Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Overhead valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An overhead valve engine (OHV engine), or pushrod engine, is a reciprocating piston engine whose poppet valves are situated in the cylinder head. An OHV engine's valvetrain operates its valves via a camshaft within the cylinder block, cam followers (or "tappets"), pushrods, and rocker arms.

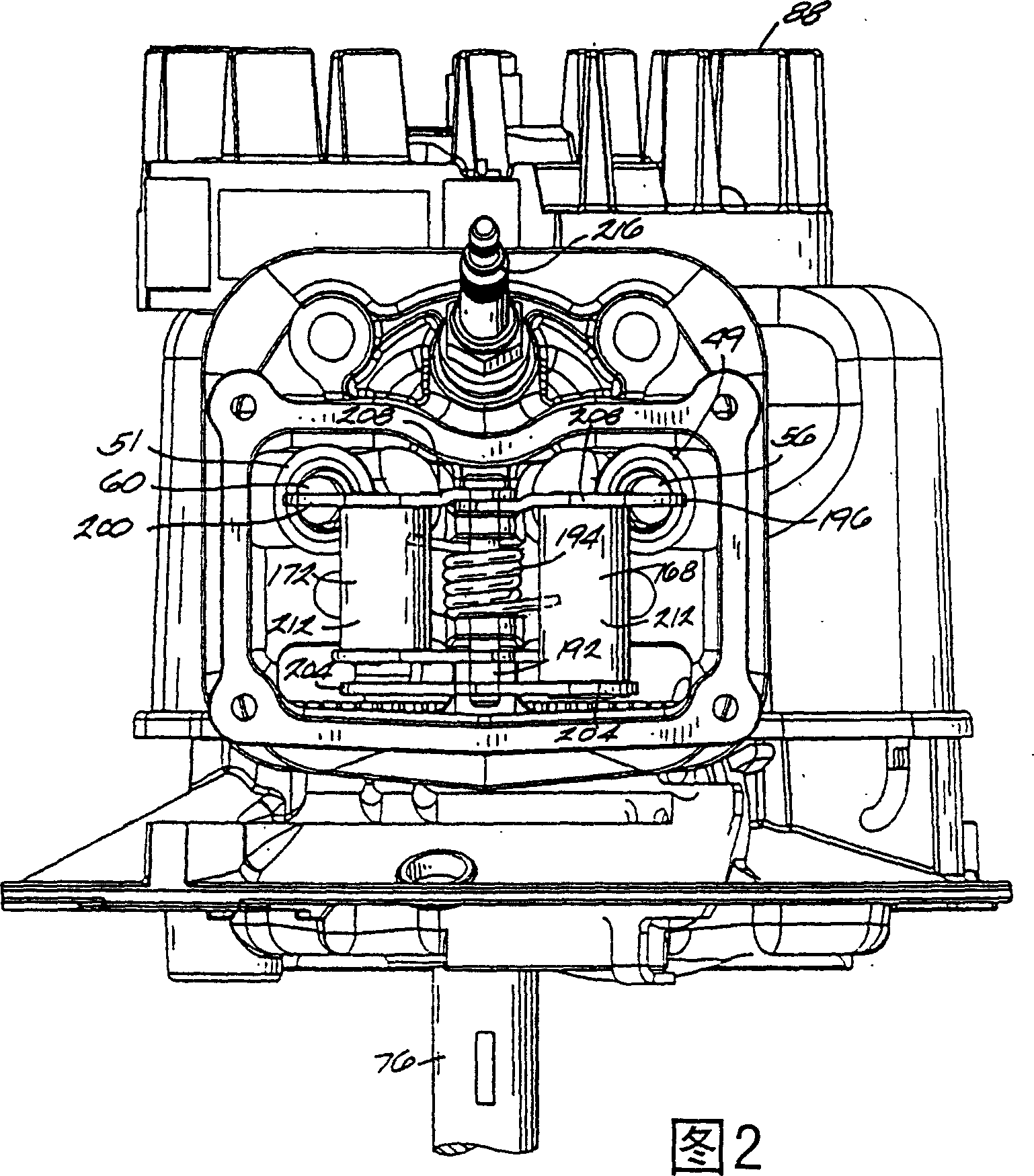

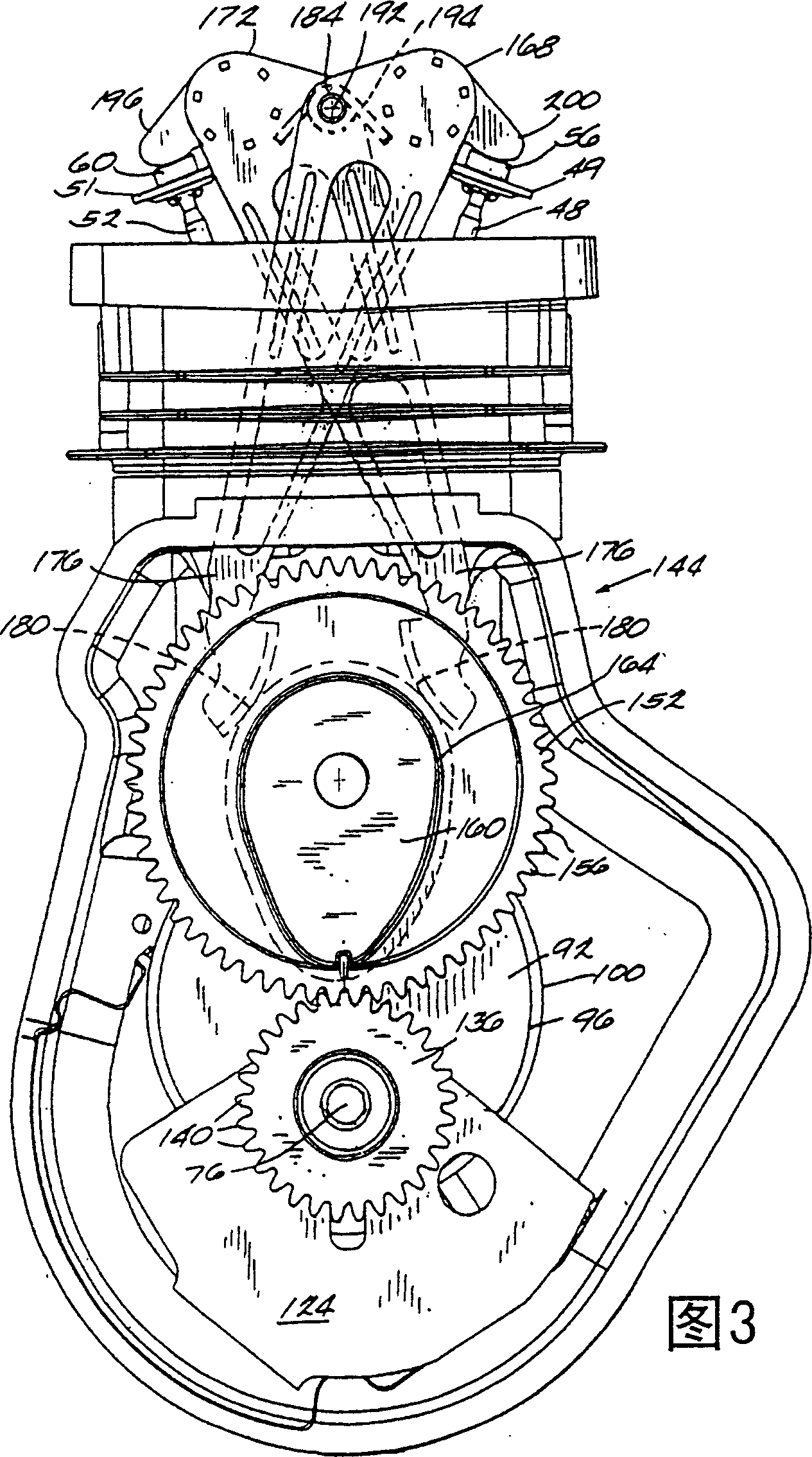

Internal combustion engine

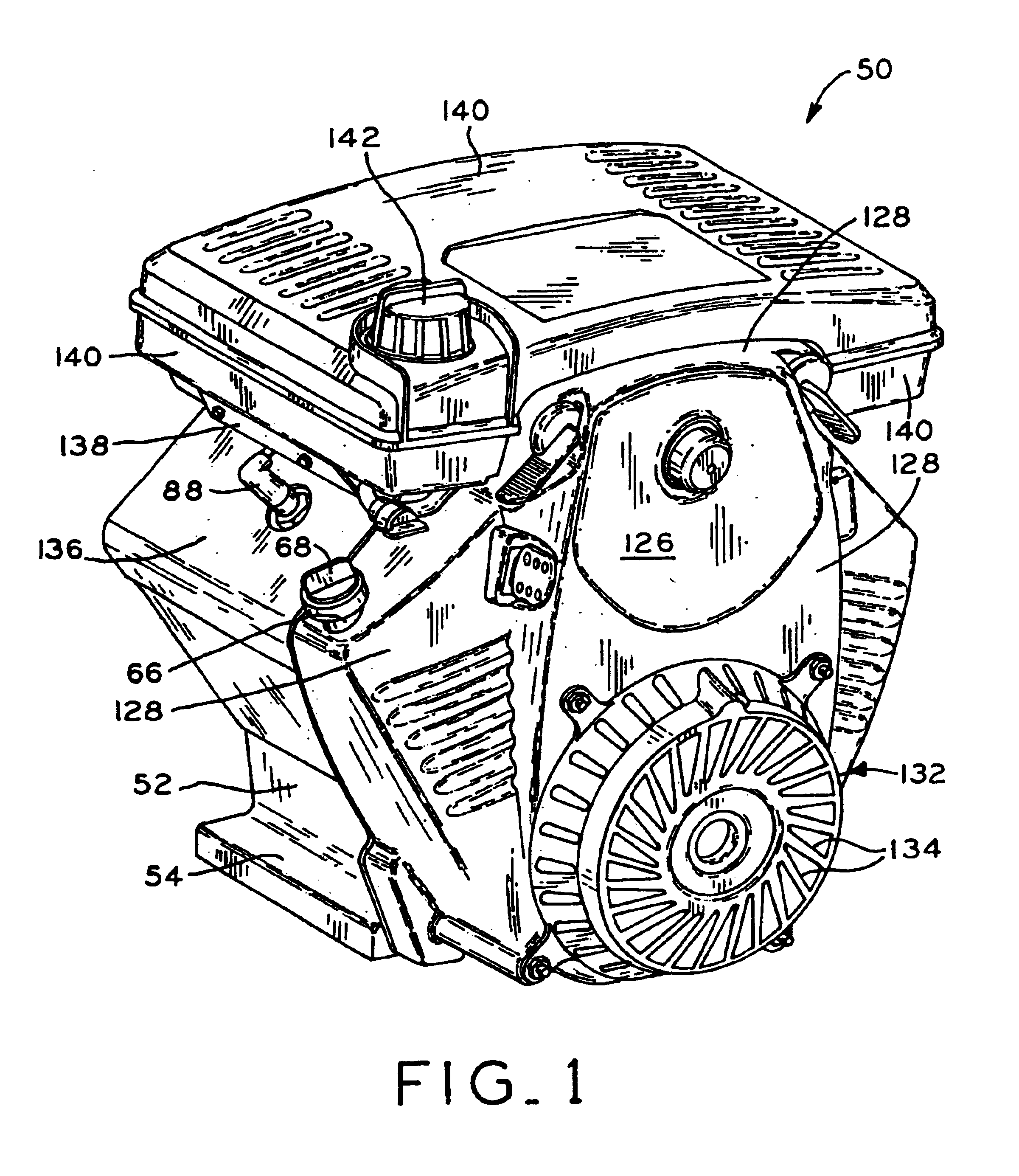

A twin cylinder engine, includes a pair of cylinder members mounted to mounting surfaces of a crankcase, and cylinder heads mounted to the cylinder members. The cylinder members are modular components, which may be pre-assembled with components of the valve train as packaged units before the cylinder members are attached to the crankcase. Each cylinder member rotatably supports a cam gear which extends into the crankcase for driving engagement with the crankshaft. The cylinder members may be configured for either side valve-type (“L-head”), or overhead valve-type (“OHV”) engines, and the cylinder members may also be used in single cylinder engines.

Owner:TECUMSEH POWER

Airless spray gun having overhead valve and removable head

InactiveUS20080296409A1Operating means/releasing devices for valvesMovable spraying apparatusFastenerOverhead valve

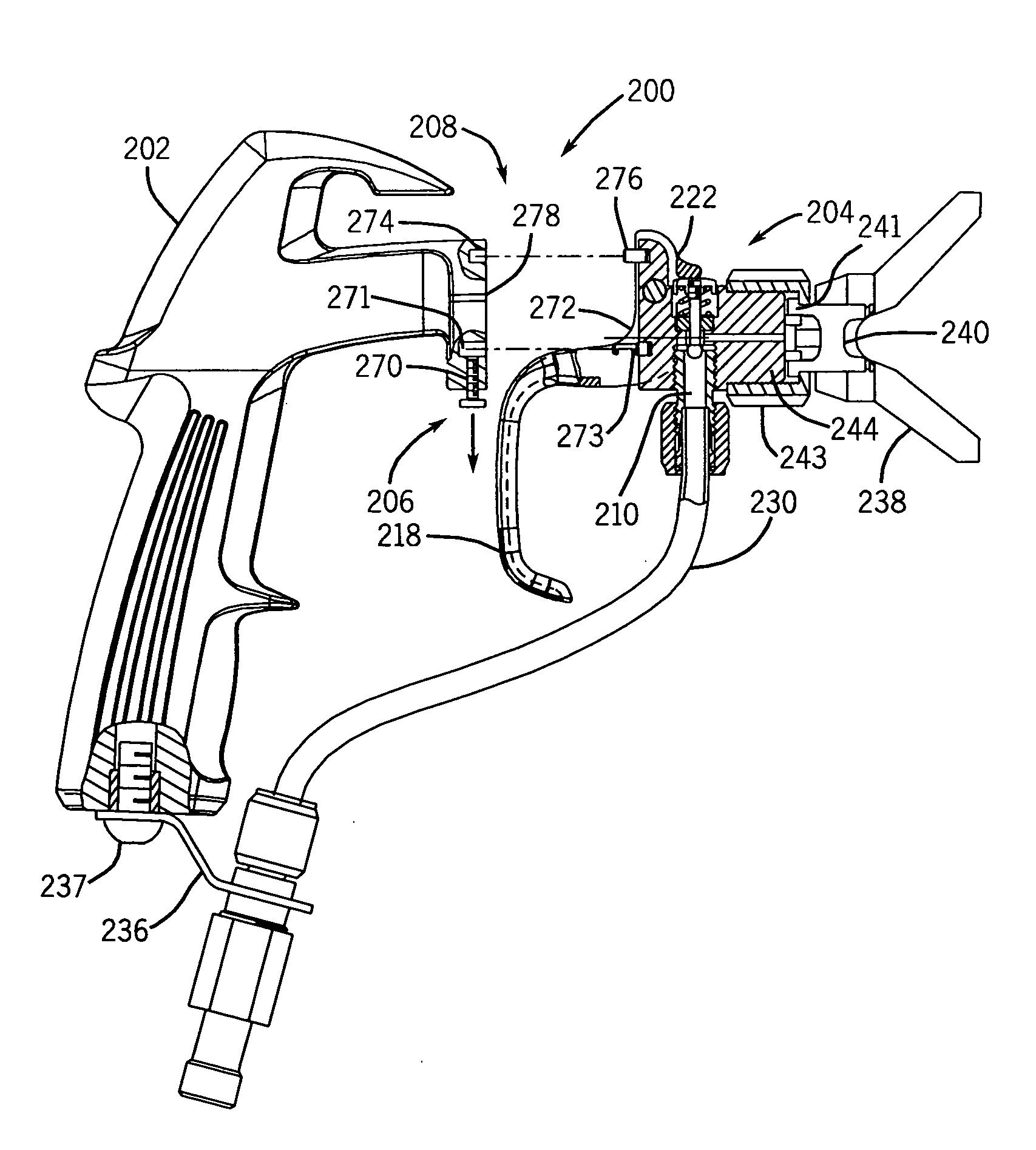

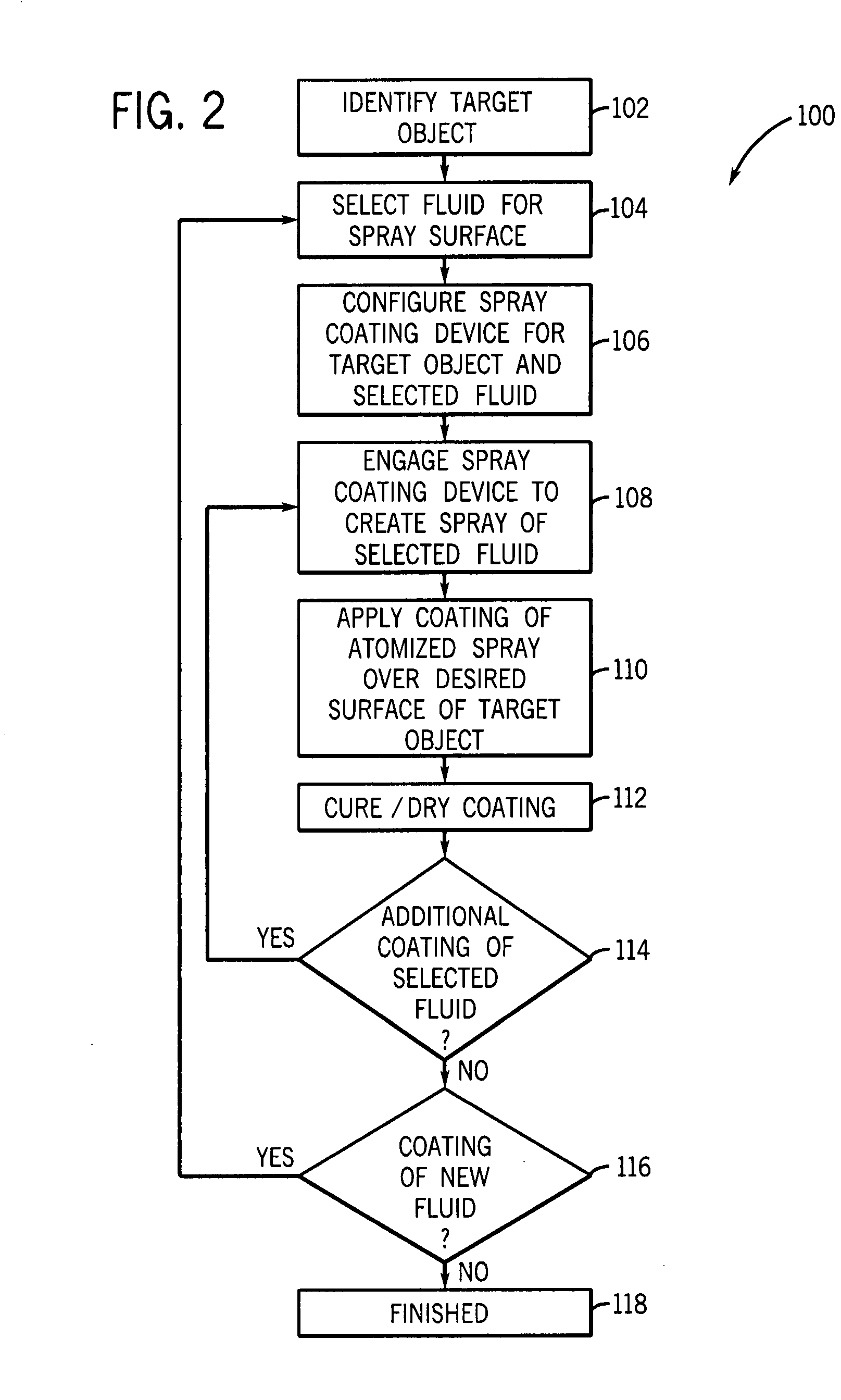

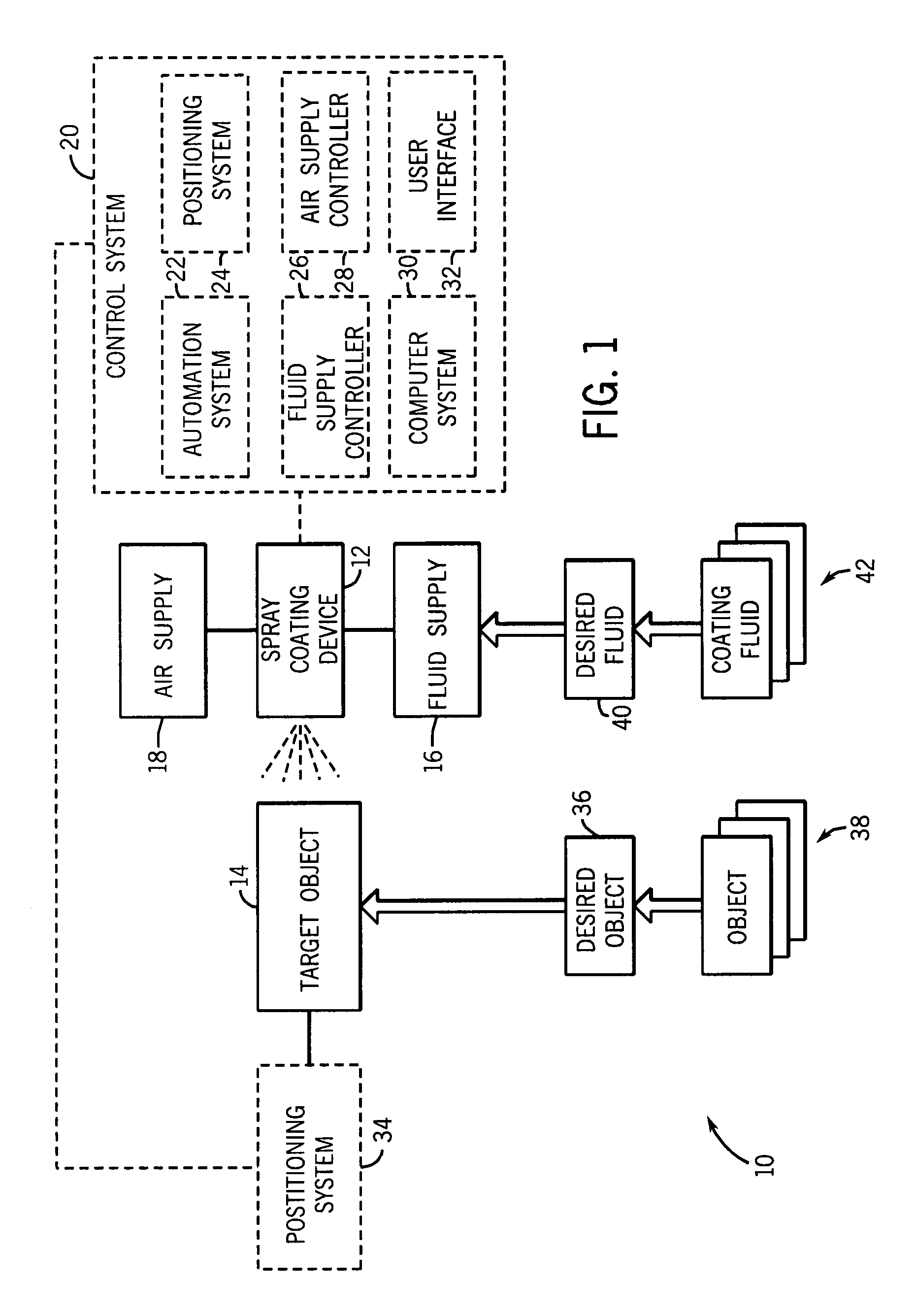

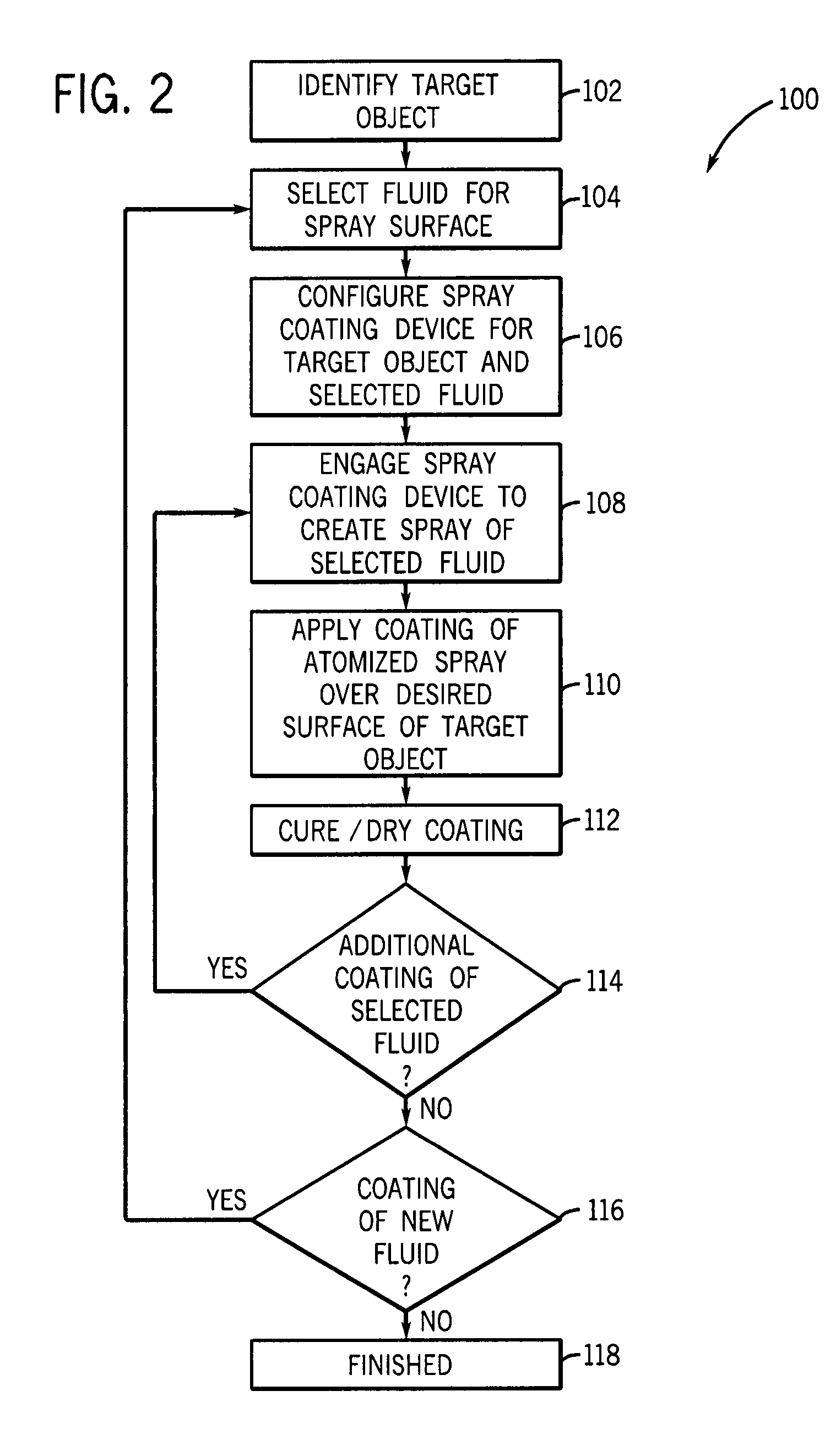

A system, in certain embodiments, may include a spray coating device having a handle, a fluid head comprising a fluid valve and a trigger coupled to the fluid valve, and a quick disconnect fastener coupling the fluid head with the handle. A system, in other embodiments, may include a spray coating device having a body, a pivot joint coupled to the body, and a trigger having a lever coupled to the pivot joint. The trigger may be configured to move in a first direction. The system also may include a valve disposed in the body and movable in a second direction crosswise to the first direction, wherein the lever is configured to bias the valve in the second direction.

Owner:CARLISLE FLUID TECH INC

Airless spray gun having overhead valve and removable head

InactiveUS8360345B2Operating means/releasing devices for valvesMovable spraying apparatusSpray coatingEngineering

A system, in certain embodiments, may include a spray coating device having a handle, a fluid head comprising a fluid valve and a trigger coupled to the fluid valve, and a quick disconnect fastener coupling the fluid head with the handle. A system, in other embodiments, may include a spray coating device having a body, a pivot joint coupled to the body, and a trigger having a lever coupled to the pivot joint. The trigger may be configured to move in a first direction. The system also may include a valve disposed in the body and movable in a second direction crosswise to the first direction, wherein the lever is configured to bias the valve in the second direction.

Owner:CARLISLE FLUID TECH INC

Multiple configuration cylinder valve spring

InactiveUS20090044391A1Effective wayLess amount of timeMetal working apparatusMetal-working hand toolsExternal combustion engineCylinder head

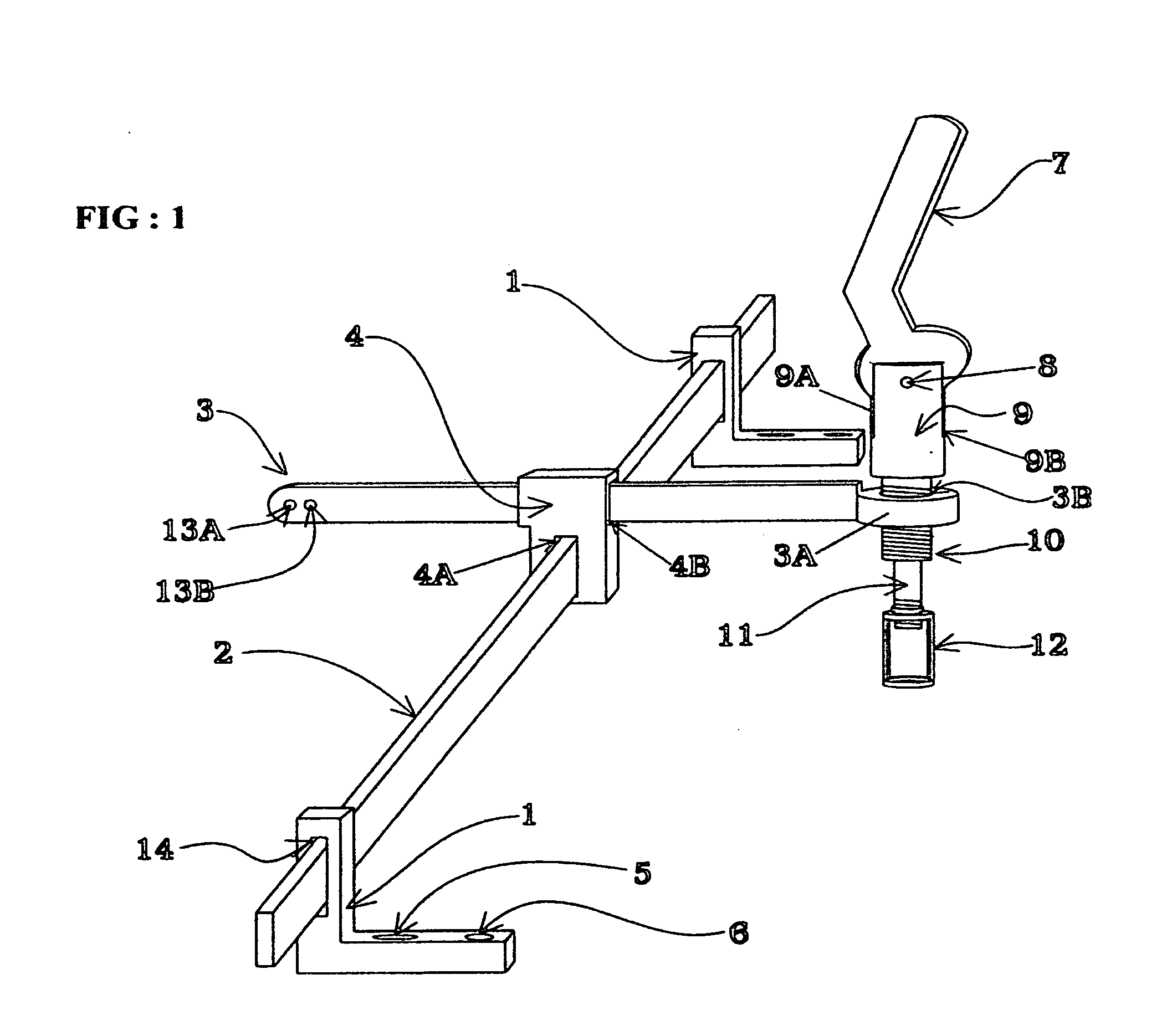

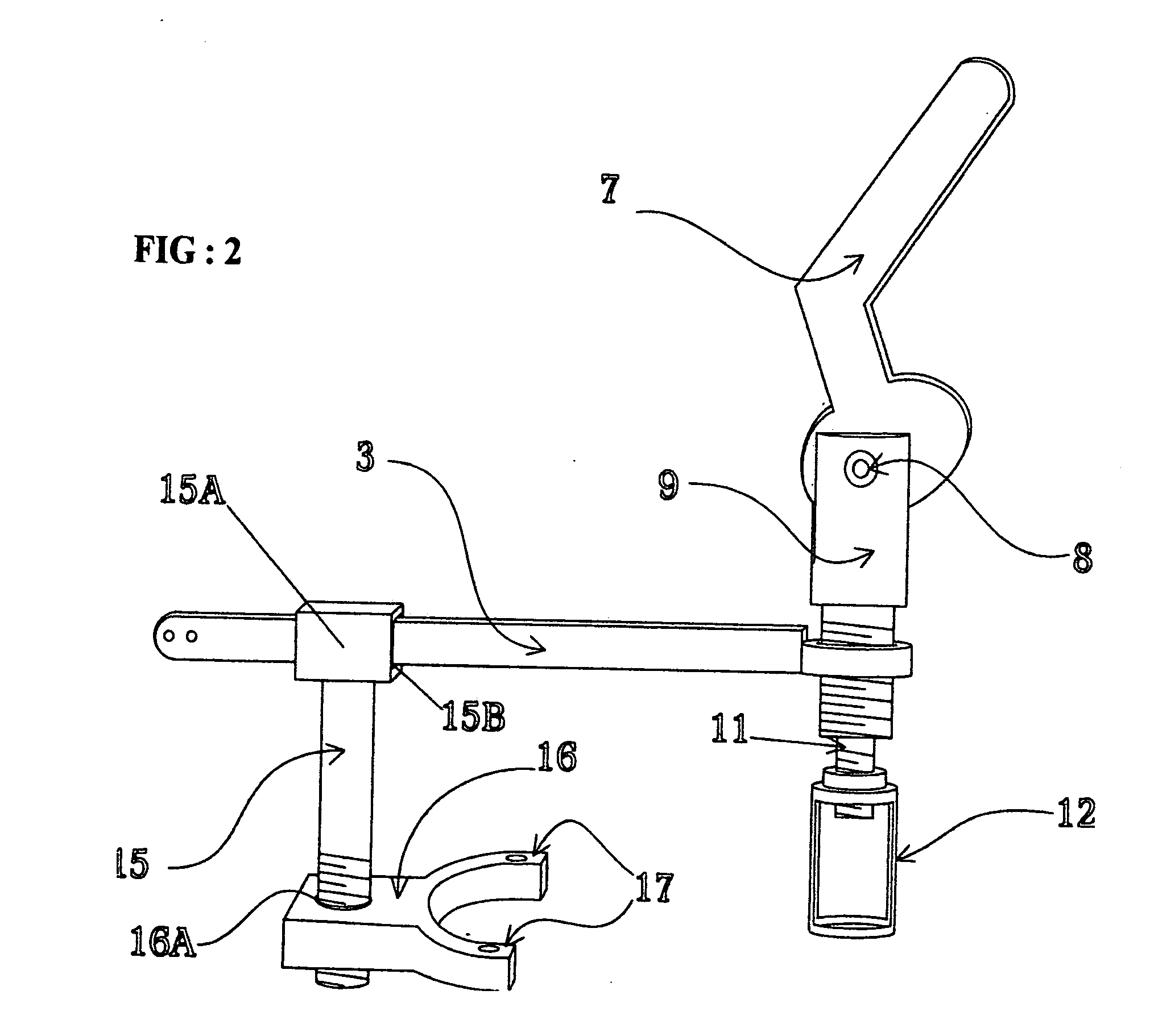

Special service tool and method for compressing cylinder valve springs for the removal and installation of their locks or keepers and for replacement of valve stem seals or brocken springs on an internal combustion engine, while the head still mounted on the engine or is on a work bench. Service tool comprising a multiple of attachment members for configuring the tool as need depending of the cylinder head design. Support means temporarily secured over the cylinder head and employing existing threaded opening for securing camshaft caps are arrange to mount the tool over slidably dispose bars and brackets, this method allow technicians to overcome the problems of removal and replacement of overhead valve springs by performing this task faster and in a safer manner.

Owner:DUARTE ROMEO ANTONIO

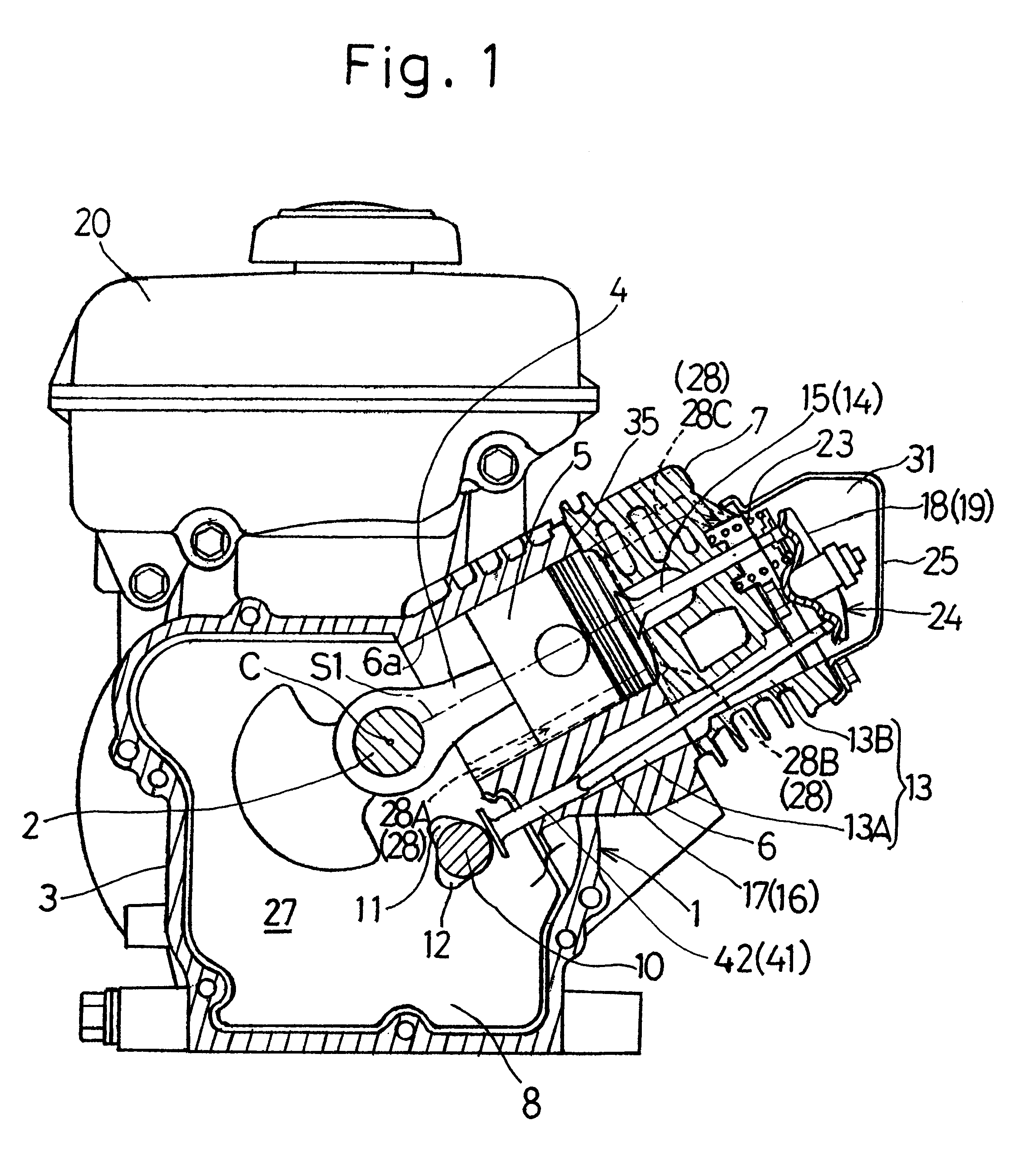

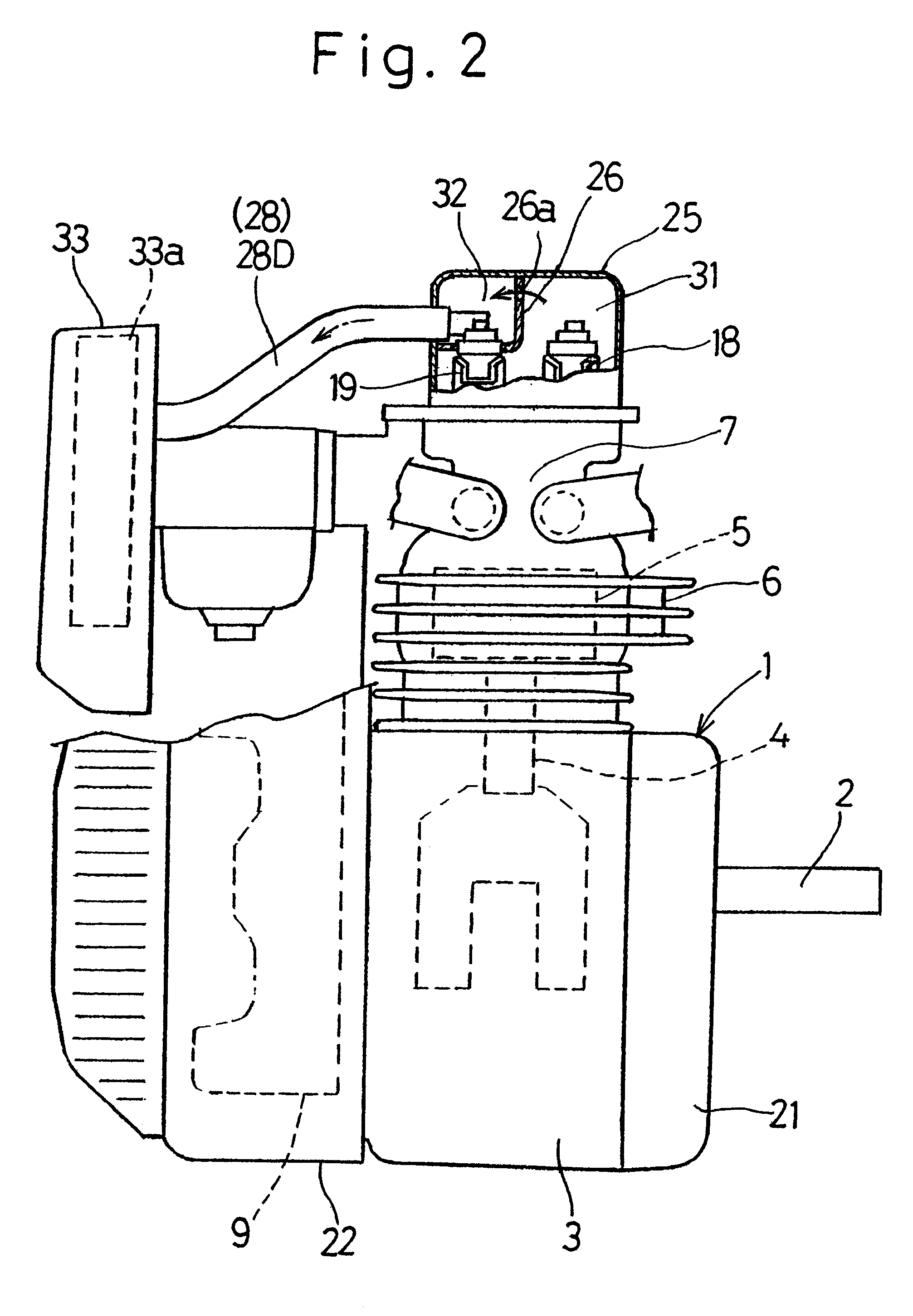

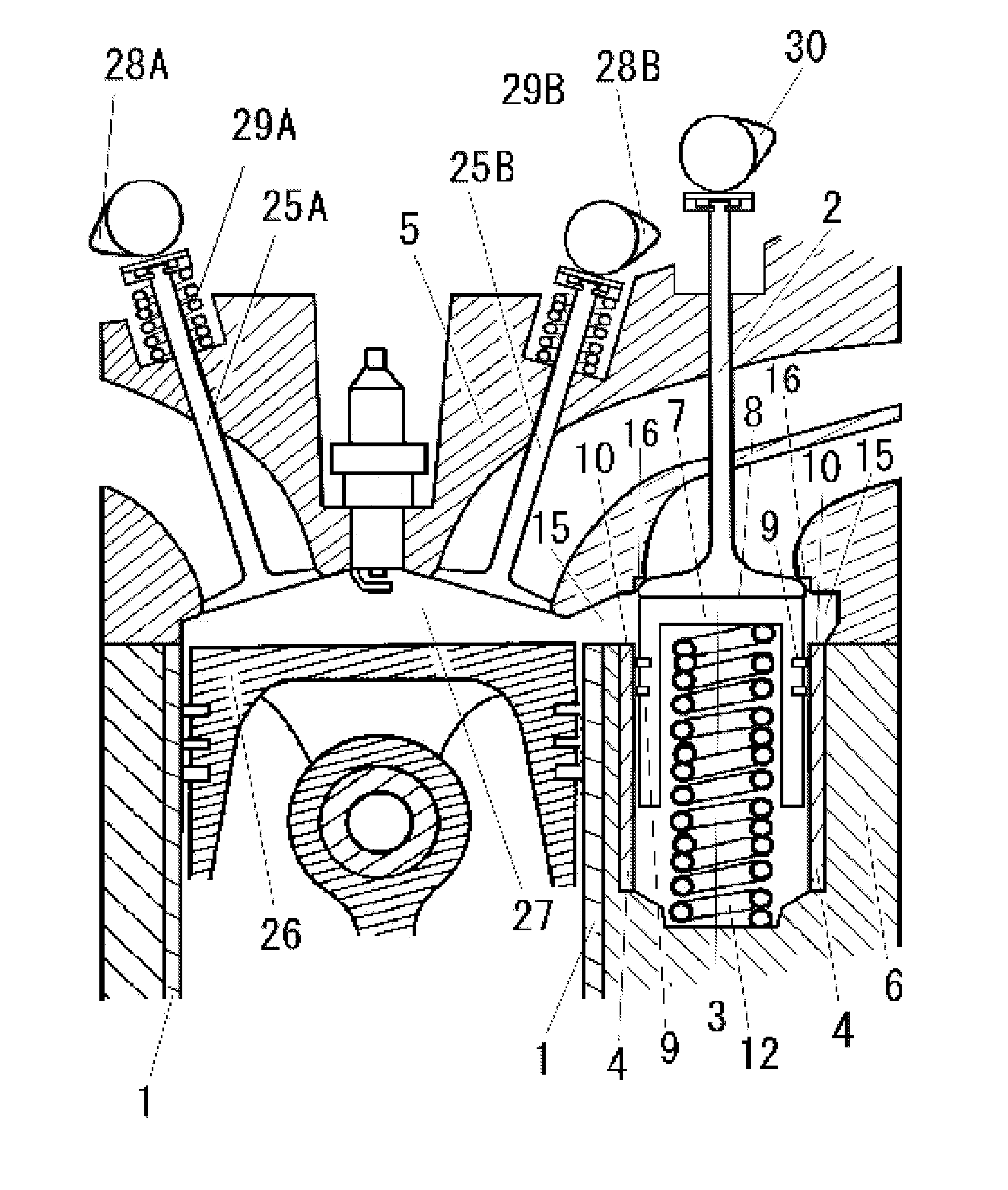

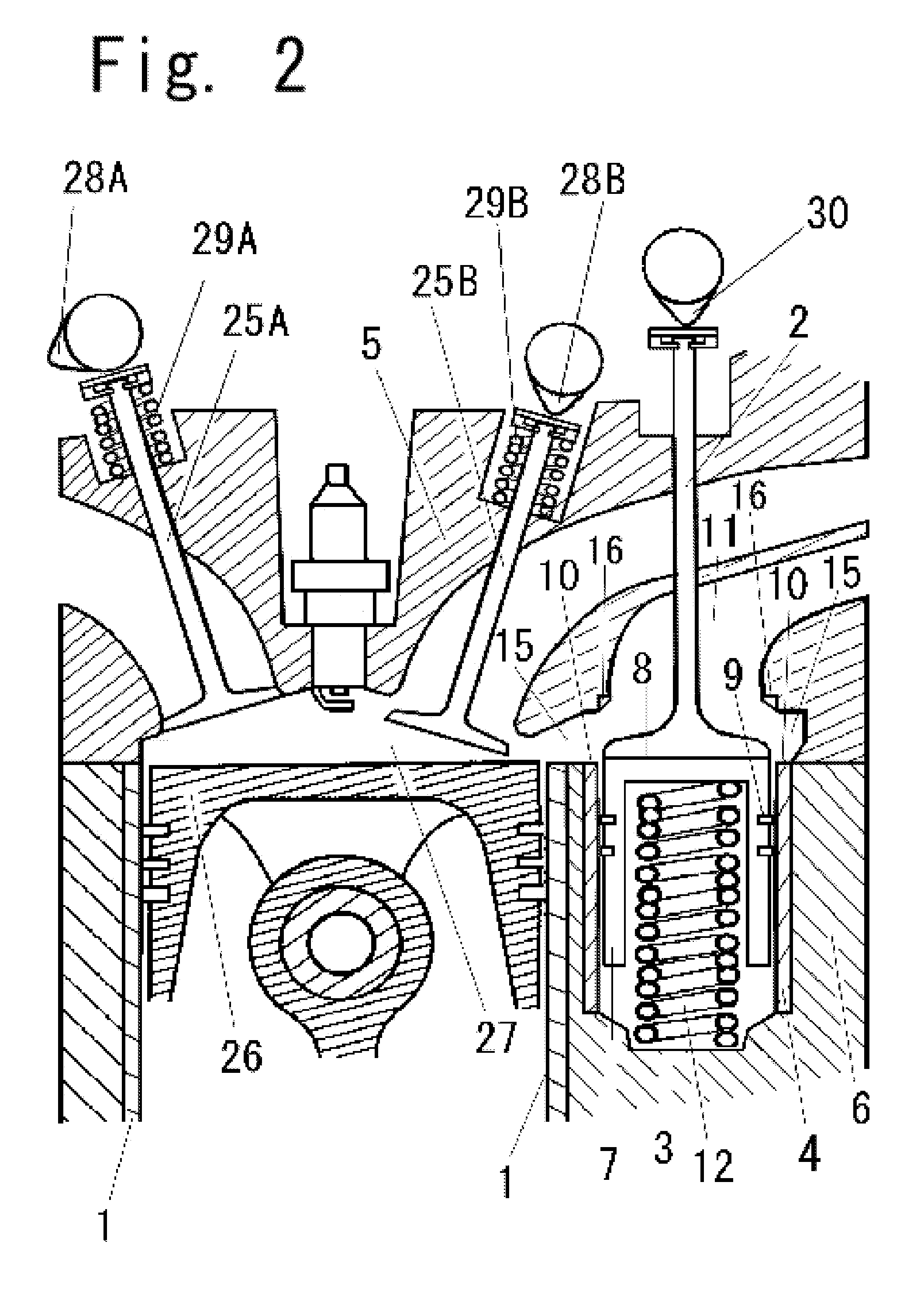

Four-cycle overhead valve engine

InactiveUS6662791B2Small sizeInhibition of volume increaseValve arrangementsInternal combustion piston enginesBreatherExhaust valve

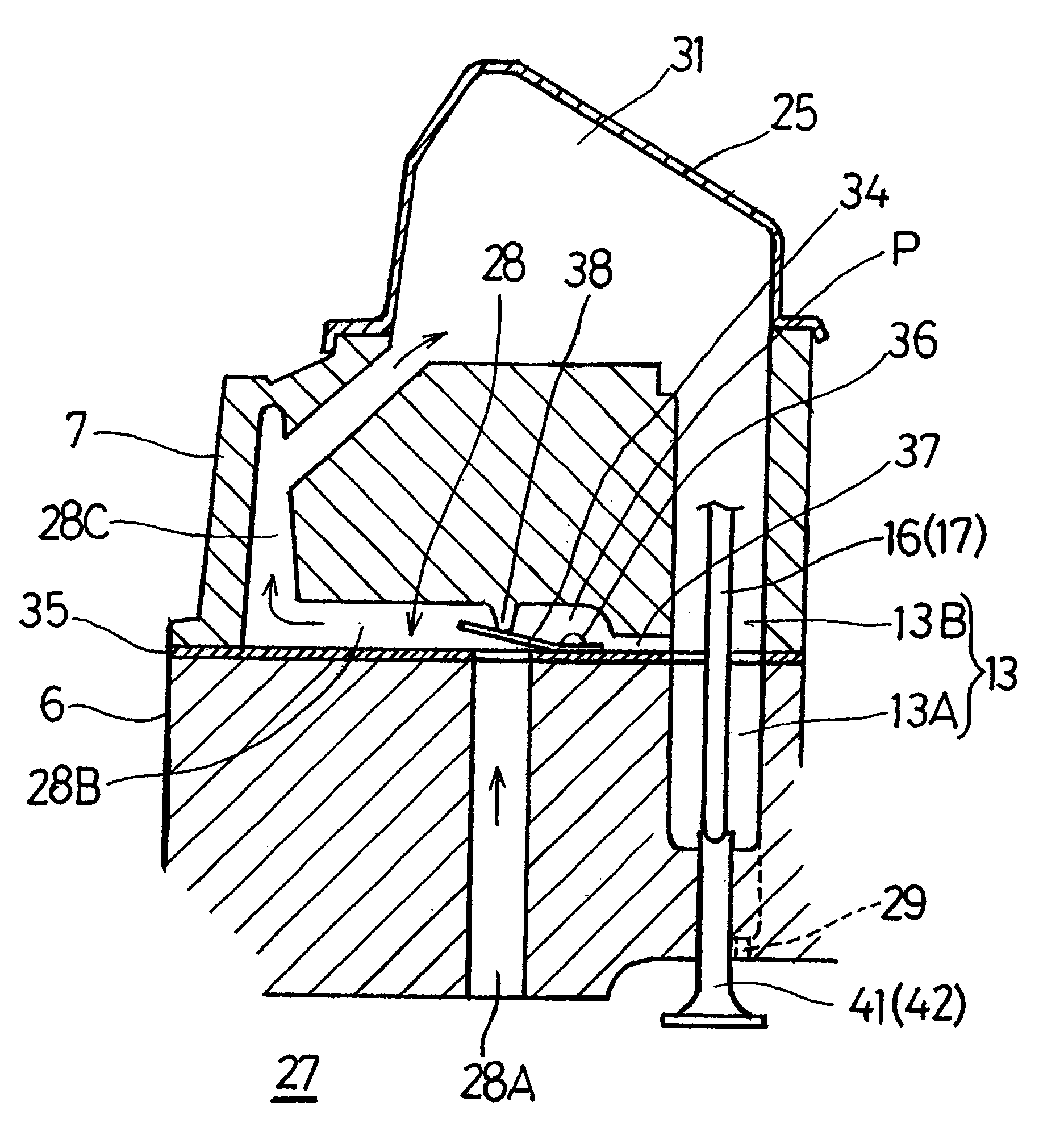

To provide a four-cycle overhead valve engine wherein the breather passage is defined to avoid an undesirable increase in size of the engine as a whole and also to avoid increase in length of the breather passage, a four-cycle overhead valve engine is provided which includes a cylinder block (6), and push rods (16 and 17) for driving intake and exhaust valves (14 and 15), respectively, that are mounted above the cylinder block (6). A breather passage (28) connecting a crank chamber (27) and a rocker arm chamber (31) with each other is made up of a first passage portion (28A) defined in the wall of the cylinder block (6) at a location adjacent a flywheel (9) and the push rods (16 and 17), and a second passage portion (28B) extending from one side adjacent the push rods (16 and 17) in a direction away from the push rods (16 and 17). A check valve (34) for the breather passage (28) is disposed at a junction between the first and second passage portions (28A and 28B).

Owner:KAWASAKI MOTORS LTD

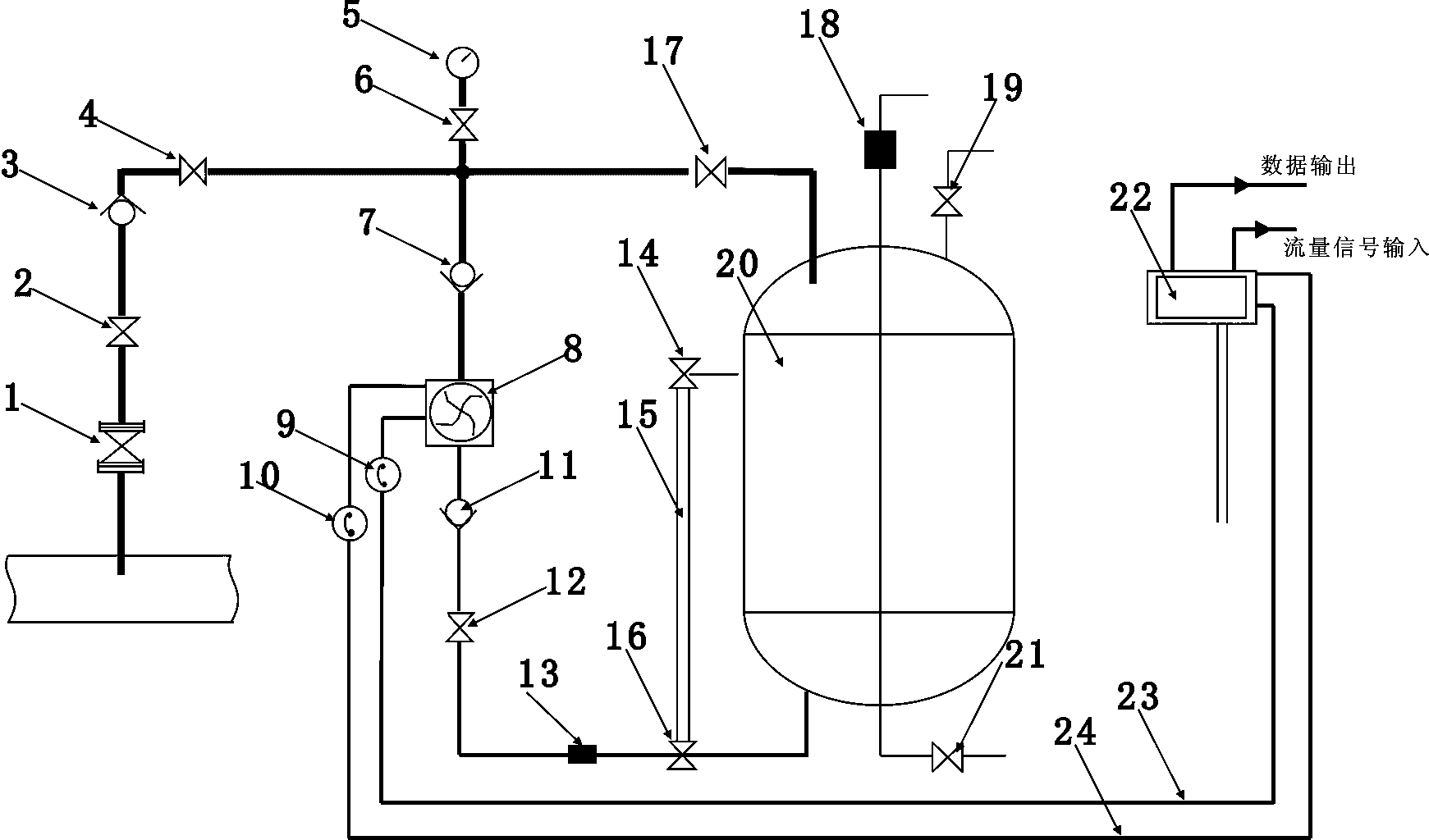

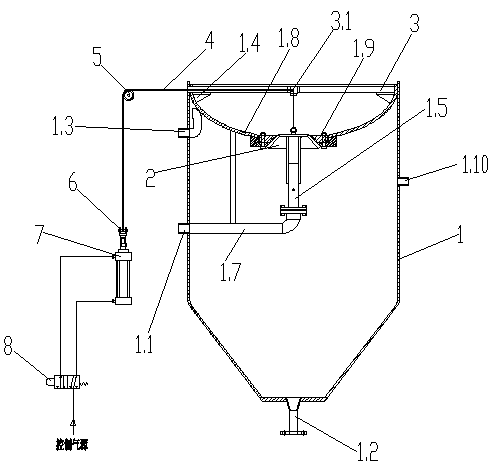

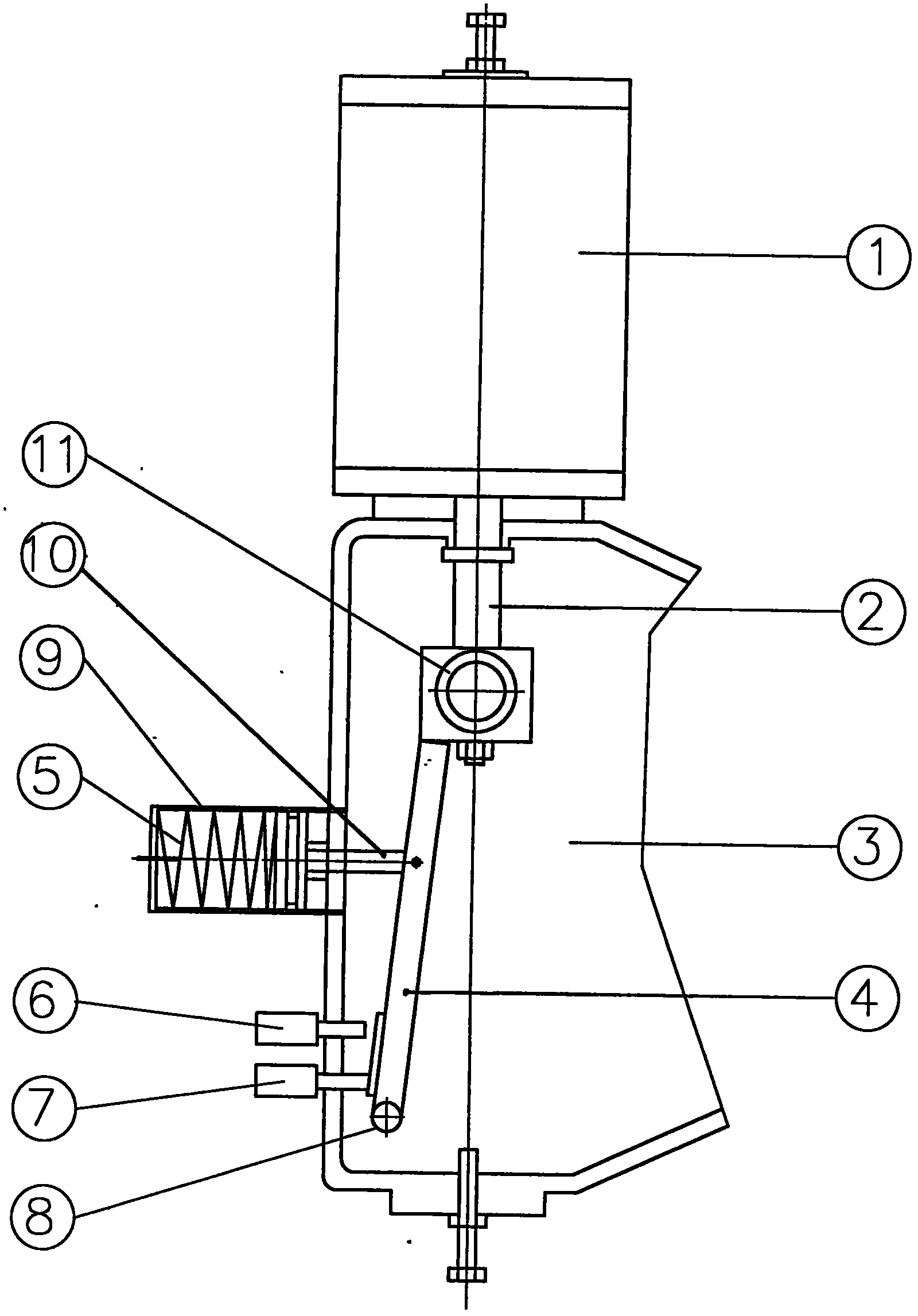

Fuel gas odorization device

InactiveCN103591462ARealize intelligent controlRealize time control functionPipeline systemsLiquid storage tankCheck valve

The invention discloses a fuel gas odorization device. The fuel gas odorization device is characterized by comprising an odorant injection nozzle, an injection switch, a check valve, an odorization valve, a pressure gauge, a pressure valve, a one-way valve A, a metering pump, an explosion-proof switch, an explosion-proof connecting box, a one-way valve B, a stop valve, a filter, an overhead valve, a liquidometer, a bottom valve, a return valve, a breather, a liquid charging valve, a liquid storage tank, a blowdown valve and a controller. According to the fuel gas odorization device, odorization is achieved mainly by pumping odorants (THT) out of the liquid storage tank and pumping the odorants (THT) in a fuel gas transmission and distribution main pipe through the micro-type diaphragm metering pump. The fuel gas odorization device has the function of manual and full-automatic switchover, and is flexible in odorization mode. To achieve the aim of accurate odorization, a flow detection device and a signal collection and transmission device are arranged in the transmission and distribution main pipe, and signals are fed back to a computer. The computer controls the odorant quantity of the metering pump according to the set odorant quantity needed by fuel gas flow per cubic meter, the odorization effect of natural gas is guaranteed, and user using safety is effectively guaranteed.

Owner:LESHAN BEICHUANG MACHINERY MFG

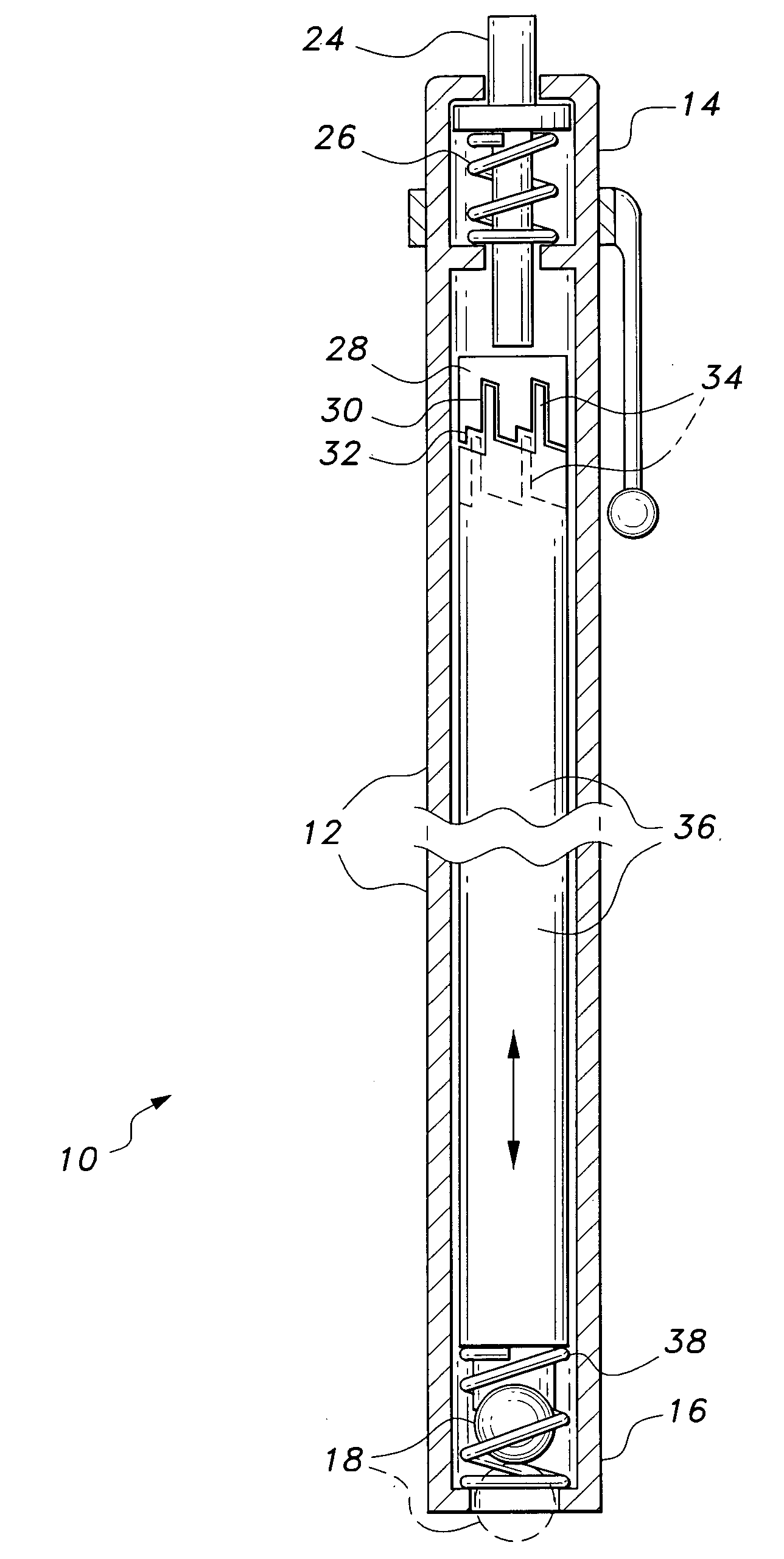

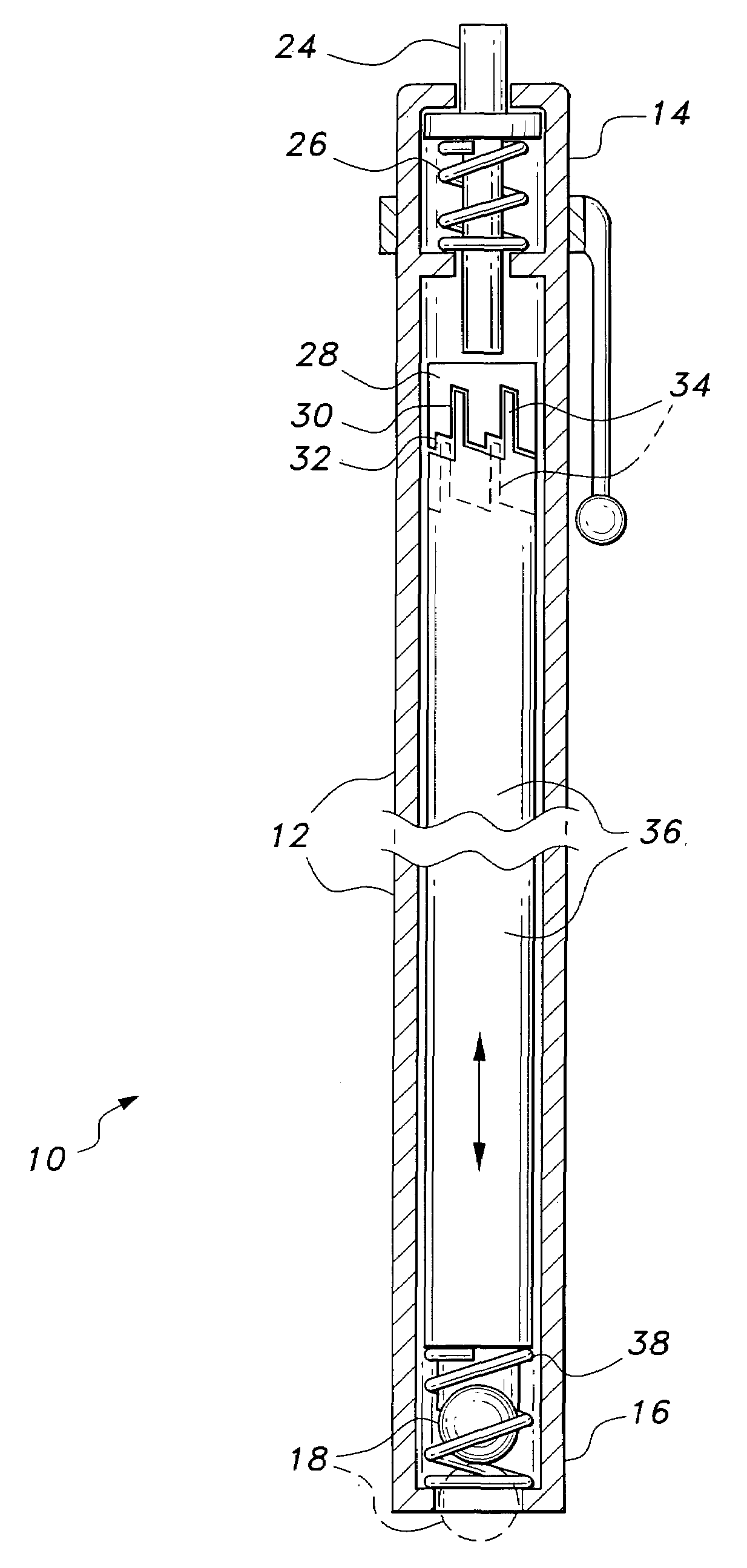

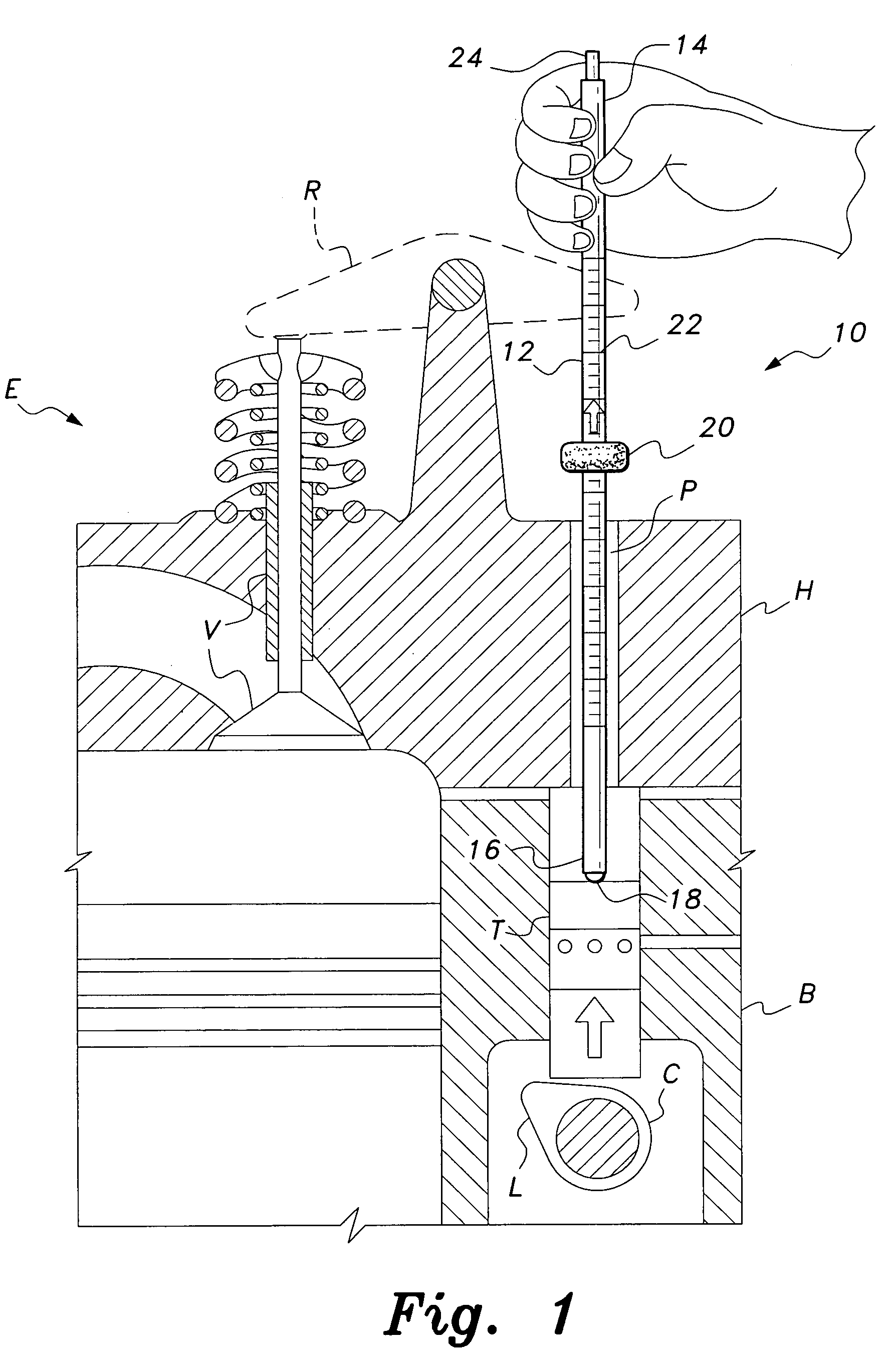

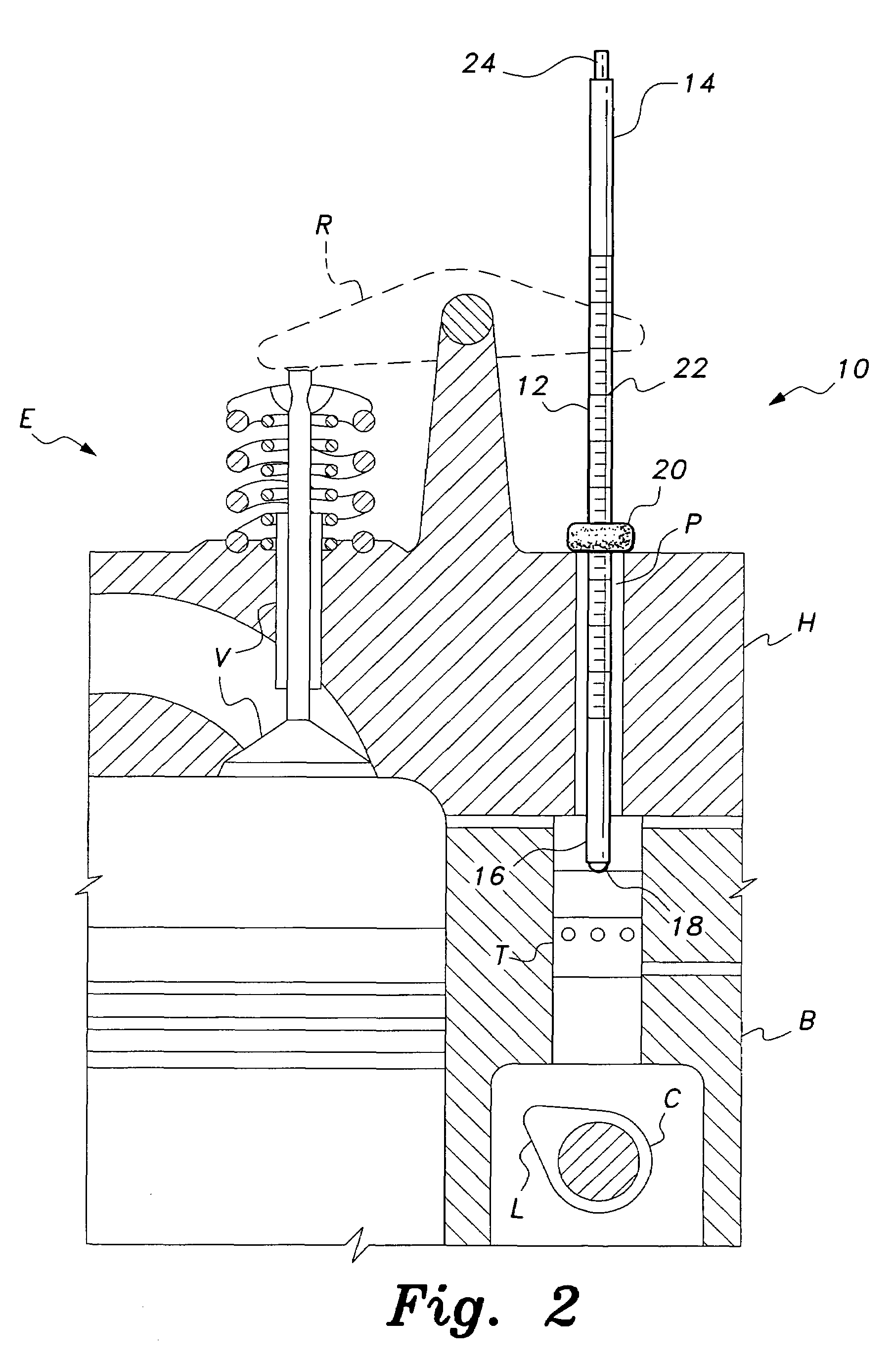

Magnetic tool

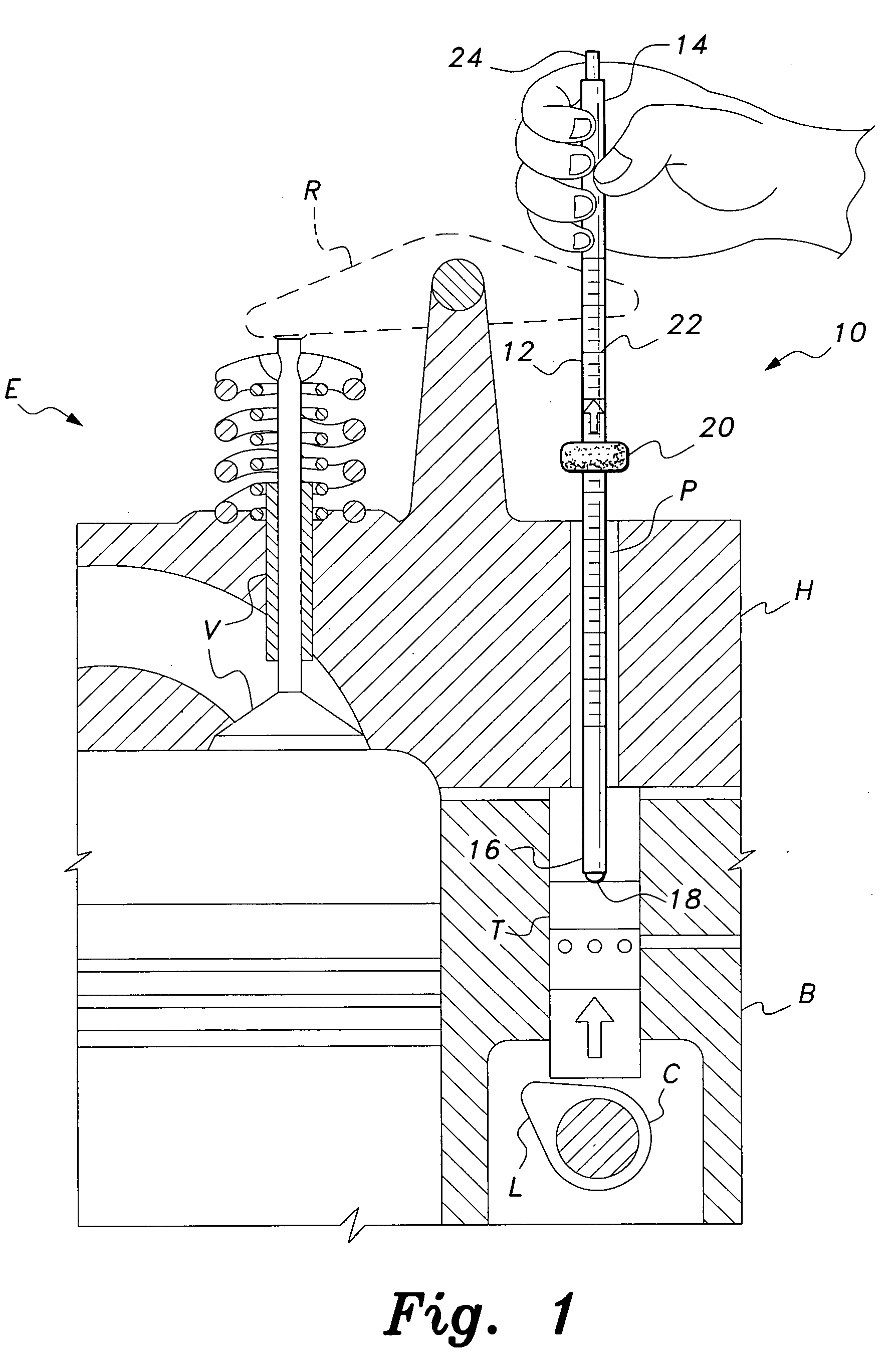

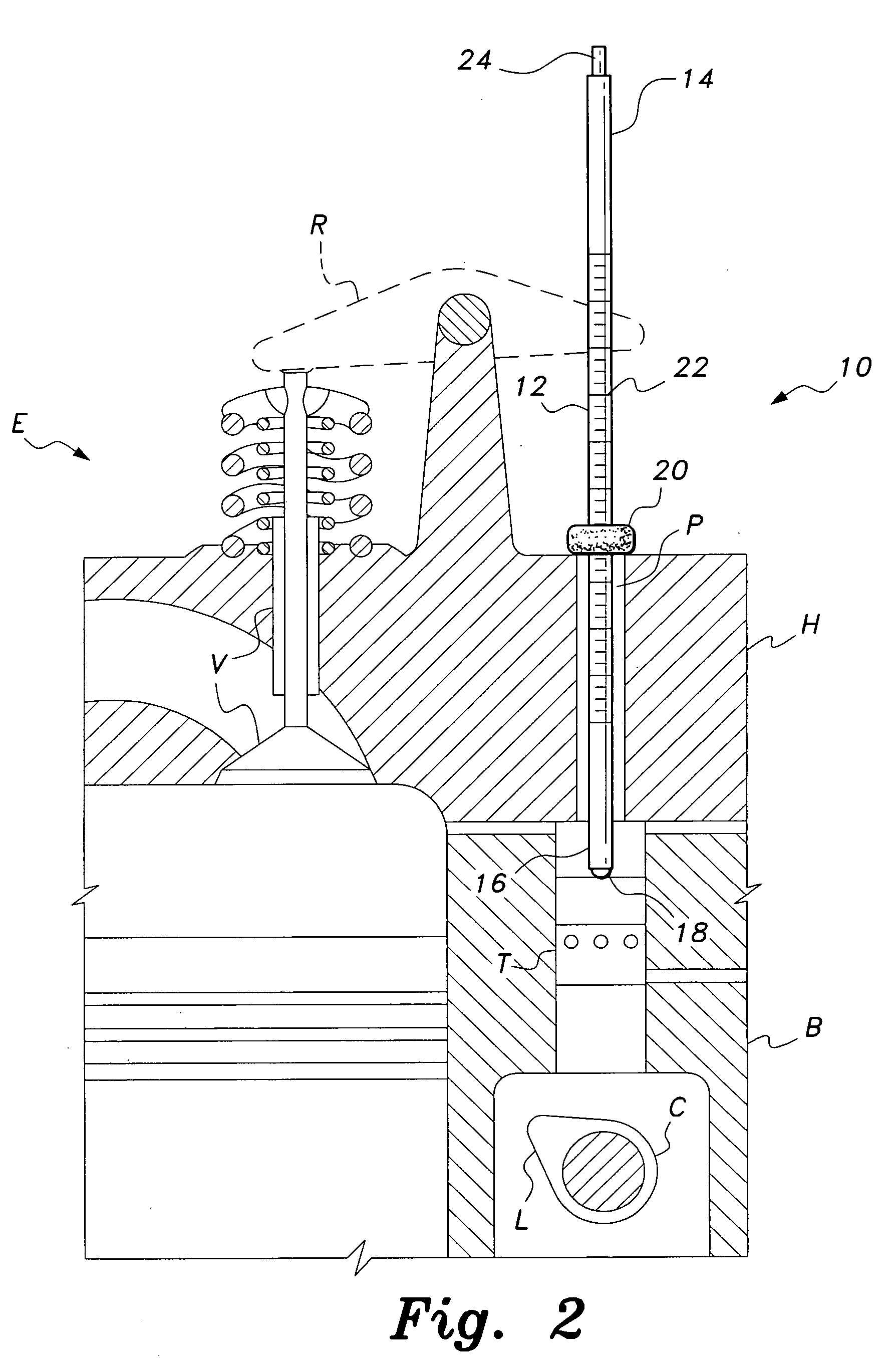

The magnetic tool has a narrow, elongate, rigid shank having a handgrip end and a selectively extendible and retractable magnet at the opposite working end. Various mechanisms are provided at the handgrip end to extend and retract the magnet. The working end of the tool may be provided with a polygonal (e.g., hexagonal, square, etc.) receptacle for the removable installation of a tool bit or square drive socket therein. The retracted magnet retains the bit or socket within the receptacle as desired. The magnetic tool is particularly well-adapted for insertion into a pushrod passage in the cylinder head of an overhead valve engine, for retracting a valve lifter away from the lobe of the camshaft to facilitate removal and replacement of the camshaft. A linear scale depth gauge may be provided, and an adjustably positionable collar may be provided to hold the tool with the lifter retracted.

Owner:ERNESTI CARL J

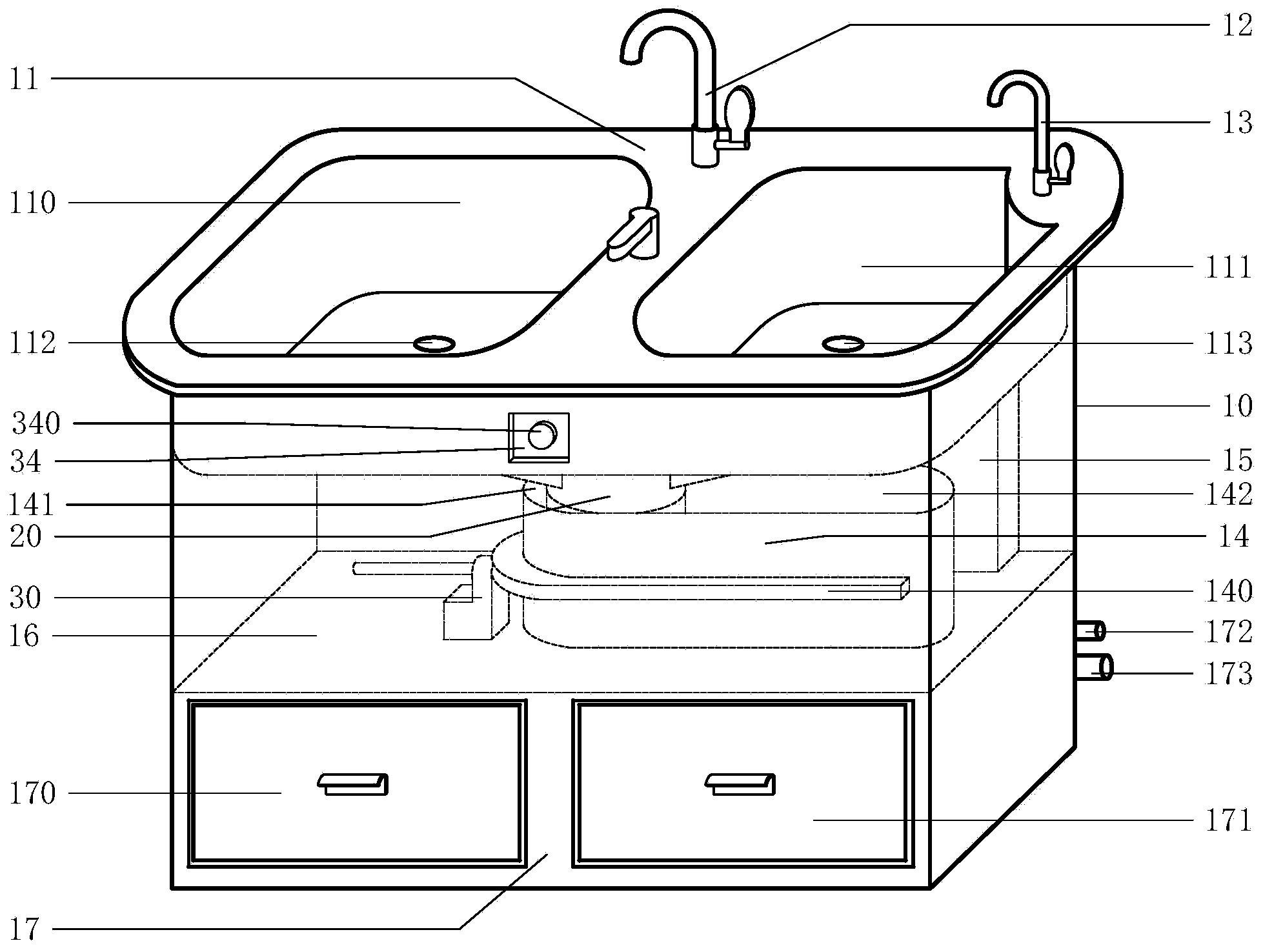

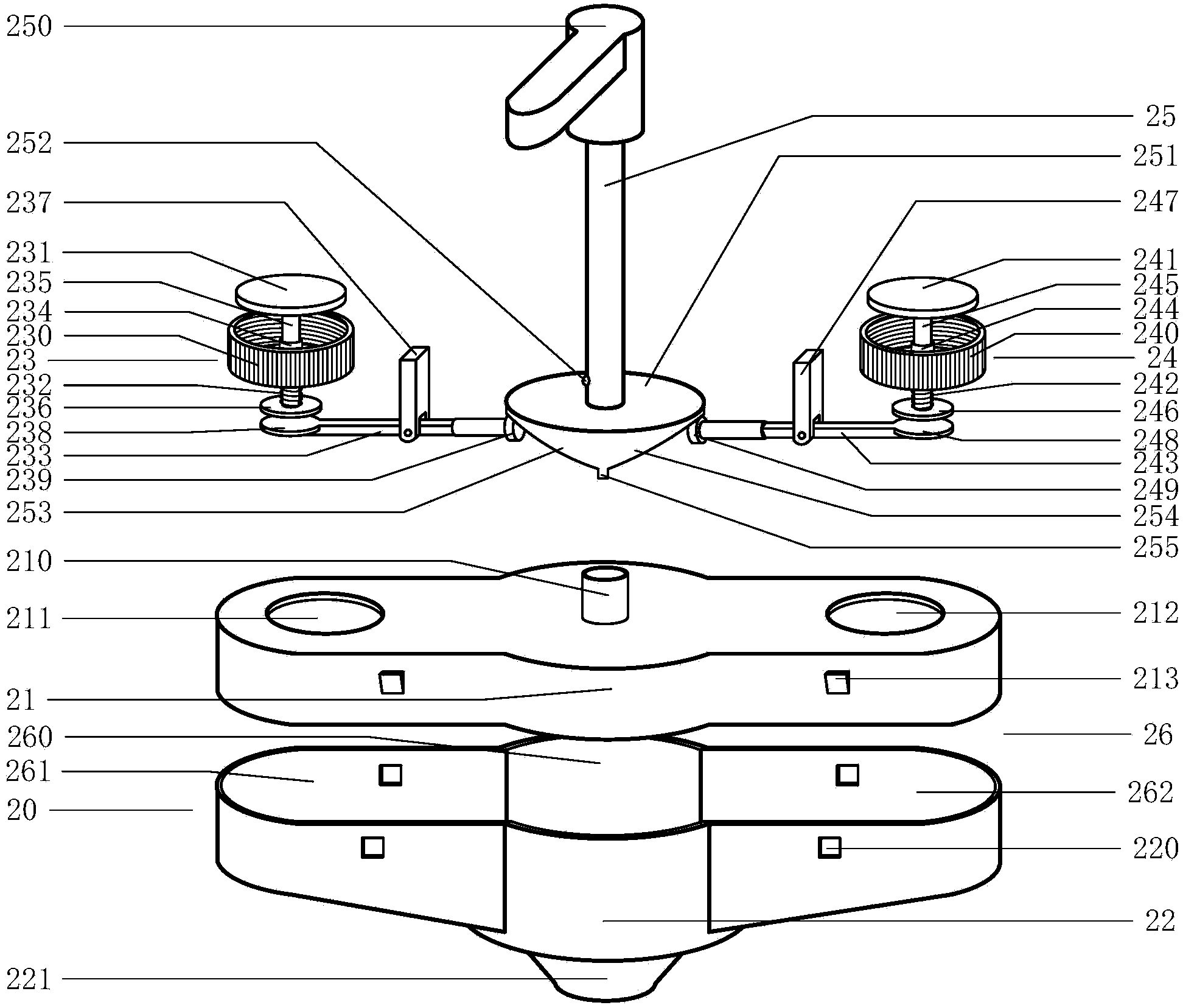

Cabinet-type kitchen sink

ActiveCN103469864AEasy to removeReasonable structureGeneral water supply conservationDomestic plumbingLife qualityWater filter

Disclosed is a cabinet-type kitchen sink. The cabinet-type kitchen sink comprises a cabinet-type sink body, a centralized drainage valve and a garbage collector. The cabinet-type sink body comprises a double-basin sink body, a tape water delivery valve, a purified water delivery valve, a cylinder support and a purification water filtering box. The centralized drainage valve comprises a positioning overhead valve, a drainage bottom valve, an elastic valve core A, an elastic valve core B and a double-control valve rod. A centralized drainage valve body is combined by the positioning overhead valve and the drainage bottom valve. The centralized drainage valve body is arranged at the bottom of the double-basin sink body. The garbage collector comprises a turnover cylinder, a rotating cylinder, a push-pull motor and a control key box. The cabinet-type kitchen sink can be independently used and can also be combined with other cabinets into a whole, the purification water filtering box can conveniently remove hazardous substances in tape water, the quality of the tape water can reach the quality of direct drinking water, the garbage collector can reduce the size of kitchen garbage and dry sewage in the kitchen garbage, and therefore the cabinet-type kitchen sink is reasonable in structure, easy to operate and control, and capable of improving the life quality of people.

Owner:中山市宁博五金科技有限公司

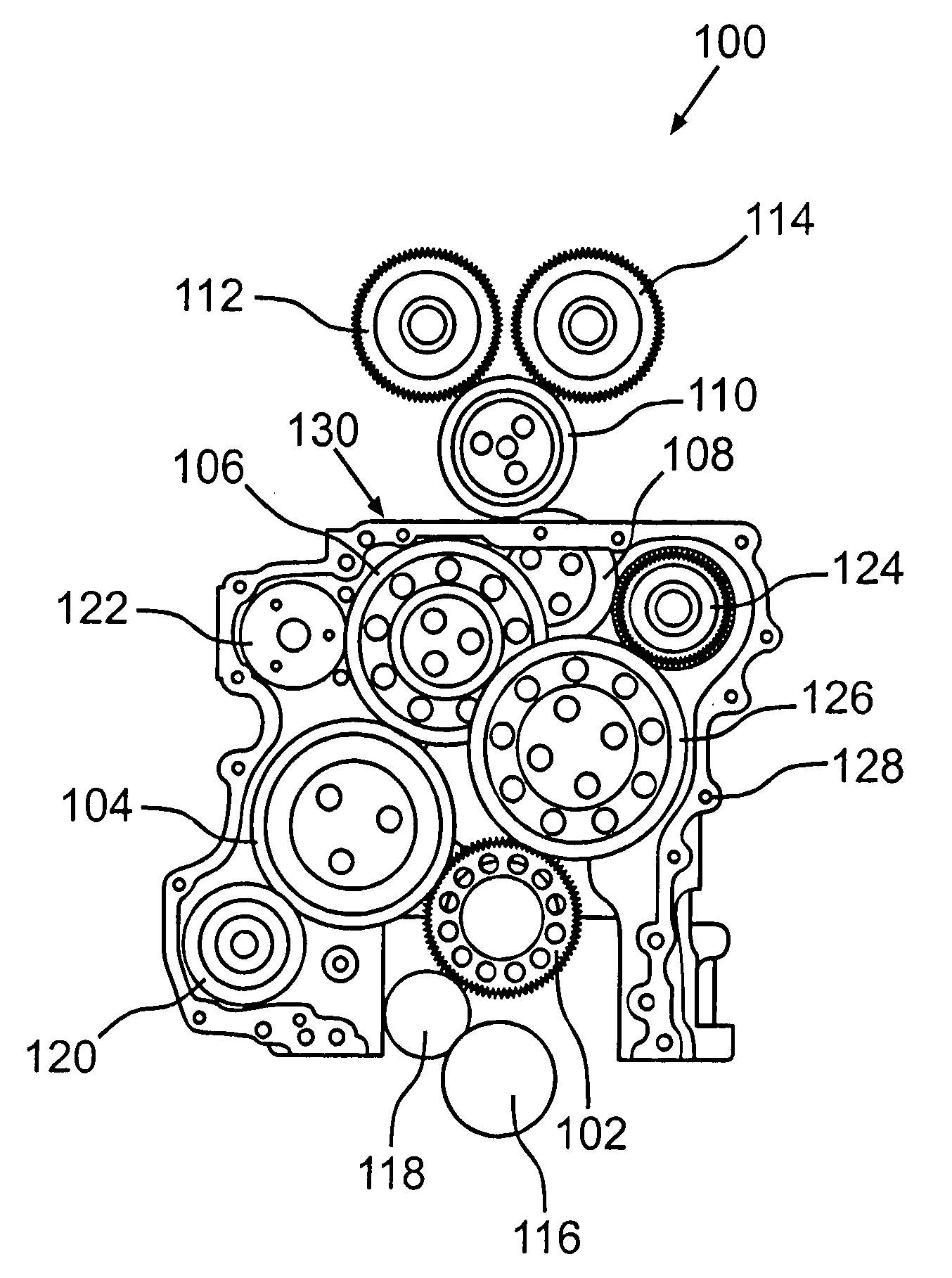

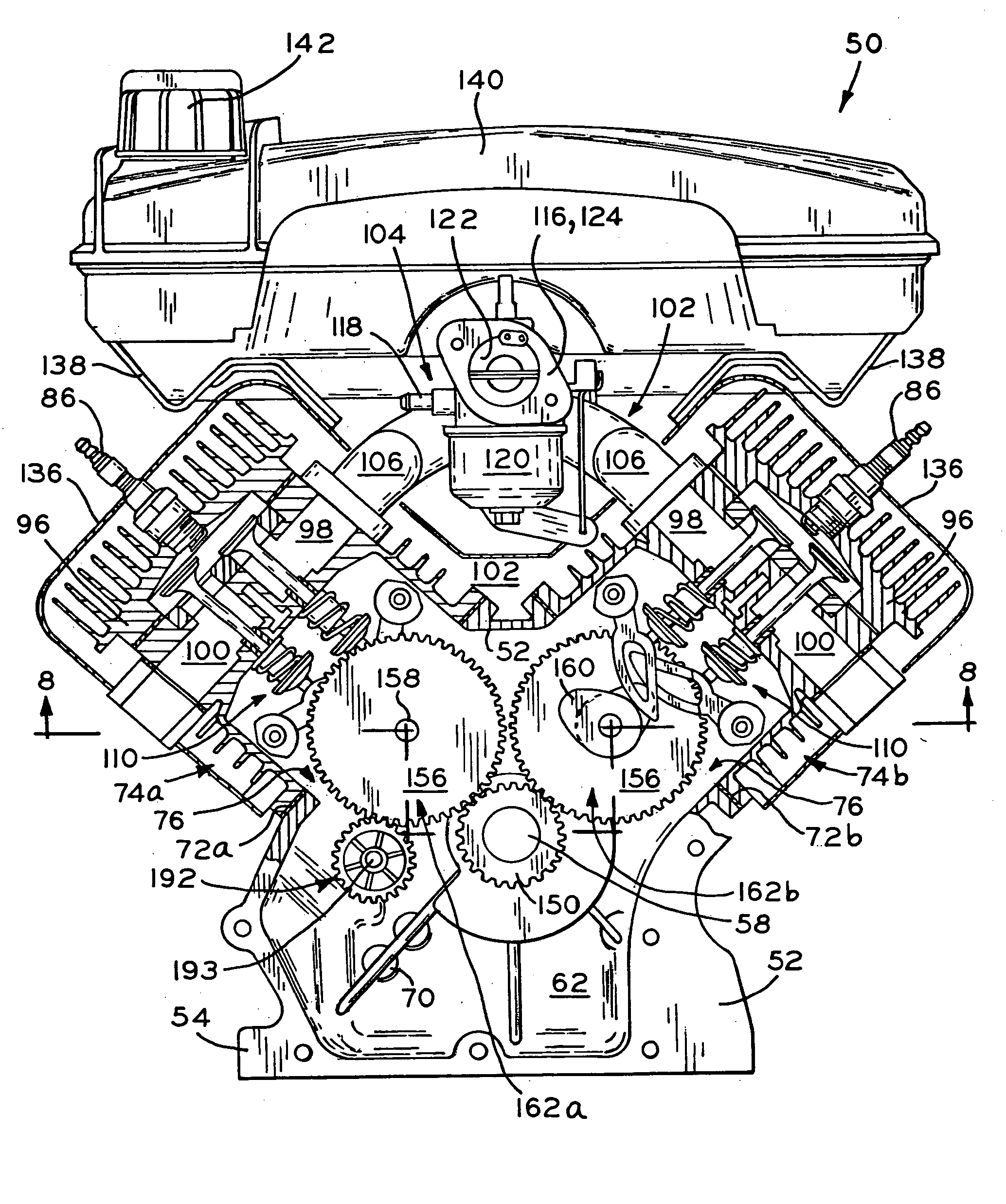

Spur gear drive for an internal combustion engine

In a spur gear drive for driving the camshaft of an overhead valve internal combustion engine wherein drive power is transmitted from the crankshaft to the camshaft via spur gears mounted on the crankshaft and the camshaft which is rotatably supported on the cylinder head, a third, intermediate, gear is adjustably supported in the power train between engine block-mounted gears and cylinder head-mounted gears so that changes in the distance between the crankshaft and the camshaft can be accommodated and, with the use of smaller gears, the spur gear drive becomes smaller and lighter overall.

Owner:DAIMLER AG

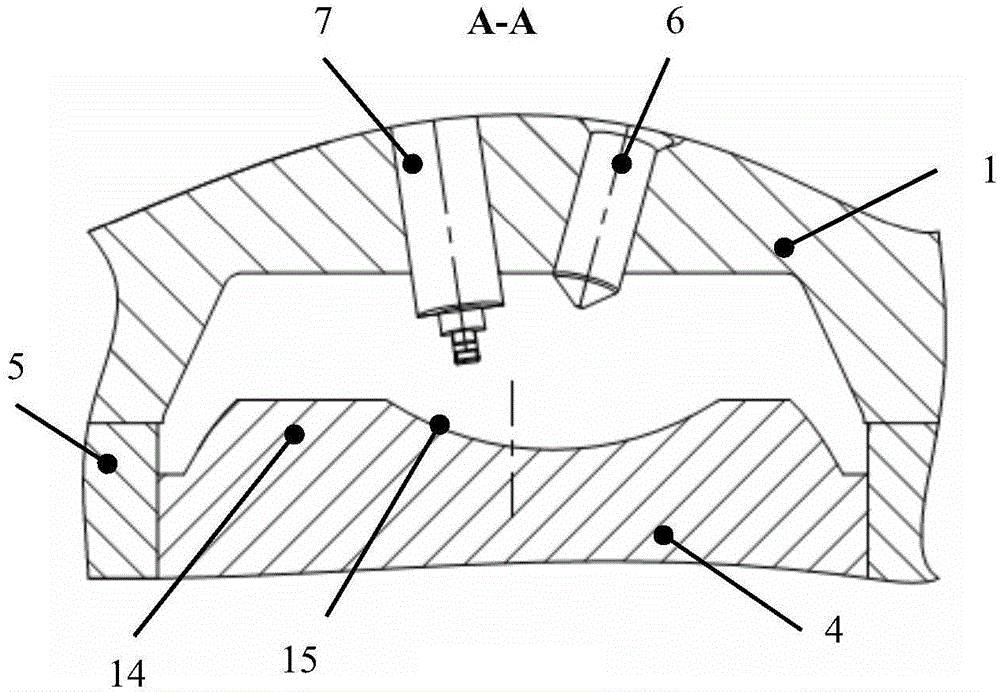

Overhead-valve combustion chamber of two-stroke gasoline direction injection engine

InactiveCN106640338AReduce bumpsMiniaturizationInternal combustion piston enginesCylinder headsCombustion chamberExhaust valve

The invention discloses an overhead-valve combustion chamber of a two-stroke gasoline direction injection engine. The overhead-valve combustion chamber is a cavity encircled by a cylinder cover, an intake valve, an exhaust valve, a piston, a cylinder sleeve, a gasoline injector and a spark plug. The inclined surface of a ceiling at the intake side of the cylinder cover is composed of two connected inclined surfaces having different included angles with the axis of the piston, and a spherical gasoline avoiding pit is sunken in the inclined surface; the position of an intake door seat is higher than the ceiling at the intake side in a vertical direction, and the intake door seat and the ceiling form a step; the gasoline injector is a piezoelectric crystal outwards-opening gasoline injector and arranged at the centre of the cylinder with the spark plug; and the centre of the piston is bulged, the top surface of the bulge is inclined, and a spherical pit is sunken in the top surface. According to the overhead-valve combustion chamber disclosed by the invention, reverse tumble scavenging is realized through the step on the ceiling, and intake short-circuit is reduced; wall wetting due to fuel oil is reduced through the gasoline avoiding pit, the top surface of the bulge of the piston and the pit of the piston; and a layered mixed gas is organized through the outwards-opening gasoline injector arranged at the centre. The overhead-valve combustion chamber disclosed by the invention is capable of realizing efficient scavenging for the two-stroke gasoline engine, optimizing the layering of the fuel oil and reducing the wall wetting due to the fuel oil, and beneficial to realizing the miniaturization of the gasoline engine.

Owner:TIANJIN UNIV

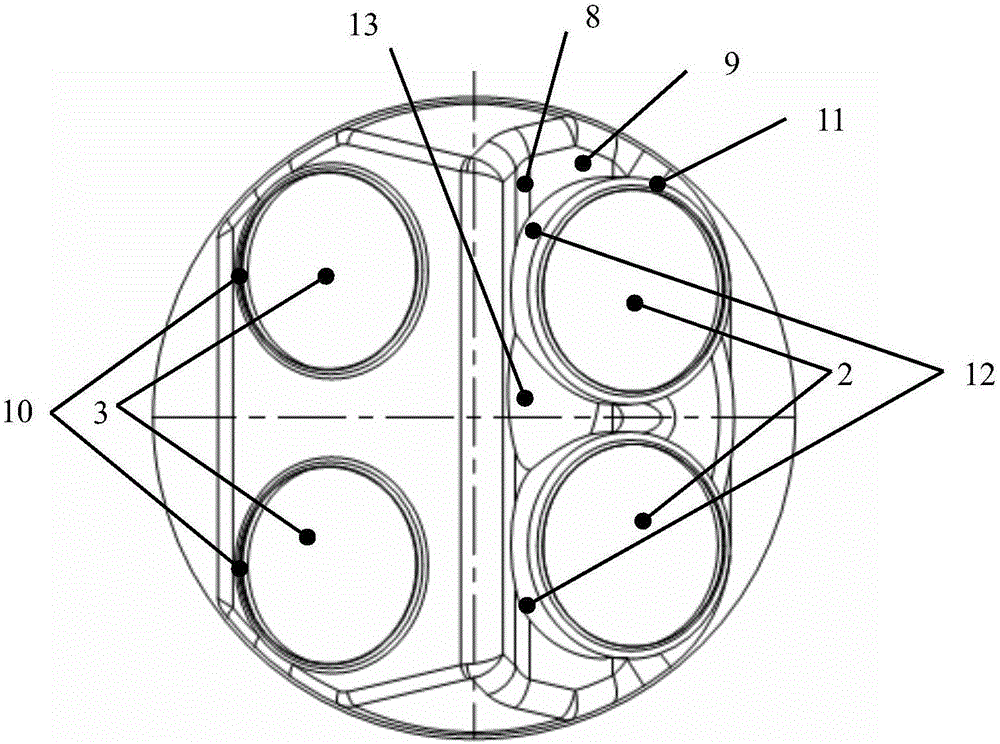

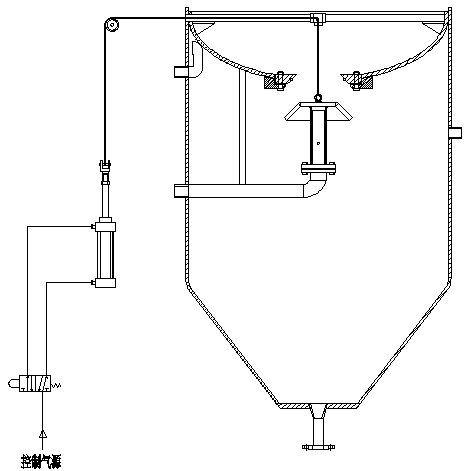

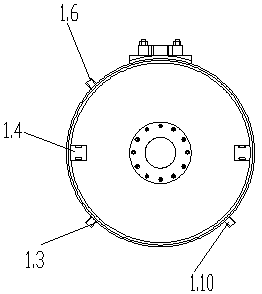

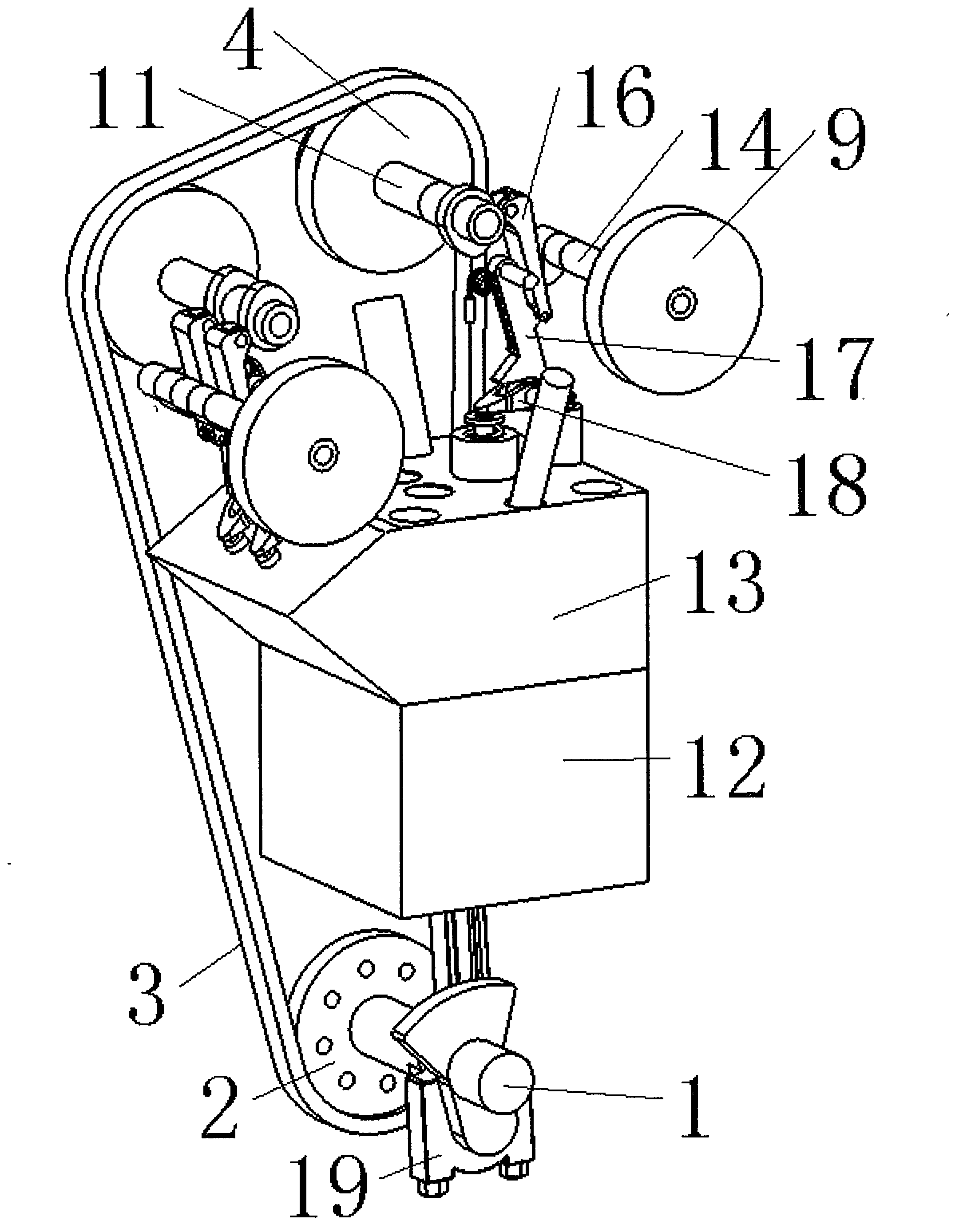

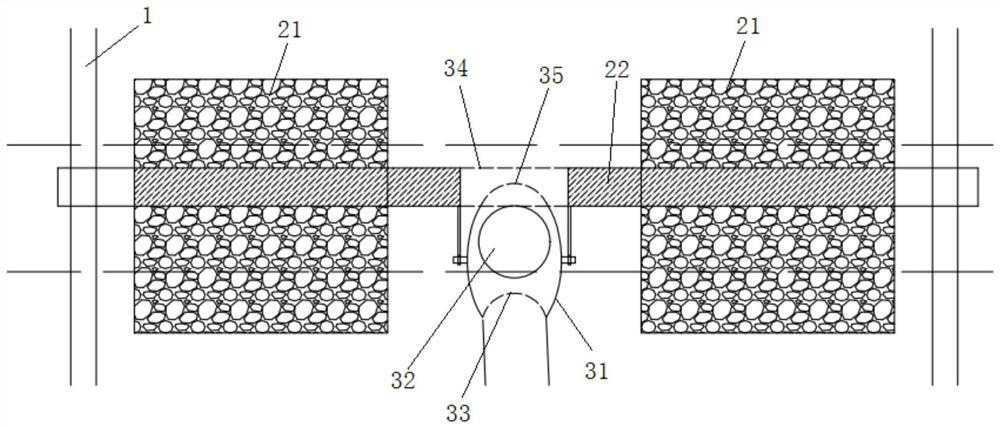

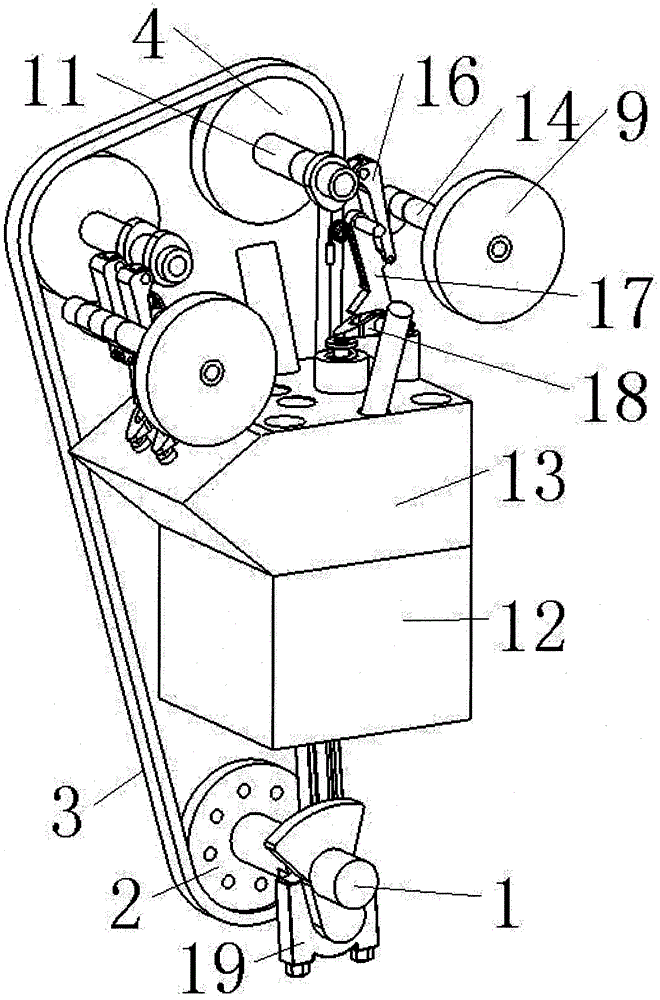

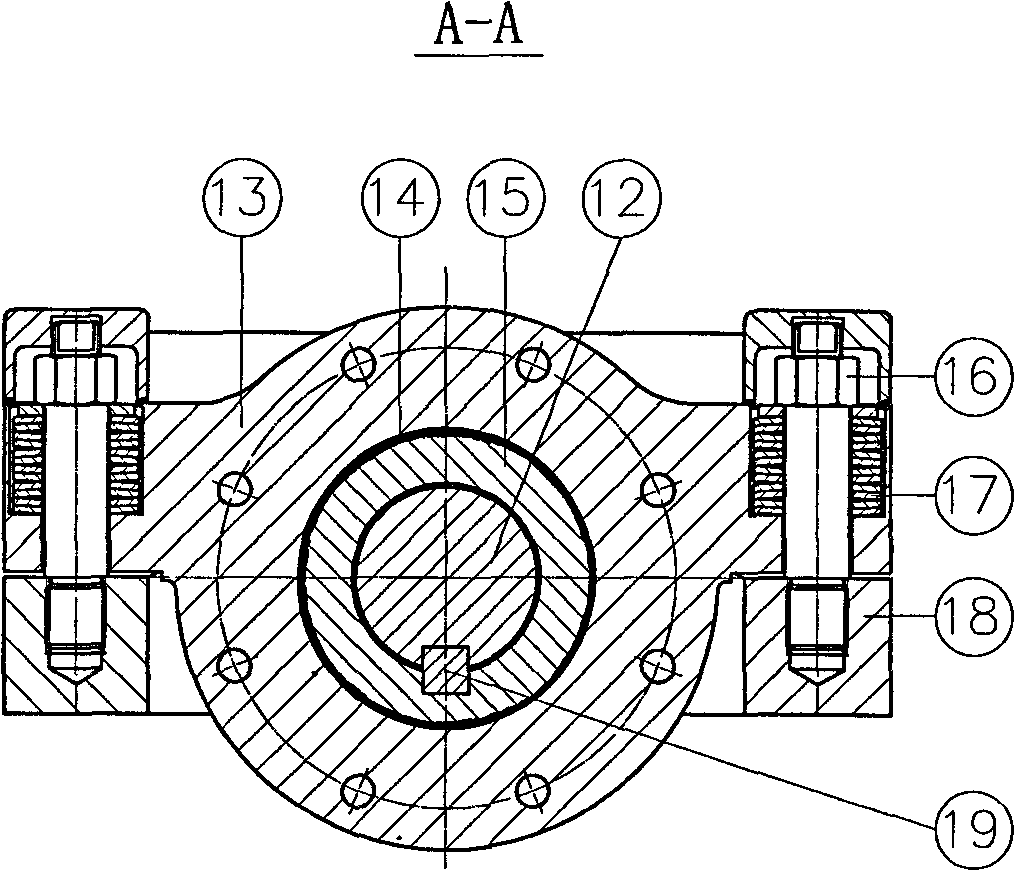

Overhead valve control device of water mist abrasive mixing cylinder

PendingCN108857923AReasonable structureImprove sealingAbrasive feedersAbrasive machine appurtenancesStainless steel wireMushroom

The invention relates to an overhead valve control device of a water mist abrasive mixing cylinder. The device comprises a water mist abrasive cylinder body, a stainless steel wire, a guide pulley anda pneumatic traction telescopic cylinder; a mushroom head positioning bracket is arranged at the top of the water mist abrasive cylinder body; an intake port and an exhaust port of the pneumatic traction extension cylinder are connected with air valves; a telescopic rod of the pneumatic traction telescopic cylinder is connected with a support; and the stainless steel wire is wound on the guide pulley, one end penetrates through the mushroom head positioning bracket to connect with a mushroom head overhead valve, and the other end is connected with the support. The device is reasonable in structure, uses the air valves for controlling opening and closing of the overhead valve to achieve good tightness, is more convenient to operate, safe and reliable, and greatly improves the working efficiency.

Owner:CHENGXI SHIPYARD +1

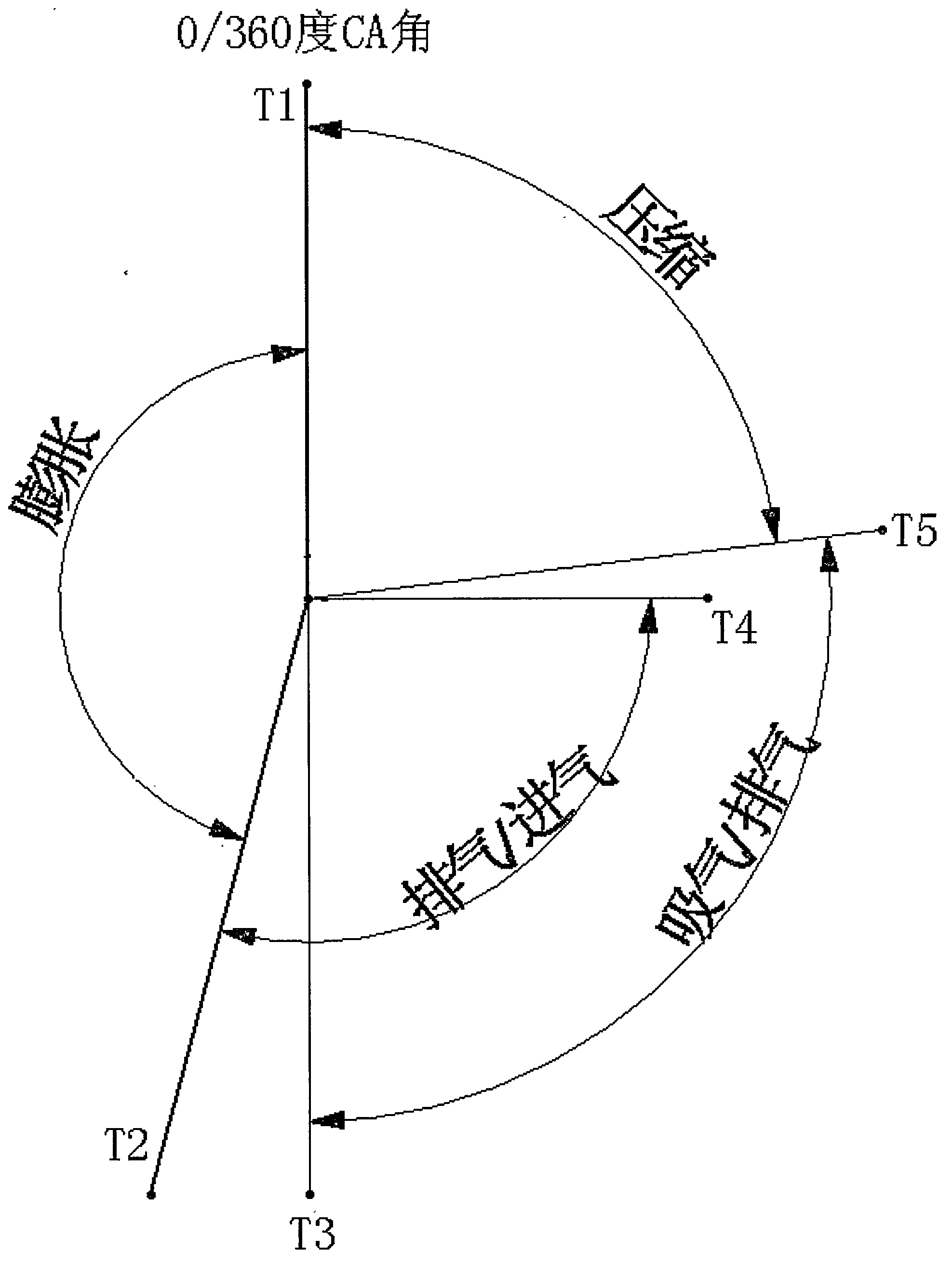

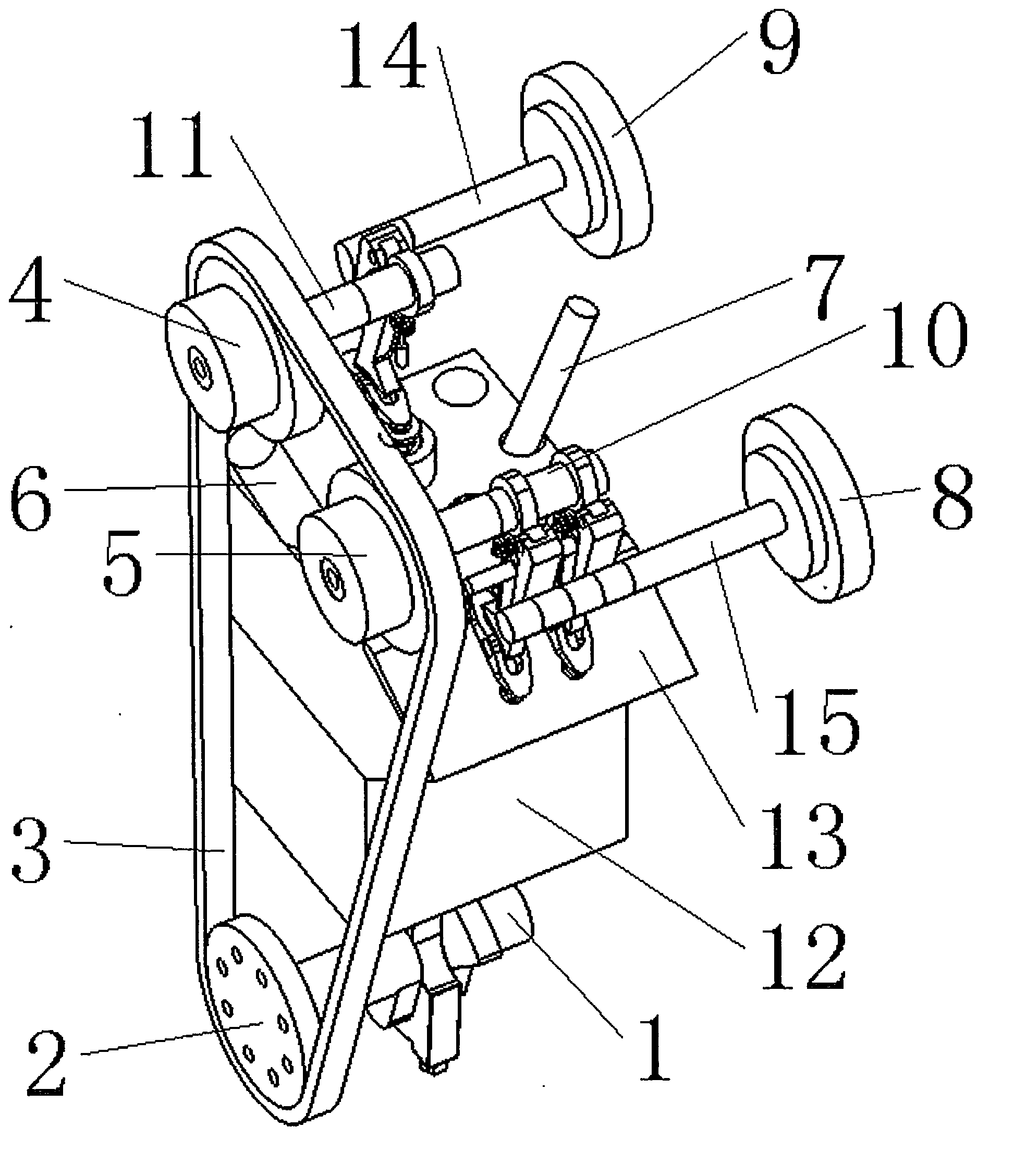

Multi-mode two-stroke atkinson cycle internal-combustion engine with fully overhead valve

InactiveCN103233789AValve arrangementsInternal combustion piston enginesExhaust valveVariable valve timing

The invention discloses a multi-mode two-stroke atkinson cycle internal-combustion engine with a fully overhead valve. According to two-stroke atkinson cycle, a scavenging process is offset on the basis of the two-stroke cycle, the distance of a compression stroke is reduced, and the distance of an expansion stroke is prolonged, and therefore, the atkinson cycle is realized and the balance of the internal-combustion engine is kept. On the basis of a common two-stroke internal-combustion engine, the multi-mode two-stroke atkinson cycle internal-combustion engine adopts an overhead embedded inlet valve with large gradient degree and an air cylinder head structure of a common exhaust valve, when the inlet valve is opened, the inlet valve temporarily serves as a separation board, a guiding function of a bulge on a formed top piston is utilized, so that a high-efficiency scavenging structure is realized; a fully variable valve timing mechanism is used to adjust the angle relation of the valve and a crank shaft, the opening and closing time of the inlet and outlet valve can be adjusted, and therefore, the internal-combustion engine has the following working modes: two-stroke atkinson cycle, two-stroke cycle and adjustable discharge capacity and compression ratio; and the efficiency of the internal-combustion engine is greatly improved.

Owner:朱譞晟

Magnetic tool

The magnetic tool has a narrow, elongate, rigid shank having a handgrip end and a selectively extendible and retractable magnet at the opposite working end. Various mechanisms are provided at the handgrip end to extend and retract the magnet. The working end of the tool may be provided with a polygonal (e.g., hexagonal, square, etc.) receptacle for the removable installation of a tool bit or square drive socket therein. The retracted magnet retains the bit or socket within the receptacle as desired. The magnetic tool is particularly well-adapted for insertion into a pushrod passage in the cylinder head of an overhead valve engine, for retracting a valve lifter away from the lobe of the camshaft to facilitate removal and replacement of the camshaft. A linear scale depth gauge may be provided, and an adjustably positionable collar may be provided to hold the tool with the lifter retracted.

Owner:ERNESTI CARL J

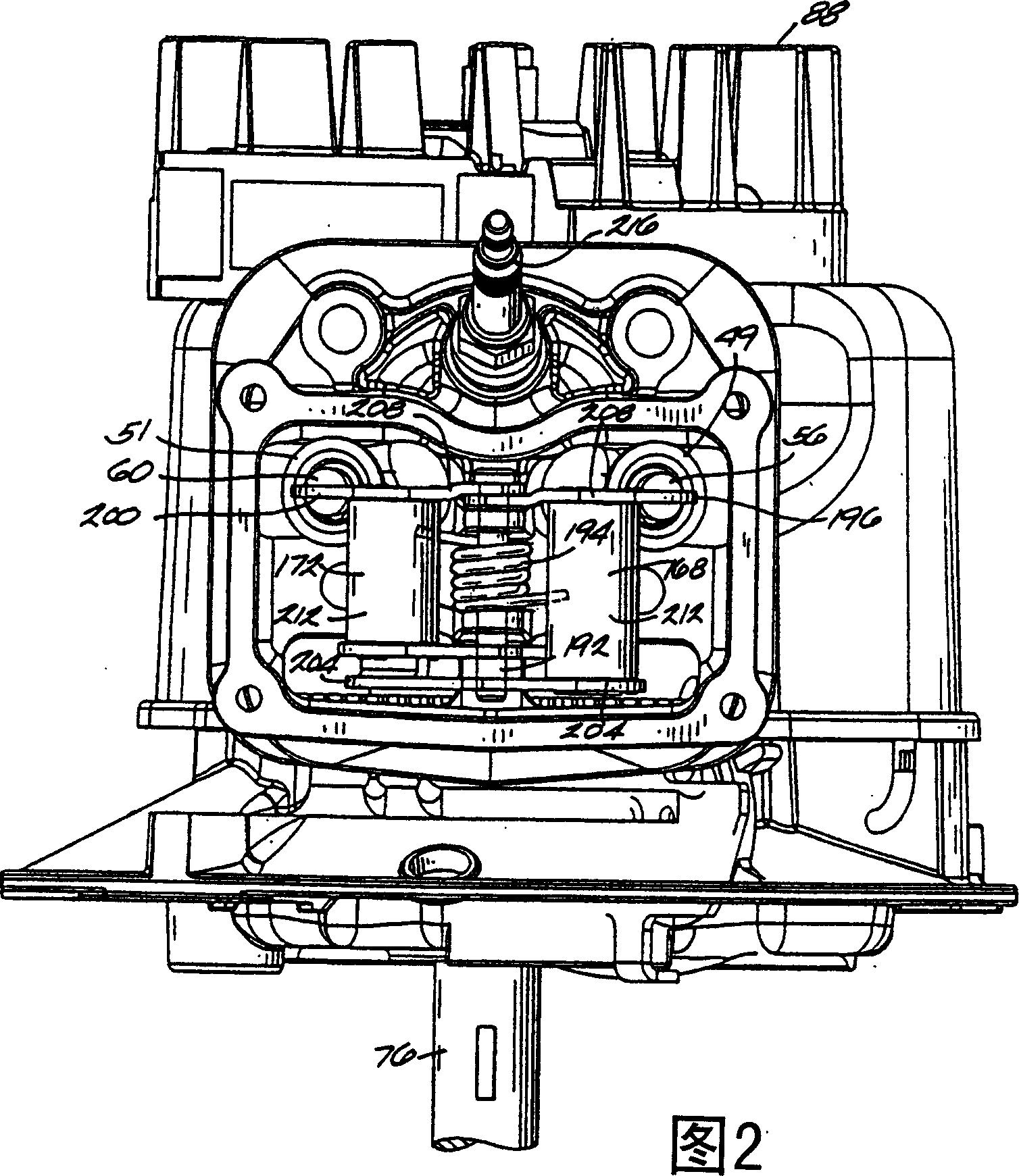

Internal combustion engine

InactiveUS20050150474A1Reduce component countEasy to assembleValve drivesCylinder headsGear wheelCylinder head

A twin cylinder engine, includes a pair of cylinder members mounted to mounting surfaces of a crankcase, and cylinder heads mounted to the cylinder members. The cylinder members are modular components, which may be pre-assembled with components of the valve train as packaged units before the cylinder members are attached to the crankcase. Each cylinder member rotatably supports a cam gear which extends into the crankcase for driving engagement with the crankshaft. The cylinder members may be configured for either side valve-type (“L-head”), or overhead valve-type (“OHV”) engines, and the cylinder members may also be used in single cylinder engines.

Owner:TECUMSEH POWER

Piston engine comprising member to cover bottom face of valve head of poppet valve

InactiveUS20100180851A1Increase the compression ratioVolume andLubrication of auxillariesLubricant conduit arrangementsCombustion chamberExhaust valve

To achieve high compression ratio and lower temperature of the exhaust poppet valve in an engine provided with a poppet valve on an extend part of a combustion chamber outside a main cylinder, disclosed is a valve cover having a cylindrical side face and upper face, an compression ring either the cylindrical side face and an inner wall of the sub cylinder, means to contact closely a bottom face of a poppet valve and the upper face of the valve cover, the upper part of the valve cover occupying most part of the combustion chamber facing with the bottom face, the valve cover moves along with the poppet valve when the poppet valve is lifted, a combination of overhead valves and the poppet valve including one intake valve and one exhaust valve, and total number of the overhead valve and poppet valve is not less than 3.

Owner:YAOITA YASUHITO

Direct lever overhead valve system

An overhead valve engine including a cylinder bore having an outer end; and a crankshaft assembly including a substantially straight crankshaft, a substantially cylindrical journal eccentrically mounted on the crankshaft, a one-piece connecting rod rotatably mounted on the journal, and a counterweight mounted on the crankshaft. The engine also includes a cam shaft having at least one cam surface and an axis inward of the outer end of the cylinder bore; two valves having opened and closed positions; two valve stems, each valve stem being attached to a valve; and two generally L-shaped and pivotably mounted valve operating levers, each lever including a first lever arm having a cam follower in contact with the cam surface, a pivot axis about which the lever pivots, and a valve arm in contact with a valve stem, where movement of the lever caused by the cam surface causes the lever to pivot and the valve arm to depress the valve stem and thus open the valve.

Owner:BRIGGS & STRATTON

Pneumatic actuator of valve

ActiveCN102588662AMovement ProhibitionAvoid misuseOperating means/releasing devices for valvesPreventing unauthorised/accidental actuationInternal pressureEngineering

The invention relates to a pneumatic actuator of a valve, which comprises a casing and an air cylinder. The casing is provided with a connector fixedly connected with the valve, and the air cylinder is fixedly mounted on the casing. One end of a piston rod is fixedly connected with a piston in the air cylinder, and the other end of the piston rod is fixedly connected with a valve stem through a drive device in the casing. The pneumatic actuator is characterized in that a safety lock is arranged on the piston rod and is locked and controlled by signals of a pressure switch of a pressure sensorin a controlled container (digester) and signals of an off travel switch. When the internal pressure of the controlled container (digester) exceeds the set pressure or when a controlled valve is switched off, the pressure switch and the off travel switch are cut off, a lock control electromagnetic valve is powered off, a control spring pushes a lock bar to butt against the lower end face of a lock block, and the safety lock is locked to prevent the piston rod from moving and avoid error action of an overhead valve of the digester. Accordingly, the pneumatic actuator of the valve has the advantages of high control safety and reliability and the like, and is suitable to be used with the overhead valve of the pulp digester.

Owner:浙江伯特利科技股份有限公司

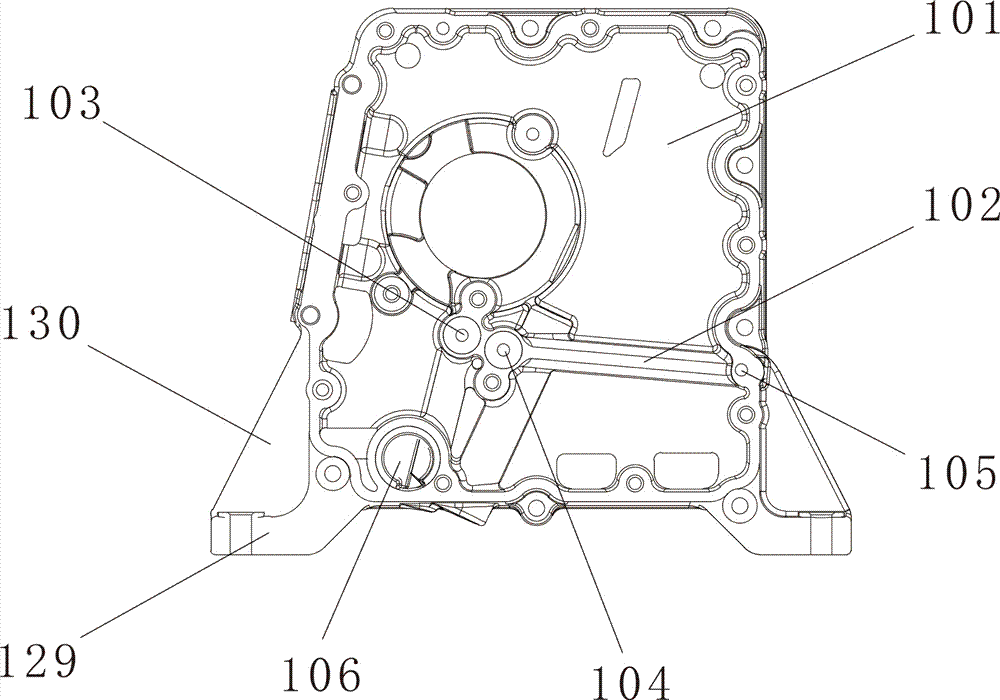

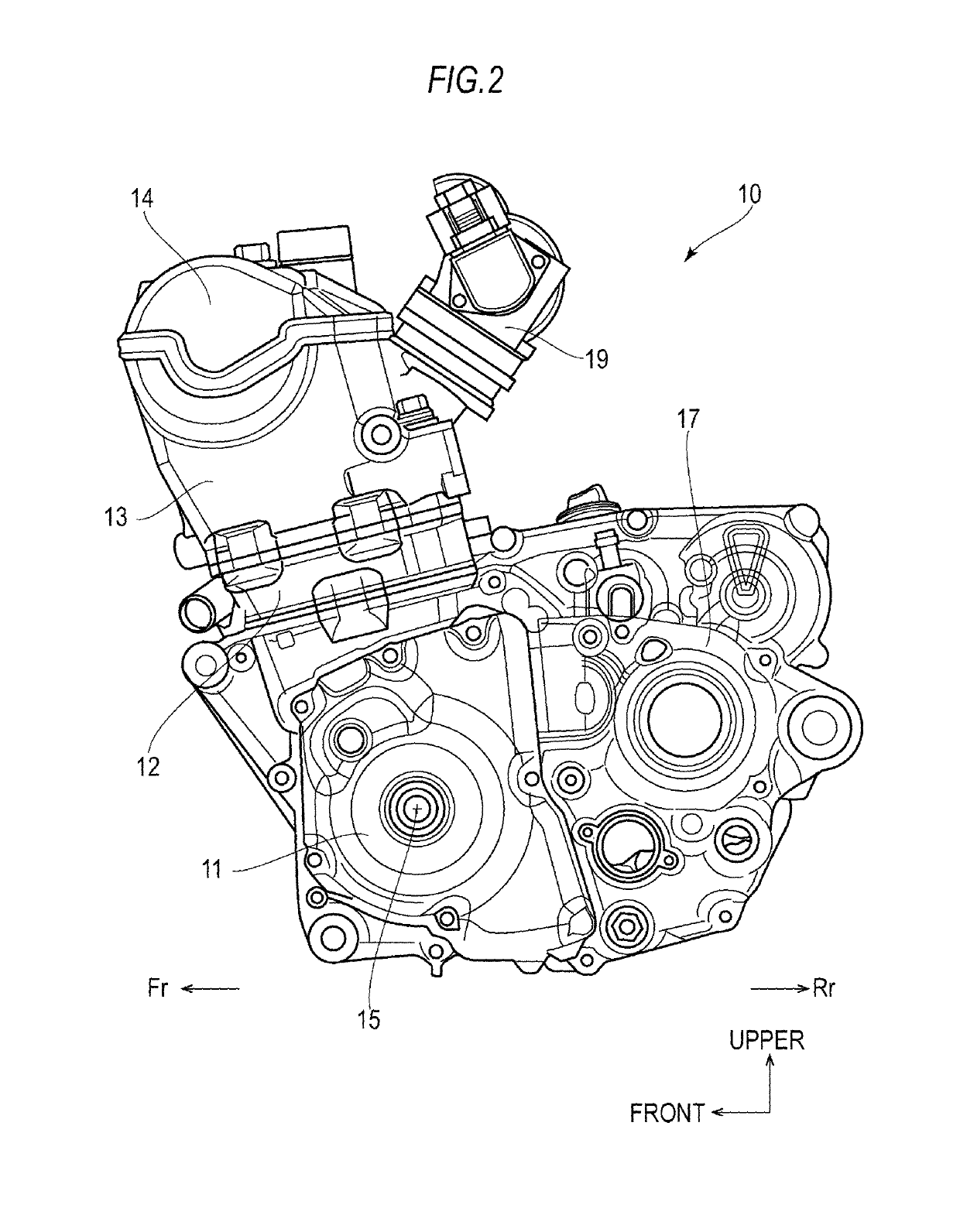

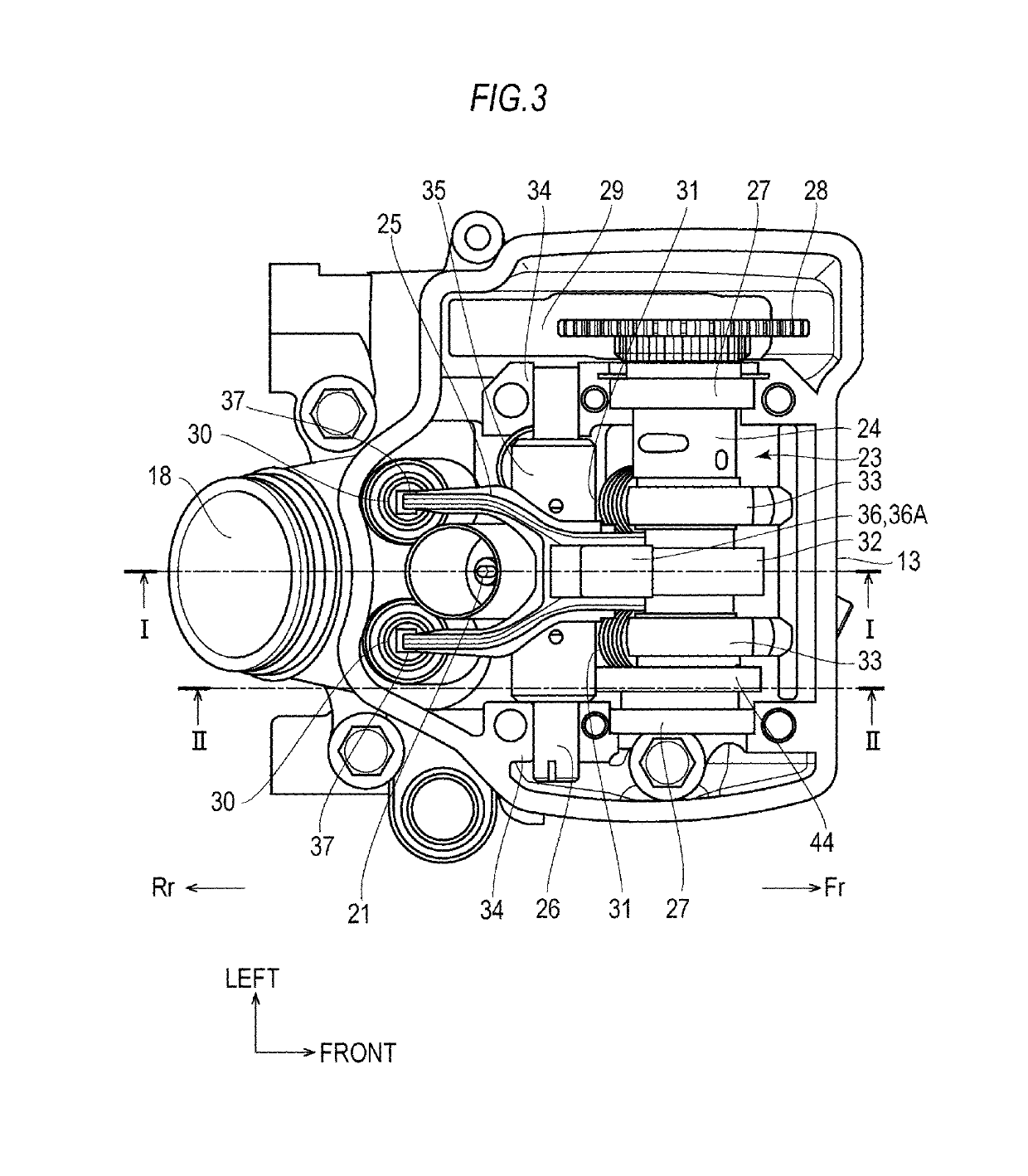

Range extender engine structure

InactiveCN107023417AReduce running noiseImprove stabilityValve arrangementsCasingsCylinder headCooling effect

The invention relates to a range extender engine structure, comprising a crankcase part, a cylinder body part and a cylinder head, the crankcase part includes a left crankcase cover and a right crankcase cover, and the left crankcase cover includes a left crankcase cover body and a set of An integrated oil supply structure on the left crankcase cover body, the right crankcase cover includes a right crankcase cover body and a bearing support seat arranged on the right crankcase cover body; the cylinder body includes a cold water cavity, a sealing cover and a The cylinder liner in the cold water cavity; the engine mechanism is also provided with a chain-type air distribution device, including a crankshaft sprocket, a timing chain, a camshaft combination device, a chain tensioning device and a rocker arm. The range extender engine structure of the present invention can effectively solve the problems of crankshaft breakage and oil leakage of the existing range extender; the inner cooling fins and the large-capacity water storage space arranged in the cold water cavity can achieve better heat dissipation effect; The top-mounted gas distribution structure can greatly improve the running stability of the range extender, making the range extender engine lower in fuel consumption and longer in service life.

Owner:CHONGQING JIANSEN POWER MACHINERY

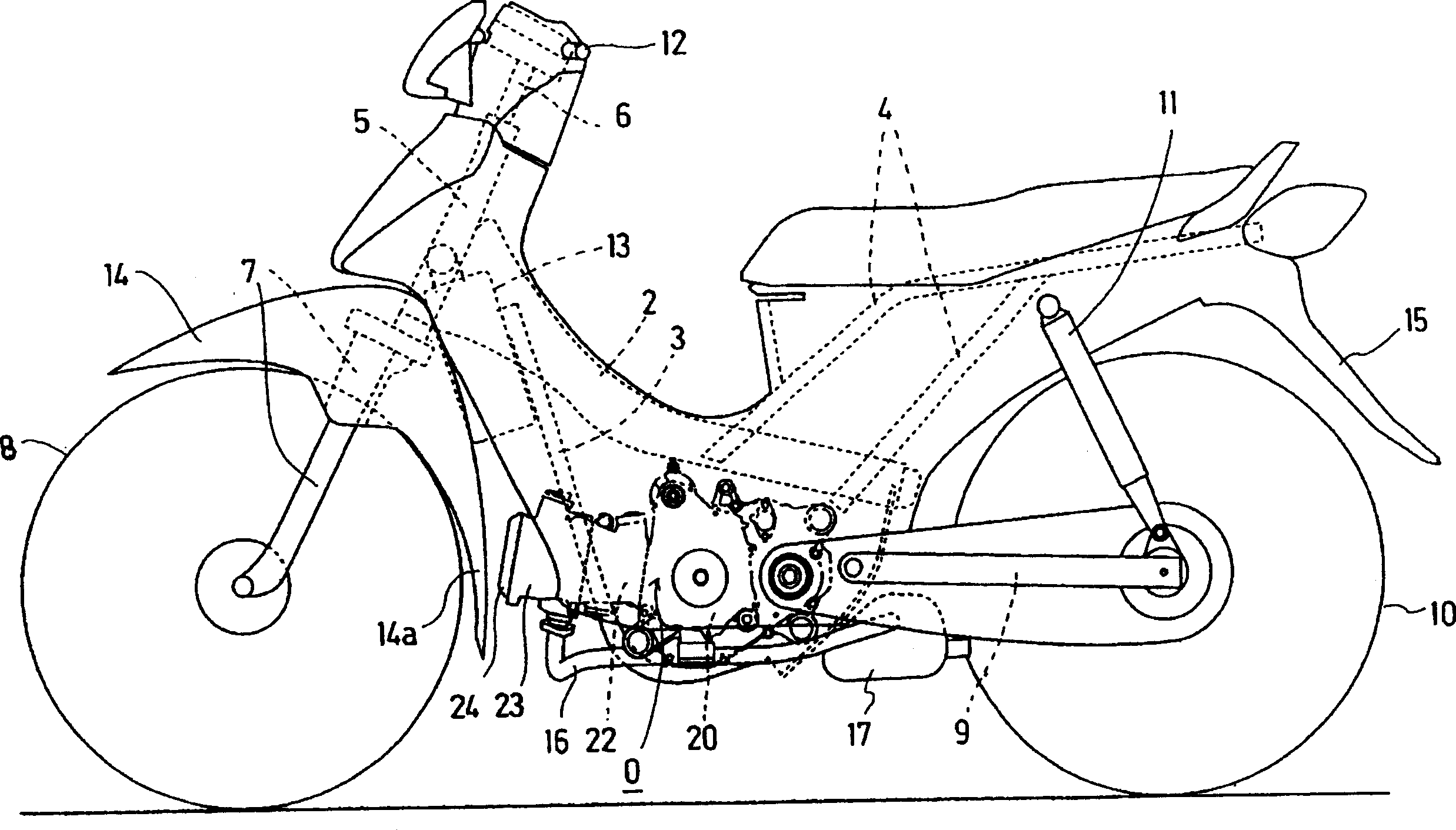

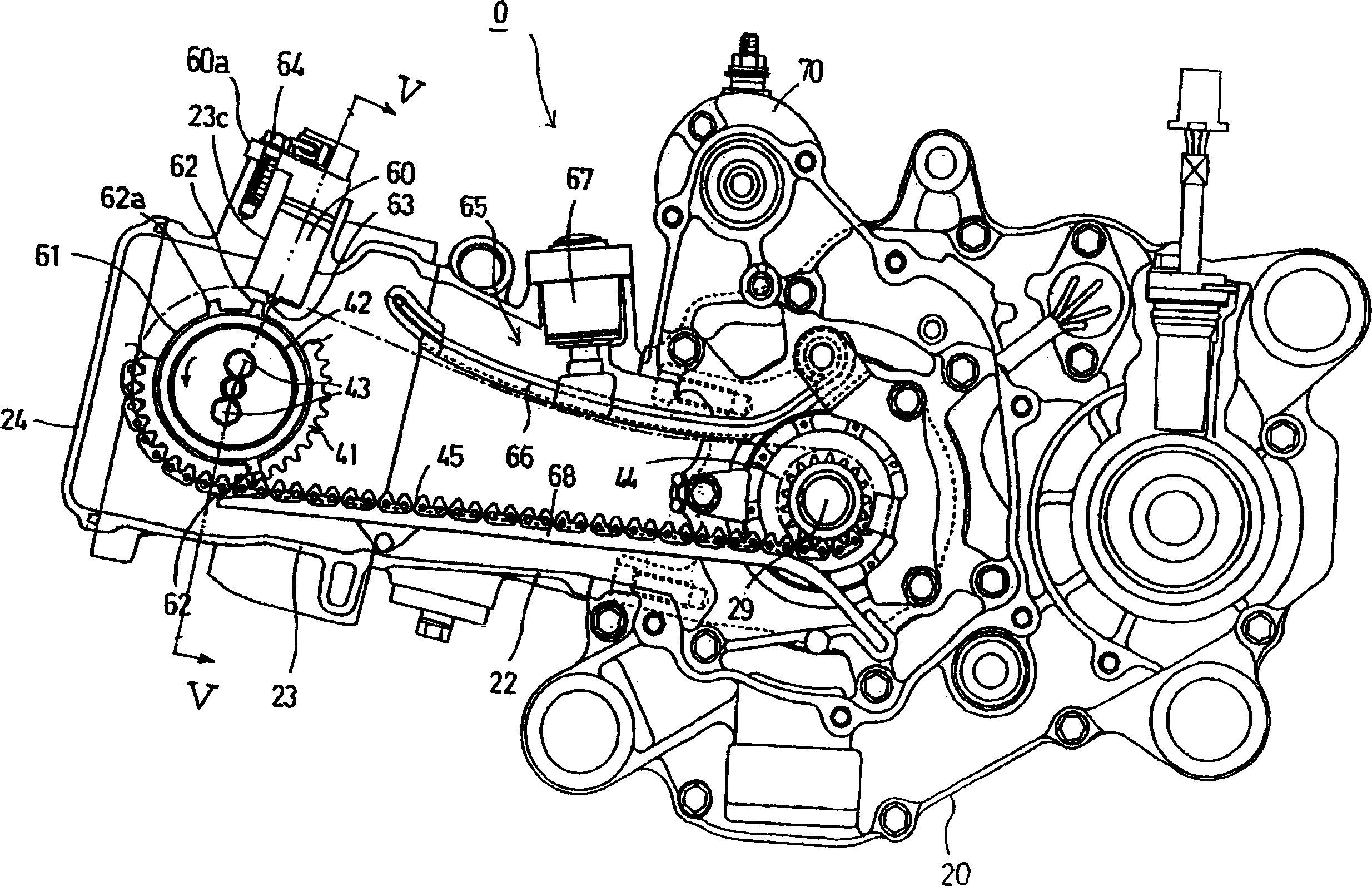

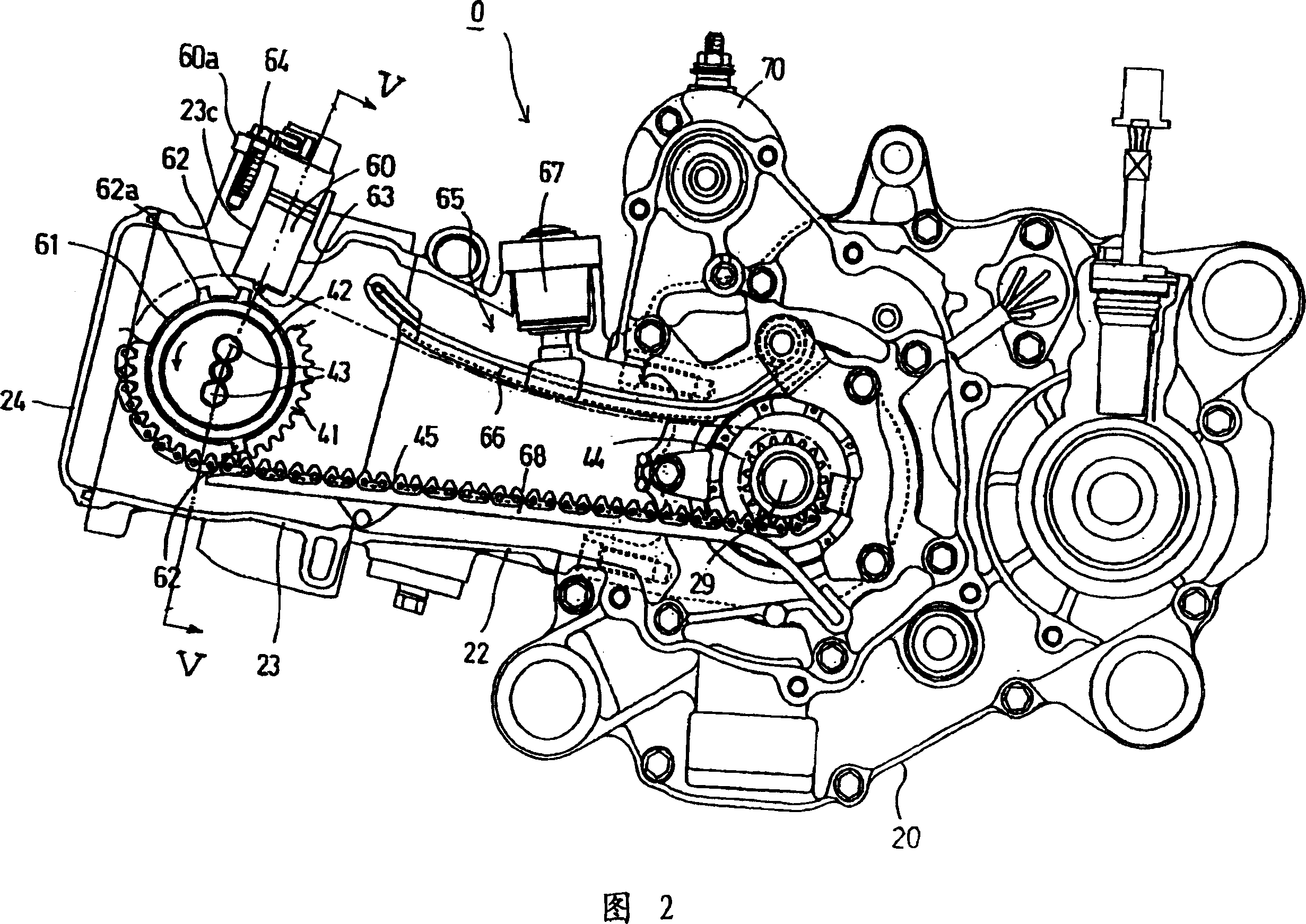

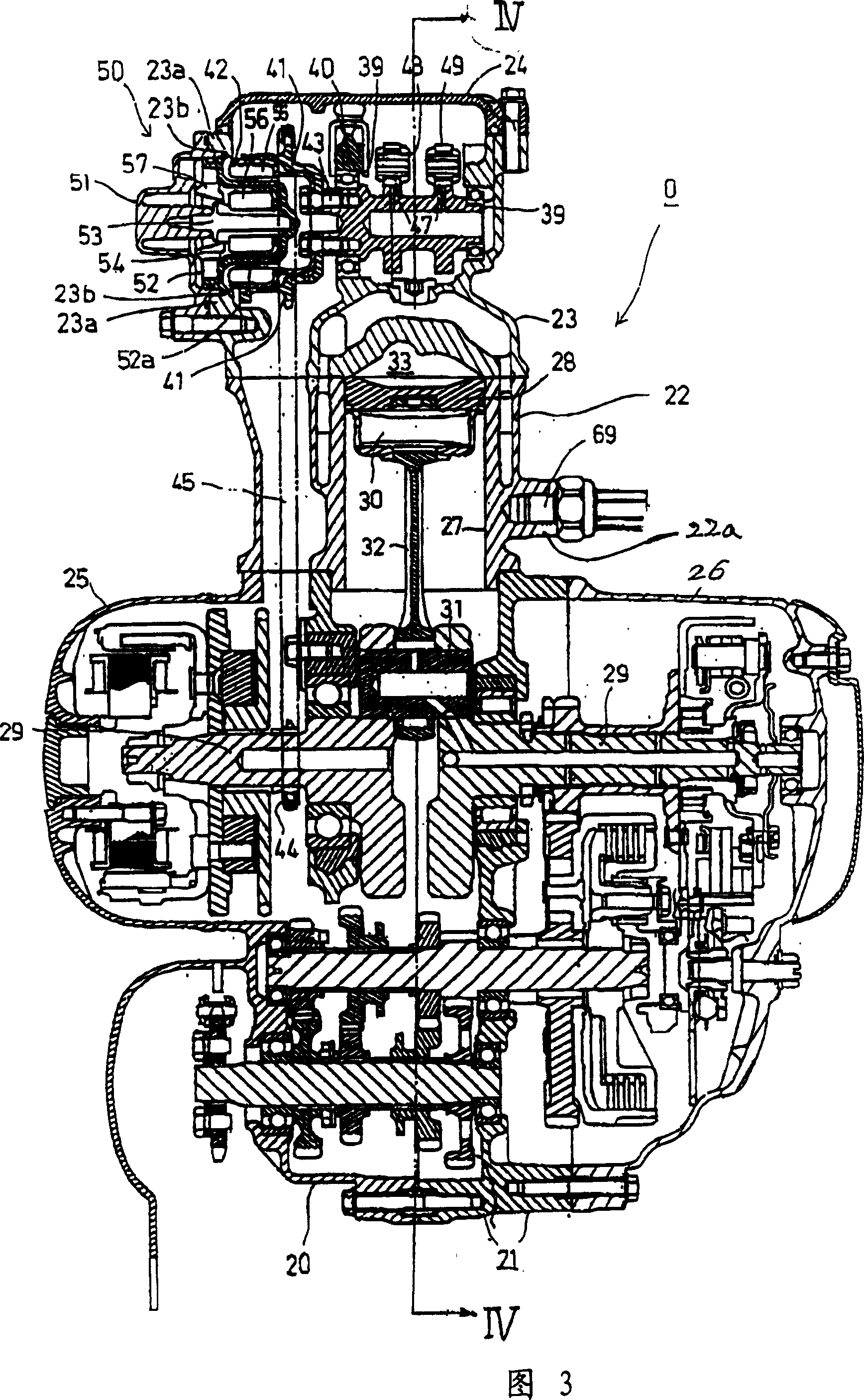

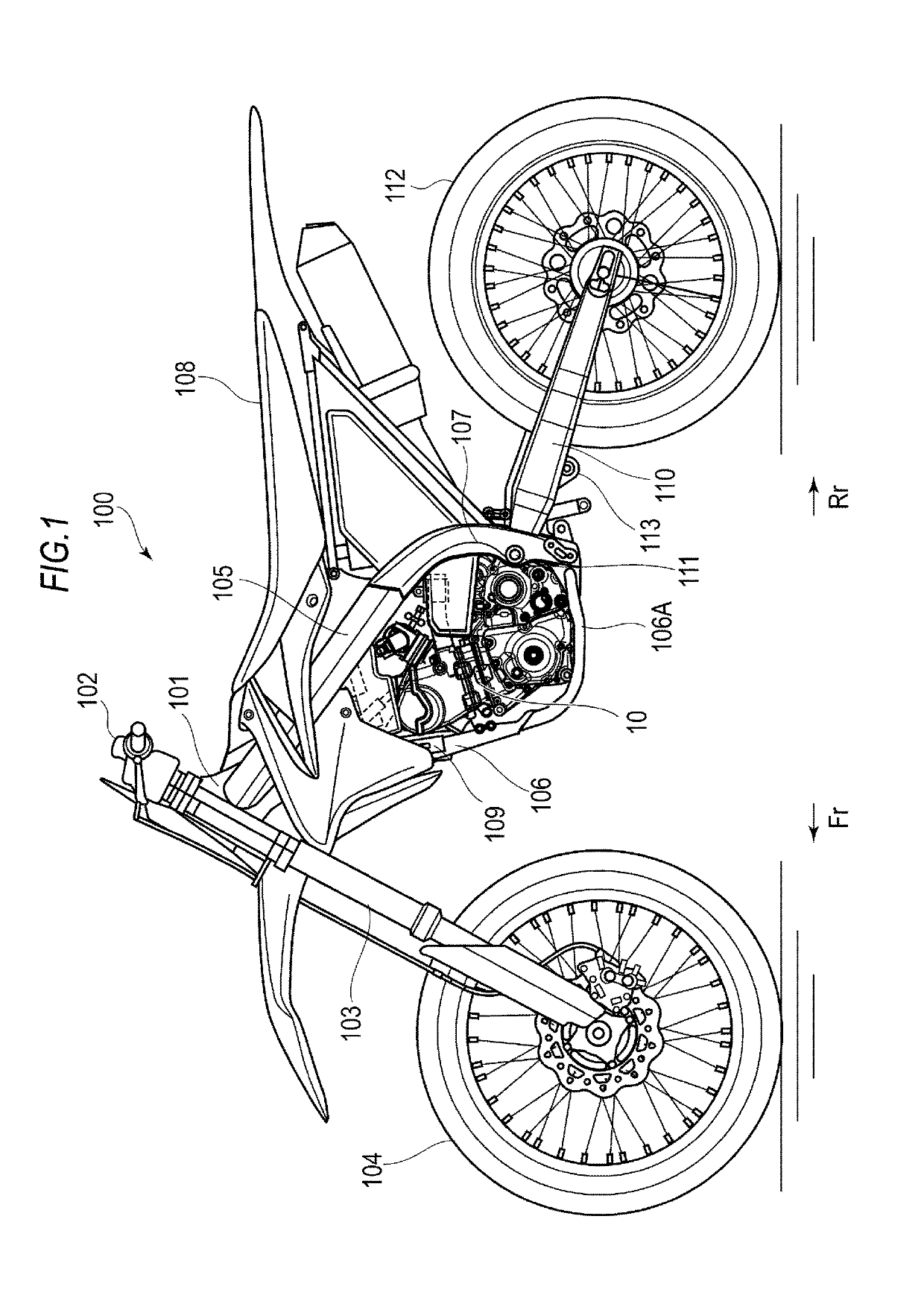

Cam shaft angle sensor mounting structure of IC engine

InactiveCN1532392APrevent protrudingReduce intervalElectric ignition installationValve drivesCylinder headFour-stroke engine

To reduce projection length of a camshaft angle sensor in relation to a camshaft angle sensor mounting structure for an overhead valve type four stroke internal combustion engine mounted on a motorcycle body. In the camshaft angle sensor 60 mounting structure for the overhead valve type four stroke internal combustion engine 0 mounted on the motorcycle 1 in an attitude inclining a cylinder 22 roughly horizontally forward, a flange 61 is formed on a side surface of a cam sprocket 41 driving a camshaft mounted on a cylinder head 23, a detected part 62 is formed on the flange 61, the flange 61 is used as a sensing rotor, the camshaft angle sensor 60 provided at a position facing to the sensing rotor 61 is projectingly mounted on an outer surface of a top or side of the cylinder head 23.

Owner:HONDA MOTOR CO LTD

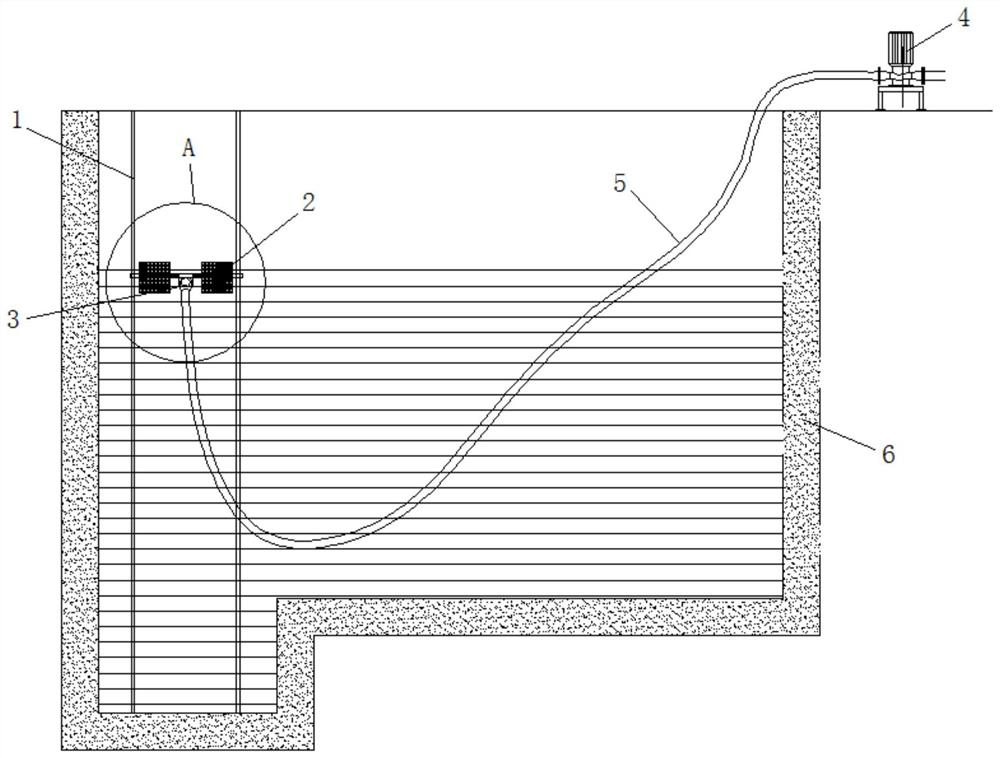

Overhead valve type water decanter

PendingCN114506921AAvoid cloggingPrevent force swingTreatment involving filtrationSustainable biological treatmentStructural engineeringBuoy

The invention discloses an overhead valve type water decanter which comprises an overhead valve assembly and a sliding rail assembly, and the sliding rail assembly is arranged in a water pool and extends in the depth direction of the water pool; the top valve assembly is connected with the buoy assembly; the buoy assembly is connected with the sliding rail assembly in a matched mode. And the lift pump assembly comprises a lift pump main body and a connecting hose which are connected with each other. According to the overhead valve type water decanter provided by the invention, water enters from the water surface by adopting the buoy and the overhead valve, the conditions that impurities are pumped and the bottom valve and the pipeline are blocked are effectively prevented, the overhead valve adopts a hollow ball as a sealing element, and the hollow ball floats at the top of the overhead valve and is tightly attached to the water inlet of the overhead valve, so that the situation that water cannot be pumped due to backflow of water in a hose is prevented. Meanwhile, sliding rails are adopted for fixing, the buoy device is effectively prevented from being stressed to swing in the pump operation process, the sliding rails are fixed to the lowest position of the pool, and the pool bottom is convenient to clean. And large-area popularization and application are worthy.

Owner:西南兵工重庆环境保护研究所有限公司

Cam shaft angle sensor mounting structure of IC engine

InactiveCN1306156CPrevent protrudingReduce intervalElectric ignition installationValve drivesCylinder headFour-stroke engine

To reduce projection length of a camshaft angle sensor in relation to a camshaft angle sensor mounting structure for an overhead valve type four stroke internal combustion engine mounted on a motorcycle body. In the camshaft angle sensor 60 mounting structure for the overhead valve type four stroke internal combustion engine 0 mounted on the motorcycle 1 in an attitude inclining a cylinder 22 roughly horizontally forward, a flange 61 is formed on a side surface of a cam sprocket 41 driving a camshaft mounted on a cylinder head 23, a detected part 62 is formed on the flange 61, the flange 61 is used as a sensing rotor, the camshaft angle sensor 60 provided at a position facing to the sensing rotor 61 is projectingly mounted on an outer surface of a top or side of the cylinder head 23.

Owner:HONDA MOTOR CO LTD

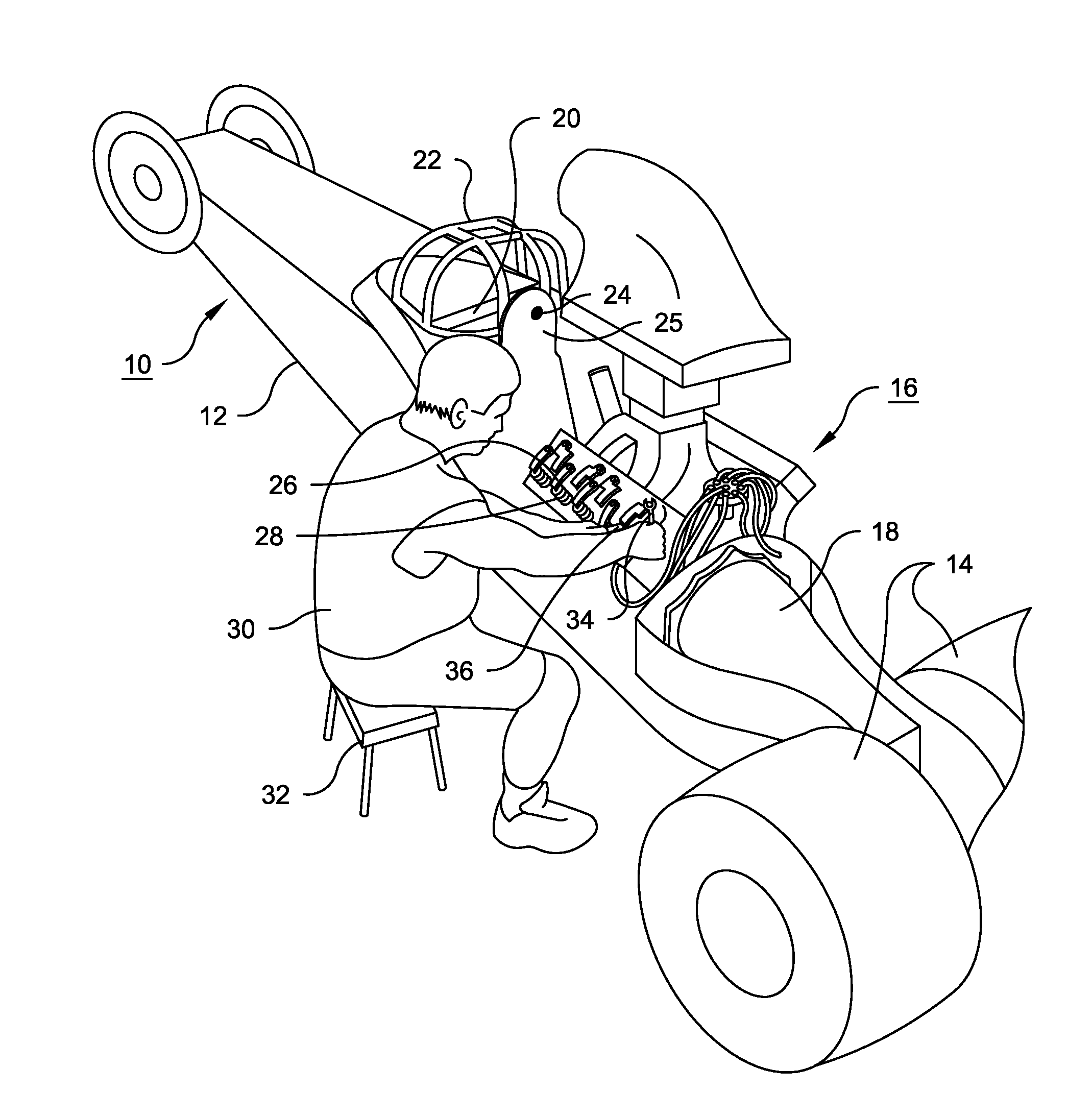

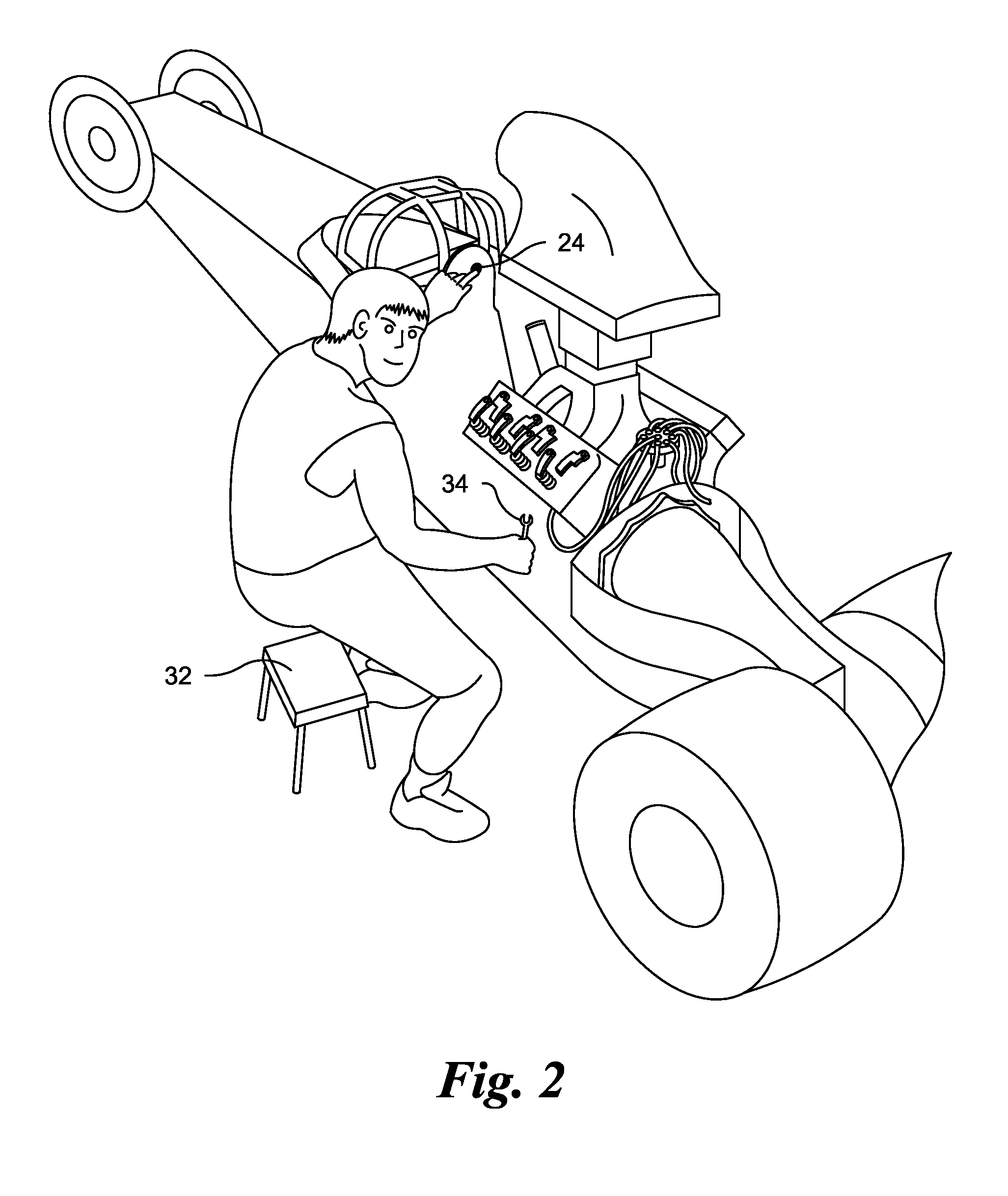

Tuning an overhead valve internal combustion engine

In a drag racing vehicle, especially one utilizing a V-block engine, valve gap measurement and adjustment, valve spring force measurement, and the like are carried out with the aid of a foot-operated switch removably connectible to a circuit that carries battery current to the vehicle's starter motor. The foot switch is provided with a cable allowing it to be positioned in either side of the vehicle. Operation of the foot switch effects rotation of the engine crankshaft and camshaft through a small angle so that each valve can be brought to a fully closed condition for measurement or adjustment.

Owner:CICCARONE THOMAS E

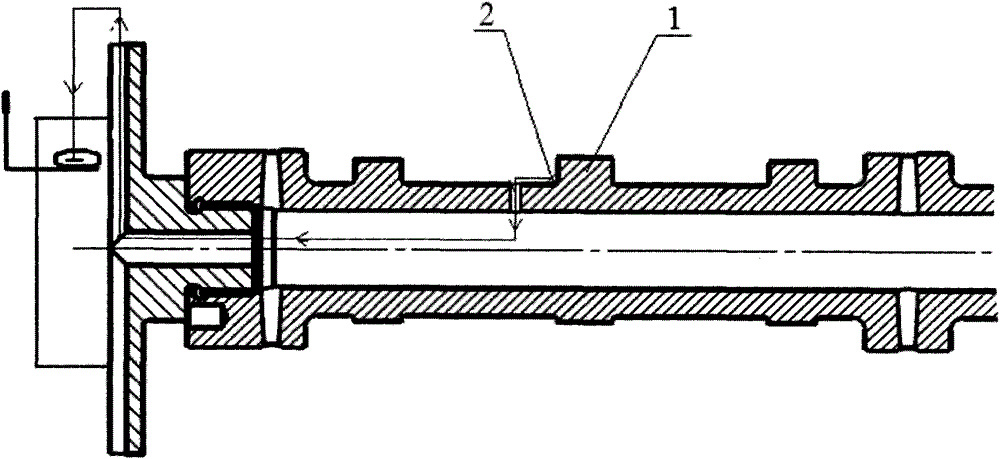

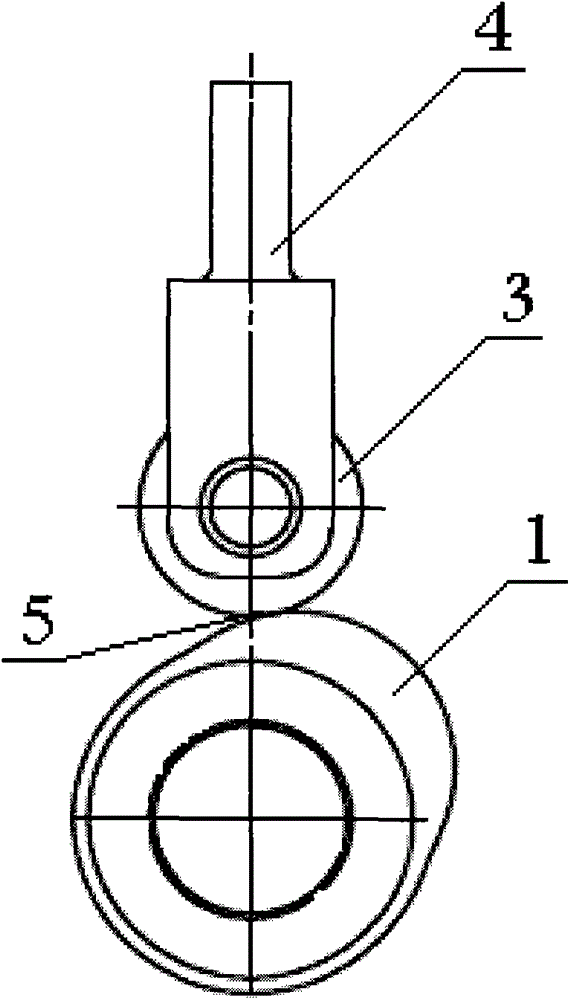

Test method for contact stress of engine overhead valve camshaft

ActiveCN103868633BRealize the test of contact stressHigh reliability of test dataForce measurementWork periodWork cycle

Owner:CHINA NORTH ENGINE INST TIANJIN

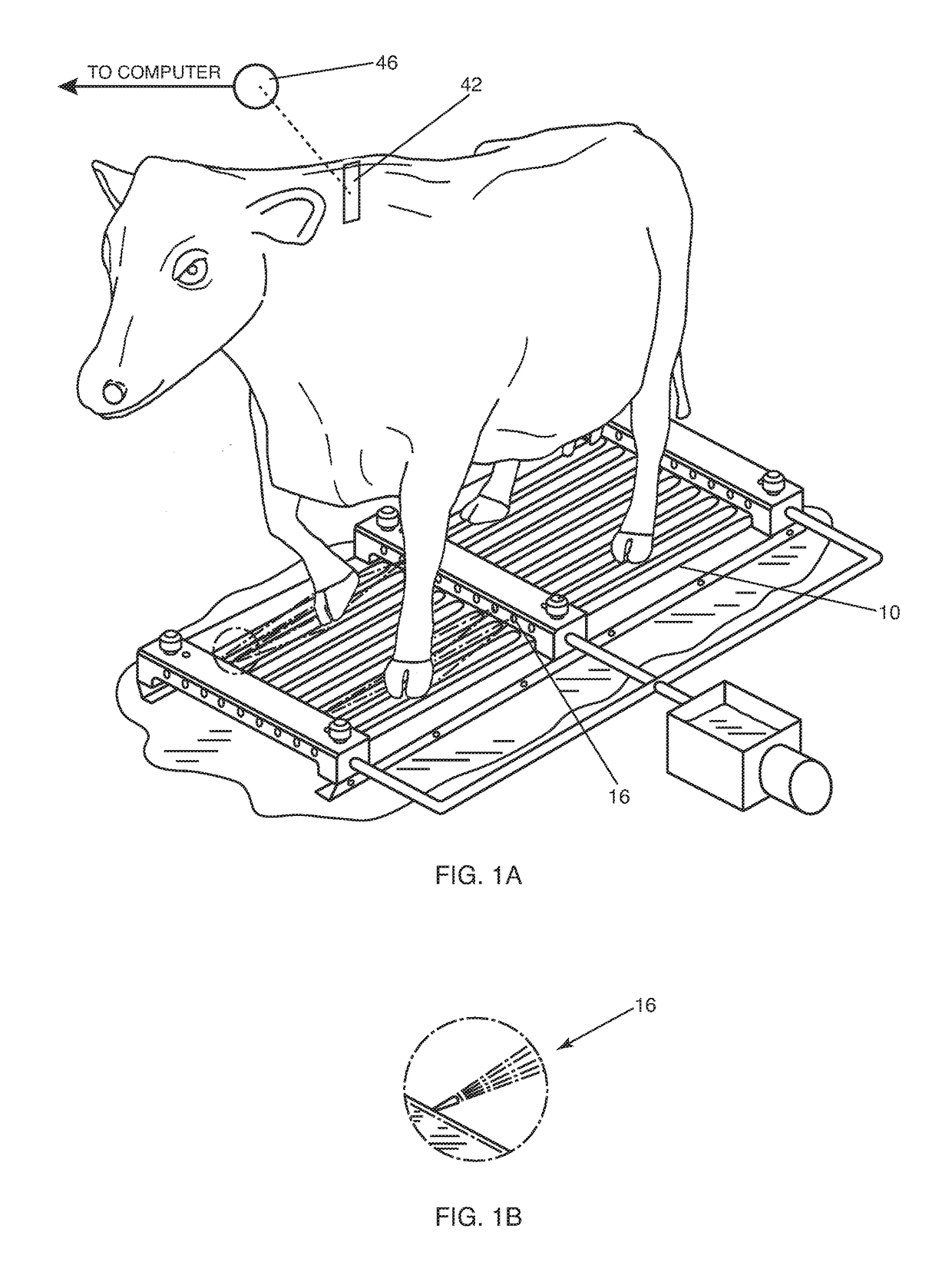

Overhead valve system for animal hoof treatment

InactiveUS20170135313A1Increase blood flowPrevent and reduce swellingProgramme controlComputer controlProcess regionOverhead valve

A method and system that incorporates spaying logic onto the sensor(s) adapted to detect and apply various liquids onto the feet of an animal. The sensor(s) actuate(s) specific valve(s) for application of the medicinal fluid. The operational components for initiating the spray treatment are located away from the treatment zone to protect the components from failures due to environmental conditions in that location. The application of the medicinal fluids can be enhanced by administering them to specific animals by tagging the animals that require more frequent or stronger treatments.

Owner:DAIRY SOLUTIONS

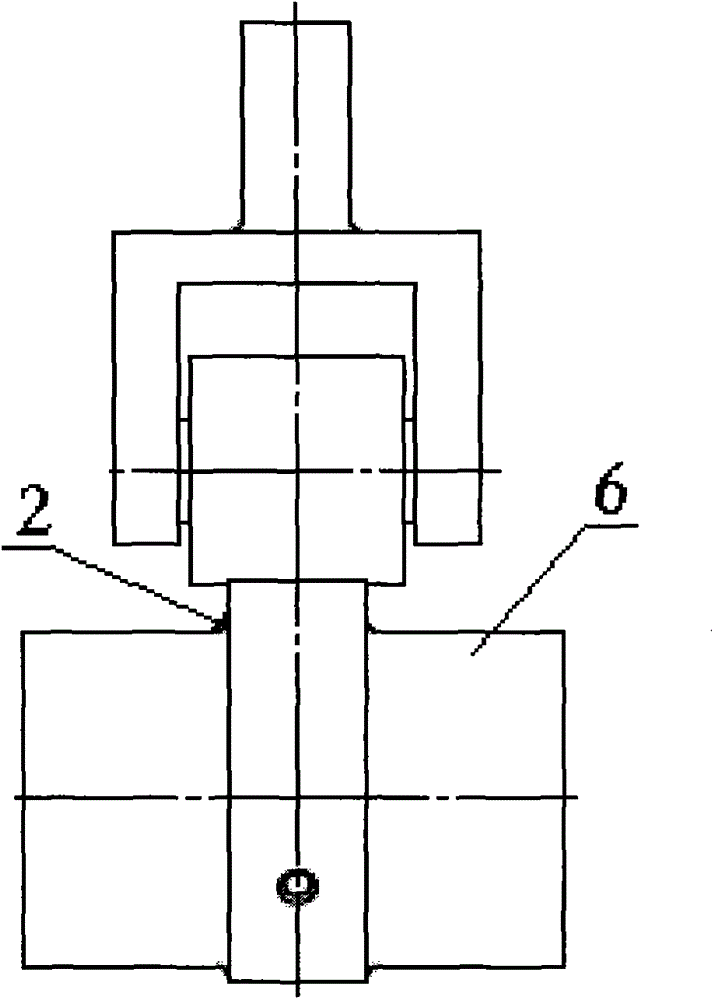

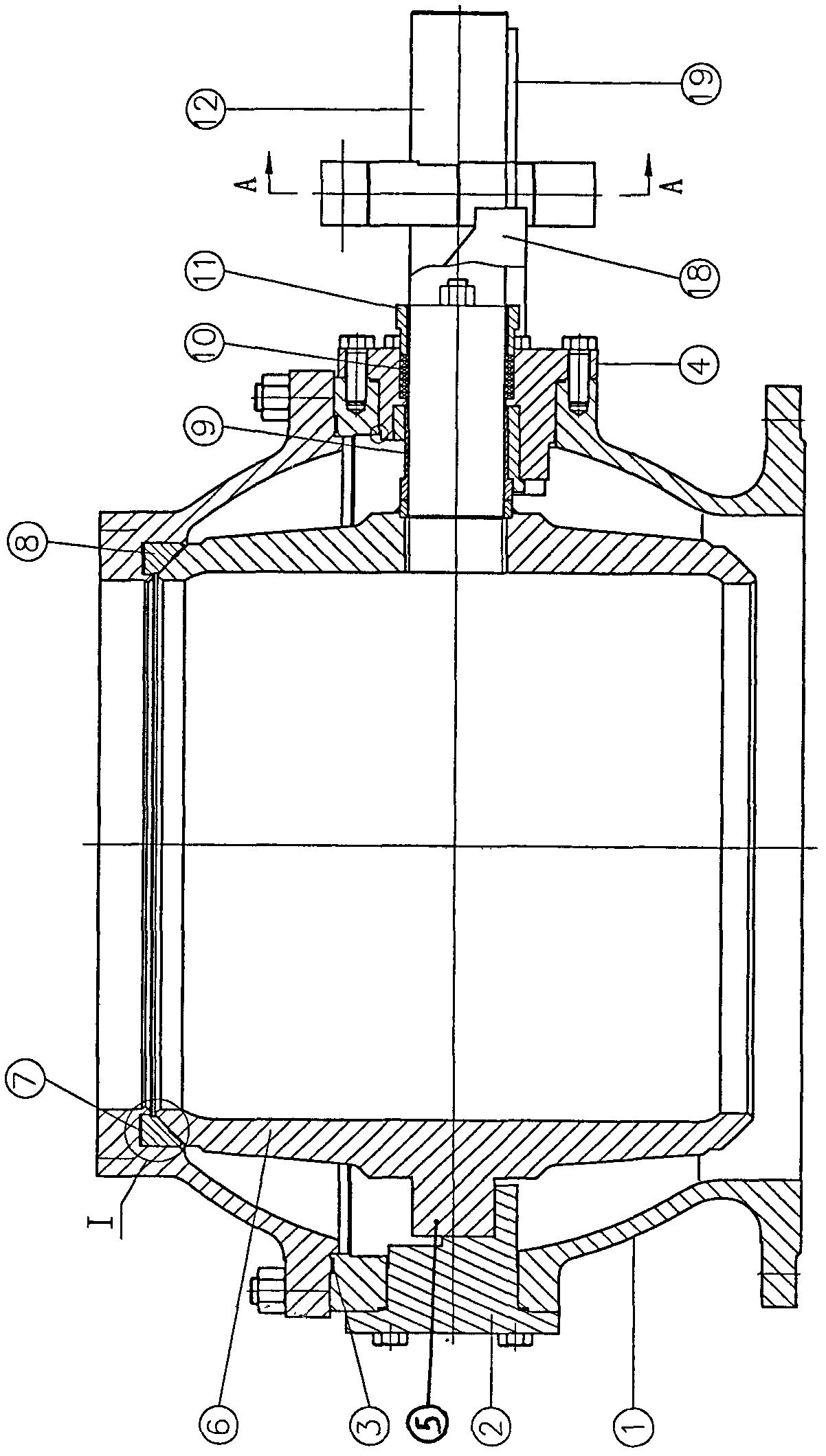

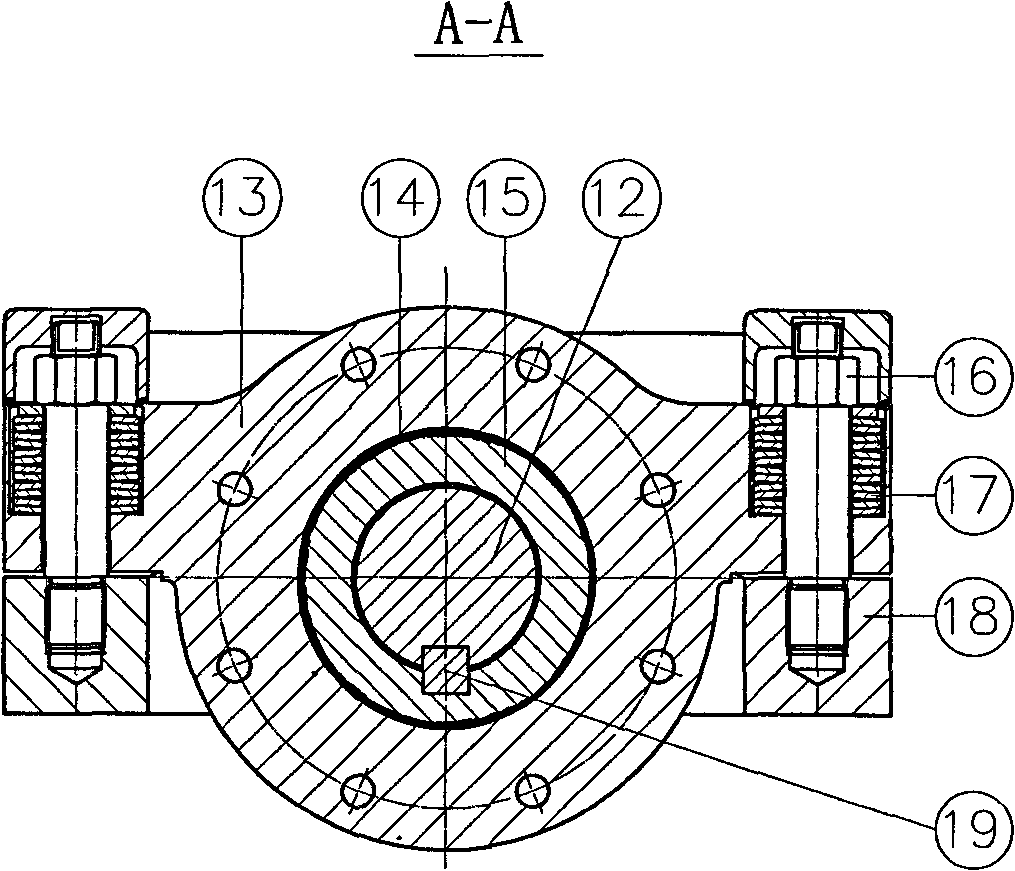

Overhead valve of pulp digester

The invention relates to an overhead valve of a pulp digester, which comprises a valve body, a valve seat, a valve stem, a ball, a bonnet, a seal part and a mounting part. The valve seat is fixedly mounted in a valve inlet passage and the ball is mounted in a floating manner. The overhead valve is characterized in that the valve seat is embedded in an annular vertical groove on the side wall of the inlet passage of the valve body to effectively prevent medium impurity entering the back of the valve seat, a seal pretension force regulator is arranged on the valve stem, the ball is pushed to besealed with the valve seat by regulating adjustable bolts of the seal pretention force regulator, and accordingly the sealing performance of the ball valve in a low-pressure state is improved. The overhead valve has the advantages of stability and reliability in running, excellent sealing performance and the like, and is suitable to be used as a control valve at a feed inlet of a batch digester in the paper making process.

Owner:浙江伯特利科技股份有限公司

Direct lever overhead valve system

Owner:BRIGGS & STRATTON

Overhead valve actuation mechanism for engine

ActiveUS10253658B2Effective regulationSimple configurationValve drivesMachines/enginesCylinder headEngineering

Owner:SUZUKI MOTOR CORP

Multimode full overhead valve two-stroke internal combustion engine using two-stroke Atkinson cycle

InactiveCN103233789BValve arrangementsInternal combustion piston enginesExhaust valveVariable valve timing

The invention discloses a multi-mode two-stroke atkinson cycle internal-combustion engine with a fully overhead valve. According to two-stroke atkinson cycle, a scavenging process is offset on the basis of the two-stroke cycle, the distance of a compression stroke is reduced, and the distance of an expansion stroke is prolonged, and therefore, the atkinson cycle is realized and the balance of the internal-combustion engine is kept. On the basis of a common two-stroke internal-combustion engine, the multi-mode two-stroke atkinson cycle internal-combustion engine adopts an overhead embedded inlet valve with large gradient degree and an air cylinder head structure of a common exhaust valve, when the inlet valve is opened, the inlet valve temporarily serves as a separation board, a guiding function of a bulge on a formed top piston is utilized, so that a high-efficiency scavenging structure is realized; a fully variable valve timing mechanism is used to adjust the angle relation of the valve and a crank shaft, the opening and closing time of the inlet and outlet valve can be adjusted, and therefore, the internal-combustion engine has the following working modes: two-stroke atkinson cycle, two-stroke cycle and adjustable discharge capacity and compression ratio; and the efficiency of the internal-combustion engine is greatly improved.

Owner:朱譞晟

Overhead valve of pulp digester

The invention relates to an overhead valve of a pulp digester, which comprises a valve body, a valve seat, a valve stem, a ball, a bonnet, a seal part and a mounting part. The valve seat is fixedly mounted in a valve inlet passage and the ball is mounted in a floating manner. The overhead valve is characterized in that the valve seat is embedded in an annular vertical groove on the side wall of the inlet passage of the valve body to effectively prevent medium impurity entering the back of the valve seat, a seal pretension force regulator is arranged on the valve stem, the ball is pushed to besealed with the valve seat by regulating adjustable bolts of the seal pretention force regulator, and accordingly the sealing performance of the ball valve in a low-pressure state is improved. The overhead valve has the advantages of stability and reliability in running, excellent sealing performance and the like, and is suitable to be used as a control valve at a feed inlet of a batch digester in the paper making process.

Owner:ZHEJIANG BETHEL TECH CO LTD

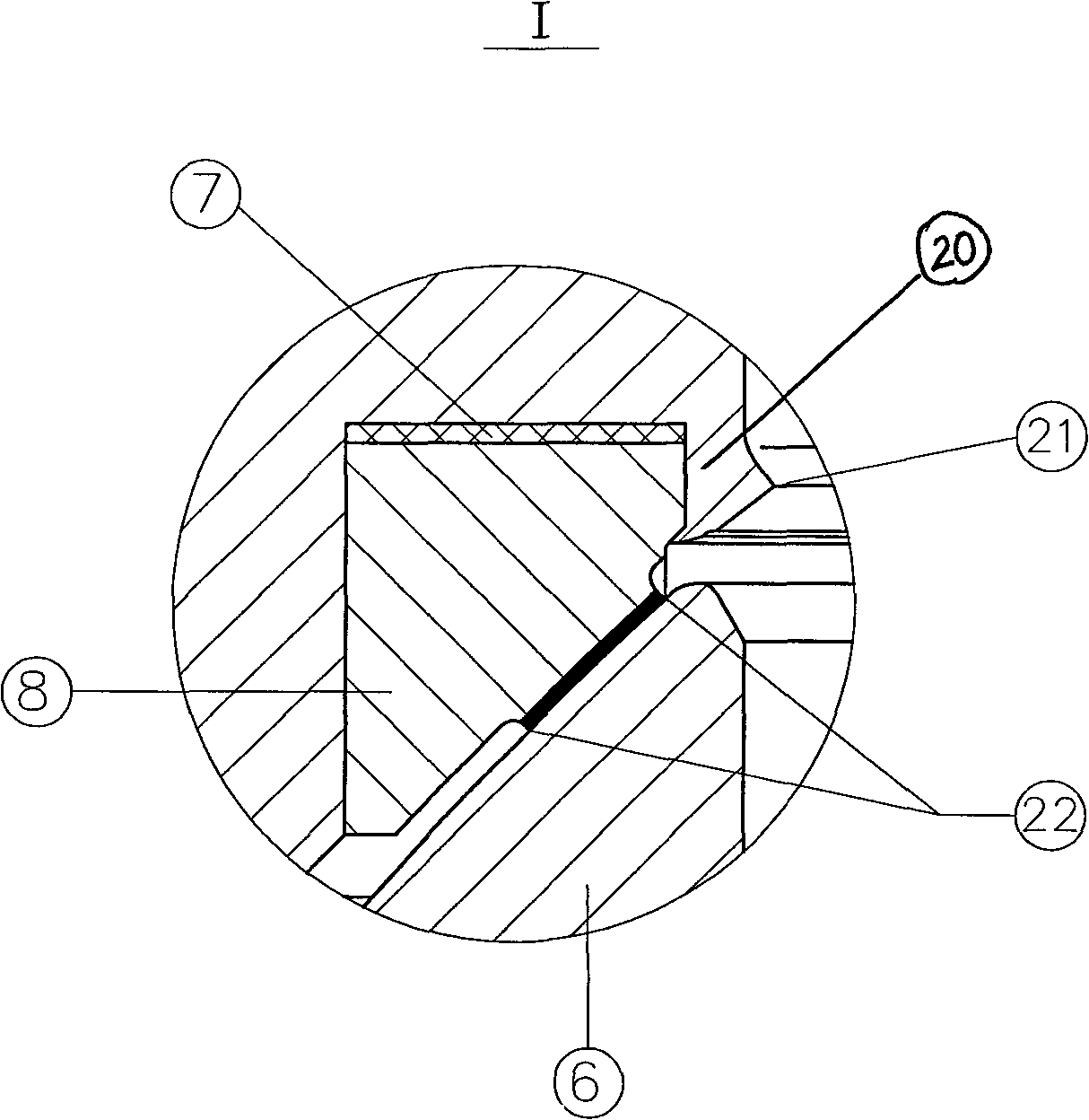

Top-mounted valve engine

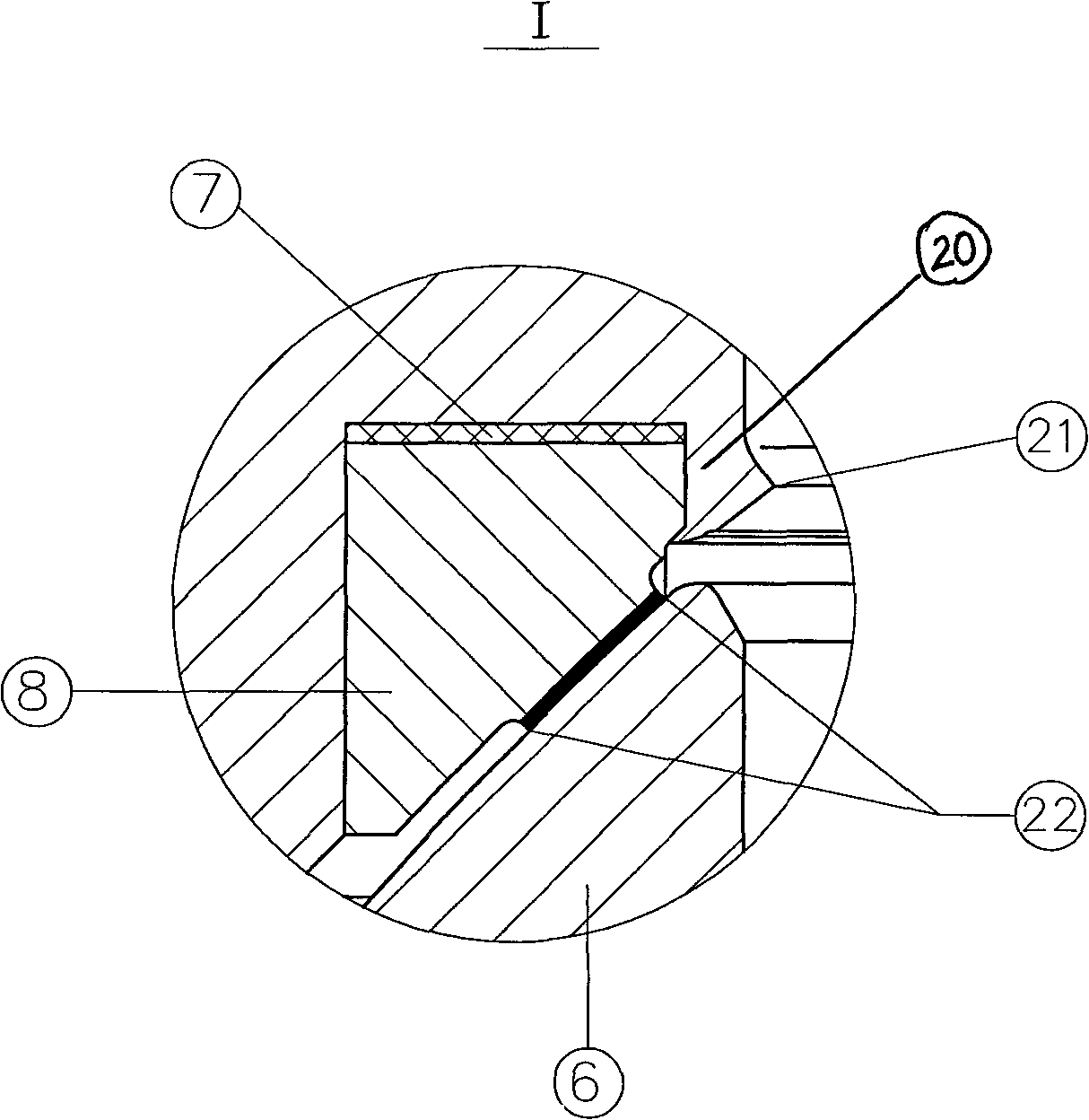

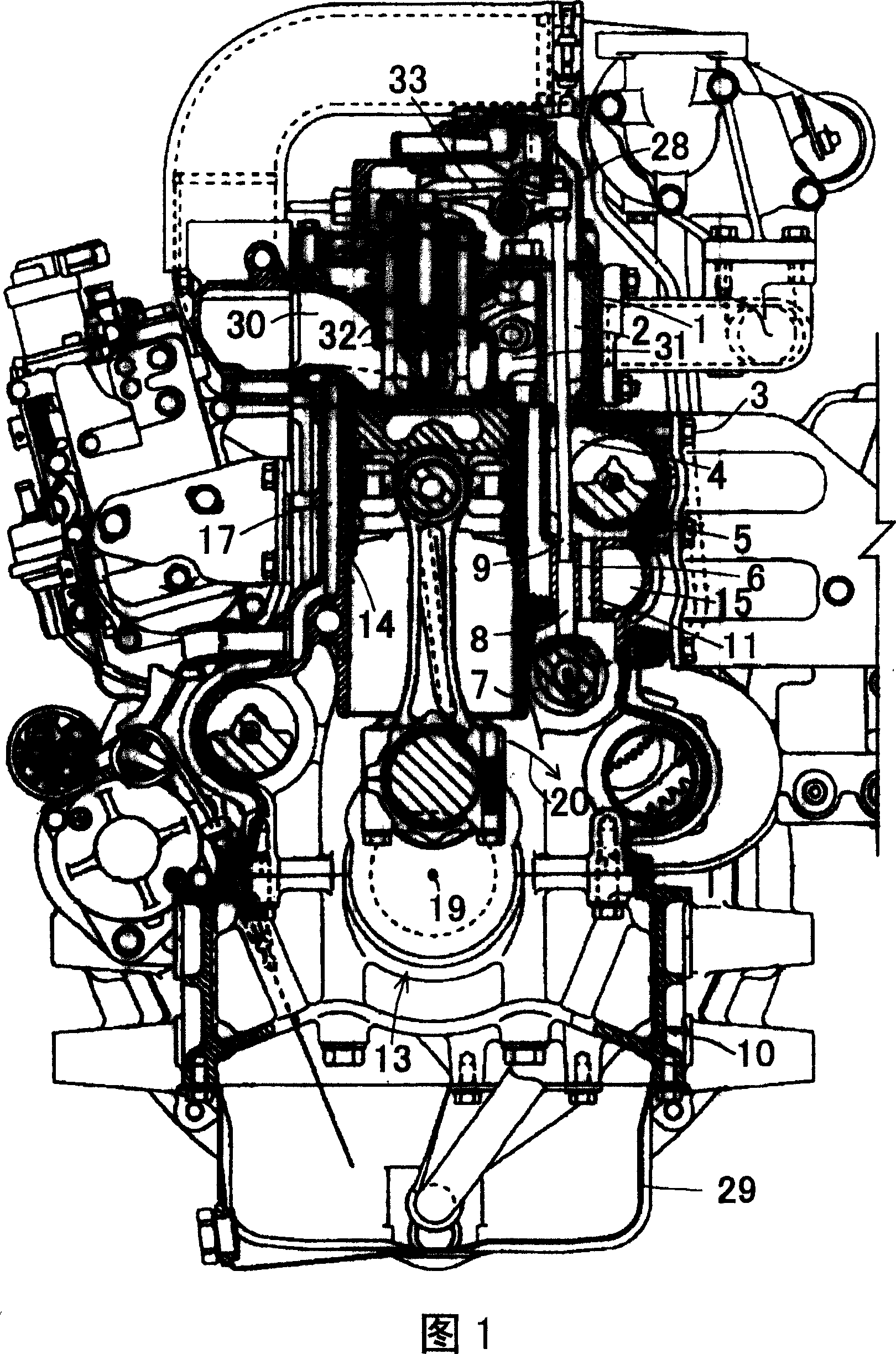

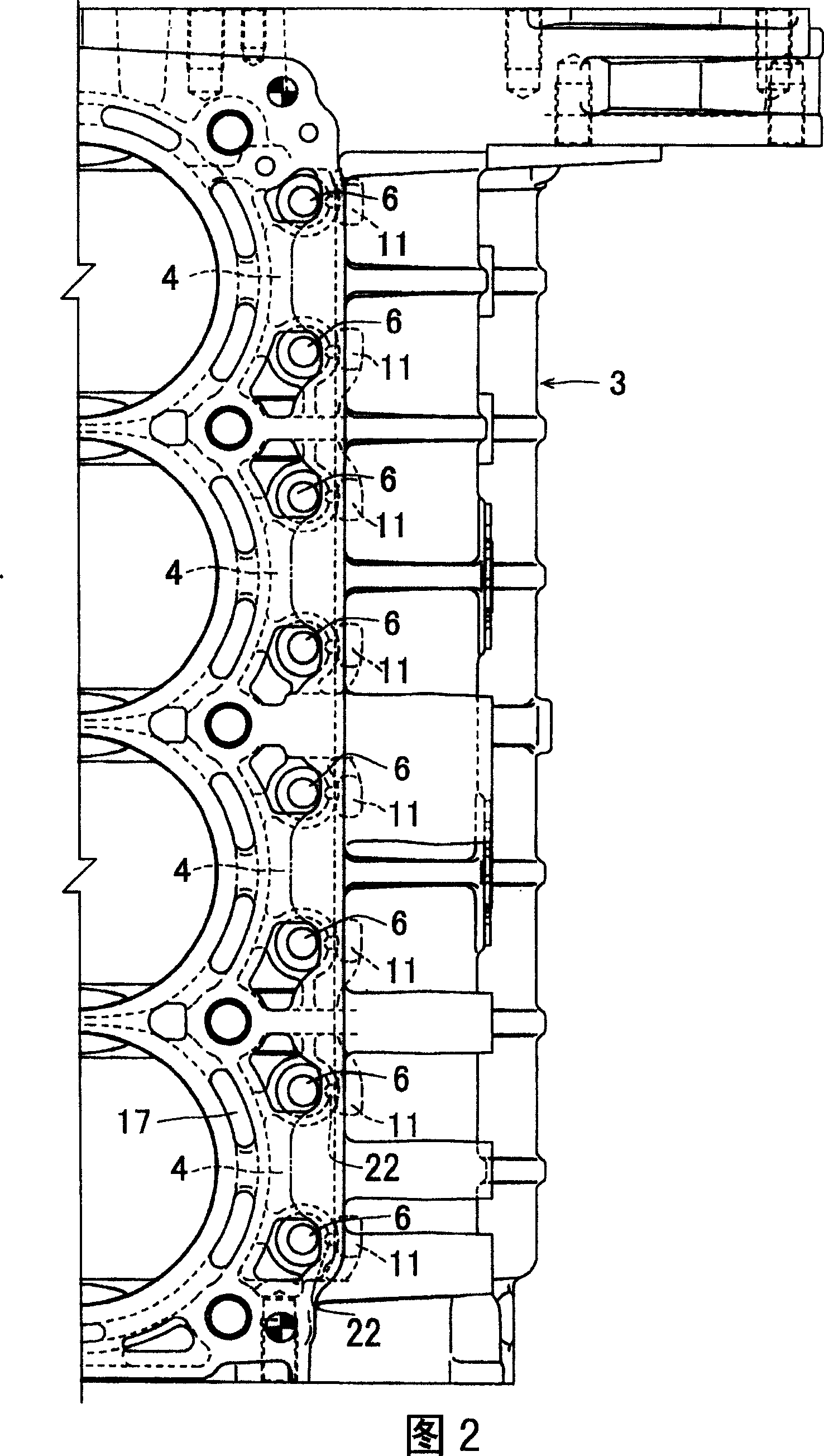

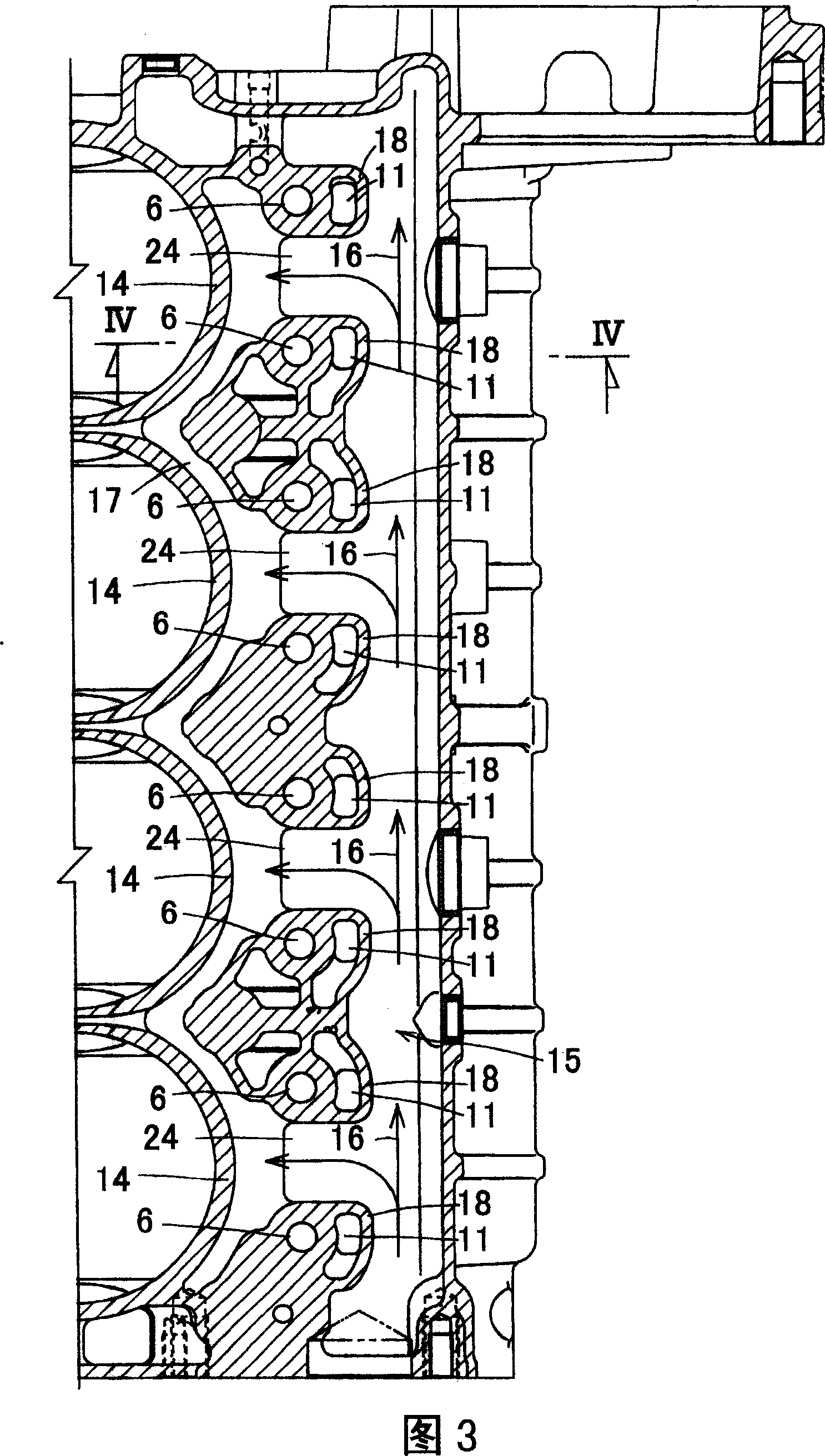

To provide an overhead valve engine having improved lubricating performance between a valve cam and a tappet. In the overhead valve engine, a tappet guide hole 6 is provided downward from a bottom wall 5 of a push rod insertion chamber 4, the valve cam 7 is arranged on the lower side of the tappet guide hole 6 for guiding the tappet 8 placed on the valve cam 7 so as to be moved up and down via the tappet guide hole 6, a push rod 9 placed on the tappet 8 is serially inserted into the push rod insertion chamber 4 and a push rod insertion hole 2, and an oil flow-out hole 11 is provided in a range from the bottom wall 5 of the push rod insertion chamber 4 into a crank case 10. An outlet 11a of the oil flow-out hole 11 is opened to the upper side of the cam face of the valve cam 7 so that oil 12 flowing out of the outlet 11a of the oil flow-out hole 11 falls on the cam face of the valve cam 7.

Owner:KUBOTA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com