Range extender engine structure

An engine and range extender technology, which is applied to machines/engines, engine components, engine sealing devices, etc., can solve the problems of severe vibration, service life and high fuel consumption, and achieve the effects of long service life, low fuel consumption, and reduced operating noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

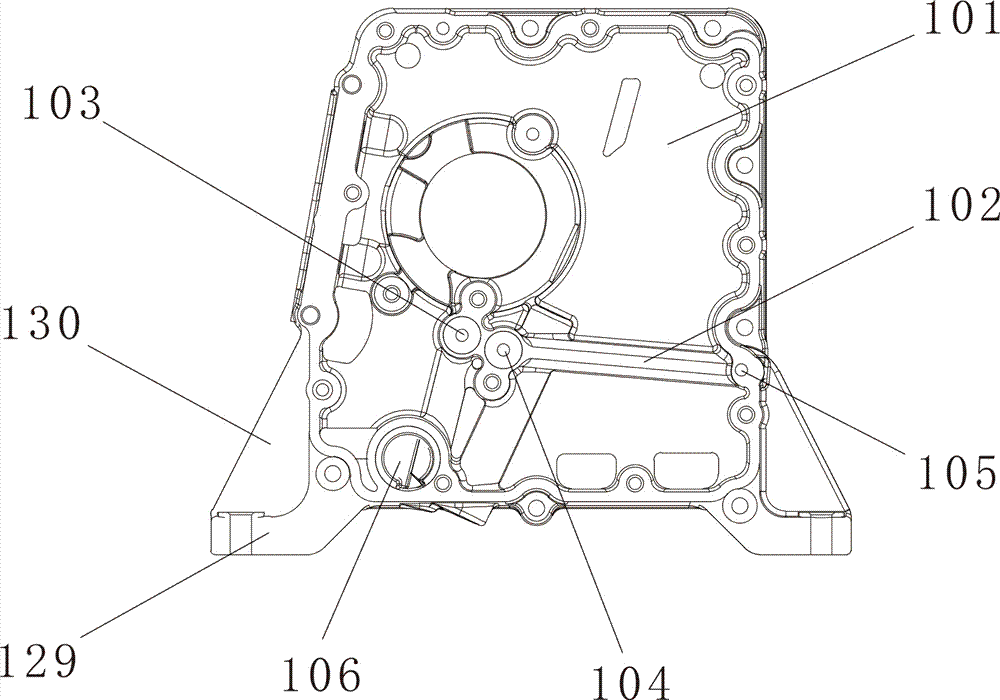

[0028] A range extender engine structure, including a crankcase part, a cylinder block part and a cylinder head part:

[0029] Depend on Figure 1 to Figure 5 As shown, the crankcase part includes a left crankcase cover and a right crankcase cover; the left crankcase cover includes a left crankcase cover 101 and an integrated oil supply structure arranged on the left crankcase cover 101, so The integrated oil supply structure includes an oil pipeline 102, an oil pump inlet hole 103, an oil pump outlet hole 104, a box oil outlet hole 105 and a filter installation groove 106; the oil pump outlet hole 104 and the box body outlet The oil hole 105 communicates with the integrated oil pipeline 102, and the filter installation groove 106 is arranged on the upper edge of the bottom edge of the left crankcase cover 101, and is located at the lower side of the oil inlet hole 103 of the oil pump, and is used for installing the oil filter. device. The integrated oil supply structure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com