Mining flame-proof latch connector

A connector, flameproof technology, applied in the direction of connection, clamping/spring connection, connecting device components, etc., can solve the problems of hidden safety hazards, high replacement and maintenance costs, laborious and other problems, to ensure safe electricity consumption, convenience Replacement, the effect of low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

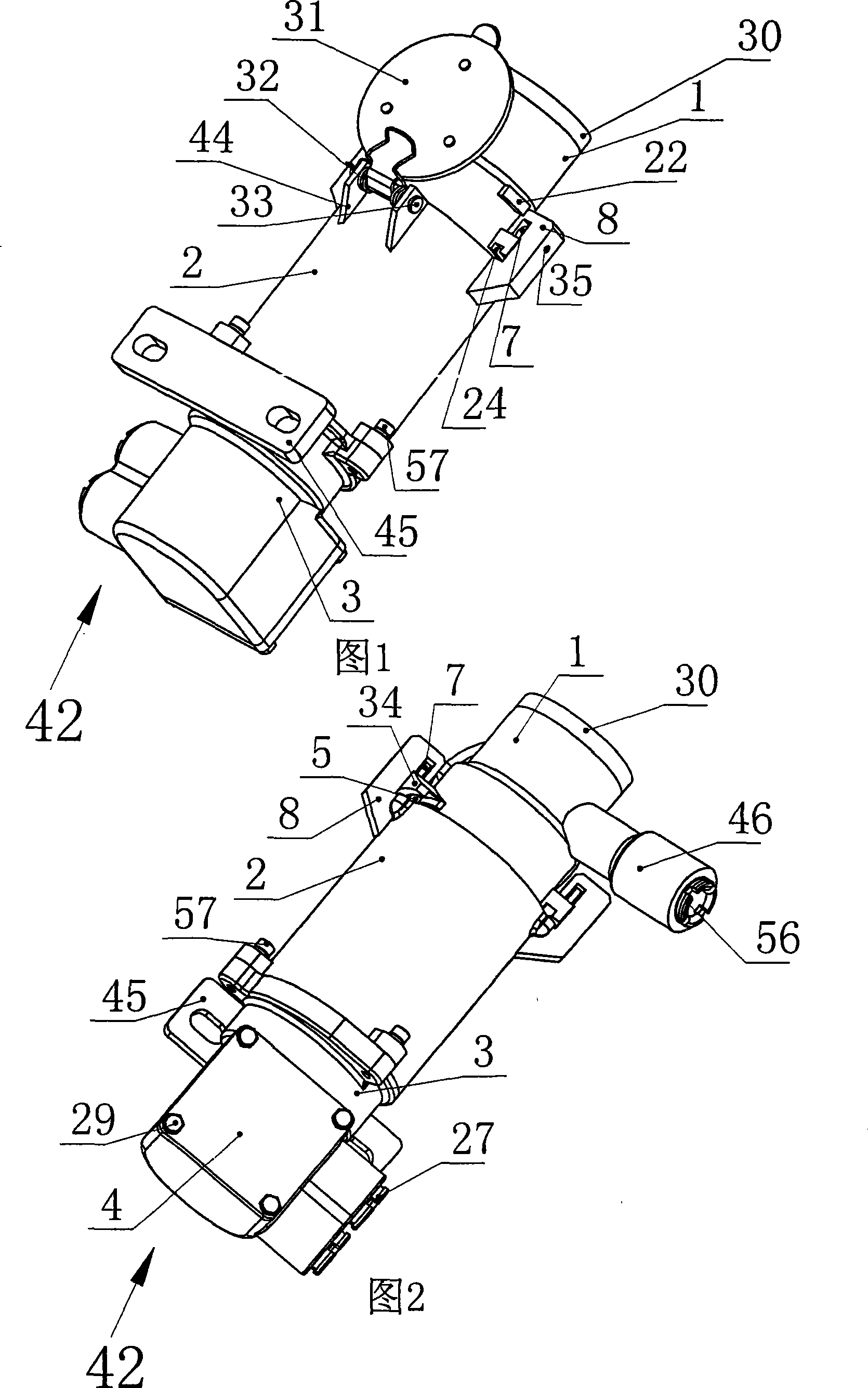

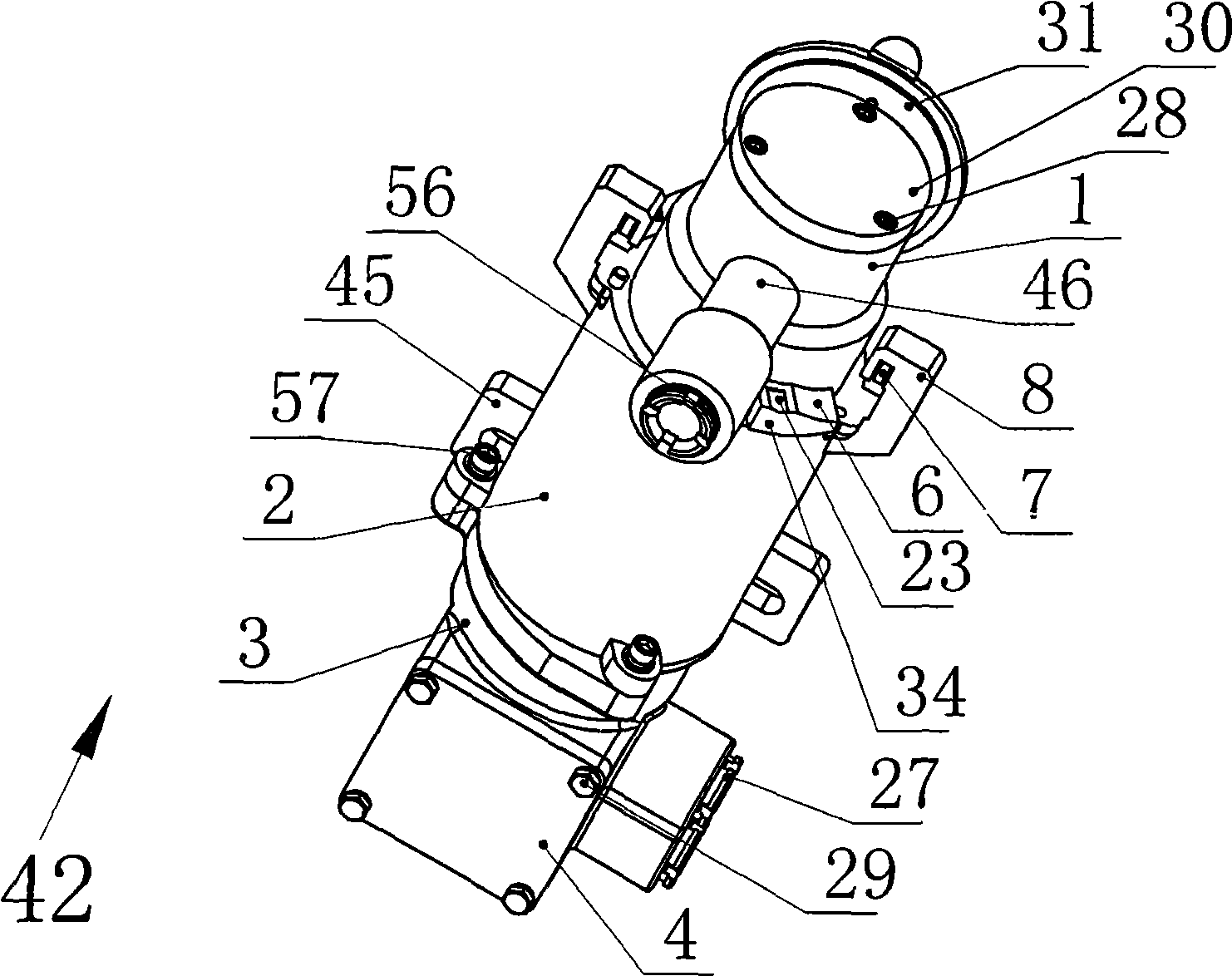

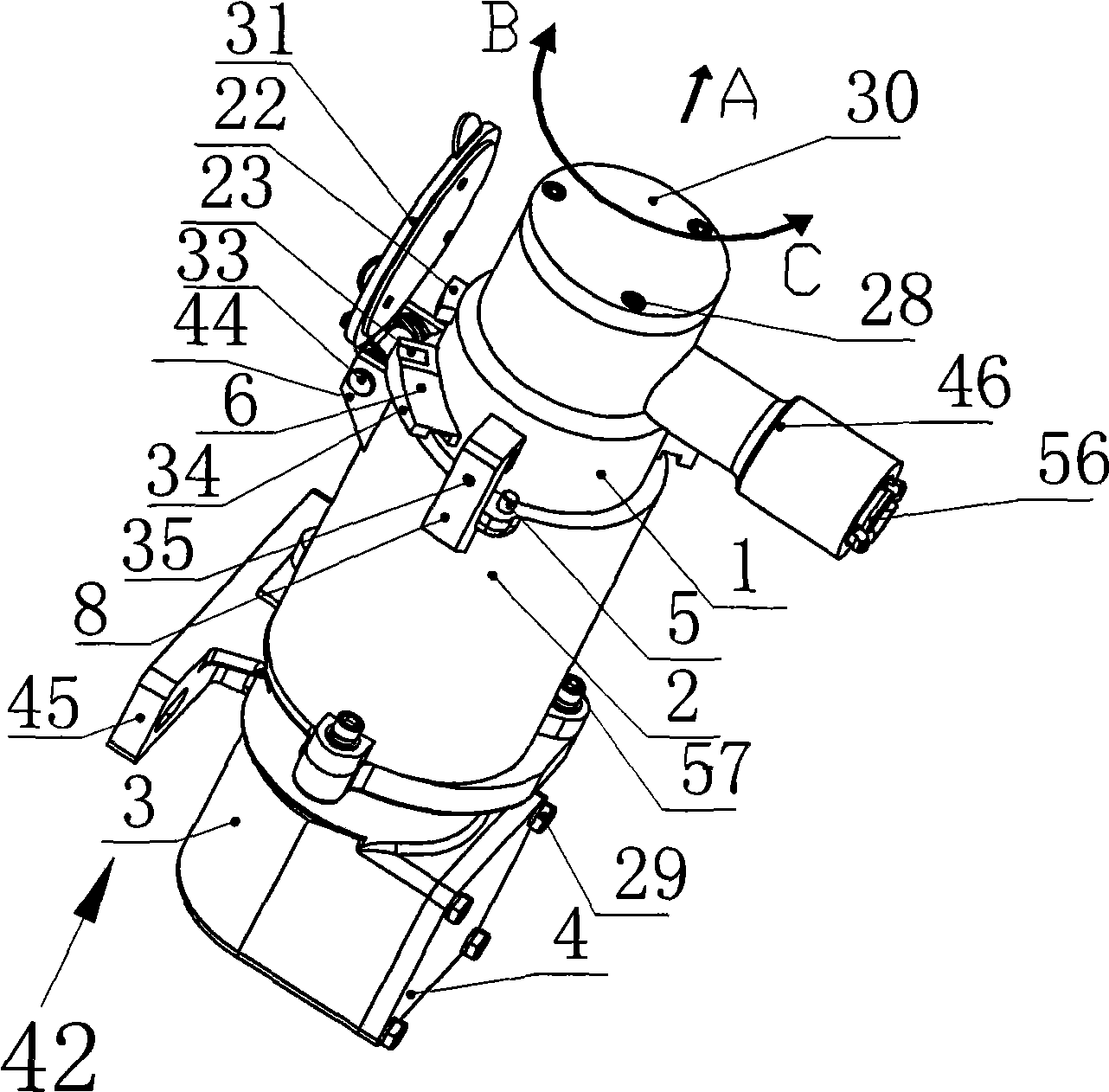

[0044] See Figure 1, Figure 2, image 3 and Figure 4 , the shell of plug connector (42) is made up of front cover (30), plug (1), socket (2), socket (3) and rear cover (4).

[0045] As shown in Figure 2, Figure 4 As shown in Figure 9, the front cover (30) is connected with the front cover threaded hole (40) of the plug (1) by three connecting screws (28), and the outer cylindrical flameproof surface of the front cover (30) is inserted into the plug ( 1) In the flameproof surface of the inner cylinder, the two are fitted with clearance to form a flameproof joint surface.

[0046] Referring to Fig. 9 and Fig. 10, the main body of the plug (1) is two concentric hollow rings connected together. In order to save material, the diameter of the upper ring is smaller than the diameter of the lower ring. There are three evenly distributed front cover threaded holes (40) on the end face of the ring, and the front cover (30) is connected to the plug (1) through three M5 connecting scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Free length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com