Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Fused core" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

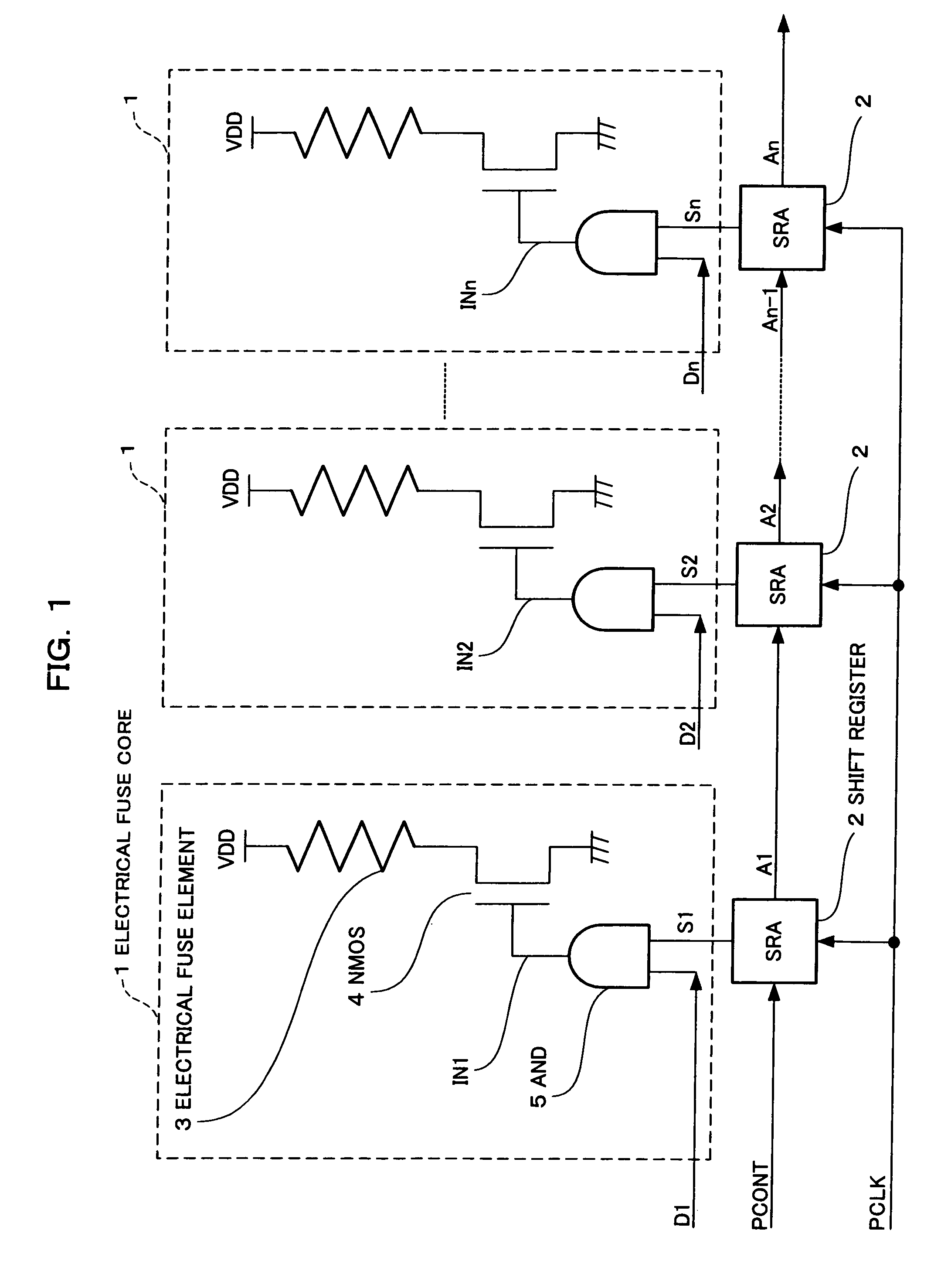

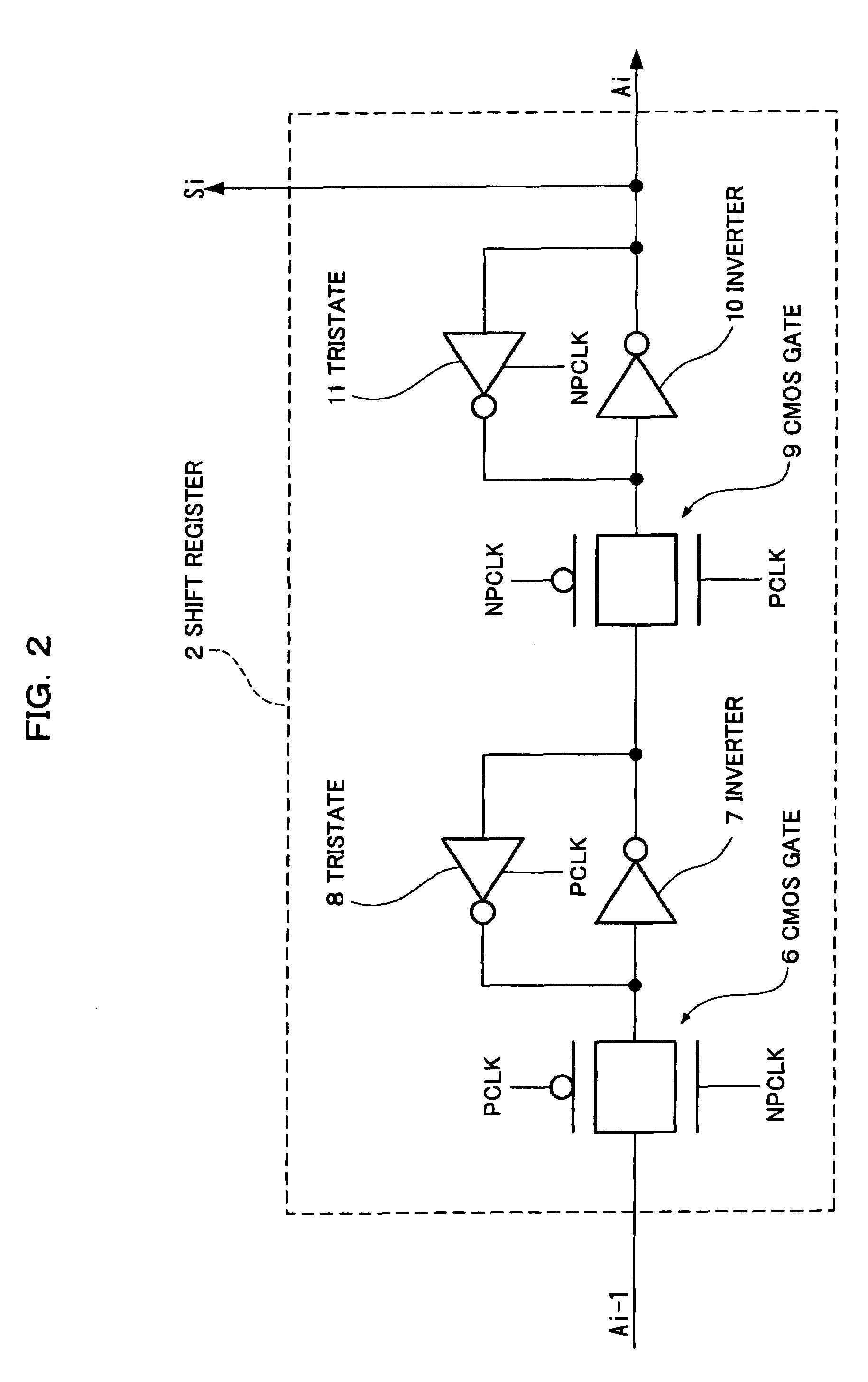

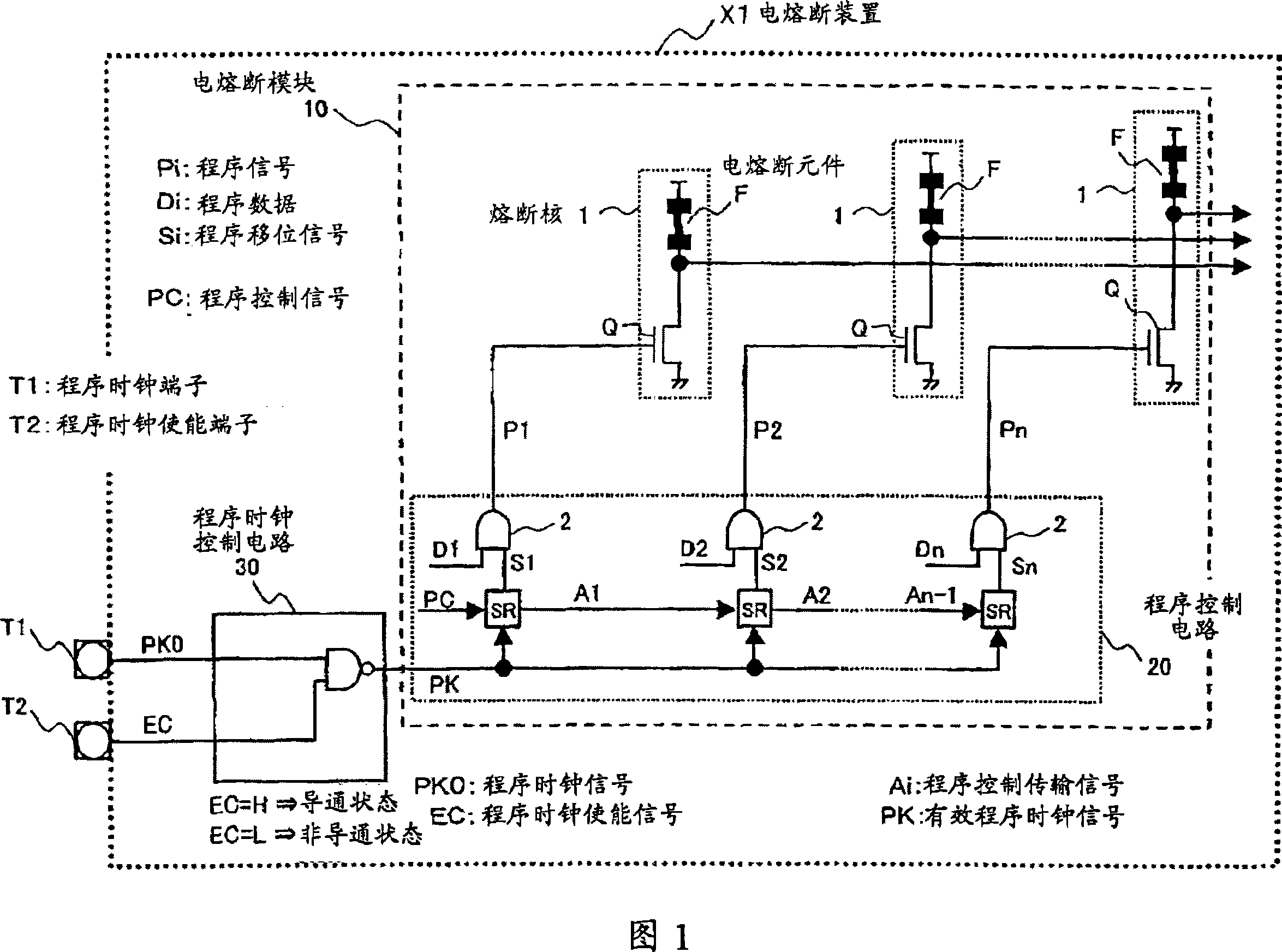

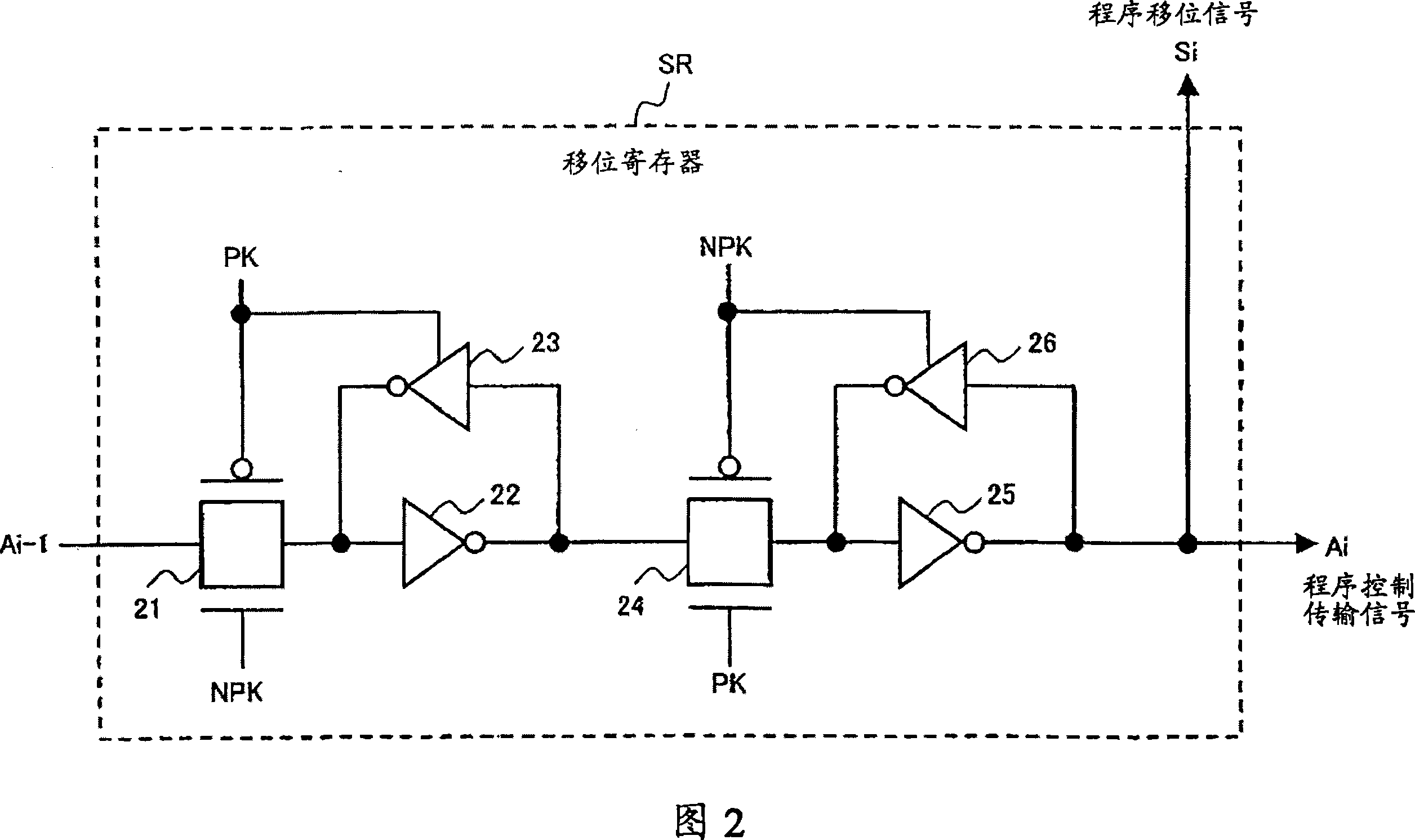

Electrical fuse circuit

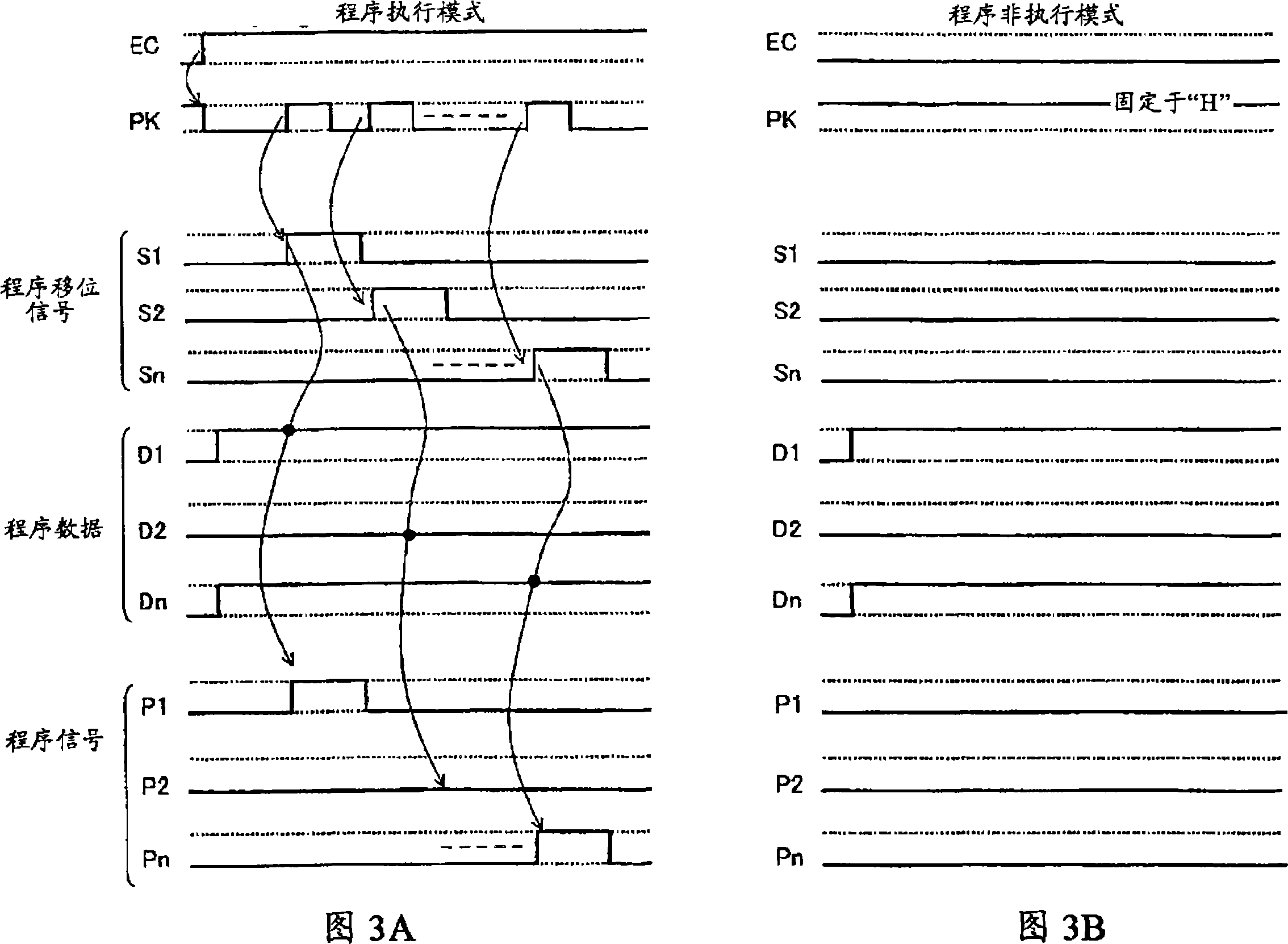

ActiveUS20060158920A1Shorten the timeReducing number of stageRead-only memoriesDigital storageShift registerElectricity

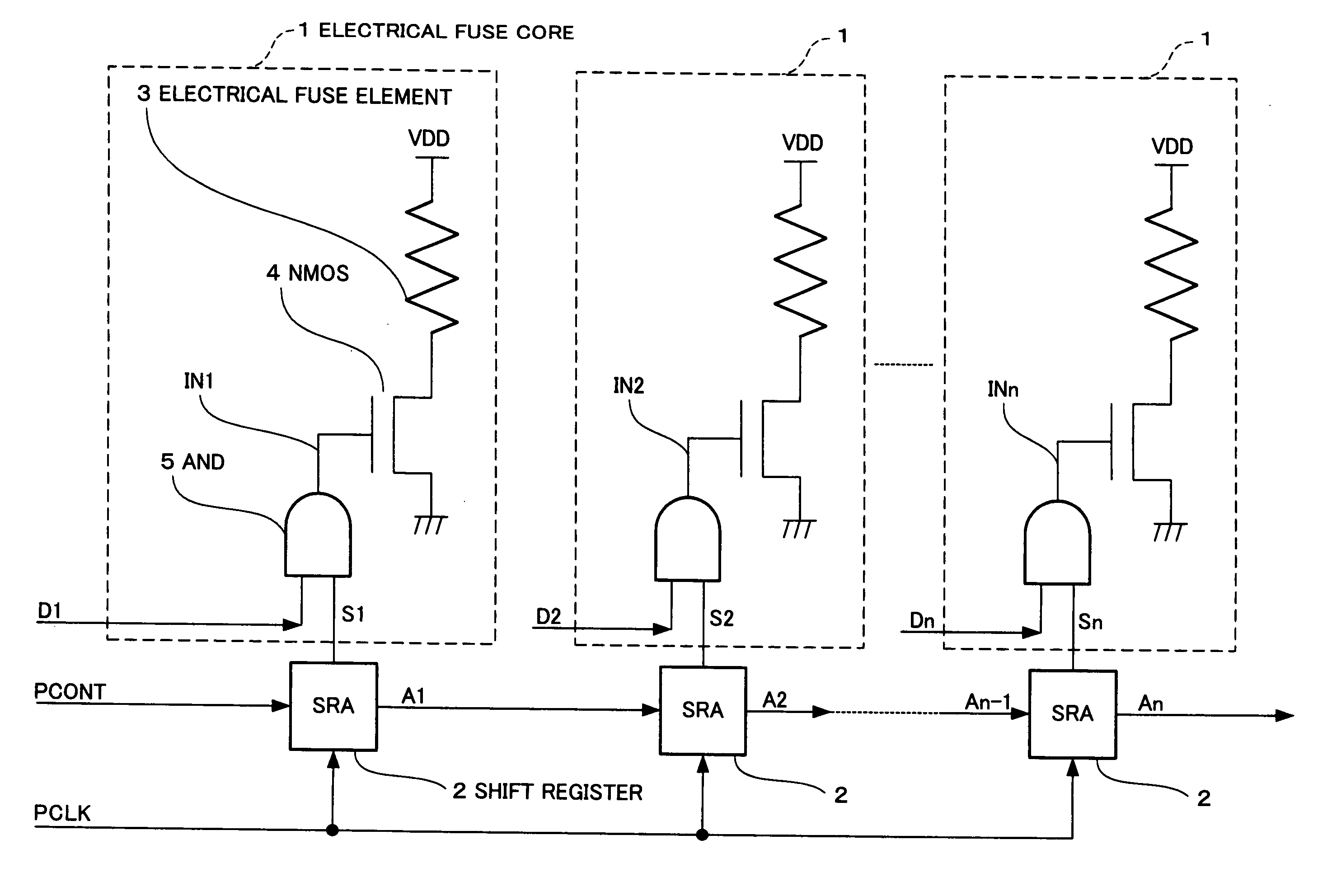

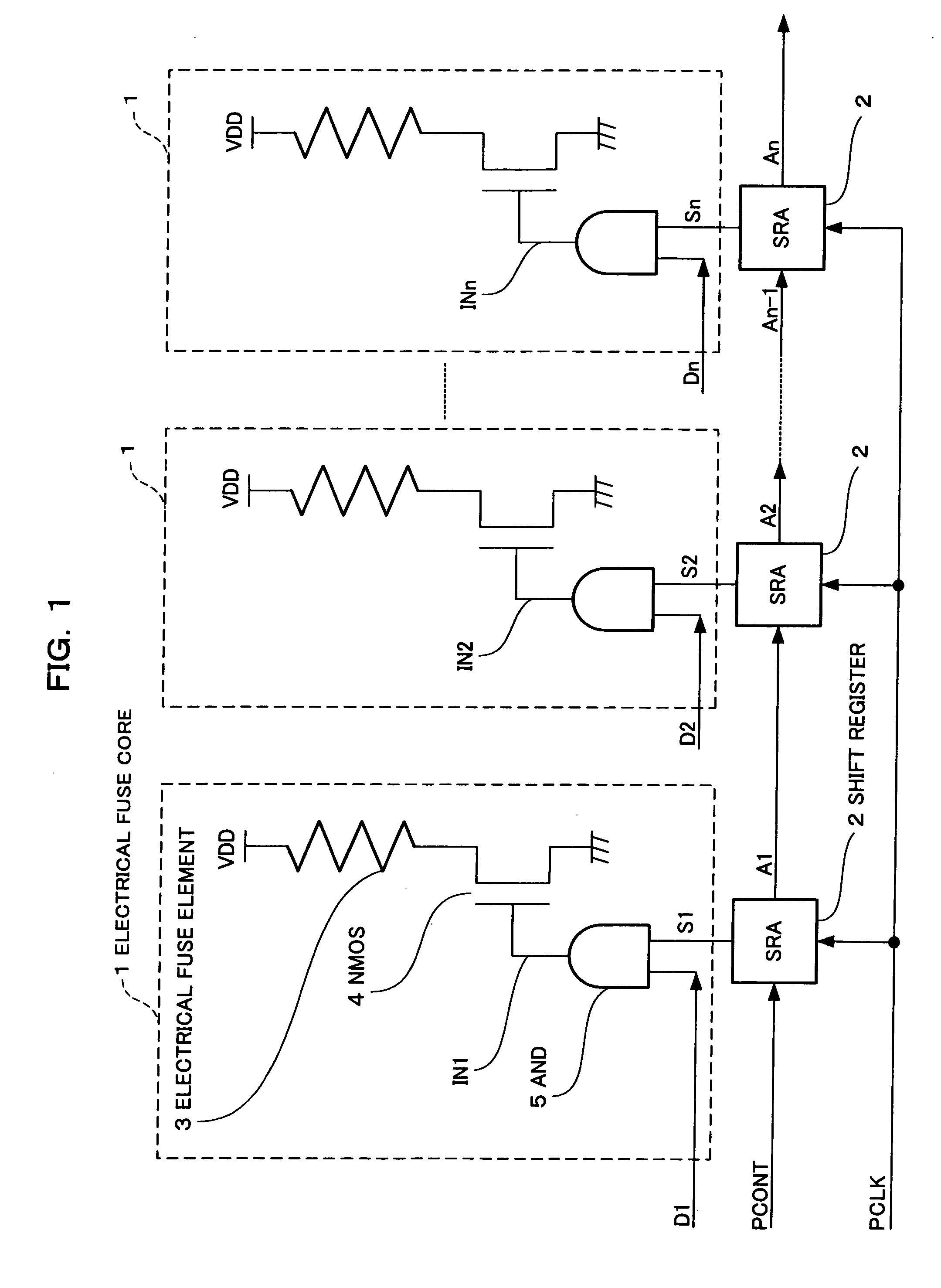

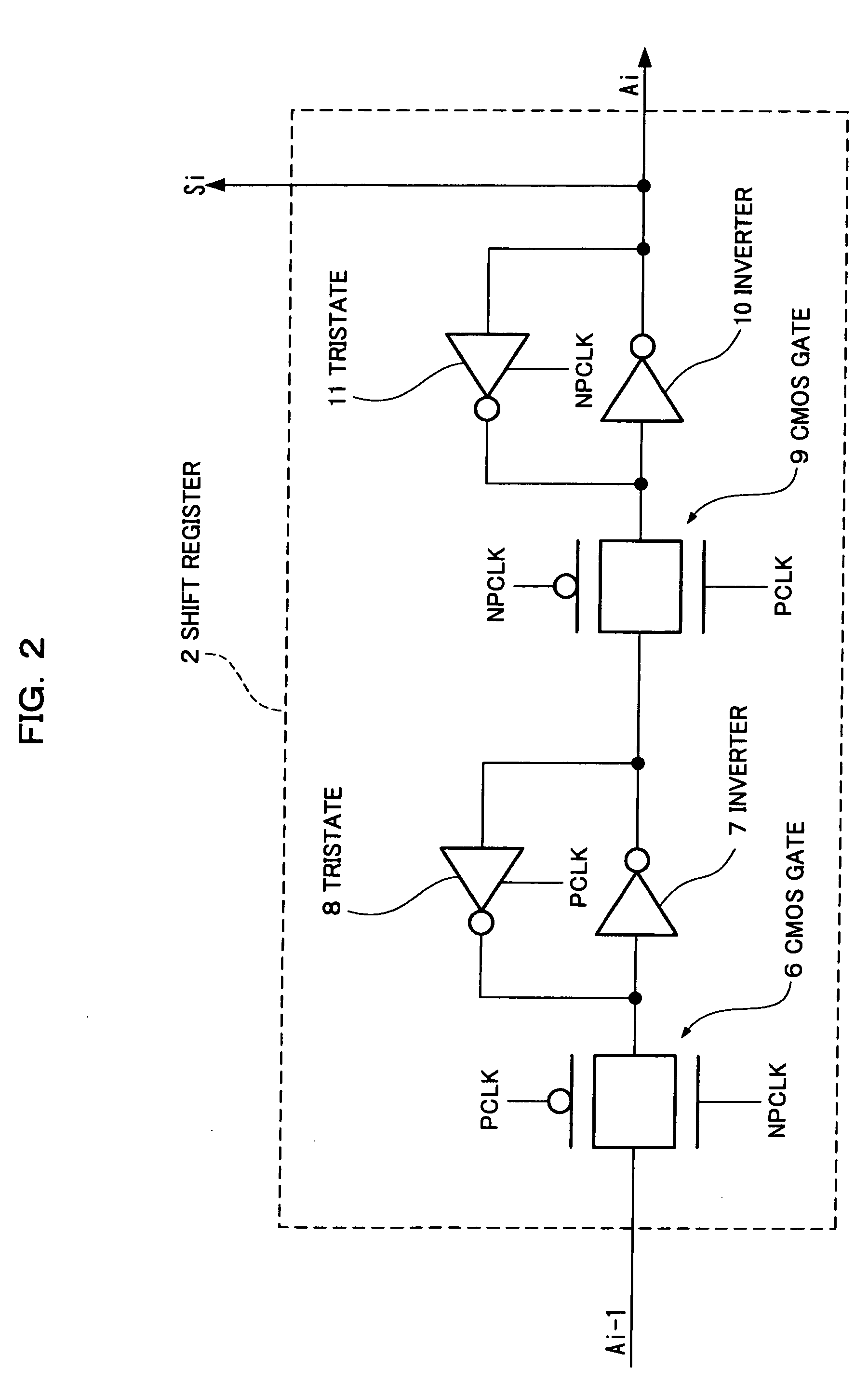

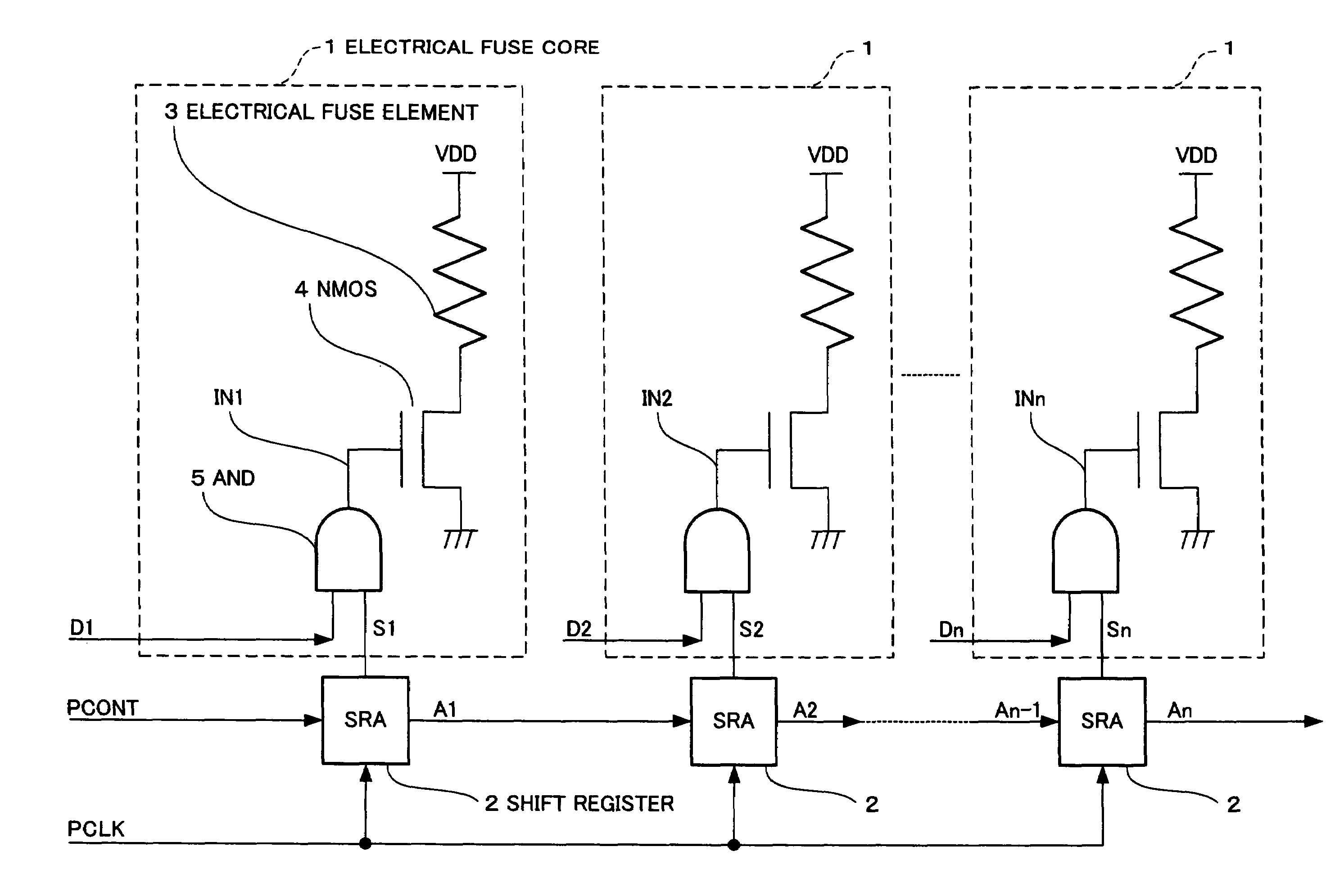

An electrical fuse circuit of the present invention includes a plurality of electrical fuse cores (1) each of which has an electrical fuse element (3) and a switch transistor (4) connected in series with each other, and shift registers (2) connected to the plurality of electrical fuse cores (1) to program the electrical fuse elements (3). Program enable signals (Si) are sequentially generated and transferred by the shift registers (2), the switch transistors (4) are sequentially brought into conduct according to the program enable signals (Si) and the information of program data (Di), and the electrical fuse elements (3) are blown one by one.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Electrical fuse circuit

An electrical fuse circuit of the present invention includes a plurality of electrical fuse cores (1) each of which has an electrical fuse element (3) and a switch transistor (4) connected in series with each other, and shift registers (2) connected to the plurality of electrical fuse cores (1) to program the electrical fuse elements (3). Program enable signals (Si) are sequentially generated and transferred by the shift registers (2), the switch transistors (4) are sequentially brought into conduct according to the program enable signals (Si) and the information of program data (Di), and the electrical fuse elements (3) are blown one by one.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

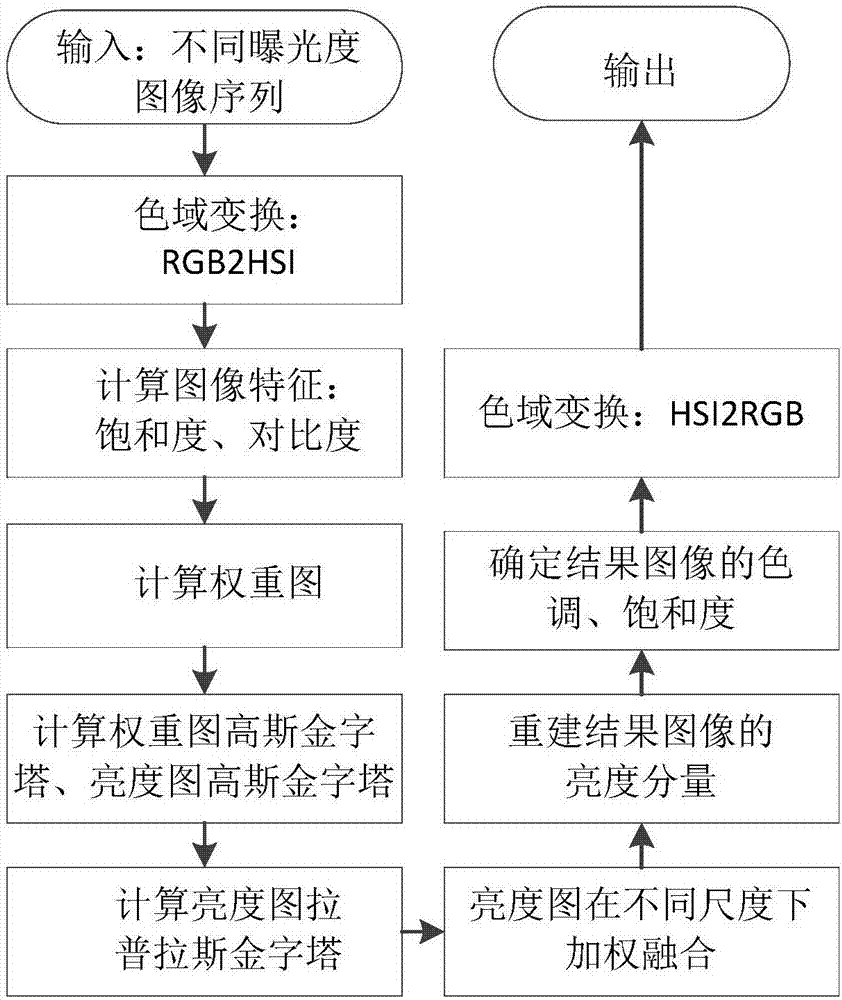

Direct multi-exposure fusion parallel acceleration method based on OpenCL

ActiveCN107292804AIncrease workloadReduce running timeImage enhancementImage data processing detailsFloating pointRunning time

The invention discloses a direct multi-exposure fusion parallel acceleration method based on the OpenCL; the method comprises the following steps: using a CPU+GPU heterogeneous parallel framework and the GPU strong floating point calculating capability, fusing cores under the OpenCL exploitation environment, caching a Gaussian kernel to a constant memory, caching reuse data to a local memory, and increasing the work load of each work item, thus shortening an access and calculation time, and realizing faster multi-exposure fusion. Compared with a conventional serial processing method, the method can obtain the maximum speed-up ratio reaching 11.19, thus effectively reducing the multi-exposure fusion algorithm operation time, and providing strong guarantee for further applications of the multi-exposure fusion algorithm; in addition, the method can obviously improve the space frequency and average gradient, thus effectively solving the scene detail information loss problems caused by insufficient electrography and display equipment dynamic scope.

Owner:XIDIAN UNIV

Lead-free low-temperature alloy for making fuse core of thermal fuse and preparation method thereof

The invention relates to a lead-free low-temperature alloy used for making a fuse core of a thermal fuse. Its raw material composition and its weight percentage range are respectively: Bi: 34%-36%; Zn: 3.5%-4.5%; Sn: balance The preparation method has the following steps: put metal tin into a stainless steel crucible, heat it in an electric furnace, after the tin is melted, add metal zinc at 250-280°C, and after melting, then add metal bismuth to melt After cleaning, conventional degassing and slag removal are performed by adding a degassing agent, and cast into a low-temperature alloy rod of the required size. The lead-free low-temperature alloy containing Sn, Bi and Zn involved in the present invention is used for making the fuse core of the thermal fuse, and the melting point is 132±2° C. It has low characteristics and is a lead-free environmental protection material, which itself has good social and economic benefits.

Owner:TIANJIN BAIRUIJIE WELDING MATERIAL

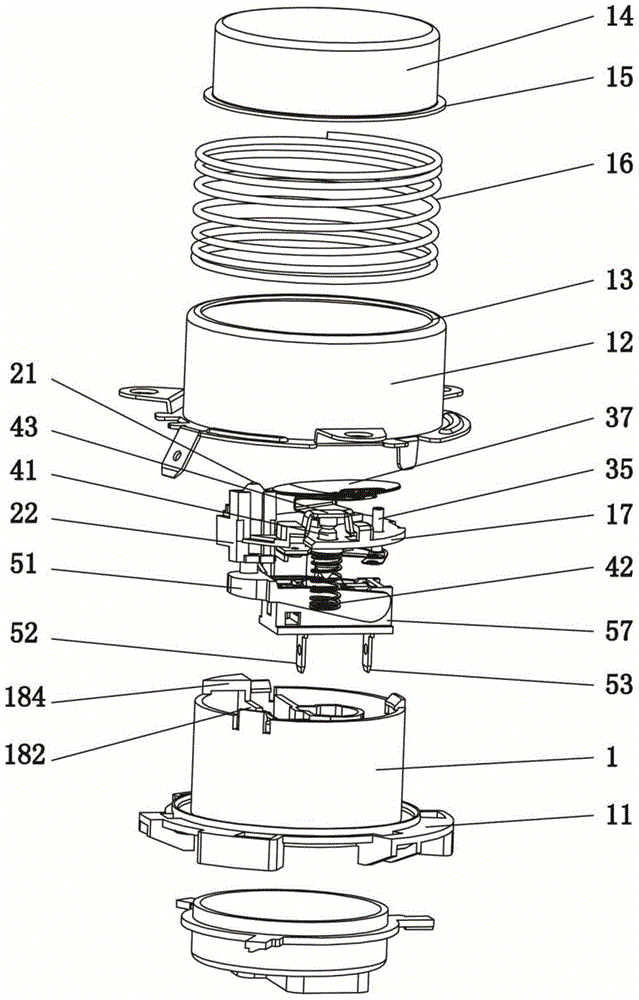

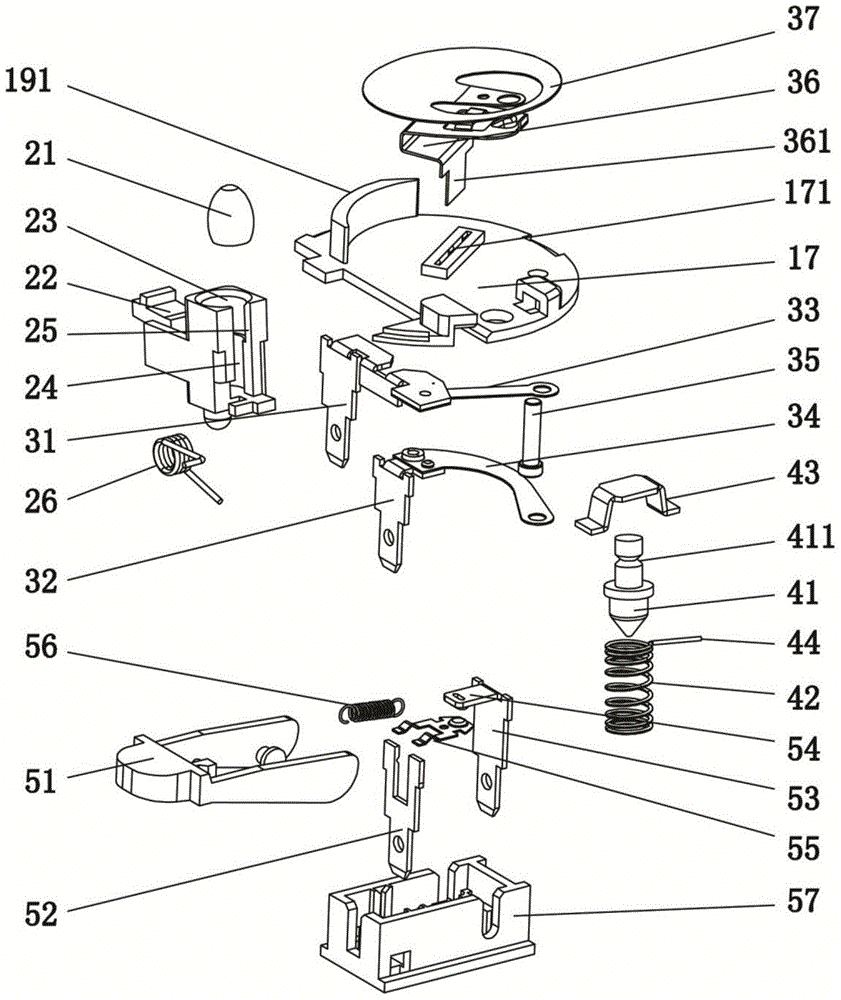

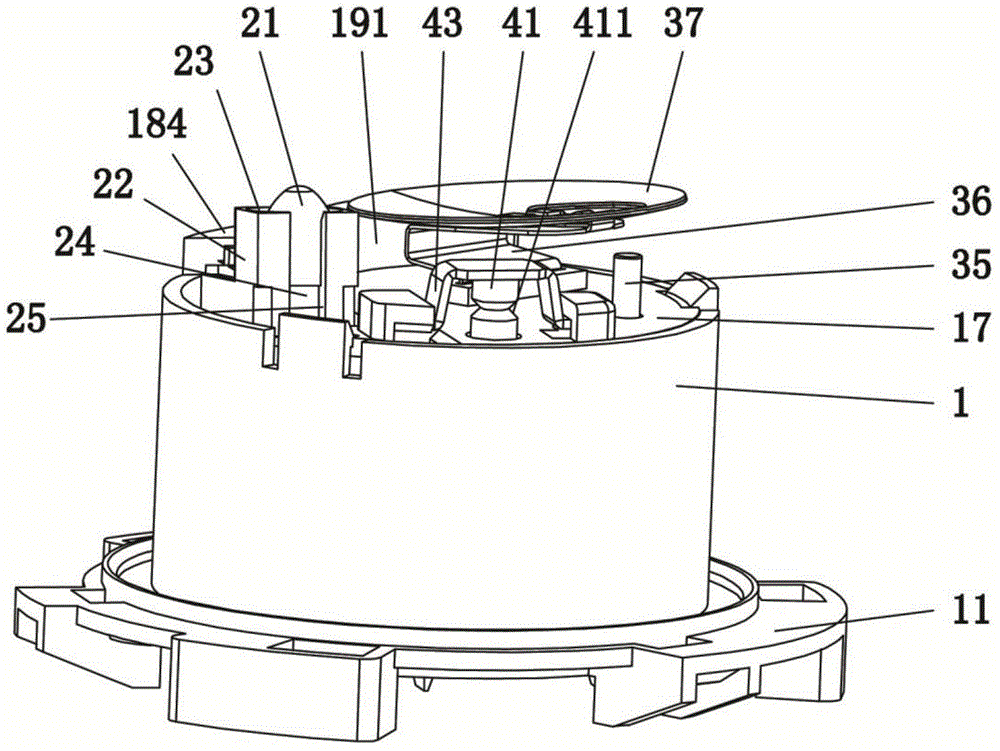

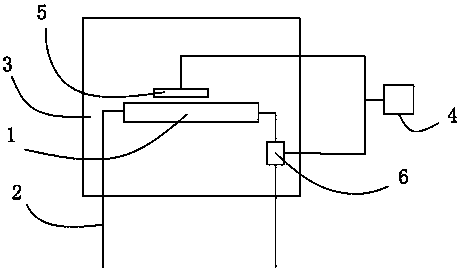

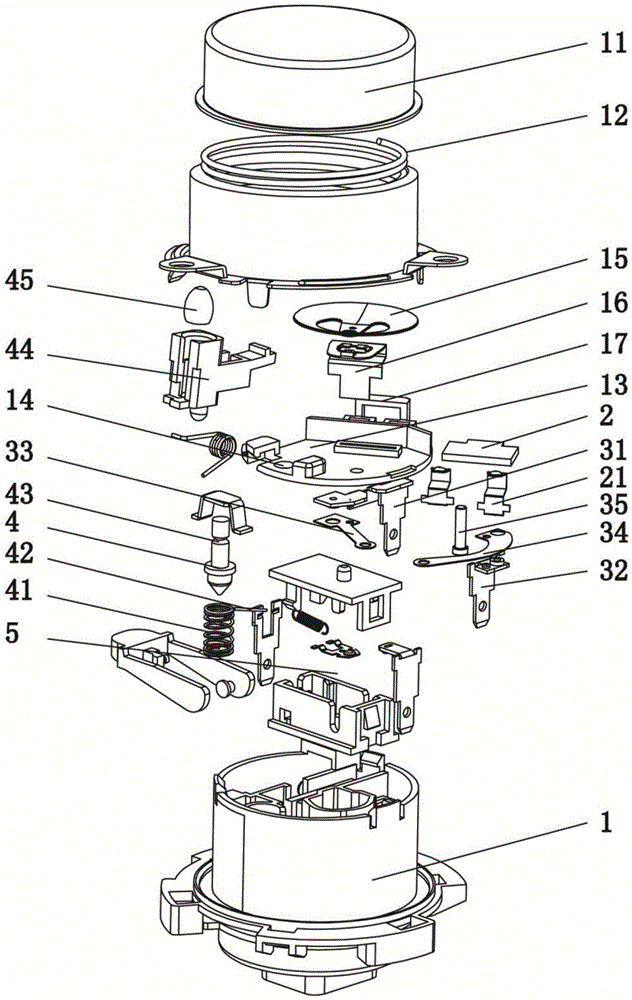

Integrated sensor

ActiveCN104797014AReduce offlineReasonable structureElectric heatingElectrical resistance and conductanceTemperature control

The invention relates to the technical field of temperature controlled sensors, in particular to an integrated sensor comprising a base. A sensing part is disposed in the base. The upper end of the base is sleeved with an upper cover which moves independently relative to the base; a compression spring is disposed between the base and the upper cover. During being pushed down, the upper cover is in butt linkage with the sensing part arranged in the base. The integrated sensor is reasonable in structure; when the temperature of an inner pot rises to a dry-braising proof set value, a thermistor cuts off a circuit of a master control board to allow power-off protection; after the temperature of a contact plate decreases, the circuit can be closed again; when the temperature rise exceeds the dry-bruising proof limit, a temperature sensing board starts a hot fusion function, a fuse core is directly fused by high temperature, a heating circuit is forcibly cut off, and final protection is achieved; the temperature sensing board and an insulating support serve as stress reaction parts, fewer lead welding spots shed, and the service life of the integrated sensor is prolonged.

Owner:三桥惠(佛山)新材料有限公司

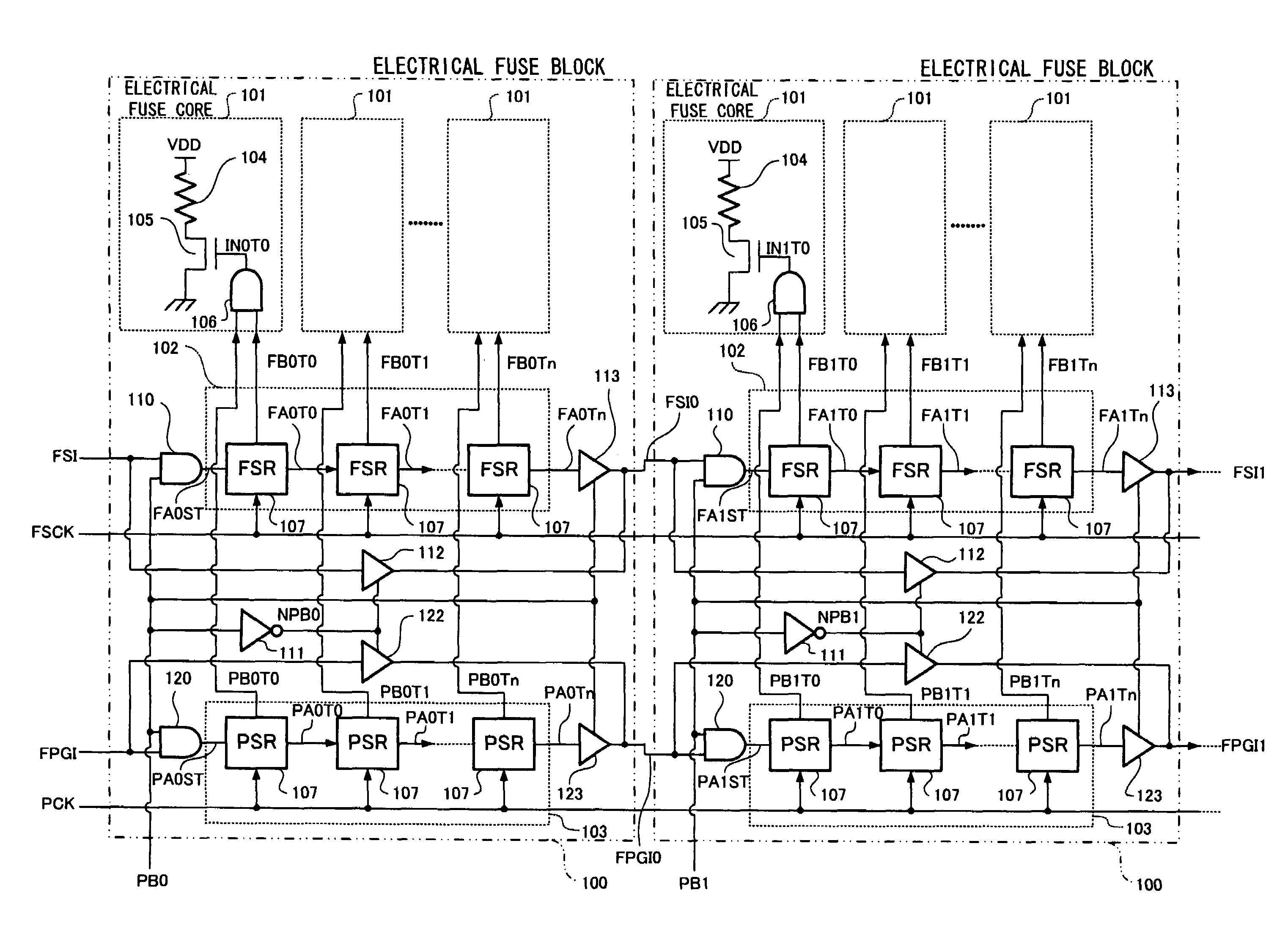

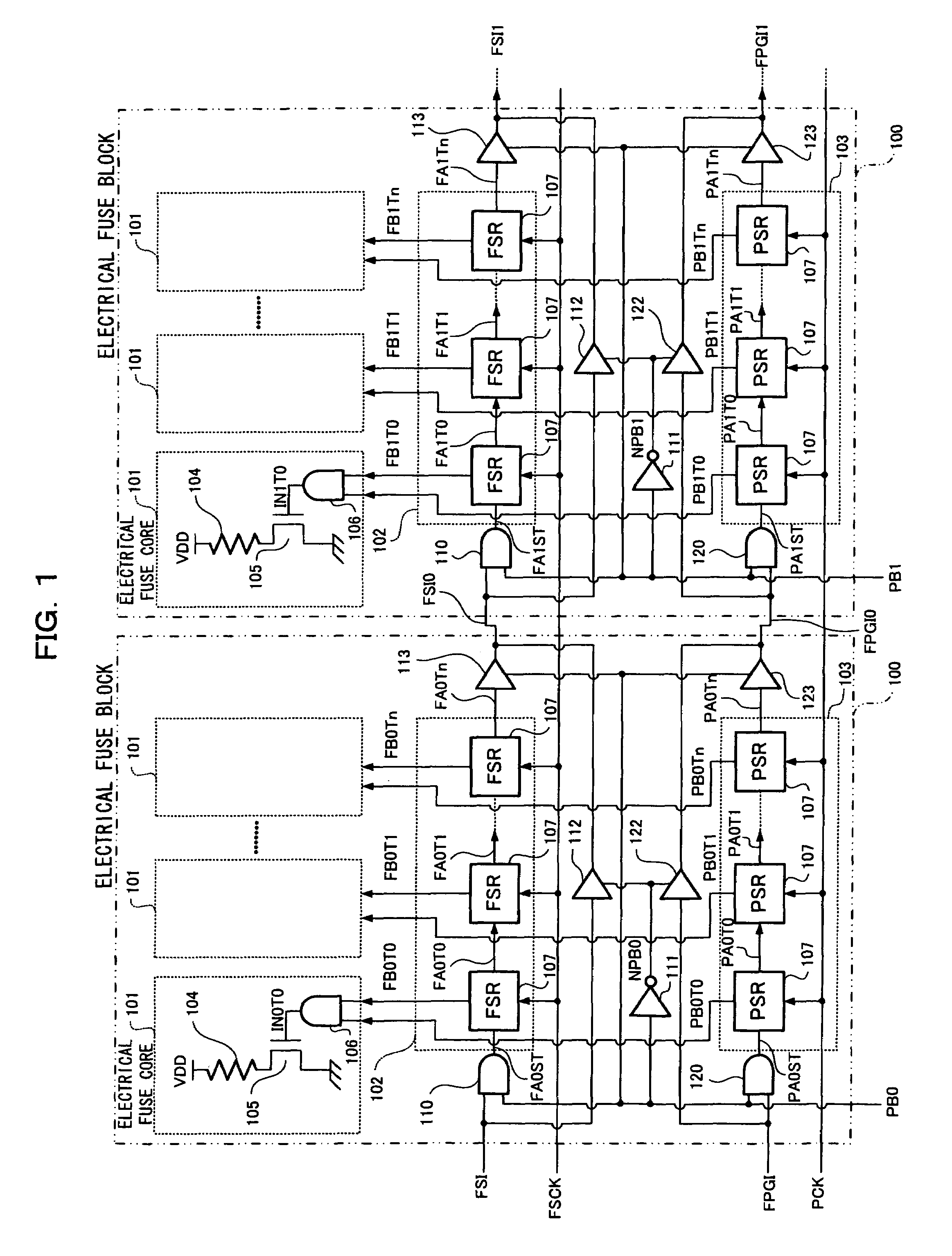

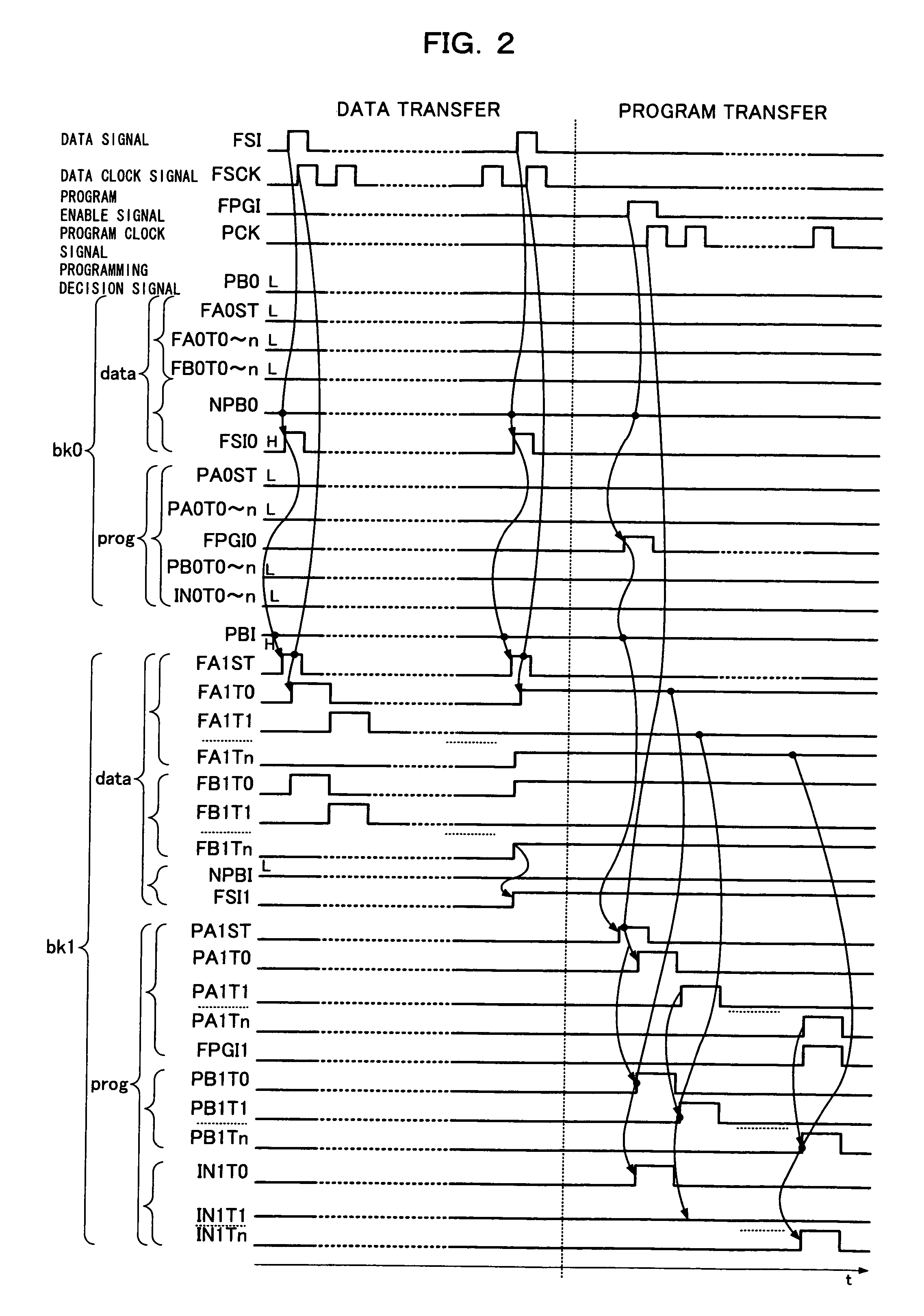

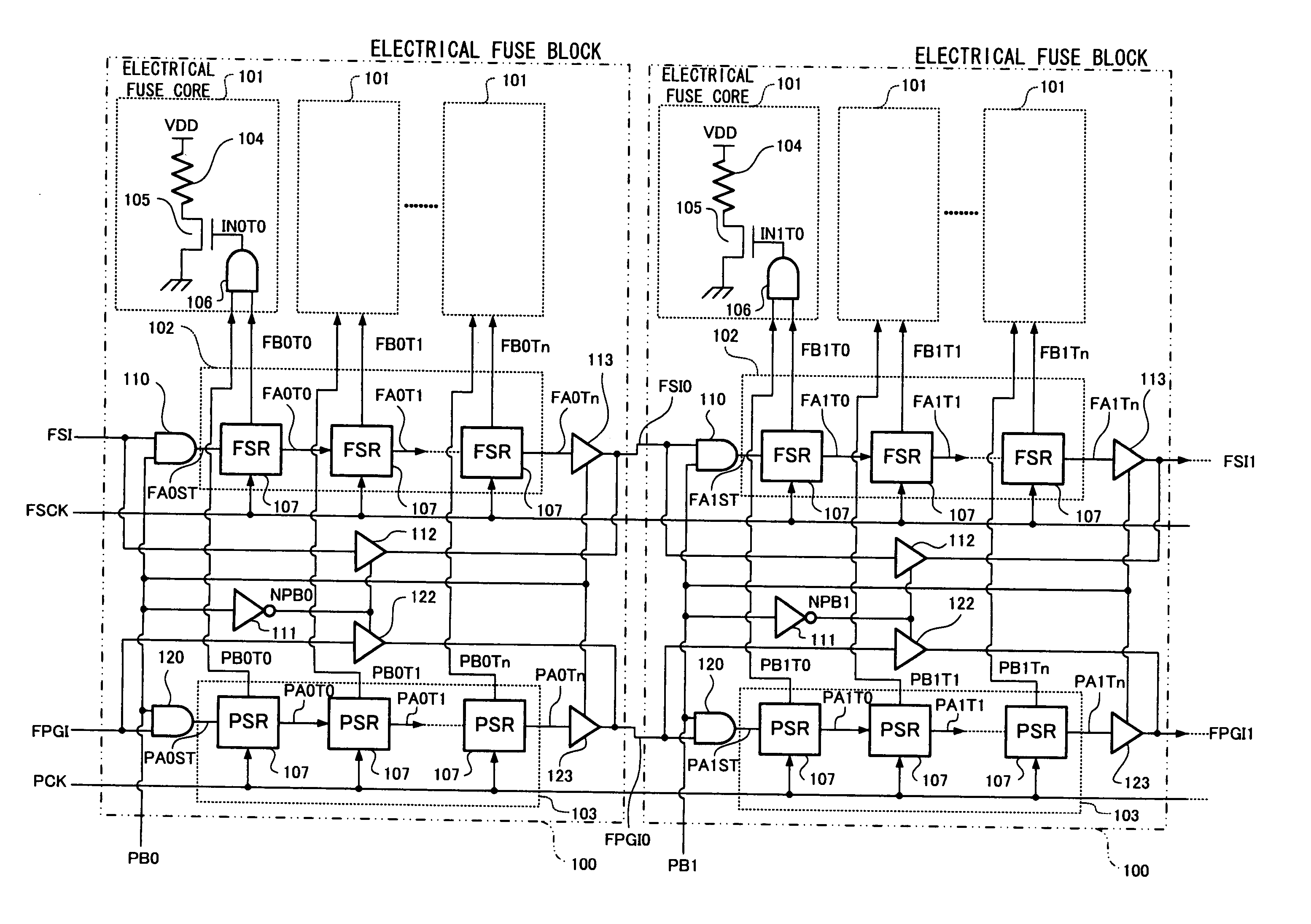

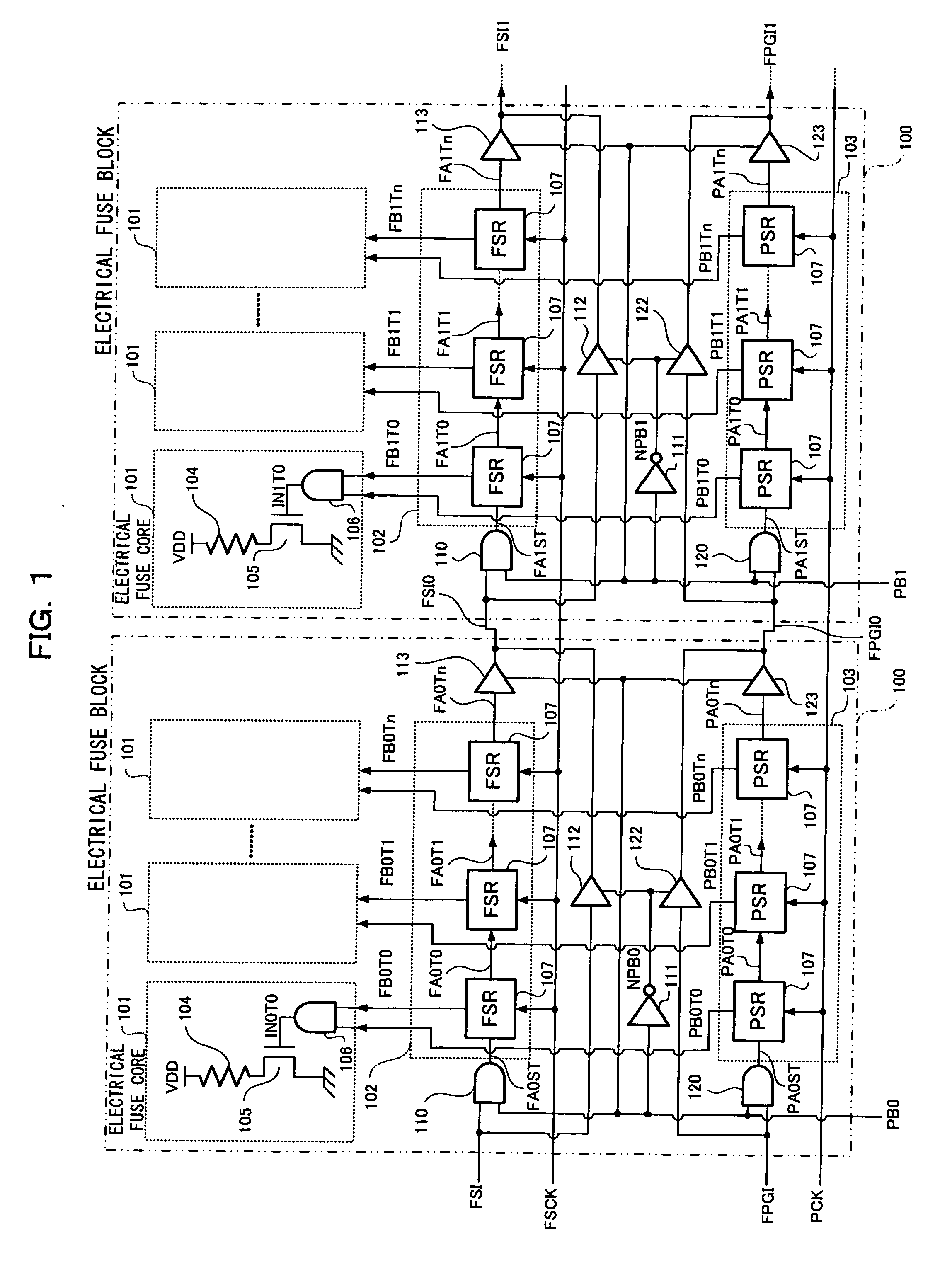

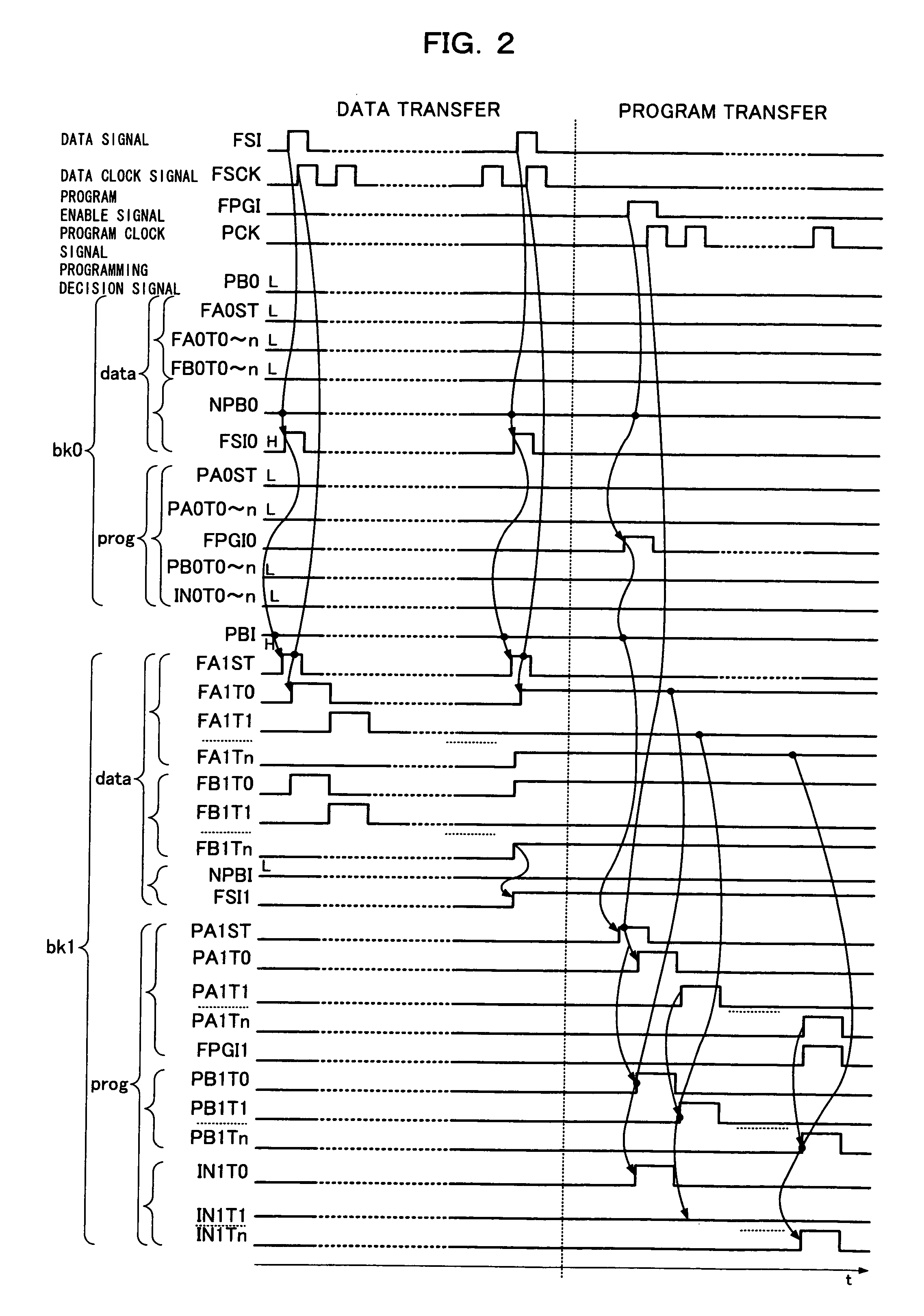

Semiconductor storage device including electrical fuse module

Electrical fuse blocks (100) of a plurality of stages are provided each of which includes a plurality of electrical fuse cores (101). The electrical fuse block (100) includes a program shift register block (103) made up of shift registers (107) which are disposed for the respective electrical fuse cores (101), sequentially transmit program enable signal FPGI, and output the program enable signal FPGI to the NMOS transistors (105) of the electrical fuse cores (101). When performing programming according to programming decision signal PBn, the program shift register block (103) transmits the program enable signal FPGI. When not performing programming, the program shift register block (103) skips the program enable signal FPGI.

Owner:SOCIONEXT INC

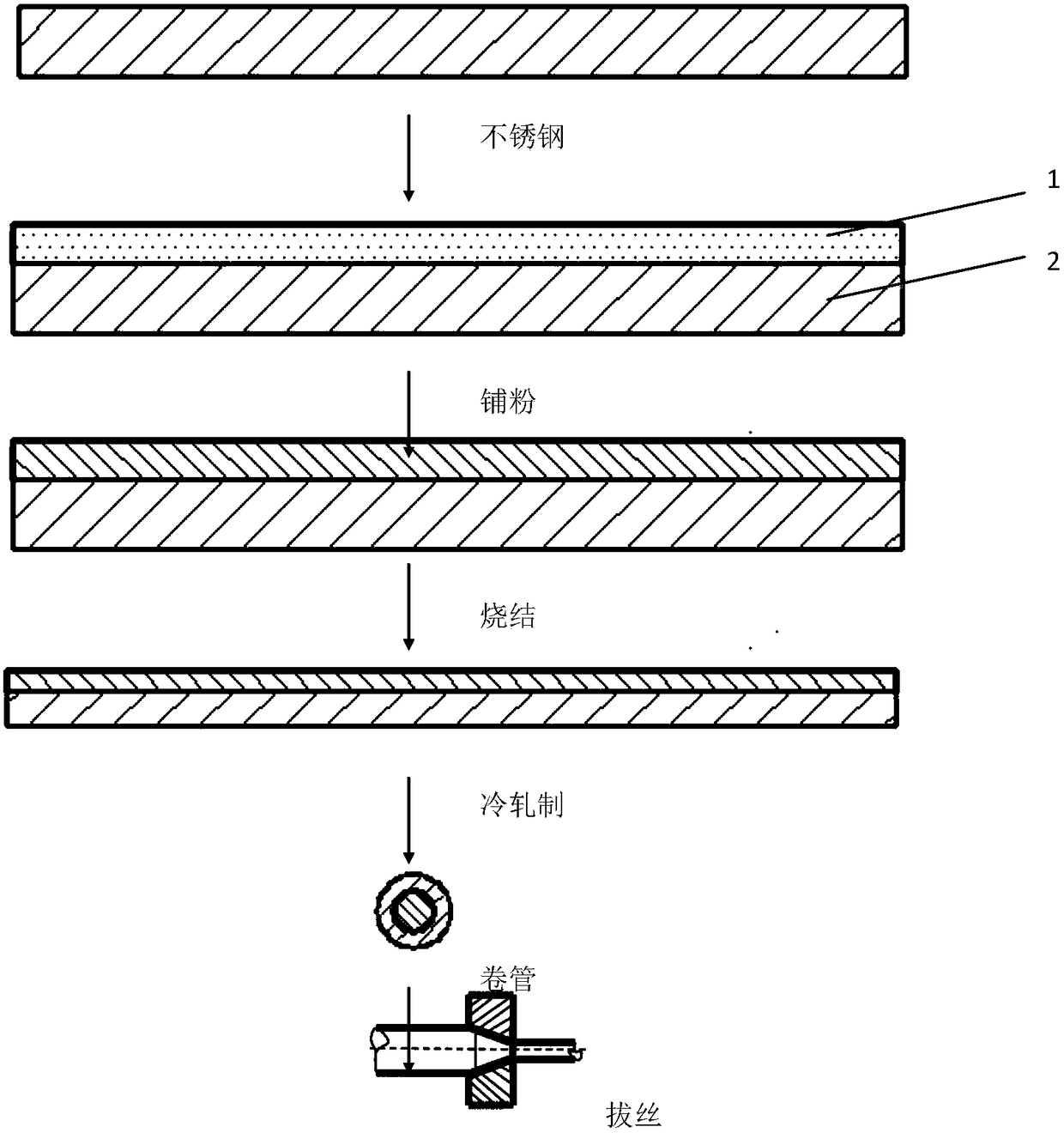

Electric-arc fusion-cladding powder core wire, and preparation method of high-entropy alloy coating

ActiveCN108998716AAvoid powder leakageLarge processing areaMolten spray coatingPower flowHigh entropy alloys

The invention provides an electric-arc fusion-cladding powder core wire, and a preparation method of a high-entropy alloy coating. The powder core wire is composed of a stainless steel strip and a powder core, wherein the thickness of the stainless steel strip is 0.8mm, and the powder core is powder of Mn, Cr, Fe, Ni, and Cu in a molar ratio of 2:2:2:2:1. A preparation method of the powder core wire comprises the following steps: (1) preparing the powder core; (2) paving powder and sintering; (3) performing cold rolling; and (4) coiling, drawing wires, reeling, installing coiled wires on a wire feeder, and spraying-deposing fused core wires on the surfaces of base materials by setting the electric-arc welding voltage to be 14 V, current to be 150A, and speed to be 8cm2 / min under the actionof 0.9MP high-pressure argon to form the high-entropy alloy coating.

Owner:JIANGSU UNIV OF TECH

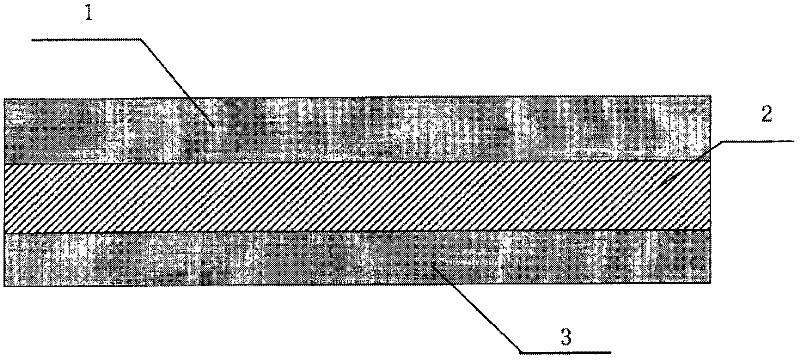

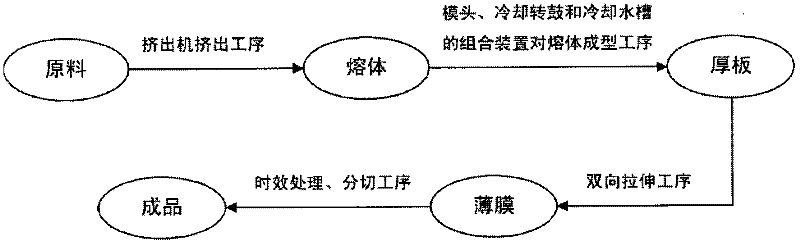

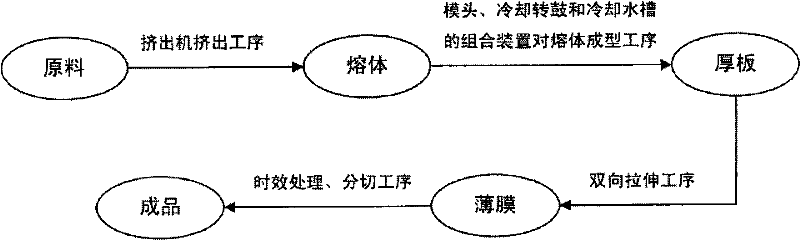

Polypropylene film capable of resisting fog and preparation method thereof

InactiveCN102350842AGood anti-fog effectHigh transparencySynthetic resin layered productsSurface layerThick plate

The invention relates to a polypropylene film capable of resisting fog and a preparation method thereof. The film comprises an upper surface layer, a core layer and a lower surface layer. The preparation method comprises the following steps that: mixed materials of the core layer are dried and tandem extruded by a first core layer extruder and a second core layer extruder to obtain a fused core layer material; mixed materials of the upper surface layer and the lower surface layer are dried and respectively extruded by an auxiliary extruder to obtain a fused upper surface layer material and a fused lower surface layer material, the fused core layer material, the fused upper surface layer material and the fused lower surface layer material are respectively filtered with a disk filter, join together in a die head of an extruder through pipelines and are extruded to obtain a thick plate, the thick plate is cooled and bidirectionally drawn to obtain a film, and the film is subjected to corona treatment, rolling up and slitting to obtain a finished product. The polypropylene film provided in the invention can prevent fog drops from forming and has an excellent fog resisting effect, good transparency and great heat-sealing strength; fog resisting films with different performance and effects can be fabricated according to different articles to be packaged, different preserving / storing conditions and different requirements of utilization, and all the performance indexes of fabricated films can meet requests for utilization.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

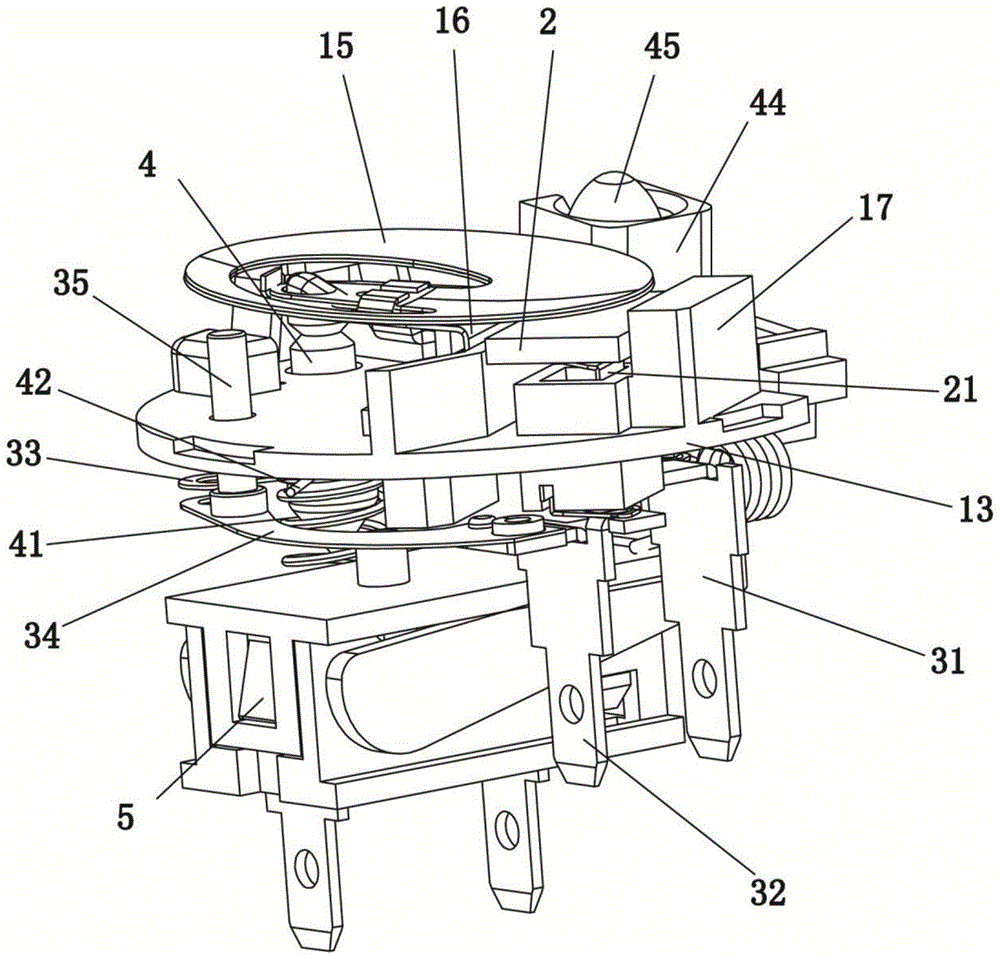

Mining flame-proof latch connector

InactiveCN101471516AReduce contact resistanceEasy to replaceCoupling device detailsClamped/spring connectionsEngineeringFused core

A mine-use explosion-proof pin connector relates to a coalmine locomotive power on / off connector. The housing of the pin connector consists of a front cover (30), a plug (1), a socket (2), a socket (3) and a rear cover (4), wherein a wiring terminal (21), flexible connection wiring harness (18), a main spring (19), a moving contact (17), a spring to break (15), a fuse core (14), a wiring column (12), a wiring bolt (25), a wiring stud (26), a wiring terminal insulating sleeve (20), an insulating sheath (16), a fuse core insulating bracket (9), a plug insulating base (13) and an anti-rotation insulating sheath (11) are arranged in the housing; the plug (1) includes a limit stop (22), a convex stage (34) and a stop (10); the socket (2) includes a bearing support (8) and a dustproof cover support (44); a mounting support (45) is arranged on the socket (3); and a pre-tightened main spring cover (41) is arranged between the socket (2) and the socket (3). The pin connector is safe in power utilization.

Owner:李向达

Semiconductor storage device including electrical fuse module

InactiveUS20070058411A1Shorten inspection timeReducing data programming timeRead-only memoriesElectricityShift register

Electrical fuse blocks (100) of a plurality of stages are provided each of which includes a plurality of electrical fuse cores (101). The electrical fuse block (100) includes a program shift register block (103) made up of shift registers (107) which are disposed for the respective electrical fuse cores (101), sequentially transmit program enable signal FPGI, and output the program enable signal FPGI to the NMOS transistors (105) of the electrical fuse cores (101). When performing programming according to programming decision signal PBn, the program shift register block (103) transmits the program enable signal FPGI. When not performing programming, the program shift register block (103) skips the program enable signal FPGI.

Owner:SOCIONEXT INC

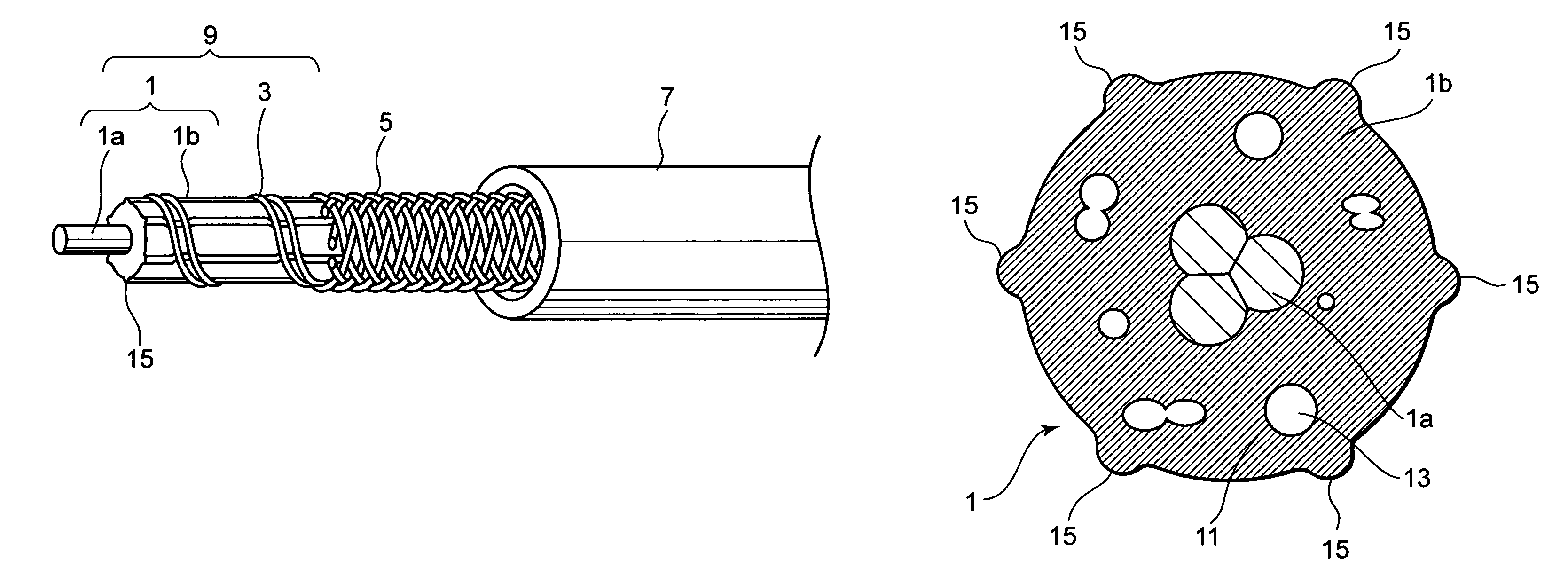

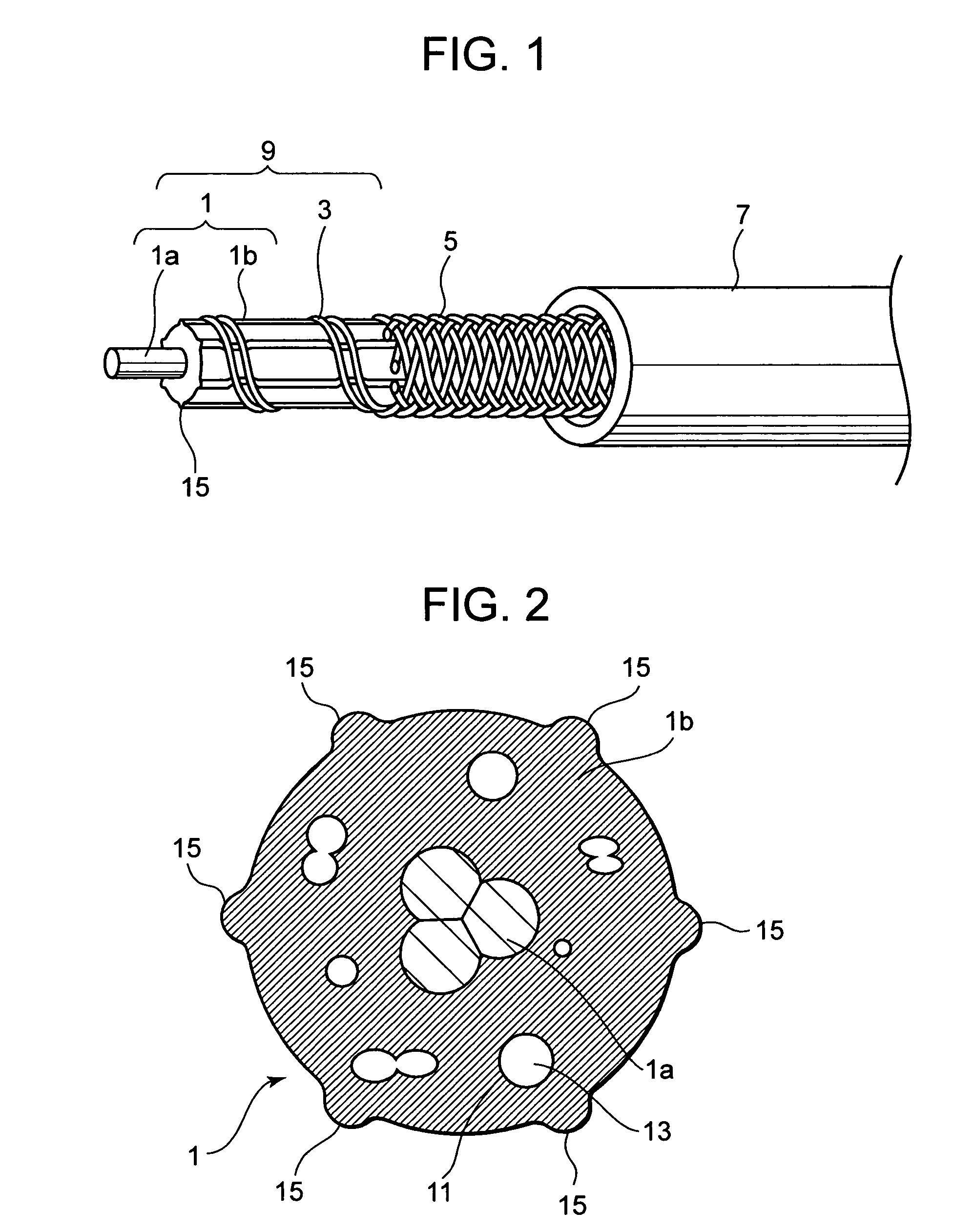

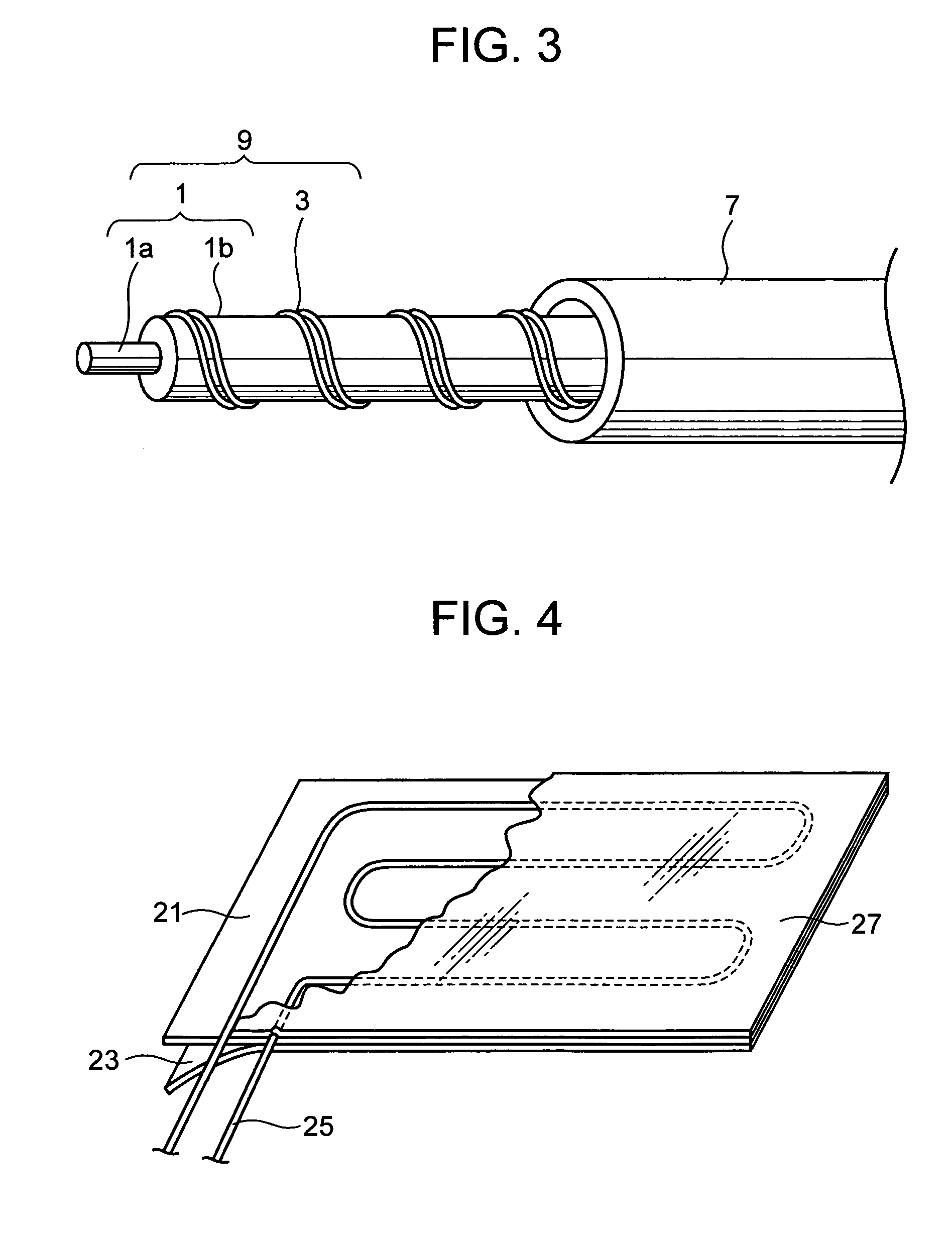

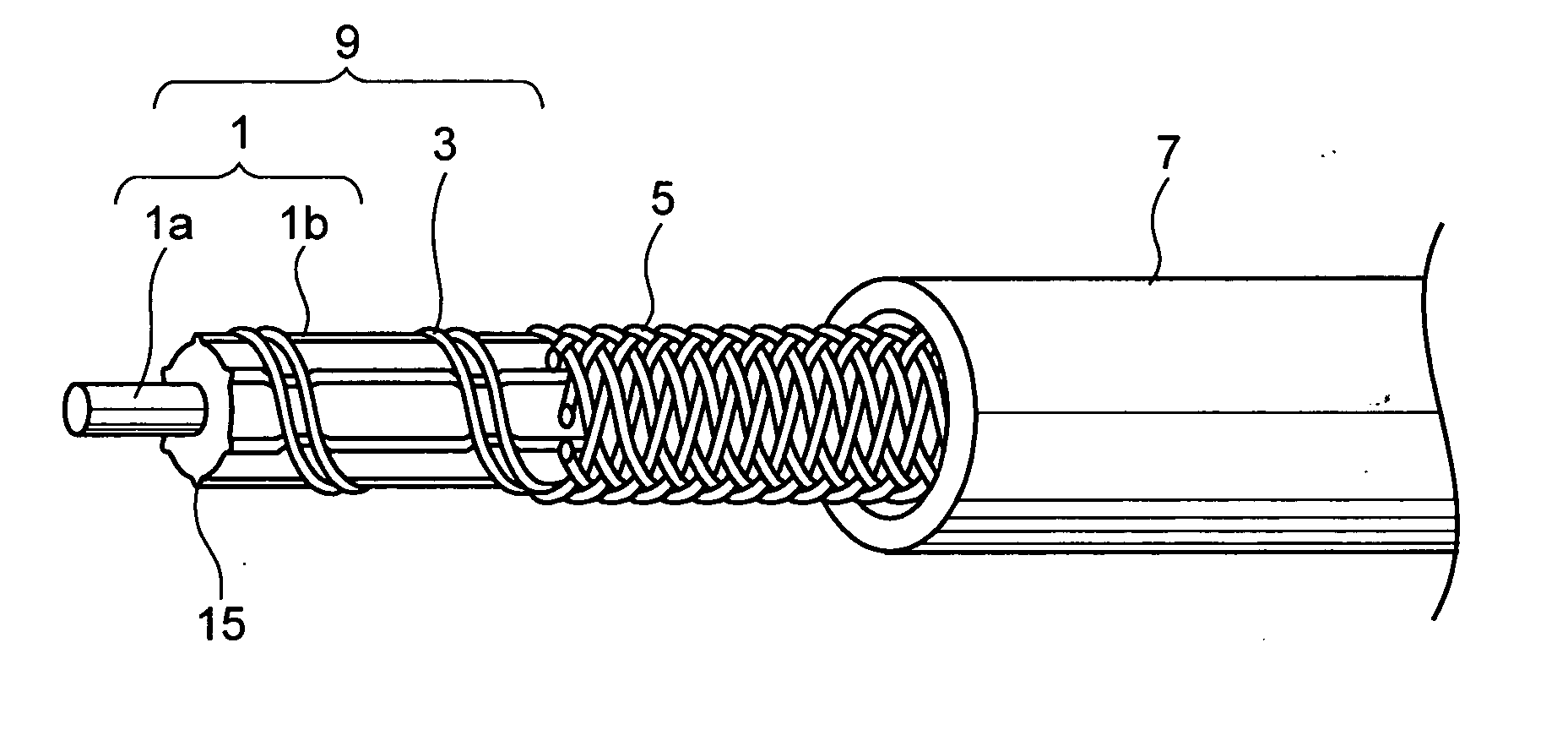

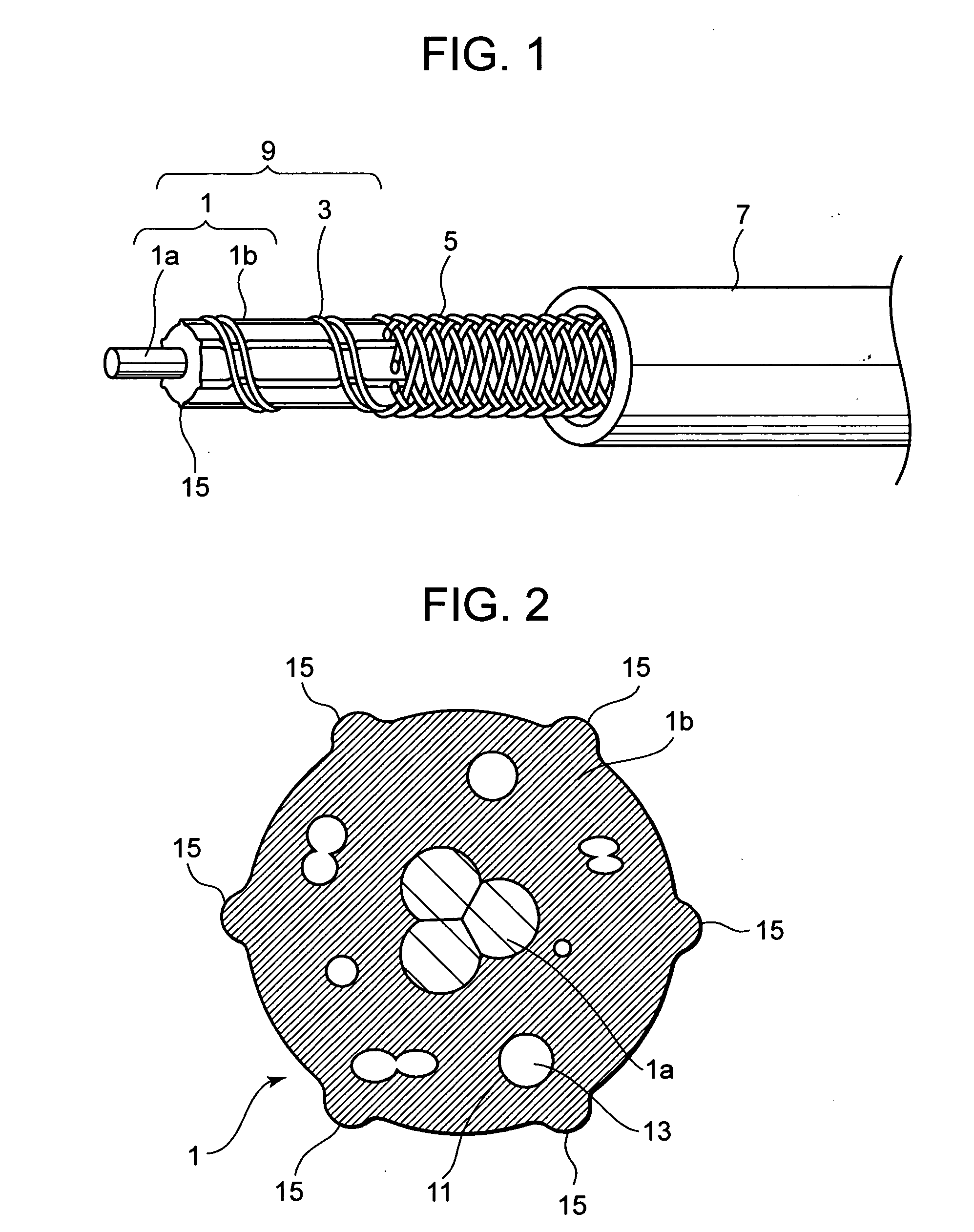

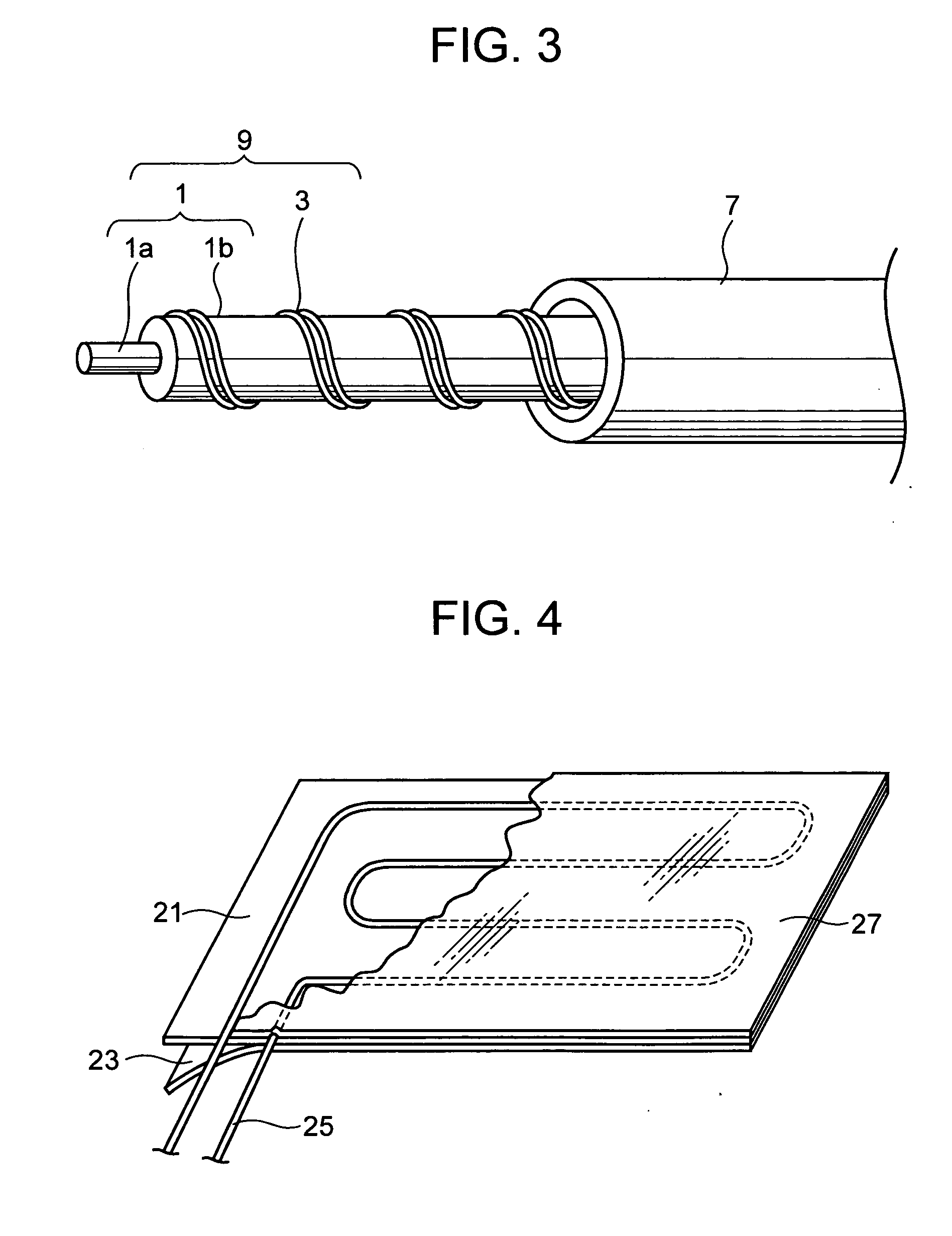

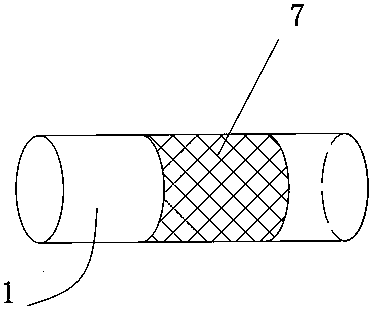

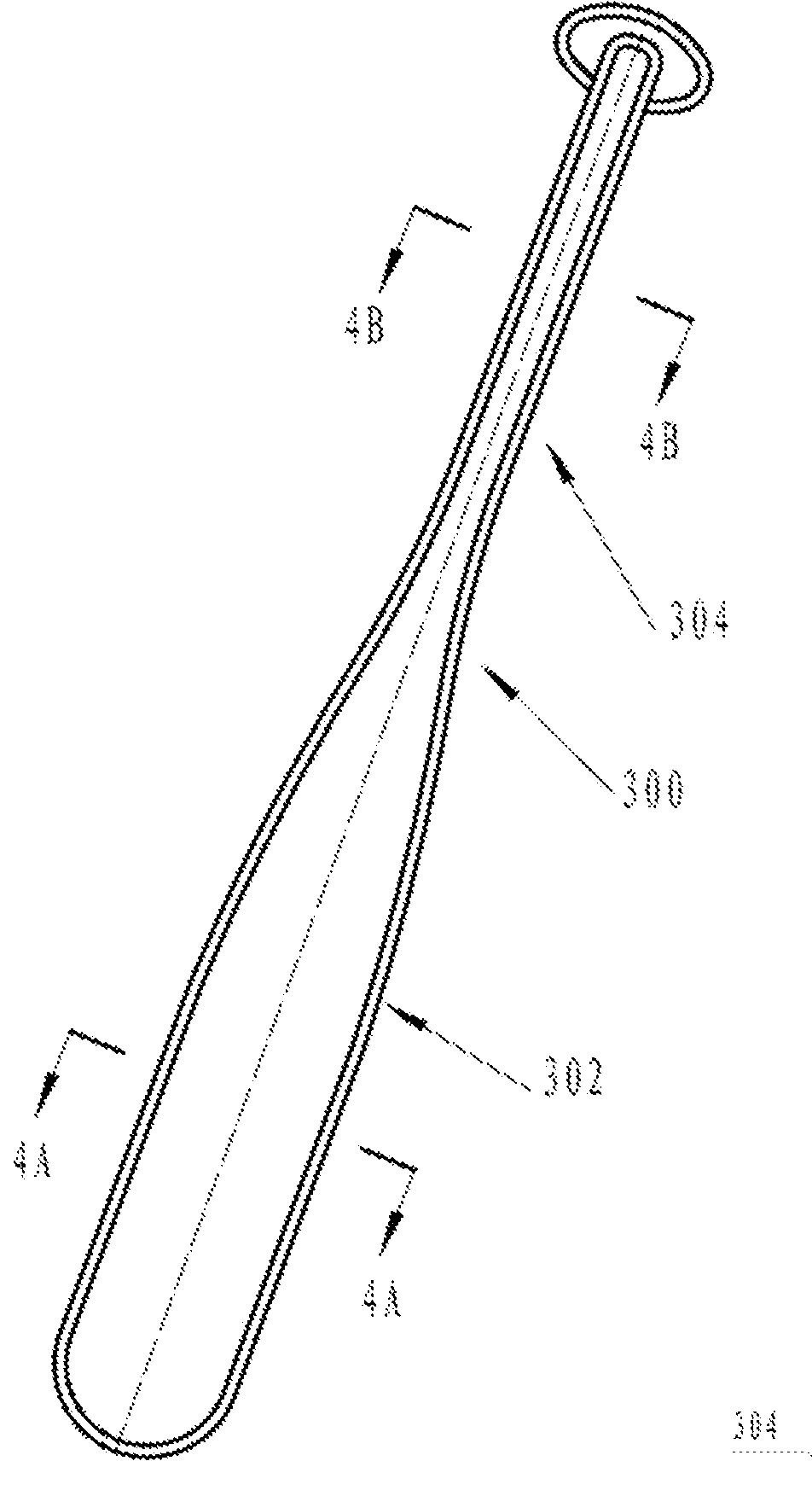

Cord type thermal fuse and sheet type thermal fuse

InactiveUS7439844B2Reduce stepsGuaranteed uptimeHeating/cooling contact switchesEmergency protective devicesElectrical conductorHot melt

A cord type thermal fuse, comprising a fuse core produced by winding a conductor meltable at a predetermined temperature on an insulating core member continuous in the length direction, and an insulating cover covering the outer periphery of the fuse core, wherein the conductor can be cut by expanding the insulating core member at a predetermined temperature and / or by contracting the insulating cover at the predetermined temperature.

Owner:KURABE IND CO LTD

Code-shaped temperature fuse and sheet-shaped temperature fuse

InactiveUS20050258928A1Reduce stepsOperational reliability is increasedProtective switch detailsElectrothermal relaysElectrical conductorFused core

A code type thermal fuse, comprising a fuse core produced by winding a conductor meltable at a predetermined temperature on an insulating core member continuous in the length direction, and an insulating cover covering the outer periphery of the fuse core, wherein the conductor can be cut by expanding the insulating core member at a predetermined temperature and / or by contracting the insulating cover at the predetermined temperature.

Owner:KURABE IND CO LTD

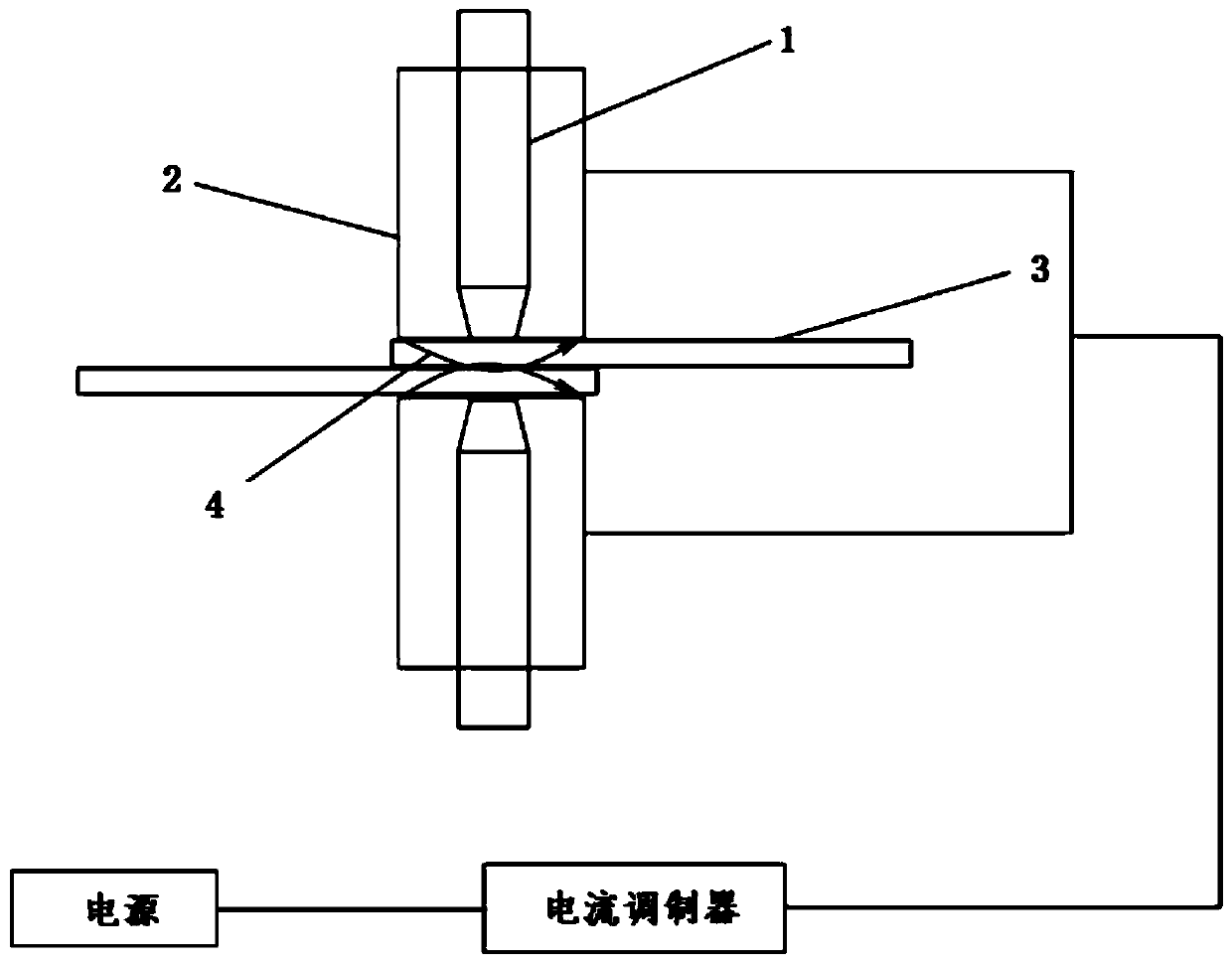

Resistor spot welding method under action of controllable rotating magnetic field

ActiveCN109759686AGrain refinement effect is obviousHigh tensile strengthResistance welding apparatusEngineeringFused core

The invention discloses a resistor spot welding method under the action of a controllable rotating magnetic field, belongs to the technical field of welding, and solves the problems that the resistorspot welding point strength is low, the tissue is large, the magnetic controlled resistor spot welding magnetic field direction is not parallel to a workpiece, and the stirring effect of Lorenz forceproduced under the magnetic field action depends on the conduction current. The resistor spot welding method comprises the specific steps that a welding workpiece is clamped and fixed, the welding parameters of a resistor welding machine are adjusted, when a welding system is started, a magnetic field generation device is opened, and the frequency, intensity, phase of excitation three-phase AC areset; and an air pressure system is checked to determine the welding position, the magnetic field generation device is started to send the signal to the welding system, the welding system monitors thesignal of a magnetic field monitoring system, the welding system is started for welding, the welding process is finished, an electrode head is lifted, and the magnetic field generation device is closed. The resistor spot welding method can be used for metal plate resistor spot welding in the industrial field, the grain refinement effect of the fusing core area of a joint after welding is obvious,the tensile strength is improved, and the welding quality is improved.

Owner:HARBIN INST OF TECH AT WEIHAI

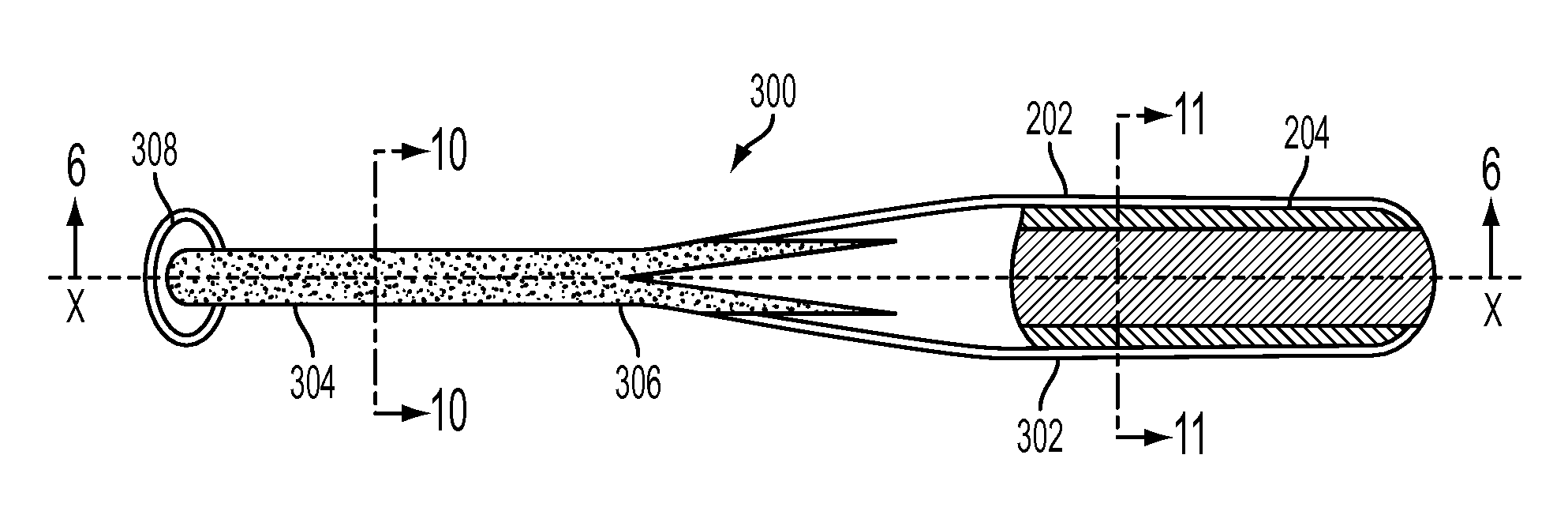

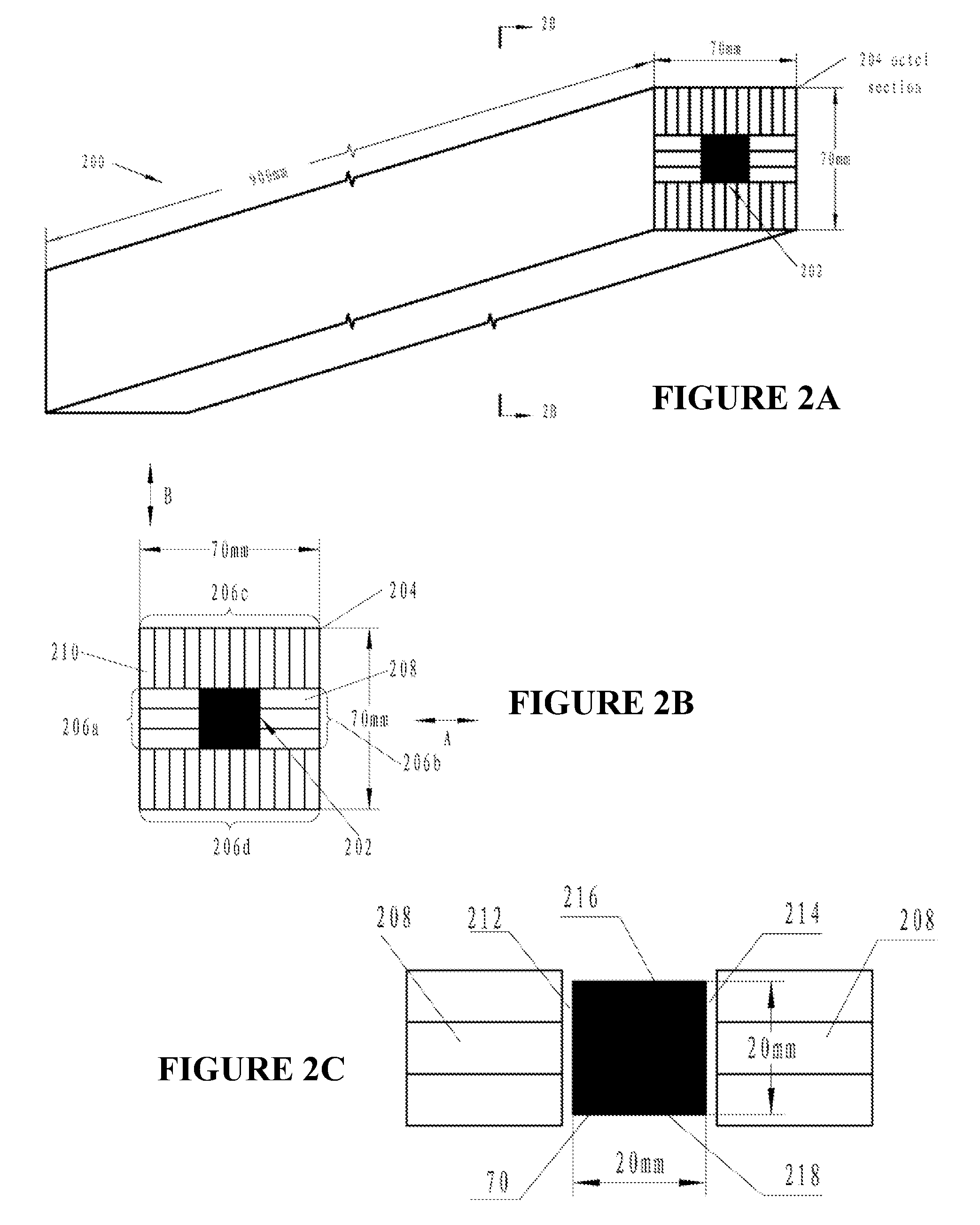

Bat having fiber-fused core section and method of manufacturing the same

InactiveUS20110312452A1Overcome disadvantagesDovetailed workCellulosic plastic layered productsFiberEngineering

Owner:STR8 TO THE SOURCE INC

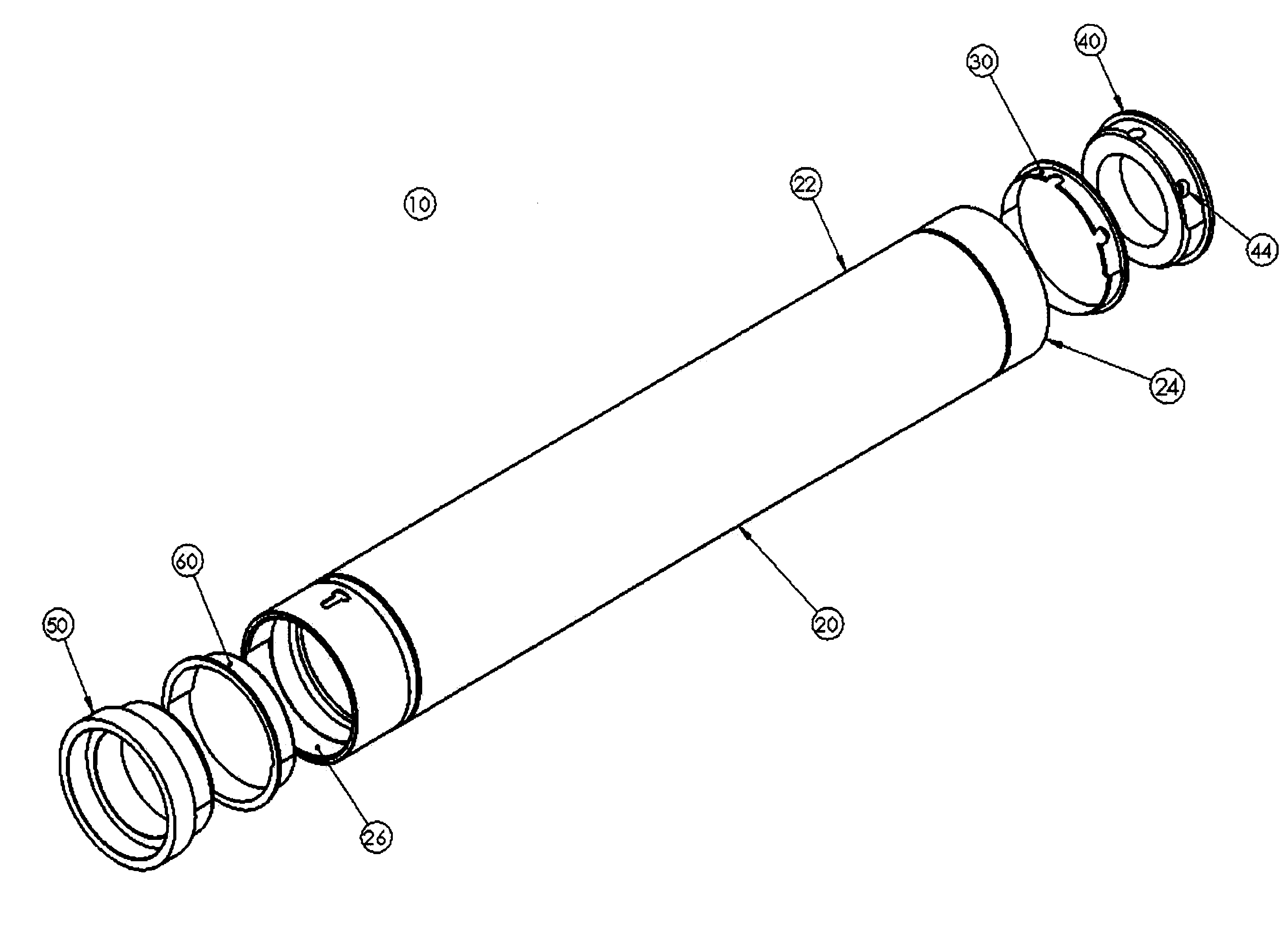

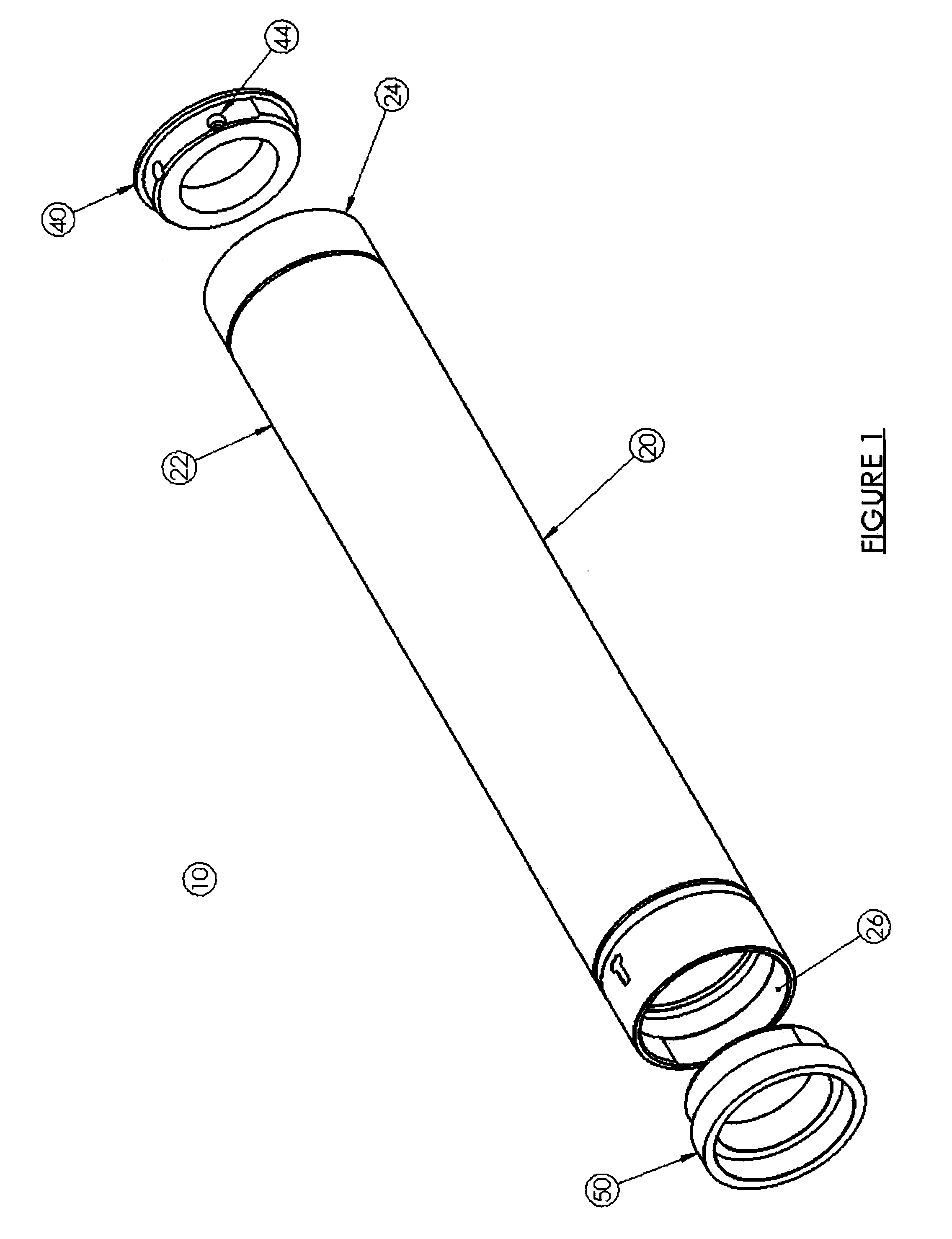

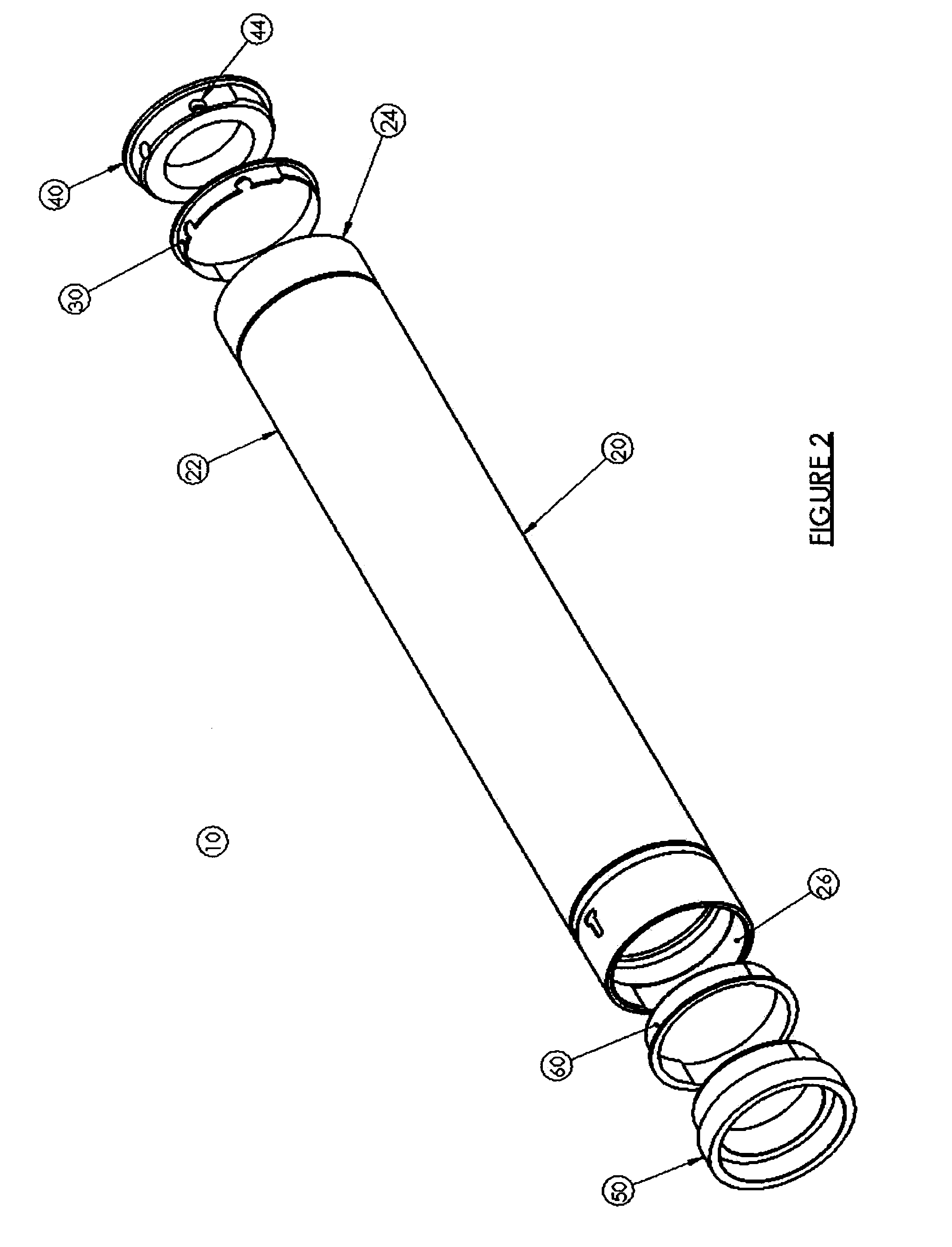

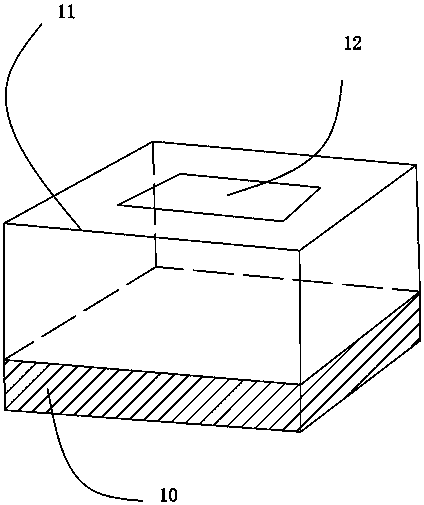

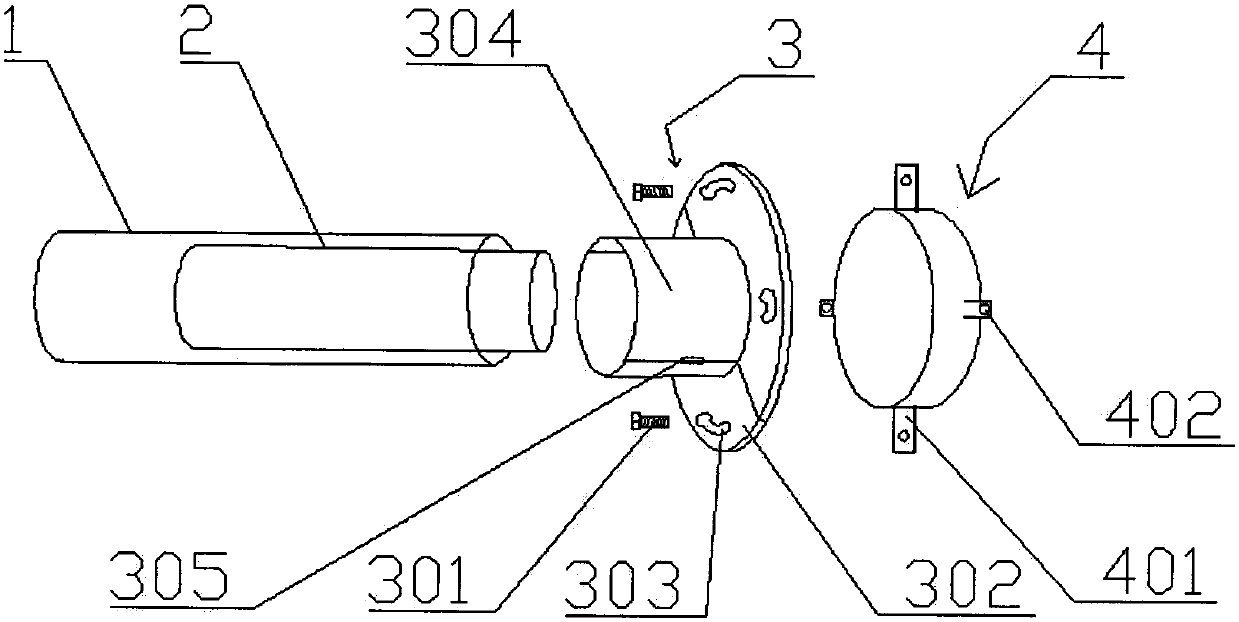

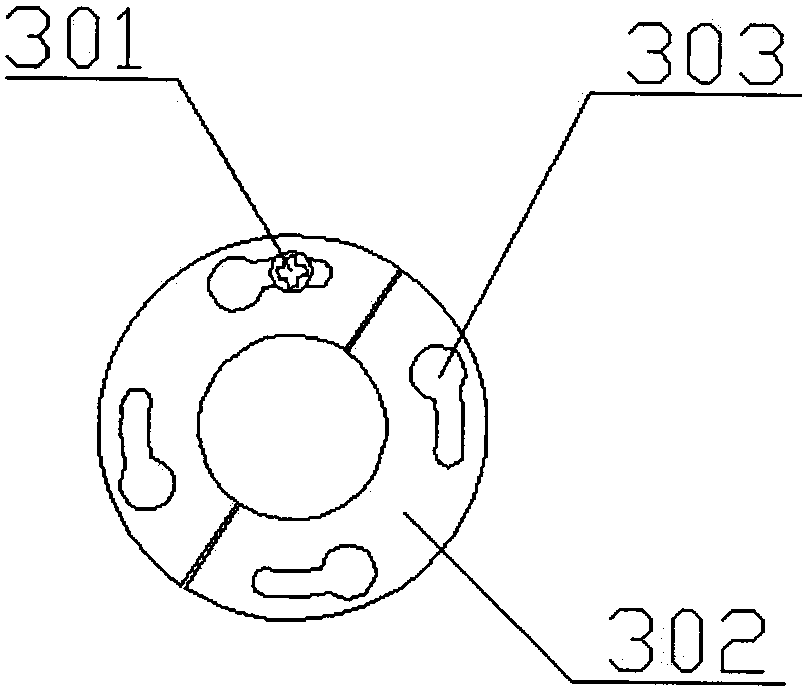

Fusing core and drive collar assembly

InactiveUS20110044738A1Reduce micro machining wear issueEliminate needOhmic-resistance heatingElectrographic process apparatusEngineeringFused core

A system for stabilizing a fuser core in an imaging device. The system includes a fuser core having a body and two opposing ends, and a pair of hubs. The opposing ends of the fuser core are configured with ratchet type geometric profiles that mate with ratchet type geometric profiles configured on the corresponding hubs. The system also includes two elastomeric collars each of which is at least partially disposed between the end of the fuser core and the corresponding mating hub.

Owner:7 SIGMA

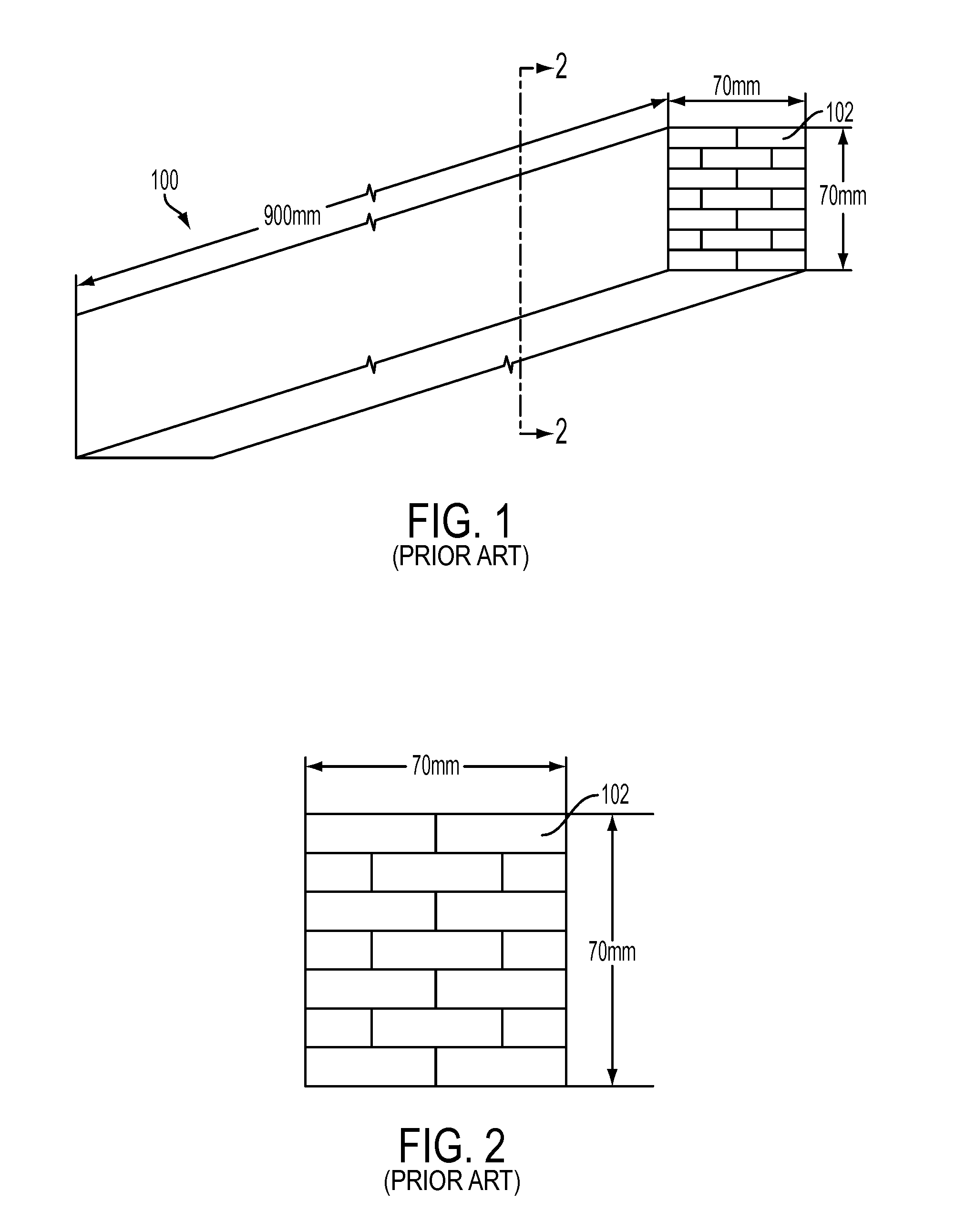

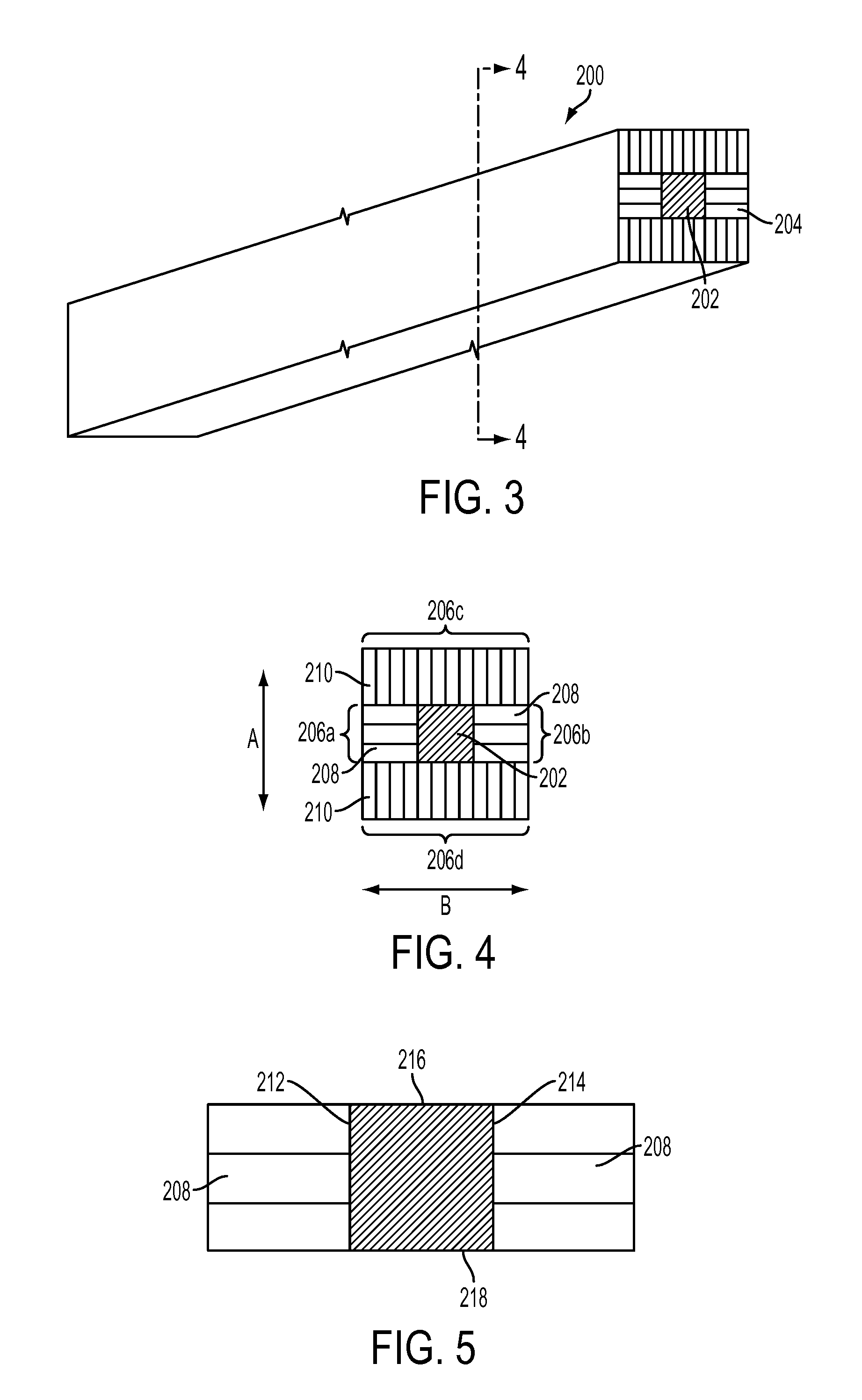

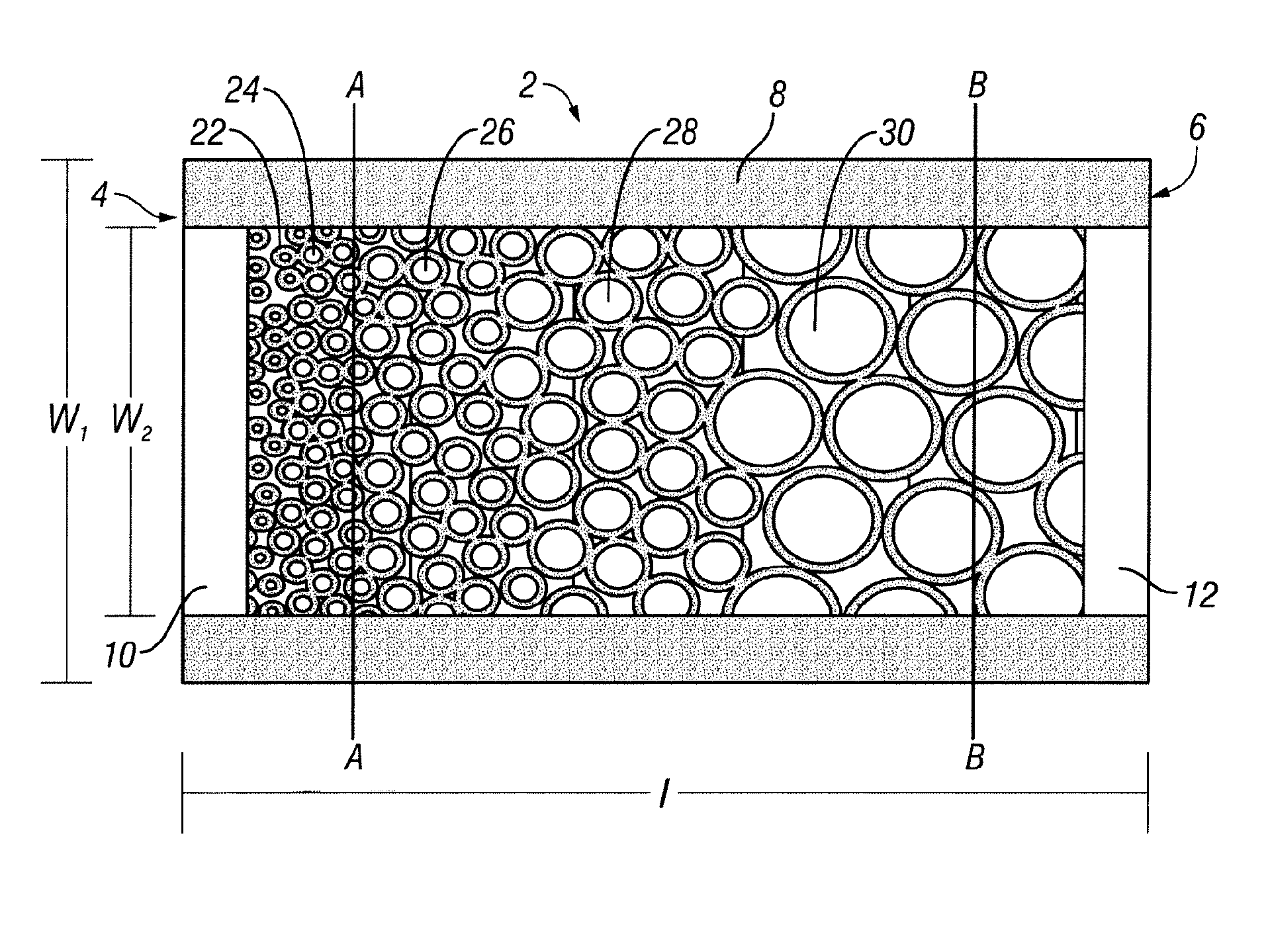

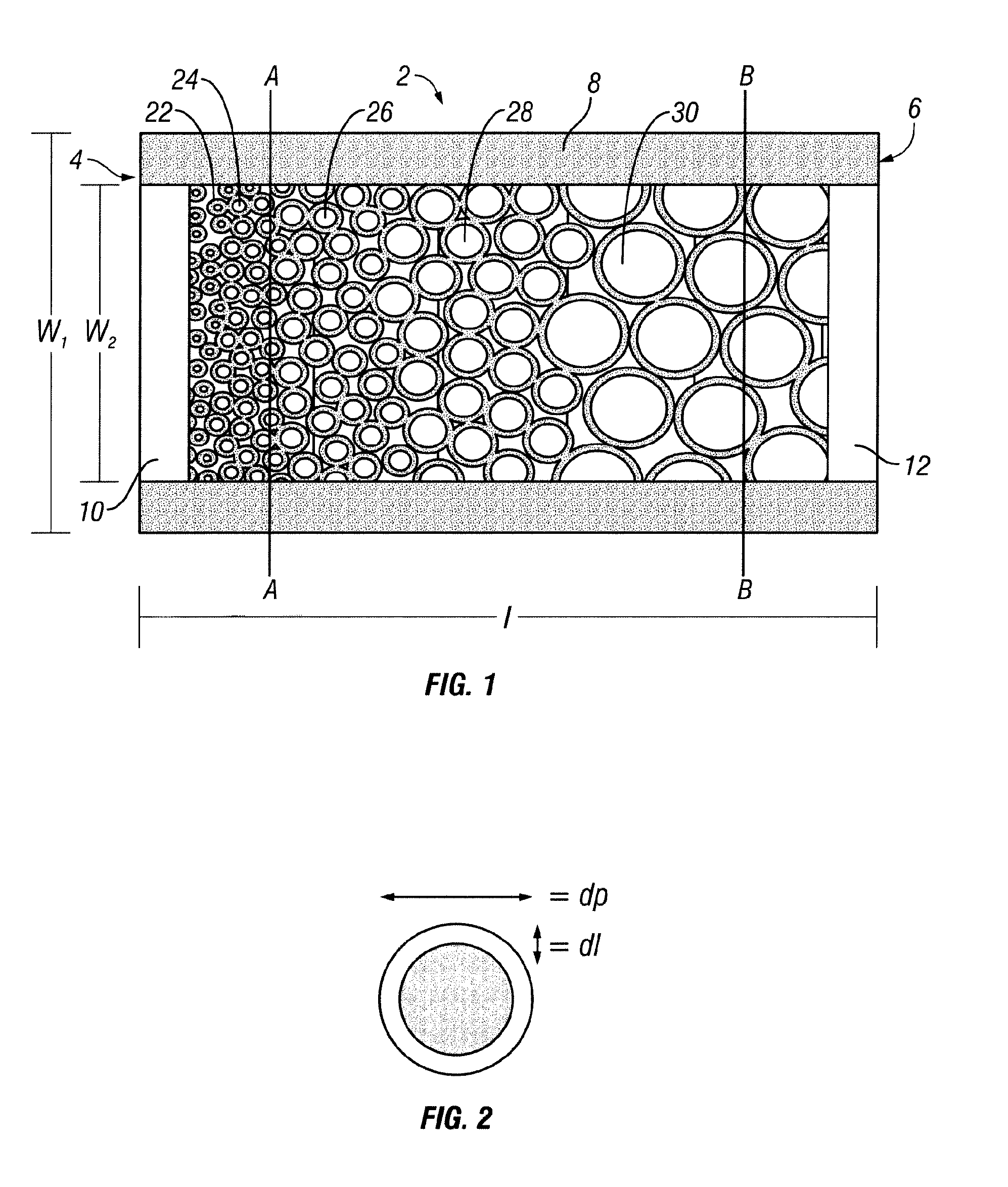

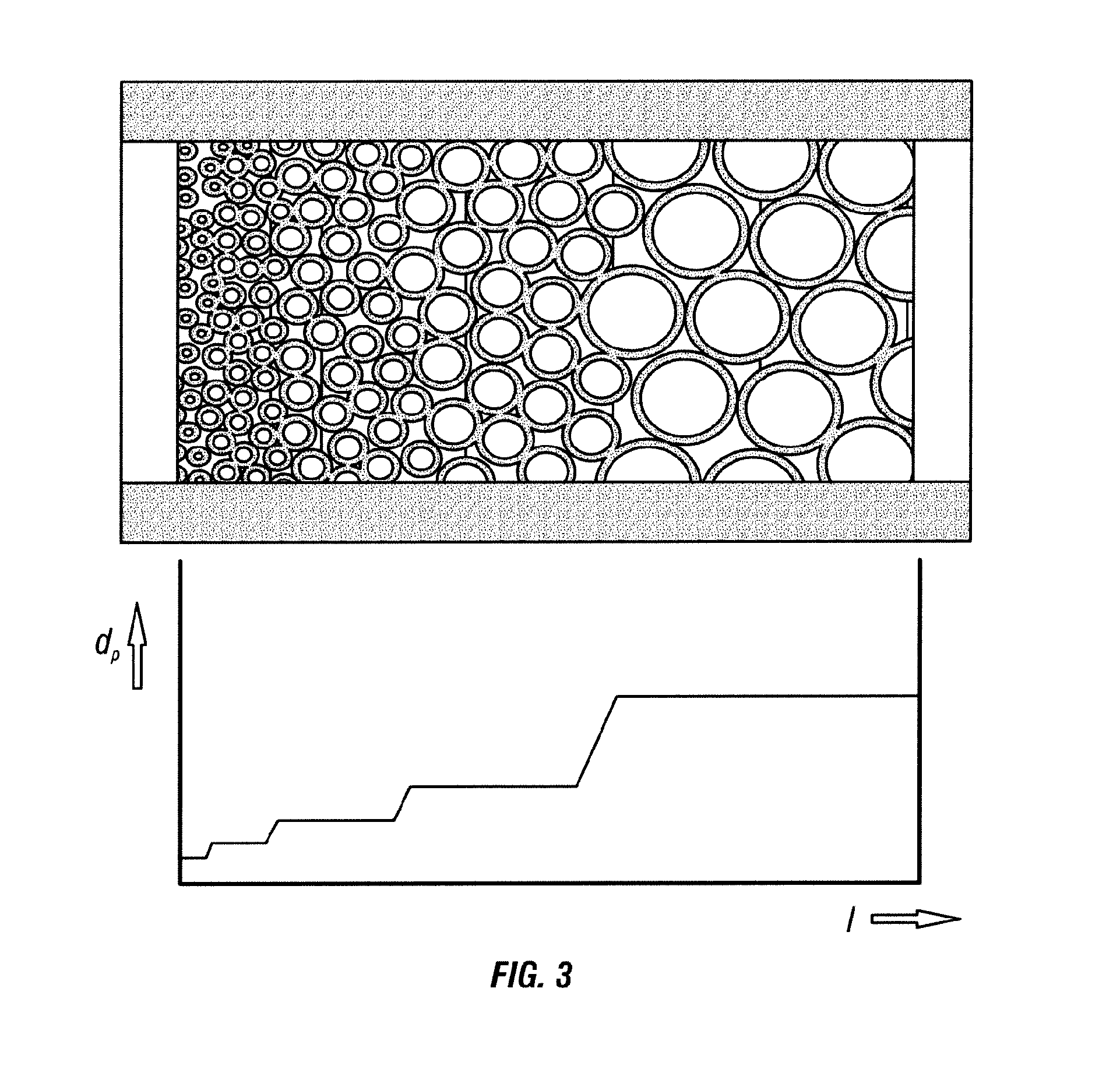

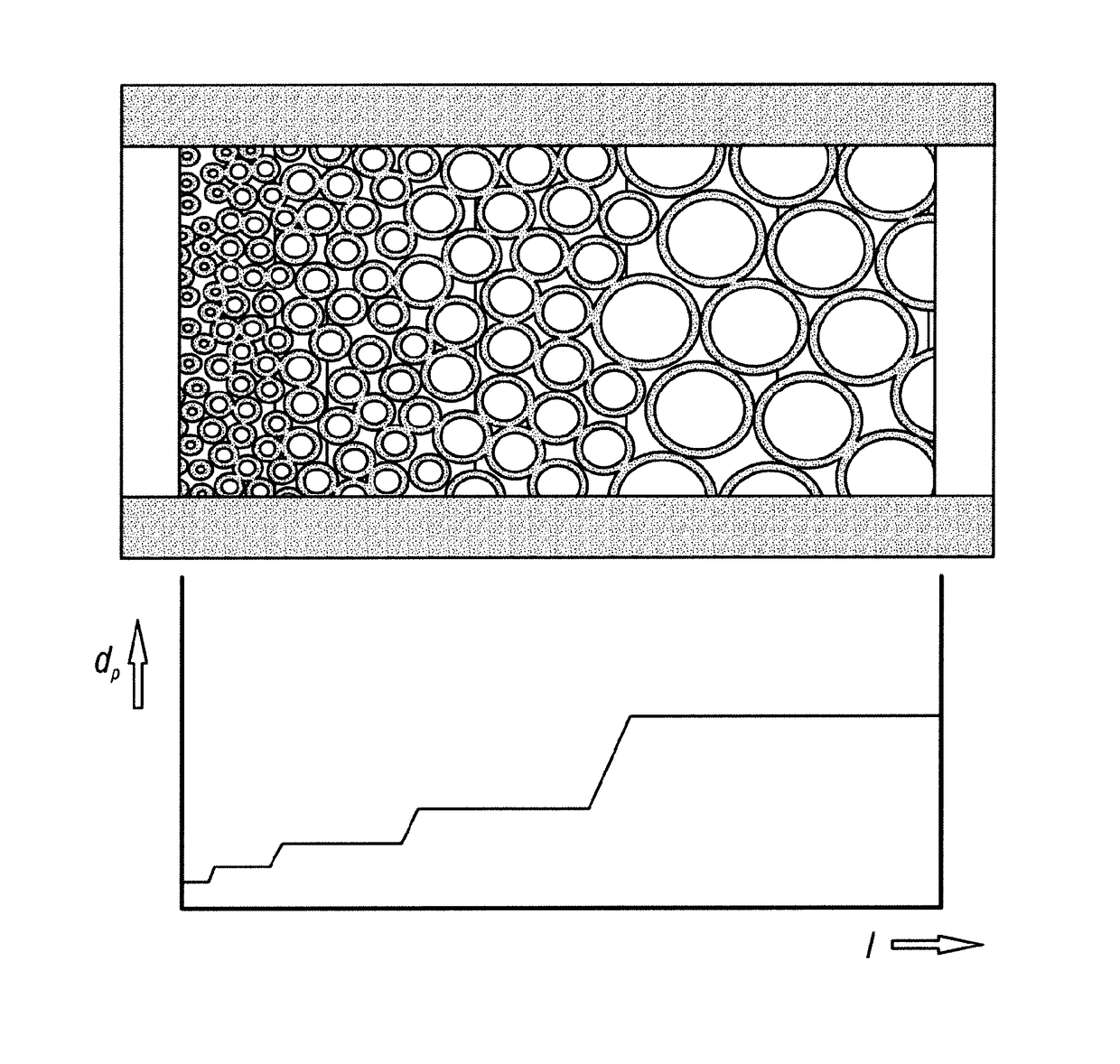

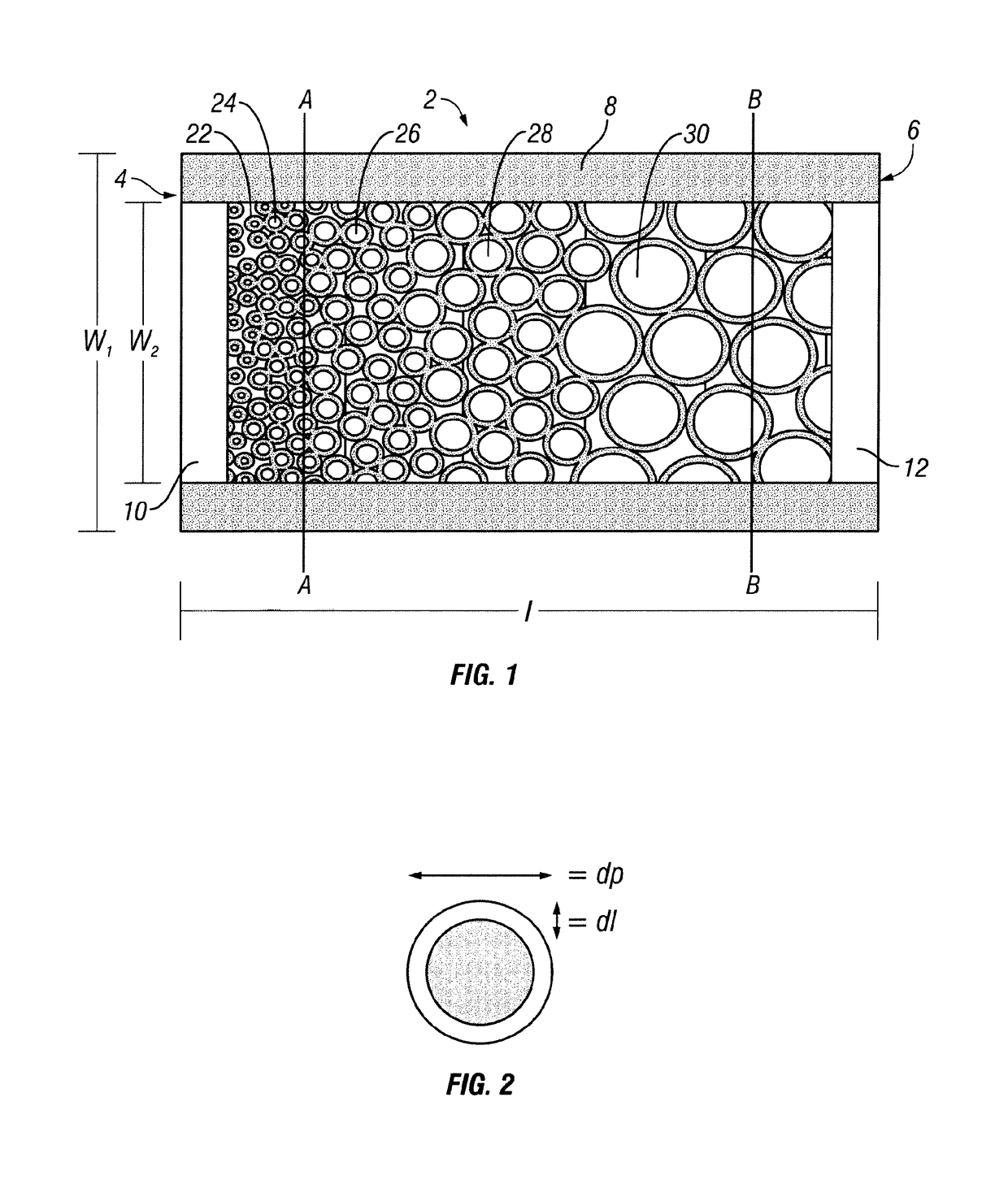

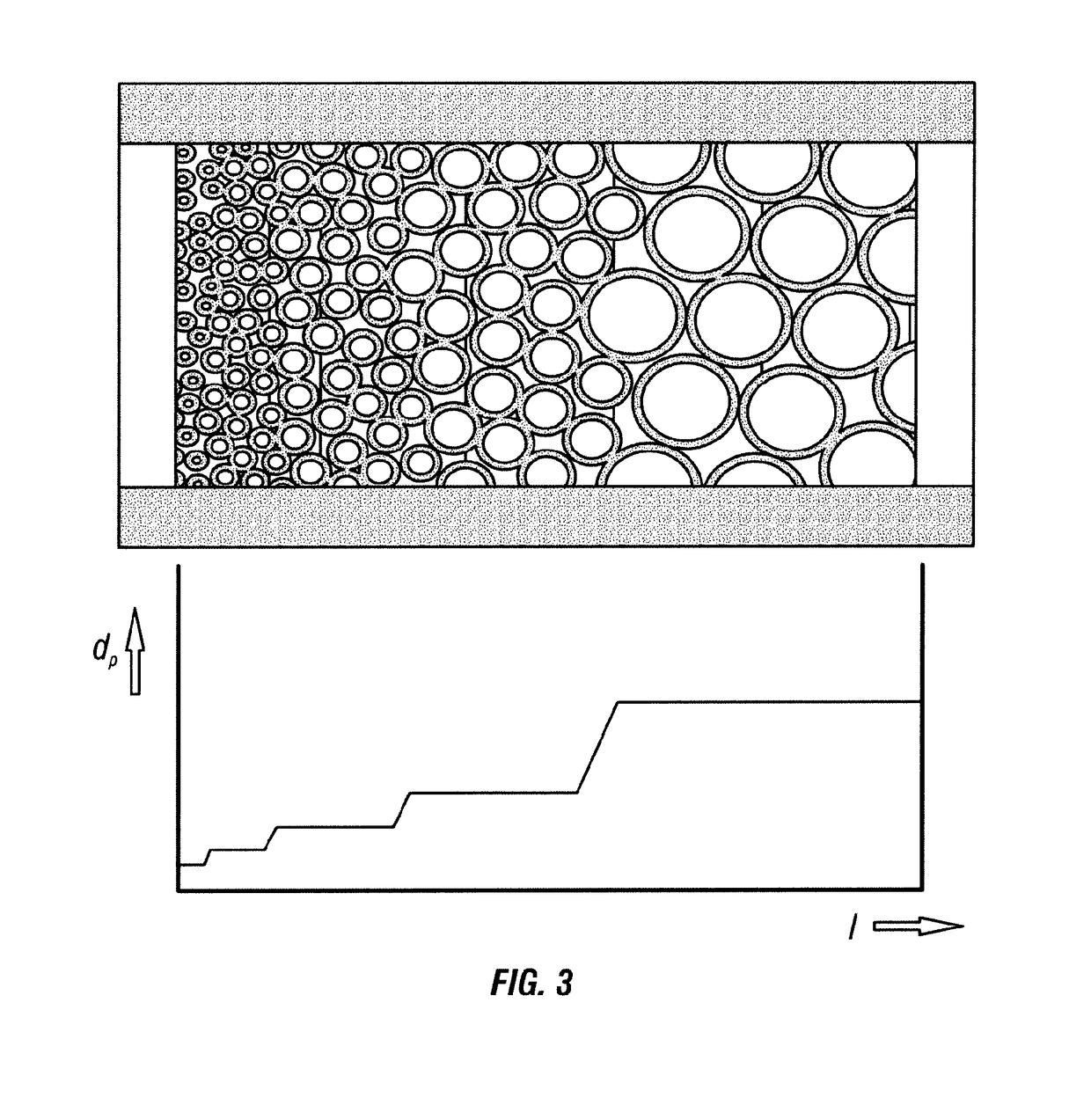

Chromatography columns

ActiveUS20150219604A1Maintains efficiency and resolutionReduce thicknessComponent separationSolid sorbent liquid separationPhysical chemistryChromatography column

A chromatography column (2) containing a bed of packed particles (22, 24, 26, 28, 30), wherein the packed particles comprise fused core particles and the particle diameters of the packed particles vary along the column. Preferably, the particles (2, 24, 26, 28, 30) are arranged according to their average particle diameter, in order of increasing average particle diameter from the inlet end (4) to the outlet end (6). The bed may comprise a plurality of bed sections and each bed section has an average particle diameter calculated from the particles in that section and there are at least two different average particle diameter bed sections, wherein the particles of each bed are separated from particles of an adjacent bed by a partition that is liquid permeable to allow through a flow of mobile phase. A high column efficiency can be provided with lower pressure drop per unit length of the column.

Owner:THERMO ELECTRON MFG

Electrical fuse device

The invention provides an electrical fuse device comprising: a plurality of fuse cores, each having an electrical fuse element and a switching element serially connected to the electrical fuse element; a program control circuit generating a program shift signal by sequentially shifting a program control transmission signal in synchronization with an effective program clock signal and subsequently generating a program signal to be sent to each of the switching elements in the plurality of fuse cores based on program data and the program shift signal; and a program clock control circuit controlling the conducting and non-conducting states of a program clock signal in accordance with a program clock enable signal and, when the program clock signal is in a conducting state, transmitting the program clock signal to the program control circuit as the effective program clock signal.

Owner:PANASONIC CORP

Reversible temperature-indicating paint and preparation method thereof, and fusible fuse core and fuse

ActiveCN108467659ARealize self-cleaning functionImprove liquidityAntifouling/underwater paintsPaints with biocidesWorking temperatureEngineering

The invention relates to the technical field of fuses, specifically to a reversible temperature-indicating paint and a preparation method thereof, and a fusible fuse core and a fuse. The intelligent early-warning fuse provided by the invention has the following advantages: the fuse is simultaneously monitored and warned through monitoring of a plurality of parameters, so a worker is helped to do relative preparation work in advance; through detachable arrangement of a shell, a fusible core and an electrode, the intelligent early-warning fuse can be continuously used by replacement of the fusecore, so the cost of usage is saved; meanwhile, a storage groove is arranged to store fusible cores with different sizes, so the use flexibility of the fuse is improved; and through detachable combination of a ceramic material and transparent plastic, the weight of the shell is reduced, and high-temperature resistance and reliability of the shell can be guaranteed. The preparation method for the fusible fuse core provided by the invention has the following advantages: through coating of a temperature-indicating layer, a worker can conveniently observe color changes and pays attention to the working temperature of the fuse in real time, so adjustment is realized in advance.

Owner:SUZHOU MAICHUANG INFORMATION TECH

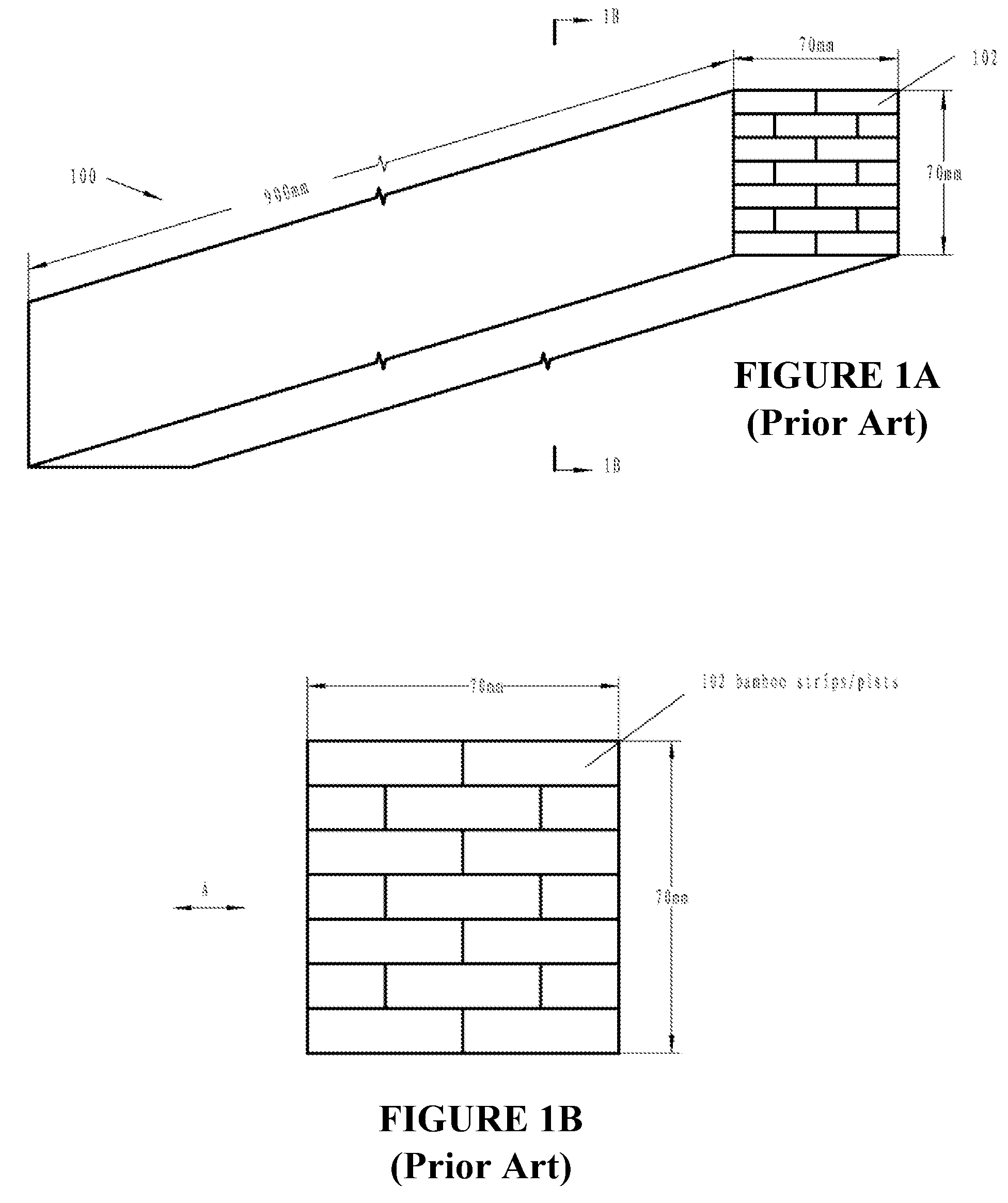

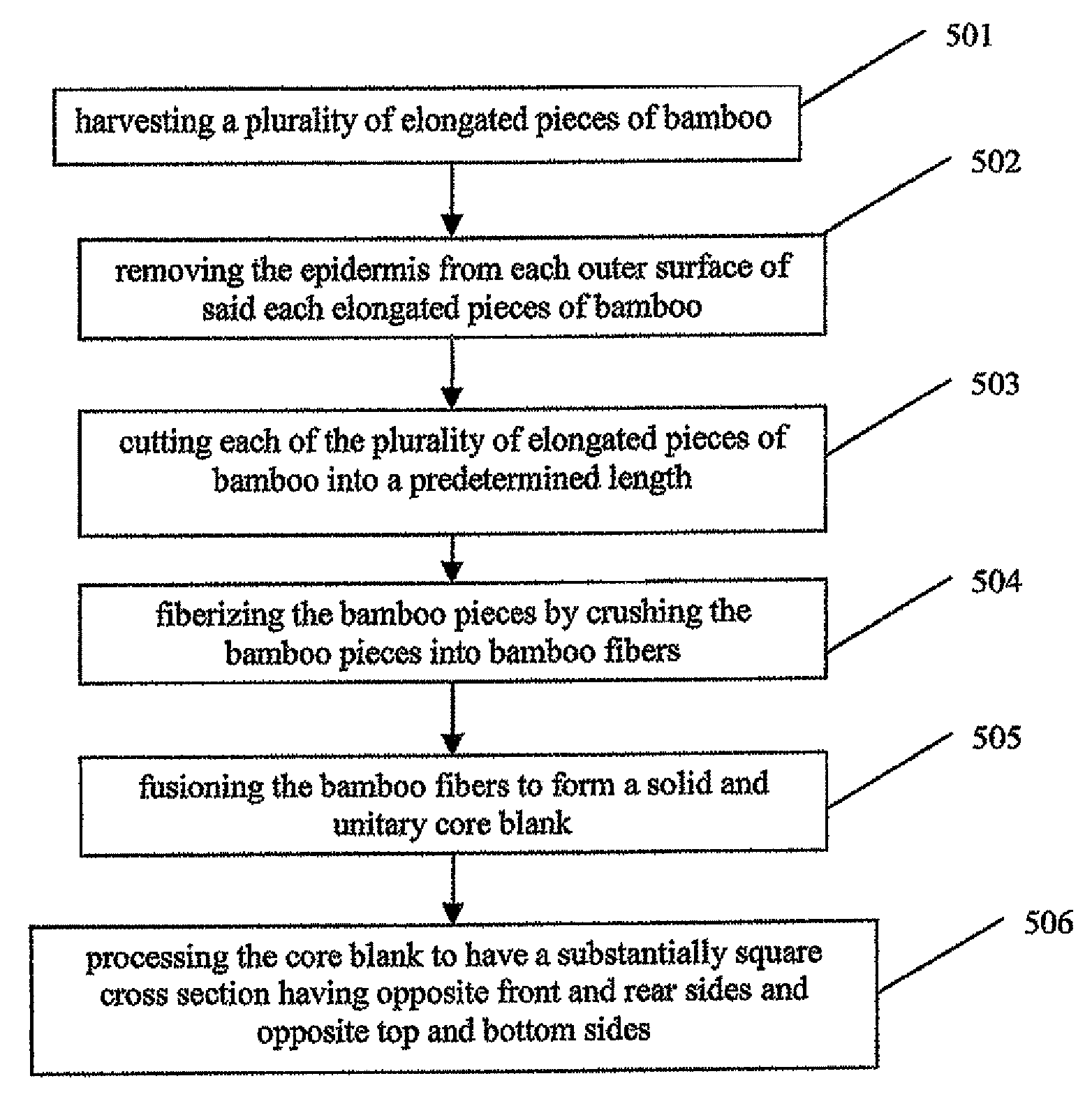

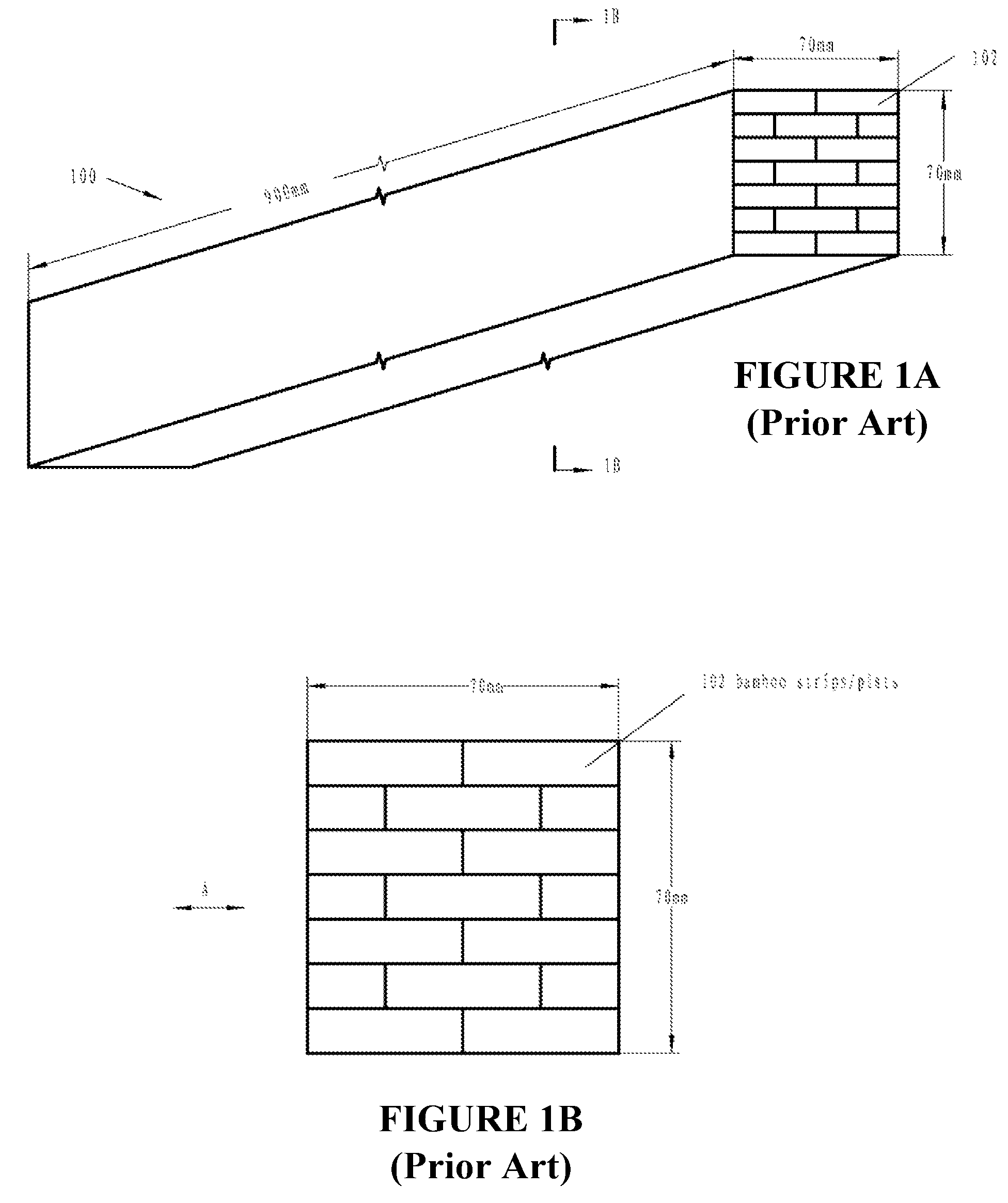

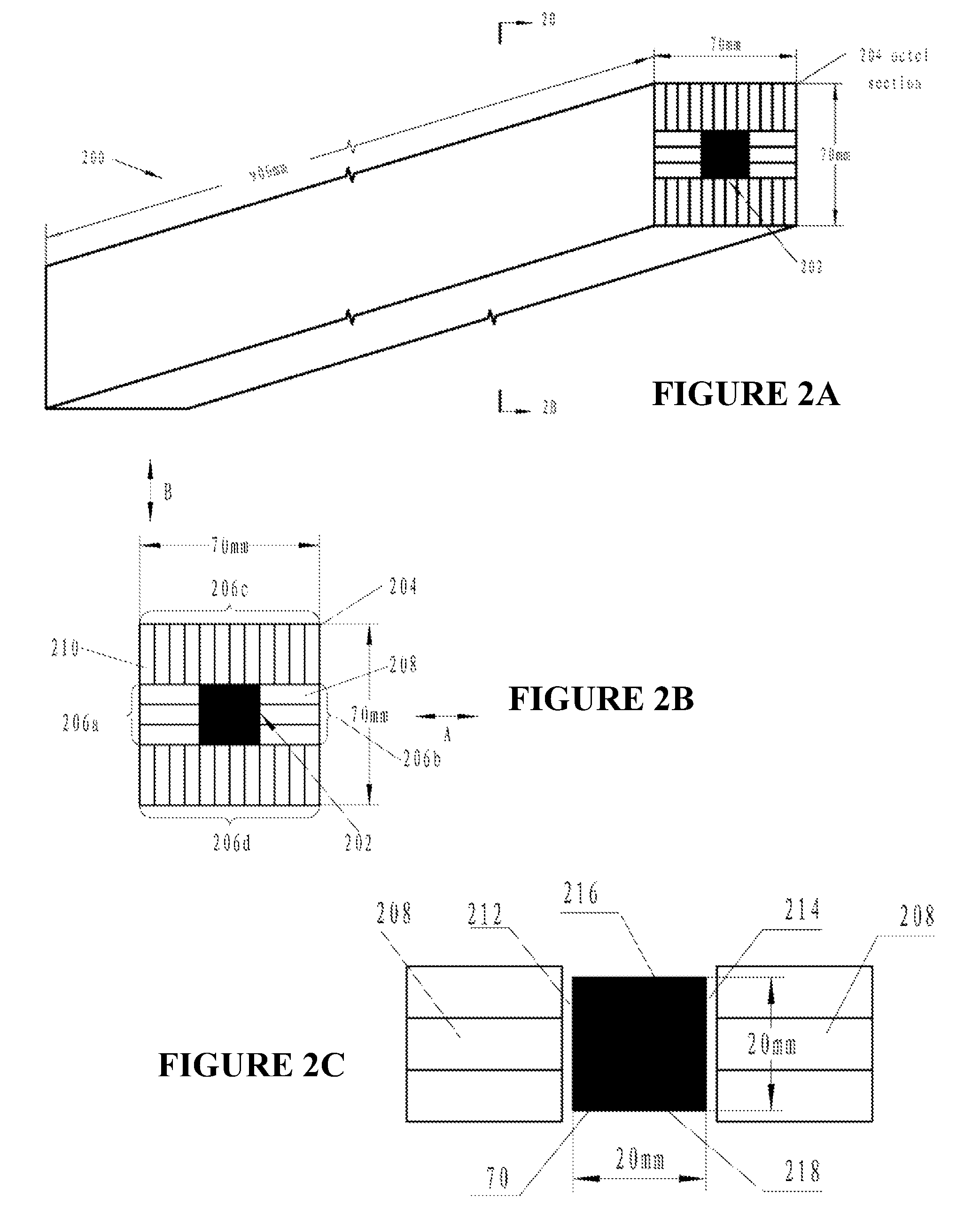

Bamboo bat having fiber-fused core and method of manufacturing the same

InactiveUS20100113193A1High impact strengthReduce breakageMechanical working/deformationWood working apparatusSquare cross sectionFiber

A baseball bat has a core section formed exclusively of bamboo fibers fused together and an outer section substantially surrounding the core section. In a method for fabricating a blank from which a baseball bat is fabricated, a core section is fabricated through harvesting elongated bamboo pieces, removing the epidermis or skin from the bamboo pieces, cutting the bamboo pieces into a predetermined length, fiberizing the bamboo pieces, fusing the bamboo fibers to form a solid and unitary core blank, and processing the solid core blank to provide a core section have a substantially square cross section having opposite front and rear sides and opposite top and bottom sides.

Owner:STR8 TO THE SOURCE INC

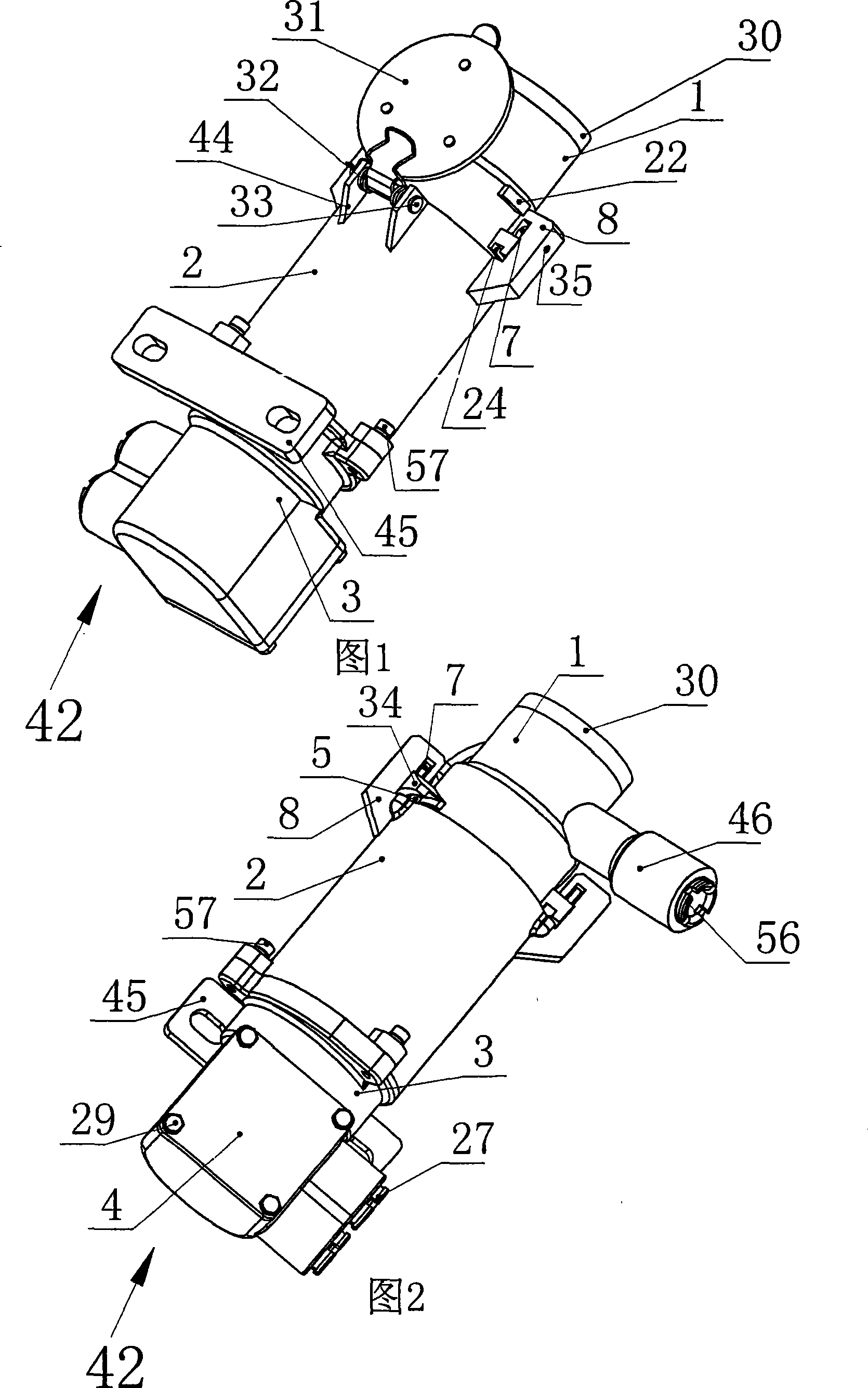

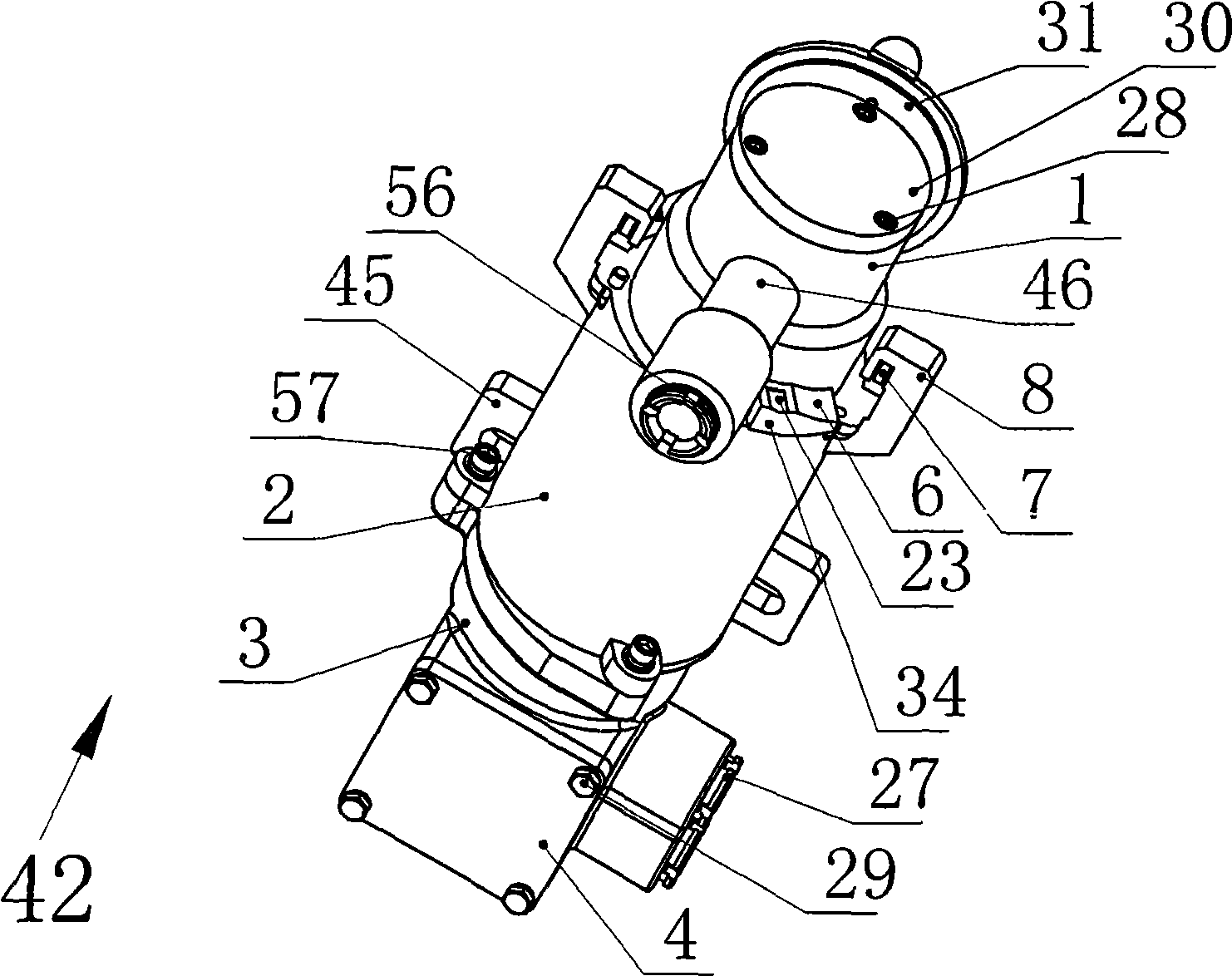

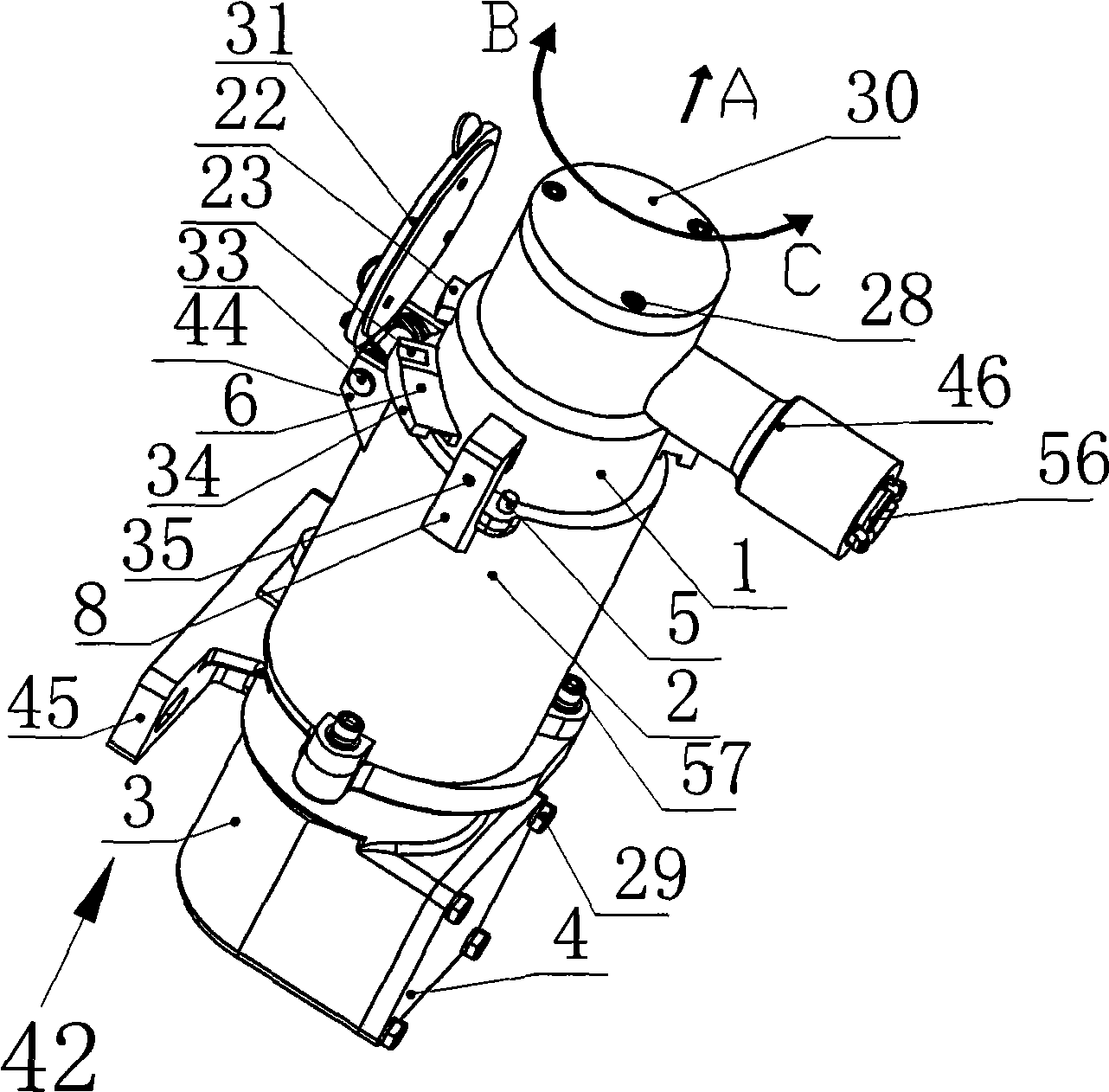

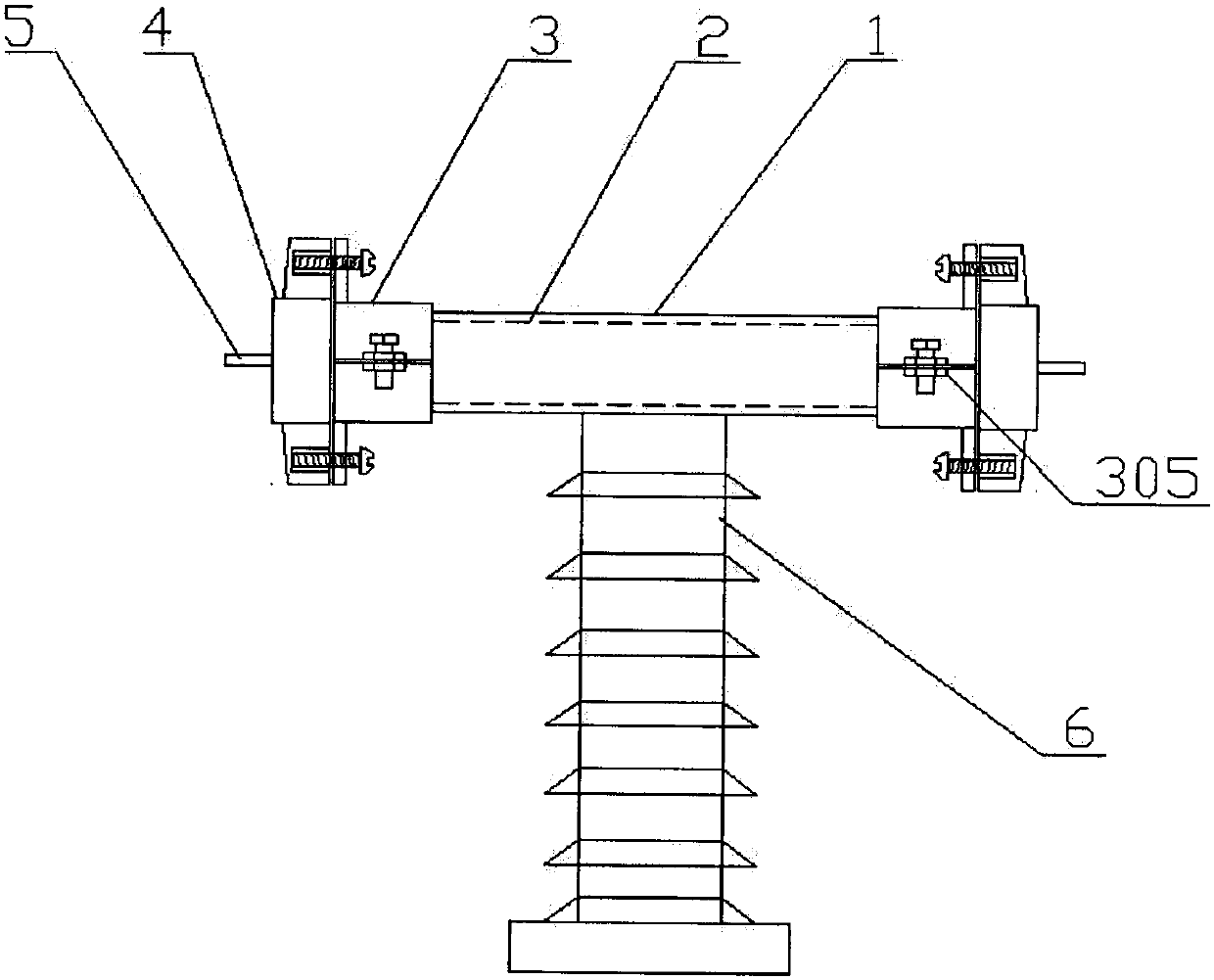

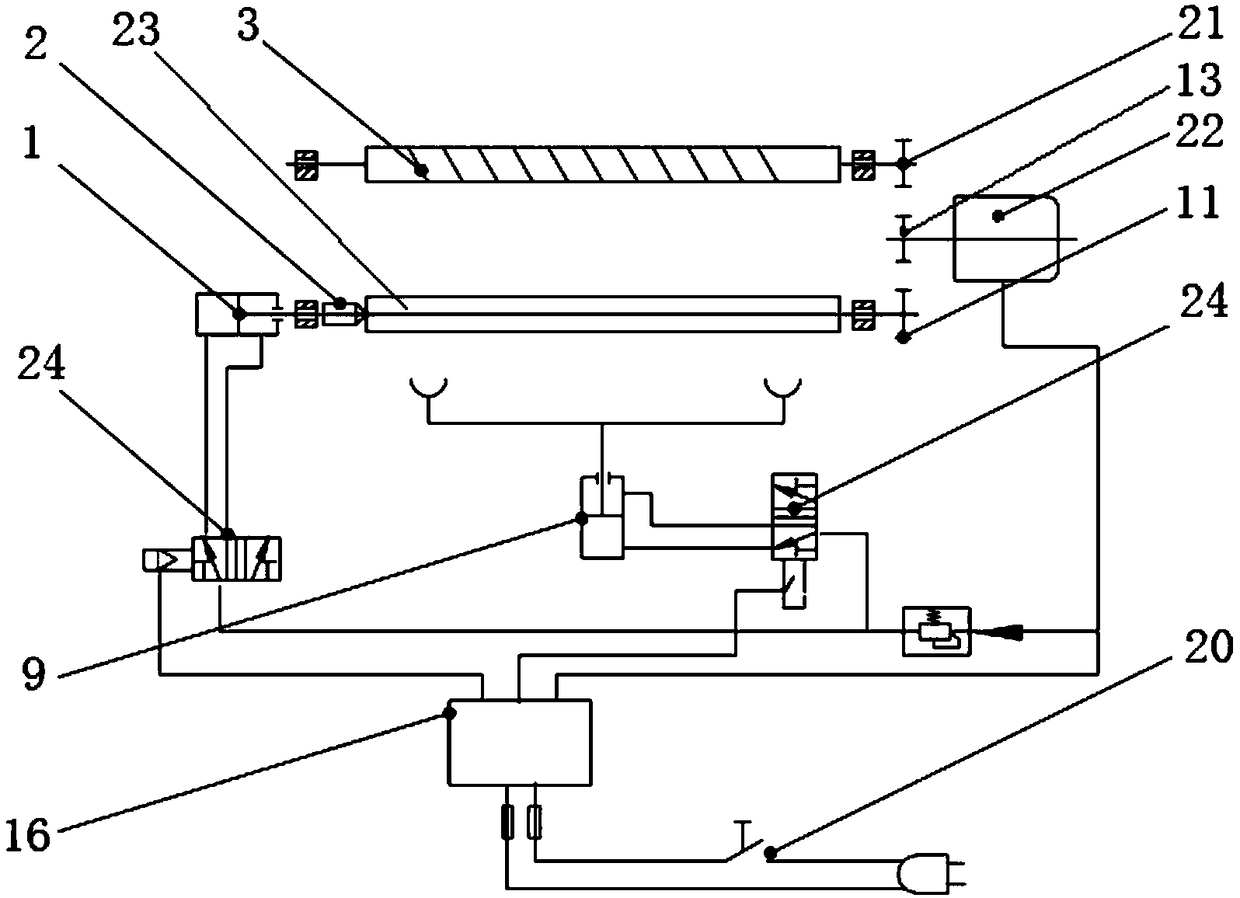

Portable 35KV fuse core replacing device and quick core replacing method

The invention discloses a portable 35KV fuse core replacing device. A fuse porcelain bushing is fixed on a support insulator. Wiring end cover plates are arranged at the two ends of the fuse porcelain bushing to form a closed area in which a fuse tube is wrapped. The fuse tube and wiring terminals form circuit connection. The fuse porcelain bushing and the wiring end cover plates are connected by cover plate clamping devices. The left ends of the cover plate clamping devices are fixedly connected with the fuse porcelain bushing, and the right ends of the cover plate clamping devices are detachably connected with the wiring end cover plates through track clamping slots. The wiring end cover plates are provided with clamping parts corresponding to the track clamping slots. When the clamping parts are in the narrow areas of the track clamping slots, the wiring end cover plates are clamped; and when the clamping parts are in the wide areas of the track clamping slots, the wiring end cover plates are released. The corresponding core replacing method of the invention comprises the steps of unscrewing connectors, removing the wiring end cover plates, replacing the fuse tube, closing the wiring end cover plates, tightening the connectors, and the like. The device and the method of the invention have the characteristics of short core replacing time and simple operation.

Owner:XINGAN POWER SUPPLY CO

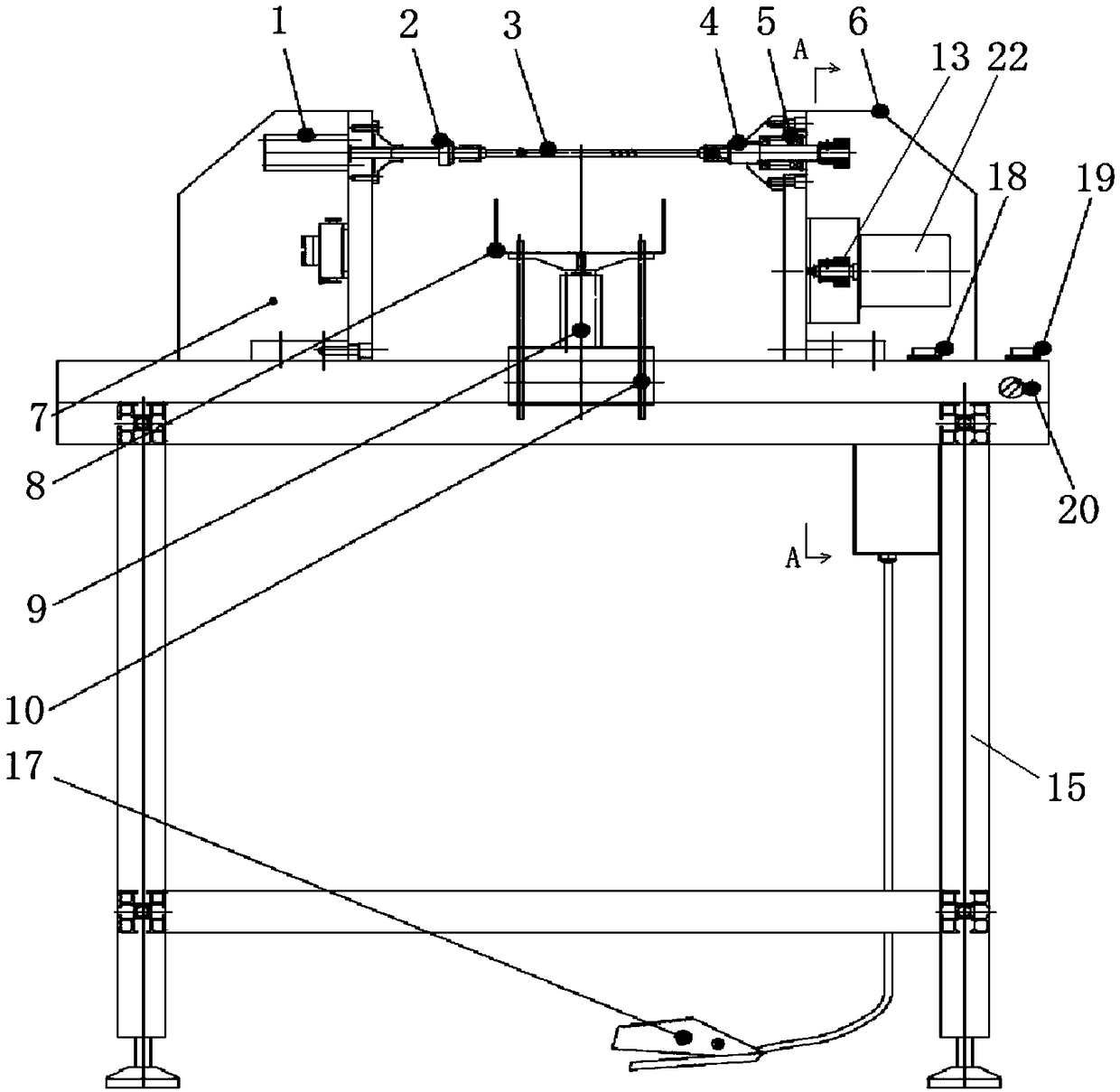

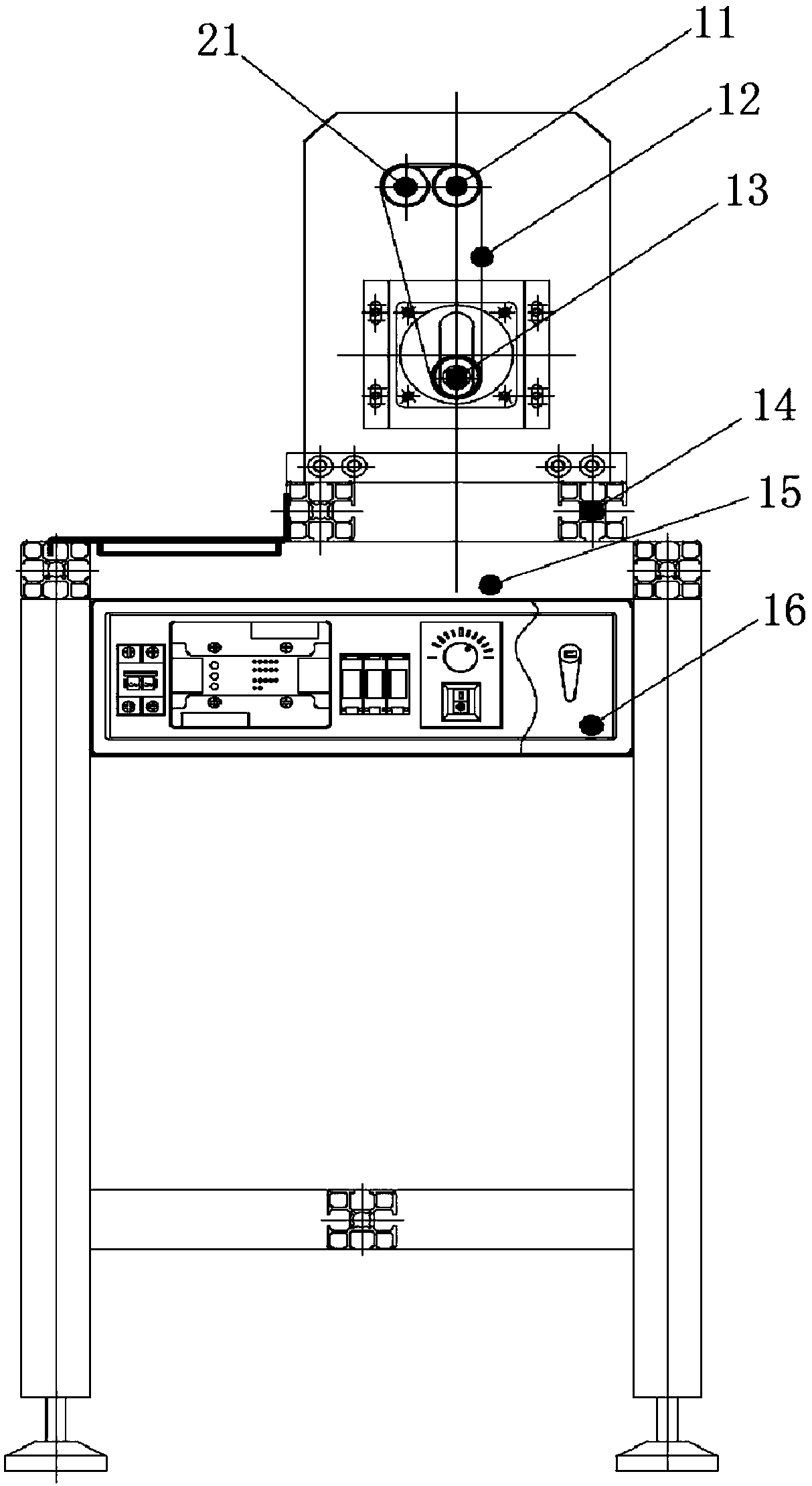

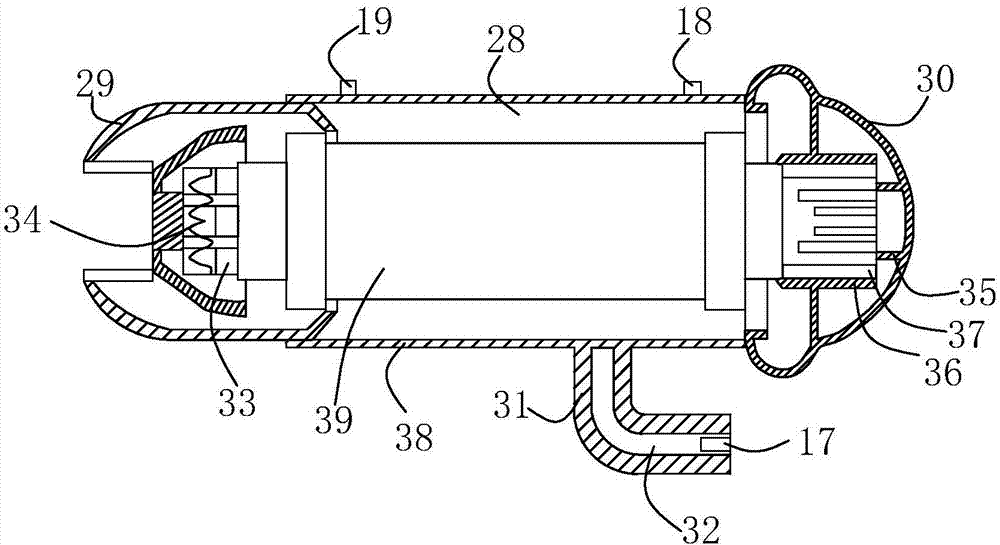

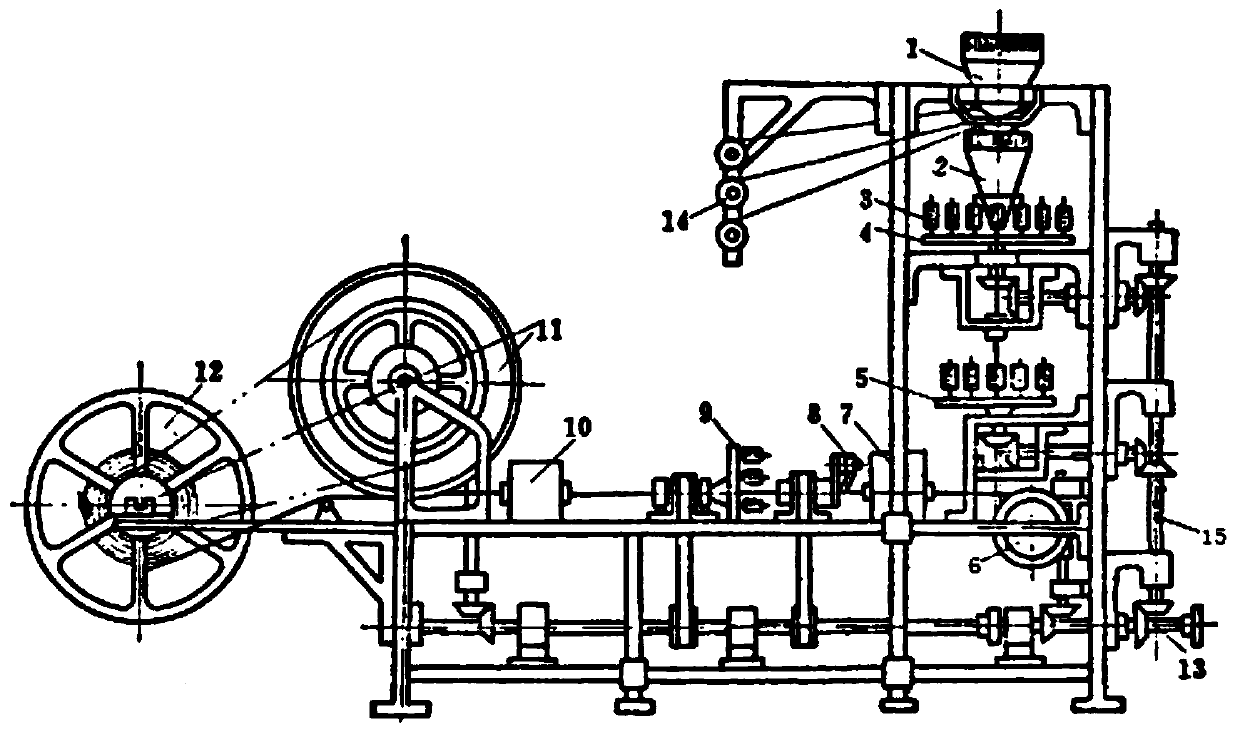

Fuse winding machine

PendingCN108455366AImprove winding qualityEasy to use and flexibleFilament handlingWinding machineEngineering

The invention relates to the technical field of fuse production, in particular to a fuse winding machine. The fuse winding machine comprises a clamping mechanism, a lifting mechanism, a rotation drivemechanism, a spiral screw rod and a support; the clamping mechanism, the lifting mechanism and the rotation drive mechanism are installed on the support; a fuse core is conveyed to a winding stationthrough the lifting mechanism; the clamping mechanism comprises a movable ejector rod, an ejector rod drive device and a fixed ejector rod; the movable ejector rod is rotationally connected with the ejector rod drive device and driven to make linear movement through the ejector rod drive device; the fixed ejector rod is rotationally arranged on the support; the fuse core located on the winding station is clamped and fixed through the movable ejector rod and the fixed ejector rod; the spiral screw rod is arranged on one side of the winding station; and the spiral screw rod and the fixed ejectorrod are driven to rotate synchronously through the rotation drive mechanism. By means of the fuse winding machine, efficiency of the winding work is improved, intervals of wires are uniform, the winding quality is greatly improved, and using is flexible and convenient.

Owner:大连北方真空开关有限公司

Lead-free low-temperature alloy having melting point of 116+/-3 DEG C and preparation method for same

The invention relates to a lead-free low-temperature alloy having a melting point of 116+ / -3 DEG C. The lead-free low-temperature alloy comprises the following raw materials in percentage by weight: 3.7-4.3% of bismuth, 51-53% of indium and the balance of tin. The low-temperature alloy disclosed by the invention is a lead-free low-temperature alloy containing Sn, Bi and In, can be used for producing the fusing core of a thermal fuse, and has a melting point of 116+ / -3 DEG C; and the low-temperature alloy is an eutectic alloy, and has the characteristics of being uniform in ingredients, narrow in melting point range, and wide in use range.

Owner:TIANJIN BAIRUIJIE WELDING MATERIAL

Lead-free low-temperature alloy with fusing point of 135+/-2 DEG C and preparation method thereof

The invention relates to lead-free low-temperature alloy with fusing point of 135+ / -2 DEG C. The lead-free low-temperature alloy is prepared from the following raw materials in percentage by weight: 56-58% of bismuth, 1.8-2.2% of indium, 0.8-1.2% of silver and the balance of tin. The lead-free low-temperature alloy disclosed by the invention contains Sn, Bi, In and Ag, can be used for manufacturing a fusing core of a thermal fuse and has the fusing point of 135+ / -2 DEG C; and the low-temperature alloy is eutectic alloy and has the characteristics of uniform ingredients, narrow fusing point range and wide range of use.

Owner:TIANJIN BAIRUIJIE WELDING MATERIAL

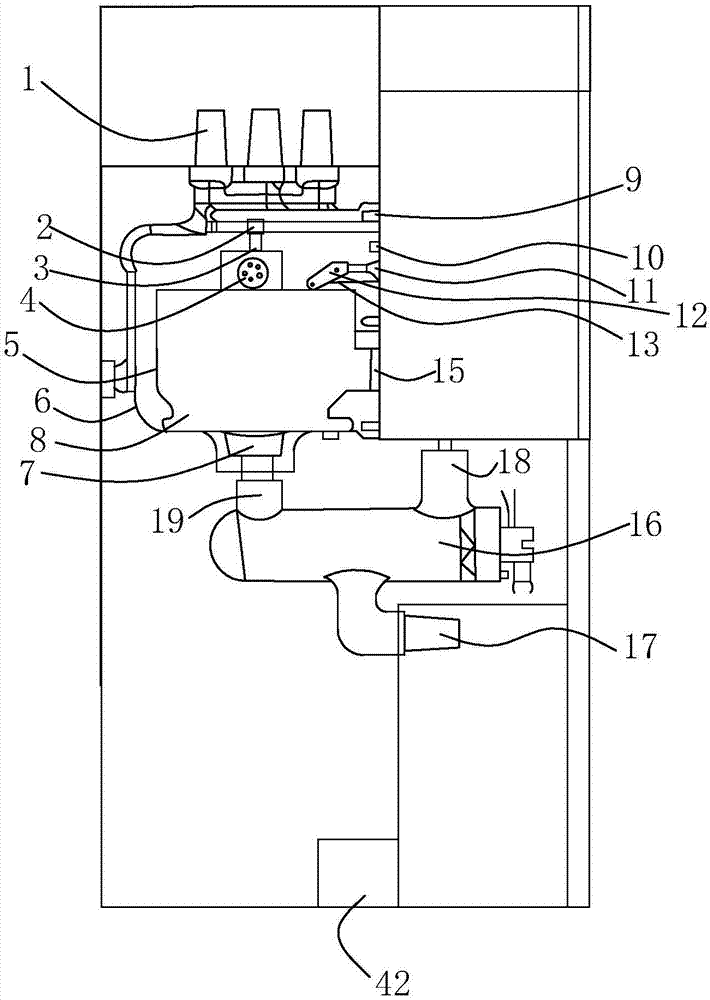

Solid insulation ring main unit

InactiveCN108011300AEasy to replaceAvoid enteringSwitchgear arrangementsSubstation/switching arrangement casingsEnvironment effectContact pressure

A solid insulation ring main unit comprises an operation panel, a seal isolation chamber, a solid-sealed polar pole and a fuse unit. The fuse unit comprises a fuse barrel and a fuse barrelhead; the fuse barrel comprises an incoming line port, an outgoing line port, a ground wire interface, a front bracing frame, a rear bracing frame and an insulation sleeve arranged between the front bracing frameand the rear bracing frame; the fuse barrel is internally provided with a fuse; the front bracing frame comprises a pedestal; the pedestal is internally provided with plum blossom contacts; a reinforcing spring is arranged at the peripheries of the plum blossom contacts to ensure contact pressure; the rear bracing frame comprises a pedestal, the pedestal is internally provided with a fuse core C-type jack, and a reinforcing spring is arranged at the periphery of the fuse core C-type jack; and the pedestal is a silica gel insulation sleeve. The structure design of the fuse unit can effectivelyreduce the generation of partial discharge to allow the ring main unit not to generate partial discharge after the ring main unit powers off, and therefore the solid insulation ring main unit is muchsafer and more reliable, is all-insulated, long in service, free in maintenance, small in occupation space and safe and reliable, cannot be influence by environments, etc.

Owner:北京华电国网电力设备有限公司

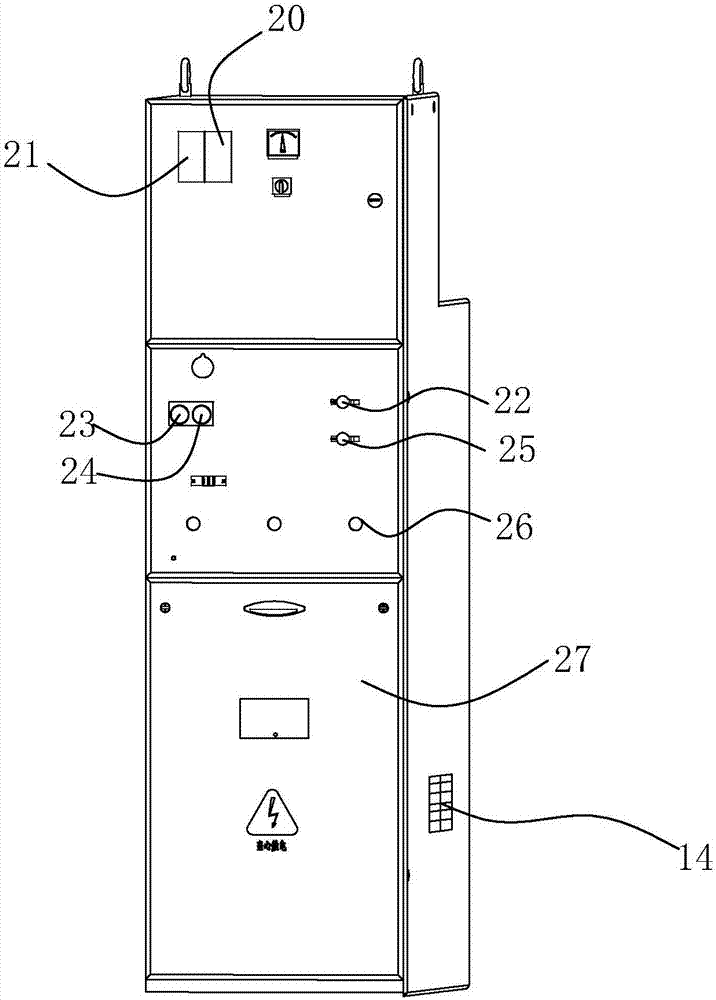

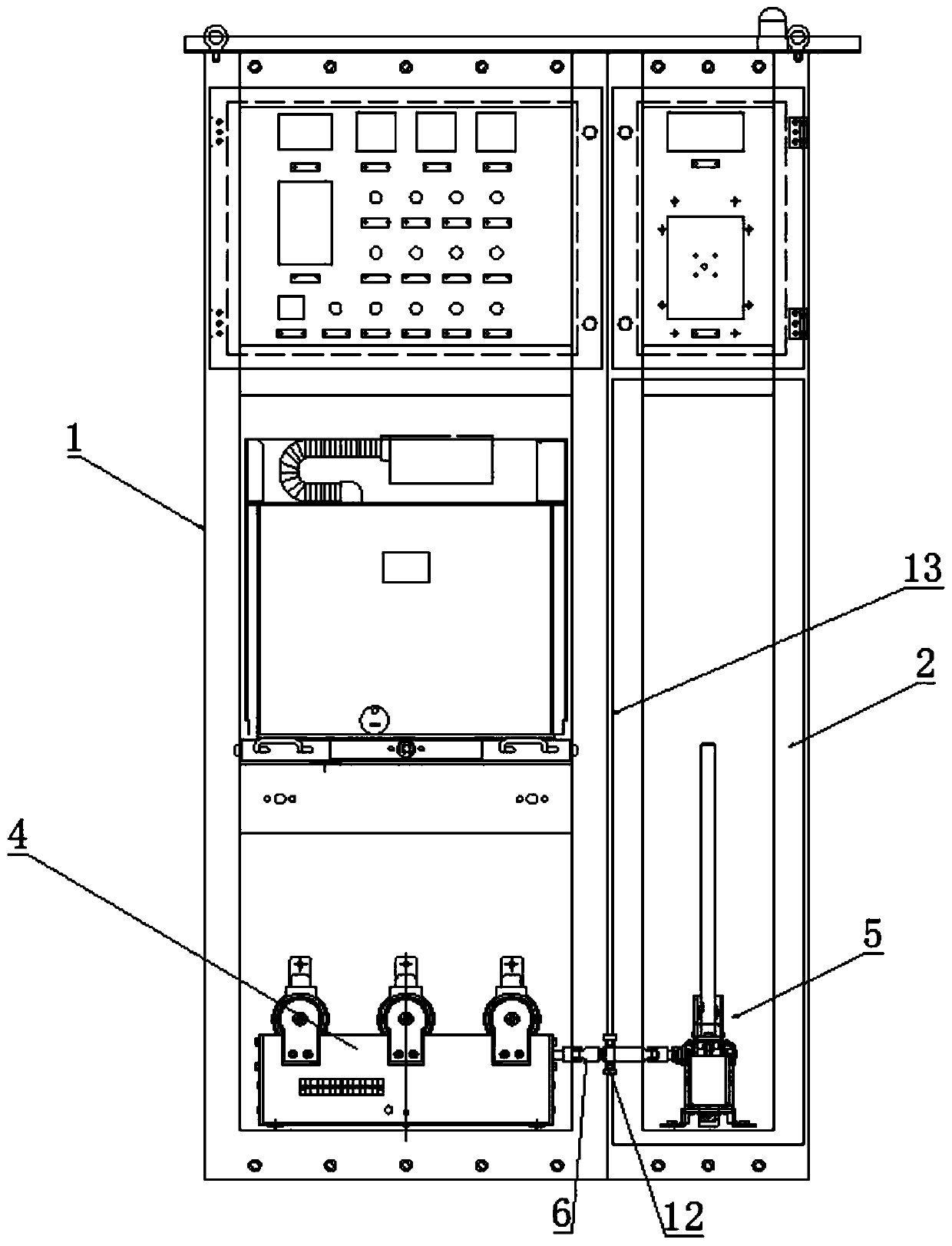

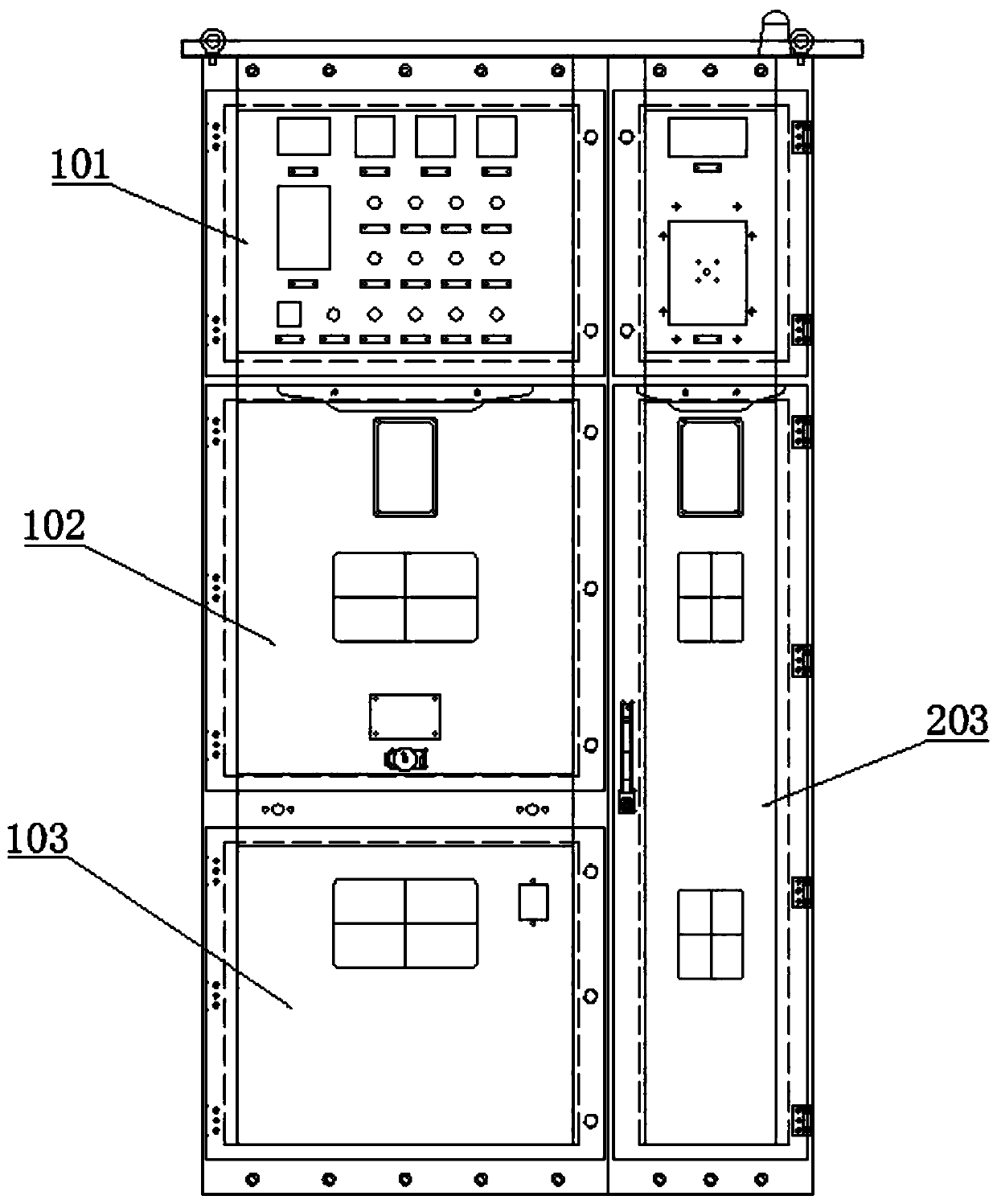

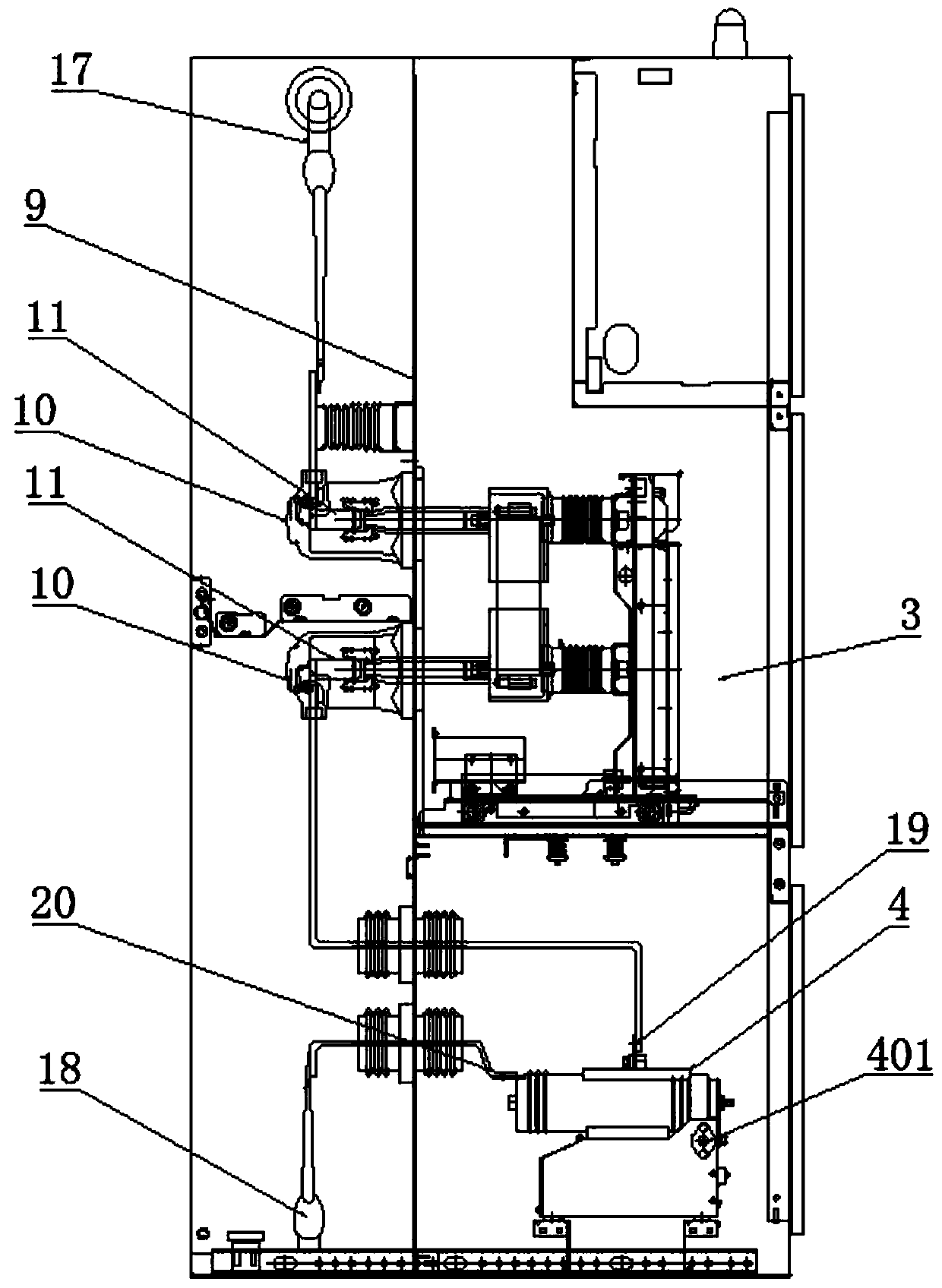

High-voltage electric fire pump control cabinet with emergency mechanical pump starter

PendingCN110098576AOperational securityEasy maintenanceSwitchgear with withdrawable carriagePump controlHigh pressureFused core

The invention discloses a high-voltage electric fire pump control cabinet with an emergency mechanical pump starter. The control cabinet comprises a control cabinet body, the control cabinet body comprises a main cabinet and an auxiliary cabinet arranged in one side of the main cabinet, an FC control loop for control a fire pump is arranged in the main cabinet, and the FC control loop comprises anF fuse cart arranged in the middle portion of the main cabinet and connected with an inlet wire of a high voltage power supply, a C high voltage vacuum contactor arranged in the bottom of the main cabinet, and an emergency manual control mechanism arranged in the bottom of the auxiliary cabinet. The high-voltage electric fire pump control cabinet with the emergency mechanical pump starter is reasonable in design, the emergency manual control mechanism can be used to safely control work of the C high voltage vacuum contactor, use of the high voltage electric fire pump when a secondary controlloop is in failure is ensured, and convenient replacement of the F fuse core and safe maintenance of the C high voltage vacuum contactor are considered in design of the control cabinet.

Owner:广东长悦电气有限公司

A kind of warm pressure fuse and preparation method thereof

ActiveCN106518587BAchieve blasting effectLow mechanical sensitivityExplosive working-up apparatusFuse detonationDetonationCombustion

The invention relates to a warm-pressing blasting fuse. The fuse comprises a fuse core and a fuse shell encapsulating the fuse core. The fuse core comprises a warm-pressing gunpowder core and a core wire placed in the warm-pressing gunpowder core. The material components of the warm-pressing gunpowder is further restricted and defined. According to the blasting fuse, the gunpowder core in the fuse core applies mainly the warm-pressing effect, wherein only under high temperature can the fire be ignited, the mechanical sensitivity is low, thus guaranteeing the safety in the whole process of preparation, transportation, storage and application with sharply decreased gas generation. The substances created from the combustion are mainly condensed phase matter which reduces the fluctuation of combustion speed, and at the same time generates high impact and heat to contribute work by breaking rocks. The fuse has the advantages of generating a large amount of heat, generating high temperature and impact energy, being able to effectively avoid detonation reaction, thus achieving a harmonious explosion work application.

Owner:ANHUI UNIV OF SCI & TECH

Lead-free low-temperature alloy having melting point of 80+/-2 DEG C and preparation method for same

The invention relates to a lead-free low-temperature alloy having a melting point of 80+ / -2 DEG C. The lead-free low-temperature alloy comprises the following raw materials in percentage by weight: 56-58% of bismuth, 25-27% of indium and the balance of tin. The low-temperature alloy disclosed by the invention is a lead-free low-temperature alloy containing Sn, Bi and In, can be used for producing the fusing core of a thermal fuse, and has a melting point of 80+ / -2 DEG C; and the low-temperature alloy is an eutectic alloy, and has the characteristics of being uniform in ingredients, narrow in melting point range, and wide in use range.

Owner:TIANJIN BAIRUIJIE WELDING MATERIAL

Bamboo bat having fiber-fused core and method of manufacturing the same

InactiveUS7771296B2High impact strengthReduce breakageWood working apparatusDomestic articlesFiberSquare cross section

A baseball bat has a core section formed exclusively of bamboo fibers fused together and an outer section substantially surrounding the core section. In a method for fabricating a blank from which a baseball bat is fabricated, a core section is fabricated through harvesting elongated bamboo pieces, removing the epidermis or skin from the bamboo pieces, cutting the bamboo pieces into a predetermined length, fiberizing the bamboo pieces, fusing the bamboo fibers to form a solid and unitary core blank, and processing the solid core blank to provide a core section have a substantially square cross section having opposite front and rear sides and opposite top and bottom sides.

Owner:STR8 TO THE SOURCE INC

PTC Integrated sensor

InactiveCN104783668AReduce offlineHighly integratedWarming devicesTemperature controlElectrical resistance and conductance

The invention relates to the technical field of temperature control sensors, in particular to a PTC integrated sensor. The PTC integrated sensor comprises a base. A sensing component is arranged in the base. The upper end of the base is sleeved with an upper cover which independently acts relative to the base. A compression spring is arranged between the base and the upper cover. The upper cover is in abutting linkage with the sensing component in the base in the downward-pressing process. The sensing component comprises an overheating power-off device provided with a heat keeping device. According to the PTC integrated sensor, when the temperature rise of an inner pot exceeds a thermistor set value, a main control panel circuit is switched off to achieve power-off protection; a heating circuit can be switched off when a contact piece deforms, at the moment, the PTC heating source heats a temperature sensing piece, and the power-off state is kept to prevent the problem that the contact piece is cooled and connected with the heating circuit again; a fusing core is directly molten through high temperature, and the heating circuit is switched off with force to achieve final protection; the temperature sensing piece and an insulation support are used as stress reaction components, the off-line problem of lead welding points is reduced, and the sensor is high in overall integration, convenient to maintain and stable to trigger and is perfectly protected.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY +1

Chromatography columns

ActiveUS9897578B2Improve stabilityMaintain efficiencyComponent separationOther chemical processesChromatography columnFused core

A chromatography column (2) containing a bed of packed particles (22, 24, 26, 28, 30), wherein the packed particles comprise fused core particles and the particle diameters of the packed particles vary along the column. Preferably, the particles (2, 24, 26, 28, 30) are arranged according to their average particle diameter, in order of increasing average particle diameter from the inlet end (4) to the outlet end (6). The bed may comprise a plurality of bed sections and each bed section has an average particle diameter calculated from the particles in that section and there are at least two different average particle diameter bed sections, wherein the particles of each bed are separated from particles of an adjacent bed by a partition that is liquid permeable to allow through a flow of mobile phase. A high column efficiency can be provided with lower pressure drop per unit length of the column.

Owner:THERMO ELECTRON MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com