Vertical lifting container

A vertical lifting and container technology, applied in the directions of transportation, packaging, storage devices, etc., can solve problems such as the inability to quickly place or take out the goods, the transmission accuracy requirements cannot be met, and the efficiency of the goods transportation is affected, so as to avoid shaking and maintenance. Fast, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

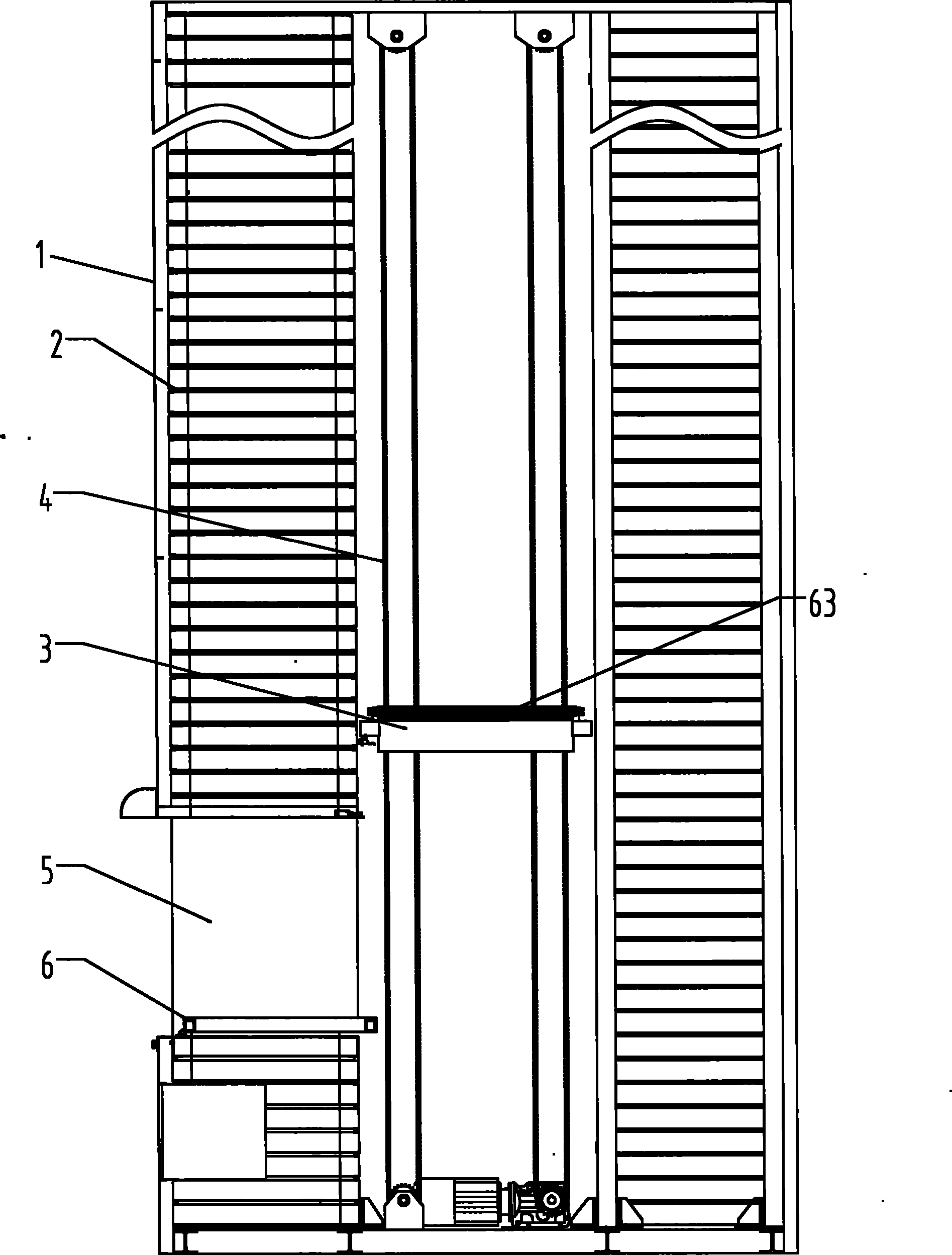

[0024] Such as figure 1 As shown, a vertical lifting container of the present invention comprises a cabinet body 1, and the two sides of the cabinet body are provided with corbels 2 for placing trays 6, and there is a lifting platform 3 running up and down between the corbels 2 on both sides of the cabinet body 1. In the channel, the lifting platform 3 is suspended in the channel by the lifting chain 4. One side of the cabinet body 1 is provided with a delivery port 5, and a pallet 6 for transporting goods in and out is arranged in the delivery port 5; the driving device drives the pallet 6 to move in translation.

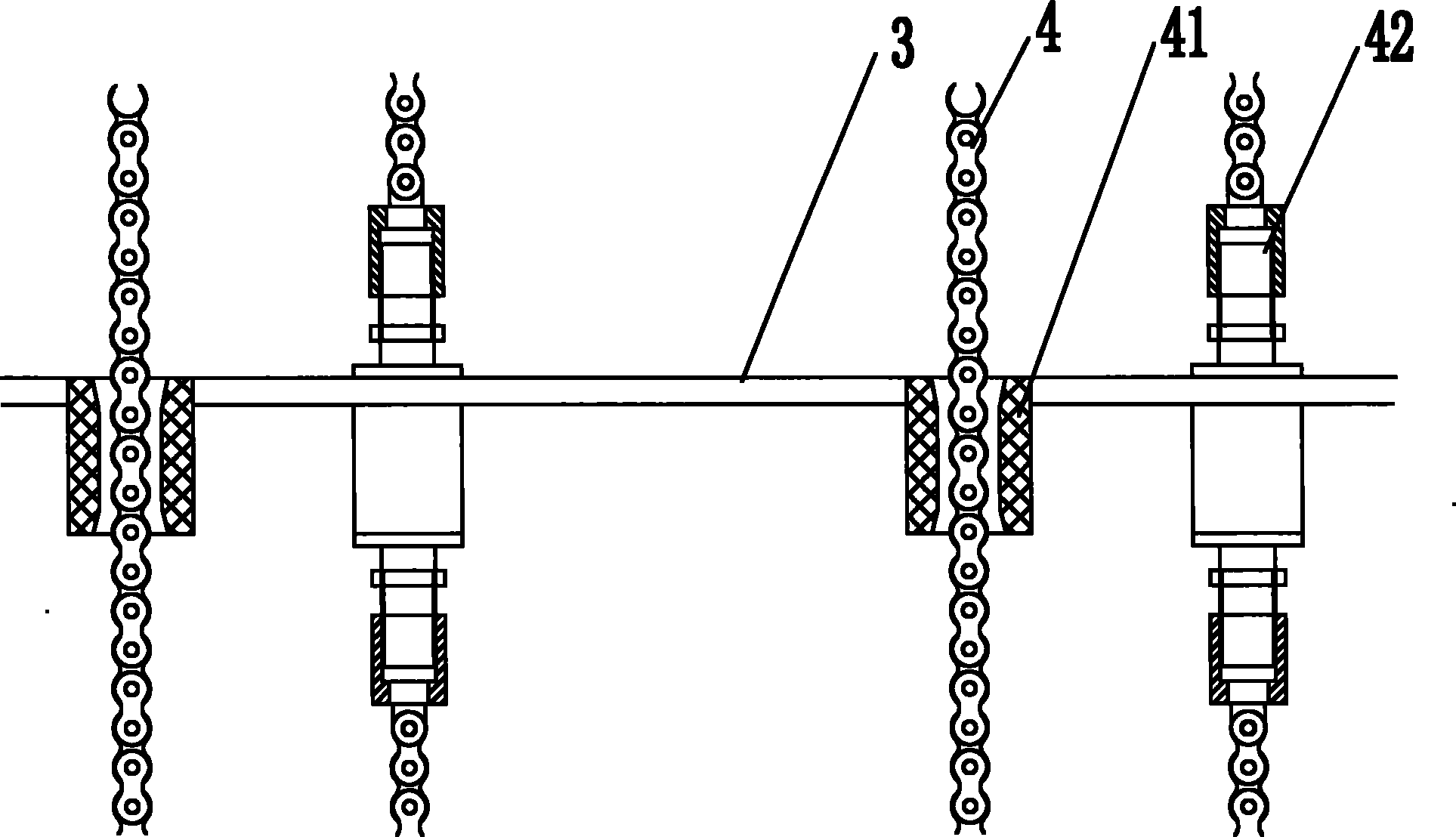

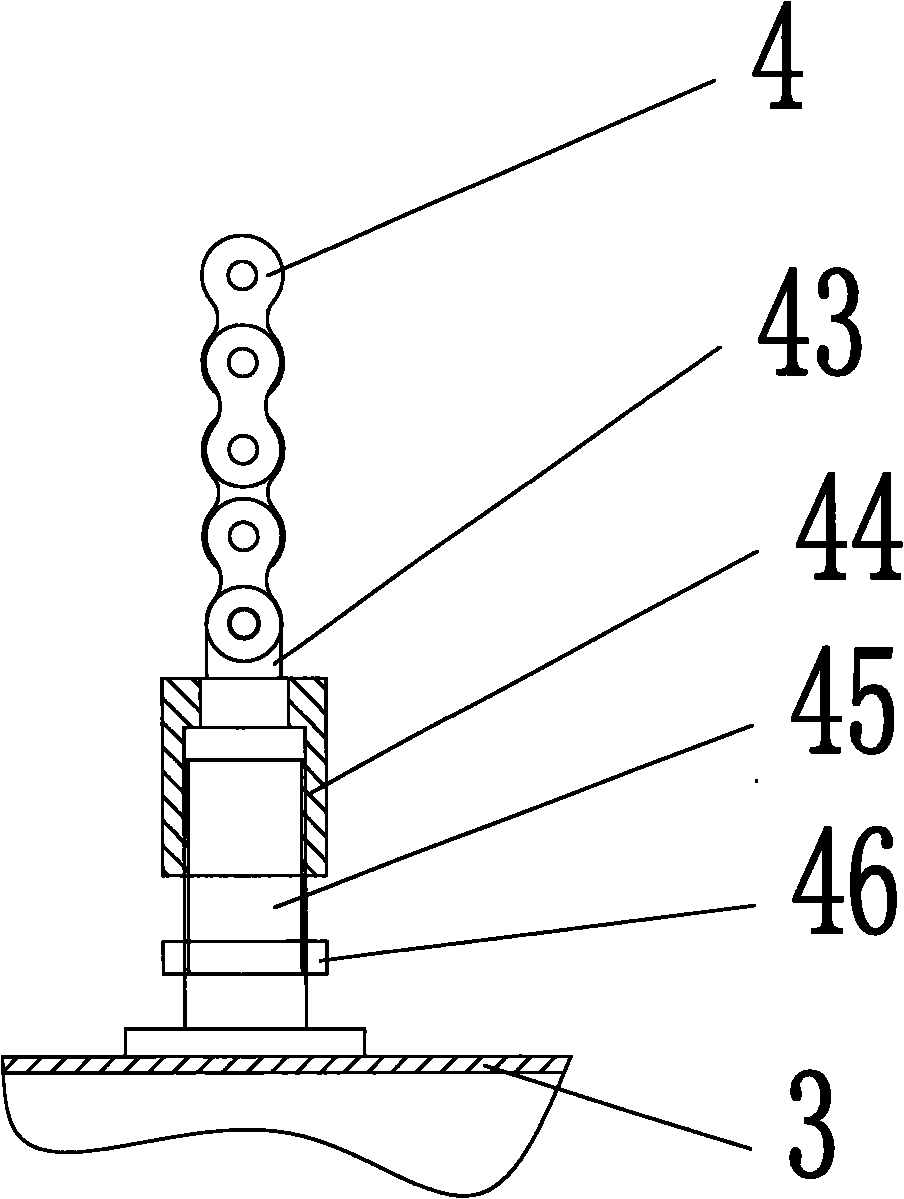

[0025] Such as figure 2 As shown, four corners of the lifting platform 3 are respectively provided with four chain suspension devices 41, the two ends of the lifting chain 4 are fixed by the chain suspension device 42, and the middle part of the chain sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com