Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Ground food" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Regular table foods ground into a soft, fine texture, using a baby food grinder or food chopper. Crispy or crunchy foods are not acceptable. Minimal chewing is required (Source: Academy of Nutrition and Dietetics Nutrition Informatics Committee 2013).

Acidified milk powder fed to calves as well as preparation method of acidified milk powder and feeding method of calves

ActiveCN105053209ACompatible with pH rangeGood storage stabilityMilk preparationAnimal feeding stuffBiotechnologyAnimal science

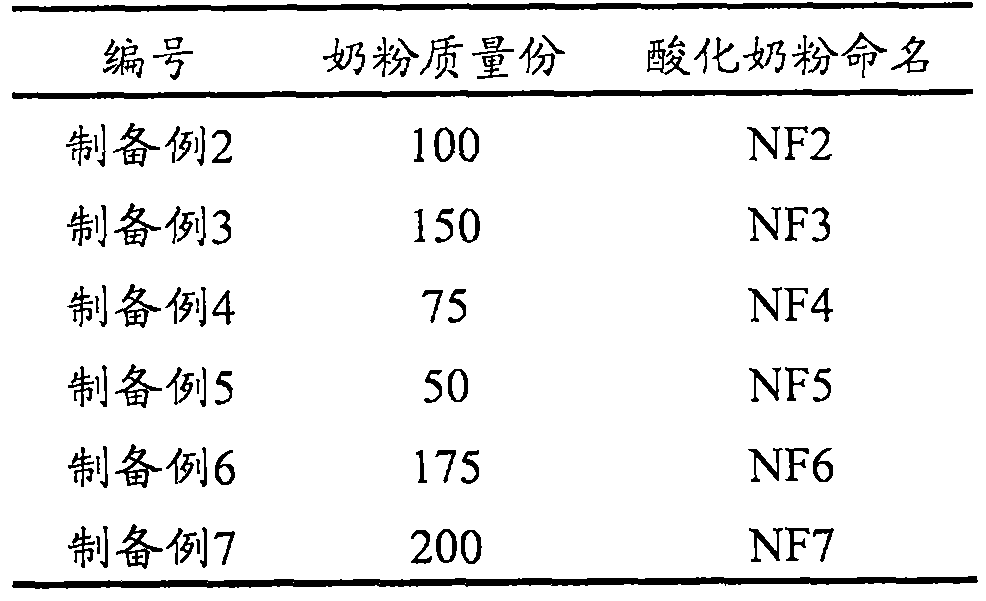

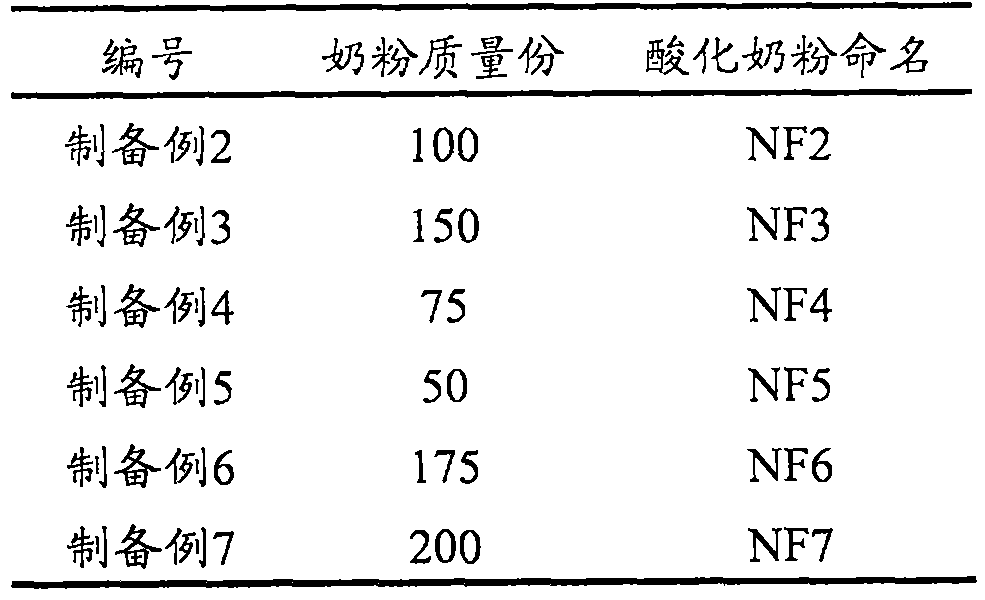

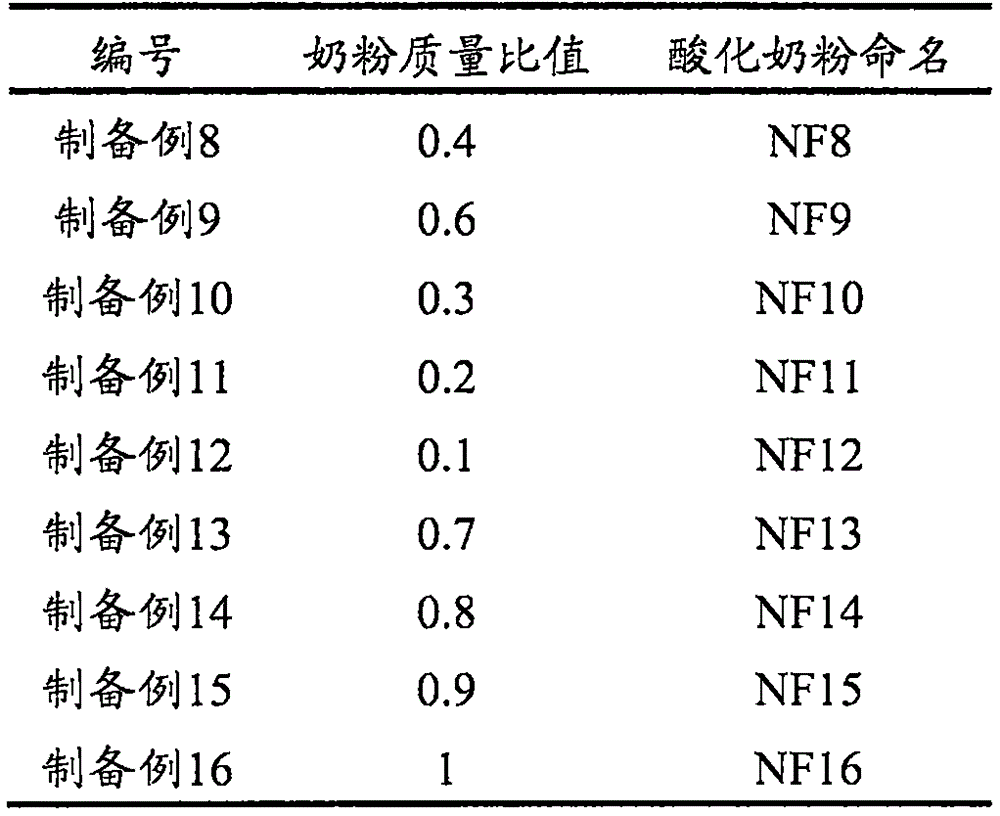

The invention provides acidified milk powder fed to calves as well as a preparation method of the acidified milk powder and a feeding method of the calves. The preparation method comprises the following steps: A1: respectively weighing milk powder and food-grade solid formic acid, grinding the weighed food-grade solid formic acid, and screening the ground food-grade solid formic acid through a 300-mesh sieve so as to obtain solid formic acid powder; and A2: under the condition that the temperature is below 8 DEG C, compounding the milk powder and the solid formic acid powder in the mass ratio of the milk powder to the solid formic acid powder being 50-200: 1, and thoroughly mixing the milk powder and the solid formic acid powder according to a specific mixing manner so as to obtain the acidified milk powder fed to the calves. The feeding method comprises the following steps: C1: firstly, preparing the acidified milk powder fed to the calves according to the preparation method; C2: pouring the acidified milk powder into water of which the temperature is 10-20 DEG C, and sufficiently stirring the acidified milk powder and the water until the acidified milk powder is melted so as to obtain acidified milk; and C3: supplying the acidified milk to the calves so that the calves freely drink the acidified milk. The acidified milk powder, the preparation method and the feeding method have quite important realistic significance and economic value in the field of breeding industry or dairy industry.

Owner:CHINTEM TECH CONSULTING BEIJING CO LTD

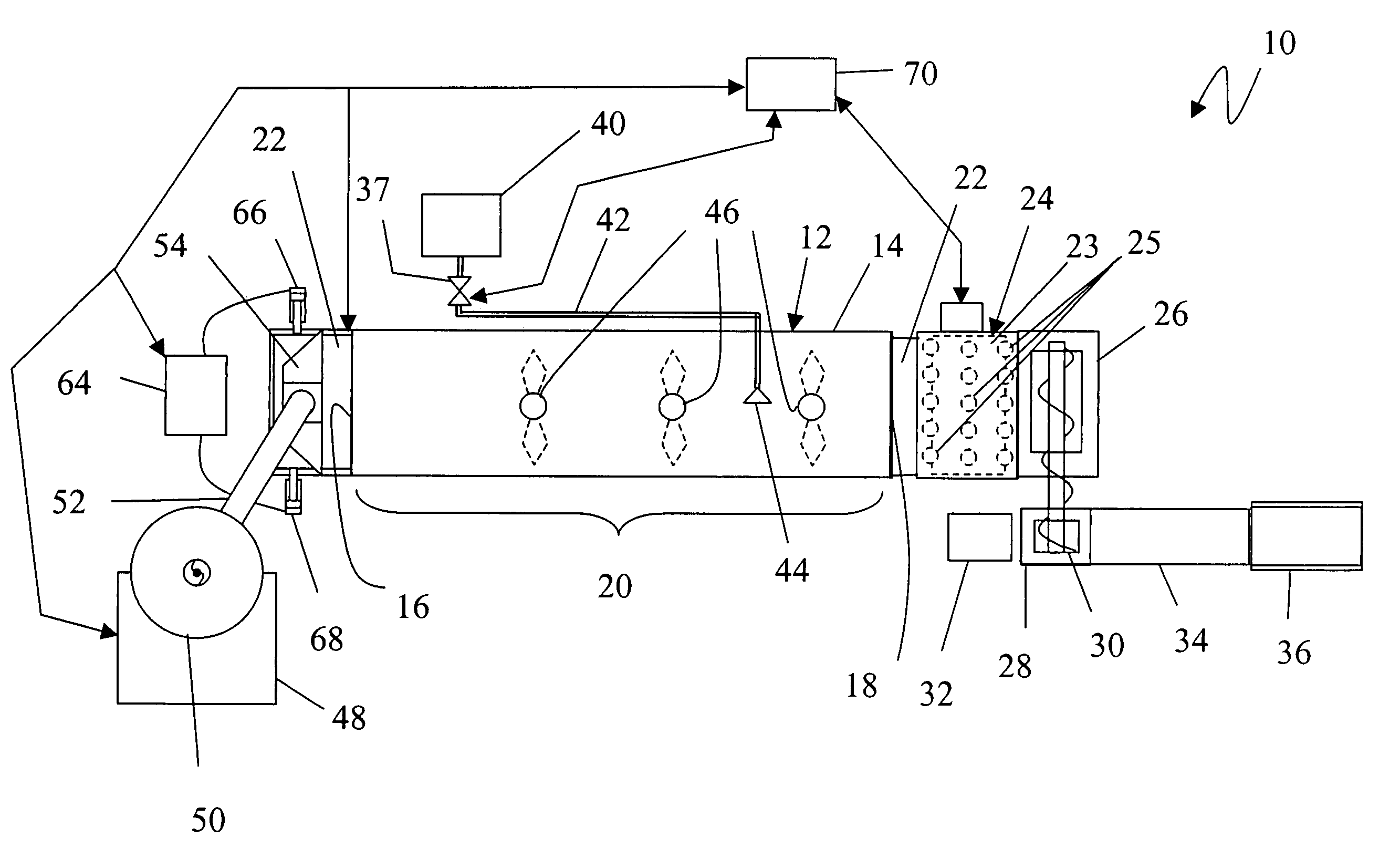

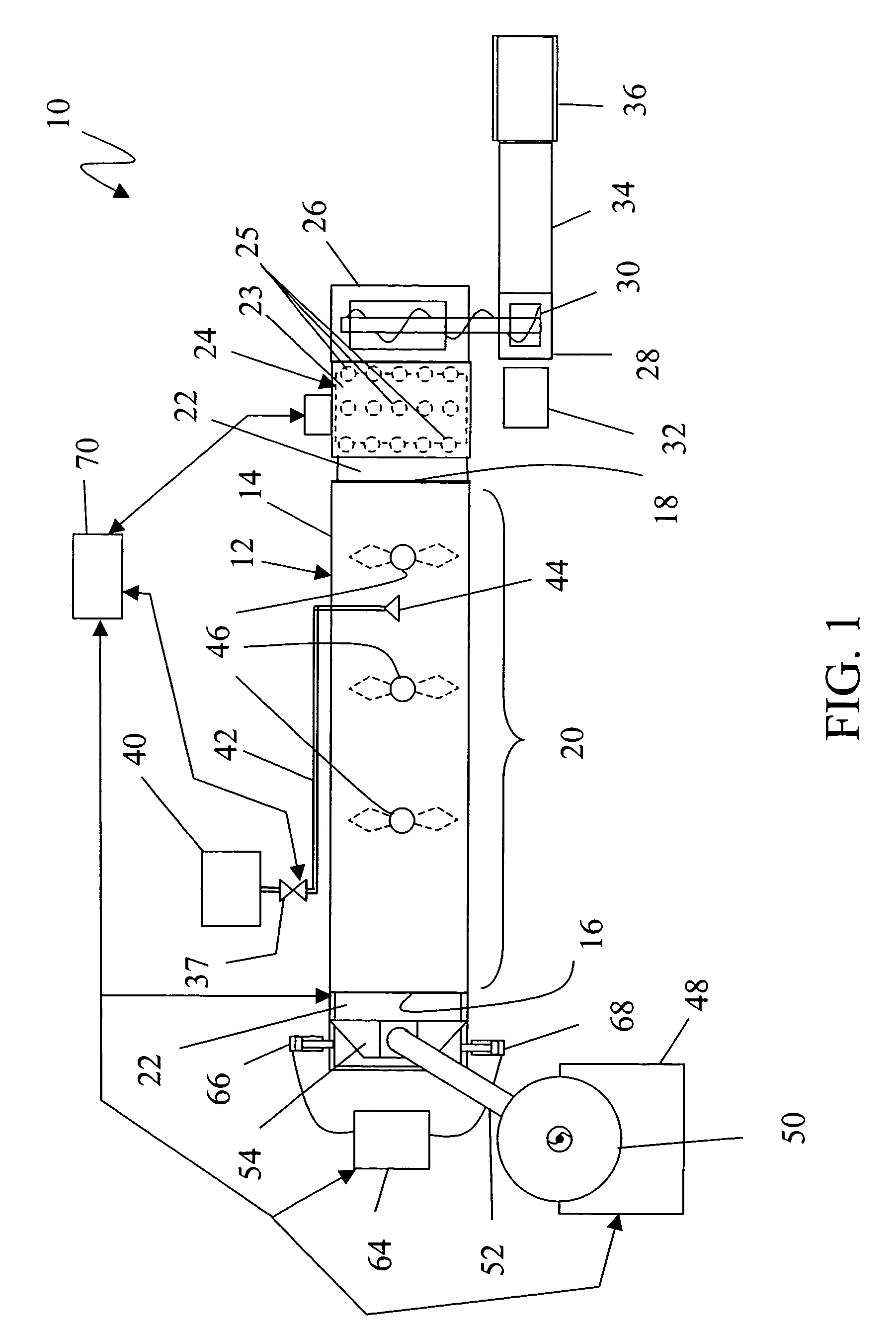

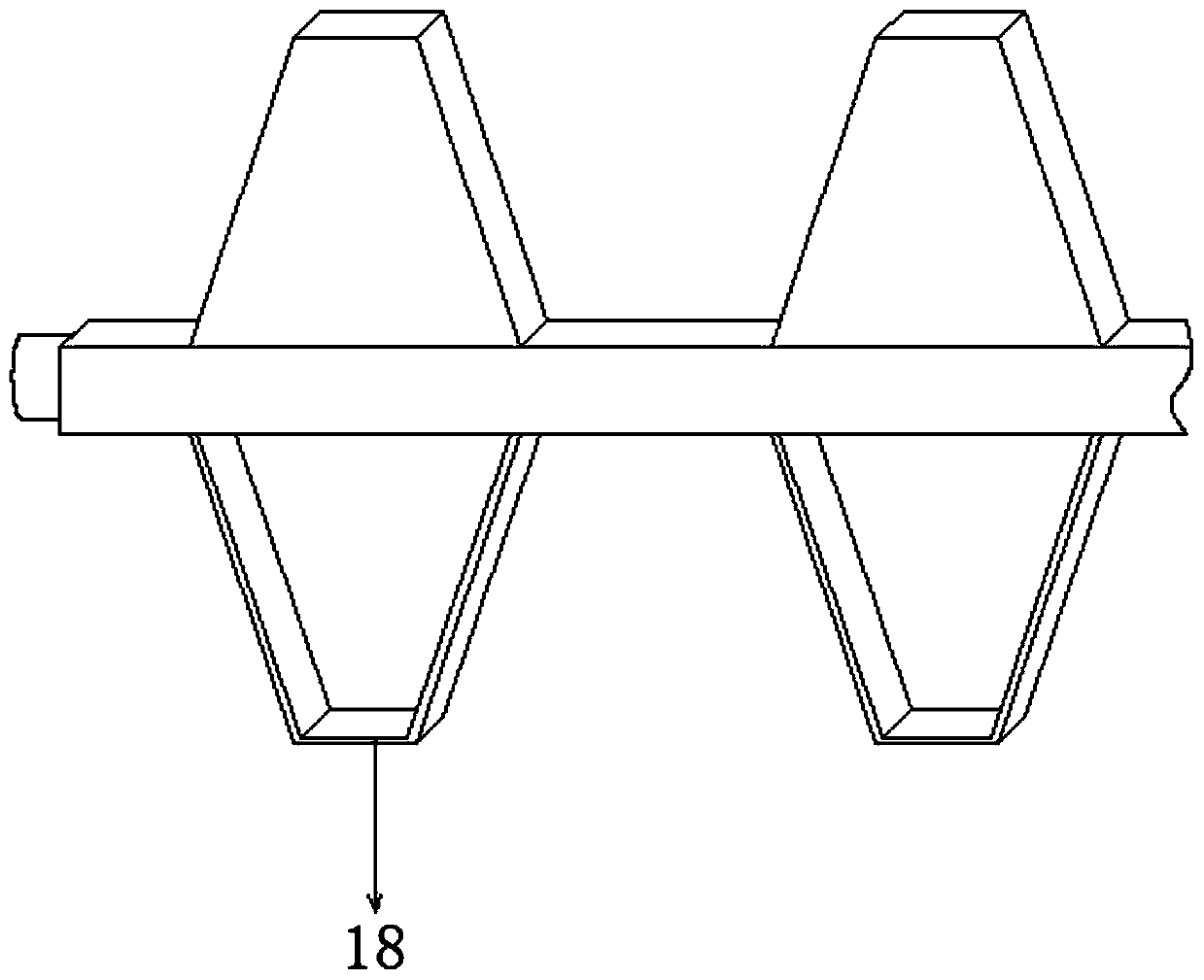

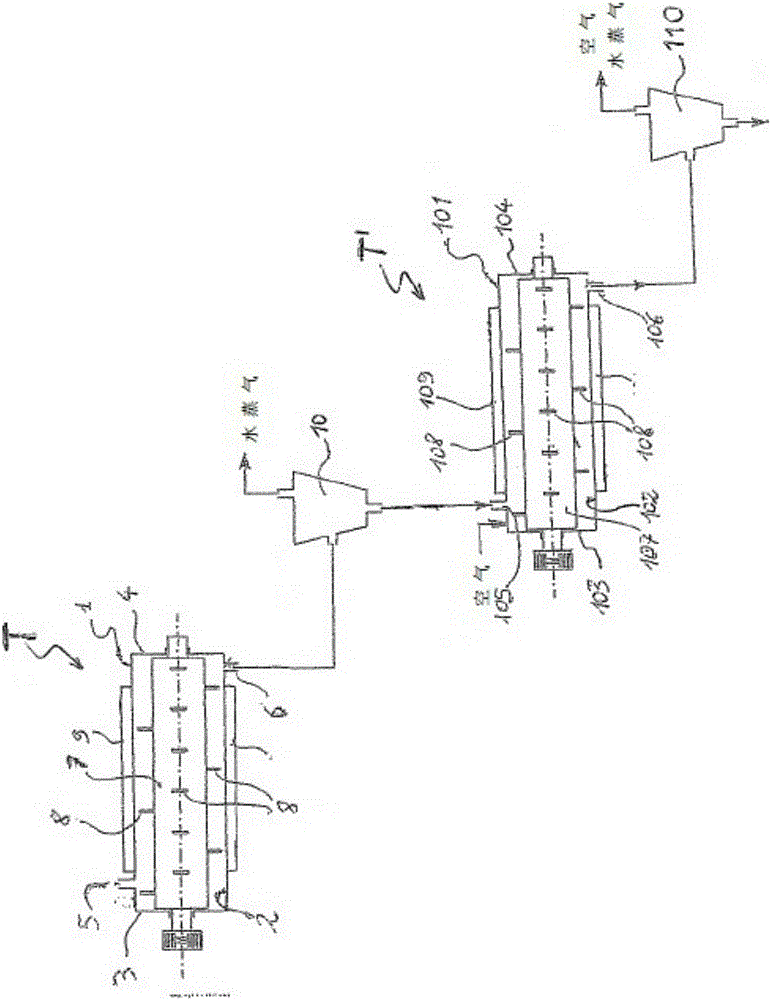

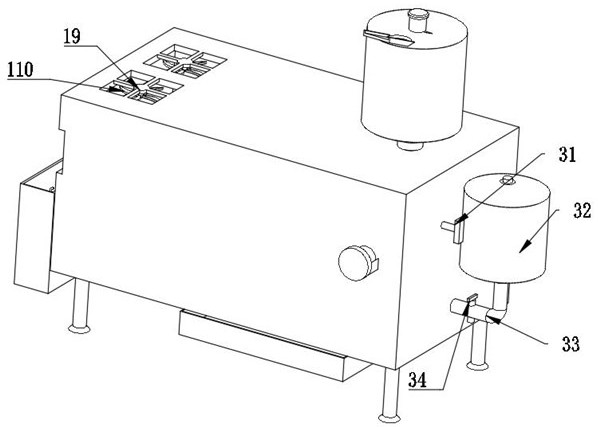

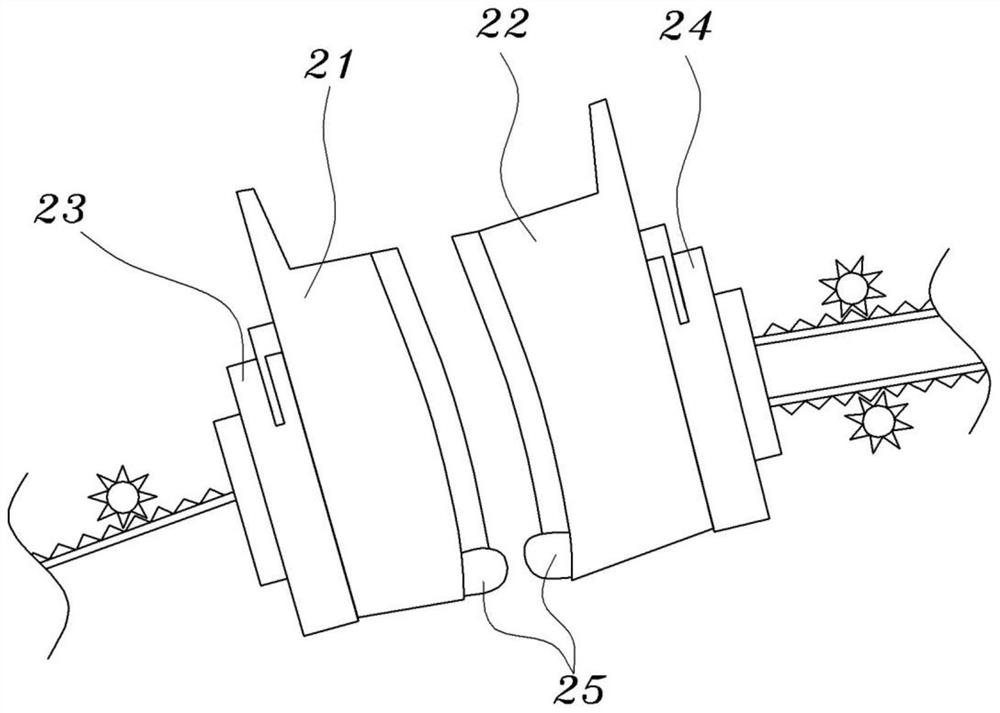

System for extruding, cutting in strands, freezing, and chopping a ground food product and method thereof

ActiveUS20060040028A1Reduce the temperatureLighting and heating apparatusMouldsEngineeringConveyor belt

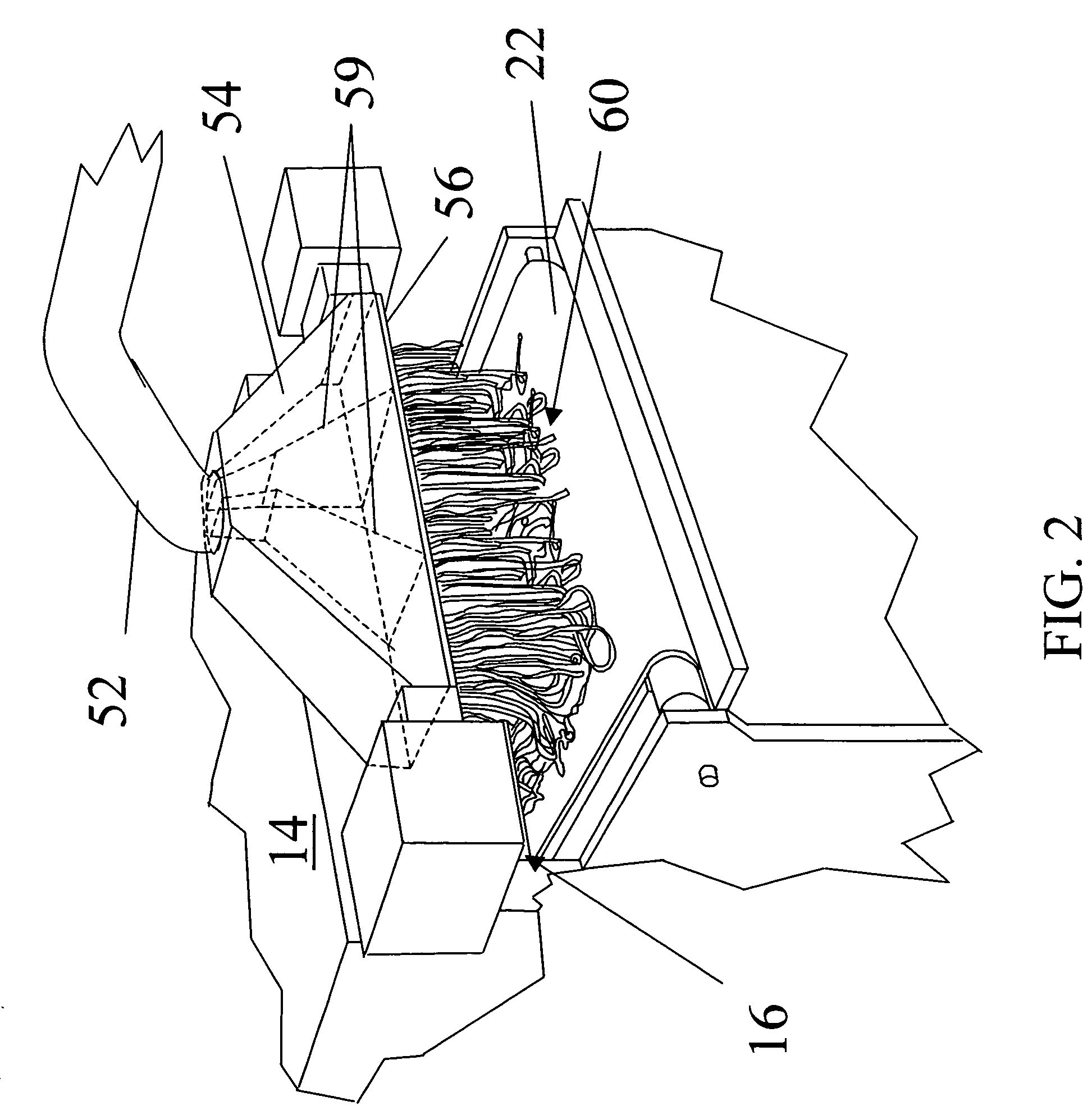

Disclosed are a method and a system for extruding, cut into strands, cooling, and chopping a ground food product. The system comprises a cooling unit, a conveyor belt urging the pieces through the unit, and a chopper for cutting the pieces exiting the unit. A cryogen source provides cryogen to the cooling unit. A feeder feeds the ground food product onto the conveyor belt adjacent an inlet of the unit. The feeder also extrudes the ground food product through a nozzle to place the stranded pieces onto the conveyor belt. A shear plate cuts the stranded pieces, while being extruded. A hydraulic system moves the shearing plate. The system is adapted to dispense cryogen to the cooling region at a rate sufficient to lower the temperature of the cut stranded pieces to a desired temperature when they exit the unit. A chopper cuts the extruded and stranded pieces immediately after freezing.

Owner:CARGILL INC

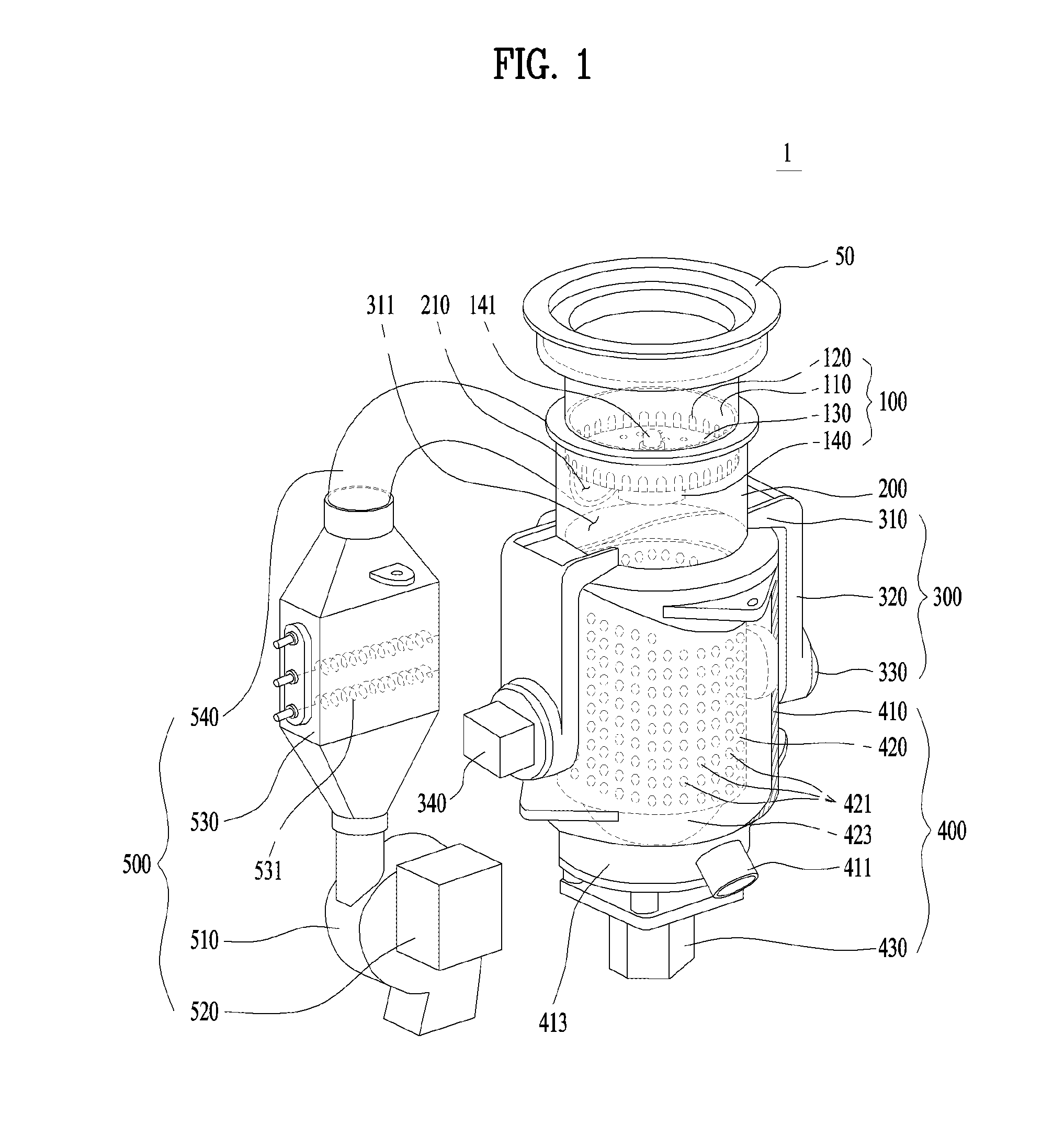

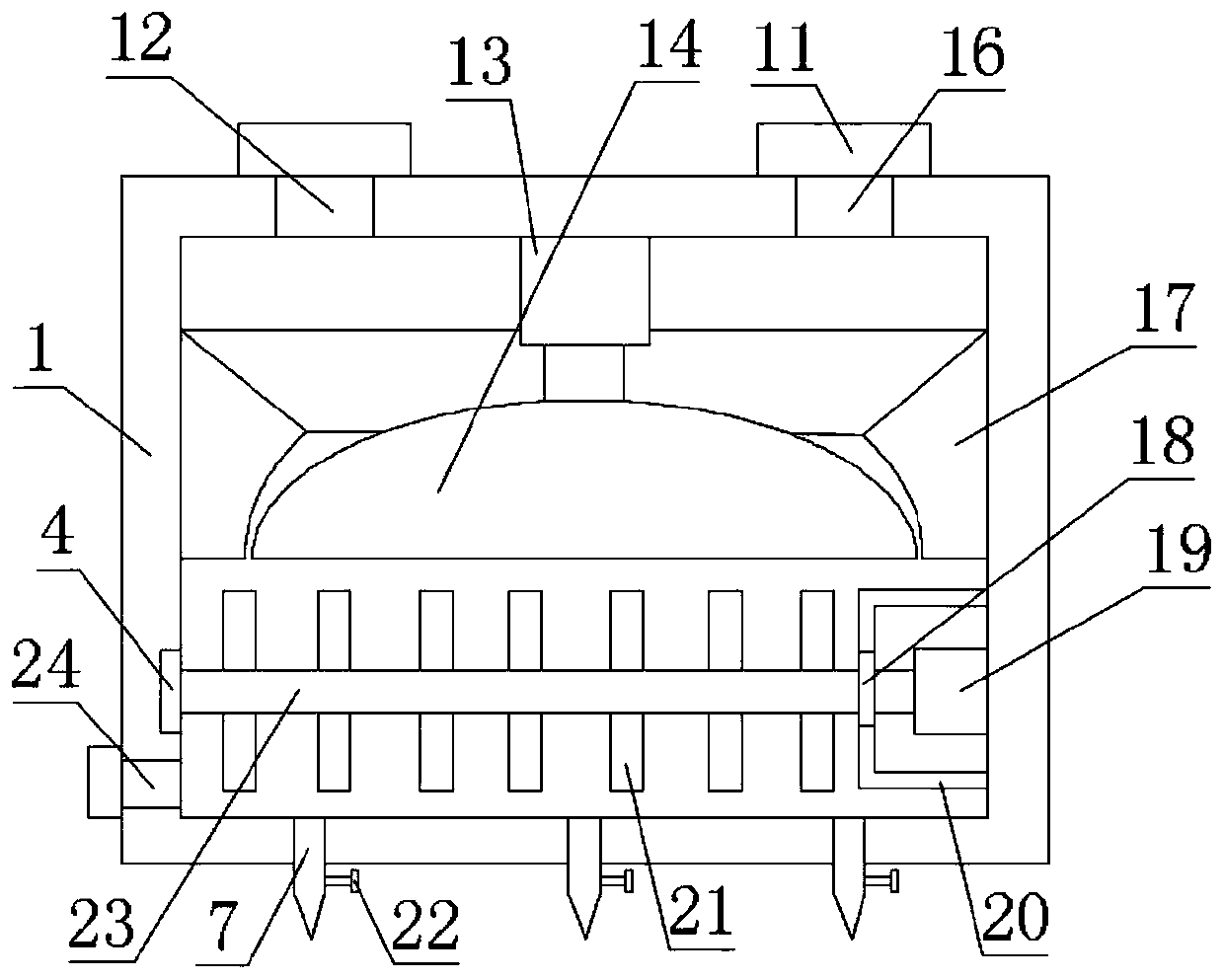

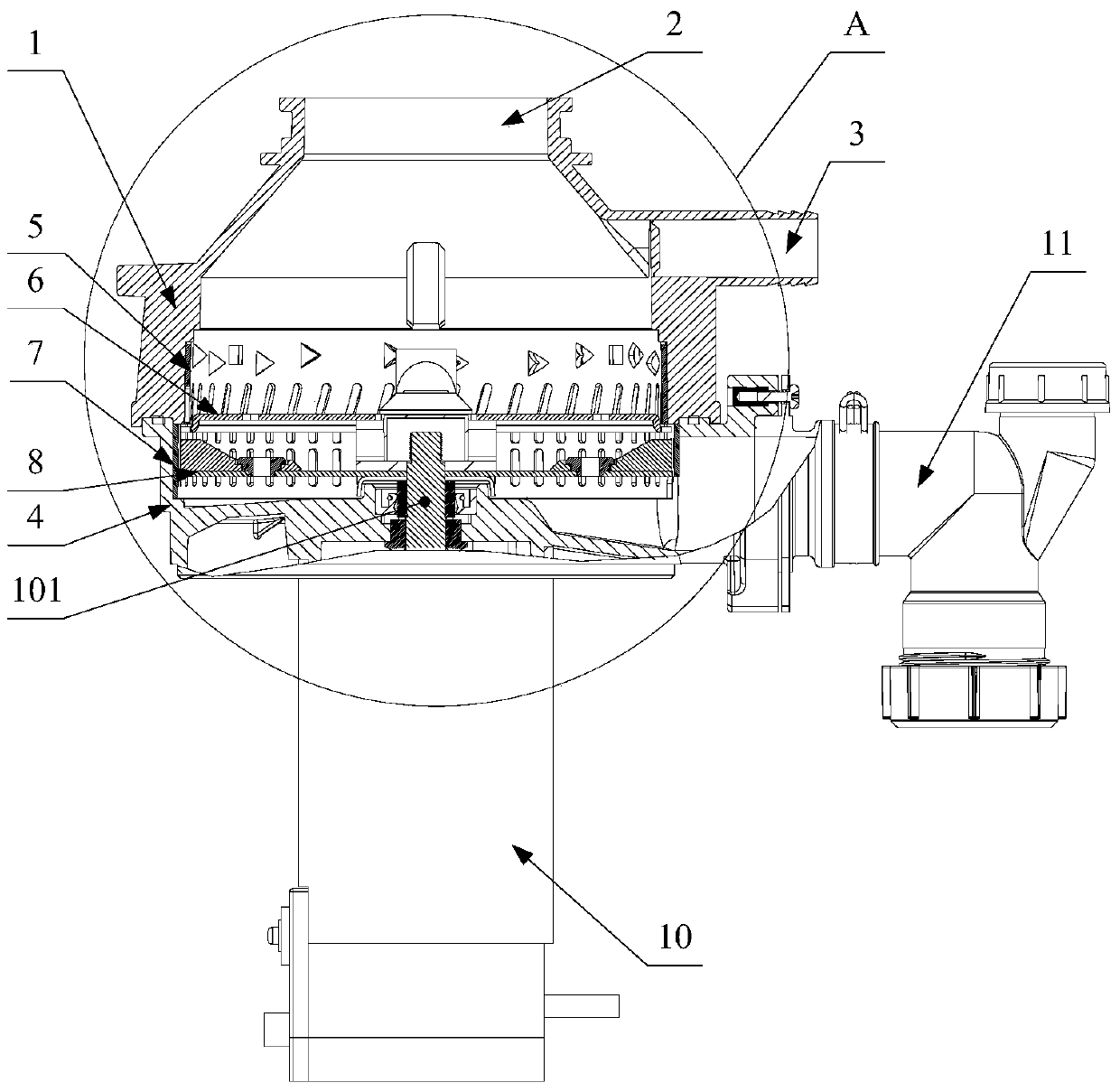

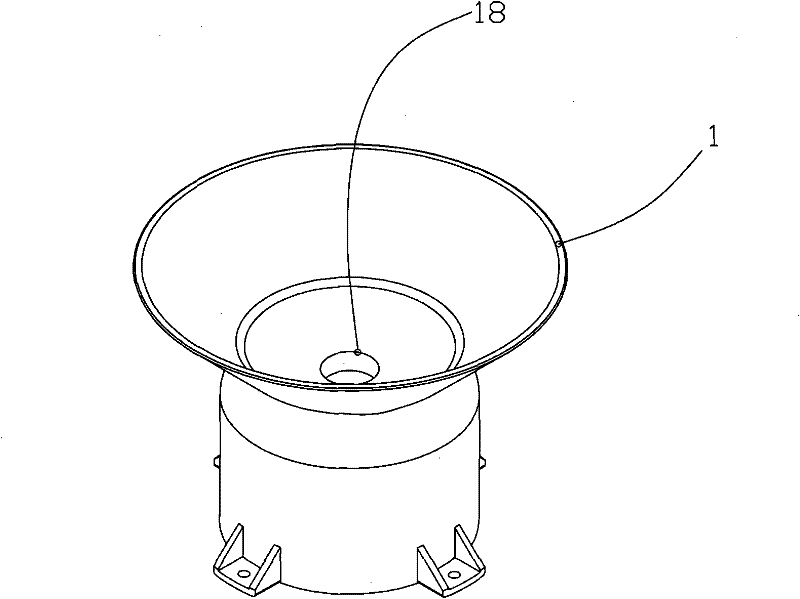

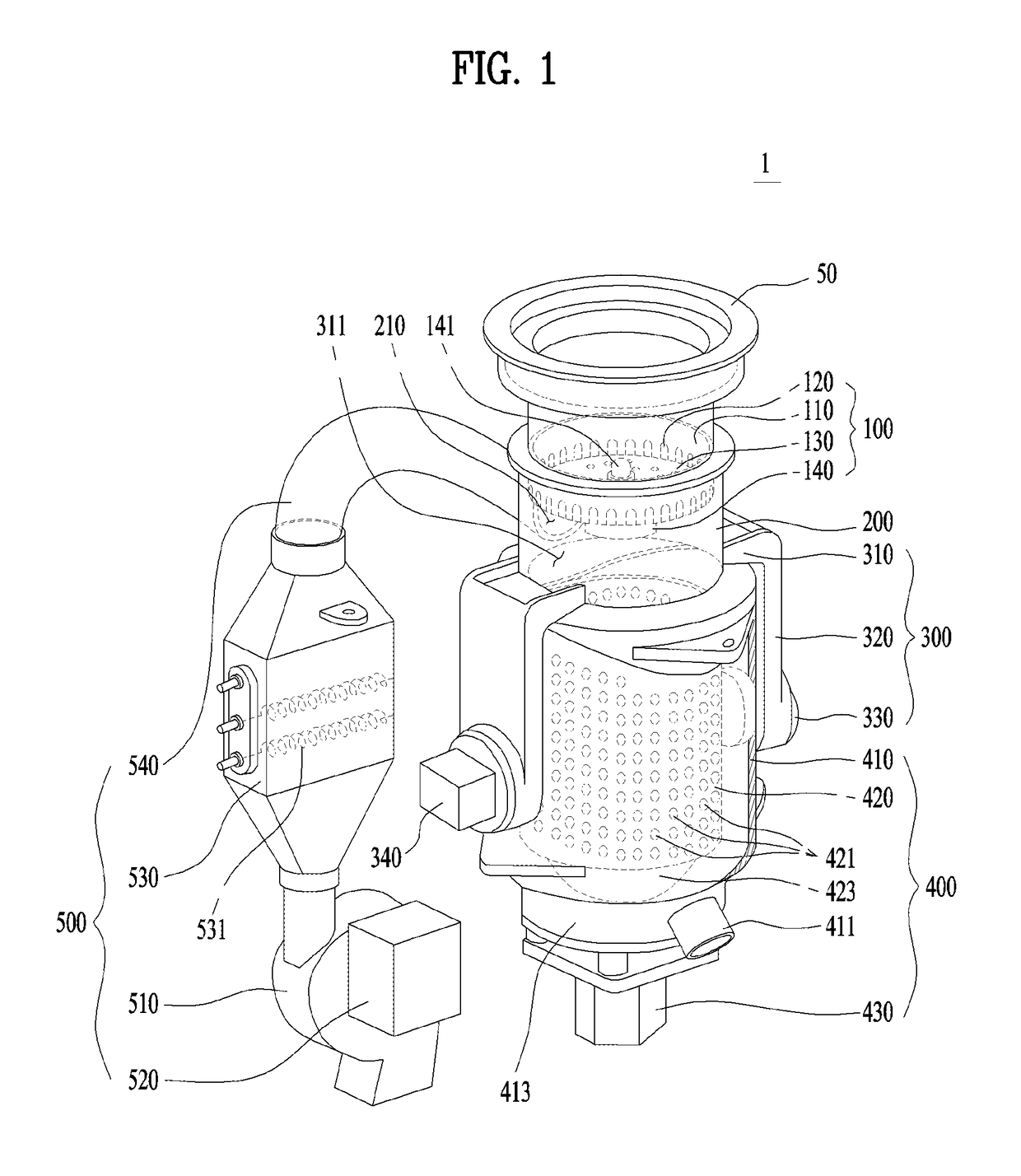

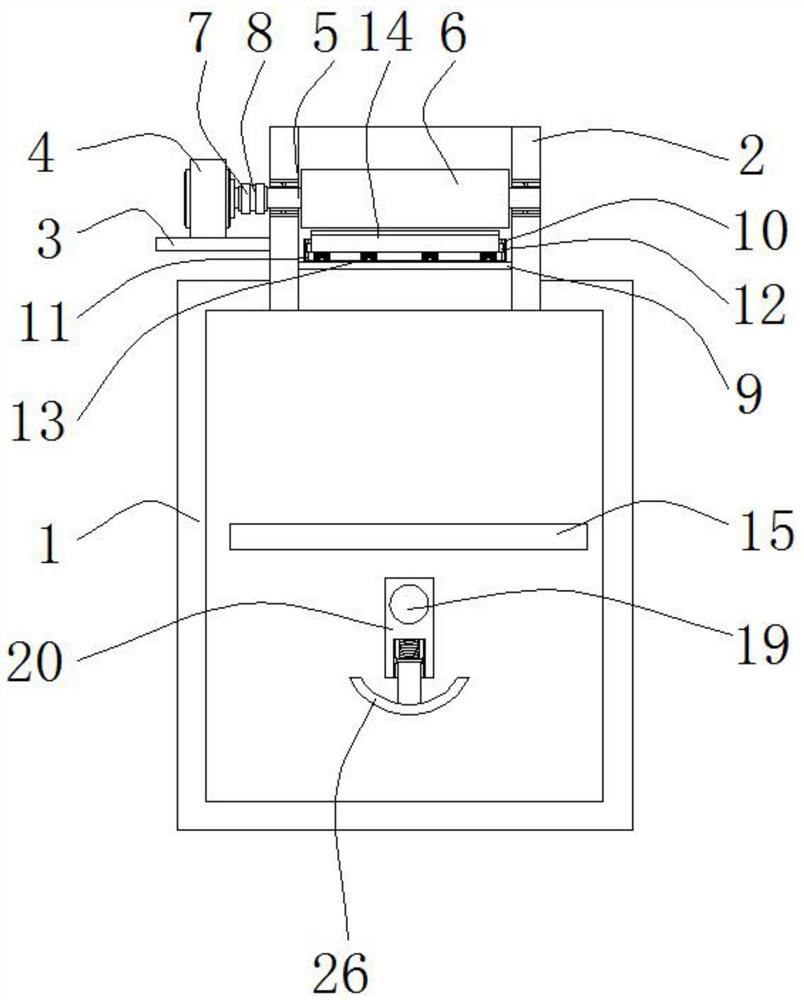

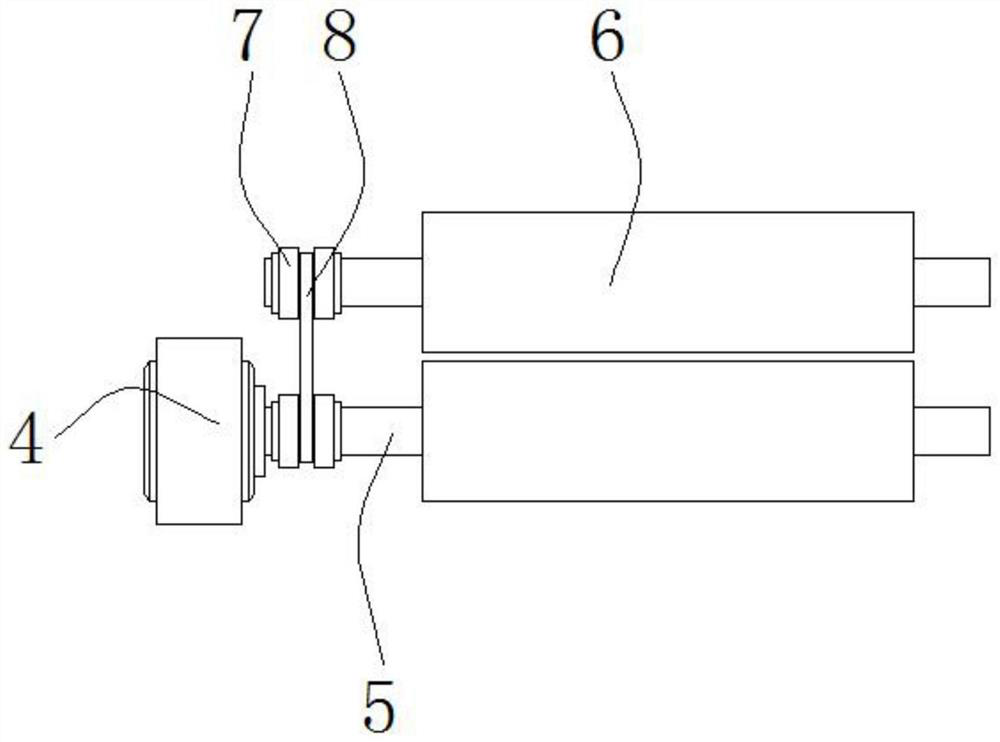

Food waste disposer and control method thereof

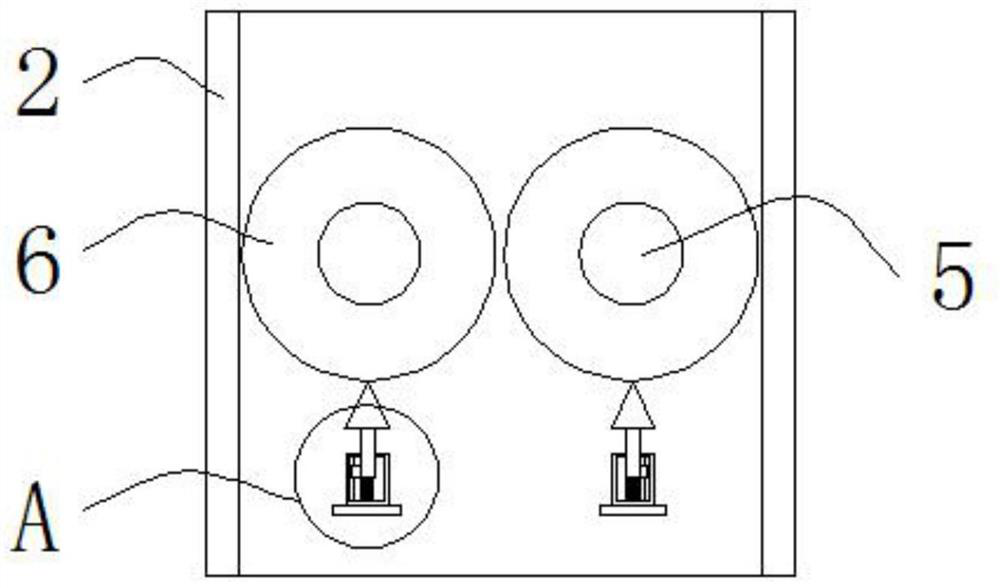

ActiveCN105435917AEasy to useAvoid processing powerDomestic plumbingGrain treatmentsSynchronous detectionConductor Coil

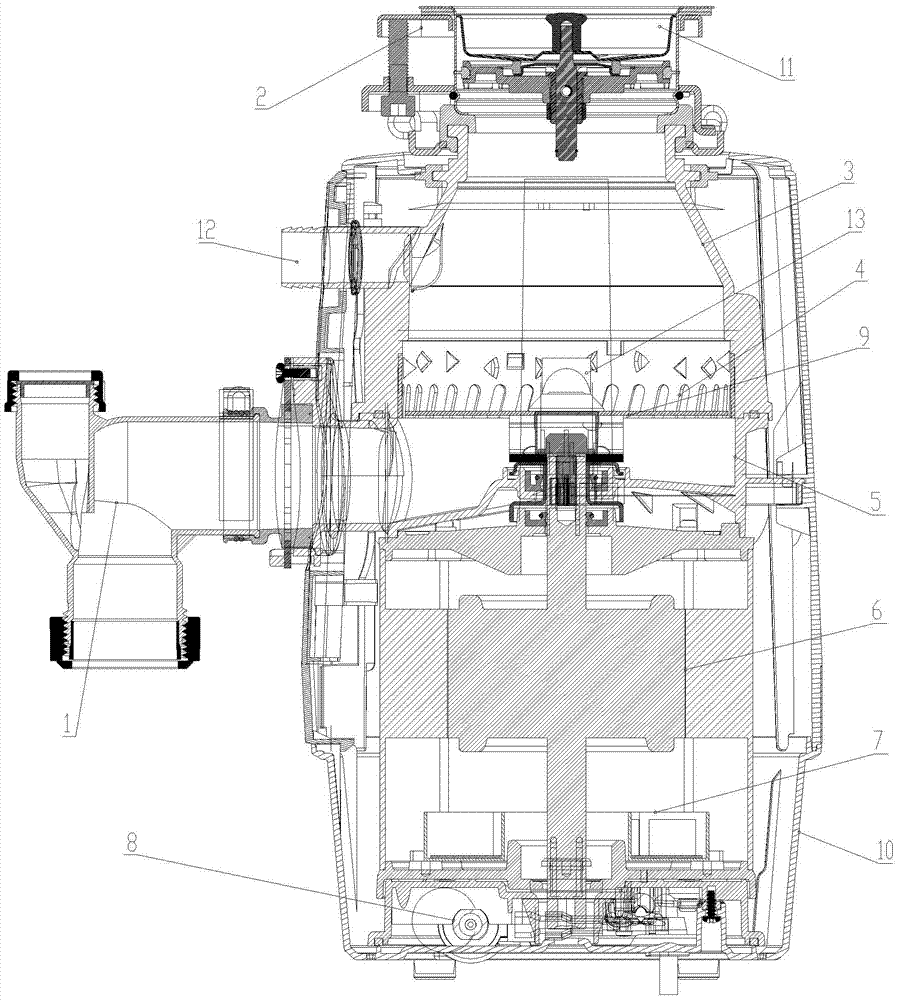

The invention discloses a food waste disposer and a control method thereof. The food waste disposer comprises a food waste inlet, a grinding device, a motor (6) and an electronic centrifugal switch (7), wherein food waste enters the grinding device through the food waste inlet; the motor (6) is connected to the grinding device and drives the grinding device to grind the entered food waste and discharge the ground food waste; the electronic centrifugal switch (7) is connected to the motor (6), the running state of the motor (6) is ensured by synchronously detecting the current value and the voltage value of the motor (6), and further the connection or disconnection of the main winding and / or secondary winding of the motor (6) is controlled according to the running state of the motor (6). According to the scheme, the food waste disposer can overcome the defects of inconvenience in use, short service life and poor universality in the prior art and realize the beneficial effects of convenience in use, long service and good universality.

Owner:GREE ELECTRIC APPLIANCES INC

Food waste disposal

ActiveUS20150231639A1Simple structureEasy dischargeGas current separationDrying solid materials without heatGround food

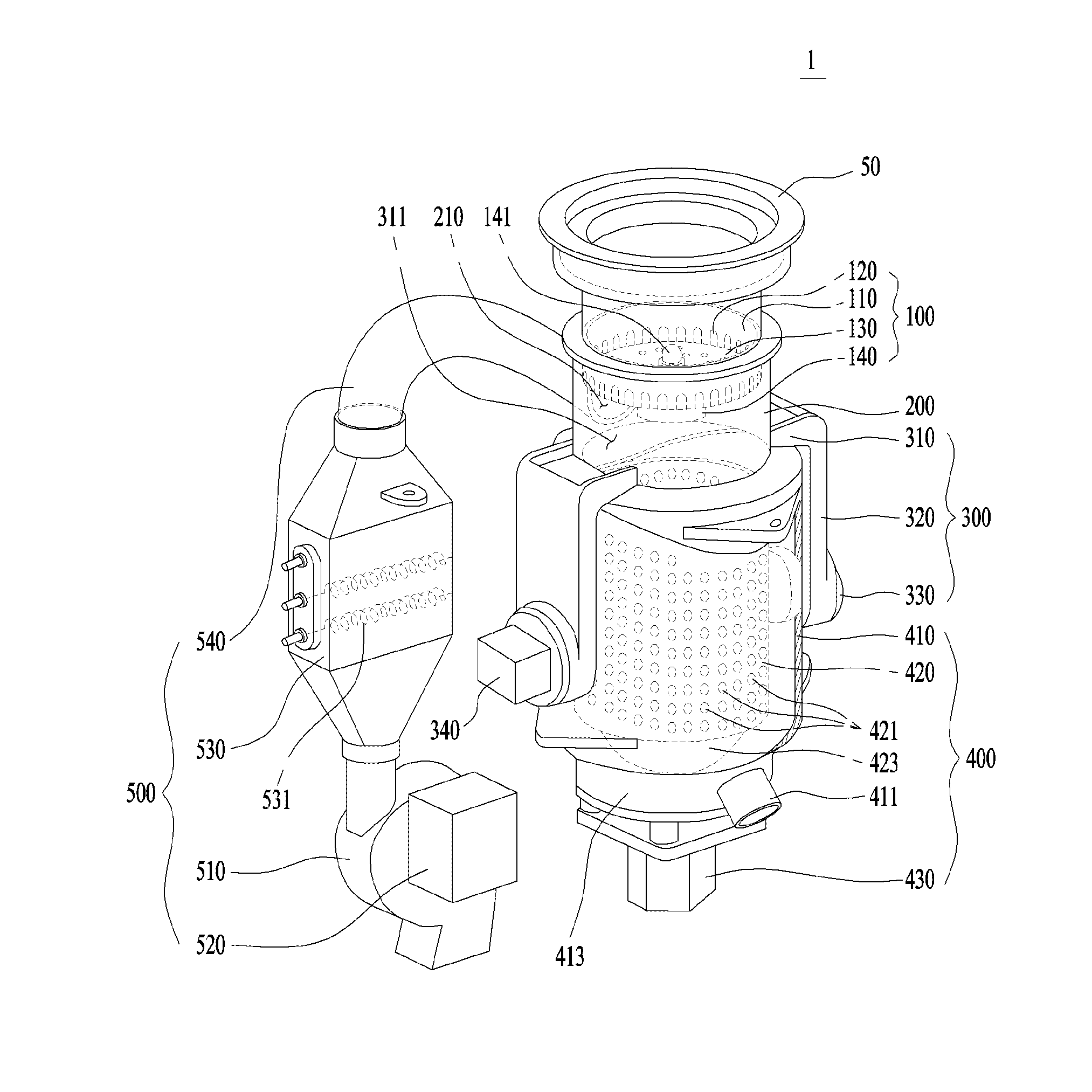

A food waste disposal includes a grinding part configured to grind food waste, a dewatering part configured to receive the ground food waste from the grinding part and to discharge water out of the received food waste, and a connecting frame having a rotating shaft. The dewatering part is rotatably coupled to the connecting frame via the rotating shaft. Further, the dewatering part is configured to be rotated vertically downward away from the grinding part in a top / bottom direction around the rotating shaft.

Owner:LG ELECTRONICS INC

Food grinder

The invention discloses a food grinder. A cutter holder system of the grinder comprises a cutter holder and a cutter shaft, wherein the cutter holder is provided with a bearing; the lower end of the cutter shaft is arranged in the bearing, and the upper end of the cutter shaft is provided with a grinding component; a cup body is provided with a material inlet communicated with the outside; a filtering device is sleeved below the grinding component on the cutter shaft; a powder discharging / heat radiating device is sleeved below the filtering device; a powder discharging / heat radiating device is sleeved above the bearing on the cutter shaft; and a position on the side wall of the cutter holder, which corresponds to the powder discharging / heat radiating device, is provided with an outlet communicated with the outside. Food is delivered to the cup body from the material inlet and ground by the grinding component; the grinding degree is controlled by the filtering device; and the ground food is discharged from the food outlet by the powder discharging / heat radiating device. A convective air cooling system is formed on a passage in a whole food treating process so as to rapidly carry heat produced by high-speed friction between the cutter shaft and an oil-containing bearing out of the cup body and realize automatic food treatment started from feeding. The grinder can run continuously without causing thermal protection and powder burning and the service life of the grinder is prolonged.

Owner:MIDEA GRP CO LTD

System for extruding, cutting in strands, freezing, and chopping a ground food product and method thereof

Disclosed are a method and a system for extruding, cut into strands, cooling, and chopping a ground food product. The system comprises a cooling unit, a conveyor belt urging the pieces through the unit, and a chopper for cutting the pieces exiting the unit. A cryogen source provides cryogen to the cooling unit. A feeder feeds the ground food product onto the conveyor belt adjacent an inlet of the unit. The feeder also extrudes the ground food product through a nozzle to place the stranded pieces onto the conveyor belt. A shear plate cuts the stranded pieces, while being extruded. A hydraulic system moves the shearing plate. The system is adapted to dispense cryogen to the cooling region at a rate sufficient to lower the temperature of the cut stranded pieces to a desired temperature when they exit the unit. A chopper cuts the extruded and stranded pieces immediately after freezing.

Owner:CARGILL INC

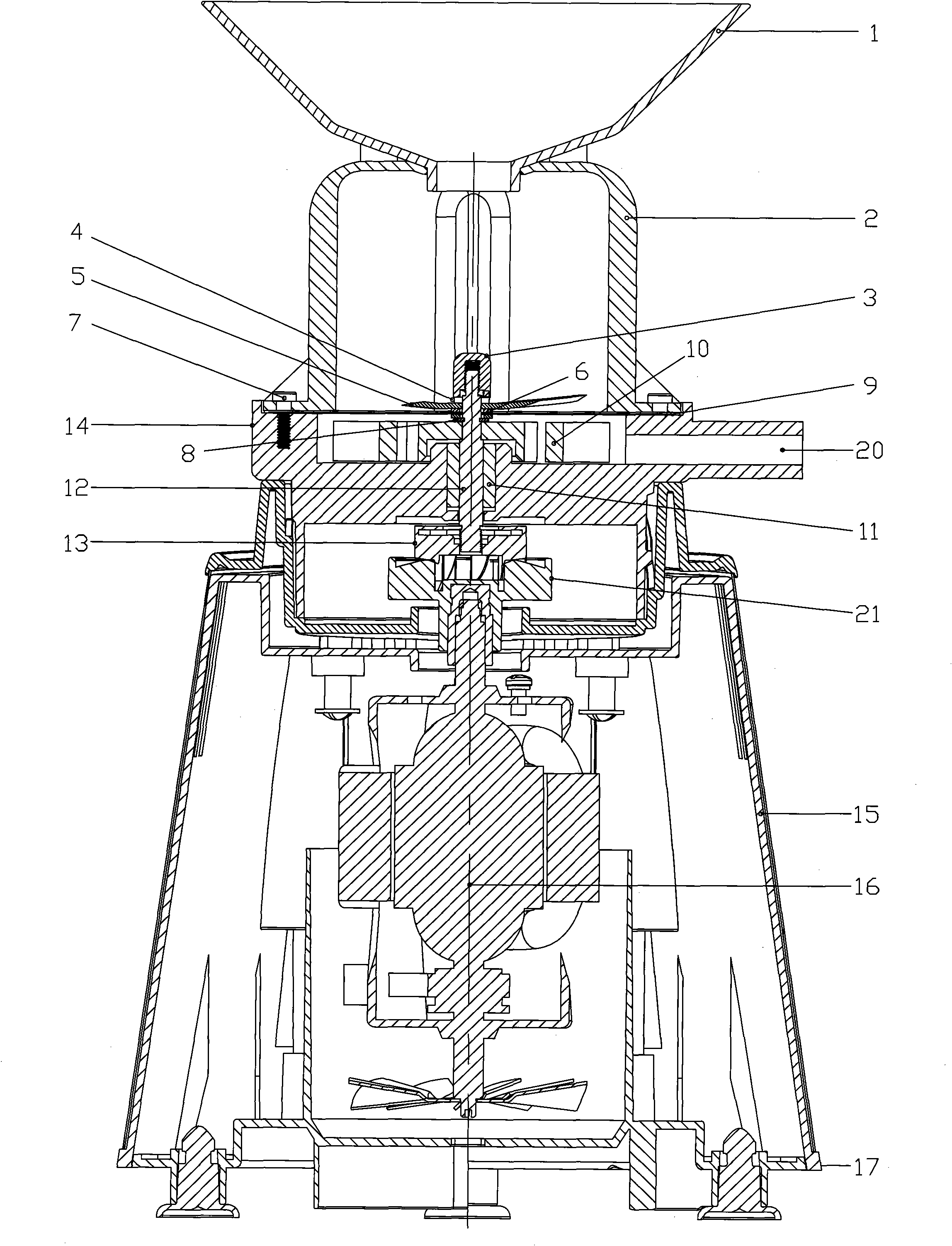

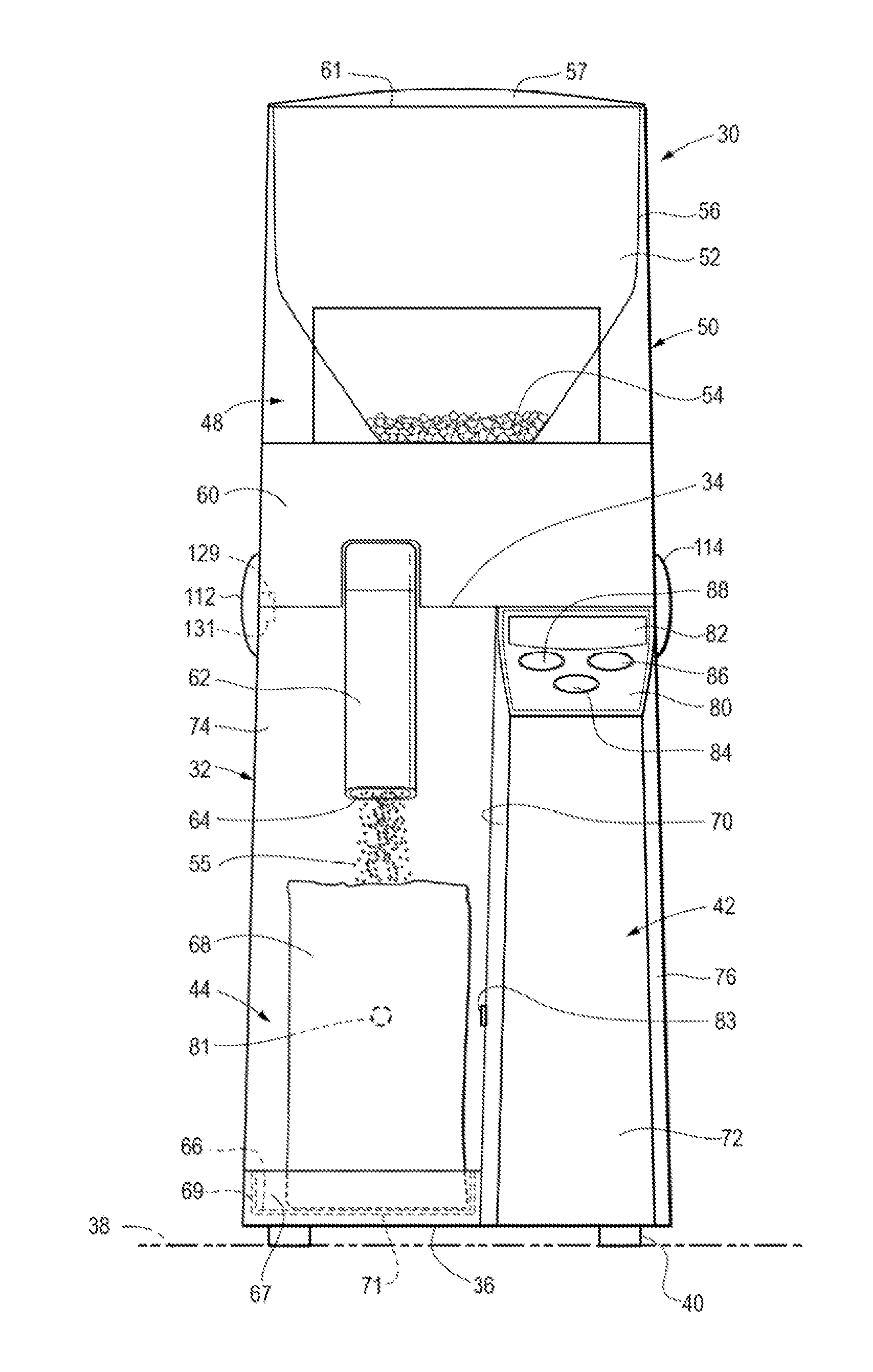

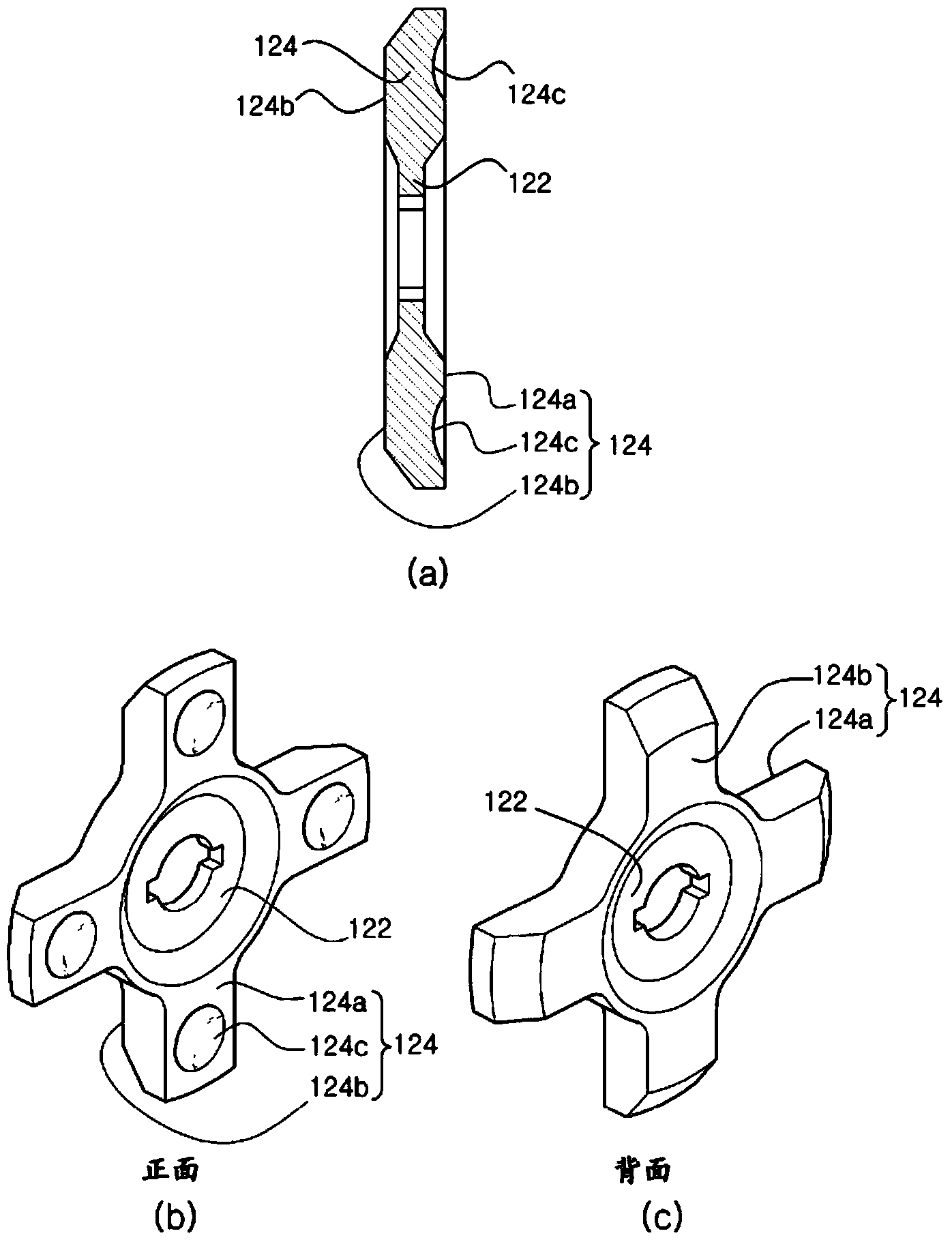

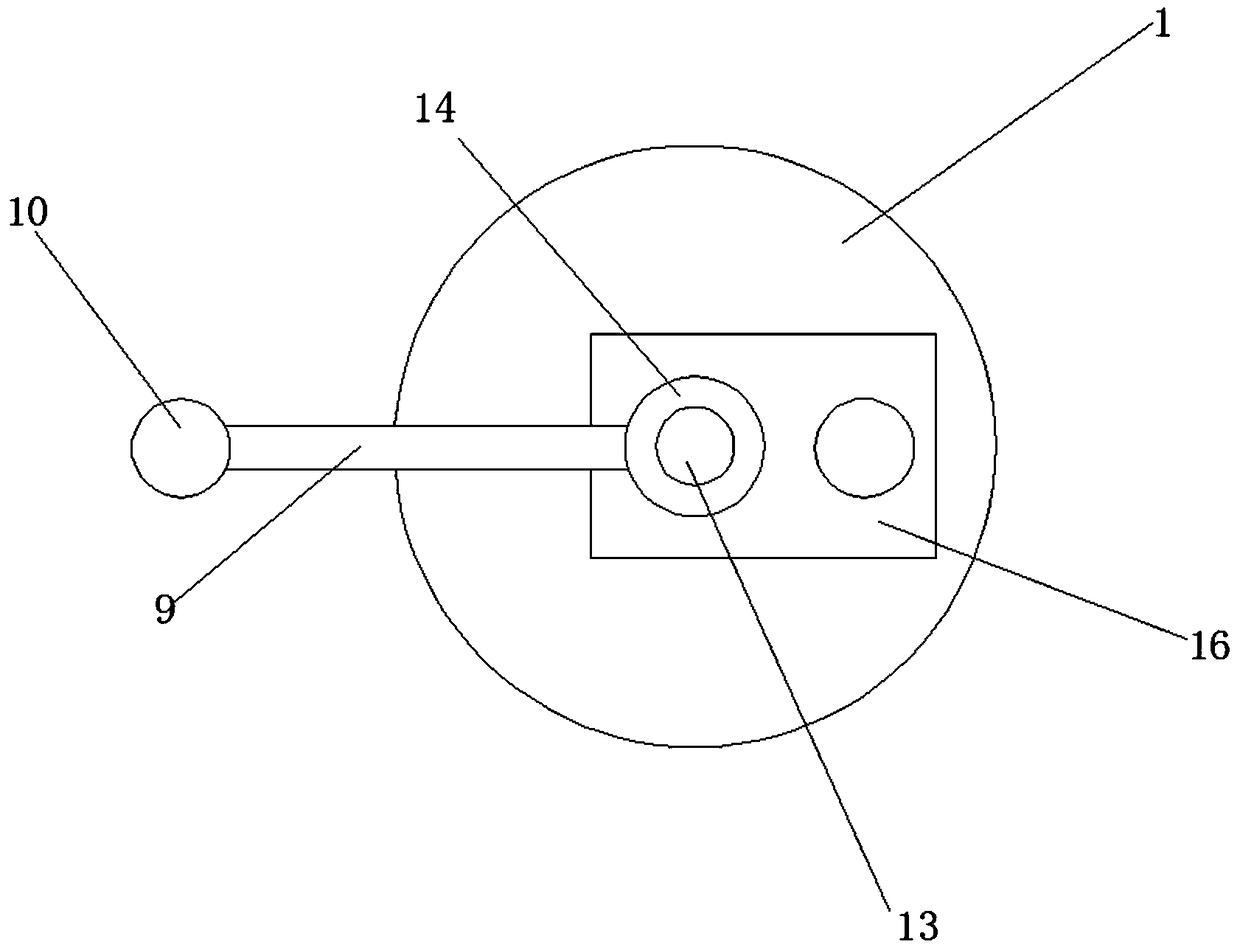

Electrical food grinder with electronically adjustable grind settings and tooless disassembly

A grinder (30) has a toolessly attached ingredient hopper assembly (50) overlying a toolessly attached fixed grinding burr (134) defining the top of a grind chamber (158) within which is received a mating rotary grinding burr (150) that is slidably mounted to a rotary drive motor (154) for adjustment relative to the fixed grinding burr (134). Adjustment is achieved automatically by control of a stepper motor (168) that pushes on the end of an elongate member (151) passing through a hollow rotary drive axle (152) and carrying the rotary grinding burr (150) at an opposite end. Start of a grinding cycle in response to actuation of a start switch is inhibited if a pair of photosensors (81, 82) do not detect location of a ground ingredient container (68) in a correct position for receipt of the ground food ingredient, if an automatically closable hopper cover lid (57) is not in a closed position or if grinding parameters, such as the fineness of the grind and the amount of ingredient to be ground has not been detected.

Owner:FOOD EQUIP TECH

Food and drug inspection dissolving device

InactiveCN110961020AReduce volumeImprove grinding effectTransportation and packagingRotary stirring mixersMedicineEngineering

The invention discloses a food and drug inspection dissolving device. The food and drug inspection dissolving device comprises a dissolving box, a grinding box is fixedly connected to one side of thetop of the dissolving box, a feeding hopper is fixedly connected to one side of the top of the grinding box, a first discharging opening is formed between the bottom of the grinding box and the top ofthe dissolving box, and a support is fixedly connected to the top of the grinding box; a second motor is fixedly connected to the top of the support, a transmission shaft is fixedly connected to thebottom, extending into the grinding box, of an output shaft of the second motor, a grinding part is fixedly connected to the outer wall of the transmission shaft, and a grinding base is fixedly connected to the inner wall of the grinding box. Food and drugs are ground, the ground food and drugs are screened through a screen, then the food and the drugs are conveyed back into the grinding box through a packing auger to be fully ground, the sizes of the food and medicine the drugs are reduced, a solution is heated through a heating pipe, dissolved liquid is stirred through a stirring piece, andthe working effect of the device is improved.

Owner:郑越中

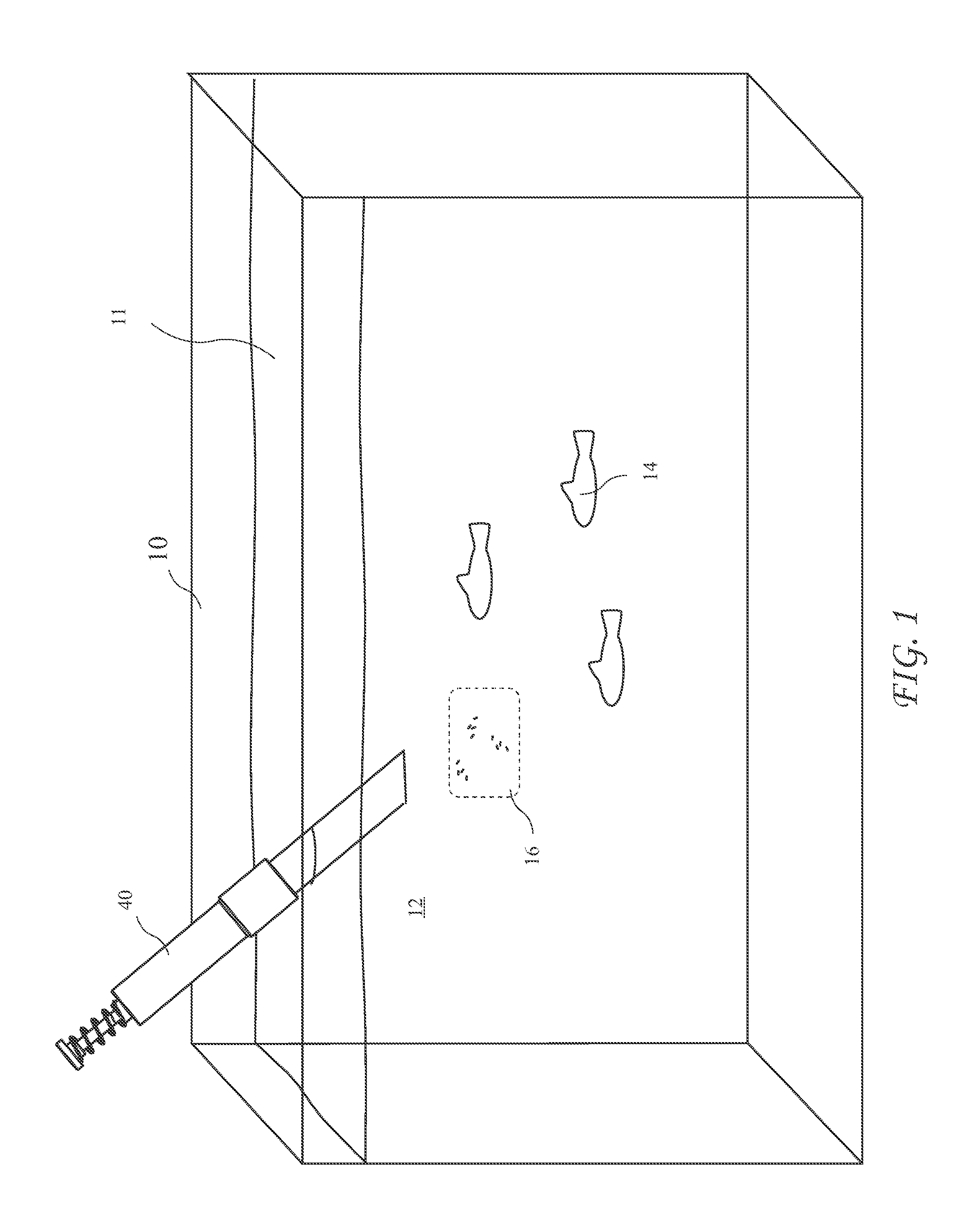

Pellet and Flake Aquarium Feeder

InactiveUS20160219840A1Easy feedingAvoid pollutionClimate change adaptationPisciculture and aquariaEngineeringAquarium fish

A pellet and flake aquarium fish feeder allows a fish keeper to conveniently feed aquarium fish. The pellet and flake feeder includes a body having separable upper and lower portions. The upper portion includes a cavity for storing the pellet and flake food and a plunger shaft including indented rings. When the pellet and flake feeder is filled with pellet and flake food and assembled, the plunger may be depressed forcing the pellet and flake food through a conical passage between the upper and the lower portions, grinding the pellet and flake food and releasing the ground food through an angled bottom of the lower portion and into aquarium water.

Owner:YIM STEVEN

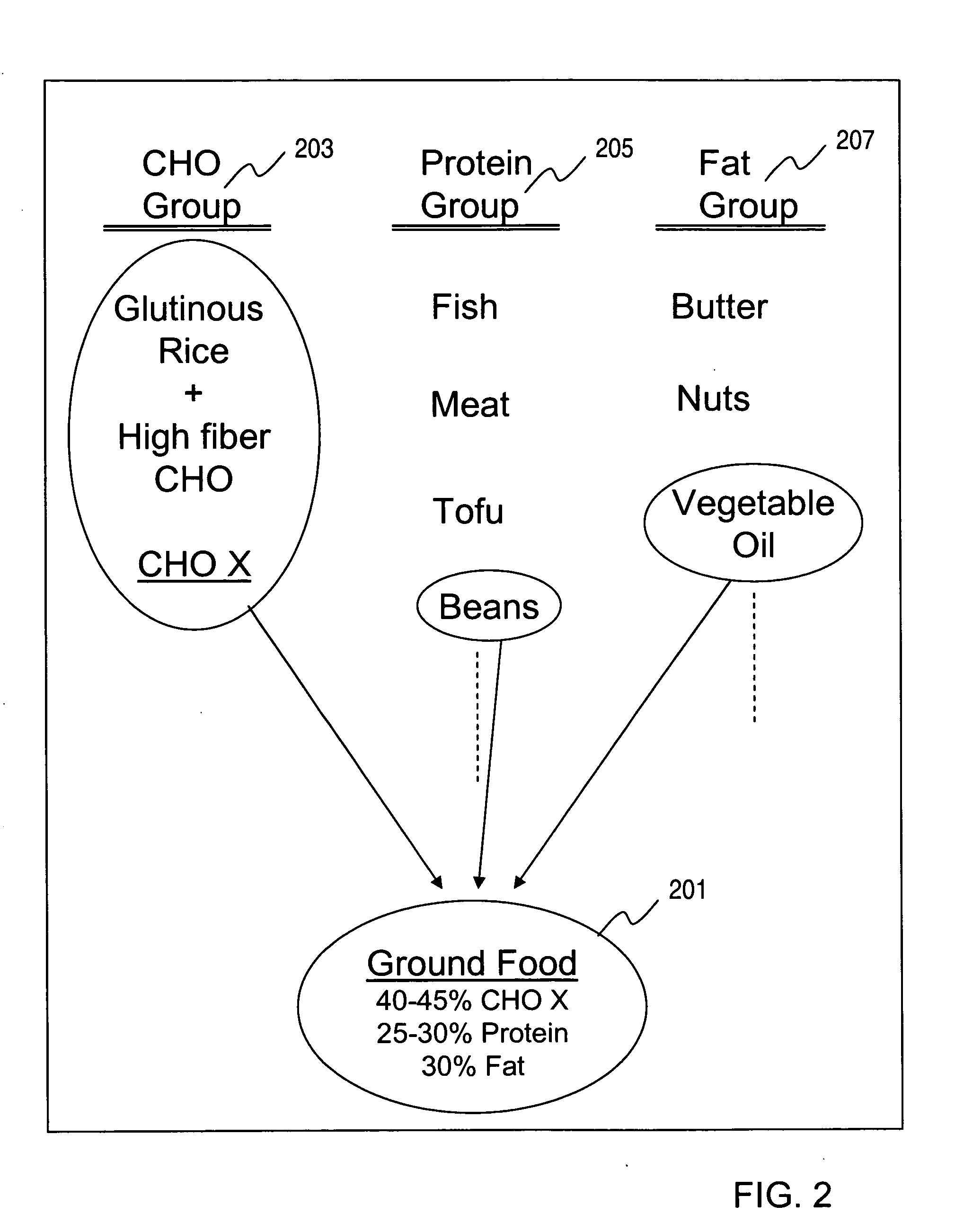

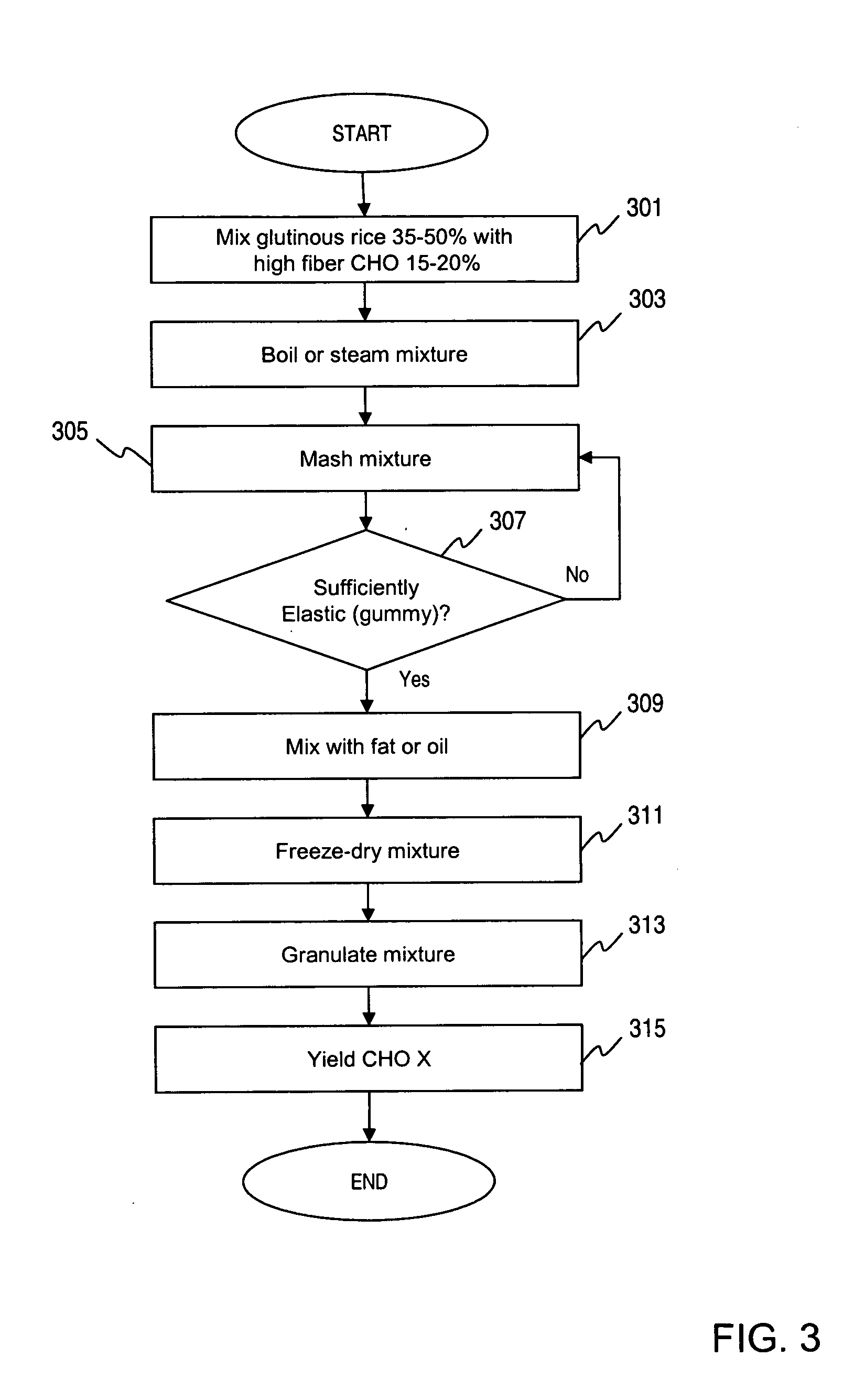

Anti-diabetic diet and method for providing a proportioned ground food

InactiveUS20050058766A1Enhance natural elastic characteristicIncrease heightDough treatmentConfectioneryFiberDiabetic diet

A method for achieving a versatile anti-diabetic diet and method for providing a viscous-high-fiber carbohydrate (CHO X) and a proportioned ground food ideally designed for a diabetic. The CHO X, according to one embodiment of the present invention, supports a delayed ingestion of carbohydrates to avoid glucose toxicity due to its natural viscosity characteristic and oil proof effect against permeability of carbohydrates in digestive system. A ground food is created based on the CHO X for pre-diabetic or diabetic patients. The ground food can be derived from three groups: a carbohydrate (CHO) group, a protein group, and a fat group. The CHO group can include glutinous rice and high fiber carbohydrates; these materials can be combined to result in a product denoted as CHO X. This new composition CHO X delays permeability of carbohydrates into a digestive system by controlling release of the carbohydrates.

Owner:HAN CHUNG WAN

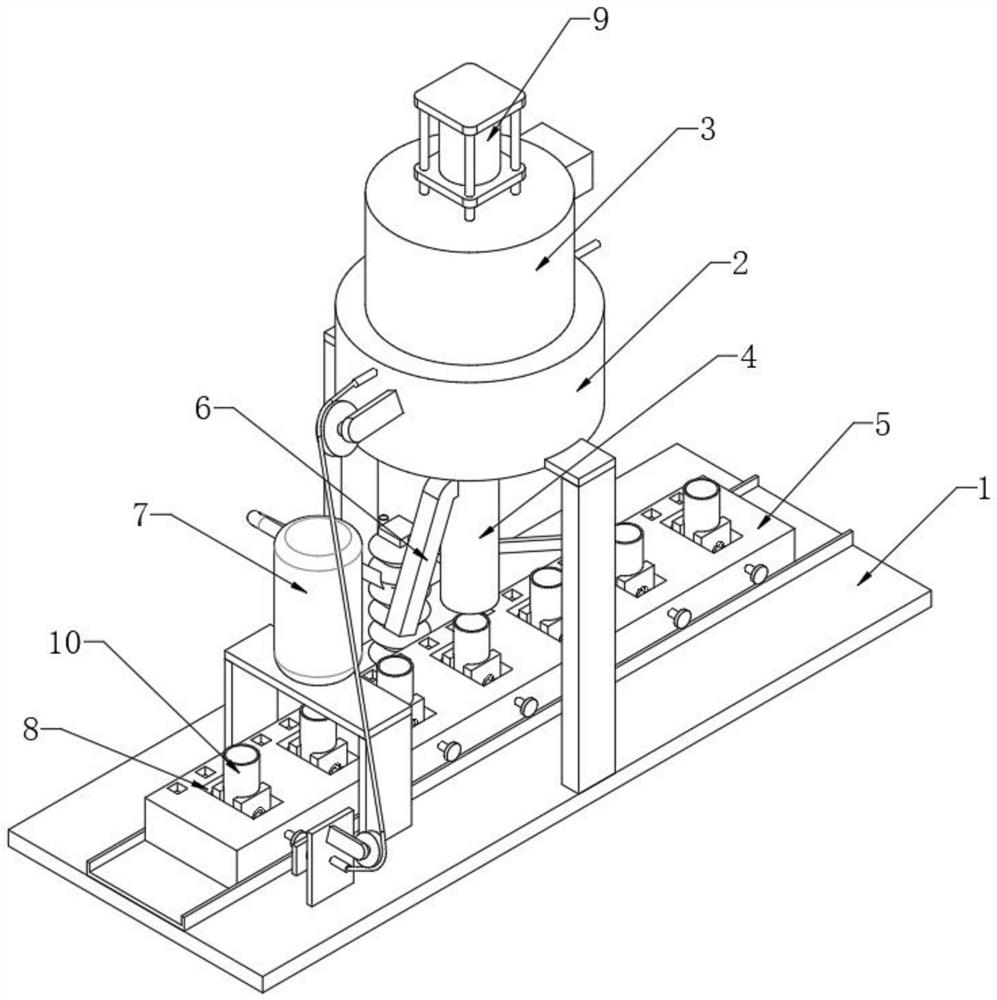

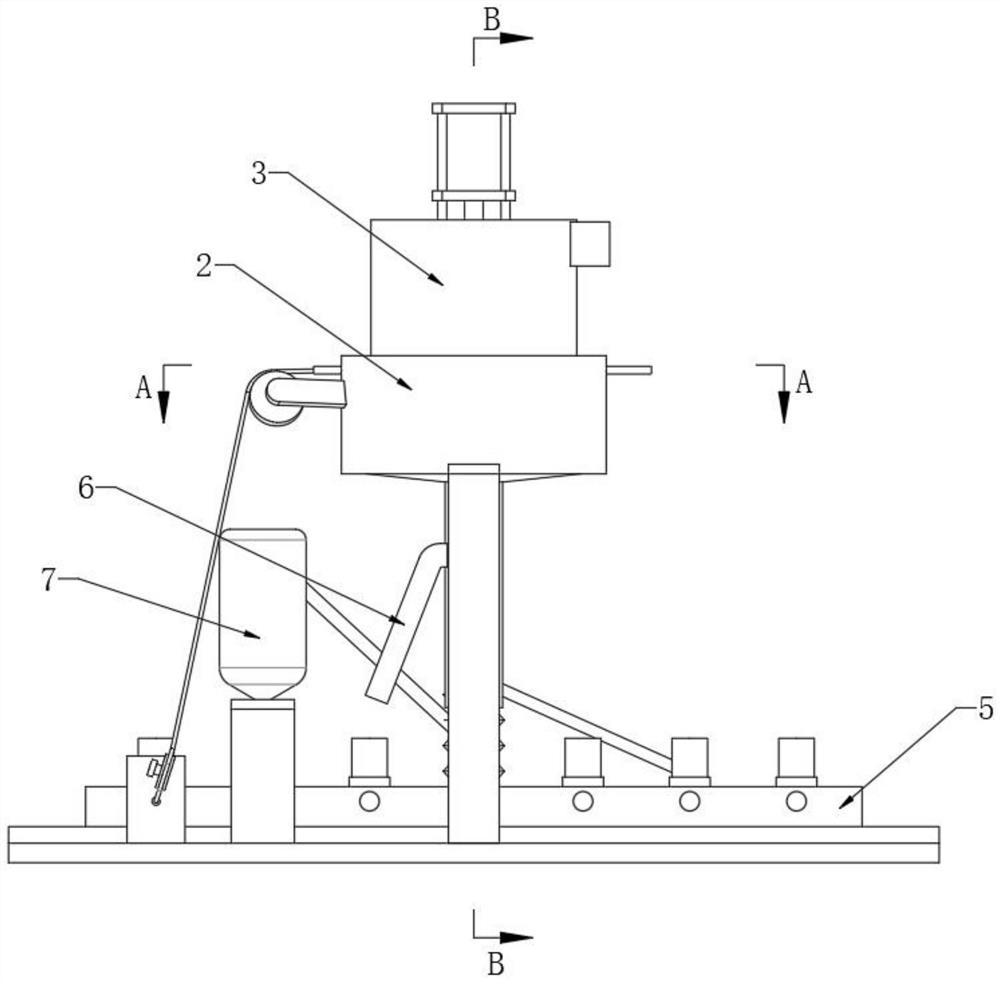

Treatment method for food waste or organic waste

The invention discloses a treatment method for food waste or organic waste which is composed of the food waste and cellulosic waste. According to the treatment method, the food waste is ground, boiled, disinfected and dried, and turbine cooking ware (T) is arranged for carrying out boiling and disinfection. The boiling and disinfection include the following steps that food waste continuous flow from the grinding step is conveyed into the turbine cooking ware (T), and a blade rotor (7) rotates at the speed of being higher than or equal to 150rpm inside the turbine cooking ware (T); the continuous flow makes centrifugal movement towards an inner wall (2) of the turbine cooking ware, so that a highly turbulent flow, dynamic, thin and tubular fluid layer is formed; ground food waste particles can be driven by blades (8) to move forwards and make contact with the inner wall of the turbine cooking ware, and the particles are heated to the temperature of at least 90 DEG C and move to a discharging outlet (6); and the disinfected and ground food waste continuous flow and water vapor continuous flow are discharged out of the discharging outlet.

Owner:AMBIENTE E NUTRIZIONE

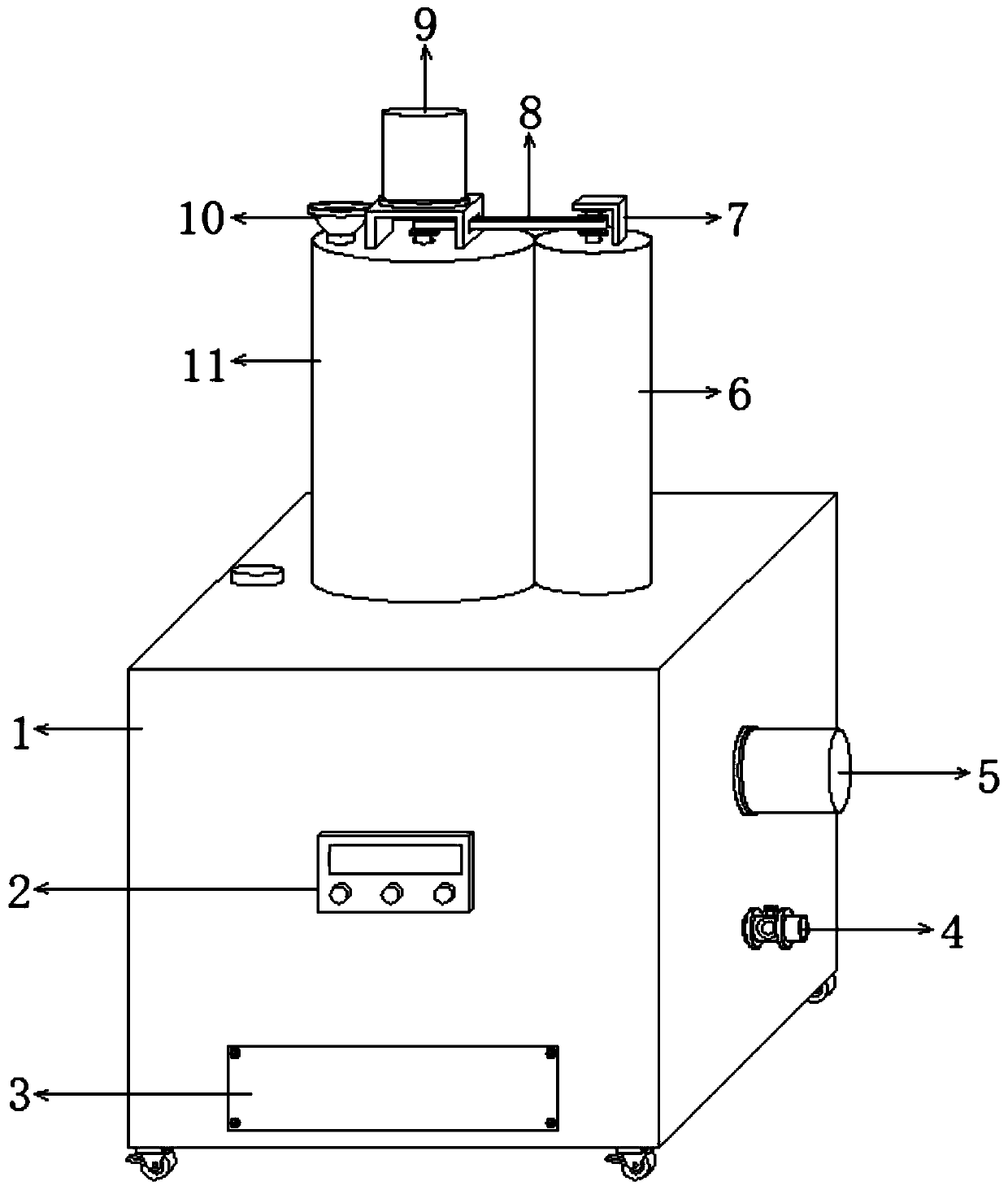

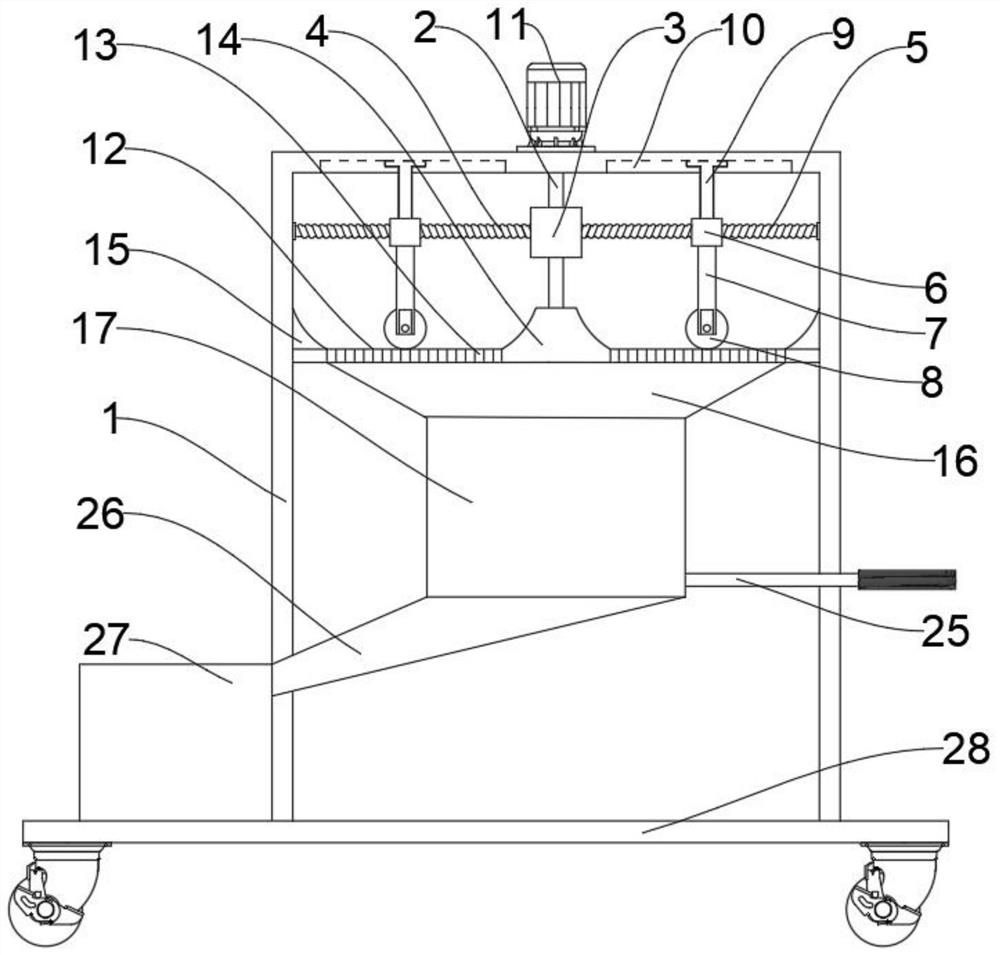

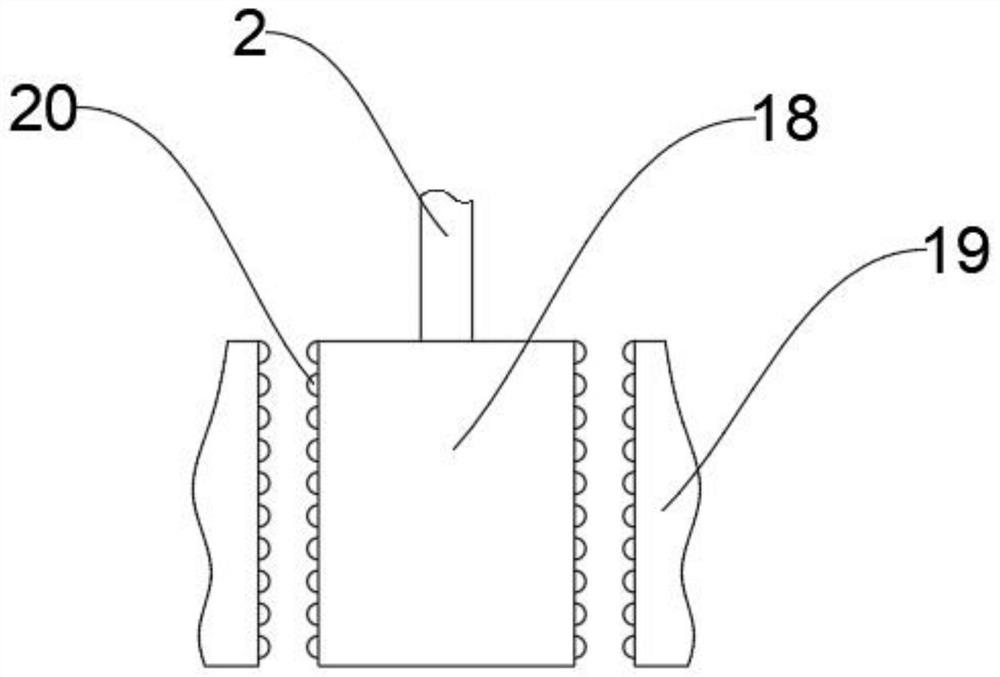

Portable intelligent food heavy metal detector

ActiveCN111208124AWell mixedQuick checkMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationBiotechnologyElectric machinery

The invention discloses a portable intelligent food heavy metal detector and relates to the technical field of food detection. The portable intelligent food heavy metal detector comprises a box body,wherein an inner top wall of the box body is fixedly connected with a first motor, and an output end of the first motor is fixedly connected with a grinding head. In the present invention, a first motor, a grinding head and a grinding frame are arranged, food grinding can be achieved, the food conforming to the size falls between the grinding head and the grinding frame, ground food fragments arestirred through a second motor, a stirring shaft and a stirring rod, uniform mixing of food products is performed, a threaded rod, a connecting plate, an L-shaped plate and a fixing plate are arranged, heavy metal test paper can be fixed. The heavy metal detection test paper is advantaged in that a solution obtained by uniformly mixing foods is dripped on the heavy metal detection test paper through a dropper and a valve so that the food can be rapidly detected, and problems of complicated process and long detection period caused by a series of operations of sampling, crushing, stirring, uniformly mixing and the like of most existing food heavy metal detectors before detection in the prior art are solved.

Owner:GONGBEI CUSTOMS TECH CENT

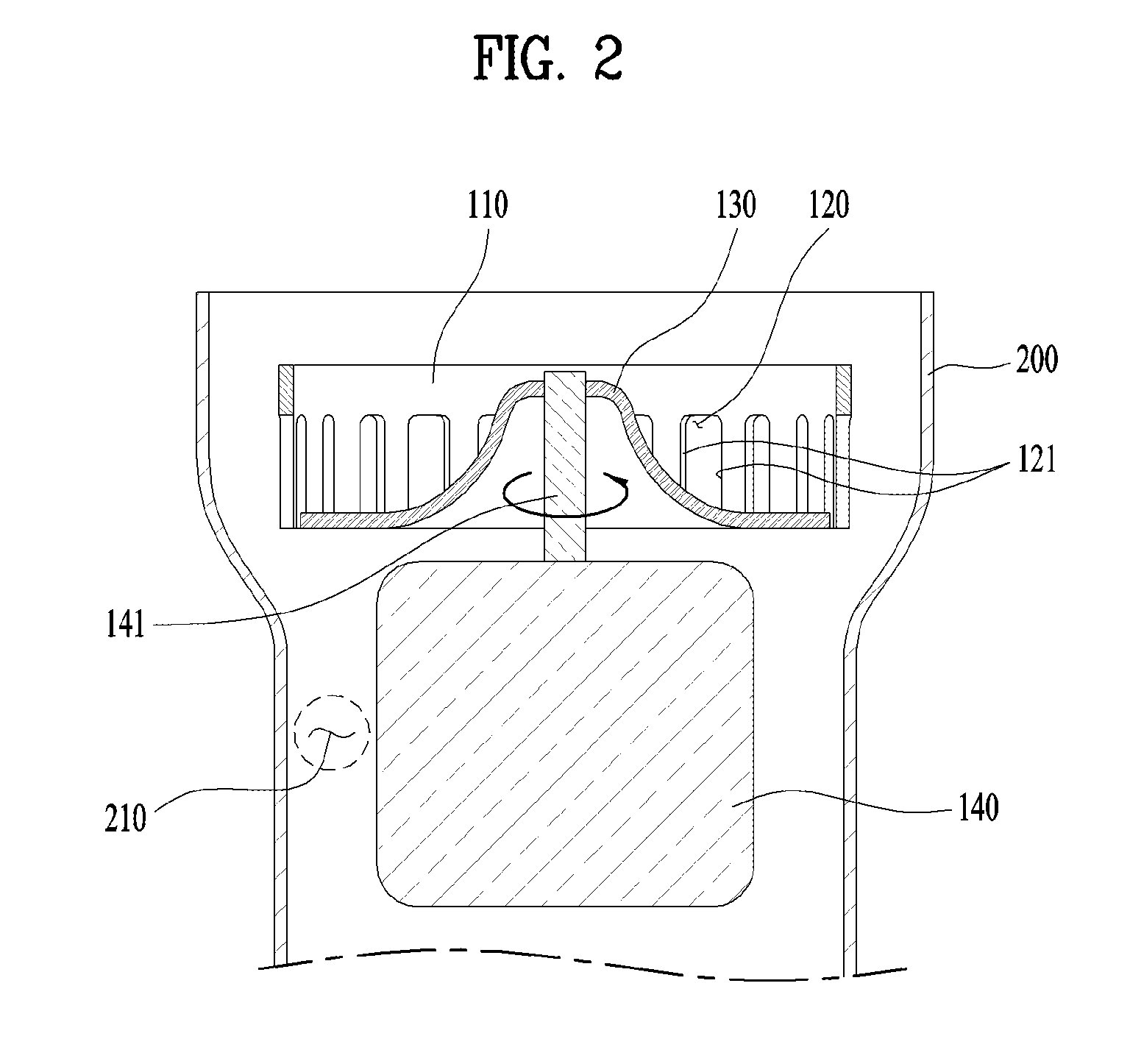

Mill for food materials

The present invention relates to a mill for food materials. The food mill for food material according to the present invention comprises: a housing having a inlet port for feeding in food materials and an outlet port for discharging the ground food materials; a pair of impellers having a central portion and a plurality of blade portions extending radially outwardly from the center portion such that the blade portions are spaced apart from each other, the pair of impellers being installed inside the housing; and a pair of driving bodies for driving the pair of impellers, respectively. The blade portions include vortex sides having recessed grooves, and the pair of impellers is arranged such that the vortex sides of the blade portions are opposite each other. The mill for food materials of the present invention grinds food materials by means of the mutual collision among the food materials and the collision between the food materials and the air during grinding, thus preventing foreign substances from being mixed with the unground food materials. The mill for food materials of the present invention can be used for dry or wet food materials, and may indirectly grind food materials by the operation of the mill rather than by direct grinding, thus maintaining the quality of the food materials. The mill for food materials of the present invention may include an impeller having a shape capable of forming a section in which the velocity is higher than the rotational speed of the impeller, thus enabling the food materials to be finely ground into uniform particles. Further, the mill for food materials of the present invention may maintain a low-temperature state during operation, thereby preventing the food materials from becoming spoiled due to high temperatures.

Owner:KOREA FOOD RES INST

Food ingredient effective component extraction mechanism and ingredient making equipment based on same

ActiveCN111713722AEasy to separateGuaranteed continuityFood mechanical treatmentFood shapingProcess engineeringFood products

The invention discloses a food ingredient effective component extraction mechanism and ingredient making equipment based on same. The food ingredient effective component extraction mechanism comprisesa processing box for grinding food ingredients, a grinding roller for grinding the food ingredients and arranged in the processing box, wherein the grinding roller divides the processing box into a storage cavity and a conversion cavity, so that the food ingredients before and after grinding are conveniently separated; and continuity of food ingredient powder from food ingredients in grinding process is ensured, the phenomenon that the grinding efficiency is reduced due to the repeatedly-ground food ingredient fragments is avoided, the discharging hole is formed below the conversion cavity, it is guaranteed that the food ingredient fragments naturally pass through the discharging hole, and effective ingredients in the food ingredient fragments are extracted through an extraction box. A rotatable centrifugal cylinder is arranged in the extraction box, water is injected into the extraction box, the food ingredient powder is centrifuged through rotation of the centrifugal cylinder, effective components in the food ingredient powder are centrifugally mixed in the water, a mixed solution with the effective components is generated, and extraction of the effective components in the foodingredient powder is completed.

Owner:HUAINAN YISHENG FOOD

Food processing sterilization device

PendingCN113040313AControl fall speedAvoid burnsFood preservationGrain treatmentsFood sterilizationEngineering

The invention discloses a food processing sterilization device which comprises a sterilization device body, wherein the sterilization device body comprises a sterilization box, supporting legs are fixedly connected to the lower end face of the sterilization box, a rotating rod is rotationally connected to the interior of the sterilization box, a groove is formed in a conveying belt, a food collecting device is arranged on the right end face of the sterilization device body, and the food collecting device comprises a hook. The invention relates to the technical field of food sterilization. The food processing sterilization device solves the problems that food is not sterilized conveniently in all directions, the ground food is not uniformly placed on a conveying device easily, and the food is inconvenient to cool when being taken out.

Owner:南京丰浩华食品供应链管理有限公司

Method for detecting fatty acid in food

InactiveCN106442797ARapid detection of relative contentReduce usageComponent separationSodium methoxideRetention time

The invention discloses a method for detecting fatty acid in food. The method includes grinding the food, sieving the ground food, filling a centrifuge tube with the sieved ground food, adding normal hexane, conducting heating extraction at 60 DEG C, adding a sodium methylate solution for methyl esterification, adding saturated sodium chloride, standing and taking liquid supernatant so as to obtain an analysis sample; detecting the analysis sample by gas chromatography and gas chromatography-mass spectrography to obtain retention time and a spectrum, and comparing the spectrum with a mass spectrum database to obtain a fatty acid components corresponding to different retention time; quantifying the peak area of corresponding fatty acid in the spectrum in terms of percentage, and computing and determining the percentage of each fatty acid component in the sample to be detected. The method for detecting the fatty acid in the food has the advantages of simplicity, convenience, less consumption of standard samples, simplified detection steps, shorter detection time, simple and feasible detection process, high repeatability and capability of being used for detecting relative content of the fatty acid in raw milk rapidly.

Owner:BEOSON JIANGSU FOOD SAFETY TECH CO LTD

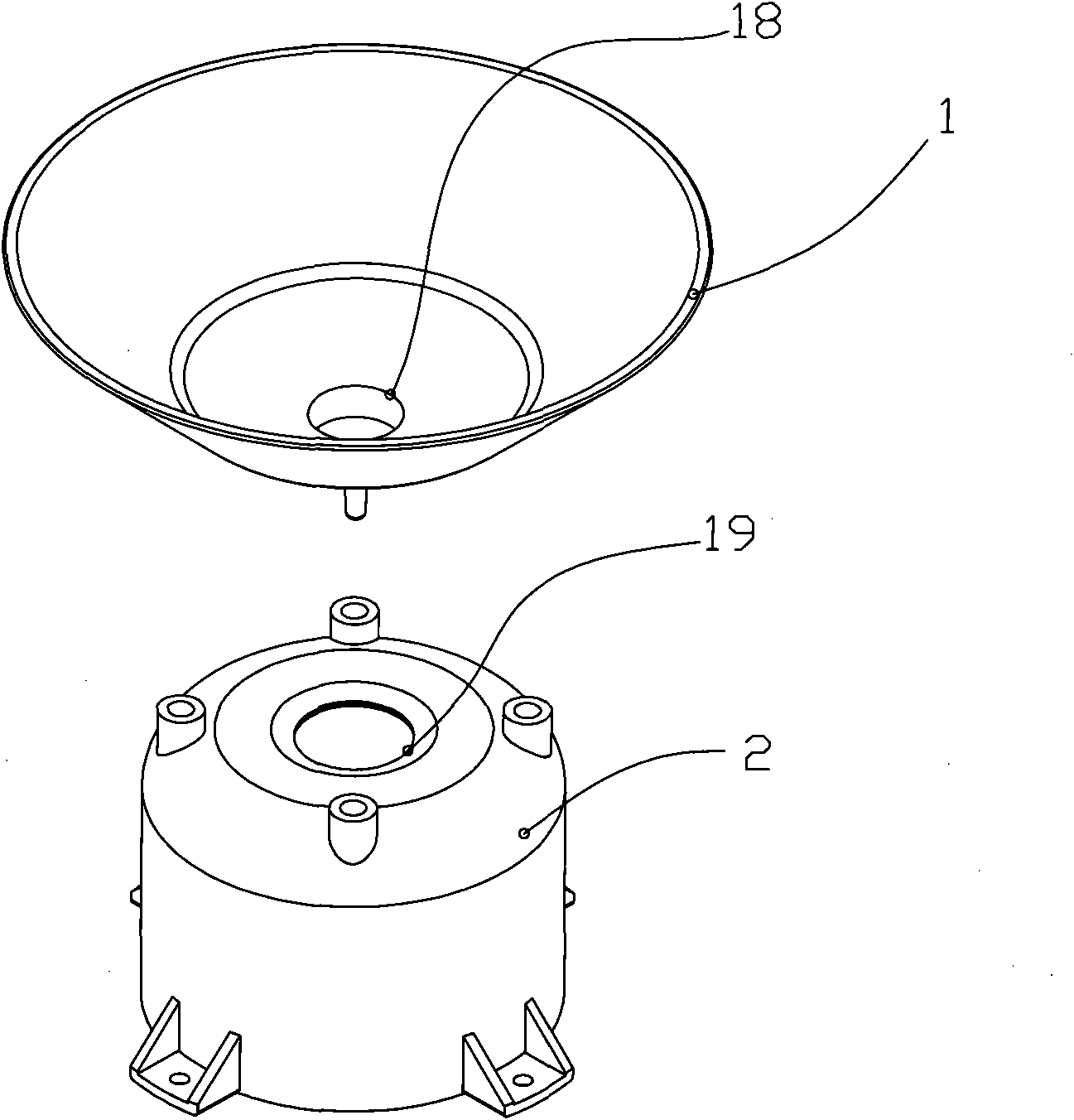

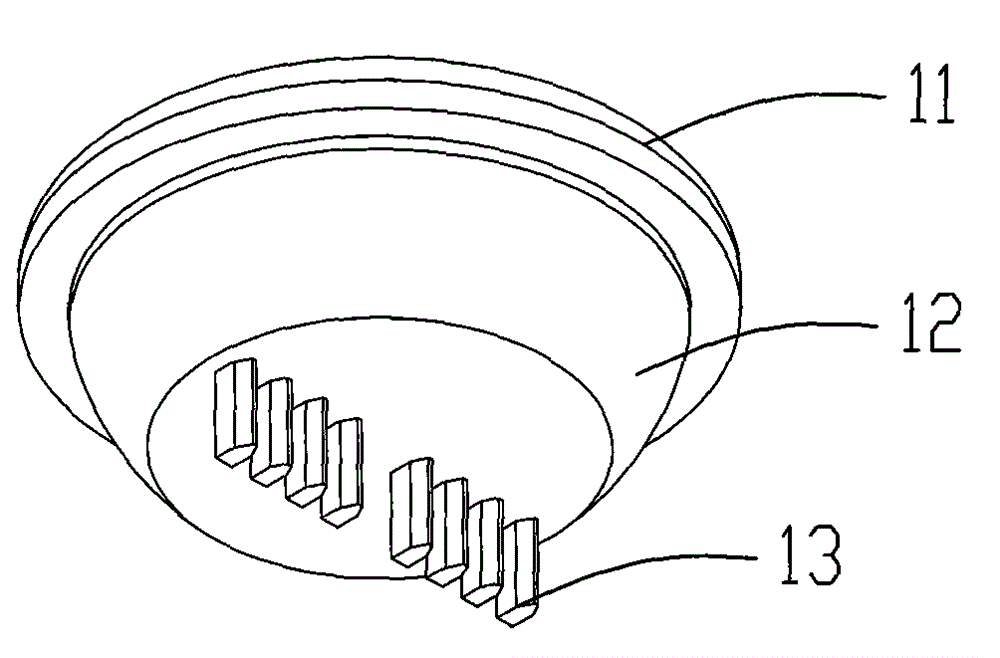

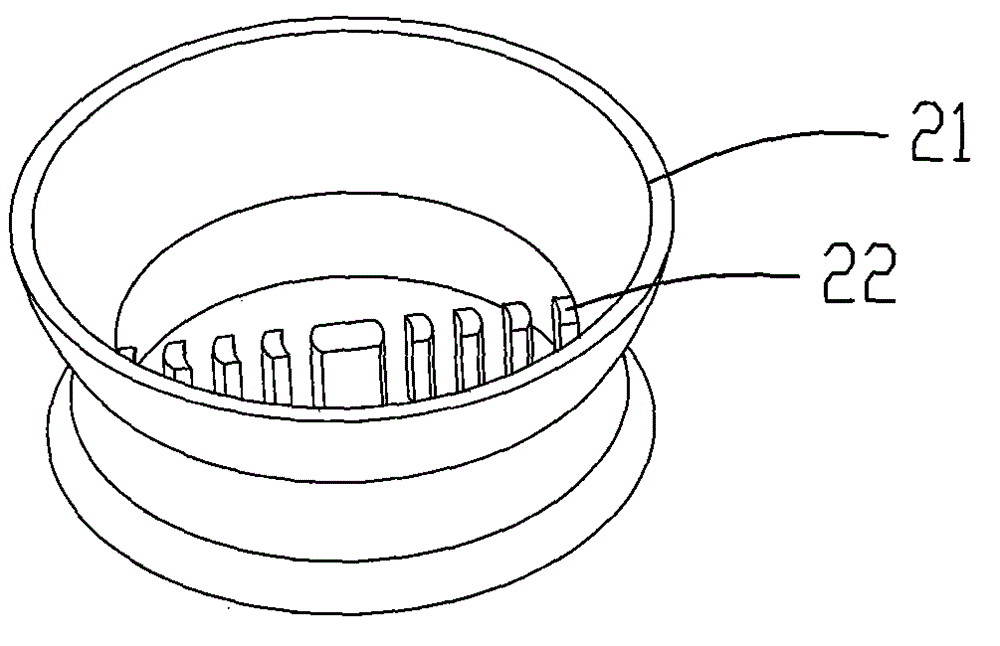

Infant food cutting and grinding bowel

The invention discloses an infant food cutting and grinding bowel. The infant food cutting and grinding bowel comprises an upper grinding body and a lower grinding bowel, wherein the upper grinding body consists of a grinding cover, a grinding post and a plurality of upper grinding teeth; the upper grinding teeth are fixed to the bottom of the grinding post; the lower grinding bowel consists of a lower grinding bowel body and a plurality of lower grinding teeth; the lower grinding teeth are fixed in the lower grinding bowel body; a cutting opening is formed in each upper grinding tooth and is used for cutting a food; the upper grinding teeth and the lower grinding teeth can be mutually intersected to form a grinding surface and are used for grinding the food. Due to the fact that the design that the upper grinding teeth and the lower grinding teeth are adopted to simultaneously cut or grind is adopted, the cutting and grinding speeds are quickened, the time is saved; due to the fact that clearances among the grinding teeth can grind and extrude the food during a cutting and grinding process, the ground food is softer; the granularity of the food can be freely controlled by manual cutting and grinding. The infant food cutting and grinding bowel is simple in structure and simple in appearance, the upper grinding body and the lower grinding bowel can be combined together during storage or carrying, a storing space is formed in the upper grinding body to store the food and a spoon, and the infant food cutting and grinding bowel has the characteristics of convenience in carrying and the like.

Owner:刘鑫

Cooled grinder head

An apparatus for grinding food products includes a housing including an inlet for receiving food products to be ground, an outlet for discharging the ground food product, and a grinding portion for housing components operable to grind the food product. The apparatus also includes a chamber for containing a coolant for cooling the grinding portion.

Owner:BLUE SKY INNOVATION GROUP

A kind of calf feeding acidified milk powder and its preparation method and feeding method

ActiveCN105053209BCompatible with pH rangeGood storage stabilityMilk preparationAccessory food factorsFood gradeDairy industry

The invention provides acidified milk powder fed to calves as well as a preparation method of the acidified milk powder and a feeding method of the calves. The preparation method comprises the following steps: A1: respectively weighing milk powder and food-grade solid formic acid, grinding the weighed food-grade solid formic acid, and screening the ground food-grade solid formic acid through a 300-mesh sieve so as to obtain solid formic acid powder; and A2: under the condition that the temperature is below 8 DEG C, compounding the milk powder and the solid formic acid powder in the mass ratio of the milk powder to the solid formic acid powder being 50-200: 1, and thoroughly mixing the milk powder and the solid formic acid powder according to a specific mixing manner so as to obtain the acidified milk powder fed to the calves. The feeding method comprises the following steps: C1: firstly, preparing the acidified milk powder fed to the calves according to the preparation method; C2: pouring the acidified milk powder into water of which the temperature is 10-20 DEG C, and sufficiently stirring the acidified milk powder and the water until the acidified milk powder is melted so as to obtain acidified milk; and C3: supplying the acidified milk to the calves so that the calves freely drink the acidified milk. The acidified milk powder, the preparation method and the feeding method have quite important realistic significance and economic value in the field of breeding industry or dairy industry.

Owner:CHINTEM TECH CONSULTING BEIJING CO LTD

Food additive detector

InactiveCN113358430AThe test result is accuratePreparing sample for investigationFood additiveThermodynamics

The invention is suitable for the technical field of food detection, and provides a food additive detector, which comprises a box body, a detection box, a primary grinding mechanism, a screening mechanism, a secondary grinding mechanism and an adjusting mechanism, wherein the primary grinding mechanism is installed at the upper half part of the box body, and is used for carrying out primary grinding on a to-be-detected food additive; the screening mechanism is fixedly mounted on the inner wall of the middle part of the box body and is used for screening the preliminarily ground food additives; the secondary grinding mechanism is connected with the bottom of the screening mechanism through a material receiving barrel and is used for improving the grinding precision; the adjusting mechanism is mounted at the bottom of the secondary grinding mechanism and used for adjusting a gap of the secondary grinding mechanism, and the food additives are ground before detection, so that it can be guaranteed that material samples detected by the detection equipment are consistent in the detection process, and the food additives with different volumes are not doped in the detection equipment; the volume of the finally detected food additive sample can be adjusted through the adjusting mechanism, so that the detection result is more accurate.

Owner:JIANGSU NUOPULE BIOTECH CO LTD

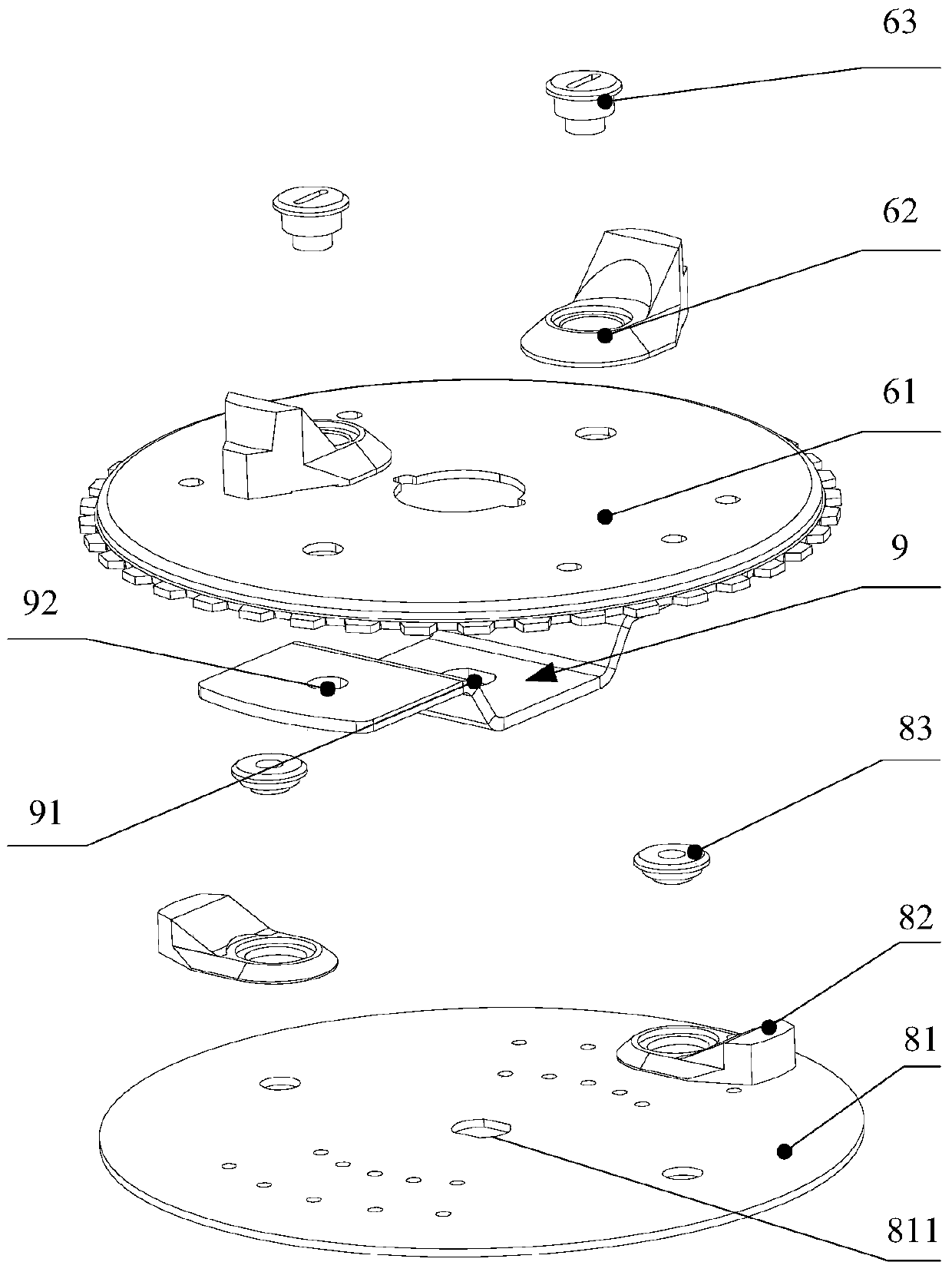

Food waste disposer and its grinding mechanism

ActiveCN105689065BImprove grinding finenessFully cutDomestic plumbingGrain treatmentsMotor shaftSewerage

Owner:GREE ELECTRIC APPLIANCES INC

Food grinder

The invention discloses a food grinder. A cutter holder system of the grinder comprises a cutter holder and a cutter shaft, wherein the cutter holder is provided with a bearing; the lower end of the cutter shaft is arranged in the bearing, and the upper end of the cutter shaft is provided with a grinding component; a cup body is provided with a material inlet communicated with the outside; a filtering device is sleeved below the grinding component on the cutter shaft; a powder discharging / heat radiating device is sleeved below the filtering device; a powder discharging / heat radiating device is sleeved above the bearing on the cutter shaft; and a position on the side wall of the cutter holder, which corresponds to the powder discharging / heat radiating device, is provided with an outlet communicated with the outside. Food is delivered to the cup body from the material inlet and ground by the grinding component; the grinding degree is controlled by the filtering device; and the ground food is discharged from the food outlet by the powder discharging / heat radiating device. A convective air cooling system is formed on a passage in a whole food treating process so as to rapidly carry heat produced by high-speed friction between the cutter shaft and an oil-containing bearing out of the cup body and realize automatic food treatment started from feeding. The grinder can run continuously without causing thermal protection and powder burning and the service life of the grinder is prolonged.

Owner:MIDEA GRP CO LTD

Food grinding device for person having weak masticatory function

PendingCN112334049AEffective intakeImprove cleanlinessCleaning using gasesMetal working apparatusProcess engineeringIngested food

The present invention relates to a food grinding device for a person having a weak masticatory function and, more specifically, to a food grinding device for a person having a weak masticatory function, which: grinds food to allow a person having a weak masticatory function to ingest the food well; enables food to be put into and then taken out of the device in a state where the food is placed ona plate, so that a person can instantly eat the food without hassle of transferring the ground food onto the plate; enables an inner portion thereof, coming into contact with food, to be clearly washed; and has a defrosting function and a food quantity limit function.

Owner:崔沃先

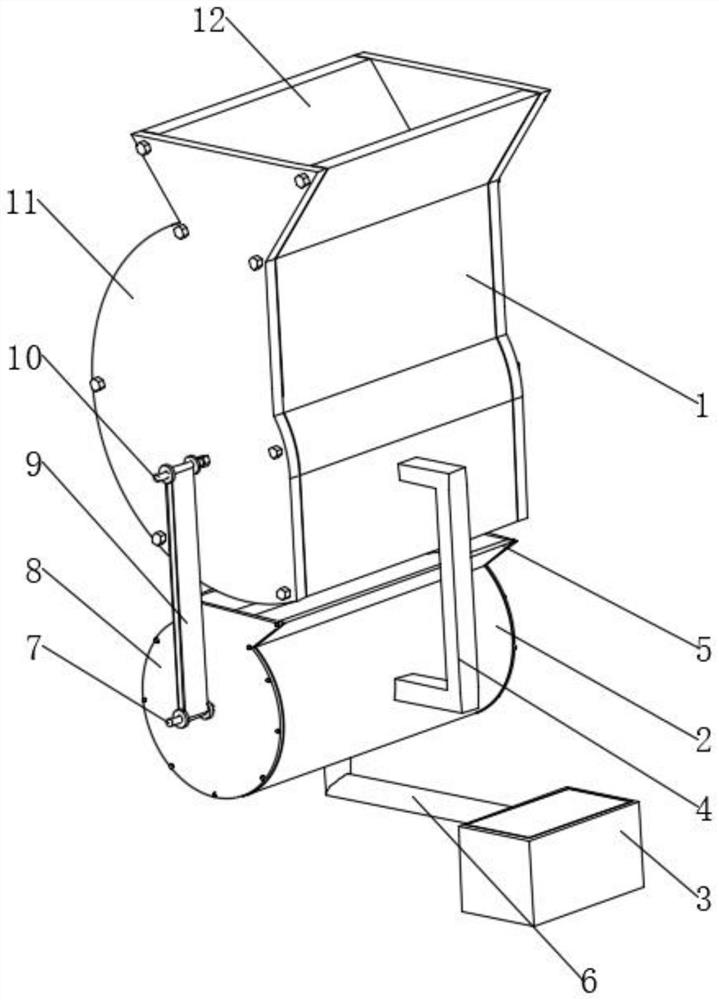

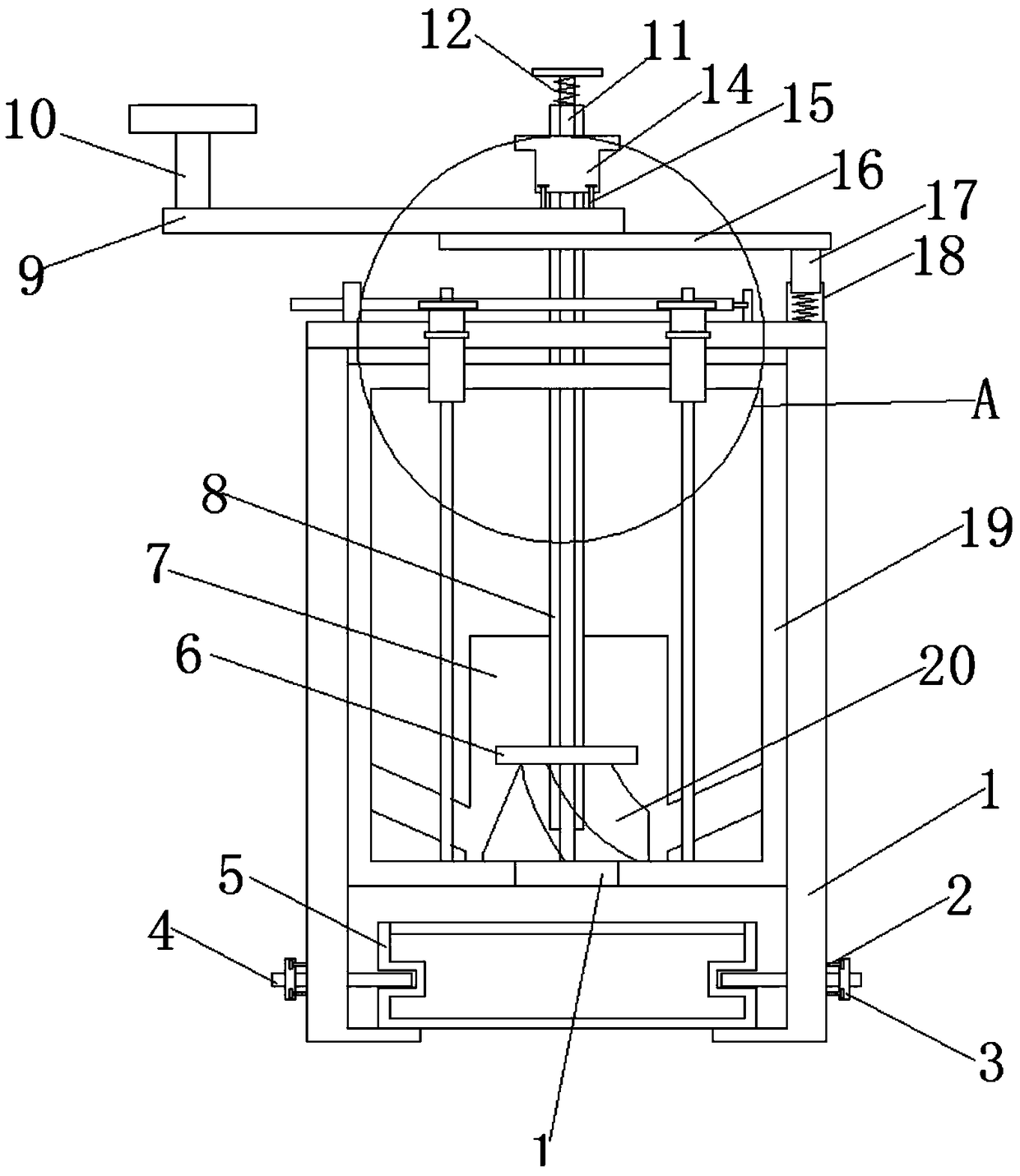

Solid waste treatment device for ground food

InactiveCN112296059AEasy to handleReduce humiditySievingSolid waste disposalEnvironmental engineeringWaste treatment

The invention discloses a solid waste treatment device for ground food. The solid waste treatment device comprises a feeding hopper, a drying pipe is connected to the bottom of the feeding hopper; a material distribution pipe is connected to the side wall of the drying pipe; a screening net is embedded in the position, close to the middle, of the inner surface of the drying pipe; an adjusting plate is embedded in the position, close to the bottom, of the inner surface of the drying pipe; electric heating wires are arranged at the positions, close to the periphery, in the drying pipe; a connecting pipe is connected to the bottom of the drying pipe; a discharging pipe is connected to one end of the connecting pipe; a containing table is fixedly installed on the outer surface of the other side of the connecting pipe; a draught fan is placed on the upper surface of the containing table; and a plurality of supporting legs are fixedly installed on the lower surface of the discharging pipe. According to the solid waste treatment device for the ground food, solid waste of the ground food can be screened, the solid waste of the ground food can be conveniently treated, and the discharging pipe can be effectively prevented from being blocked.

Owner:徐州中泰生物科技有限公司

Food waste disposal

A food waste disposal includes a grinding part configured to grind food waste, a dewatering part configured to receive the ground food waste from the grinding part and to discharge water out of the received food waste, and a connecting frame having a rotating shaft. The dewatering part is rotatably coupled to the connecting frame via the rotating shaft. Further, the dewatering part is configured to be rotated vertically downward away from the grinding part in a top / bottom direction around the rotating shaft.

Owner:LG ELECTRONICS INC

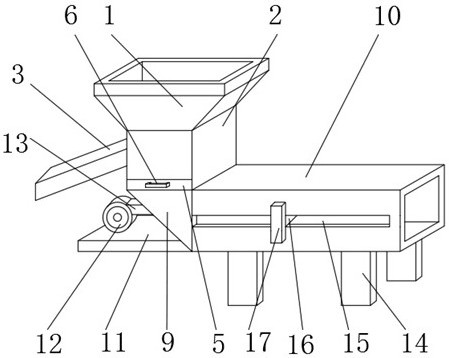

Grinding machine

The invention discloses a grinding machine. The grinding machine includes a rack and a bracket; a glass cover is arranged on the inner wall of the bracket, a casing pipe is welded to the top of the bracket, a spring is welded to the bottom of the inner wall of the casing pipe, a first jacking rod is welded to the other end of the spring, the other end of the first jacking rod penetrates through the casing pipe, and a second fixing plate is welded to one end of the first jacking rod; a through hole is formed in the top of the second fixing plate, and a second fixing rod is arranged in the through hole. Through the structures including a second jacking rod, a second screw block, a worm wheel, a worm and the like, finished Sichuan pepper products can enter a plastic block to be ground by a smashing device, the freshness of food materials is ensured, the food materials are used directly after being ground, and the taste of the food materials is guaranteed and is pure. Through the structures including a rotating plate, the smashing device, a second fixing rod, a fourth fixing rod and the like, the food materials are better ground into powder, and the efficiency of grinding the food materials is ensured; after the food materials are ground well, the ground food materials are taken out conveniently and quickly, then next grinding is carried out, and the working efficiency is improved.

Owner:新沂新昆金属制品有限公司

Equipment for detecting heavy metal ions in food

PendingCN114235535AAdequate responseReduce mistakesMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationStructural engineeringColor reaction

The invention discloses equipment for detecting heavy metal ions in food. The equipment comprises a bottom plate, and a grinding assembly used for grinding the food is arranged above the bottom plate; the grinding assembly comprises a grinding box fixed to the top of the bottom plate through a support, a rotatable rotating shaft is arranged in the grinding box, an eccentrically-arranged gear is arranged at the bottom end of the rotating shaft, the bottom of the grinding box communicates with a vertical pipe, and a fixing rod is fixed to the inner bottom of the vertical pipe. A grinding disc is fixed to the top end, stretching into the grinding box, of the fixing rod, and a grinding disc making contact with the grinding disc is fixed to the bottom end of the gear. Food can be ground into powder, a color developing agent can be in full contact with the food powder after being added, so that heavy metal in the food reacts with the color developing agent more sufficiently, meanwhile, the ground food powder can be subjected to multi-part collection and color developing reaction, and the error of a detection result is further reduced through combination of the collection and the color developing reaction; and the detection result is more accurate.

Owner:莒南县检验检测中心

Grinding machine for food detection pretreatment

PendingCN114405596AEasy to cleanReduce labor intensityPreparing sample for investigationGrain treatmentsEngineeringMechanical engineering

The grinding machine for food detection pretreatment comprises a device box, a feeding hopper, first rotating shafts, a mounting frame, a first connecting rod and a connecting plate, the feeding hopper is mounted at the top end of the device box, the first rotating shafts are mounted on the side walls of the two ends in the feeding hopper through bearings, and roller bodies are mounted on the outer walls of the first rotating shafts; second supporting plates are mounted on the side walls of the two ends in the feeding hopper, mounting frames are mounted at the top ends of the second supporting plates, a through hole is formed in the side wall of one side of the device box, a conical scraping plate penetrating through the through hole is mounted on the side wall of one side in the device box, and a mounting box is mounted on the side wall of one end of the device box. According to the grinding machine for food detection pretreatment, an arc-shaped plate is driven to ascend and descend in a reciprocating mode through deformation of a second spring body, vibration discharging is conveniently conducted on a conical scraper through the arc-shaped plate, and the situation that the discharging efficiency of ground food is affected due to the fact that food is accumulated at the top end of a discharging plate is avoided.

Owner:湖南吉大检验检测有限公司

Sugar reduction of food products

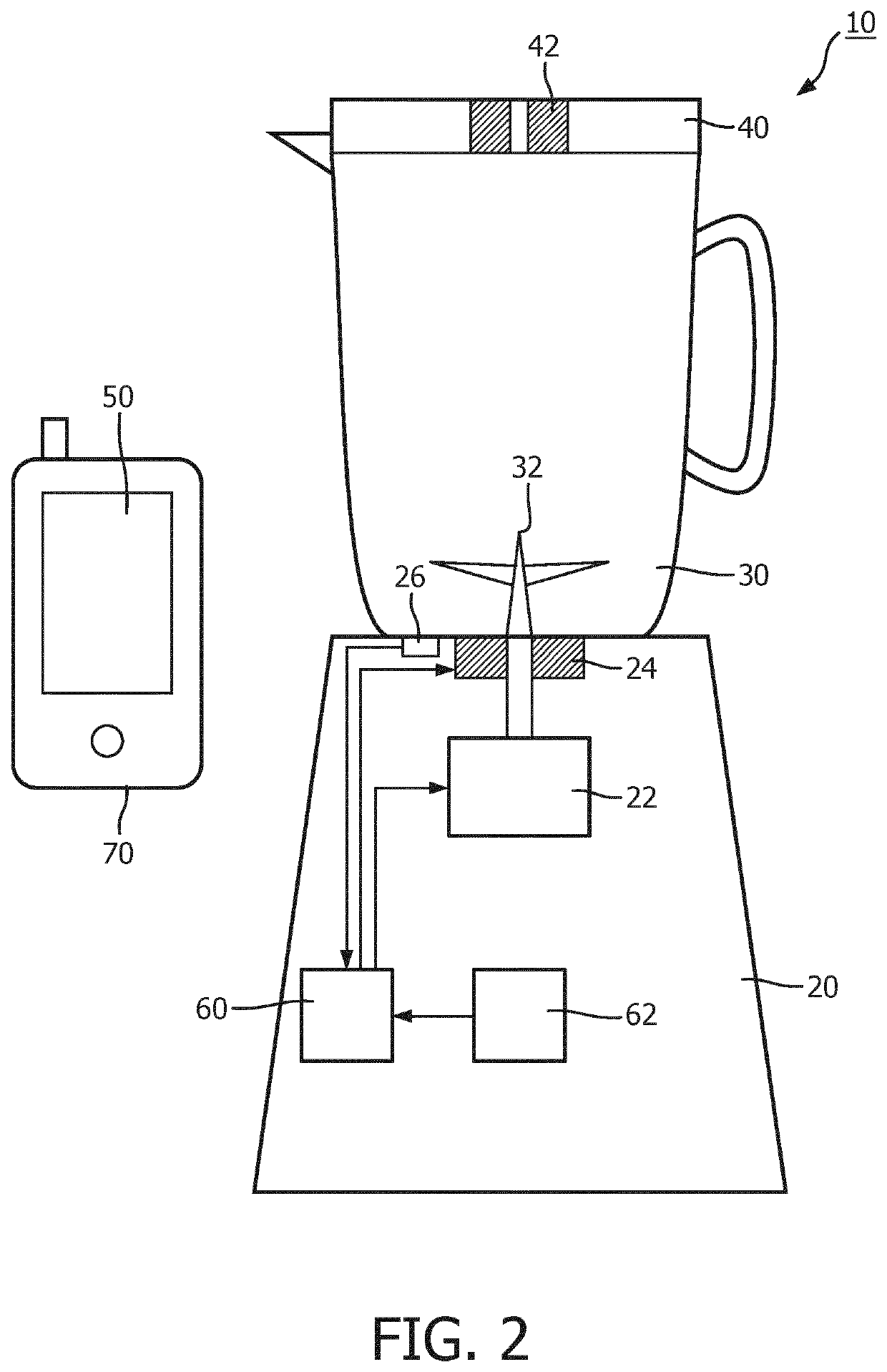

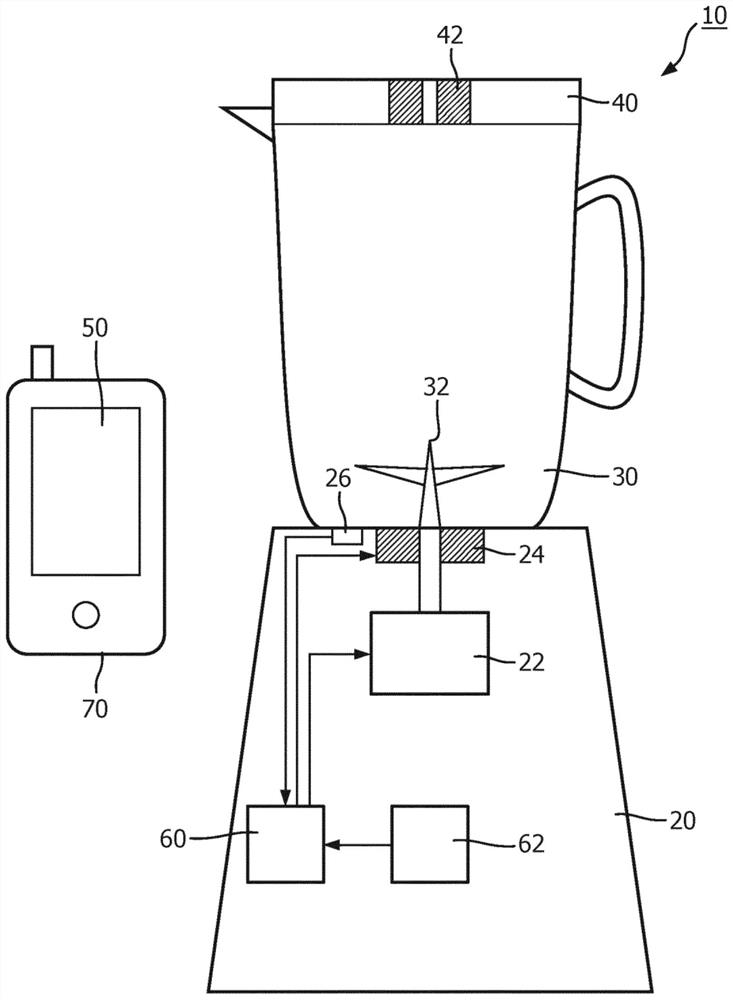

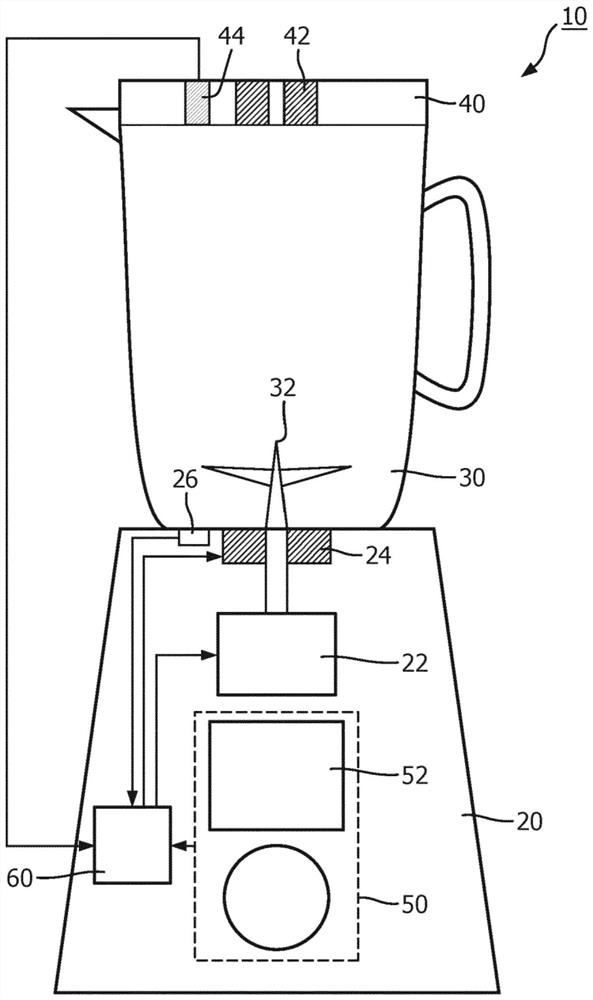

PendingUS20220175191A1Reduced reducing sugar contentImprove health benefitsVessels with intergral heatingTime-controlled ignitorsElectric machineryProcess engineering

A food processing apparatus and method reduces a sugar content of a food product. The food processing apparatus includes a food processing compartment including a blade arrangement, a base including a motor to drive the blade arrangement, a heating arrangement for heating the food product in the food processing compartment, and a controller to control the motor and the heating arrangement. The controller, in a fermentation mode of operation of the food processing apparatus, operates the motor to grind the food product with the blade arrangement. The controller further operates the heating arrangement to heat the ground food product to a temperature in a range of 30-40° C. The controller further terminates the mode of operation after a period of time indicative of the completion of the mode of operation.

Owner:VERSUNI HLDG BV

Sugar reduction of food products

A food processing apparatus (10) is disclosed for reducing a sugar content of a food product. The food processing apparatus comprises a food processing compartment (30) including a blade arrangement (32); a base (20) including a motor (22) arranged to drive the blade arrangement; a heating arrangement (24) for heating a food product in the food processing compartment; and a controller (60) arranged to control the motor and the heating arrangement. The controller is arranged to, in a fermentation mode of operation of said food processing apparatus, operate the motor to grind the food product with the blade arrangement; operate the heating arrangement such as to heat the ground food product to a temperature in a range of 30-40 DEG C; and terminate said mode of operation after a period of time indicative of the completion of said mode of operation. Also disclosed is a method of reducing the sugar content of a food product with such a food processing apparatus.

Owner:KONINKLJIJKE PHILIPS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com