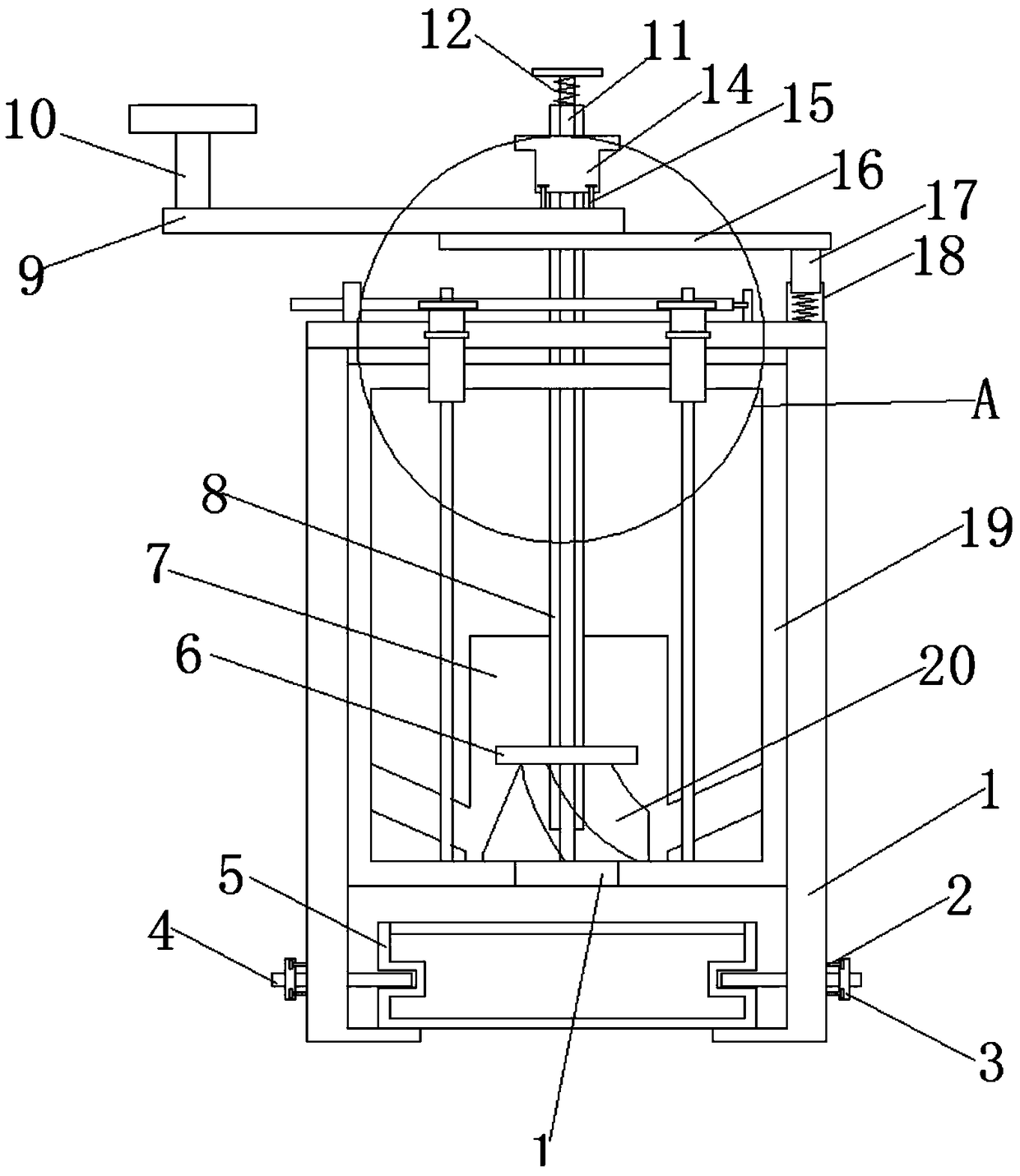

Grinding machine

A grinding machine and fixed rod technology, applied in the field of grinding machines, can solve the problems of original taste loss collection box, inability to fix resources, long grinding time, etc., to achieve the effect of shortening work efficiency, ensuring grinding efficiency, and ensuring taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

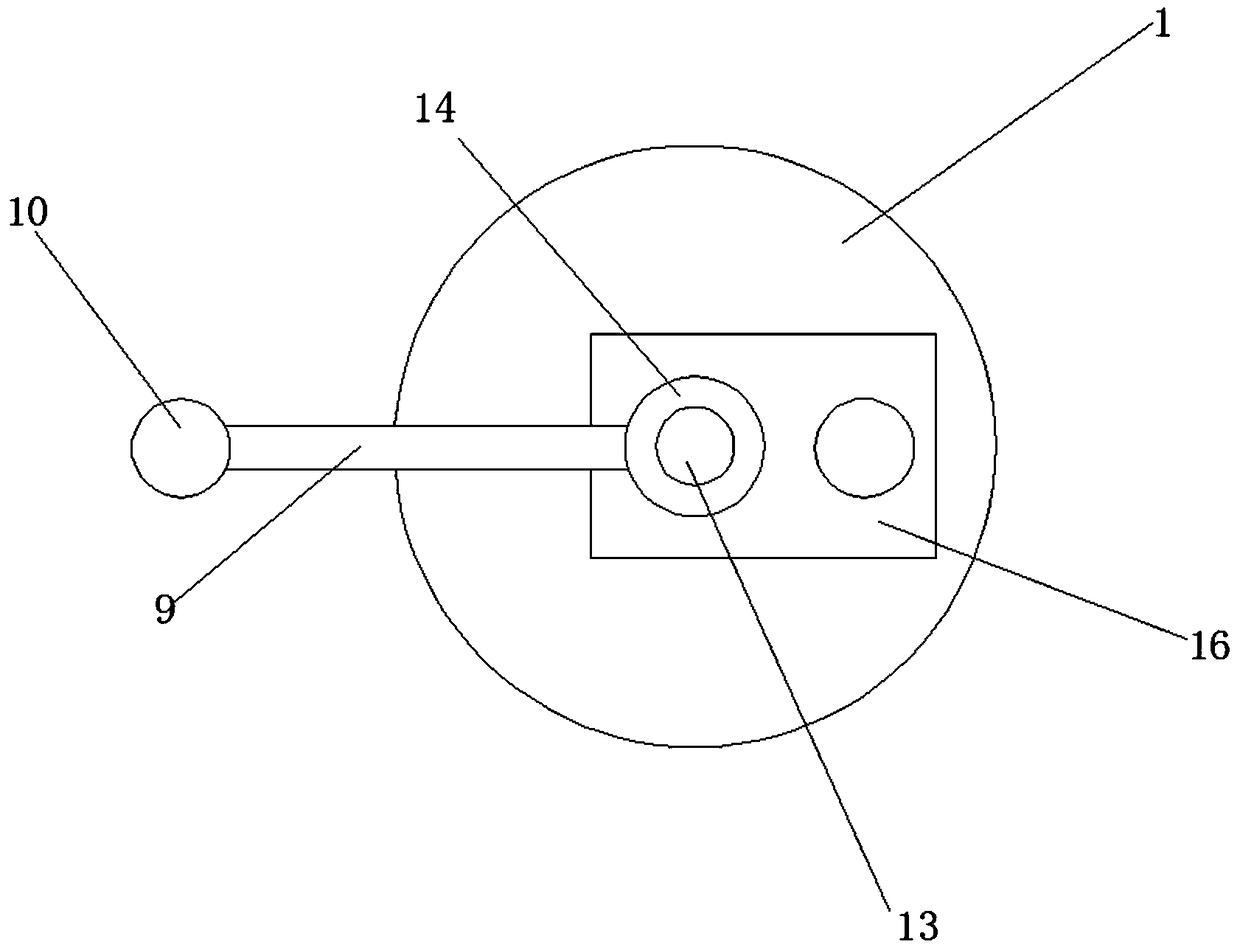

Embodiment 1

[0020] Embodiment 1. Firstly, the ingredients are poured from the through hole at the top of the second fixing plate 16. The bracket 1 and the top of the glass cover 19 are provided with through holes, and the straight lines where the central axes of the through holes are located are all on the same straight line. The food enters the glass cover 19 Inside, enter on the slope of plastic block 7, enter the inside of plastic block 7 along the slope through hole of plastic block 7, turn worm screw 13 at this moment, worm screw 13 drives worm wheel to rotate, and worm wheel drives second screw block 22 to rotate, and second screw block 22 drives The second ejector rod 21 moves upwards. The second ejector rod 21 cannot completely block the ingredients from entering the blender 20. The ingredients enter the mixer along the slope. At this time, the worm 13 is reversed so that the second ejector rod 21 blocks the passage again. Rotate the third fixed rod 10, the third fixed rod 10 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com