Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127 results about "Flexible manufacture system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A flexible manufacturing system (FMS) is a group of numerically-controlled machine tools, interconnected by a central control system. The various machining cells are interconnected, via loading and unloading stations, by an automated transport system.

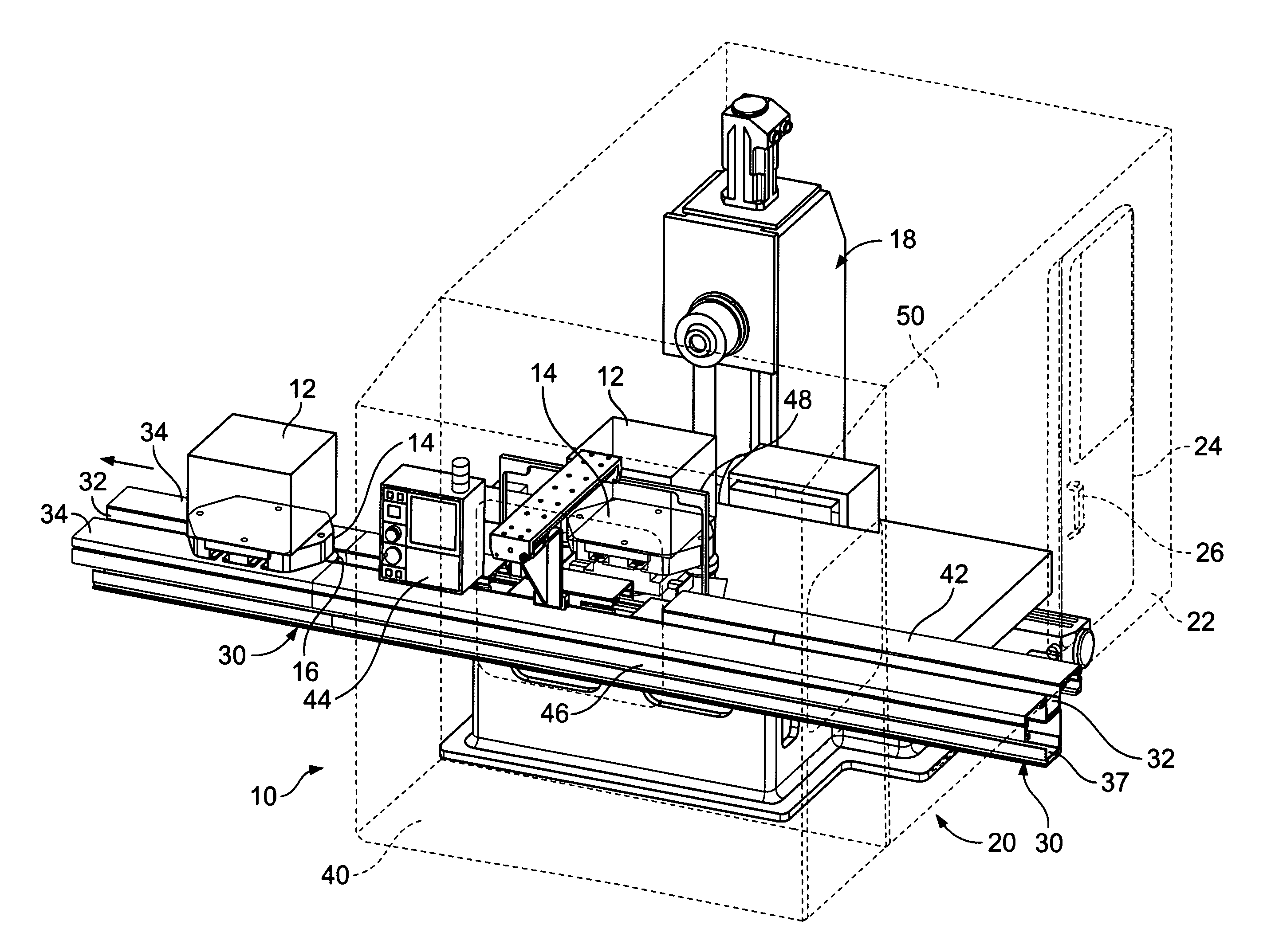

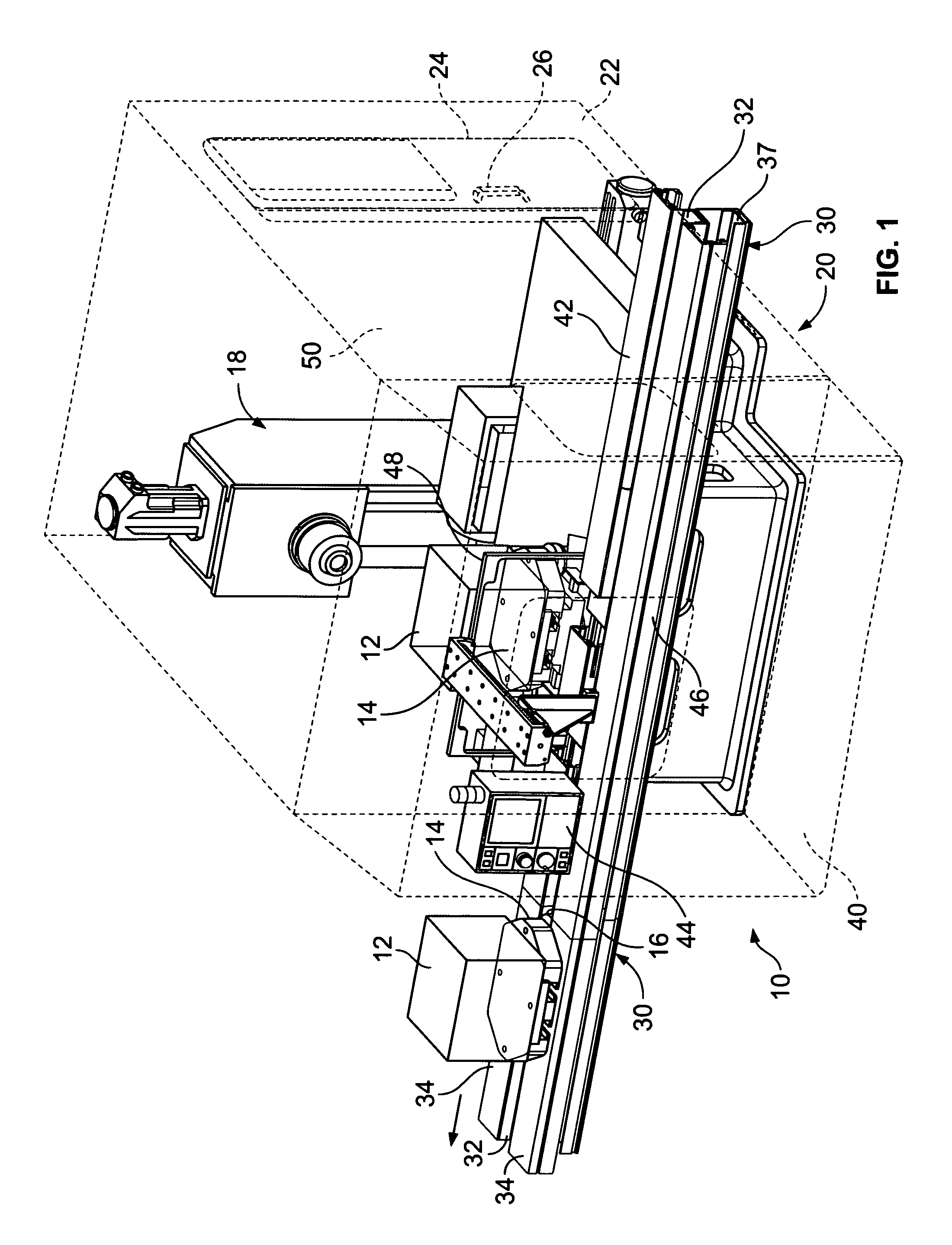

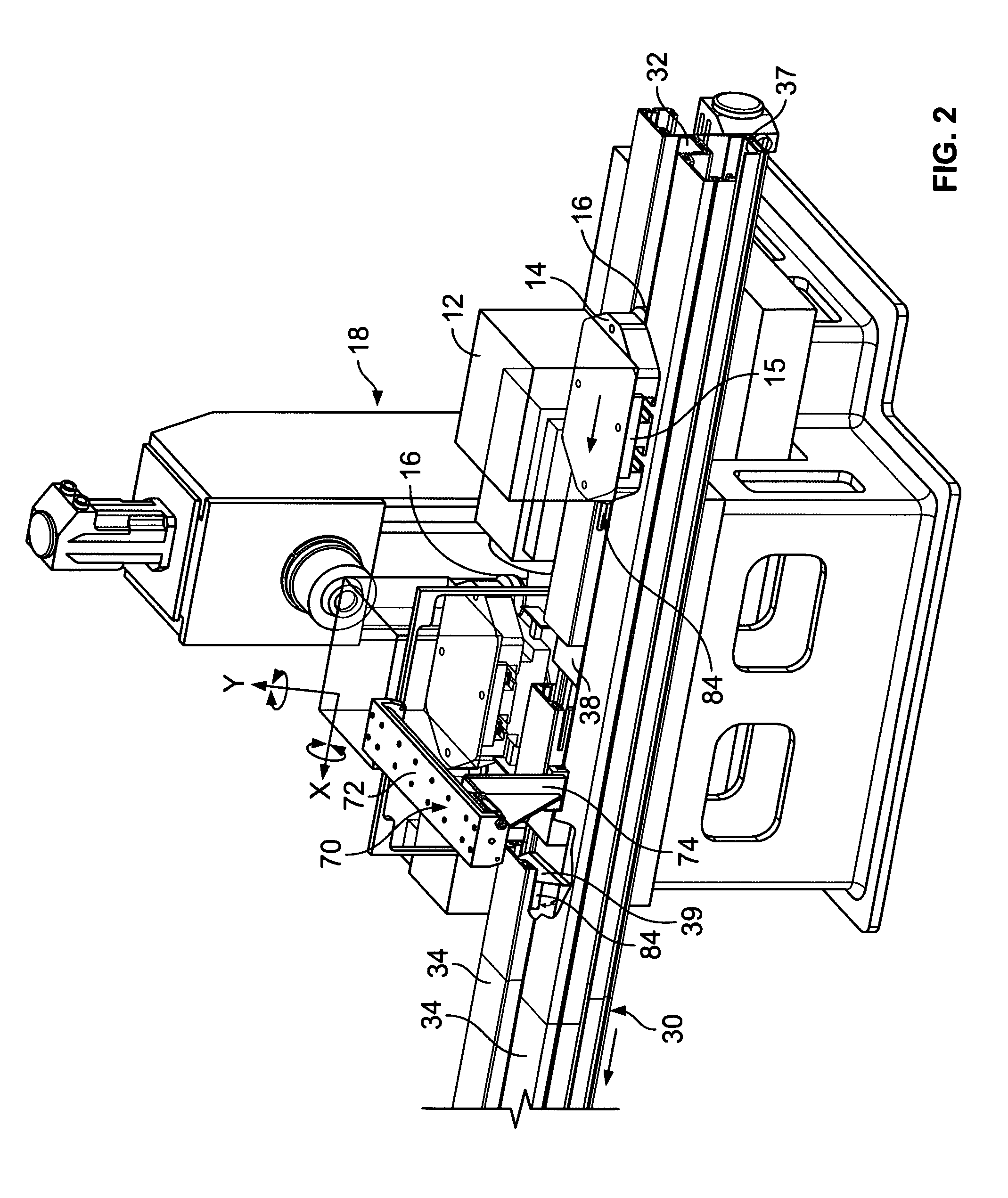

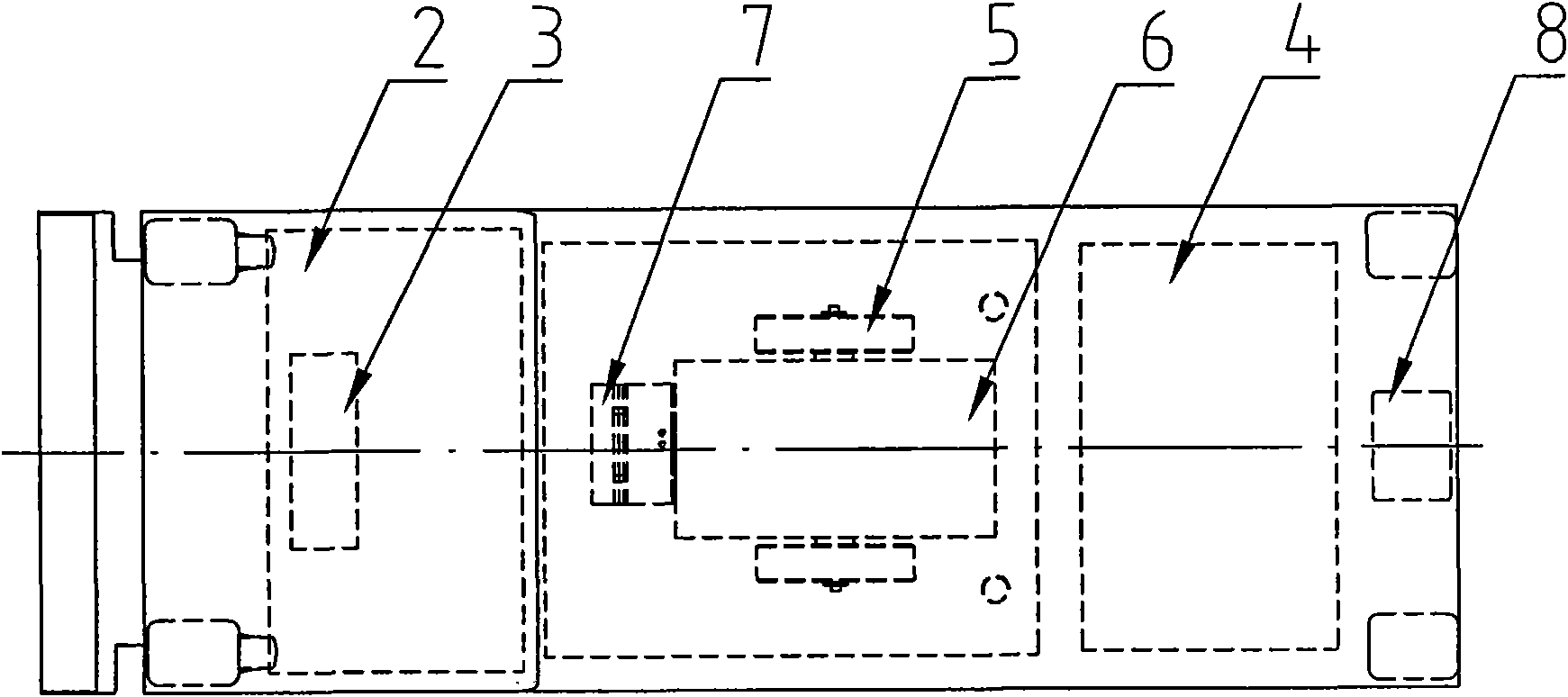

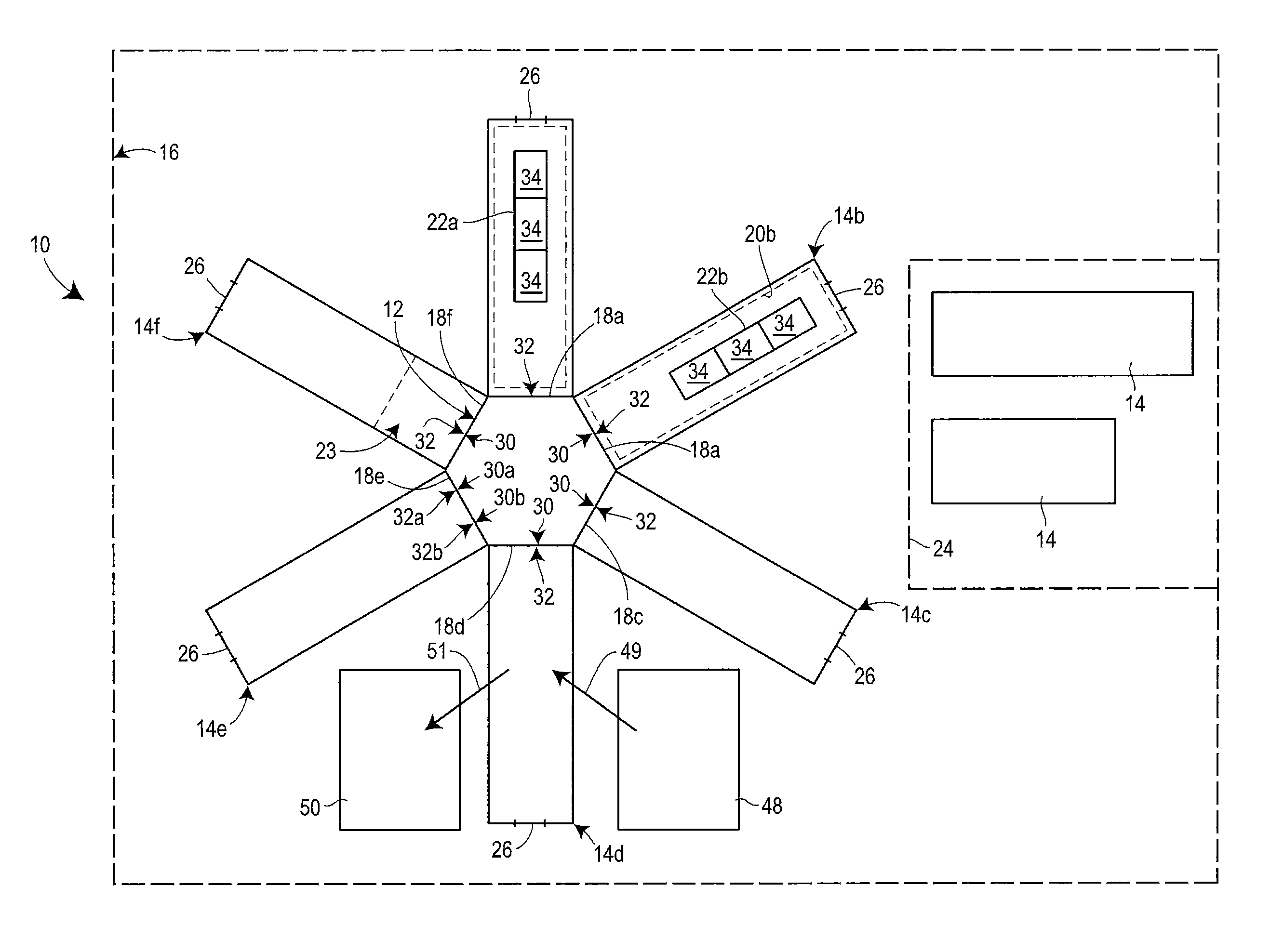

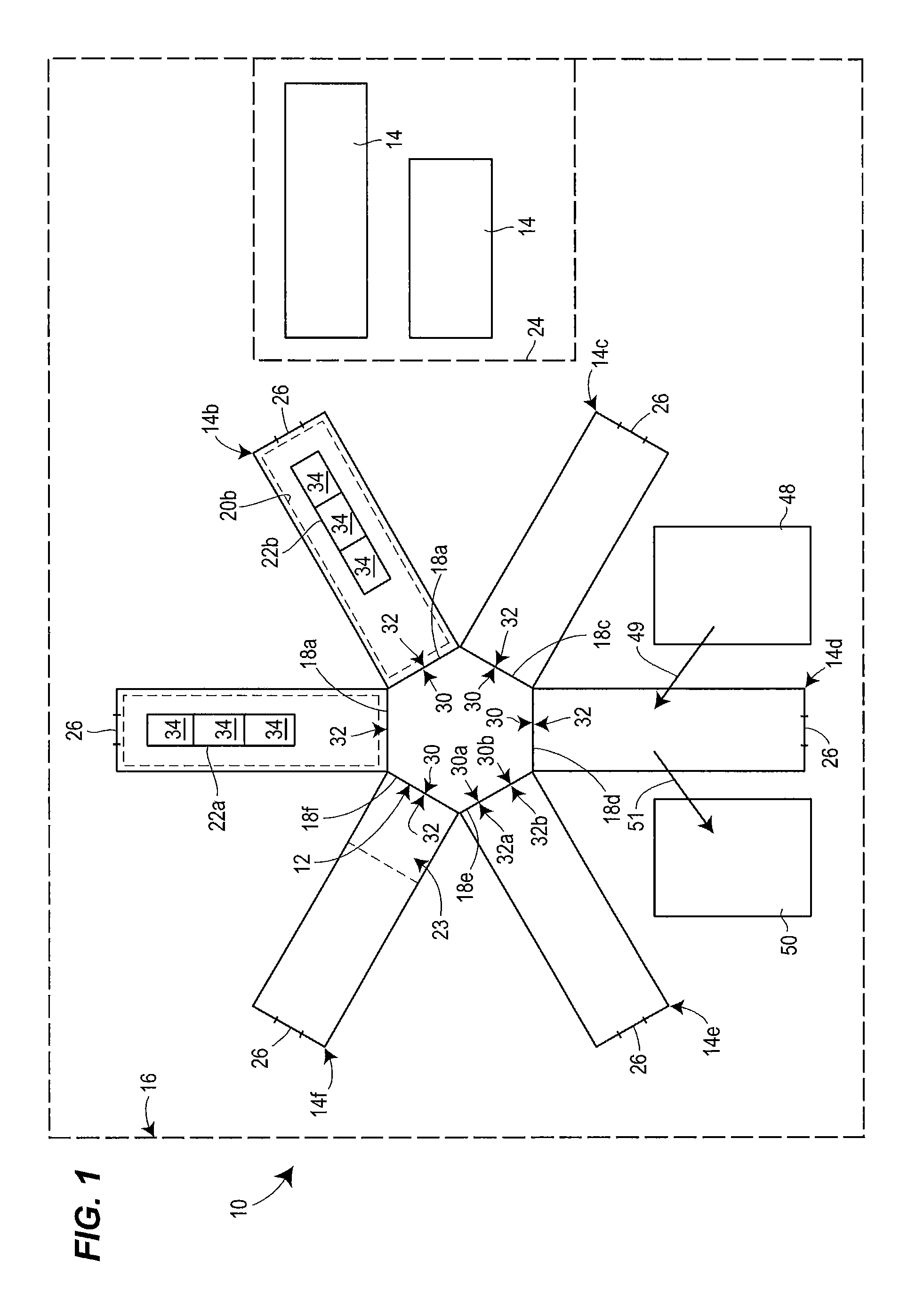

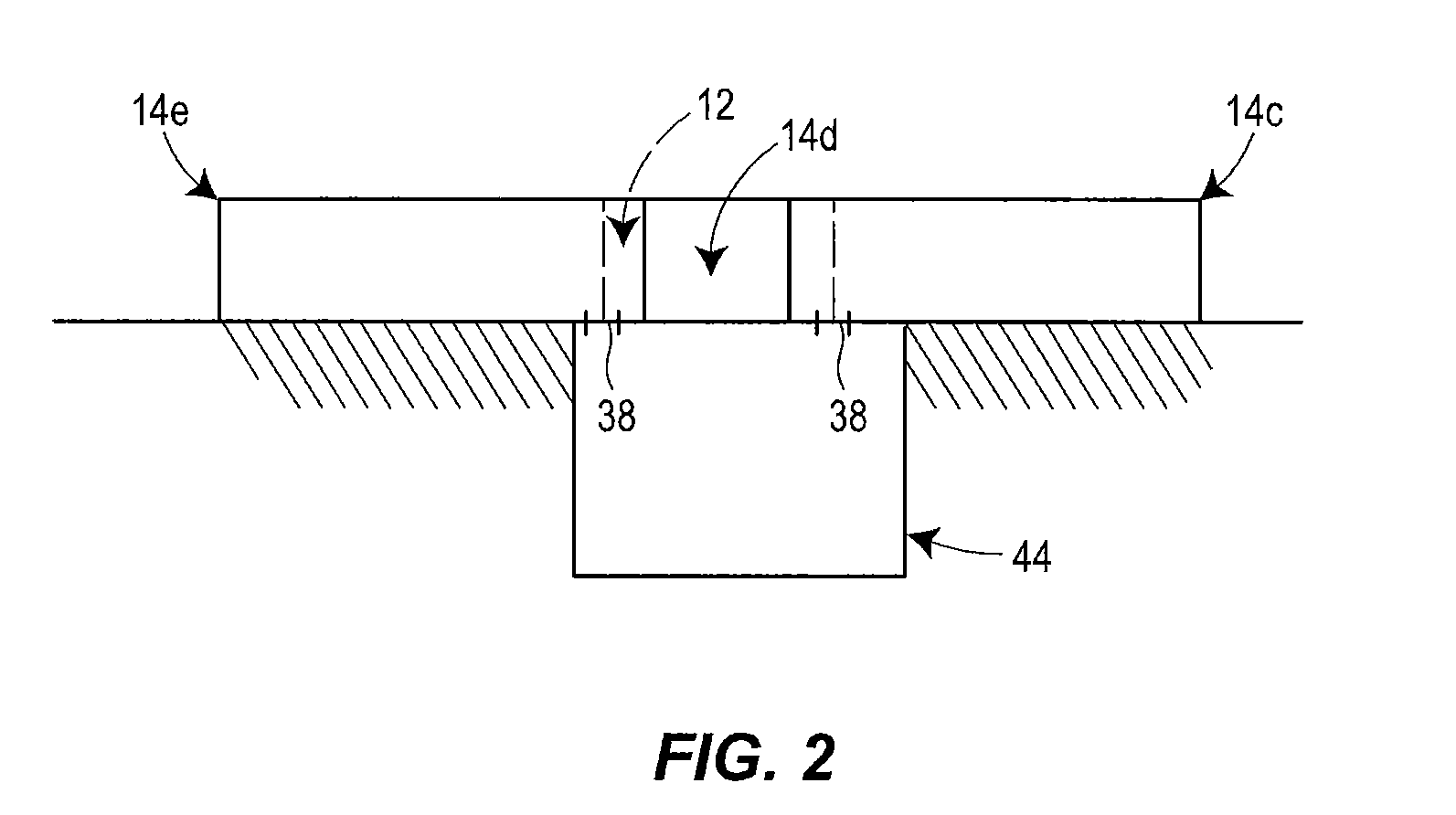

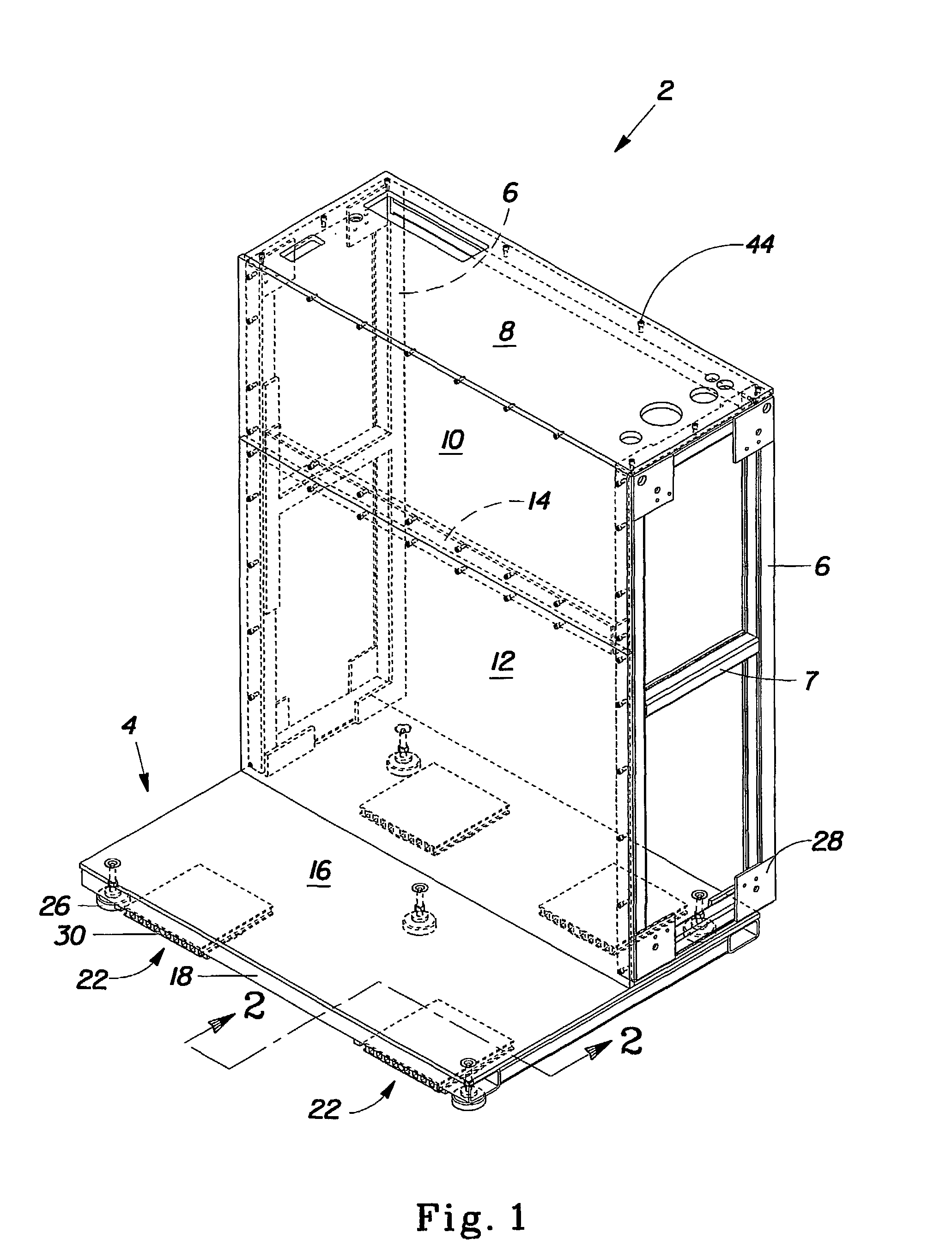

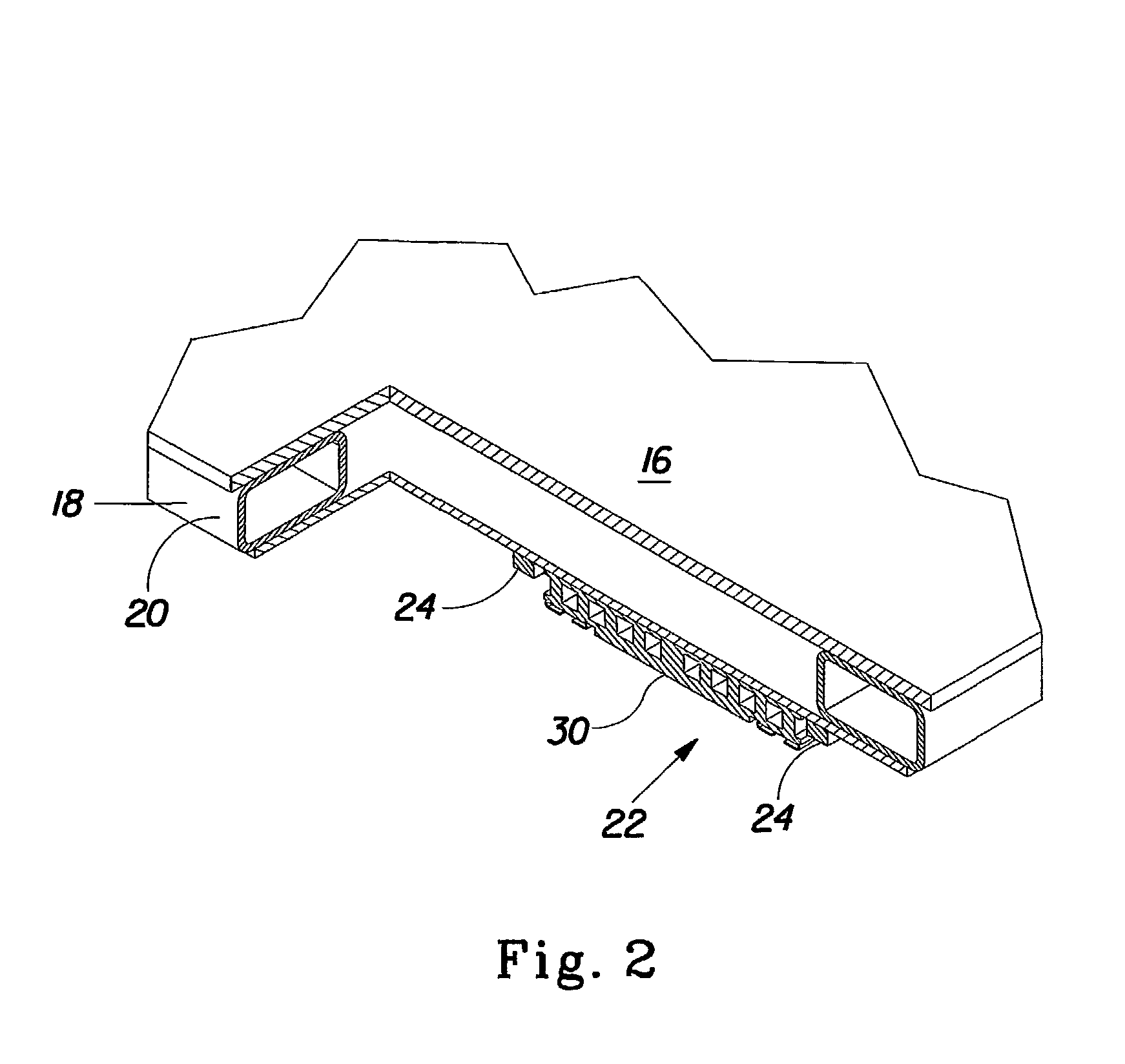

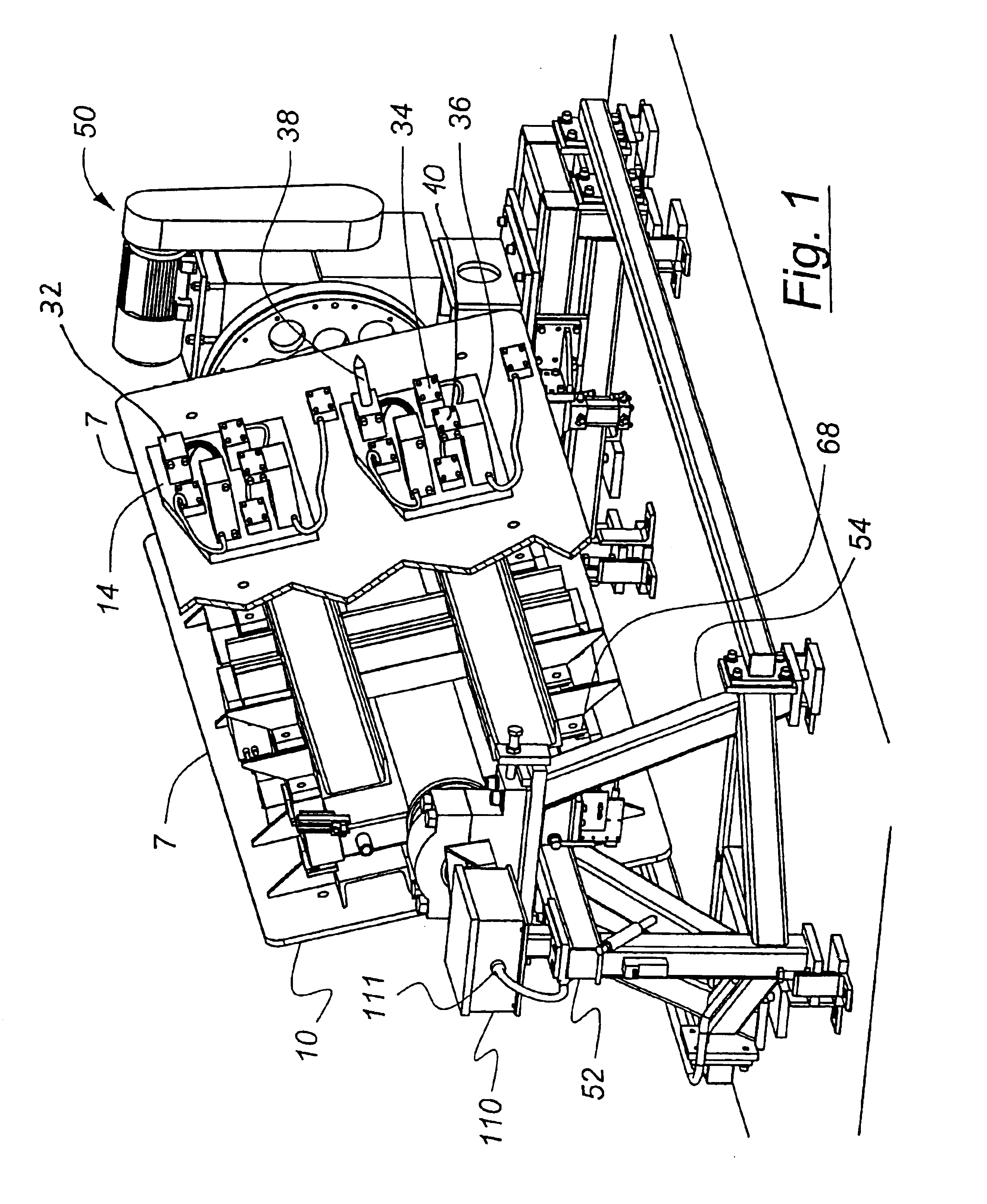

Flexible manufacturing system having modular work stations

InactiveUS7490710B1Easy maintenanceImprove accessibilityControl devices for conveyorsMeasurement/indication equipmentsFlexible manufacturing systemAsynchronous operation

A flexible manufacturing system utilizing modular work stations configured to provide asynchronous operations on a plurality of work pieces mounted on fixtures or pallets that are transported through the system by means of a conveyor or rail arrangement. The pallets are diverted from the track on which they are transported linearly to a desired machining module adjacent to, but removed from, the track, such that the machining is performed in a chamber isolated from the track. Each machining module may be utilized in more than one location on the track and the modules may be interchanged depending on the desired operation sequence and the tools available in each of the machining station modules.

Owner:WES TECH AUTOMATION SOLUTIONS

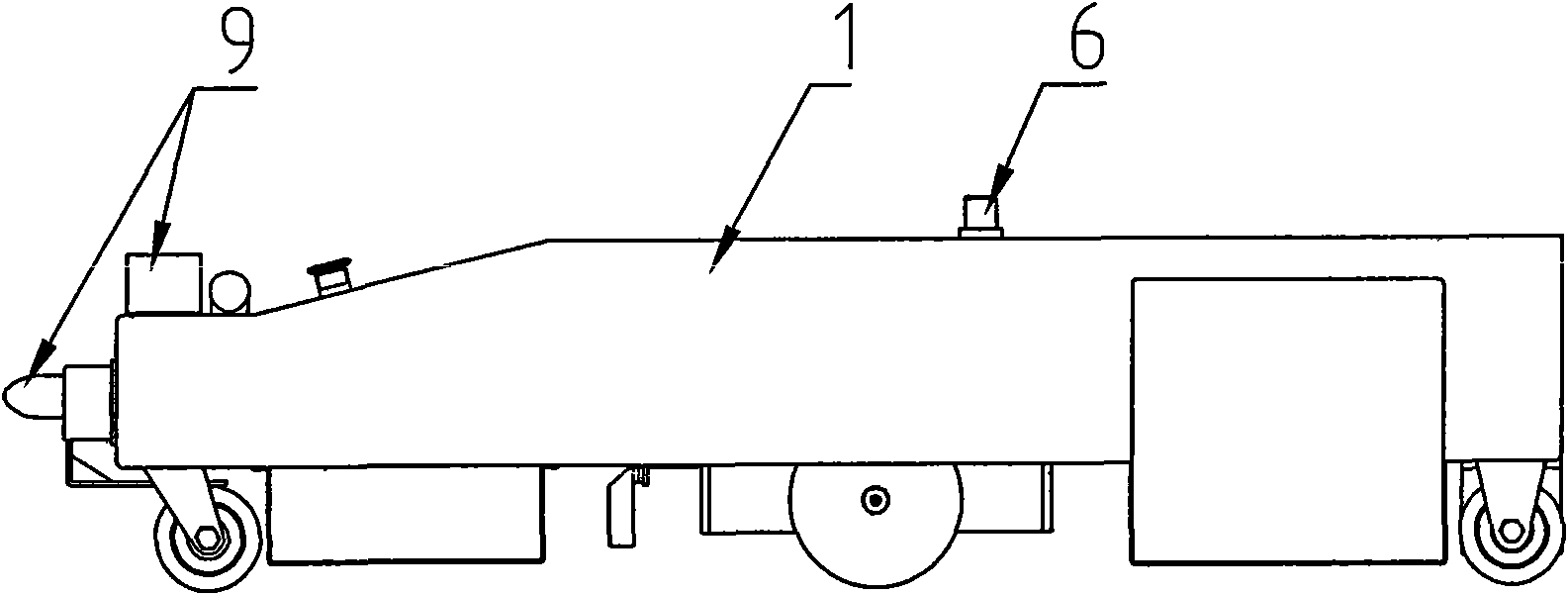

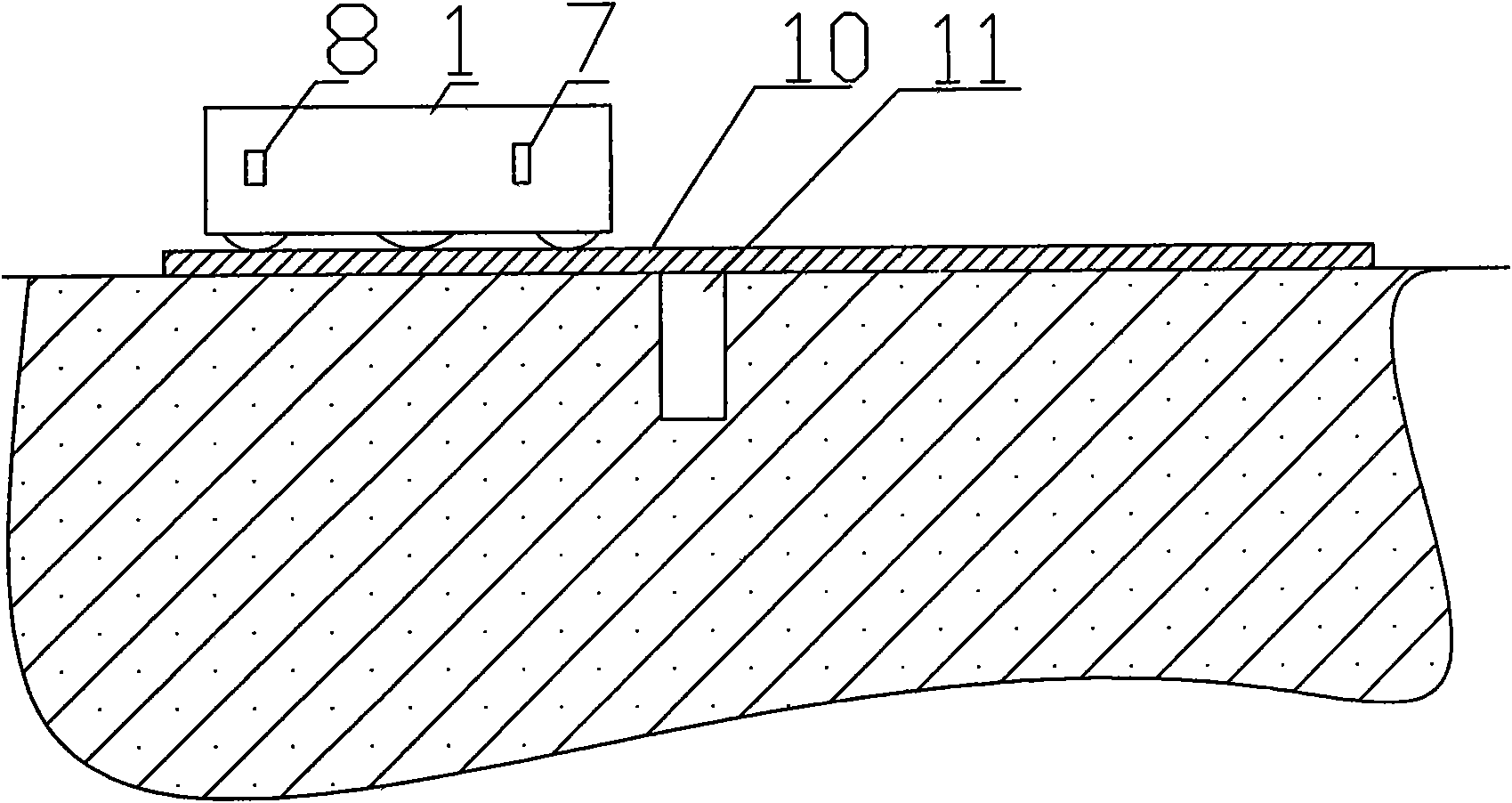

Automatic navigation vehicle system and multiple task control method

InactiveCN101603830AImprove reliabilityImprove stabilityNavigation instrumentsSensing record carriersFlexible manufacturing systemComputer module

The invention discloses an automatic guild system and a multiple task control method and belongs to the transport vehicles field. The automatic guild vehicle system comprises a vehicle part and a guild part; wherein, the vehicle part comprises a vehicle body, an electronic control tank, a central control device, a battery group, a driving mechanism, a suspending mechanism, a road magnetic strip signal sensor, a road RFID radio frequency identification card reader, an anti-knocking mechanism and the like. The guild part comprises a magnetic strip paved on the road and an RFID radio frequency identification card; the vehicle body is provided with a road magnetic strip signal sensor and a road RFID radio frequency identification card reader; the road magnetic strip signal sensor is directly connected with an AD module of the central controller for processing the analog signal transmitted by the road magnetic strip signal sensor. In the invention, the magnetic strip paved on the road and the RIFD radio frequency identification card are used for guiding so as to change lines flexibly and be applicable to flexible manufacturing system.

Owner:GUANGZHOU JINGYUAN MECHANO ELECTRIC EQUIP

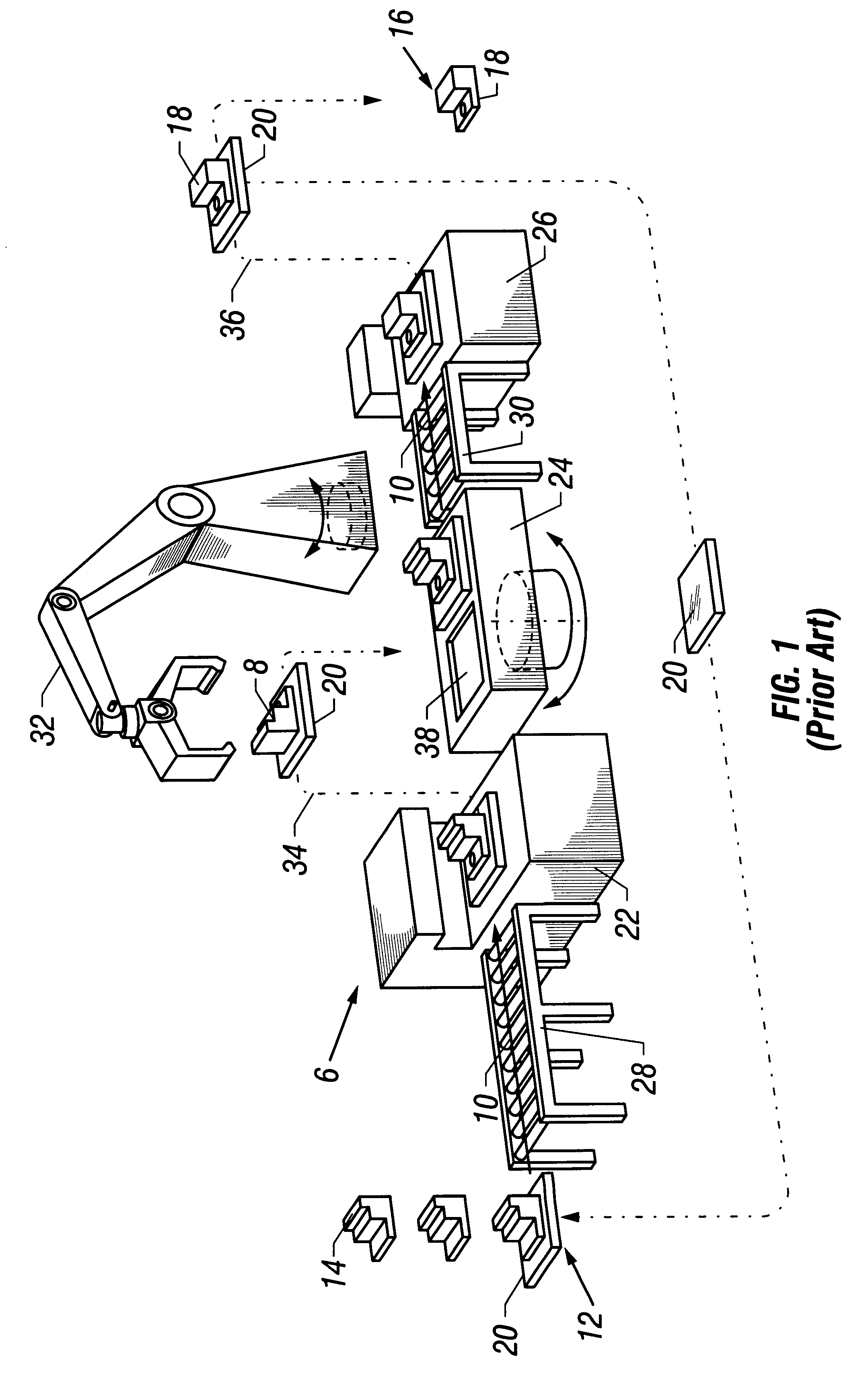

Method and apparatus for testing and controlling a flexible manufacturing system

InactiveUS6185469B1ResourcesTotal factory controlFlexible manufacturing systemFlexible manufacture system

The invention comprises in various embodiments controllers and apparatus for testing flexible manufacturing systems and methods of operating same. The controller includes a computer, a program, output lines from the computer, and devices connected to the output lines. The program uses matrix logic equations to determine when to start and stop jobs. The devices start and stop individual resources in response to logic signals from the computer. In one embodiment, the controller obtains sensor feedback on the distribution of work pieces and available resources in the manufacturing system. The invention also includes an apparatus and methods for testing a flexible manufacturing system. In response to the input of initial data, the apparatus for testing a flexible manufacturing system solves matrix equations and determines the activity and / or production of the manufacturing system. The apparatus for testing a flexible manufacturing system sends logical signals to a recording device which, in one embodiment, produce a cumulative display of the time dependent production or activity of the system.

Owner:TEXAS SYST UNIV OF

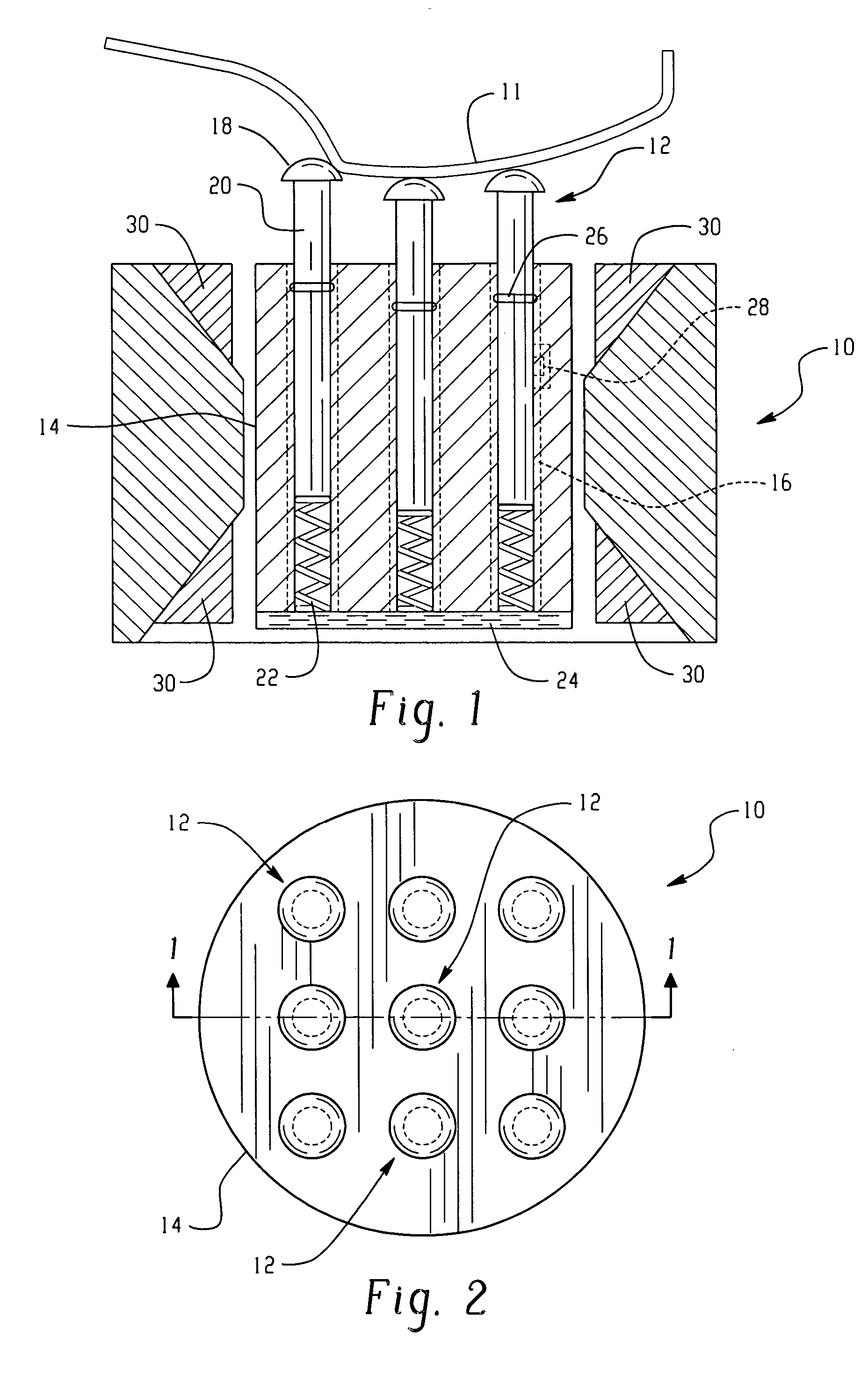

Magnetorheological reconfigurable clamp for a flexible manufacturing system

InactiveUS20050269758A1Welding/cutting auxillary devicesWork holdersFlexible manufacturing systemMagnetorheological fluid

A reconfigurable clamp for a flexible manufacturing system comprises a body portion, a plurality of pins slidably engaged within sleeves formed in the body portion, a compression spring attached to each shaft of the plurality of pins, a reservoir comprising a magnetorheological fluid in operative communication with the plurality of pins, and an electromagnet in operative communication with the magnetorheological fluid, wherein the electromagnet selectively increases a yield stress property of the magnetorheological fluid; and a matching pressure foot.

Owner:GM GLOBAL TECH OPERATIONS LLC

Flexible manufacturing system

ActiveUS8584349B2Increase supplyDischarging wasteSpace heating and ventilationTreatment involving filtrationFlexible manufacturing systemProcess engineering

Owner:XOMA (US) LLC

Flexible manufacturing system

A flexible manufacturing system having a feature section including at least one module, at least one operational unit mounted to the module and a local controller operatively connected to the operational unit. The local controller is adapted to receive a reference signal and to control the operation of the operational unit based upon the reference signal.

Owner:THE PROCTER & GAMBLE COMPANY

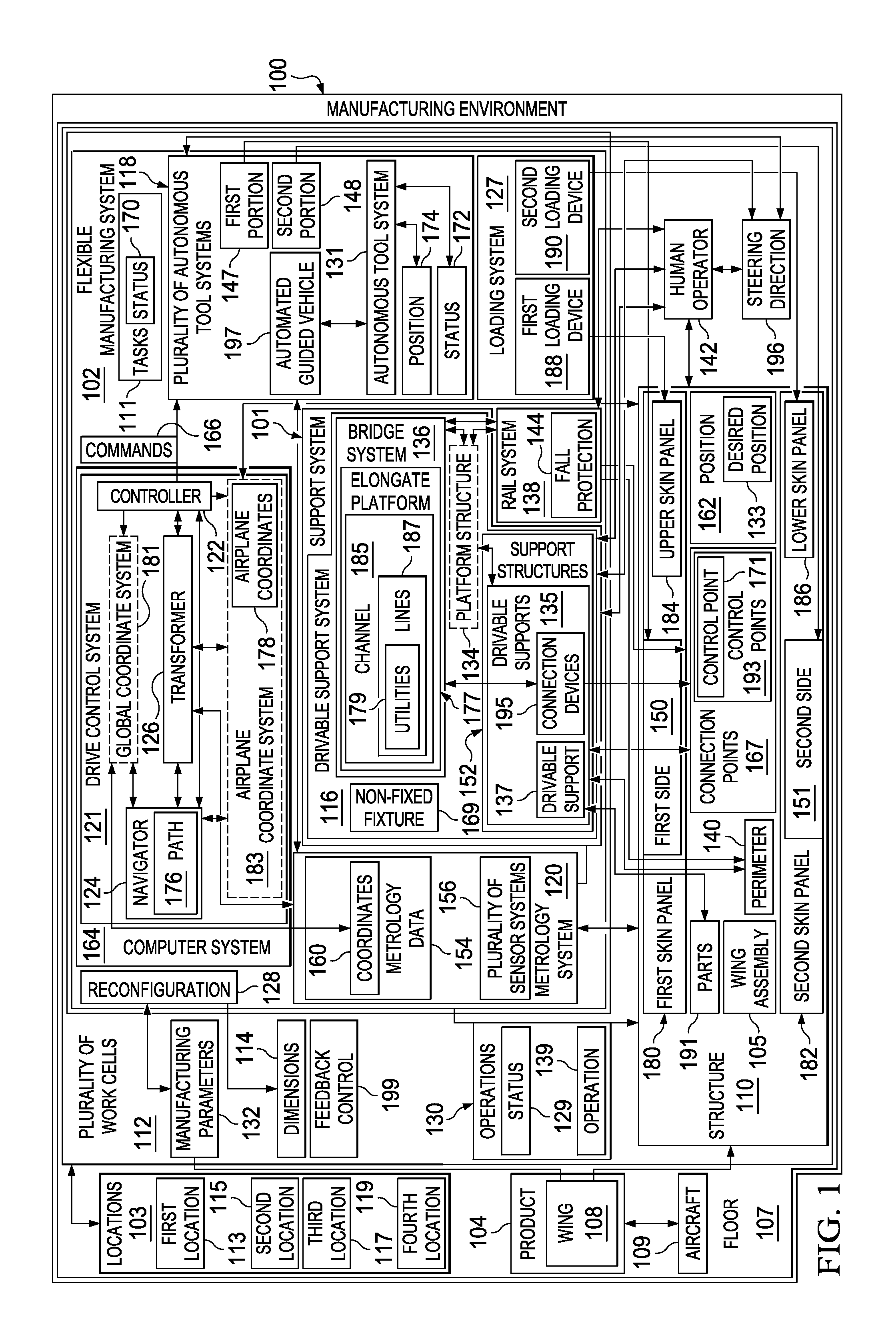

Flexible Manufacturing System for Aircraft Structures

ActiveUS20150314889A1Thread cutting feeding devicesAssembly machinesSupporting systemFlexible manufacturing system

A method and apparatus for manufacturing an aircraft structure. A drivable support may be driven from a first location to a second location to bring the drivable support together with at least one other drivable support to form a drivable support system. A structure may be held in a desired position using the drivable support system.

Owner:THE BOEING CO

Intelligent flexible manufacturing system and method for automobile bodies

InactiveCN106249718AImprove utilization efficiencyReduce usageTotal factory controlProgramme total factory controlControl signalThe Internet

The invention discloses an intelligent flexible manufacturing system and a method for automobile bodies. The manufacturing method comprises the steps of searching the information of product parts and process data in a product data management system by means of a production resource central control system; generating operation instructions for each of all intelligent equipment, and respectively outputting the operation instructions to each of all manufacturing resources through the internet of things; and starting corresponding programs to finish the machining process by each manufacturing resource after the manufacturing resources receive corresponding operation instructions according to manufacturing resource codes. The manufacturing system comprises a product data management system, an internet of things system, an intelligent container, a modular intelligent tool and an industrial robot. According to the technical scheme of the invention, the intelligentization of a container tool is realized. Based on the distributed data management and the central control of the internet of things system, the rapid switching among welding robot programs is realized. Therefore, the mixed production of automobile parts of different configuration modes and different types can be realized, so that the production efficiency is improved. The error rate is lowered. Moreover, the number of special welding robots is reduced and the field utilization efficiency is improved. Furthermore, the manufacturing cost is reduced.

Owner:CHONGQING TECH & BUSINESS UNIV

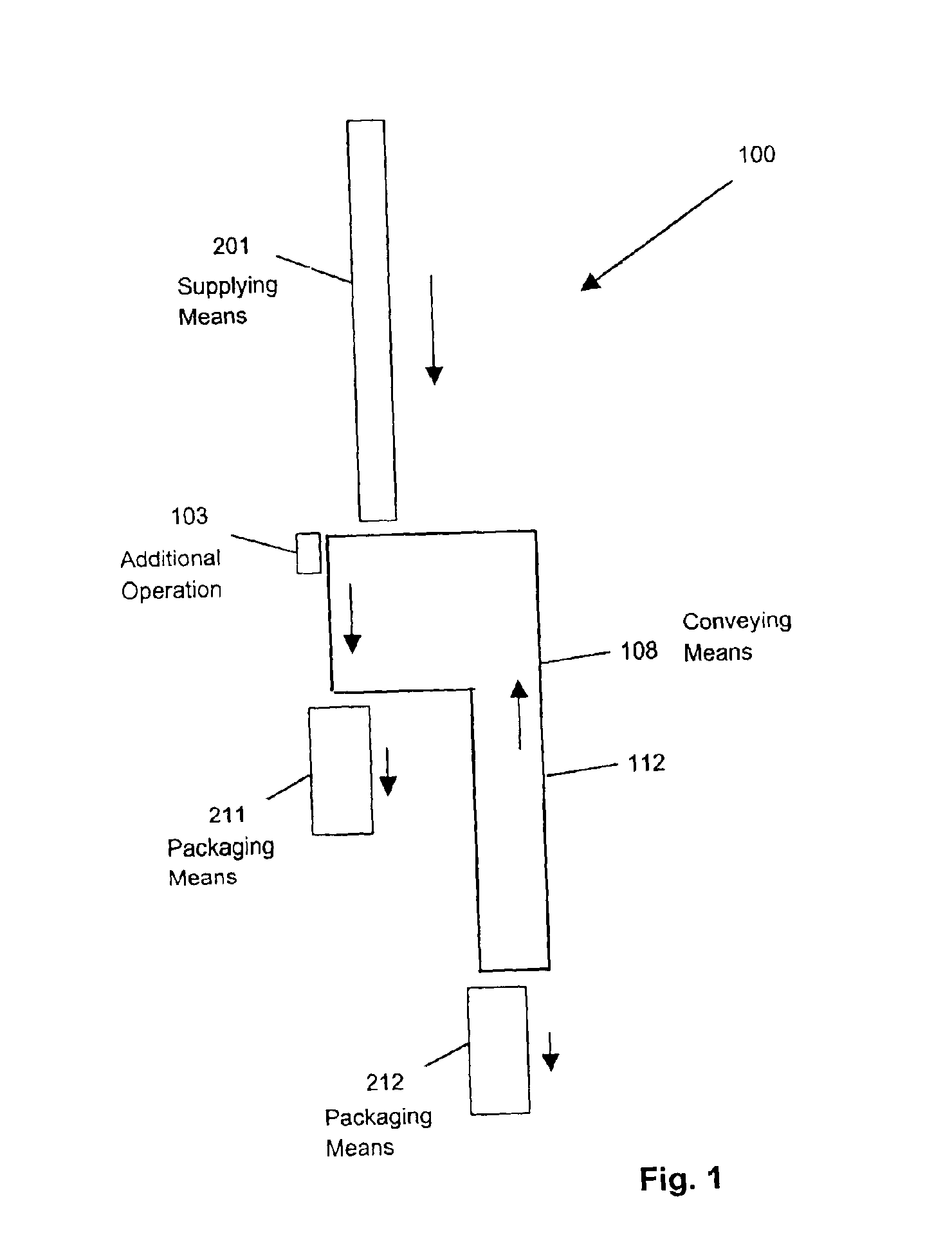

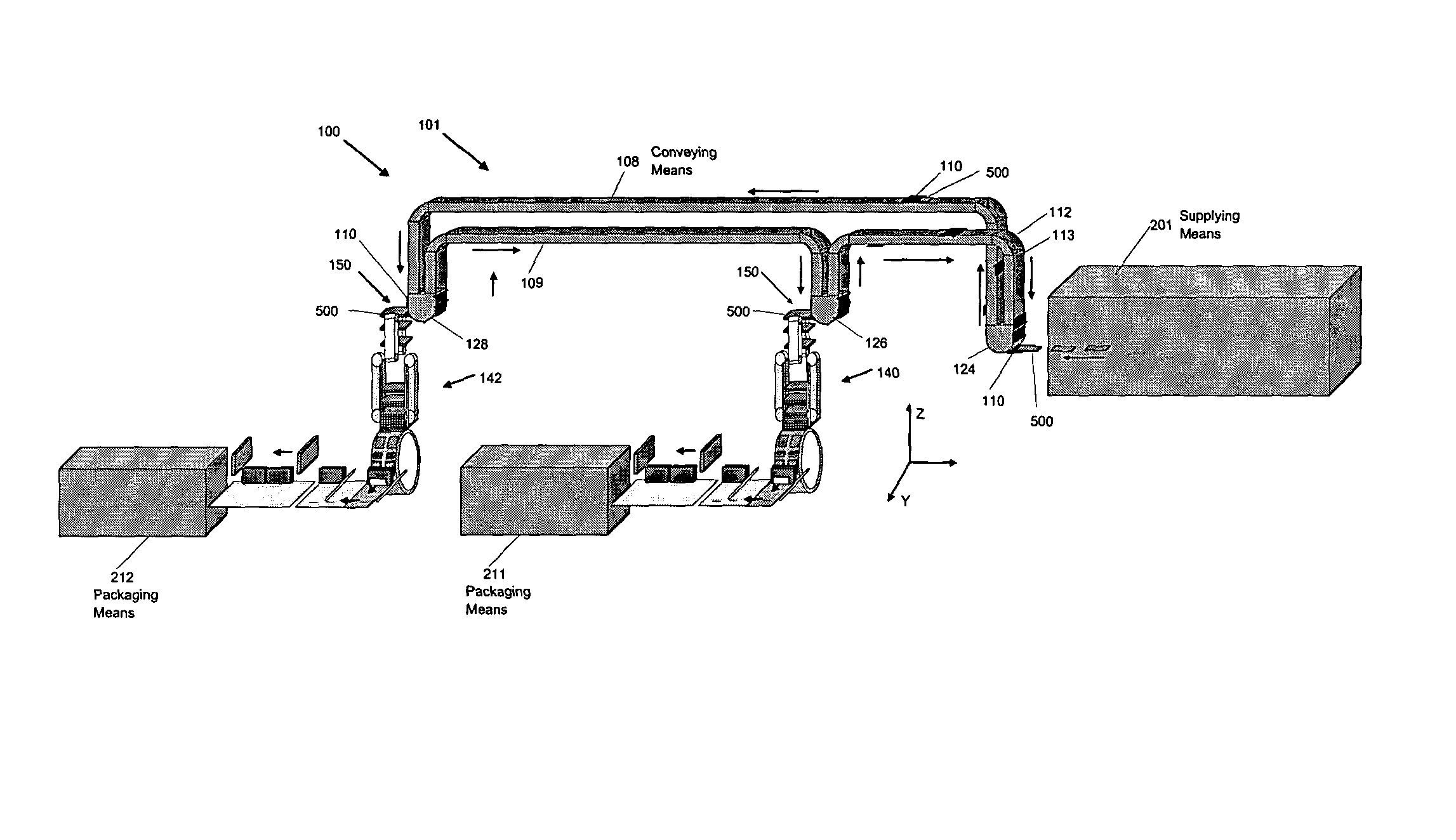

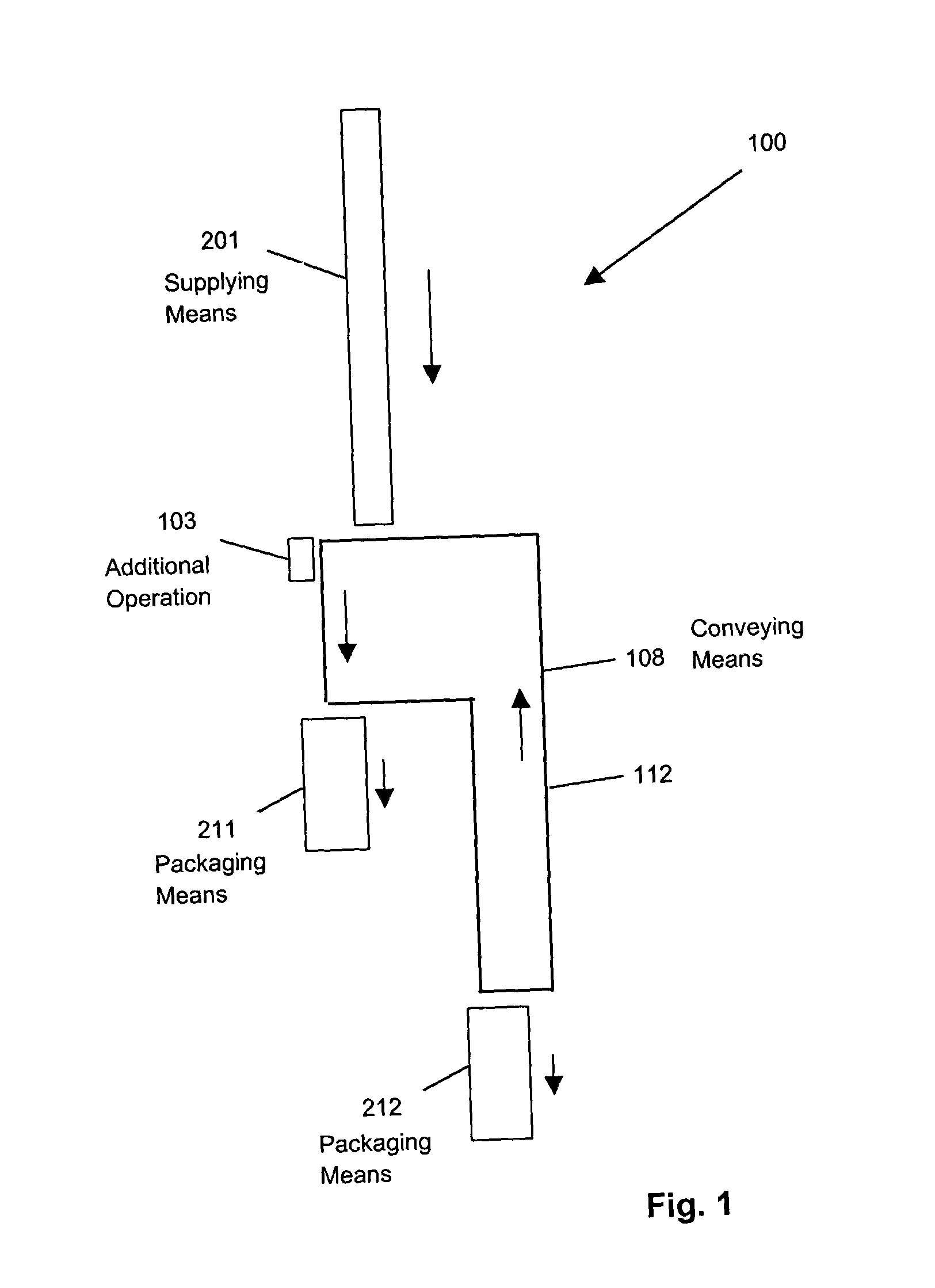

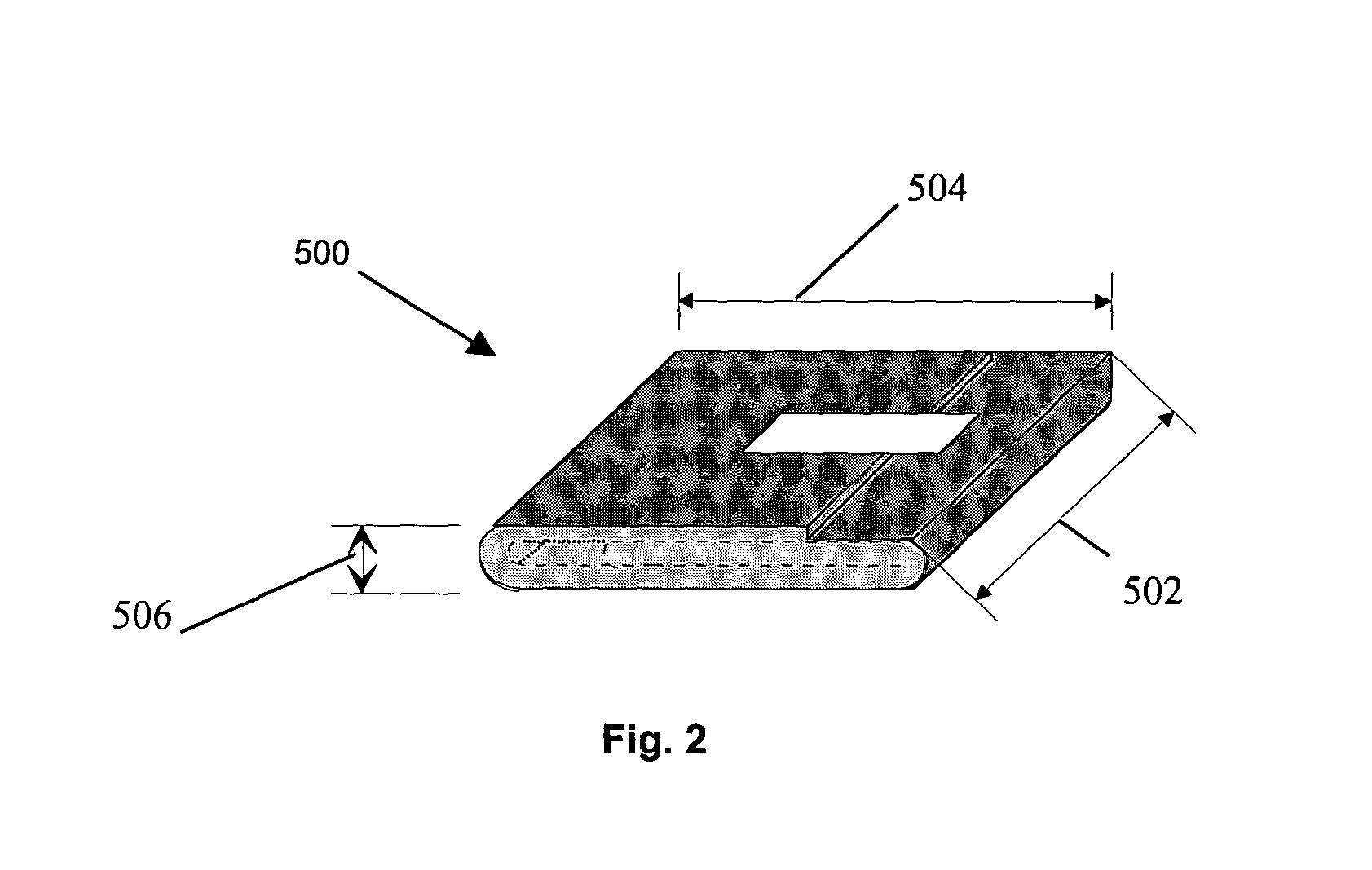

Flexible manufacturing system for consumer packaged products

InactiveUS6925784B2Paper article packagingOral administration deviceFlexible manufacturing systemFlexible manufacture system

A flexible manufacturing system for producing and packaging consumer products into different packages is disclosed. The system includes one or more supplying means for providing the consumer products, and a multiplicity of packaging means for packaging the consumer products into different packages. The system further includes one or more conveying means for conveying the consumer products from the supplying means to the packaging means. The conveying means forms a continuous path linking the supplying means with the packaging means. The continuous path includes a multiplicity of receptors capable of accepting, carrying, and discharging the consumer products. Further, the system includes one or more stacking means for arranging the consumer products into separate stacks of products prior to packaging.

Owner:THE PROCTER & GAMBLE COMPANY

Intelligent management system for FMS (Flexible Manufacture System) cutters based on two-dimensional technology

InactiveCN104408554ALarge storage capacityEasy to readProgramme controlResourcesProduction lineTime information

An intelligent management system for FMS cutters based on a two-dimensional technology comprises a central cutter storeroom (1), a cutter presetting instrument (2), a machine tool (3), a workshop LAN (Local Area Network) system, a cutter conveyor (5) and a cutter management computer (6) and is characterized in that the central cutter storeroom (1) comprises a combined cutter with a two-dimensional label and a cutter rest with a two-dimensional code reader; the cutter presetting instrument (2) is used for presetting assembled or polished cutters before the cutters are stored in the storeroom; the two-dimensional code reader is arranged on the machine tool 3; the workshop LAN system (4) covers the whole workshop LAN; when the status information of the cutter changes, the information immediately gives a feedback to notify the central cutter storeroom and a FMS production line and cutter management system; the cutter conveyer (5) is in charge of conveying cutters; and the cutter management computer (6) is used for dispatching and controlling the whole cutter system. The real-time information tracking for the single-item level of the cutters in a full-life circle is realized and the efficiency of the FMS production line is improved.

Owner:CHONGQING UNIV

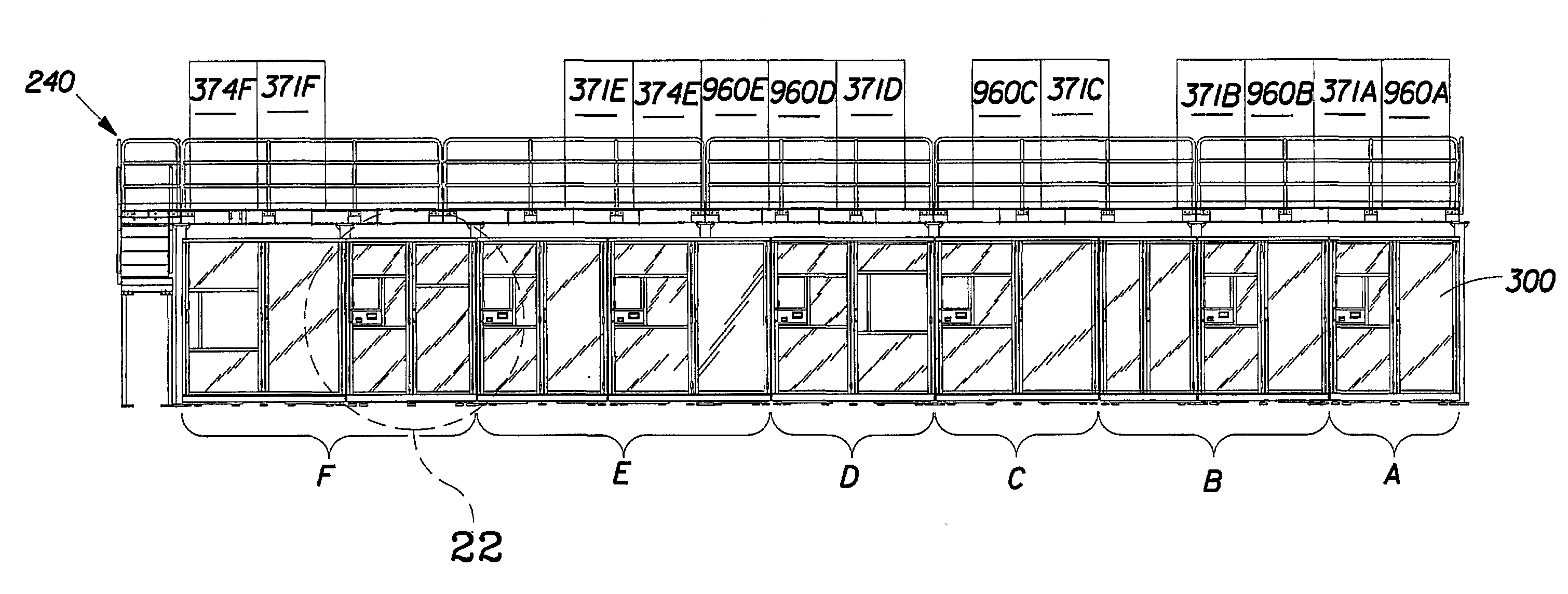

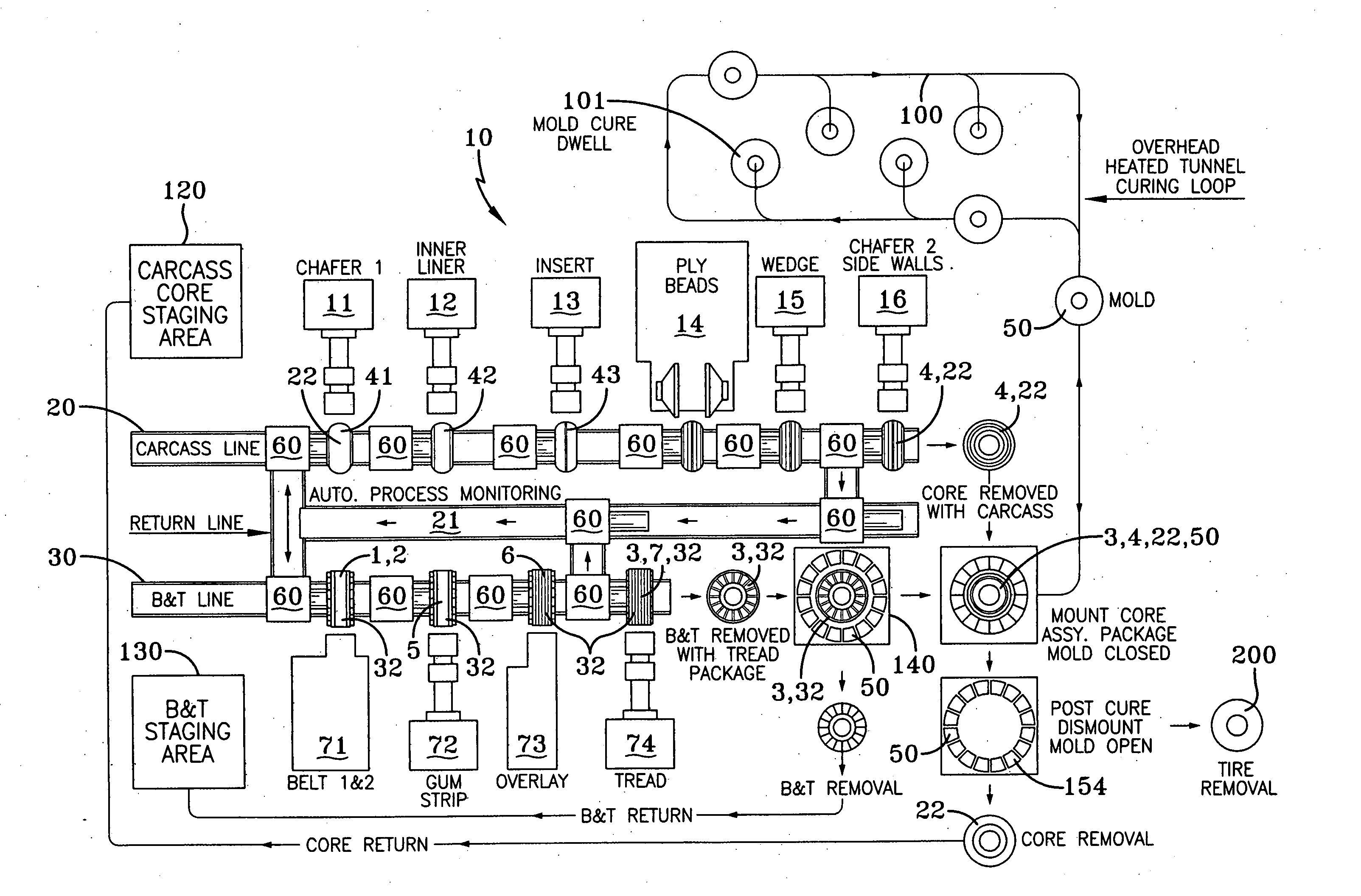

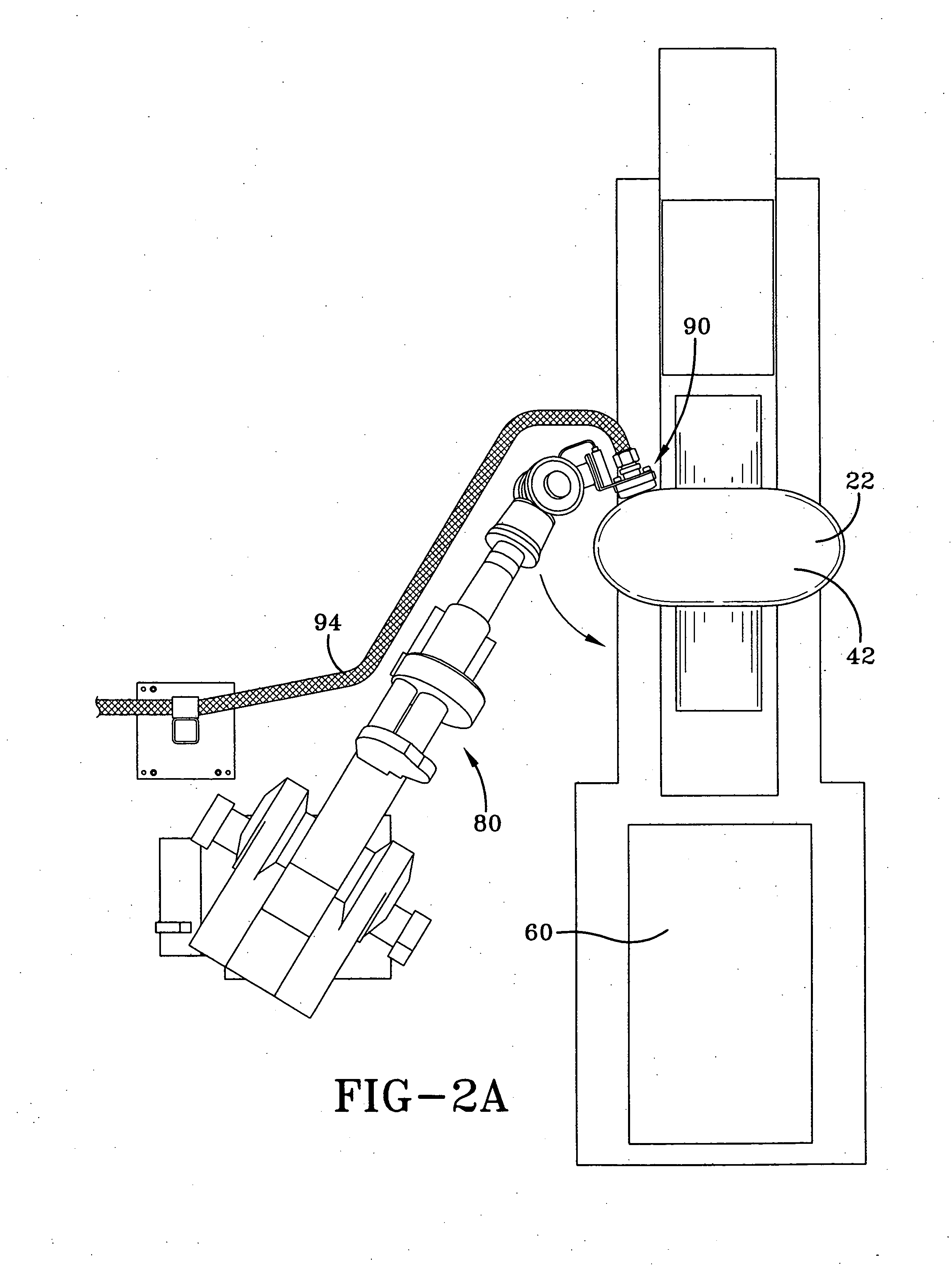

Method for manufacturing tires on a flexible manufacturing system

A method of simultaneously producing production runs of tires 200 on a multi-station sequential tire manufacturing system 10, the tires 200 being from a group of tire types of different build specifications in lot sizes of one or more tires is disclosed. The steps include: scheduling the production run by imputing tire build software, wherein the software program performs the steps of: selecting the tire building equipment and materials required for the respective tire types; calculating the corresponding number of cycles each piece of building equipment must perform to build a given lot; and automatically changing to a second build specification at a lot change by switching to the second build specification after the last tire 200 of the first build specification passes; repeating the automated changing to the next build specification at each station 11-16 and 71-74) as each last tire 200 of each prior lot passes until a final lot is produced. The multi-station sequential tire manufacturing system 10 has at least four stations for carcass 4 building, each station (11-16) being spaced at a predetermined distance and preferably a multistation tread belt assembly line 30 having workstations (71-74) separate from the carcass building line 20 wherein the carcass 4 and the tread belt assemblies 3 are joined in a segmented self-locking mold 50.

Owner:THE GOODYEAR TIRE & RUBBER CO

Flexible manufacturing system for consumer packaged products

InactiveUS20050055988A1Paper article packagingOral administration deviceFlexible manufacturing systemEngineering

A flexible manufacturing system for producing and packaging consumer products into different packages is disclosed. The system includes one or more supplying means for providing the consumer products, and a multiplicity of packaging means for packaging the consumer products into different packages. The system further includes one or more conveying means for conveying the consumer products from the supplying means to the packaging means. The conveying means forms a continuous path linking the supplying means with the packaging means. The continuous path includes a multiplicity of receptors capable of accepting, carrying, and discharging the consumer products. Further, the system includes one or more stacking means for arranging the consumer products into separate stacks of products prior to packaging.

Owner:THE PROCTER & GAMBLE COMPANY

Magnetorheological reconfigurable clamp for a flexible manufacturing system

InactiveUS7204481B2Welding/cutting auxillary devicesWork holdersFlexible manufacturing systemMagnetorheological fluid

A reconfigurable clamp for a flexible manufacturing system comprises a body portion, a plurality of pins slidably engaged within sleeves formed in the body portion, a compression spring attached to each shaft of the plurality of pins, a reservoir comprising a magnetorheological fluid in operative communication with the plurality of pins, and an electromagnet in operative communication with the magnetorheological fluid, wherein the electromagnet selectively increases a yield stress property of the magnetorheological fluid; and a matching pressure foot.

Owner:GM GLOBAL TECH OPERATIONS LLC

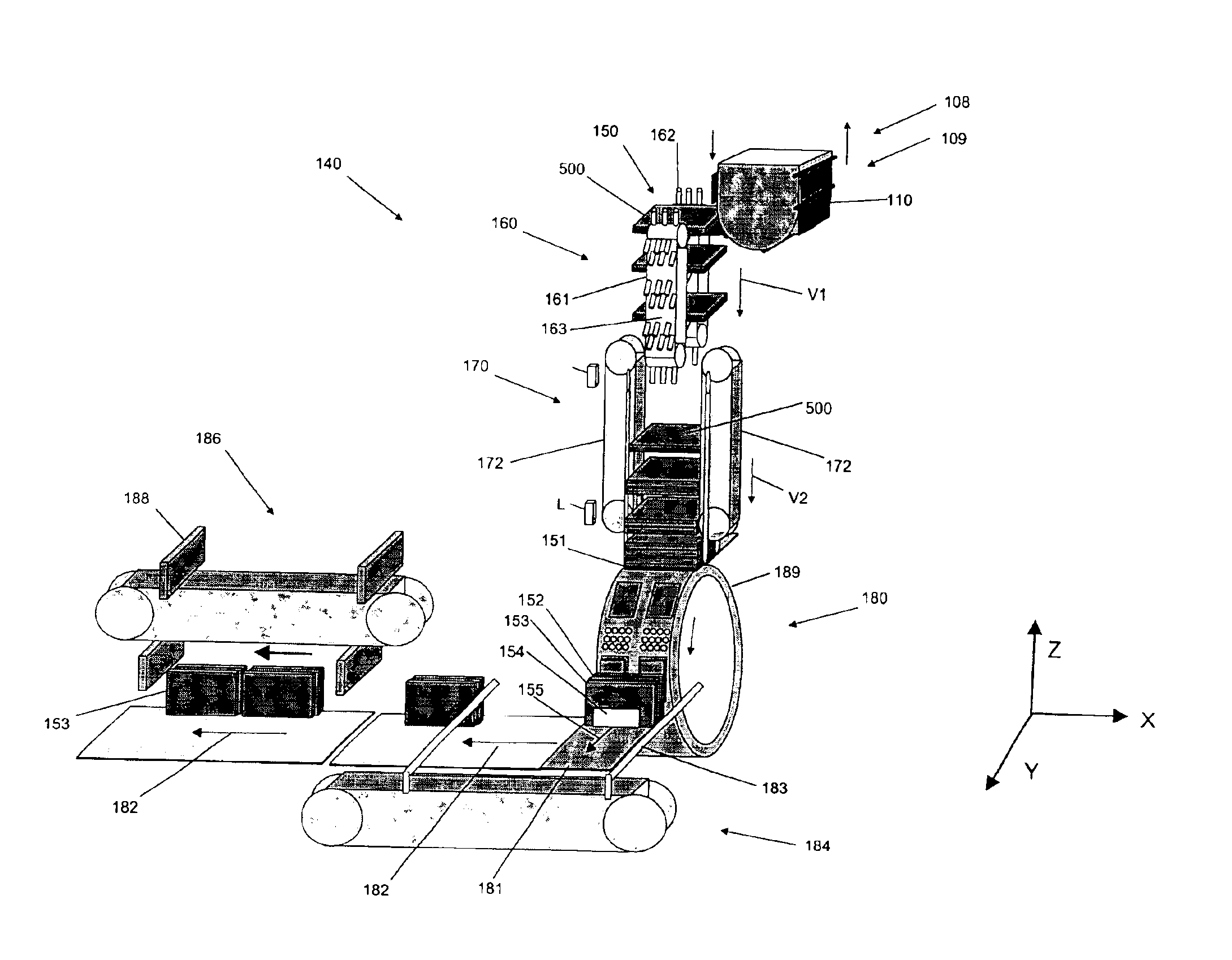

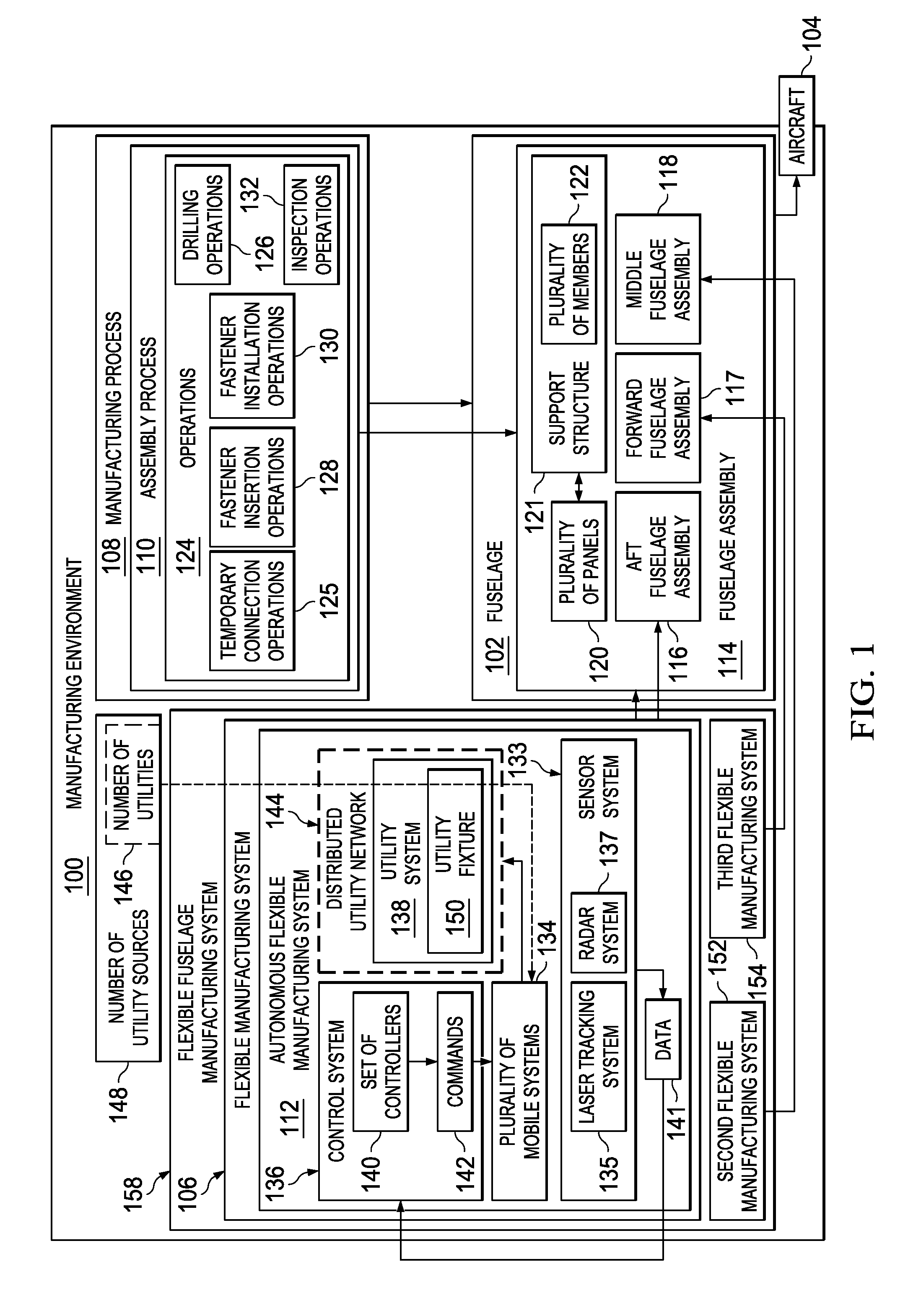

Autonomous Flexible Manufacturing System for Building a Fuselage

ActiveUS20160009422A1Programme-controlled manipulatorFuselage framesFlexible manufacturing systemFuselage

Owner:THE BOEING CO

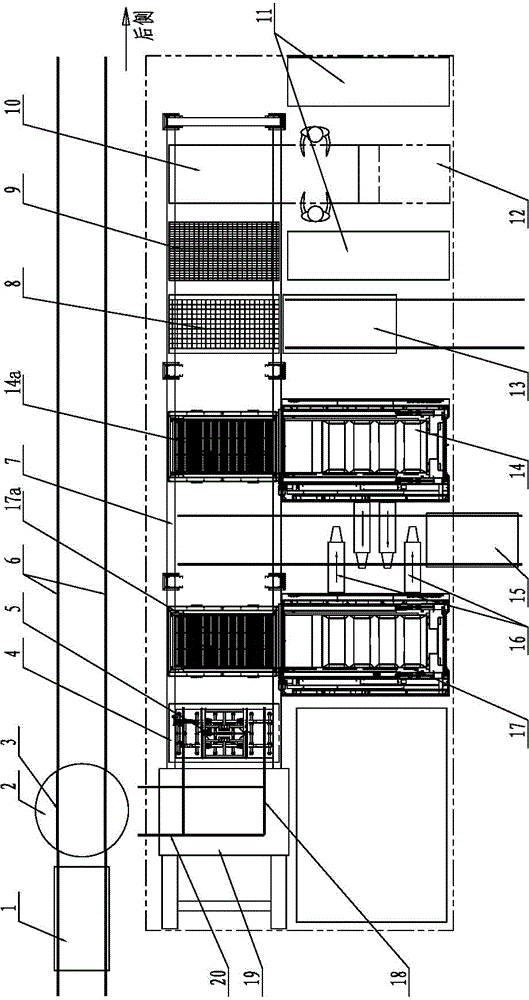

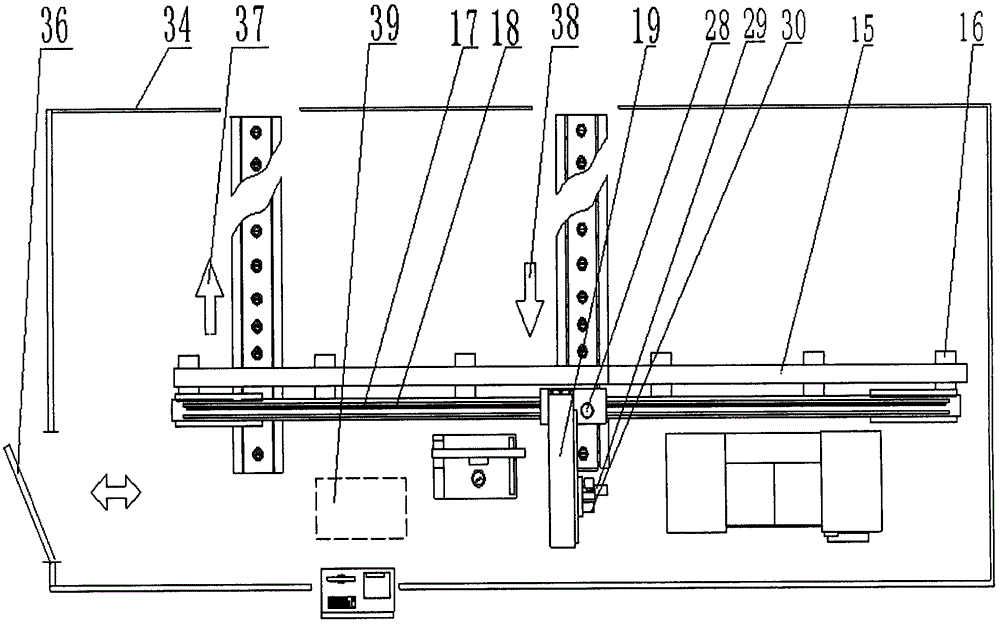

Laser cutting flexible manufacture system

ActiveCN103979274AIncrease productivityLaser beam welding apparatusConveyor partsEngineeringLaser cutting

The invention relates to a laser cutting flexible manufacture system. The laser cutting flexible manufacture system comprises at least two laser cutting machines which are arranged under a girder frame in a parallel mode; the front end of the girder frame is connected with a material storeroom; a feeding guide rail is arranged under the girder frame; a feeding trolley is arranged on the feeding guide rail; a storeroom entering guide rail is arranged on the lateral side of the material storeroom; two transporting guide rails are arranged in a mode parallel to the girder frame; transporting vehicles are installed on the transporting guide rails; a rotary platform is arranged between the storeroom entering guide rail and the transporting guide rails; rotary platform guide rails are arranged on the rotary platform; the rotary platform guide rails are connected with the storeroom entering guide rail and the transporting guide rails; a feeding manipulator and a discharging manipulator which can move along the girder frame are arranged on the girder frame; a waste separation device is arranged on the rear portion of the laser cutting machines corresponding to the position of the discharging manipulator; a waste tank is arranged on the lateral side of the waste separation device; the rear side of the waste separation device is provided with a sorting conveying device; the lateral side of the sorting conveying device is provided with a part temporary storage box. The laser cutting flexible manufacture system has the advantages of being good in integral cooperative performance and substantially improves the production efficiency.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

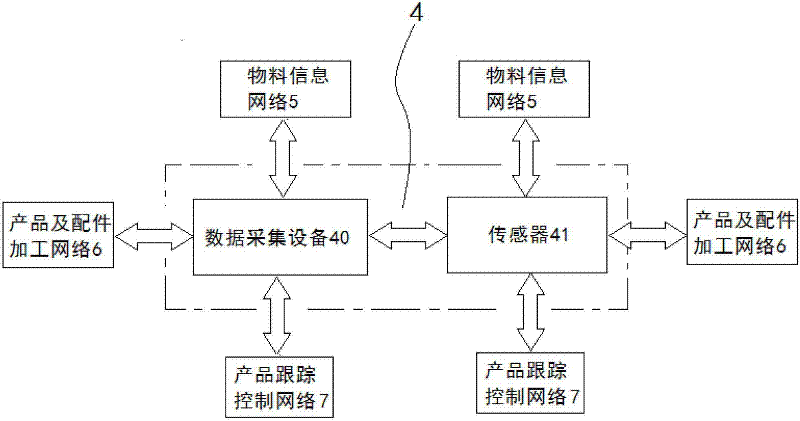

Intelligent flexible manufacturing system

InactiveCN102650880ATightly fusedCollaborate closelyTotal factory controlProgramme total factory controlFlexible manufacturing systemDecision control

The invention discloses an intelligent flexible manufacturing system which comprises a decision control center 1, a customer order and market analysis 2, distributed computing equipment 3, a communication network 4, a material information network 5, a product tracking control network 6 and a product and fitting processing network 7, wherein the decision control center 1 is a data, information and computation center, receives information from the customer order and market analysis 2, the distributed computing equipment 3, the material information network 5, the product tracking control network 6 and the product and fitting processing network 7 through the communication network 4 for computational analysis, and gives out a command after making a decision to carry out the system control on the the customer order and market analysis 2, the distributed computing equipment 3, the material information network 5, the product tracking control network 6 and the product and fitting processing network 7 through the communication network 4. The intelligent flexible manufacturing system provides fast execution and response abilities for multi-variety and small-amount orders, and is widely applicable to various manufacturing systems.

Owner:FOSHAN UNIVERSITY

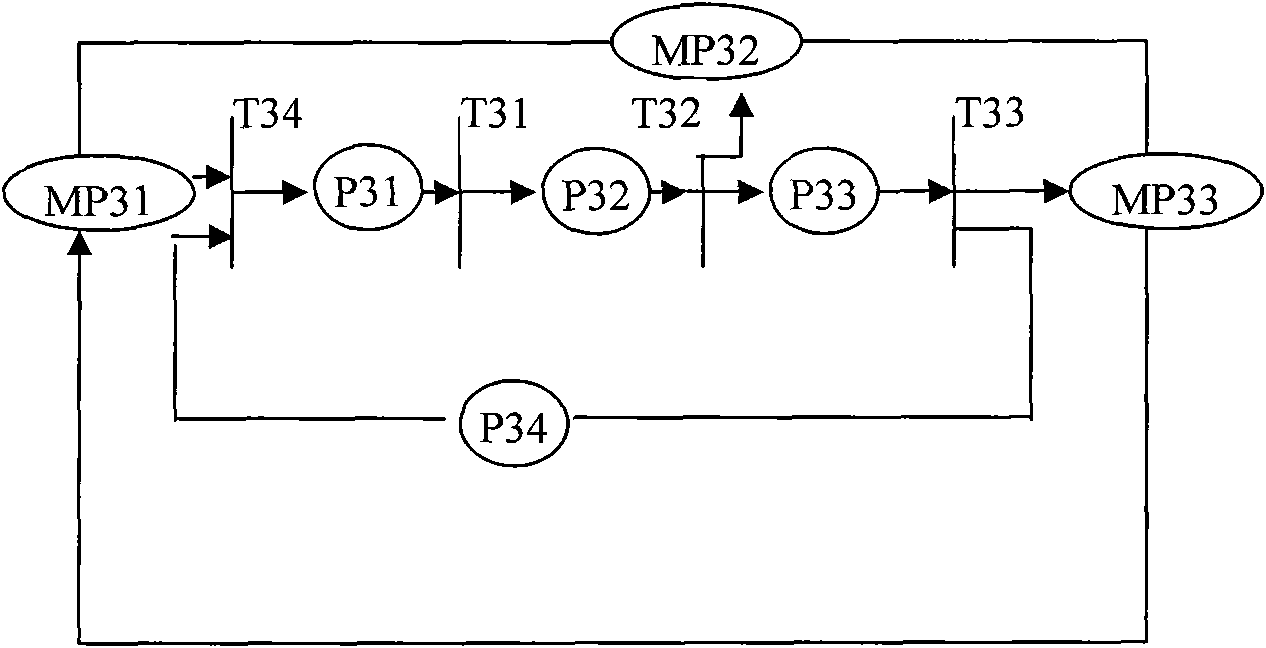

Flexible manufacturing system deadlock-free scheduling method based on improved genetic algorithm

InactiveCN111563336AEasy to operateIncrease productivityForecastingDesign optimisation/simulationFlexible manufacturing systemProcessed Genes

The invention belongs to the technical field of production scheduling of flexible manufacturing systems, and particularly relates to a deadlock-free scheduling method for a flexible manufacturing system based on an improved genetic algorithm. The method comprises the following specific steps of: establishing a Petri net model of the flexible manufacturing system, determining genetic parameters, encoding and decoding, generating an initialized population, performing detecting and repairing, calculating processing time and fitness, judging whether a termination rule and genetic operation are metor not, and outputting an optimal individual; adjusting all chromosomes into control feasible chromosomes through a two-step forward looking method, and decoding the control feasible chromosomes intoa deadlock-free scheduling sequence; optimizing and improviing the genetic algorithm in the design process of the scheduling strategy. Meanwhile, in the variation process, the chromosome gene is divided into a path gene and a process gene, variation operation is conducted on the path gene and the process gene at the same time, the variation rates of the path gene and the process gene are the same, and therefore the operation steps are simple, the production efficiency is greatly improved, and the application environment is friendly.

Owner:NANTONG UNIVERSITY

AGV scheduling technique for flexible manufacturing system

InactiveCN108415430APosition/course control in two dimensionsVehiclesFlexible manufacturing systemDatabase server

The application relates to an AGV scheduling technique for a flexible manufacturing system. According to the AGV scheduling method in a manufacturing system, the manufacturing system is composed of amanufacturing execution system (MES), a plurality of independent units separated from each other, a plurality of AGVs for material distribution, an AGV scheduling unit for the plurality of AGVs, and an AGV-PLC in communication with the plurality of AGVs and the AGV scheduling unit. The method comprises: the AGV-PLC communicates with the AGV scheduling unit to inquire a current available AGV; whenany AGV is available, the AGV-PLC accesses an AGV scheduling task table maintained by the MES in a database server to obtain a to-be-executed AGV scheduling task; the AGV-PLC parses the obtained AGV scheduling task and generates a corresponding AGV transportation task; and the AGV-PLC transmits the AGV transport task to the AGV scheduling unit.

Owner:PHOENIX CONTACT NANJING R&D ENG CENT

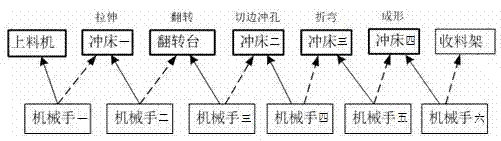

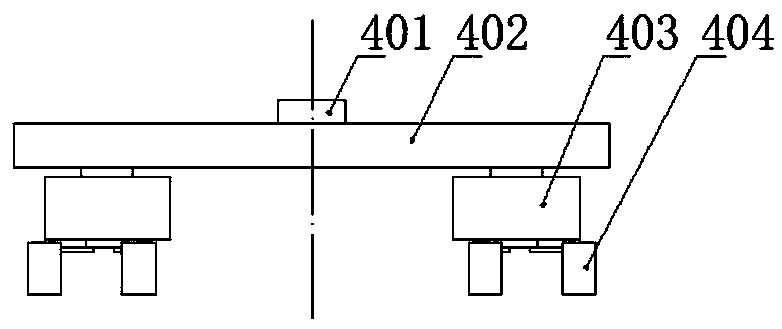

Automatic control device for punching machine production line

ActiveCN105436277AMeet the needs of receiving stamped objectsIntegrate extensivelyMetal-working feeding devicesPositioning devicesAutomatic controlPunch press

The invention relates to the technical field of punch forming equipment, in particular to an automatic control device for a punching machine production line. The automatic control device comprises a controller, a punching mechanism and a control mechanism. The signal output end of the controller is in electric connection with the signal input end of the punching mechanism and the signal input end of the control mechanism. The punching mechanism and the control mechanism are oppositely arranged in two rows. The first row is the punching mechanism. The control mechanism comprises six manipulators. The input / output signal control end of the control mechanism is electrically connected with the controller through an M / II bus. The input / output signal control end of the punching mechanism is electrically connected with an I / O interface of the controller. The manipulators can move rotationally, left and right, and up and down to meet the requirements of the punching machine production line for collecting punching objects. An Ethernet interface circuit is arranged in the controller, so that through a network communication mode, it is convenient for a punched refrigerator compressor support plate to be integrated into a more extensive flexible manufacturing system and an Internet of things system to achieve remote operation and control.

Owner:JIANGSU UNIV OF TECH

Flexible manufacturing system experimental equipment based on industrial robots

PendingCN106205266ACosmonautic condition simulationsEducational modelsFlexible manufacturing systemRobot hand

The invention relates to flexible manufacturing system experimental equipment based on industrial robots. A master control station comprises a PLC main console and conveying equipment controlled by the PLC main console; the conveying equipment comprises a conveying track, a transfer robot is arranged on the conveying track and connected with a stepping motor; the transfer robot transfers workpieces into a welding station, a material station is connected with a welding table, work is controlled by an electrical control cabinet, a welding robot is controlled by the master control station to transfer the workpieces to a CNC milling machine in a digital machining station for drilling, and the CNC milling machine is connected with a visual detection station; the visual detection station comprises a conveying belt, the workpieces conveyed by the CNC milling machine on the conveying belt are shot into images through cameras fixed beside the conveying belt, and unqualified workpieces are removed through a portal robot hand. Through the equipment, relevant practical training can be provided for the industrial robot application technology, the electromechanical maintenance and management specialty, the mechatronics specialty, the electric automation specialty, the machinery manufacturing and automation specialty and the like.

Owner:魏志丽

Hybrid-system modeling and simulation platform and method based on HSTPN model

ActiveCN107229789AImprove scalabilityReduce Model ComplexityDesign optimisation/simulationResourcesDecision takingPetri net

The invention discloses a hybrid-system modeling and simulation platform and method based on a HSTPN model. The hybrid-system modeling and simulation platform comprises a human-computer interaction module, a logic expression module, a simulation analysis module, a file storage module and an equivalent rule library. The platform can carry out modeling and simulation on a hybrid system with five hybrid characteristics of dispersing, continuation, delaying, random and decision at the same time, the hybrid characteristics are only defined in a five-type library, the modeling complexity can be reduced, the transitional moment theory is guaranteed, and the modeling expandability is improved; a hybrid state of the HSTPN model is jointly described through a library identification and the continuous state; the platform provides the equivalent function of the HSTPN model by establishing equivalent rules of a hybrid Petri net and a derivative model of the hybrid Petri net. The hybrid-system modeling and simulation platform and method can be applied to modeling and simulation of hybrid systems such as an information physical fusion system, a flexible manufacturing system, a logistic system and defense industry.

Owner:NORTHEASTERN UNIV

Object-oriented Petri network modeling method in flexible manufacturing system

InactiveCN101625569AEasy to refactorAvoid deadlockTotal factory controlProgramme total factory controlFlexible manufacturing systemManufacturing cell

The invention discloses an object-oriented Petri network modeling method in a flexible manufacturing system. Modeling steps are as follows: step one, establishment of a structure model in an FMS; step two, construction of a single physical object OPN model; and step three, establishment of an OPN model in the FMS; wherein when no task exists, various organization units in the system have no need for mutual connection; however, once the task appears, various basic units are stimulated so that the connectivility possessed by a manufacturing unit can function, the units mutually send connection requirements, and Gate 1, Gate 2 and Gate 3 are used for realizing the connection. Compared with a common Petri network, in the invention, an OOPN model in the FMS can be expanded and easily reconstructed, and an FMS control software based on the OOPN model can be directly and correspondingly obtained and can prevent deadlock and conflict from happening in the system.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

Tooling plate for a flexible manufacturing system

InactiveUS6918577B2Easy to disassembleAvoid less flexibilityPrecision positioning equipmentWelding/cutting auxillary devicesFlexible manufacturing systemMechanical engineering

Owner:FORD MOTOR CO

Efficient four-station magnetic shoe chamfering grinder

ActiveCN104608022ARapid productionImprove qualityEdge grinding machinesGrinding drivesEngineeringMagnet

The invention discloses an efficient four-station magnetic shoe chamfering grinder. The efficient four-station magnetic shoe chamfering grinder comprises a magnetic shoe shifting mechanism, a magnetic shoe pushing mechanism, an inner magnetic shoe chamfering grinding head mechanism, an outer magnetic shoe chamfering grinding head mechanism, a magnetic shoe guide rail component, a magnetic shoe input mechanism and a magnetic shoe output mechanism, wherein the output end of the magnetic shoe input mechanism is matched with the input end of the magnetic shoe guide rail component, the magnetic shoe shifting mechanism is correspondingly arranged at the output end of the magnetic shoe input mechanism, the magnetic shoe pushing mechanism is correspondingly arranged at the input end of the magnetic shoe guide rail component, a corresponding magnetic shoe is pushed into a grinding area formed by the inner magnetic shoe chamfering grinding head mechanism and the outer magnetic shoe chamfering grinding head mechanism through the magnetic shoe pushing mechanism, and the output end of the magnetic shoe guide rail component is matched with the magnetic shoe output mechanism. According to the efficient four-station magnetic shoe chamfering grinder, the structure of the chamfering grinder is simplified, grinding efficiency is improved, the using efficiency of other grinding equipment in an intelligent flexible arc magnet manufacturing system is improved, production speed of the intelligent flexible arc magnet manufacturing system is increased, arc magnets with better quality are produced, and economic benefits are higher.

Owner:SICHUAN MAGUNION TECH CO LTD

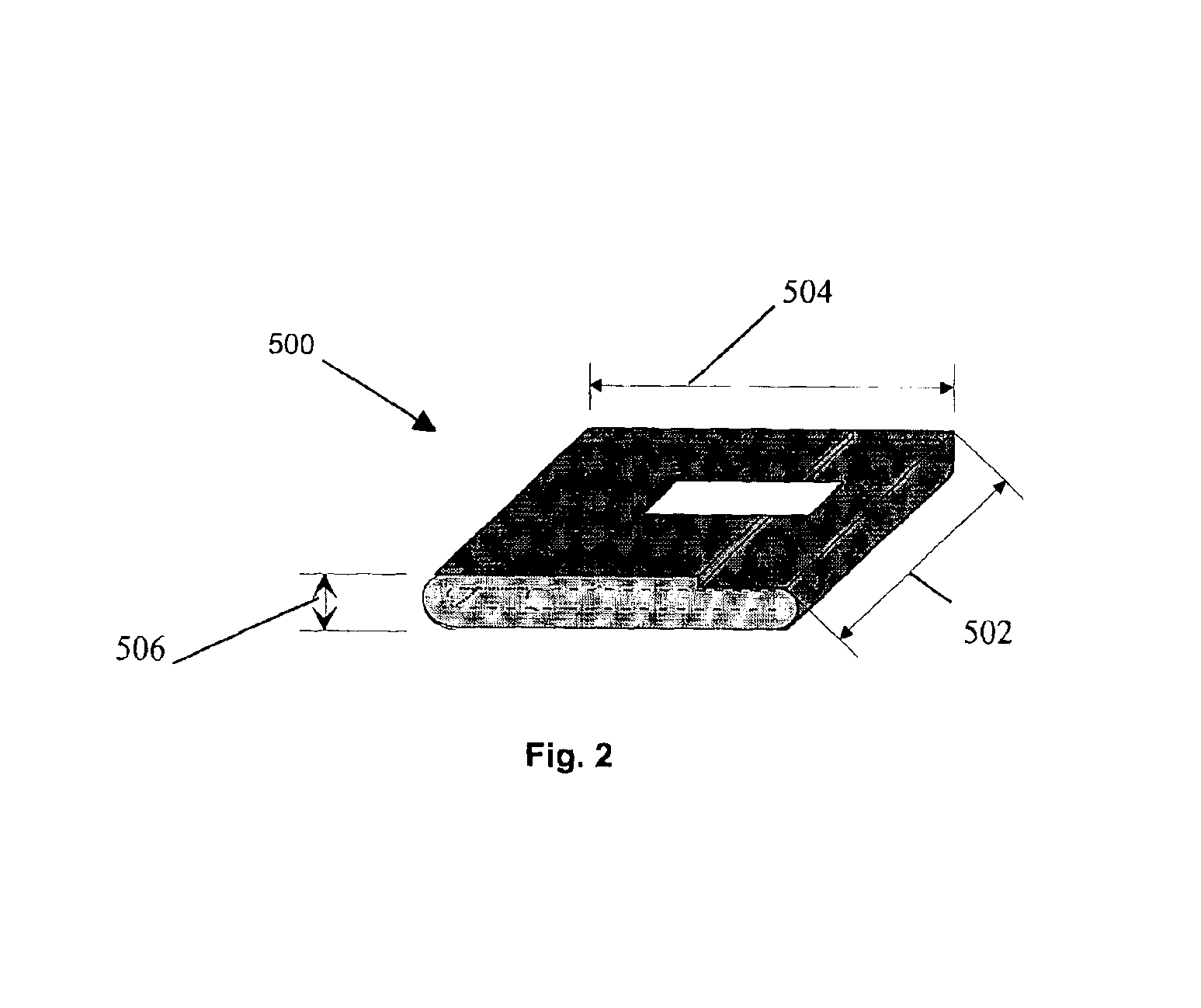

Leadframe semiconductor integrated circuit device using the same, and method of and process for fabricating the two

InactiveUSRE43443E1Wide range of sizesSuppress package body crackingSemiconductor/solid-state device detailsSolid-state devicesFlexible manufacturing systemCrack resistance

In order to improve the package body cracking resistance of an LSI package at the reflow soldering and to provide both a leadframe suitable for fabricating the LSI package according to the flexible manufacturing system and an LSI using the leadframe, the adhered area between a semiconductor chip 2 and a resin is enlarged by making the external size of a die pad 3 smaller than that of the semiconductor chip to be mounted thereon. Moreover, a variety of semiconductor chips 2 having different external sizes can be mounted on the die pad 3 by cutting the leading ends of leads 5 to a suitable length in accordance with the external sizes of the semiconductor chips 2.

Owner:RENESAS ELECTRONICS CORP

Apparatus and method for handling short run quick changeover fabrication jobs

InactiveUS20090030542A1Increase material costLow costDigital data processing detailsTotal factory controlFlexible manufacturing systemTransport system

In a flexible manufacturing system (FMS), a shelving module of a work cell is fitted with a dedicated lift conveying mechanism so that work materials of desired sizes may be retrieved individually from different shelves of the shelving module for conveyance to the machine of the work cell. By having its own dedicated lift conveying mechanism that operates independently from the transport system that transports raw materials to the wok cells of the FMS, the operation of each cell becomes unaffected by the transport system. As such, materials may be fed to the machine in each cell for fabrication, piece by piece if so desired, by the lift conveying mechanism while the various shelves of the shelving module continue to be stocked by the transport system. Any remnants that prior to the instant invention would have been wasted may be returned to the appropriate shelves of the shelving module for future use by the lift conveying mechanism.

Owner:FINN POWER INT

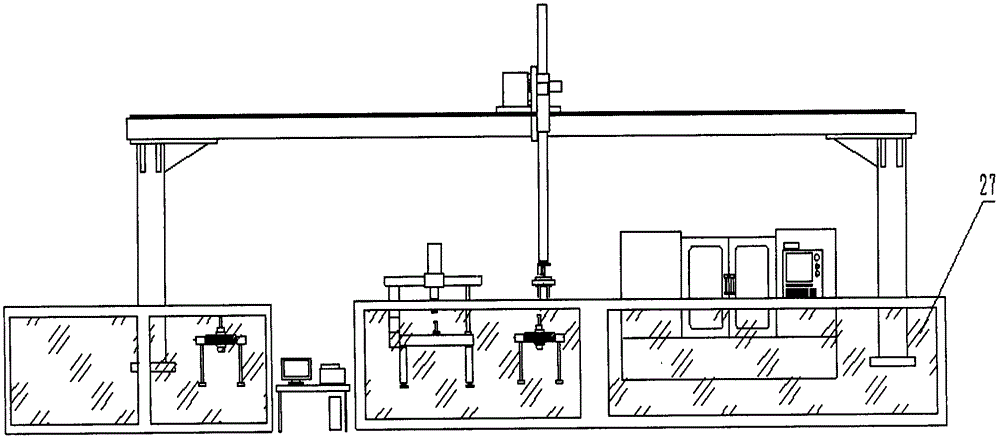

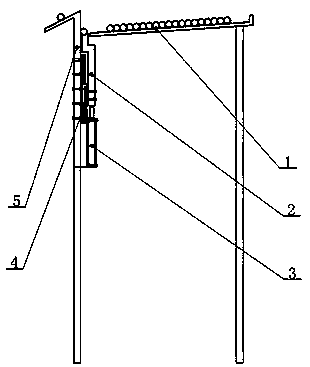

Blade intelligent grinding flexible manufacturing system

InactiveCN105290926AReduce production capacityLow costBelt grinding machinesAutomatic grinding controlNumerical controlFlexible manufacturing system

The invention discloses a blade intelligent grinding flexible manufacturing system and mainly solves the problems of traditional blade single-machine grinding, such as high manual feeding and discharging labor intensity, wrong inspection and incomplete and difficult-to-trace precision detection performance indexes. The system comprises a gantry, a laser measurement device, a numerical control grinder, a workpiece feeding and conveying conveyor belt mechanism, a central computer and a transparent protective fence. Blades are clamped and transported through the gantry, blade precision information is acquired through laser scanning measurement, a grinding procedure is automatically generated, and machining and subsequent intelligent processing are realized in a DNC mode. The blade intelligent grinding flexible manufacturing system is skillful in structural design, complete in detection functions, strong in universality, realizes precision data whole-process tracing in the blade manufacturing process, avoids detection leakage and wrong detection problems, greatly improves blade massive manufacture quality, realizes unmanned intelligent manufacture on complicated curved surface components, such as blades, effectively reduces the massive manufacture cost of blade production, and has great practical and popularization values.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

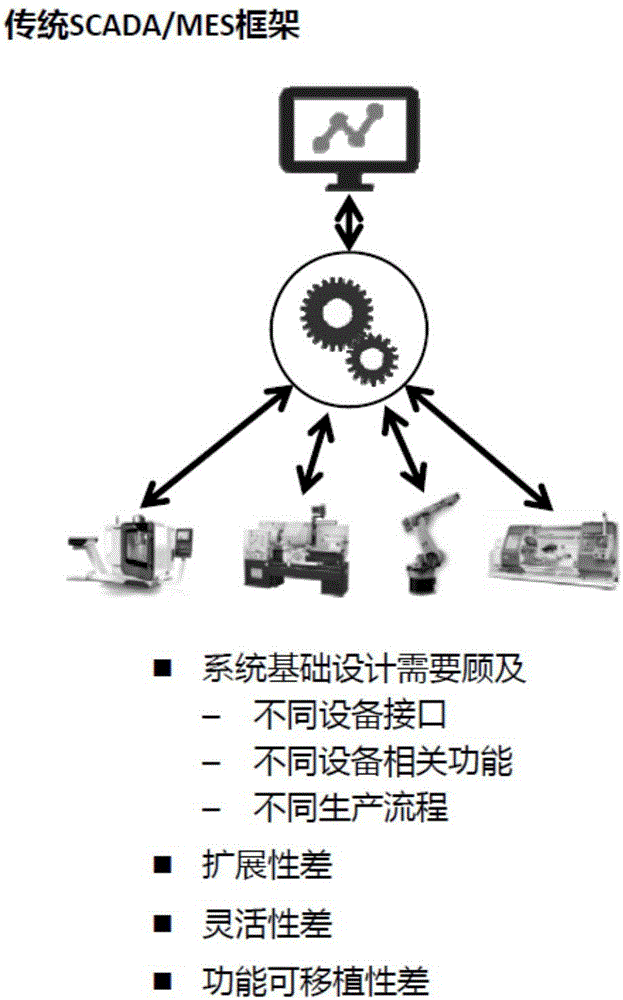

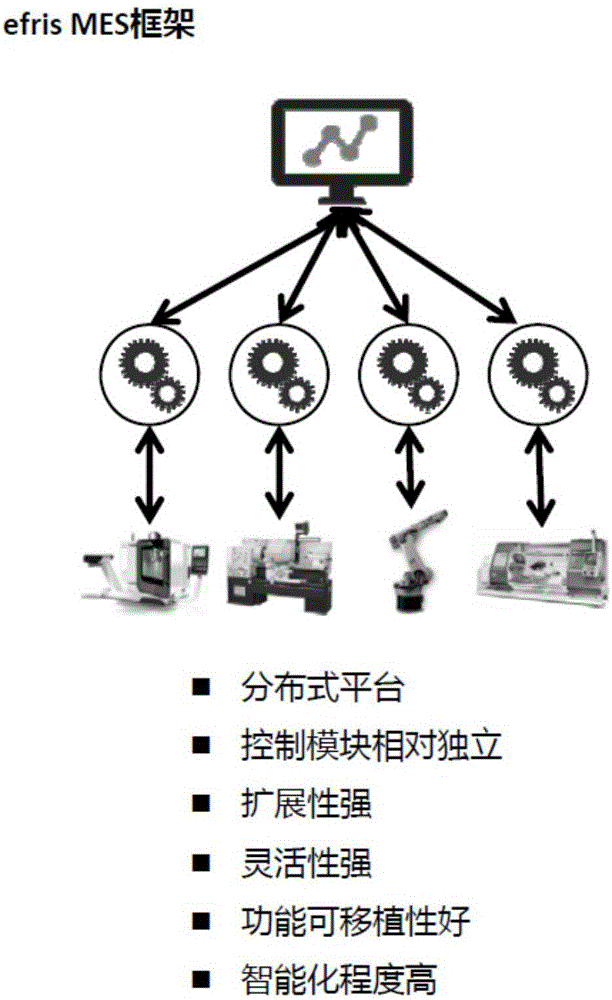

Flexible manufacturing system based on modularized control unit

InactiveCN106292584AIncrease flexibilityReduce development costsData processing applicationsTotal factory controlFlexible manufacturing systemModularity

An embodiment of the invention provides a flexible manufacturing system based on a modularized control unit. The system comprises an ERP system, a MES system and manufacturing equipment. The MES system comprises control units. Each control unit at least comprises a capability module and a control module; the capability module is used to read an operation logic file and a function library sent from outside; and the control module is used to load and run the operation logic file and the function library. The system comprises the MES system with the control unit which can read the operation logic file and the function library transmitted from the outside and use the operation logic file and the function library to define the functions of the control unit. A program developer can customize the operation logic files and the functions in the function libraries according to needs, so that different functions can be completed by different control units and the functions of the control units do not need to be fixed in the system beforehand. Compared with the prior art, the flexibility of manufacturing process control is improved, and the development cost is reduced.

Owner:苏州朋泰智能科技有限公司

Flexible manufacturing system

PendingCN109664115AUse less equipmentIncrease productivityOther manufacturing equipments/toolsMetal working apparatusFlexible manufacturing systemRobot position

The invention relates to a flexible manufacturing system. The flexible manufacturing system comprises a six-axis robot, a conveying belt, a stacking tray, a high-precision machining center, a lathingcenter, a special clamp, a feeding manipulator and a blank tray; the special clamp is installed at the end part of the manipulator of the six-axis robot; the annularly arranged conveying belt is installed at the outer circumference of the six-axis robot; the stacking tray is installed at the radial side of the six-axis robot positioned at the inner ring of the conveying belt; the outer sides, positioned at the other two sides of the six-axis robot, of the conveying belt are correspondingly provided with the high-precision machining center and the lathing center; the blank tray used for placinga blank raw material is installed at the outer circumference of the conveying belt; one feeding robot is installed at one side of the blank tray; and the feeding robot can be used for grabbing a blank on the conveying belt from the blank tray. The flexible manufacturing system provided by the invention uses few equipment, a workshop occupies a small area, the production efficiency is high, mixedflow production can be realized, and losses caused by shutdown are prevented. The flexible manufacturing system can realize batch production, is good in product uniformity and good in yield, and realizes low work intensity of workers.

Owner:TIANJIN TIANSEN INTELLIGENT EQUIP CO LTD

Automatic loading and unloading device of numerical control lathe

InactiveCN109048450AReduced precision requirementsHigh positioning accuracy requirementsMetal working apparatusNumerical controlFlexible manufacturing system

The invention relates to an automatic loading and unloading device of a numerical control lathe, and belongs to the technical field of part machining. The device comprises a lifting device, a feedingdevice, a conversion conveying device and an unloading device; the lifting device lifts workpieces to be machined placed on a feeding frame through a lifting cylinder in sequence; a feeding cylinder feeds the workpieces to be machined into a main shaft hole of the numerical control lathe in sequence; the workpieces are clamped by the numerical control lathe, and are machined according to set numerical control programs; and after the workpieces are machined, the machined workpieces are ejected out by an unloading cylinder in sequence, and are delivered by a conveying belt of a conversion device. The device and the numerical control lathe form a flexible manufacturing system to replace manual loading, positioning and unloading procedures, so that the worker labor intensity and labor time arereduced, and the automation degree in the production process is improved; and the device can be used for large-batch machining of rod parts as outer circular turning and drilling, and achieves the operation convenience and the maintenance simplicity.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com