Top-mounted valve engine

A technology of overhead valves and engines, which is applied to the lubrication of engine components, machines/engines, and engines, and can solve problems such as low lubrication and easy wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described below with reference to the accompanying drawings.

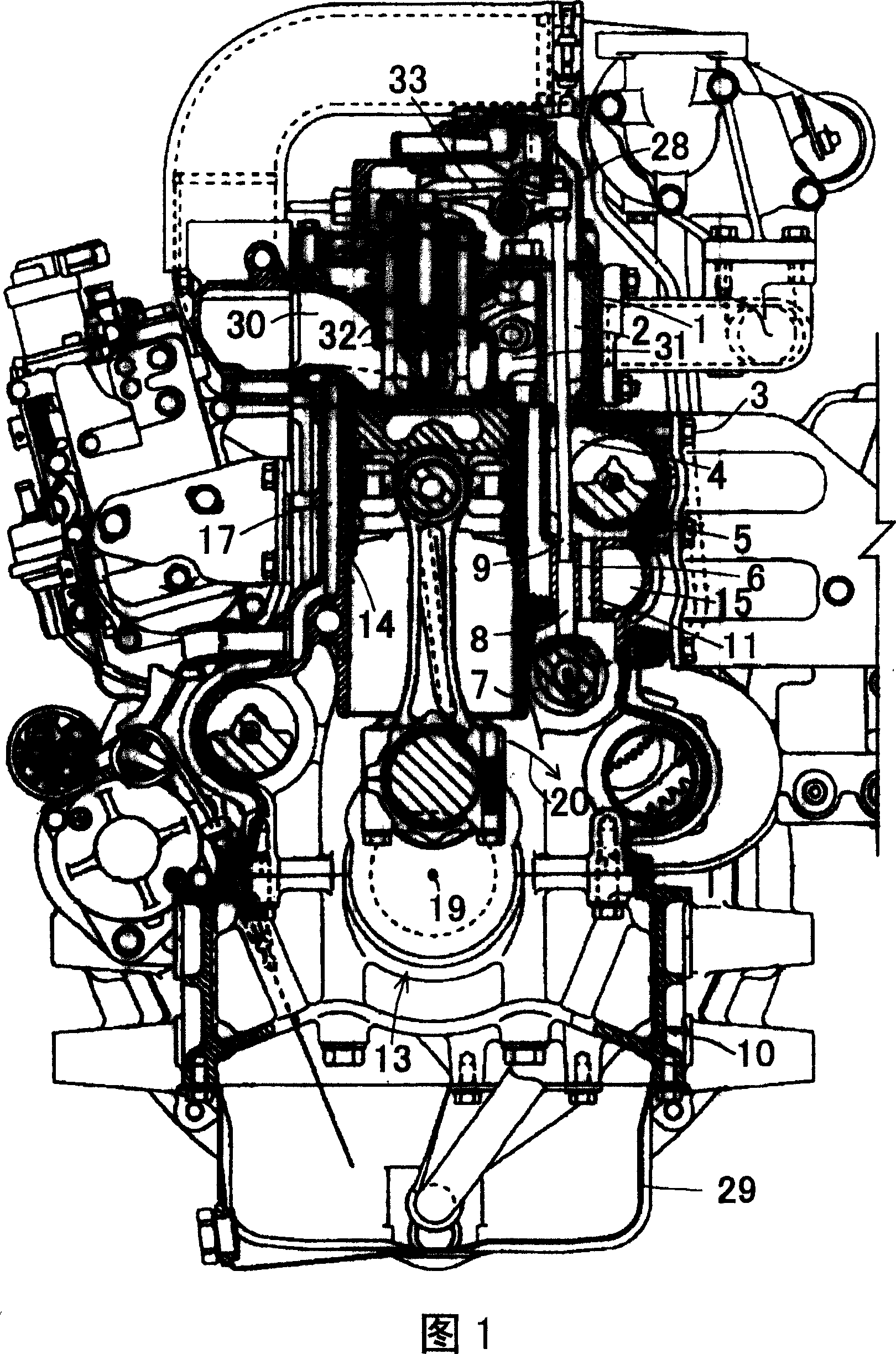

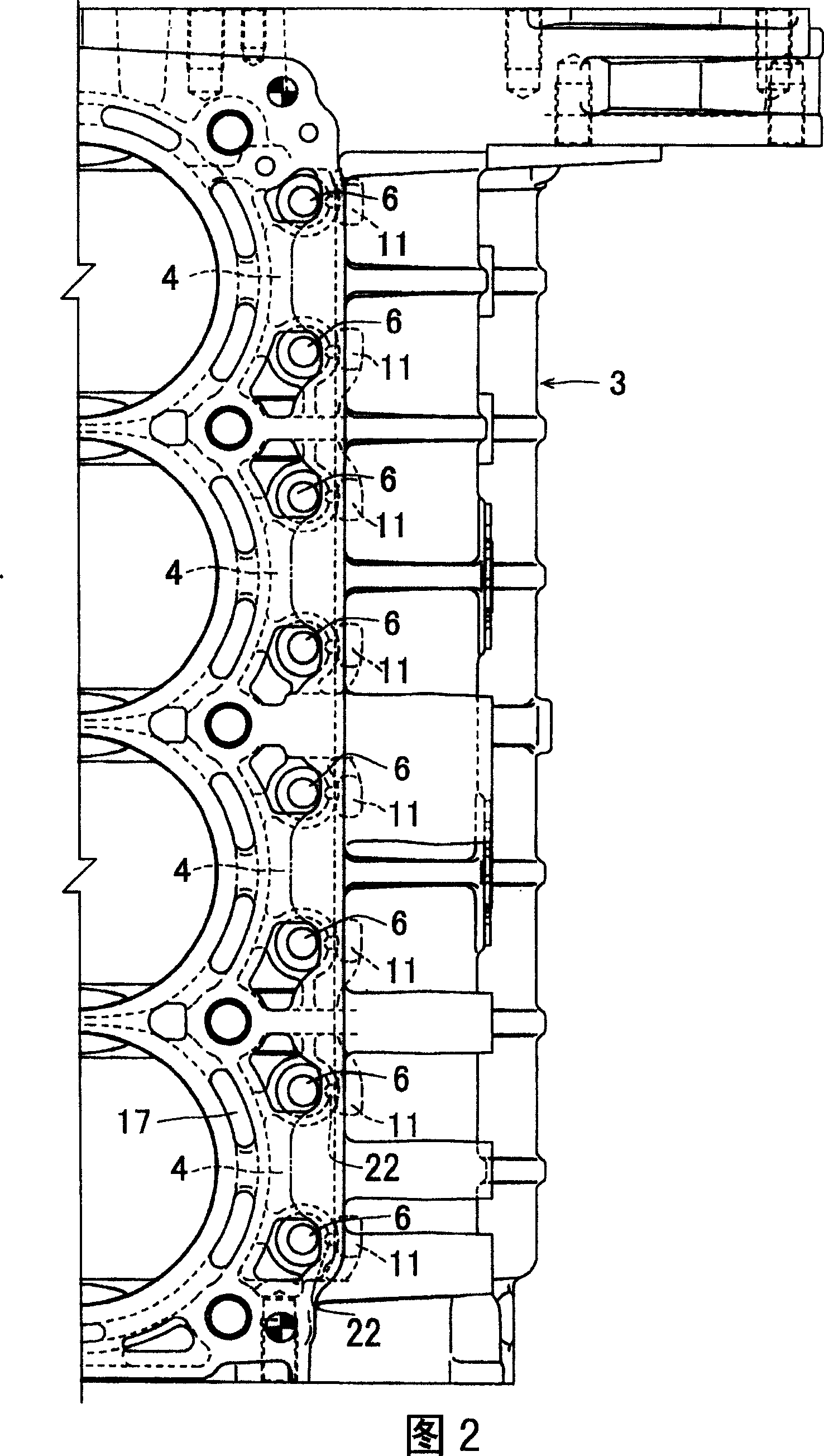

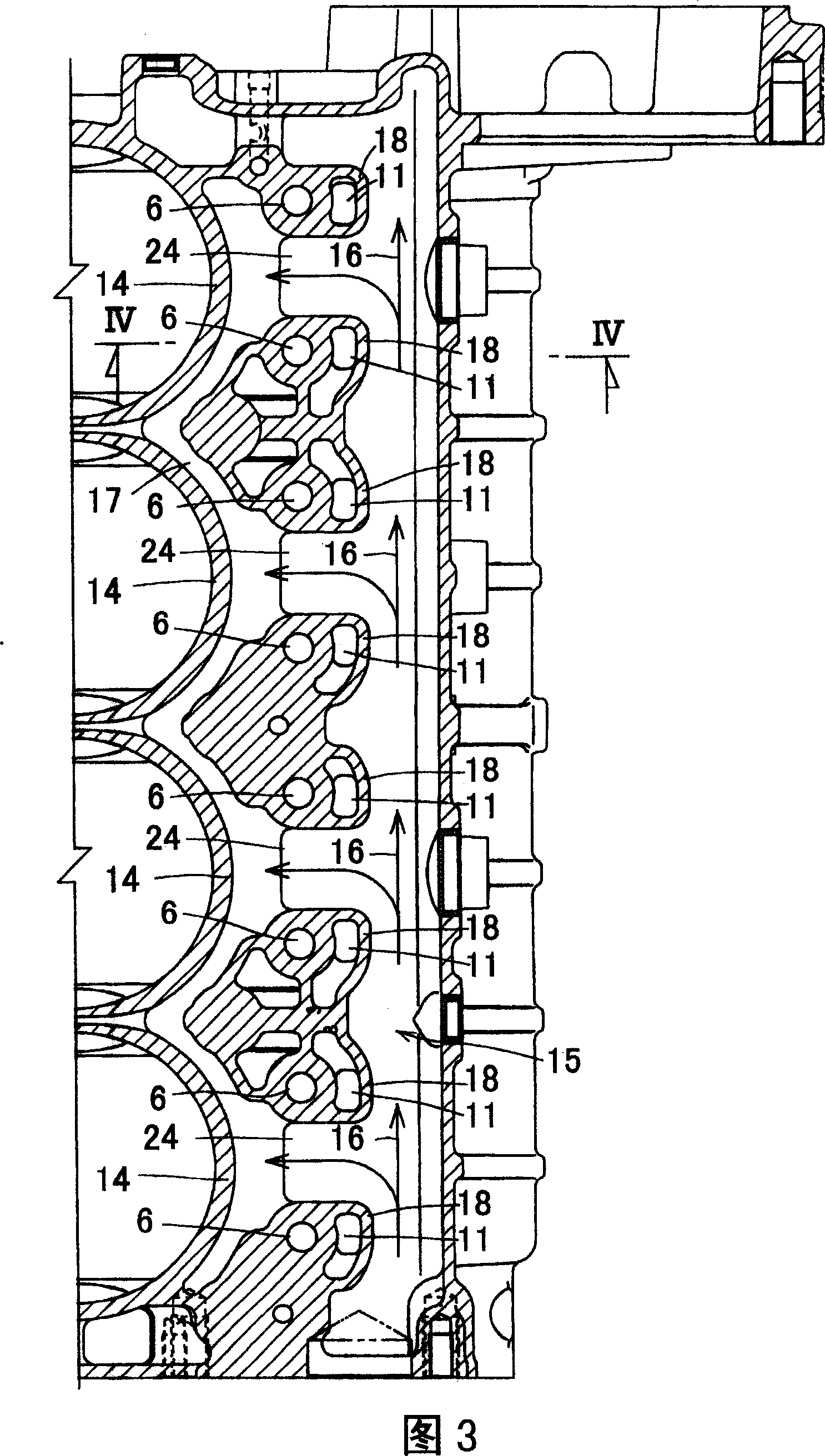

[0051] 1 to 4 show an overhead valve engine according to a first embodiment of the present invention. In this embodiment, a water-cooled multi-cylinder vertical overhead valve engine will be described.

[0052] The engine is outlined below:

[0053] As shown in FIG. 1 , the engine has a cylinder block 3 . The cylinder block 3 comprises an upper cylinder 14 and a lower crankcase 10, both forming a complete structure. The cylinder 14 is surrounded by a cylinder liner 17 . The cylinder head 1 is mounted on the top of the cylinder block 3 . A head cover 28 is mounted on the upper portion of the cylinder head 1 . An oil pan 29 is mounted on the lower portion of the crankcase 10 . The cylinder head 1 is formed with an intake port 30 and an exhaust port 31 . These port holes are opened and closed by intake valves 32 and exhaust valves (not shown). The intake valve 32 and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com