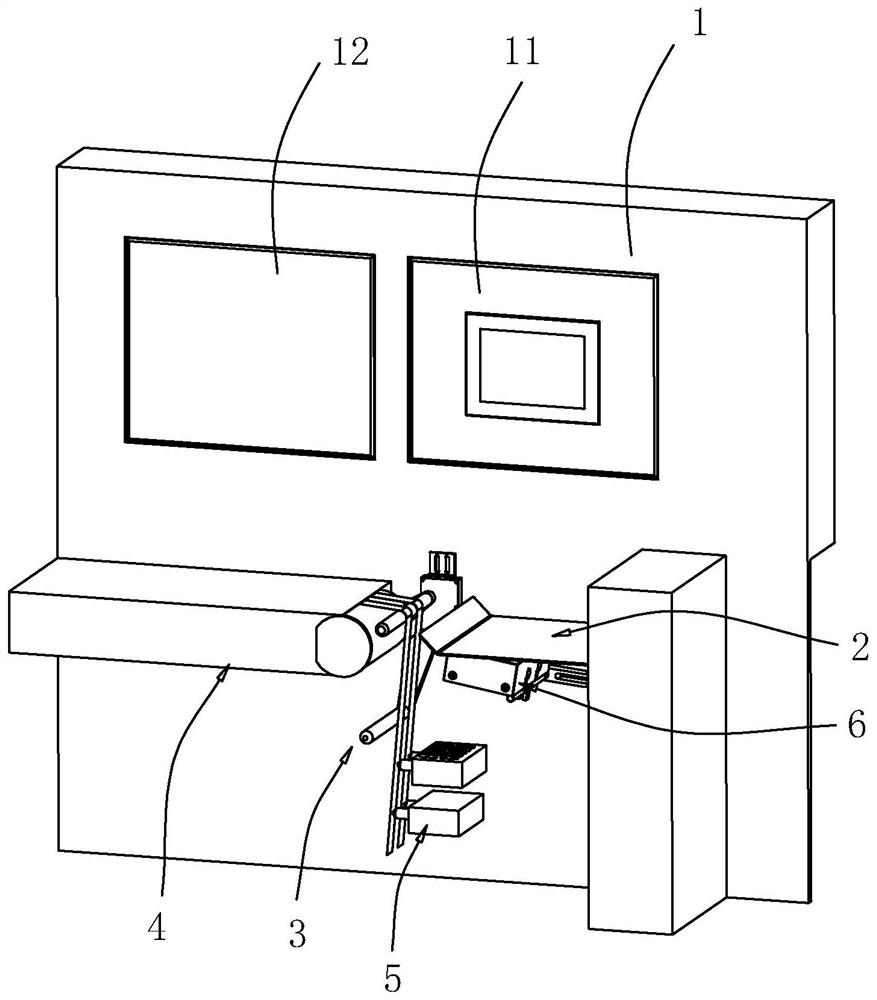

Special glue line visual detection device for double-gun type forming machine

A visual detection device and visual detection technology, applied to the surface coating liquid device, application, tobacco, etc., can solve the problems of affecting the quality of cigarettes, missing glue, and not being able to watch the glue spraying of the forming paper all the time, to achieve The effect of increasing light intensity and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-6 The application is described in further detail.

[0036] The embodiment of the present application discloses a special glue line visual inspection device for a double-gun molding machine. refer to figure 2 , a special glue line visual inspection device for double-gun molding machines. The visual inspection mechanism 6 and the light supplement mechanism 7 are arranged on the molding machine body 1. The molding machine body 1 is provided with a display screen 11, and the display screen 11 is used to display For the pictures taken by the visual inspection mechanism 6, the main control box 12 is arranged on one side of the display screen 11 of the molding machine body 1 . The supplementary light mechanism 7 is used to increase the light intensity on the molding machine body 1 , so that the visual detection mechanism 6 can clearly collect pictures, and the visual detection mechanism 6 transmits the collected pictures to the display sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com