Piston engine comprising member to cover bottom face of valve head of poppet valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0069]A first embodiment will be described.

[0070]The first embodiment is included in the first aspect.

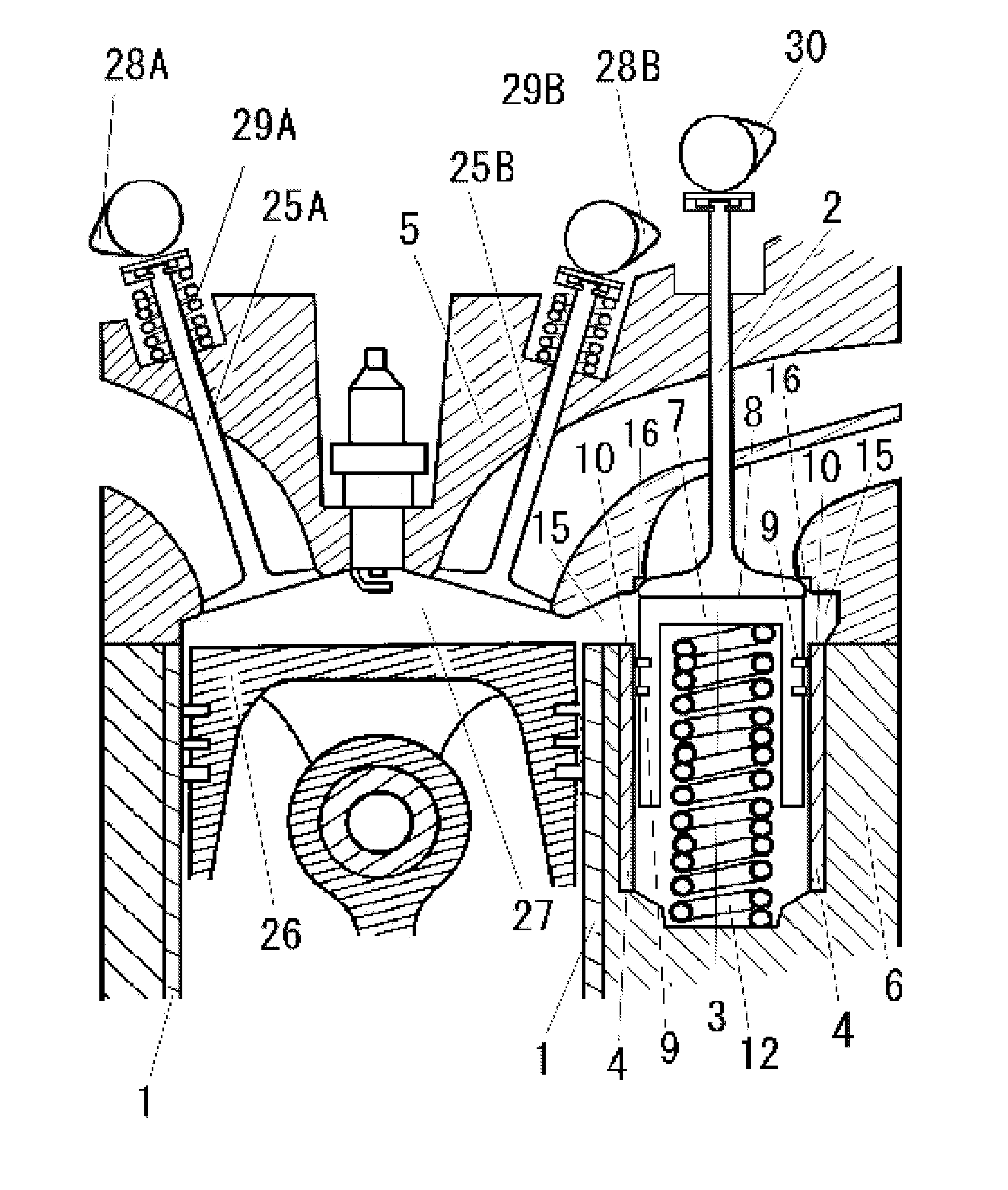

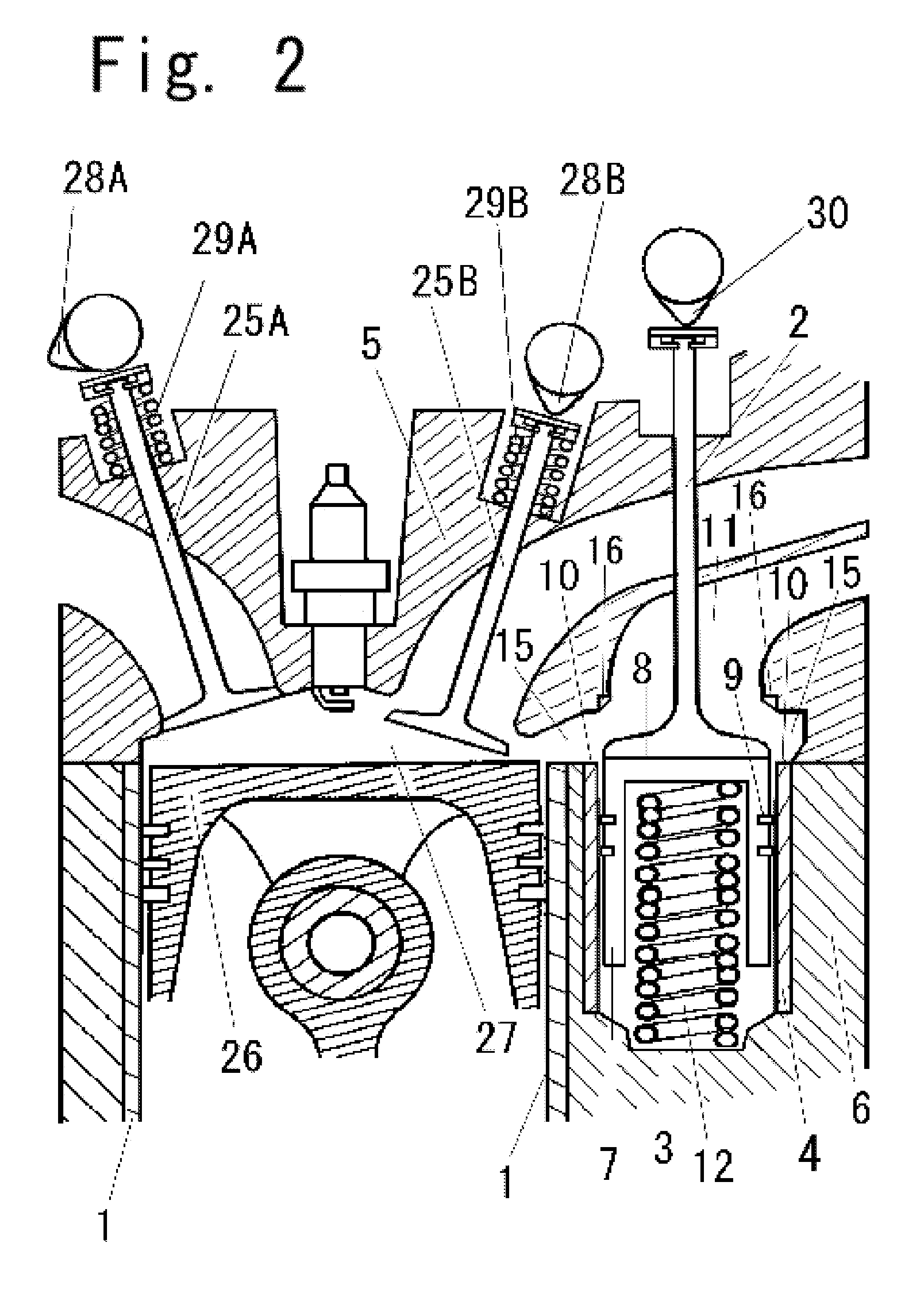

[0071]A piston engine shown in FIGS. 1 and 2 comprises a cylinder head 5, a cylinder block 6, a main cylinder 1, a piston 26, a sub cylinder 4, overhead valves 25A and 25B, and a poppet valve 2.

[0072]The piston 26 reciprocates in the main cylinder 1. A combustion chamber 27 is defined between the cylinder head 5 and the piston 26. The combustion chamber 27 further extends outside the main cylinder 1. An inner wall of the combustion chamber 27 comprises a first part and a second part. The first part represents the inner wall which faces with an upper face of the piston 26. The second part represents the inner wall of the extended part outside the main cylinder 1.

[0073]The combustion chamber 27 may extend both right and left sides outside the main cylinder 1.

[0074]The sub cylinder 4 is installed in the cylinder block 6 which locates outside the main cylinder 1.

[0075]The overhead valve...

second embodiment

[0125]The second embodiment will be described.

[0126]In FIG. 4, the sub cylinder 4 is provided in the cylinder head 5. In this case, the gas path contacting with the poppet valve 2 is provided in the cylinder block. The poppet valve 2 provided outside the cylinder is a side valve.

third embodiment

[0127]The third embodiment will be described.

[0128]In FIG. 5, a pneumatic unit, hydraulic unit 19, electromagnetic unit or electric unit is employed in place of the spring 12. These units bias the valve cover 7 so that the upper face 8 presses the bottom face of the poppet valve 2. These units and the third spring 12 are to bias the valve cover 7 toward the valve sheet 16.

[0129]In FIG. 5, the compression ring 9 is subject to the pressure of the combustion gas so that the valve cover is pushed downwards. The valve cover and the bottom face of the poppet valve are not separated from each other by the pressing force.

[0130]The above-described units including the hydraulic unit 19 bias the valve cover toward the valve sheet 16 of the poppet valve 2 with a force not less than this pressing force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com