Overhead valve of pulp digester

A digester and pulp technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of poor sealing performance, poor working reliability, easy leakage, etc., and achieve good sealing performance, stable and reliable operation, The effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

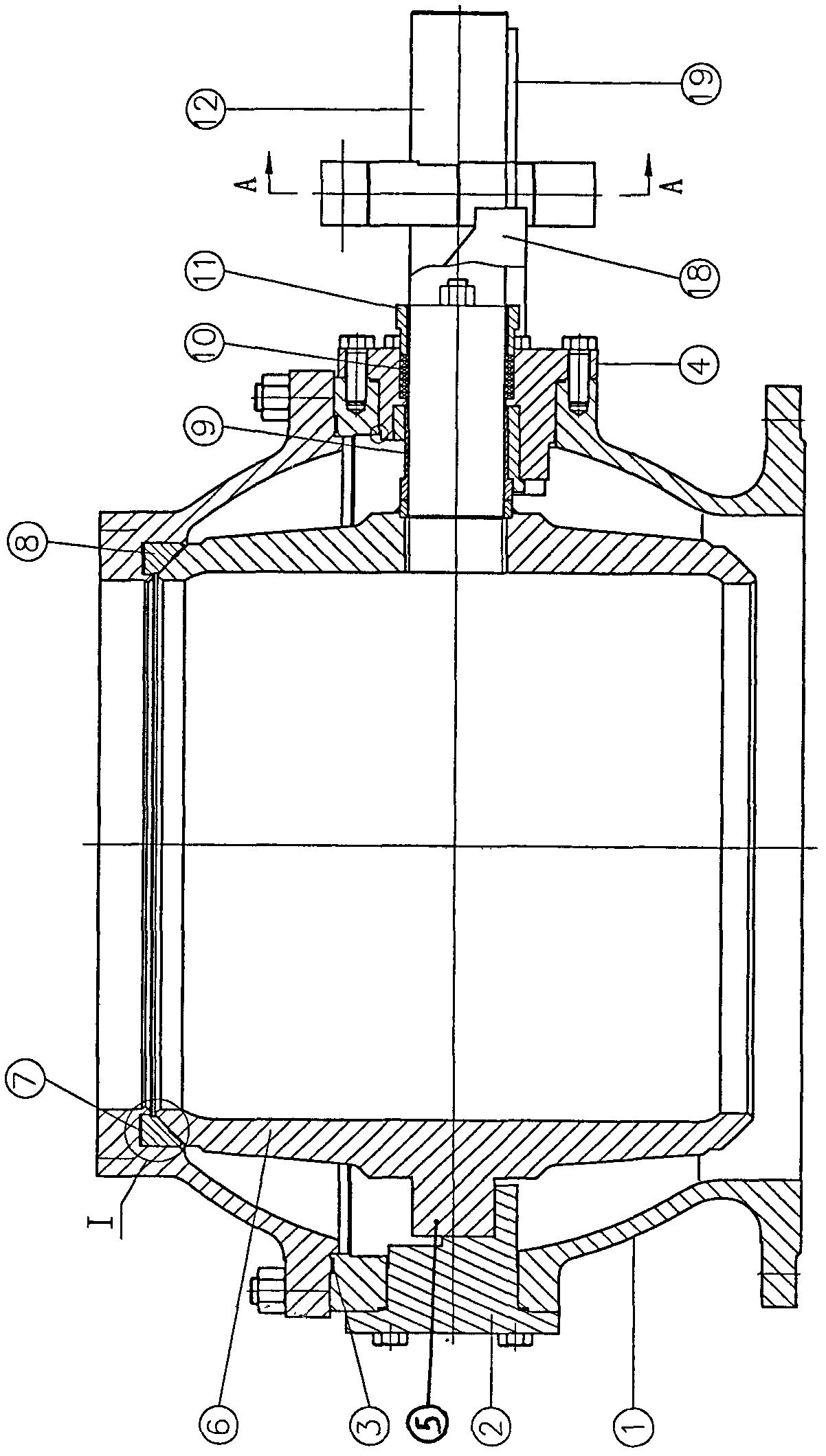

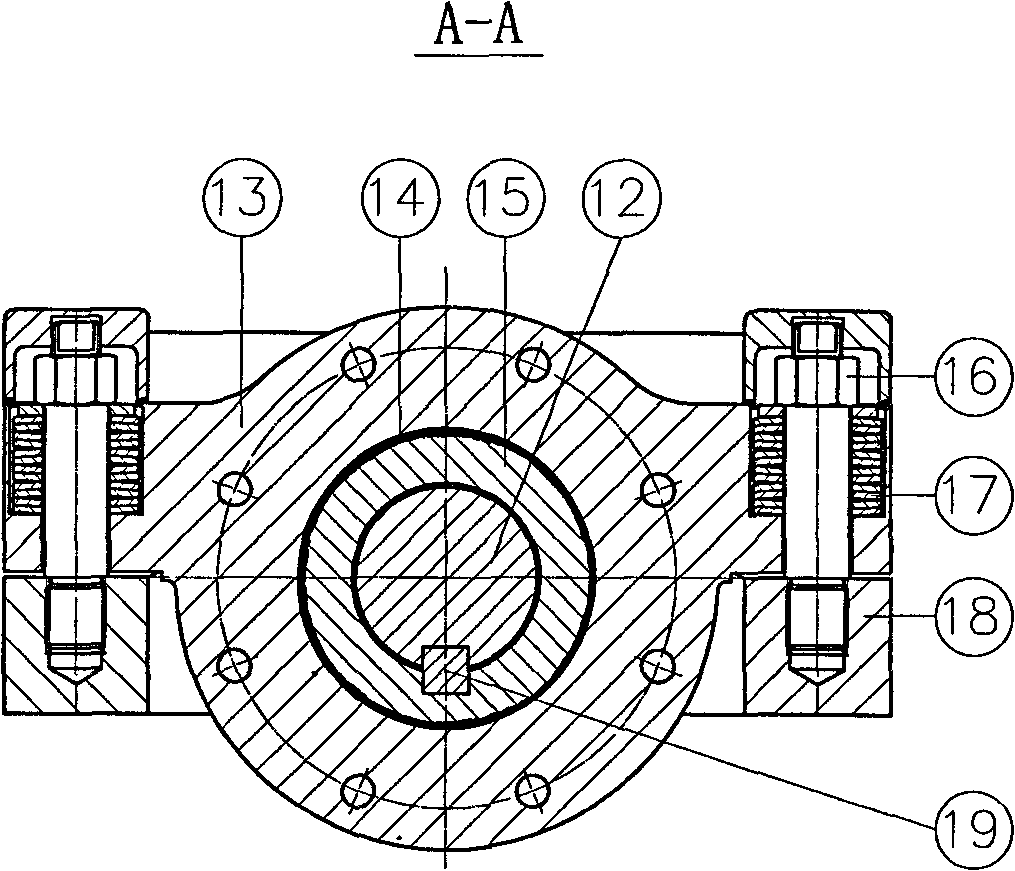

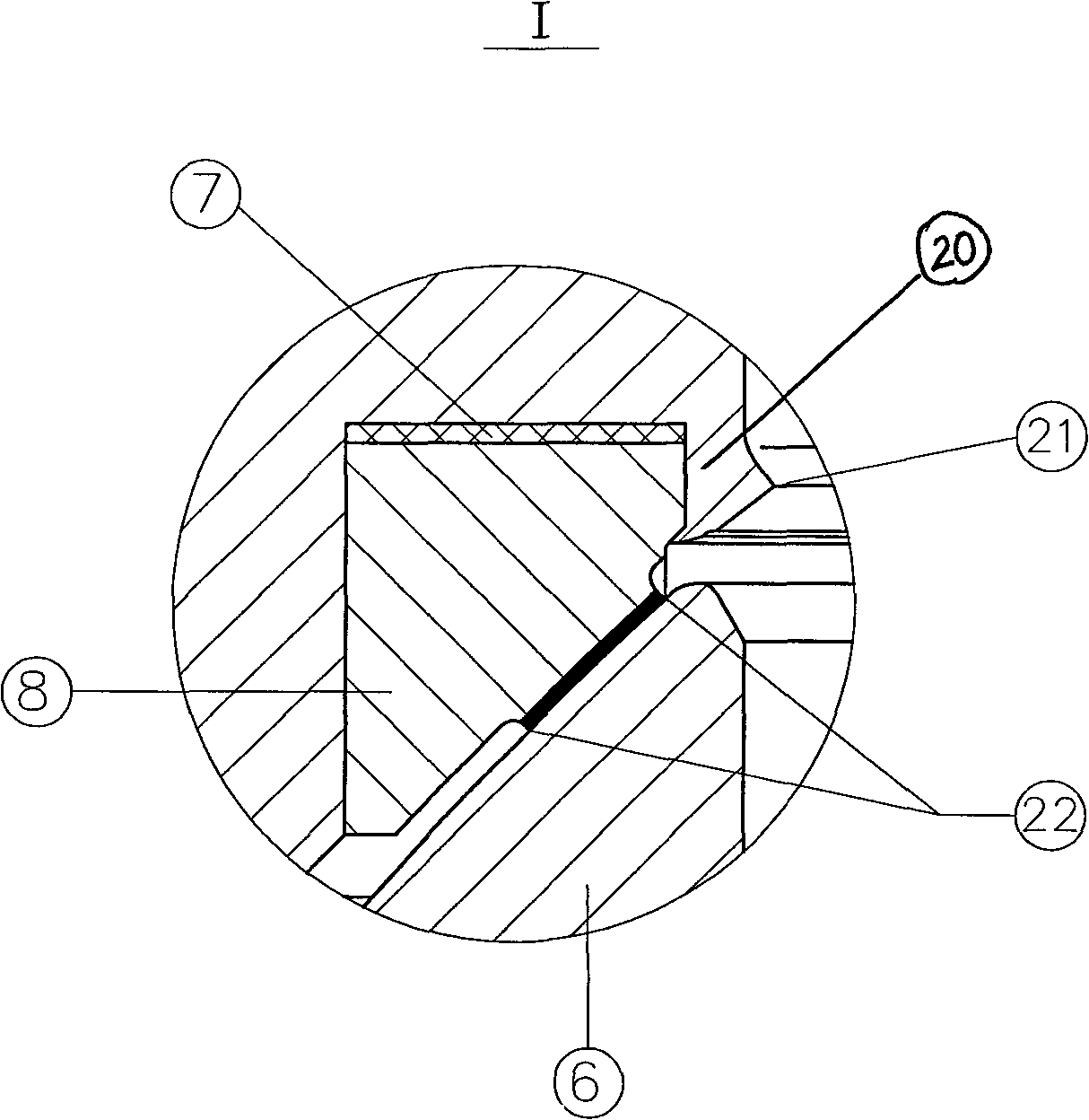

[0014] like figure 1 The pulp digester top valve shown includes a valve body 1, a valve seat 8, a valve stem 12, a ball 6, a valve cover 4, seals and mounting parts, the valve seat 8 is fixedly installed in the inlet channel of the valve body 1, and the ball 6 Floating installation is adopted, and the hard alloy sealing surface is surfacing on the valve seat 8. The hard alloy sealing surface has a sealing curved surface that cooperates with the sealing surface of the ball 6. The ball 6 is fixedly connected with the valve stem 12, and the valve stem 6 is connected to the valve cover. Between 4 there is a sleeve bearing 9 and a sealing device, the sealing device is composed of a sealing packing 10 pressed into the packing chamber between the bonnet 4, the valve stem 12 and the sleeve bearing 9 through the pressure ring 11. The valve seat 8 is embedded in the annular vertical groove on the side wall of the inlet passage of the valve body 1, and the inner groove wall 20 of the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com