Mill for food materials

A pulverizer and raw material technology, applied in the fields of food science, cocoa, grain processing, etc., can solve the problems of the decline in the quality of food raw materials, the increase of time, and the inability to obtain food pulverized products, and achieve the effect of preventing deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] 1) device

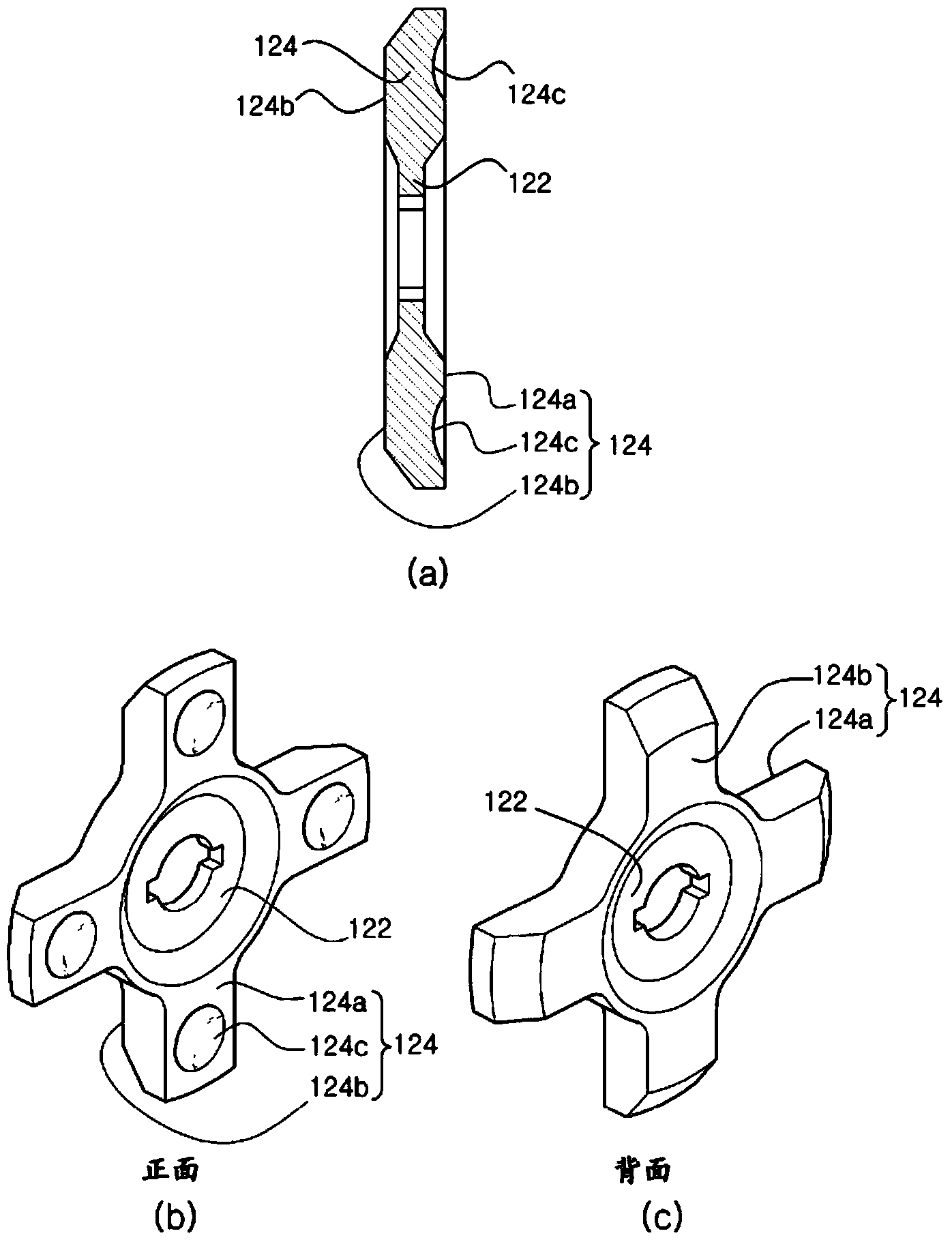

[0047] exist image 3 (a) The cyclone mill is suitable image 3 (b) The impeller.

[0048] 2) Input food raw materials

[0049] Japonica rice harvested in Yangpyeong, Gyeonggi-do in 2011, glutinous rice harvested in Jincheon, North Chungcheong-do in 2011, and brown rice harvested in Cheorwon, Gangwon-do in 2011 were used.

experiment example

[0061] Each experiment was carried out after driving the food raw material pulverizers of Examples and Comparative Examples under the conditions of impeller speed 7000 rpm, blowing speed 2000 rpm, and input speed 20 Hz.

[0062] 1) Determination of powder loss rate (%) and production capacity (kg / hr)

[0063] The input weight and output weight are measured to determine the loss rate. As for the production volume, the production volume per hour is calculated by measuring the time from input to output. The calculated values are shown in Table 1 below.

[0064] Table 1

[0065]

[0066] From the results in Table 1, it was confirmed that the loss rate of the example was 0.5% lower or the same as that of the comparative example 1 when the impeller having the grooves was attached. Also, compared with Comparative Example 2, the loss rate of the Example was 1% lower or the same. Due to the difference in loss rate, compared with Comparative Example 1 and Comparative Example 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com