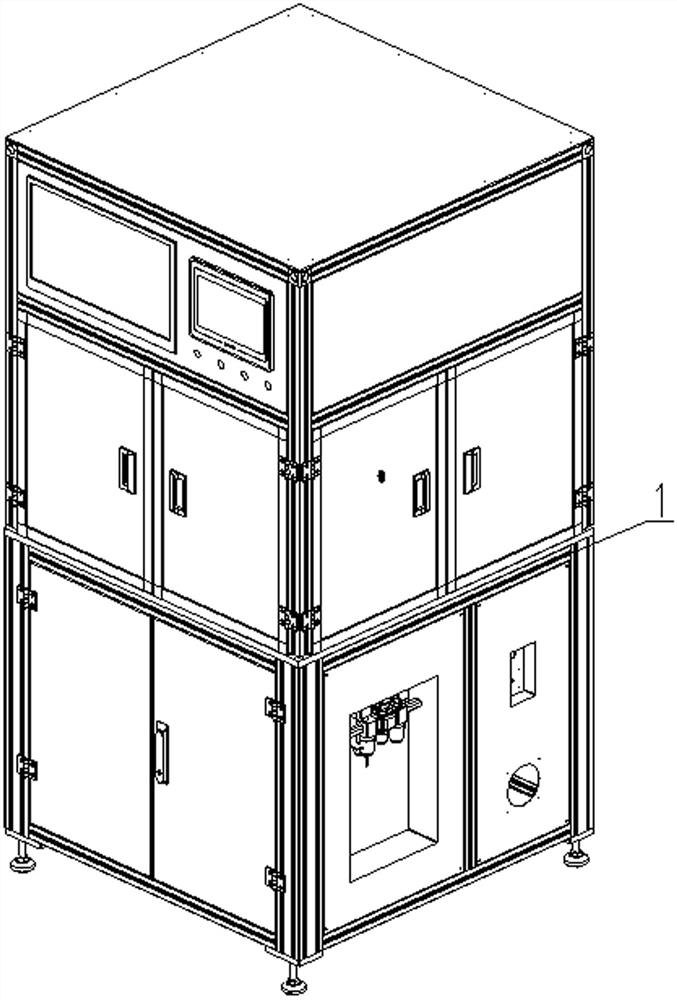

Fully automatic betel nut halogenating equipment

PendingCN107296234ARealize selectionGuaranteed single production requirementsMaterial analysis by optical meansFood scienceBetel nutsMachine

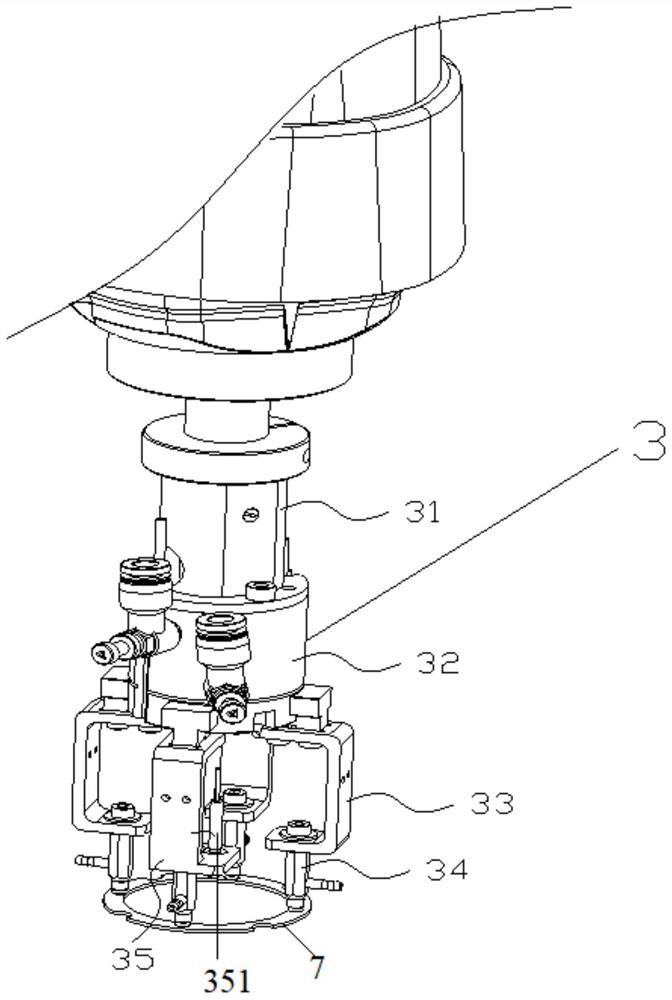

The invention discloses fully automatic betel nut halogenating equipment, which comprises a machine frame assembly, wherein the middle part of the machine frame assembly is horizontally provided with a betel nut material disc; a feeding conveying mechanism is arranged on the machine frame assembly arranged under the betel nut material disc; a visual inspection assembly is arranged on the machine frame assembly arranged above the betel nut material disc; a halogenating mechanism is arranged in the machine frame assembly arranged between the betel nut material disc and the visual inspection assembly; a heating barrel connected with the halogenating mechanism is also arranged at the side of the machine frame assembly; a heating mechanism of the heating barrel, the controlled end of the halogenating mechanism, the controlled end of the feeding conveying mechanism and the output end of the visual inspection assembly are respectively connected with a control device arranged on the machine frame assembly. The fully automatic betel nut halogenating equipment has the advantages that through the whole application, the working procedures such as automatic material disc feeding, automatic heating and automatic halogenation are realized; the automation degree and the work efficiency of factories are improved; the labor cost is reduced.

Owner:无锡汉塔科技有限公司

Insert part laser solder ball device and welding method

PendingCN111745243AReduce labor intensityReduce processSolder feeding devicesSoldering auxillary devicesSolder ballVisual inspection (procedure)

Owner:JINING AVOVE ELECTRONICS TECH CO LTD

L-shaped steel plate visual inspection equipment with bending angle detection function

InactiveCN112170248AWith bending angle detection functionFully automatedShearing machinesSortingLine sensorGear wheel

The invention discloses L-shaped steel plate visual inspection equipment with a bending angle detection function. The equipment comprises a bottom plate and a cross arm, wherein the cross arm is arranged at the upper left end of the bottom plate; T-shaped holes are arranged in the left side and the right side of a storage bin; a lifting rod is arranged at the right side of an inductor; a half gearis arranged above the left part of the bottom plate; a conveyor belt is arranged above a full gear; a pushing block is arranged at the left end of a flat plate; a push rod is arranged in front of a clamping block; a first motor is arranged at the right side of the half gear; a supporting plate is arranged at the top end of a stand column; a hydraulic rod is arranged above a cantilever; a shell isarranged on the periphery of a visual detector; a detector is arranged above a rotating plate; a slide rail is arranged at the right side of a first light sensor. Compared with existing visual inspection equipment, the L-shaped steel plate visual inspection equipment with the bending angle detection function has the advantages that the bending angle of an L-shaped steel plate can be visually detected, the detection process is simplified, and the L-shaped steel plate visual inspection equipment with the bending angle detection function is well integrated into machining and production procedures of plates.

Owner:广州市金点子机电科技发展有限公司

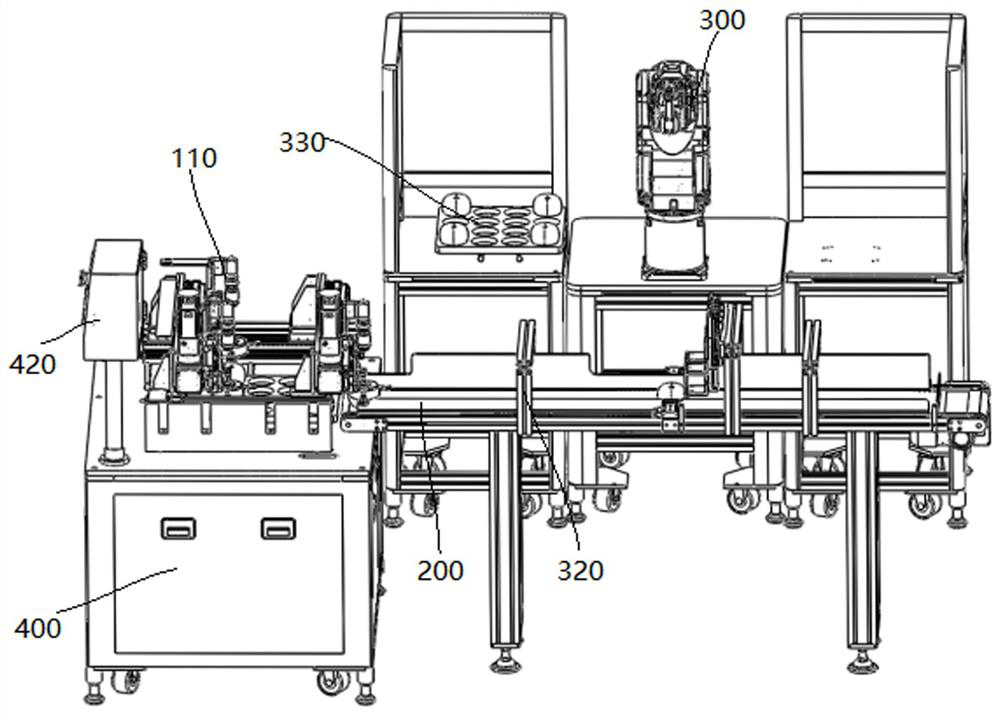

Flowerpot injection molding production line

ActiveCN113273405AHigh degree of intelligenceImprove yield rateReceptacle cultivationHollow articlesProcess engineeringVisual inspection (procedure)

The invention discloses a flowerpot injection molding production line. The flowerpot injection molding production line comprises flowerpot injection molding equipment, and flowerpots subjected to injection molding are transplanted to a conveying line through a first manipulator, sequentially pass through a first visual inspection system, a polishing station, an assembling station, a second visual inspection system and a film covering station, finally enter a finished product station and are stacked to a finished product frame. According to the flowerpot injection molding production line, automatic machining of procedures such as visual inspection, edge grinding, assembling, assembling effect detection and film covering of the flowerpots subjected to injection molding can be integrally achieved, the intelligent degree of the flowerpot production process is greatly improved, the labor intensity of workers is reduced, the production efficiency is improved, and the final yield of the flowerpots is high.

Owner:莱茵科斯特智能科技(青岛)有限公司

Full-automatic in-mold labeling and visual detection system

PendingCN113071774AReduce conversion spaceHigh degree of automationConveyor partsLabelling machinesReciprocating motionProcess engineering

The invention discloses a full-automatic in-mold labeling and visual detection system which is used for carrying out in-mold labeling and visual detection on cup-shaped products. The full-automatic in-mold labeling and visual detection system comprises a material carrying frame, a labeling device, a material moving device, a product receiving platform, a first visual detection device, a turnover mechanism, a reciprocating motion device and a conveying line; the labeling device places labels on the material carrying frame into a mold cavity and takes out the cup-shaped products subjected to in-mold injection molding and labeling, the material moving device transfers the taken-out cup-shaped products to the product receiving platform, and the turnover mechanism drives the product receiving platform to overturn to a photographing position; the first visual detection device is respectively aligned with each cup-shaped product under the driving of the reciprocating motion device and is used for carrying out visual detection on the interior of each cup-shaped product; and the conveying line receives and conveys the plurality of cup-shaped products subjected to visual inspection. Therefore, the system can simultaneously complete product in-mold labeling and detection procedures, the automation degree is high, and the machine table conversion space is reduced.

Owner:东莞市景华自动化科技有限公司

Preparation method of LCD (Liquid Crystal Display)

PendingCN114236889AExposure photoproduct increasedSolve the problem of incomplete developmentNon-linear opticsScreen printingGraphics

The invention relates to a preparation method of an LCD (Liquid Crystal Display). The preparation method comprises the steps of glass input, first-time cleaning, gluing, exposure, developing, etching, demolding, pattern detection and repair, TIP (Transfer In Placement) working procedure, PI working procedure, orientation, screen printing, spraying, combination, hot pressing, cutting, liquid filling, sealing, last-time cleaning, electric visual inspection, surface mounting and packaging. The method can effectively solve the problem that the product yield is not high easily due to the fact that the preparation technology is not perfect enough in the preparation process of an existing LCD.

Owner:ANHUI GOLDEN VISION OPTOELECTRONICS TECH

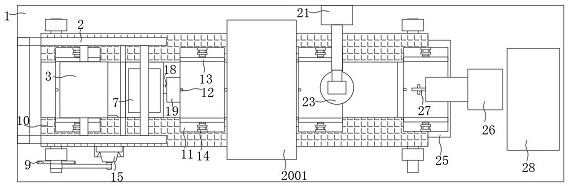

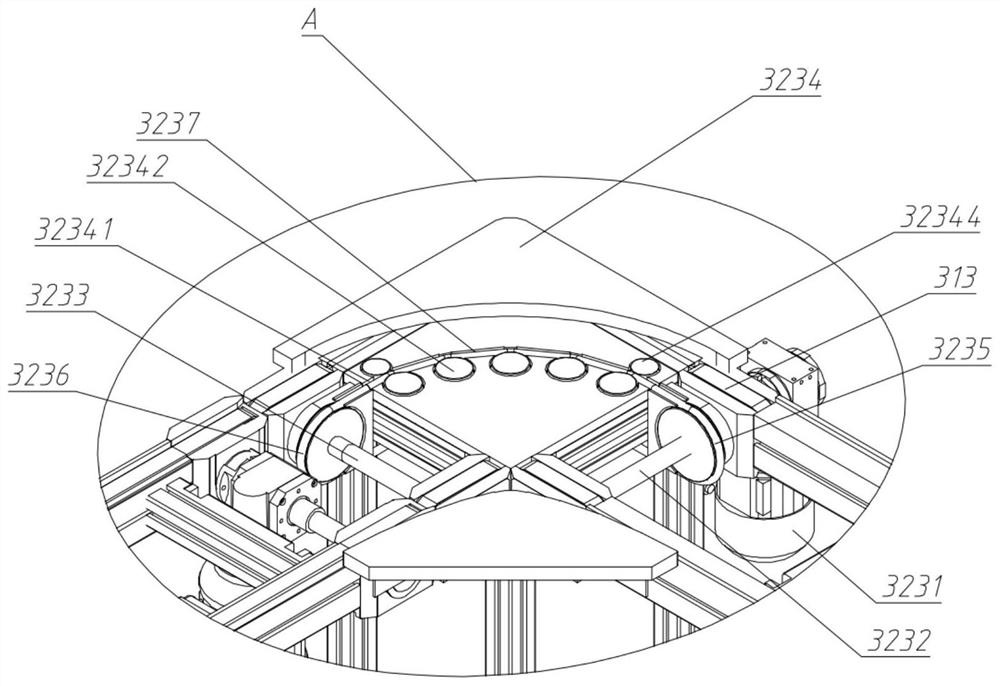

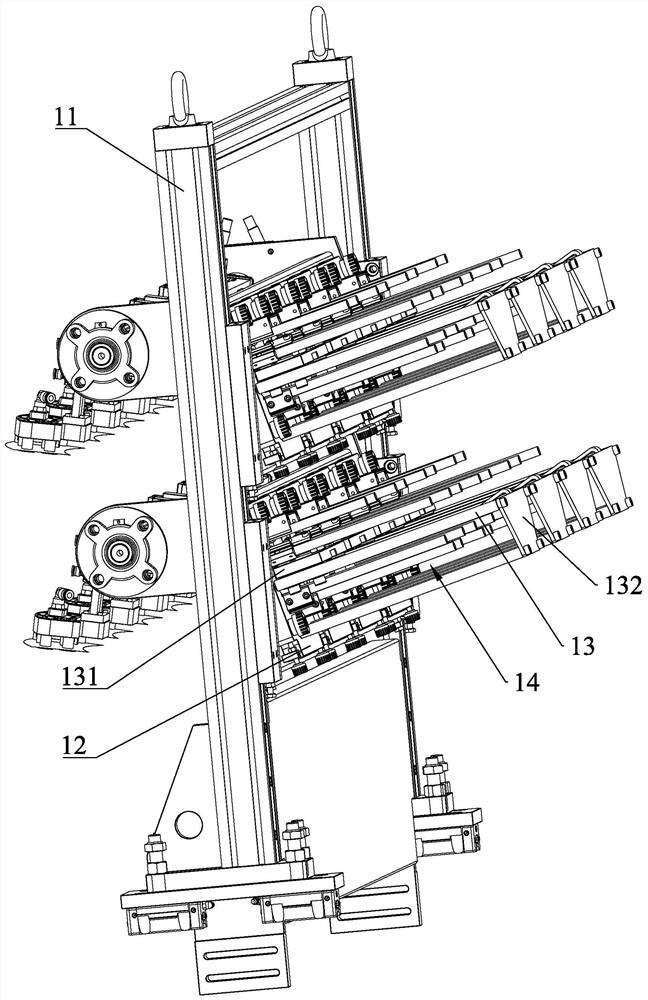

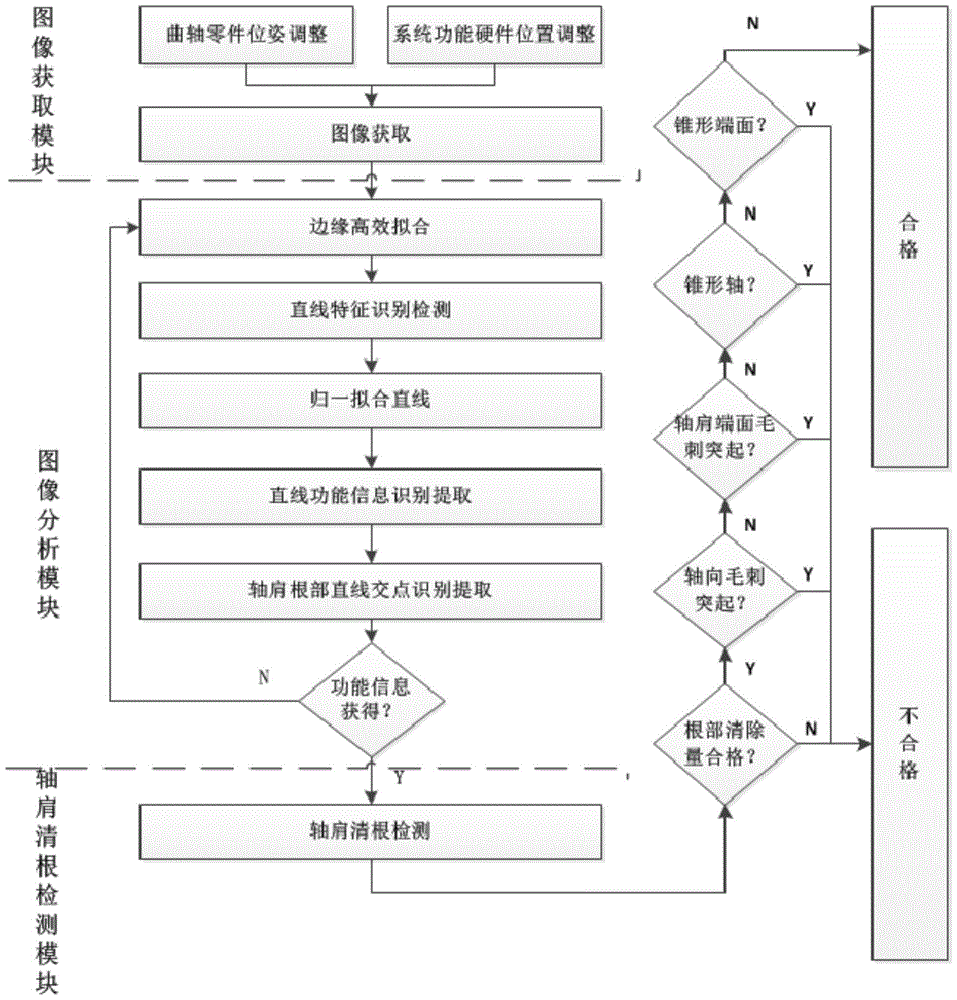

A visual inspection method and device for root cleaning of crankshaft shoulder

InactiveCN104748684BEfficient identification and detectionRapid Identification DetectionUsing optical meansStructural engineeringVisual inspection (procedure)

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

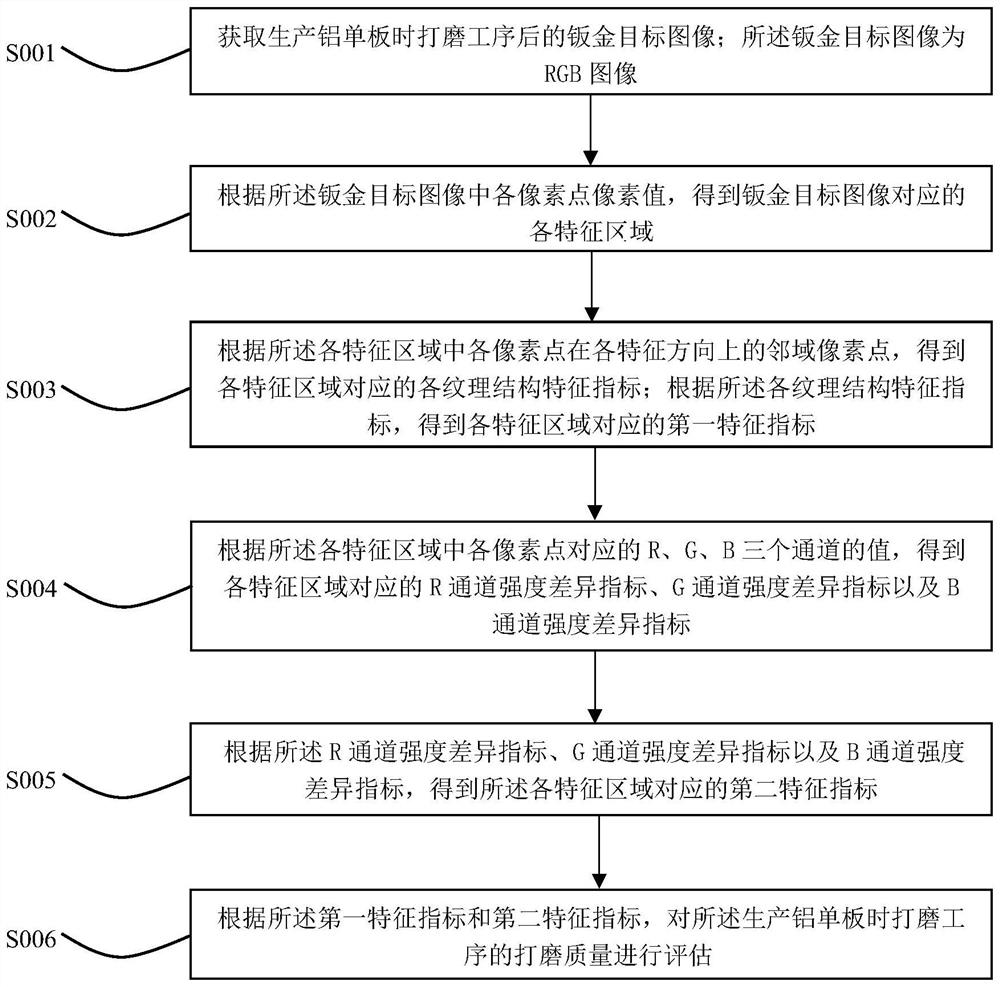

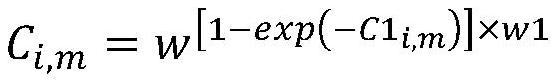

Aluminum veneer polishing quality evaluation method and system based on computer assistance

The invention relates to a computer-aided aluminum veneer polishing quality evaluation method and system, and belongs to the technical field of electronic data digital processing. According to the method, a computer is used for aided design and processing, and the method can be applied to novel software and novel technical services. The method comprises the following steps: obtaining a first feature index corresponding to each feature region according to each texture structure feature index; obtaining a second feature index corresponding to each feature region according to the R channel intensity difference index, the G channel intensity difference index and the B channel intensity difference index; and according to the first characteristic index and the second characteristic index, the polishing quality corresponding to the polishing procedure during aluminum veneer production is evaluated. Compared with a mode of evaluating the grinding quality of the aluminum veneer based on manual visual inspection, the method has the advantages that the grinding quality corresponding to the grinding procedure during production of the aluminum veneer can be evaluated more reliably, and the working efficiency of evaluating the grinding quality corresponding to the grinding procedure is also higher.

Owner:江苏本峰新材料科技有限公司

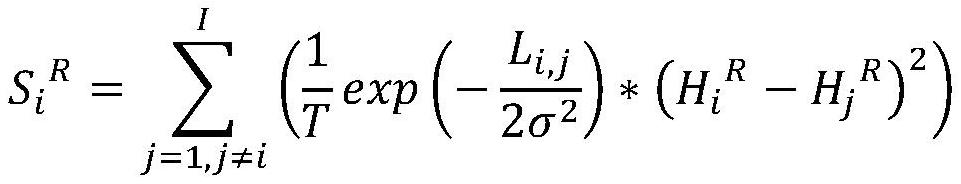

Automatic production line for producing automobile injection-molded coated products

The invention discloses an automatic production line for producing automobile injection-molded coated parts. The automatic production line comprises an automatic feeding system, an injection molding machine, a low-pressure injection mold, a weighing system, a laser coding tracing system, a plurality of groups of flexible mechanical arms, laser cutting equipment, automatic edge cladding welding equipment and visual inspection equipment; and all the procedures can be integrated, the part production time is shortened, occupied workshops are reduced, the production efficiency and the percent of pass are improved, and automatic, intelligent and unmanned production is achieved.

Owner:江苏新泉模具有限公司

Efficient visual detection method and system

InactiveCN114345741AImprove feeding effectImprove collection effectSortingPattern recognitionMedicine

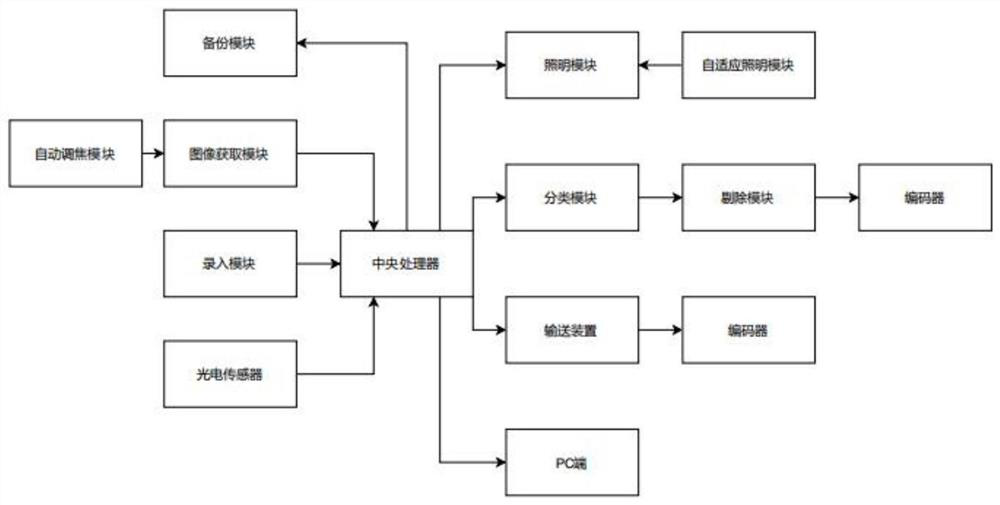

The invention relates to the technical field of visual inspection, in particular to an efficient visual inspection method and system, and the visual inspection system improves the workpiece inspection effect, improves the visual inspection efficiency and improves the practicability. The image acquisition module is used for acquiring an image of a to-be-detected workpiece and transmitting the image into the central processing unit; the classification module is used for analyzing and detecting the images uploaded to the central processing unit and classifying qualified images and unqualified images; the input module is used for uploading the image of the standard workpiece into the central processing unit; the conveying device is used for driving the workpiece to be fed below the image acquisition module, and the image acquisition module is used for carrying out image acquisition on the workpiece and conveying the detected workpiece to the next working procedure; and the rejecting module is electrically connected with the central processing unit and is used for rejecting the unqualified workpieces analyzed by the classifying module.

Owner:科芃智能科技(苏州)有限公司

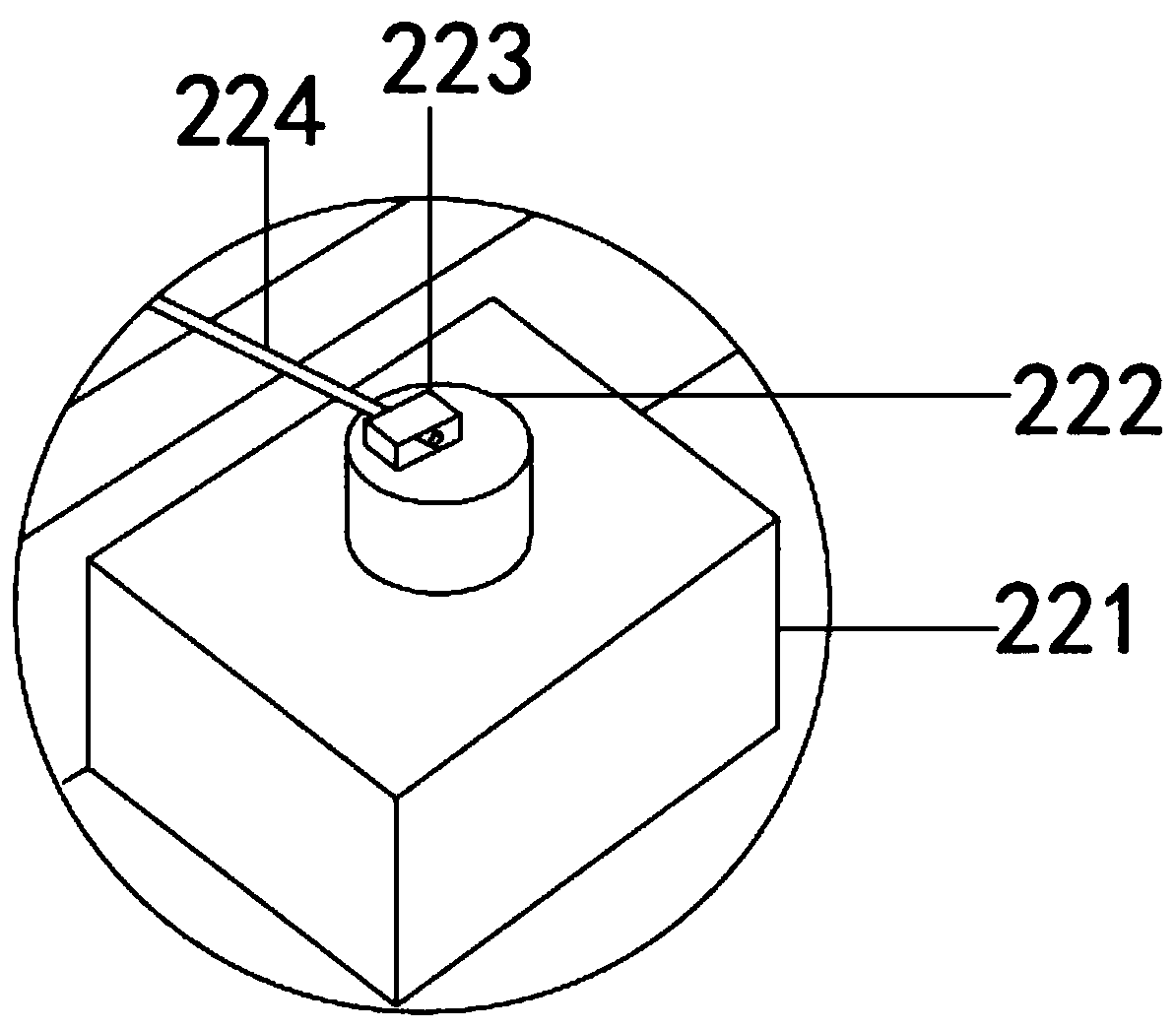

Guide vane ring feeding device based on visual positioning and using method thereof

InactiveCN112606417AImprove reliabilitySimple structureSortingControl engineeringVisual inspection (procedure)

The invention discloses a guide vane ring feeding device based on visual positioning. The guide vane ring feeding device comprises a base, an SCARA robot, an end effector used for taking and placing guide vane rings, a feeding slideway and a visual device, wherein the base is mounted on a workbench; the SCARA robot is fixedly mounted on the base; the end effector is connected to the tail end of the SCARA robot; the feeding slideway is connected to the visual device and located on the lower right portion of the end effector; the visual device is fixedly mounted on the workbench and located on the lower left portion of the feeding slideway; and the visual device conducts visual inspection and positioning on the guide vane rings coming from the feeding slideway in the previous procedure, and preparation is made for feeding of the robot in the next step. The guide vane ring feeding device further comprises a removing device used for removing the guide vane rings which are unqualified after visual inspection of the visual device; and the removing device is fixedly mounted on the upper rear portion of the visual device and located on the left side of the feeding slideway and used for removing the guide vane rings which are unqualified after visual inspection of the visual device.

Owner:WUHU HIT ROBOT TECH RES INST

Automatic device and method based on visual inspection

ActiveCN113522765AHigh degree of automationReduce usageSortingVisual inspection (procedure)Reclaimer

The invention relates to an automatic device and method based on visual inspection, and belongs to the technical field of visual inspection. According to the technical scheme, the automatic device comprises a rack, a feeding mechanism is arranged on one side of the rack, a material taking mechanism, a feeding mechanism, a detection mechanism and a discharging mechanism which are arranged according to the working procedure sequence are arranged on the rack, and the feeding mechanism comprises a first conveying belt, a limiting assembly and a positioning assembly; and the material taking mechanism comprises a material taking assembly and a second conveying belt arranged at the bottom end of the material taking assembly. According to the automatic device and method, plastic trays are conveyed to the rack through the first conveying belt, the plastic trays on the rear portion are blocked through the limiting assembly in the conveying process, the plastic tray on the foremost portion is positioned through the positioning assembly, the material taking mechanism grabs the plastic trays on the positioning assembly from the first conveying belt to the rack, and a series of working procedures are completed through the feeding mechanism, the detection mechanism and the discharging mechanism, so that the automation degree of the equipment is improved, and the effect that manual feeding is not needed by personnel is achieved.

Owner:荣旗工业科技(苏州)股份有限公司

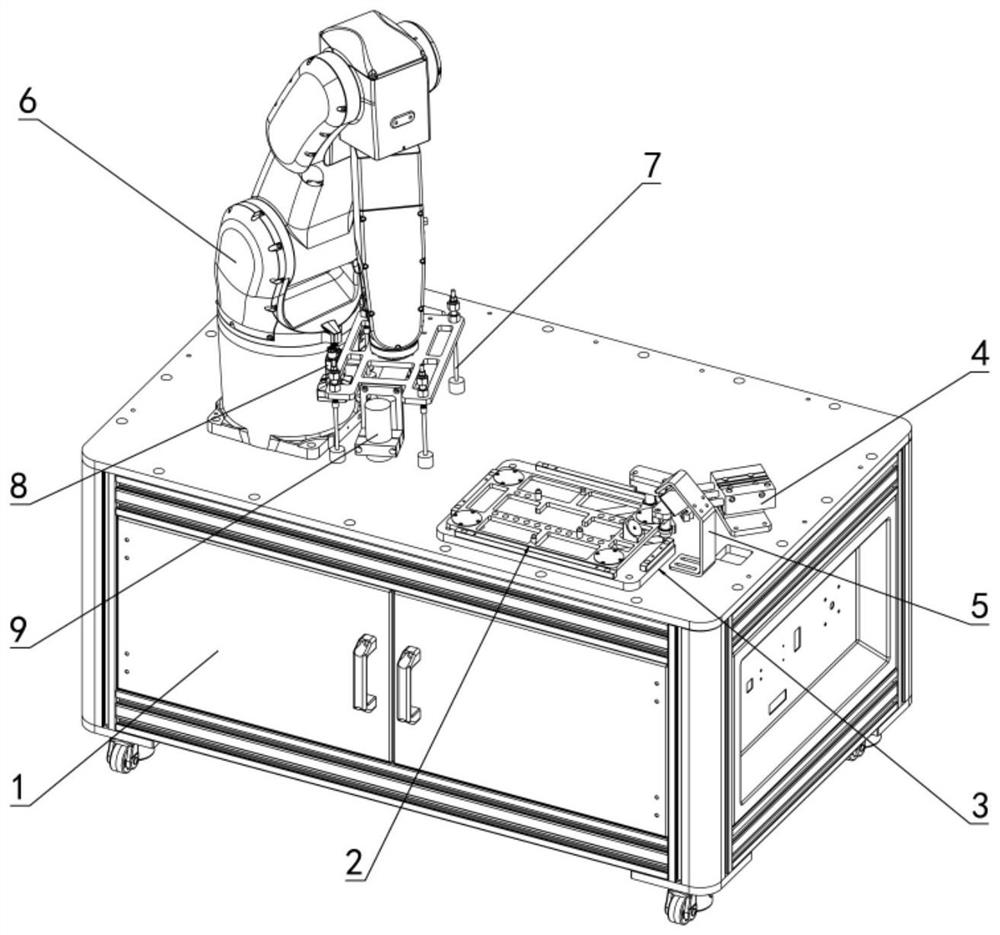

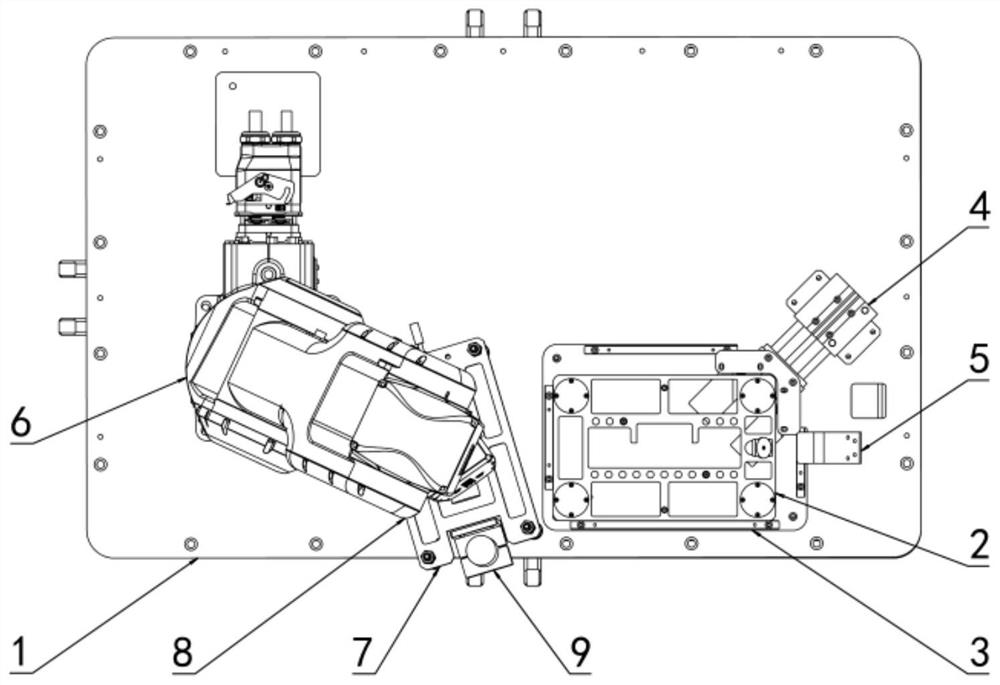

An industrial pallet handling and precise positioning unit

ActiveCN109571246BMeet the requirements of automatic assembly linesEnsure consistencyGrinding feed controlGrinding feedersVisual inspection (procedure)Industrial engineering

The invention belongs to the technical field of industrial automatic assembly and logistics production lines, and particularly relates to an industrial pallet handling and precise positioning unit. Including working platform; tray; tray positioning mechanism, used to accurately locate the posture and position of the tray; tray pressing mechanism, used to press and fix the tray; sensor reading device, used to identify the storage elements on the tray, read and Record the information of pallets and the materials they carry; six-degree-of-freedom robots are used to carry tooling to complete transfer and processing tasks; pallet grabbing mechanisms are used to grab and carry pallets; visual inspection devices are used to take photos of the working area and Real-time transmission to the control system to analyze the working status; processing equipment, used to complete a series of processing tasks such as gluing, assembly, grinding, and coding. The present invention can carry pallets, perform precise positioning and pressing and fixing, achieve high precision to meet the requirements of automatic assembly, and ensure the consistency of assembly and processing procedures.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

A substrate automatic processing equipment for circuit boards

ActiveCN111511119BGuaranteed left and right transmissionGuarantee processing qualityCharge manipulationPrinted circuit manufactureLaser etchingVisual inspection (procedure)

The invention relates to the technical field of electronic equipment processing, and provides an automatic substrate processing equipment for circuit boards. Detecting problems that are basically impossible to solve, including the strip-shaped transmission box, the inner cavity of the strip-shaped transmission box is horizontally installed with multiple transmission rollers, the upper end of the strip-shaped transmission box is provided with a processing room, and the inner cavity of the processing room is along the According to the moving direction of the substrate, it is divided into a cutting chamber and an etching chamber in turn. A detection box is installed on the front wall of the etching chamber. A visual inspection camera group is installed on the inner top wall of the detection box. A cutting mechanism is installed in the cutting chamber. A laser etching mechanism is installed in the etching chamber; the cutting mechanism includes two hydraulic rods I symmetrically installed on the top wall of the cutting chamber. The invention is especially suitable for the automatic processing of the substrate of the circuit board, and has high social use value and application prospect.

Owner:广东圣邦尼电子科技有限公司

Method for Diagnosing and Treating Hemorrhoids

PendingUS20180303402A1Avoid it happening againSurgeryComputerised tomographsInsertion stentVisual inspection

A method of determination of a cause of hemorrhoids in a subject includes a determination of the presence of hemorrhoids in the subject by visual inspection, and by one or more of a non-invasive medical imaging procedure and / or an intra-vascular visualization procedure, determining if there is an obstruction or occlusion in an iliac vein of the subject, and if so, determining that the hemorrhoids were caused by such obstruction or occlusion. If the obstruction or occlusion are determined to be the cause of the hemorrhoids, a procedure for compressing the obstruction or occlusion in the iliac vein of the subject, such as by angioplasty or stenting, is performed. After an appropriate time period, changes to the hemorrhoids in the subject are determined by a subsequent visual inspection.

Owner:GUILLEUMA JUAN

Firework inner barrel detecting and waste removing mechanism based on vision

ActiveCN111380414ARealize qualified inspectionRealize the automatic elimination functionFireworksVision basedProcess engineering

The invention belongs to the technical field of firework production, and particularly relates to a vision-based inner barrel detecting and waste removing mechanism. The device comprises a rack, a waste removing mechanism and a visual inspection mechanism, the waste removing mechanism comprises a driving mechanism supporting mounting plate, an inner cylinder supporting adjusting support, a detection position blocking mechanism, a waste removing mechanism, a sectional material conveying line body and the visual inspection mechanism, and a detection station and the sectional material conveying line body are sequentially arranged on the inner cylinder supporting adjusting support from top to bottom; the detection position blocking mechanism and a waste removing mechanism are sequentially arranged on the driving mechanism supporting mounting plate from top to bottom, the detection position blocking mechanism is used for receiving materials or releasing firework inner barrels on a detectionstation to fall, and the waste removing mechanism is used for removing unqualified firework inner barrels; and the sectional material conveying line body is used for conveying qualified firework innerbarrels to the next procedure. The device is compact in structure, all action mechanisms are pneumatically driven, a mechanical structure has no friction during action, and the device can adapt to complex environments in production, and is safe and reliable.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Visual inspection rear-end material receiving assembly line

PendingCN111056083ARealize automatic material distributionAchieve positioningPackaging automatic controlEconomic benefitsEngineering

The invention provides a visual inspection rear-end material receiving assembly line. The visual inspection rear-end material receiving assembly line comprises a rack and an assembly line arranged onthe rack; a separation area and a positioning area are arranged on the assembly line; the positioning area is located behind the separation area; a separation mechanism is arranged on the separation area; the separation mechanism is used for separating products on the assembly line into the positioning area; the positioning area is provided with a positioning mechanism; the positioning mechanism comprises a plurality of fixing parts symmetrically arranged on two sides of the positioning area; the fixing parts are arranged in parallel at equal intervals in the length direction of the positioning area; gap are reserved between every two adjacent fixing parts; and the products are positioned in the gaps. Compared with the prior art, the visual inspection rear-end material receiving assembly line can separate and position OK products which are visually detected, so as to reduce procedures and save manpower, thereby improving economic benefits.

Owner:SUZHOU KANGHONG INTELLIGENT EQUIP CO LTD

Silkworm cocoon pretreatment equipment and pretreatment process thereof

ActiveCN113798212AEasy to pick outAvoid mixingDe-gumming silkSortingProcess engineeringVisual inspection (procedure)

The invention relates to the field of raw silk production, in particular to silkworm cocoon pretreatment equipment. The equipment comprises a degumming pool, a first net chain type partition plate conveyor, a material distributing mechanism, an inspection mechanism, a visual inspection mechanism and a sorting guide mechanism, wherein the material distributing mechanism is arranged at the bottom of the discharging end of the first net chain type partition plate conveyor, the inspection mechanism comprises a conveying surface, and the feeding end of the conveying surface is arranged at the bottom of the material distributing mechanism; the visual inspection mechanism is arranged at the top of the inspection mechanism; and the sorting guide mechanism is arranged at the discharging end of the conveying surface. According to the equipment, the glossiness of a single silkworm cocoon can be detected, so that the sorting guide mechanism can sort out silkworm cocoons which are not completely degummed, and the silkworm cocoons with different degumming degrees can be prevented from being mixed together and directly subjected to the next treatment procedure. The invention further designs a silkworm cocoon pretreatment process.

Owner:那坡同益新丝绸科技实业有限公司

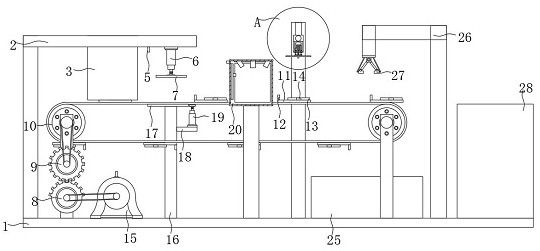

PCB tin brushing patch production process method

InactiveCN112672634AGood moistureLarge spreading ratePrinted circuit assemblingElectrical componentsMetallurgyActive agent

The invention discloses a PCB tin brushing patch production process method comprising a feeding system, tin paste printing, accurate patch pasting, reflow soldering, visual inspection and a general control operation system; a formula of tin paste is designed in the PCB tin brushing patch production process method, and an active agent, a solvent, a thixotropic agent and the like of a compounding system are added; therefore, the tin paste has the properties of good wetting degree, high spreading rate, excellent cold and hot collapse performance and the like. A visual system is introduced into the feeding procedure, automatic feeding is achieved, and the production efficiency is greatly improved. A machine visual system and a printing screen micro-positioning system for marking MARK points on a PCB of printing equipment are improved, a cooling air conditioner is added into a printing machine to achieve rapid cooling of the tin paste, the effect that the tin paste is rapidly separated from a printing screen and does not adhere to the printing screen can be achieved, and the problem that the tin paste adheres to the screen in the industry is greatly solved.

Owner:图尔克(天津)科技有限公司

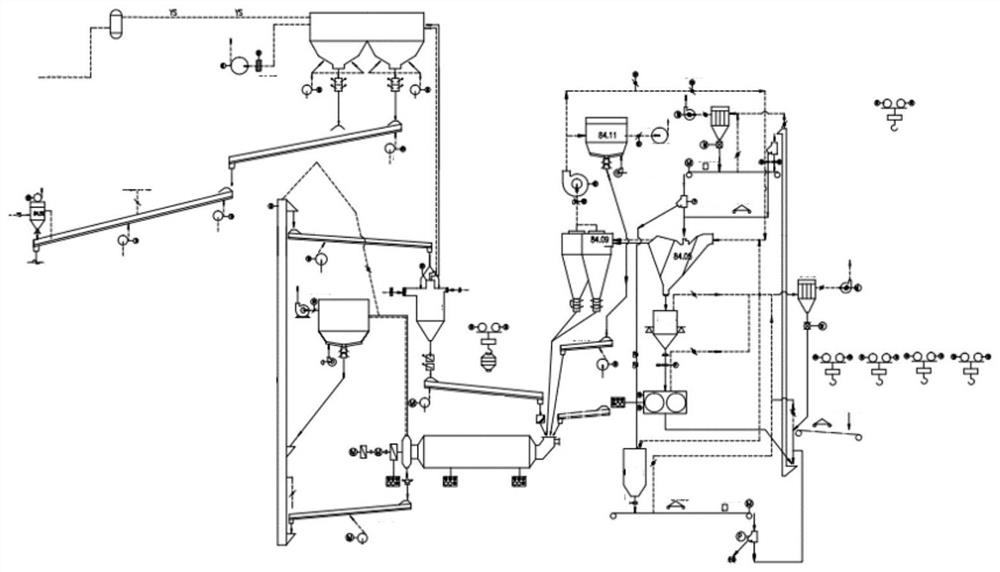

Method for testing retention time of materials in cement mill based on image recognition technology

PendingCN113792737AImpact Quantitative StatisticsQuickly implement quantitative statisticsCharacter and pattern recognitionPlastic materialsFluorescein

The invention discloses a method for testing residence time of materials in a cement mill based on an image recognition technology, and belongs to the technical field of cement production. The method comprises four procedures, namely, fluorescein material cake sample preparation, fluorescein feeding and taking, fluorescein image acquisition and fluorescein image recognition and quantification. The retention time of the materials in the cement mill can be rapidly and accurately tested. A plastic material cake is prepared by adding water into fluorescein powder and the mill entering materials, the fluorescent powder is prevented from being quickly blown to the tail of the mill along with ventilation in the mill to influence a test result, fluorescein recognition adopts an image recognition method, a shooting task can be completed only by using a portable handheld microscope with a low price, shooting of each sample only needs 3-4 minutes, the shooting of all the samples only needs one hour; and by using a computer image recognition technology, quantitative statistics of the fluorescein can be quickly realized, subjective judgment of manual visual inspection is avoided, and a test result is more accurate and reliable.

Owner:华润水泥技术研发(广西)有限公司

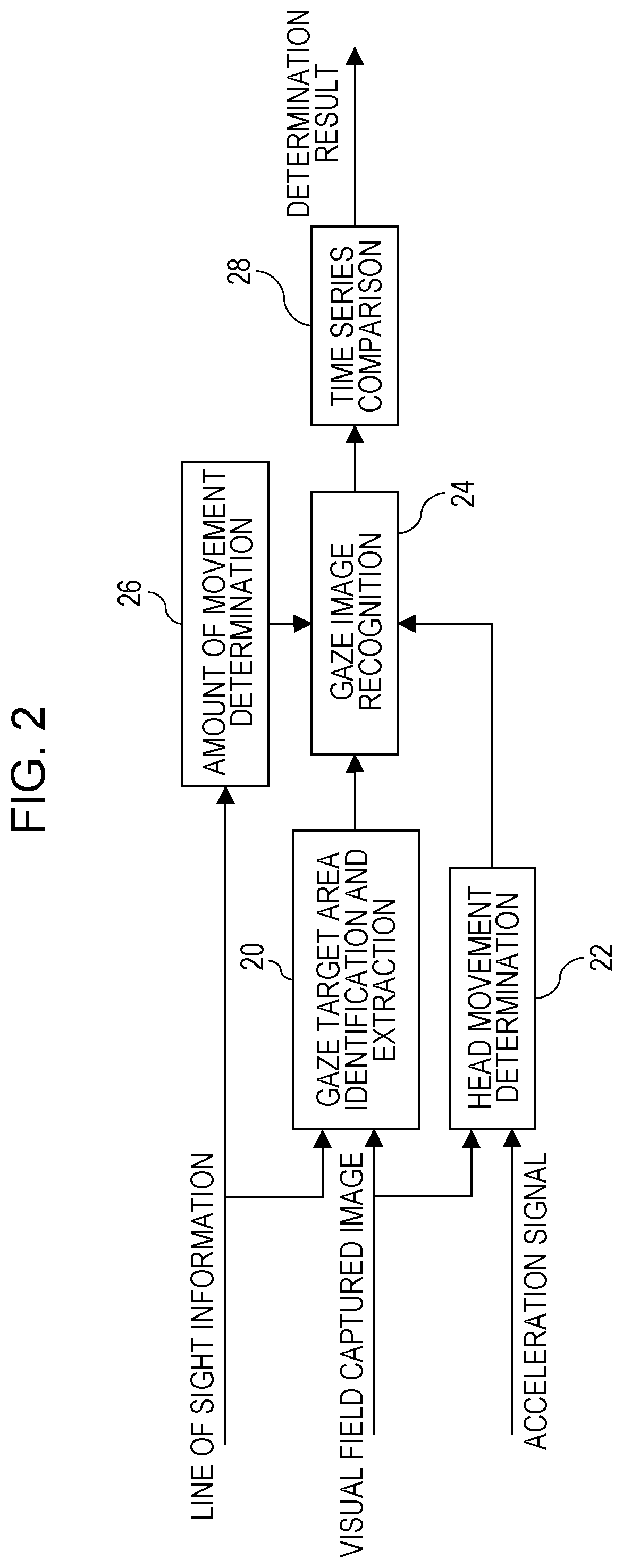

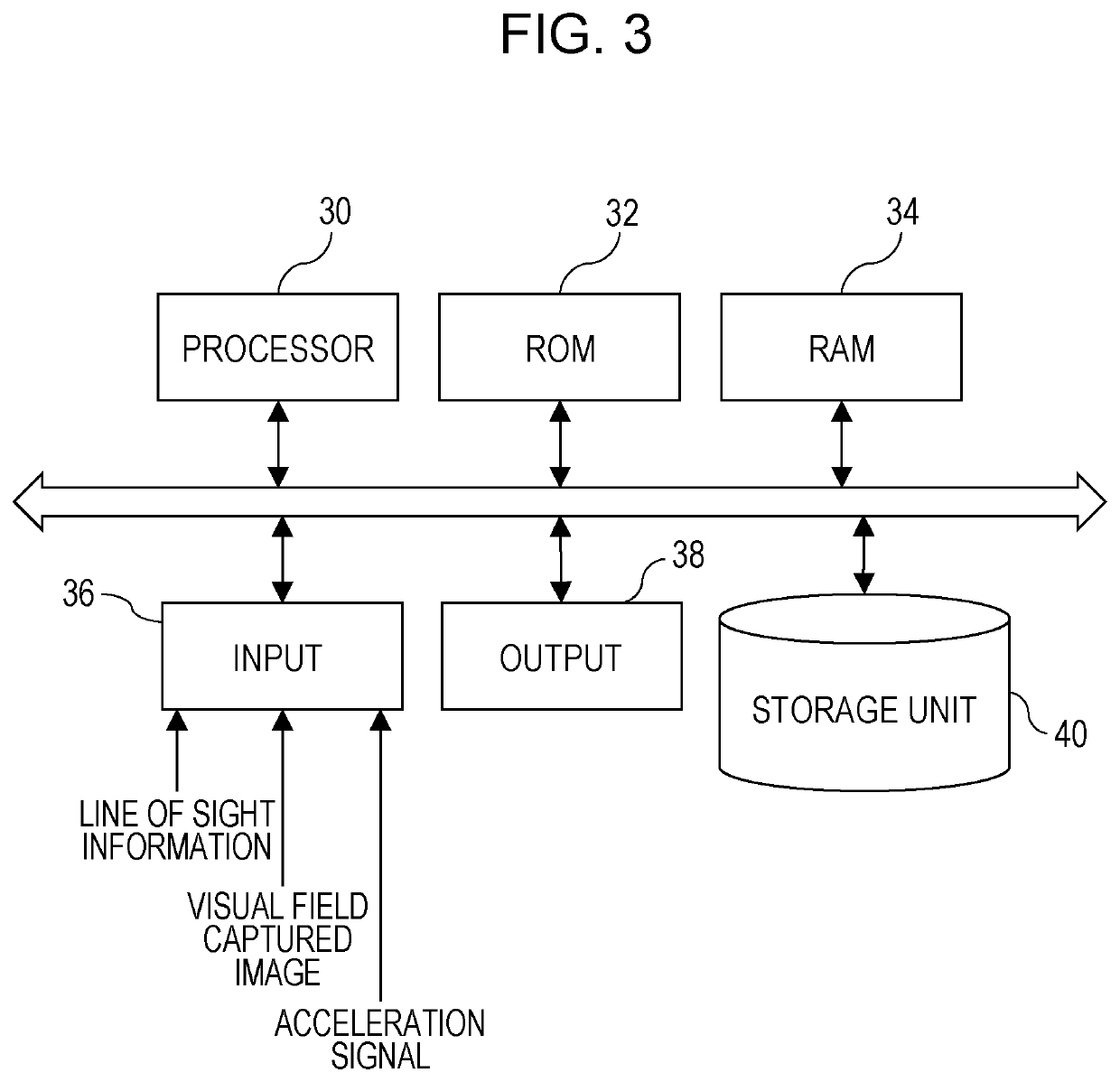

Visual inspection confirmation device and non-transitory computer readable medium storing program

A visual inspection confirmation device includes: a visual field capturing camera that captures a visual field image of an inspector who visually inspects an inspection target; a line of sight information detecting unit that detects line of sight information on the inspector; and a processor configured to execute a program, and identify points of inspection in the inspection target of the inspector in time series from the visual field image based on the line of sight information, compare the identified points of inspection with predetermined work procedure information in time series, and output a result of comparison.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Board end connector assembly testing machine

ActiveCN113922182AGuaranteed YieldImprove work efficiencyTesting dielectric strengthContact member assembly/disassemblyStructural engineeringVisual inspection (procedure)

The invention relates to the technical field of connector production equipment, in particular to a board end connector assembly testing machine which comprises a base, a rotating disc rotationally installed on the base and a driving piece for driving the rotating disc to rotate, wherein the output end of the driving piece is rotationally connected with the rotating disc, and an upper shell mechanism, an upper insulating sheet mechanism, an upper contact pin mechanism, a height difference testing mechanism, a voltage withstanding testing mechanism and a visual inspection mechanism are sequentially installed on the base in the circumferential direction of the rotating disc. According to the invention, the automatic assembly of the board end connector is completed through the arrangement of the upper shell mechanism, the upper insulating sheet mechanism and the upper pin mechanism, through the arrangement of the height difference testing mechanism, the voltage withstanding testing mechanism and the visual detection mechanism, the height difference between the contact pin end part of the assembled board end connector and the end part of the shell on the side where the contact pin end part is located, the insulating property and the concentricity of the contact pin and the shell are detected respectively, and the testing procedure is directly performed after the assembling procedure is completed, so that the working efficiency is improved, and the yield of the output board end connector is ensured.

Owner:CHANGZHOU AMPHENOL FUYANG COMM EQUIP CO LTD

Special glue line visual detection device for double-gun type forming machine

PendingCN114009830AAffect qualityIncrease brightnessLiquid surface applicatorsCigarette manufactureEngineeringGlue line

The invention relates to a special glue line visual detection device for a double-gun type forming machine, and belongs to the field of cigarette production machinery. The device comprises a visual detection mechanism arranged on a forming machine body, and the visual detection mechanism is located between a glue spraying mechanism and a filter stick feeding mechanism; and the visual inspection mechanism comprises a camera support arranged on the forming machine body and a camera arranged on the camera support, the camera support and the camera are arranged towards the forming paper, and a light source device is arranged on the forming machine body. The detection device has the effects that: bad filter rods are removed, defective products are prevented from flowing into the next procedure, and the quality of cigarettes is not affected.

Owner:深圳市联君科技股份有限公司

Agricultural product sorting device based on machine vision technology

ActiveCN112495818AReduce manual sorting costsImprove sorting efficiencySortingMachine visionRobot hand

The invention discloses an agricultural product sorting device based on a machine vision technology. Agricultural products sequentially pass through a moving module, a conveying device and sorting execution equipment; the moving module comprises an X-Y axis simple robot and a feeding tray; the sorting execution equipment comprises a six-axis manipulator, a sorting storage device, visual inspectionequipment and a sorting tray, the visual inspection equipment is arranged above the conveying device, and the sorting storage device is connected with the six-axis manipulator; the agricultural products are conveyed to the sorting storage device through sorting suction cups, and transferred to the sorting tray through the six-axis manipulator; the sorting storage device is composed of a first supporting plate and a second supporting plate; a plurality of guide rails anda plurality of driving sliding blocks are arranged at the bottom of the first supporting plate; the driving sliding blocks are connected with a plurality of drill pipes; a plurality of through holes are formed in the second supporting plate; and the drill pipes are telescopic pieces, and the two ends of each drill pipe areconnected with a negative pressure suction pump in the corresponding driving sliding block and the sorting suction cup respectively. The device meets the requirements of feeding, conveying, detectingand transferring procedures, objective evaluation is achieved with adoption of the machine vision technology, and the sorting efficiency and precision are greatly improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com