Electrical fuse circuit

a fuse circuit and circuit technology, applied in the field of electric fuse circuits, can solve the problems of increasing the number of defective memory cells, the inability of electrical fuse devices to mount for ram redundancy repair the inability of electrical fuse devices to be mounted in the system lsi, so as to reduce the number of circuits, reduce the number of shift register stages, and shorten the time for programming the fuse elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0038]The following will discuss an electrical fuse circuit according to Embodiment 1 of the present invention.

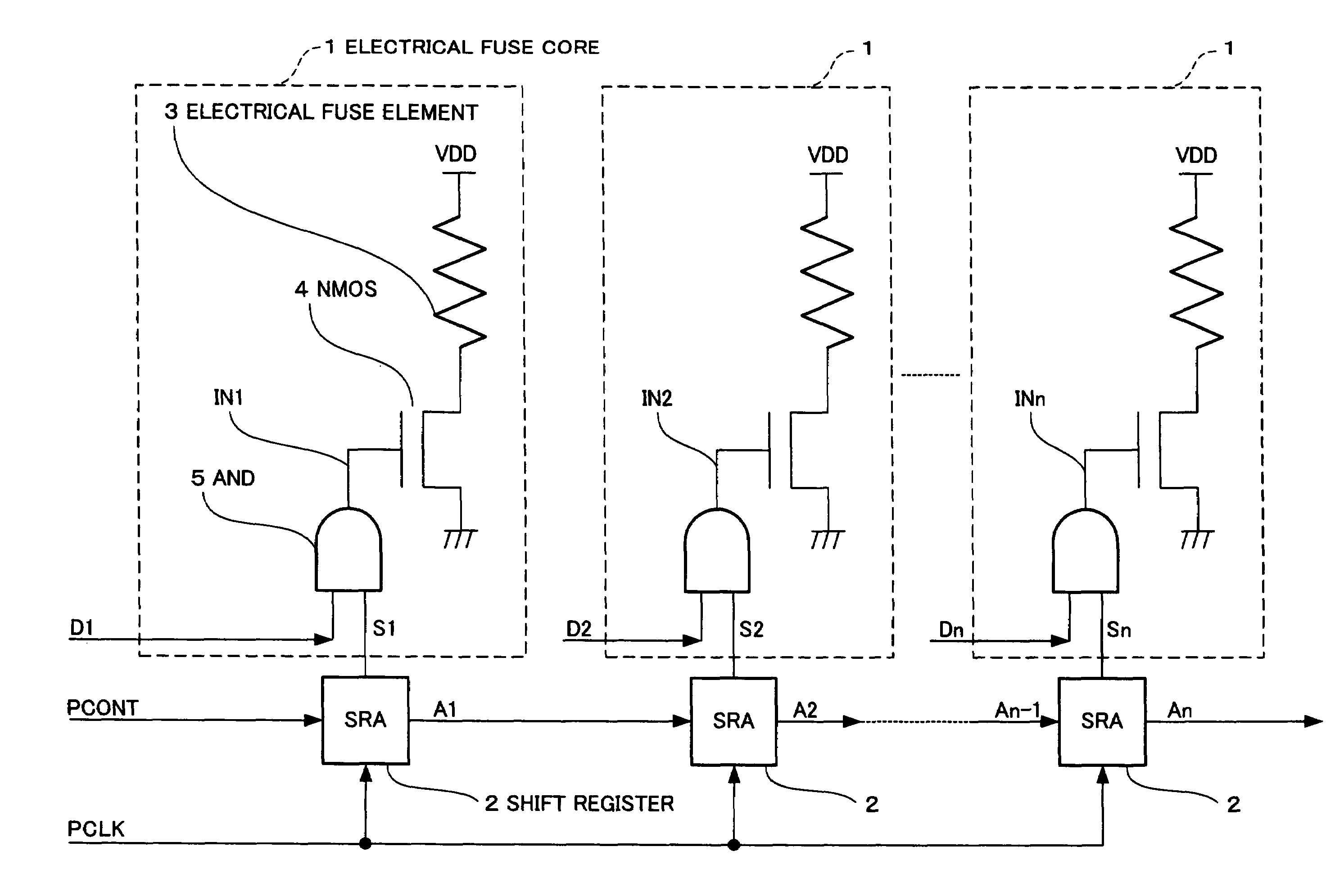

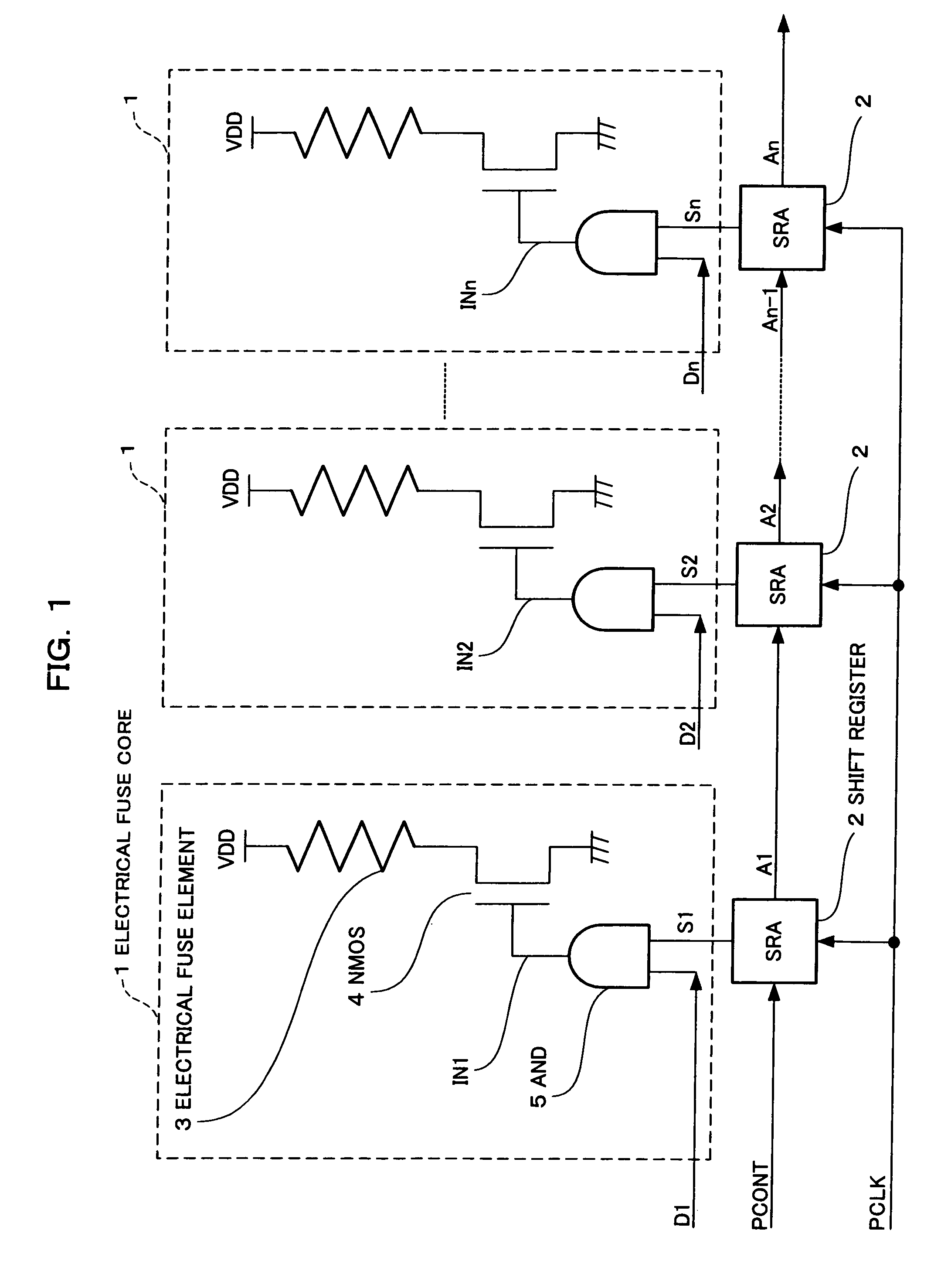

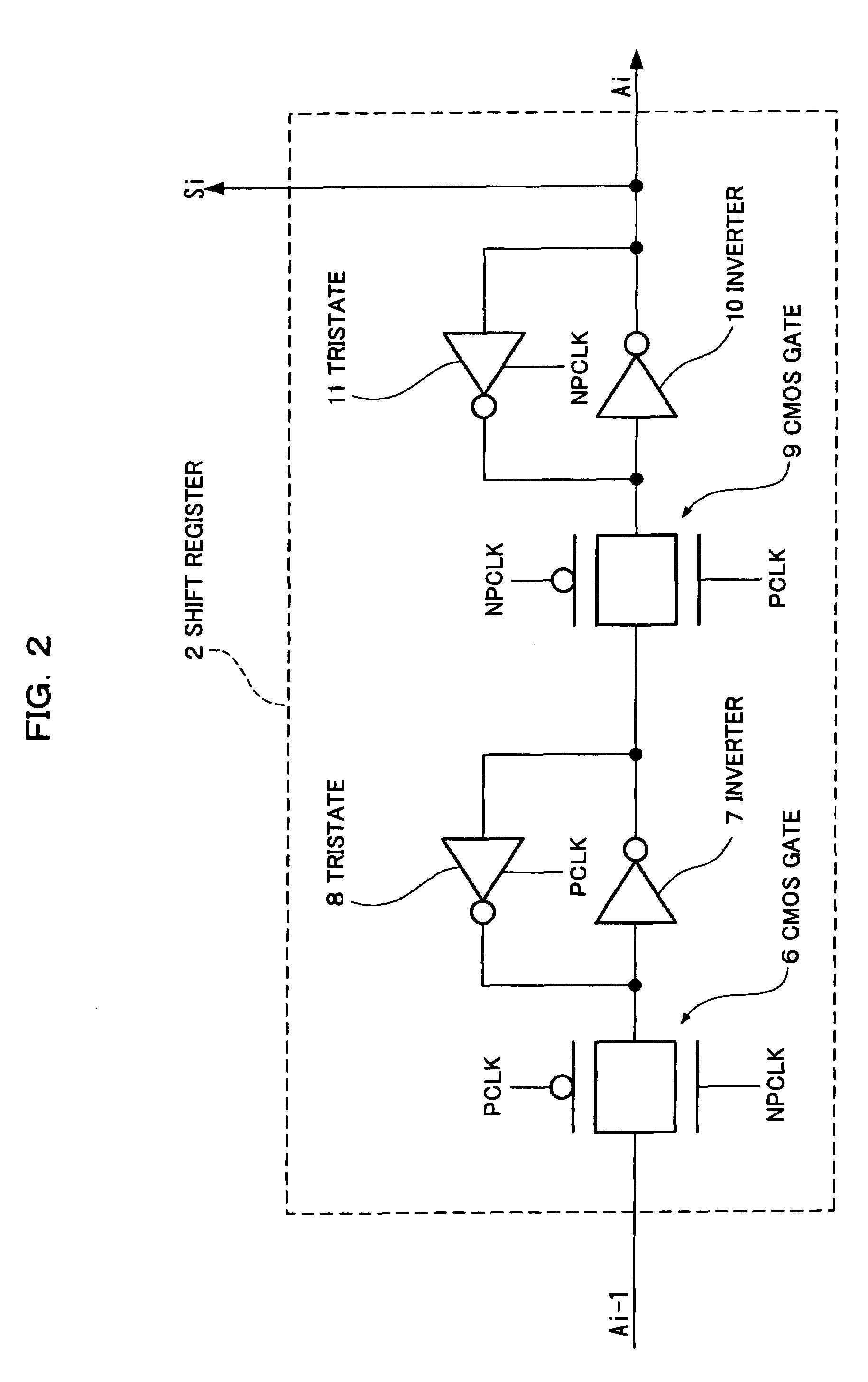

[0039]FIG. 1 is a circuit diagram showing the configuration of the electrical fuse circuit of Embodiment 1, in which two or more (n) fuse elements are configured as one module. In the electrical fuse circuit of FIG. 1, reference numeral 1 denotes n electrical fuse cores and reference numeral 2 denotes shift registers of n stages.

[0040]In the electrical fuse core 1, reference numeral 3 denotes an electrical fuse element having one end connected to a power supply (VDD), reference numeral 4 denotes an NMOS transistor which is connected in series with the electrical fuse element 3 and has its source connected to a ground terminal, and reference numeral 5 denotes a two-input AND circuit which has as its input a program data signal Di (i=1 to n) and a program enable signal Si (i=1 to n) from the shift register 2 and outputs a program signal INi (i=1 ton) to the gate of the NMOS t...

embodiment 2

[0056]The following will discuss an electrical fuse circuit according to Embodiment 2 of the present invention.

[0057]FIG. 4 is a circuit diagram showing the configuration of the electrical fuse circuit of Embodiment 2, in which two or more (n) electrical fuse elements are configured as one module. The same constituent elements as FIG. 1 are indicated by the same reference numerals.

[0058]In FIG. 4, reference numeral 20 denotes shift registers of n stages. Unlike FIG. 1, the input of the shift register 20 of the first stage is fixed at a power supply (H level). The shift registers 20 are serially connected from the first stage to the n-th stage in such a way that the output of the previous stage is connected to the input of the subsequent stage. Program enable transmission signals B1 to Bn are outputted from the respective stages. A program clock signal PCLK is connected in common from the first stage to the n-th stage of the shift registers 20. Further, program enable signals F1 to F...

embodiment 3

[0073]The following will discuss an electrical fuse circuit according to Embodiment 3 of the present invention.

[0074]FIG. 7 is a circuit diagram showing the configuration of the electrical fuse circuit of Embodiment 3, in which two or more (n) electrical fuse elements are configured as one module. The same constituent elements as FIG. 4 are indicated by the same reference numerals.

[0075]In FIG. 7, reference numeral 20 denotes shift registers of n / 4 stages. As in FIG. 4, the input of the shift register 20 of the first stage is fixed at a power supply (H level). The shift registers 20 are serially connected from the first stage to the n / fourth stage in such a way that the output of the previous stage is connected to the input of the subsequent stage. Program enable transmission signals are represented as B1 to Bn / 4. Program enable signals F1 to Fn / 4 outputted from the shift register 20 are each connected to a program enable signal shared by four of n electrical fuse cores 1. Four elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com