Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Burst charge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

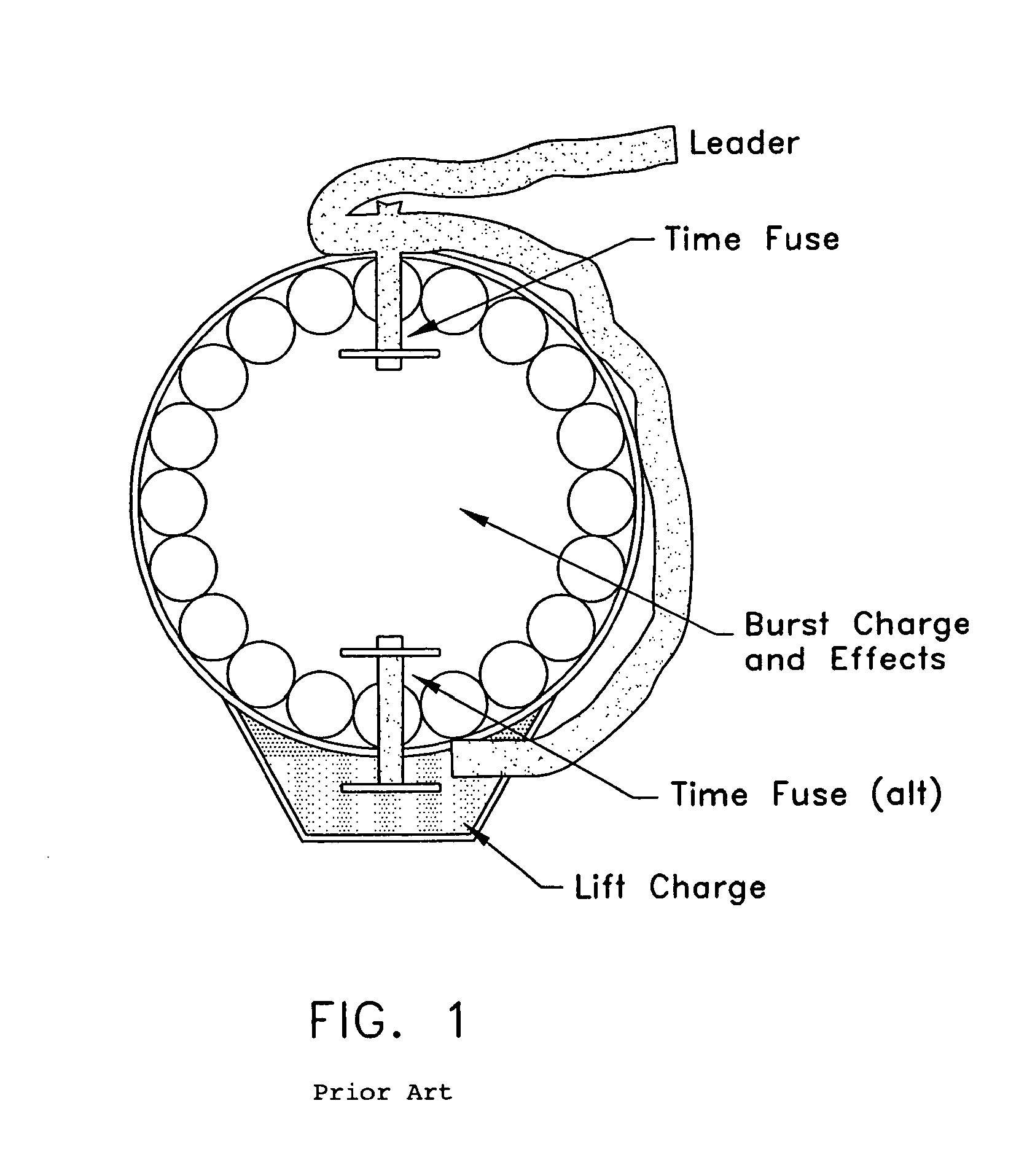

In fireworks, a burst charge (usually black powder) is a pyrotechnic mixture placed in a shell which is ignited when the shell reaches the desired height in order to create an explosion and spread the stars. Burst charge compositions are usually coated onto rice hulls or other low-density fillers, which increases the rate of combustion.

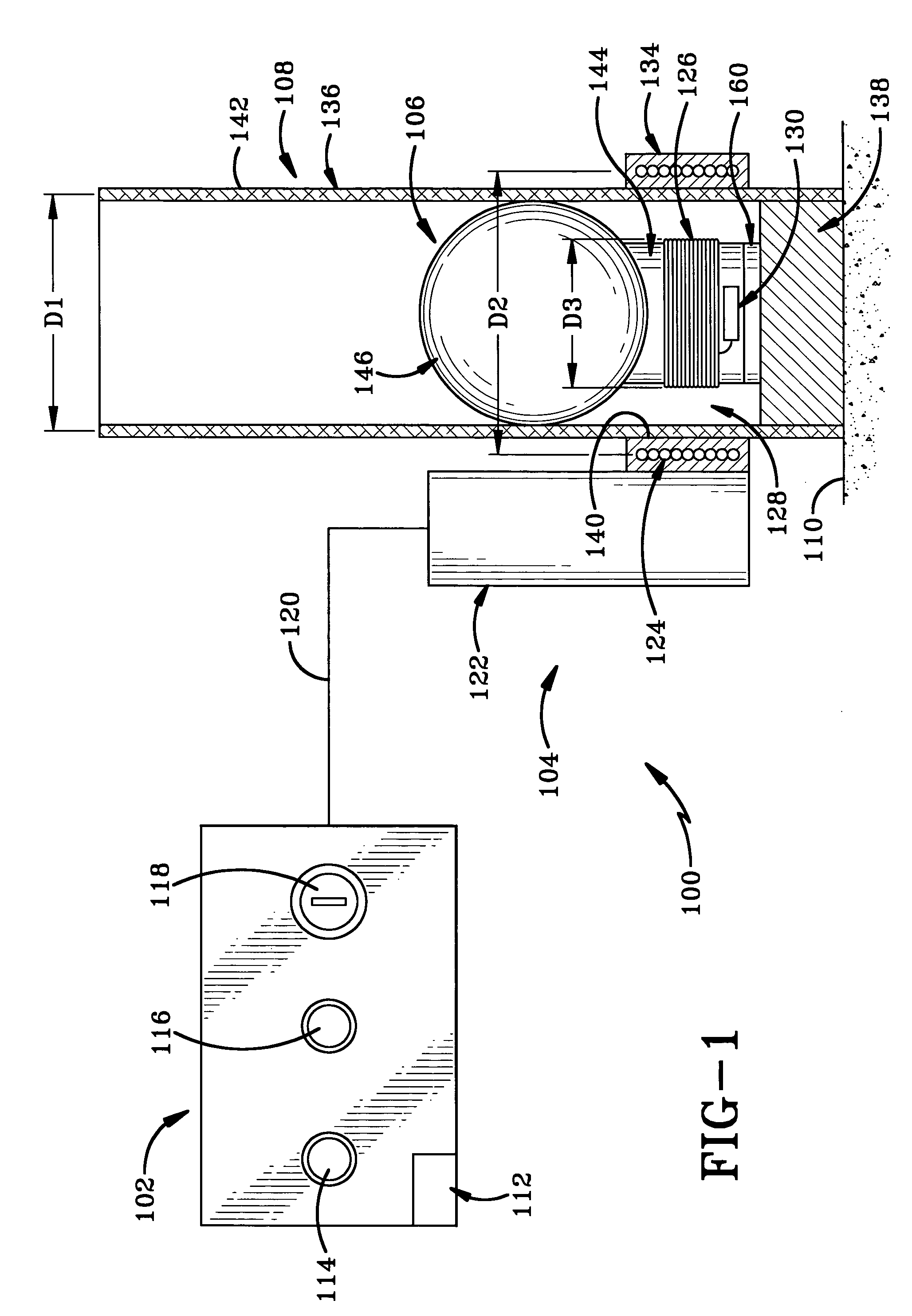

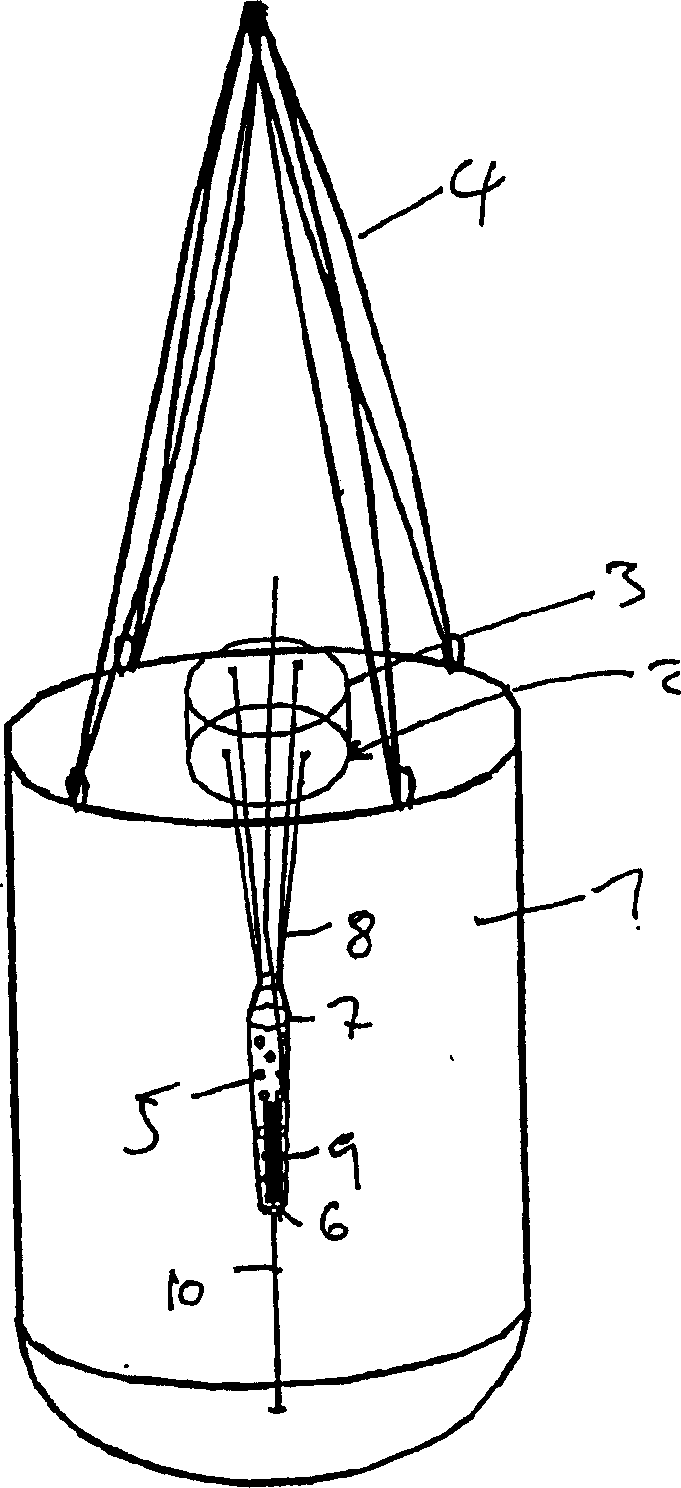

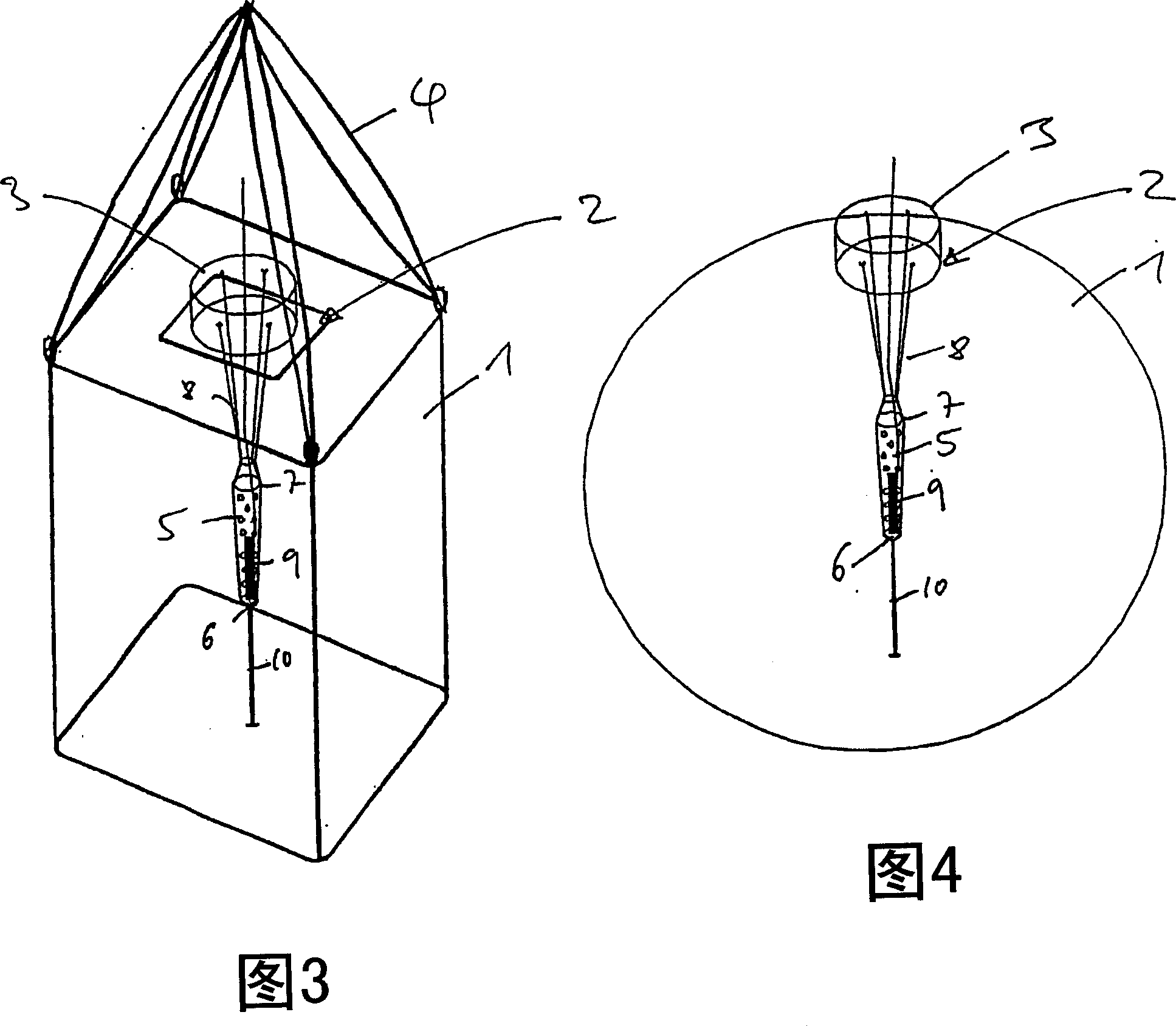

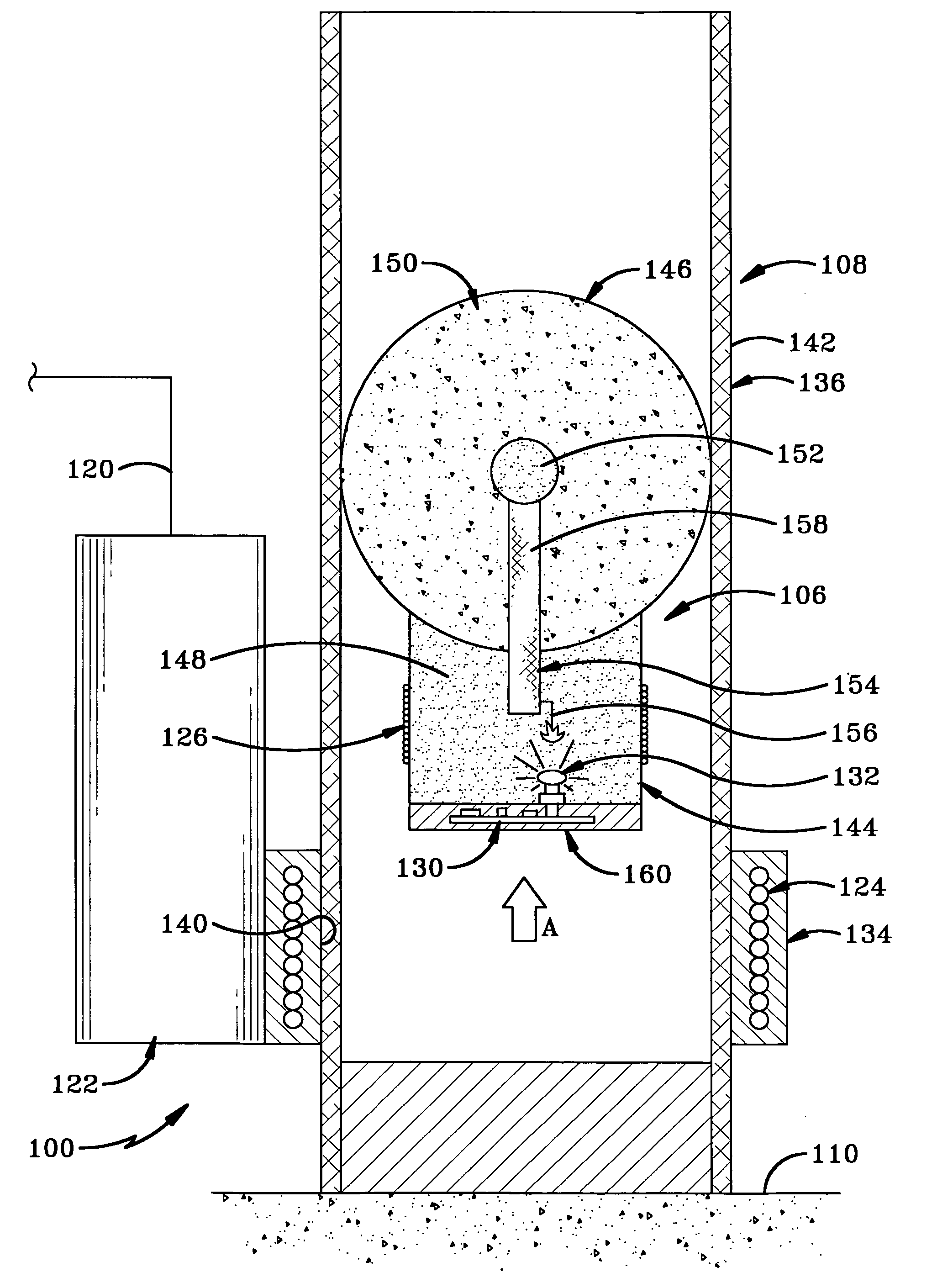

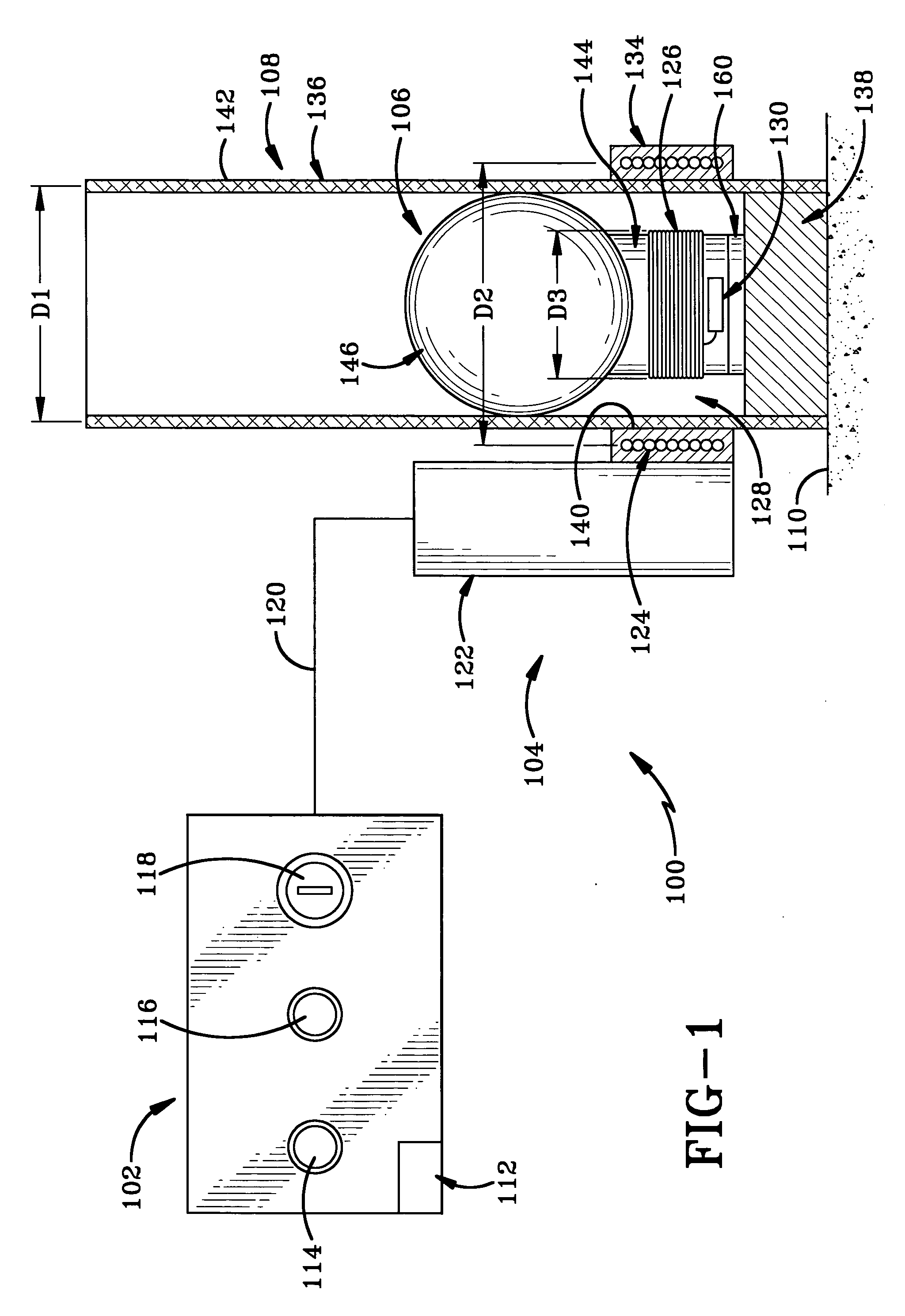

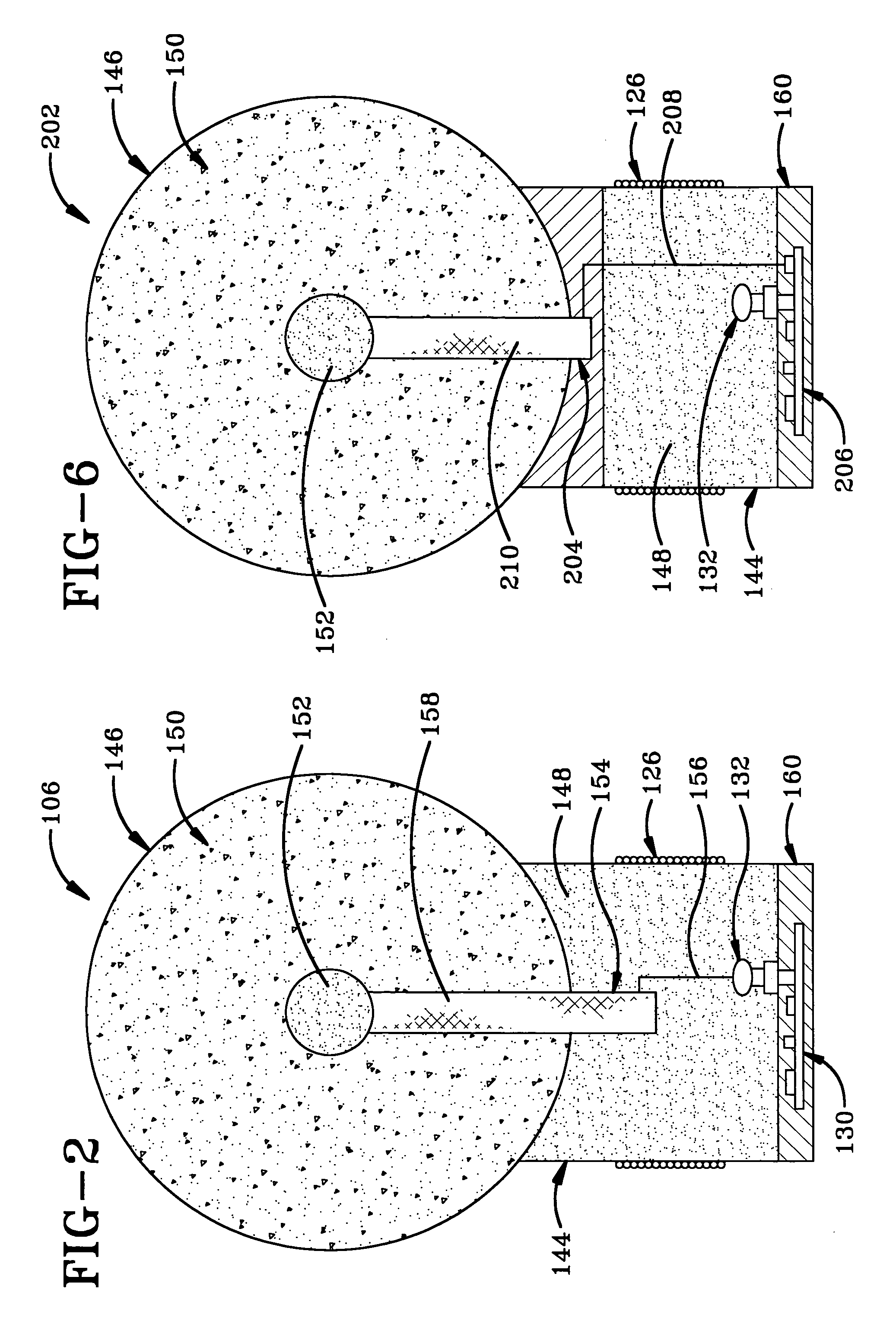

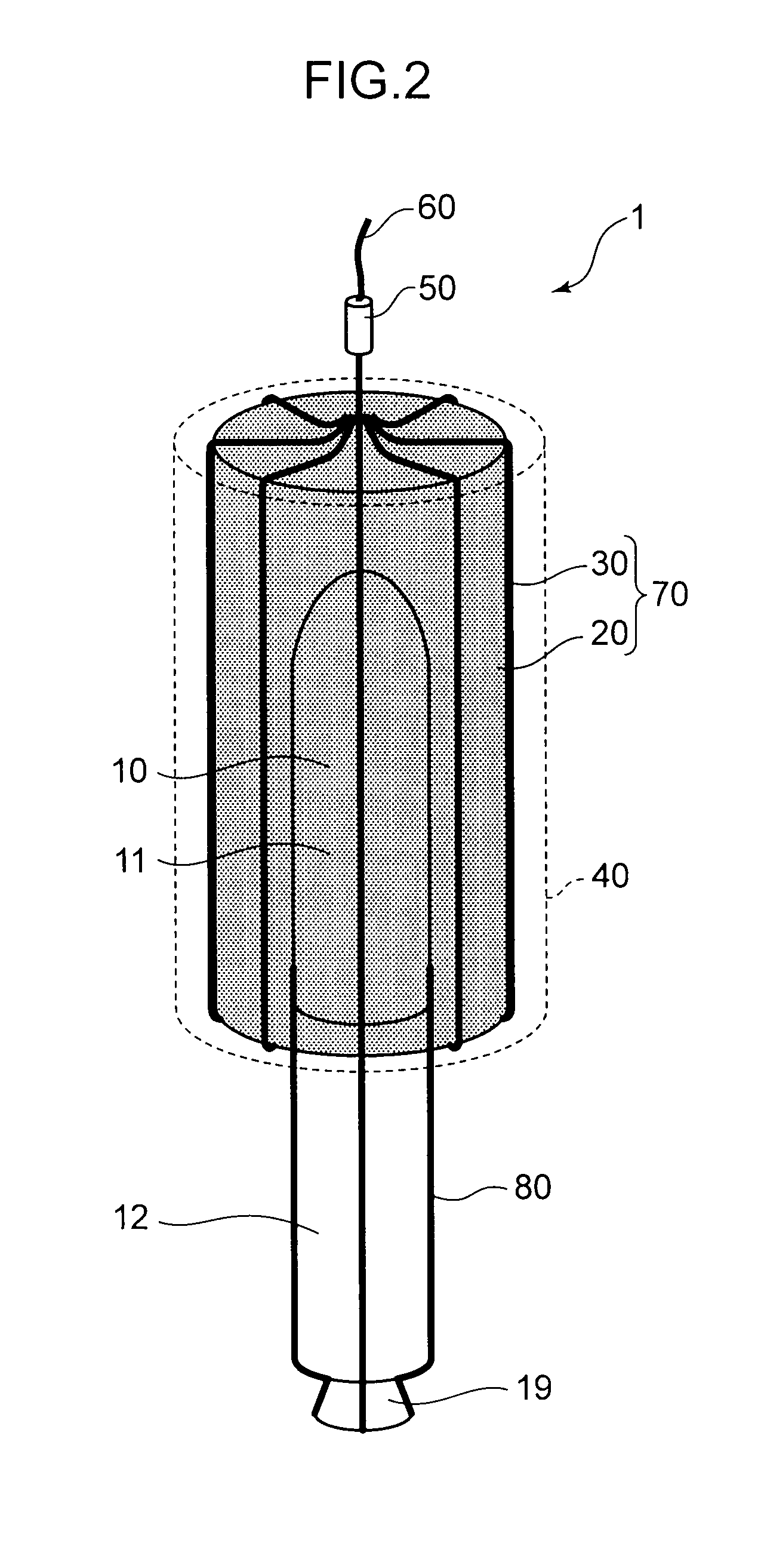

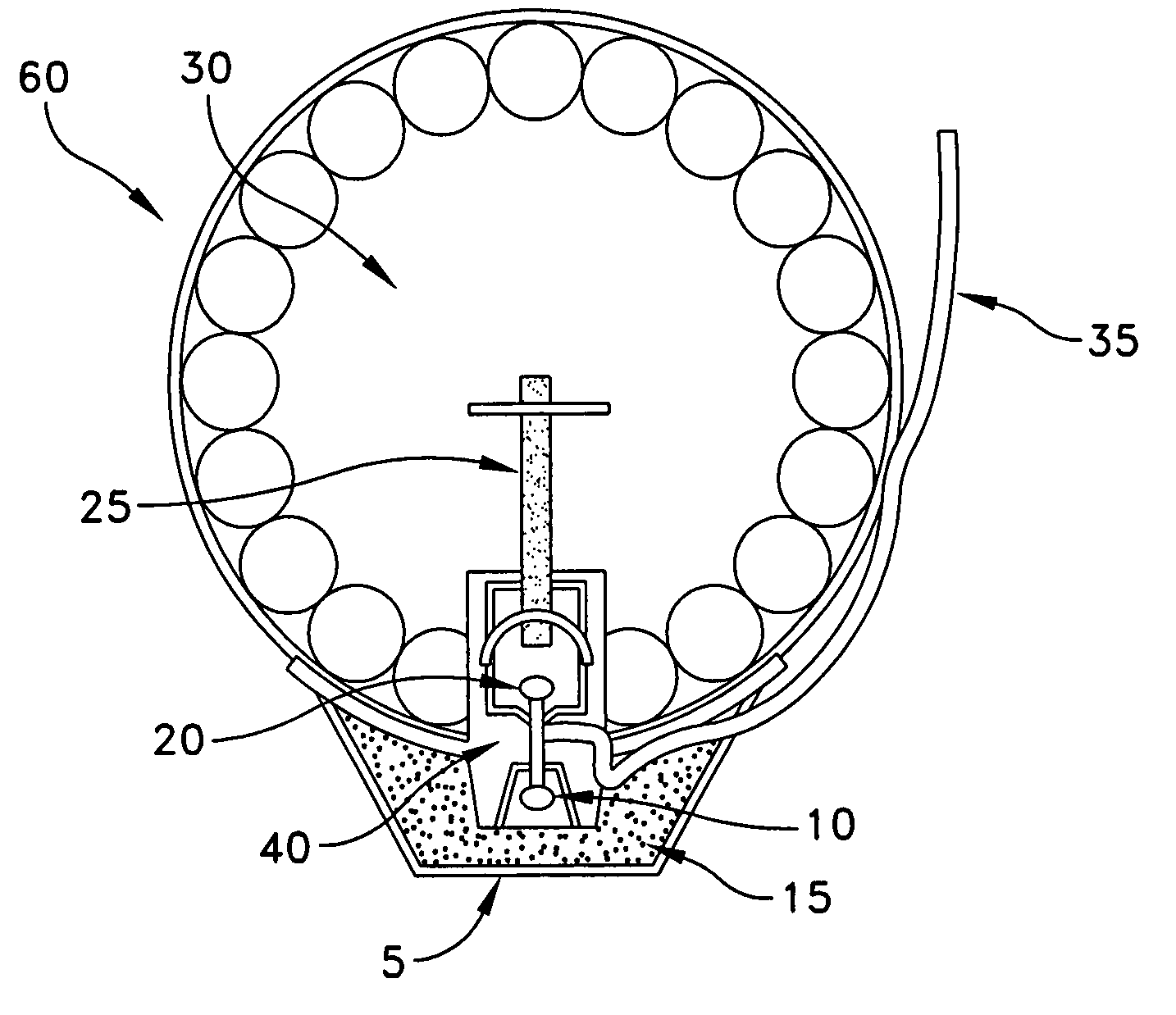

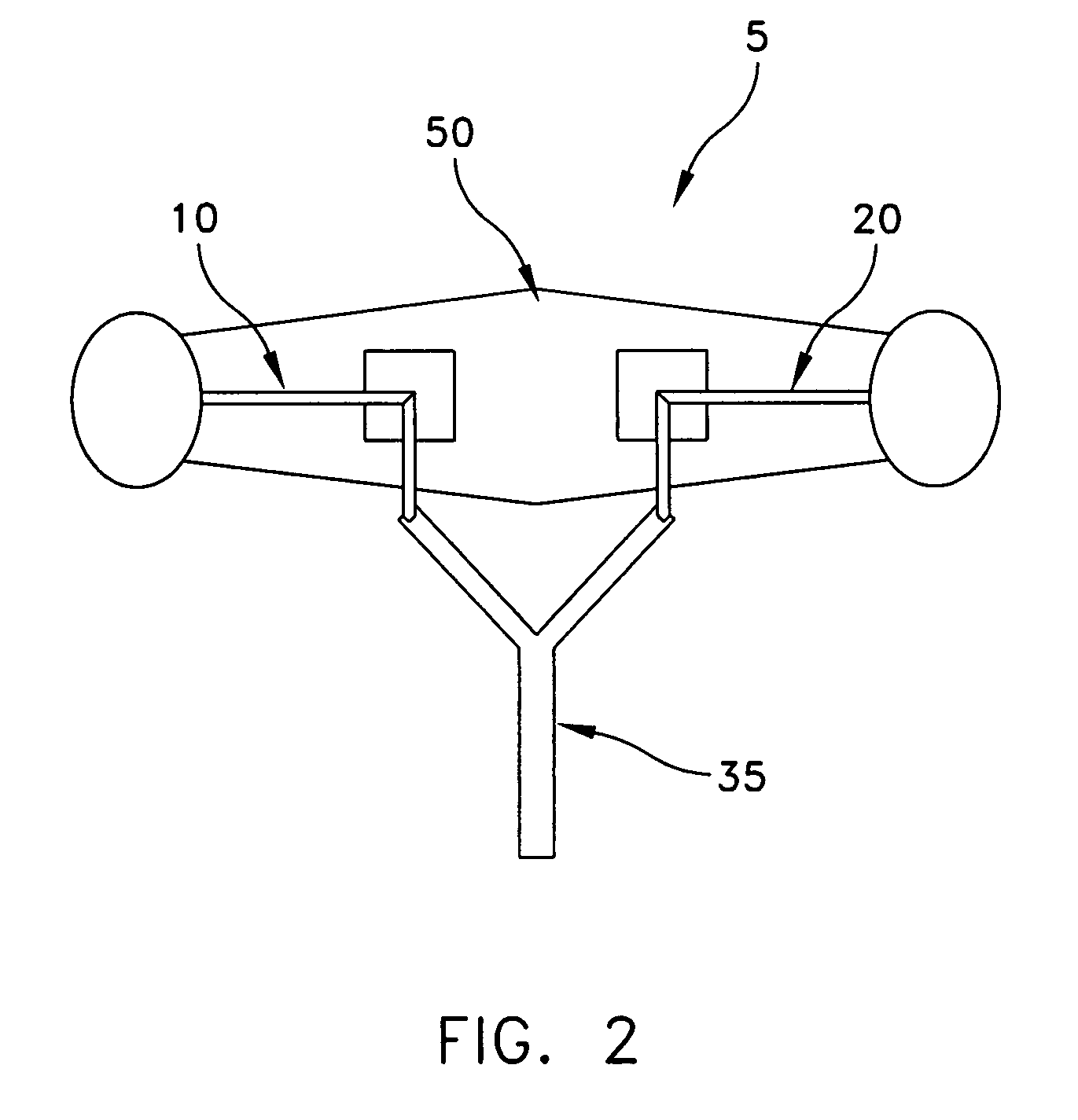

Remotely controlled ignition system for pyrotechnics

A remote pyrotechnic ignition system includes a power supply for producing an electrical current in a transmitting induction coil to induce an electrical current in a receiving induction coil for igniting a pyrotechnic device. Thus, a wireless ignition communication section allows pyrotechnic mortars to be reused and substantially reduces set-up time by eliminating the wiring of fireworks normally required for a pyrotechnic production. Optionally, a capacitor is charged by the power source via a charging circuit and discharged via a firing circuit to produce the electric current in the transmitting coil in a pulse. The capacitor provides a two-stage firing safety feature. An electronic control device such as a circuit board may be mounted on the pyrotechnic device for controlling ignition of the pyrotechnic device and is especially useful in controlling ignition sequencing and overall ignition timing of a lift charge and burst charge of the pyrotechnic device.

Owner:DEYE JAMES G

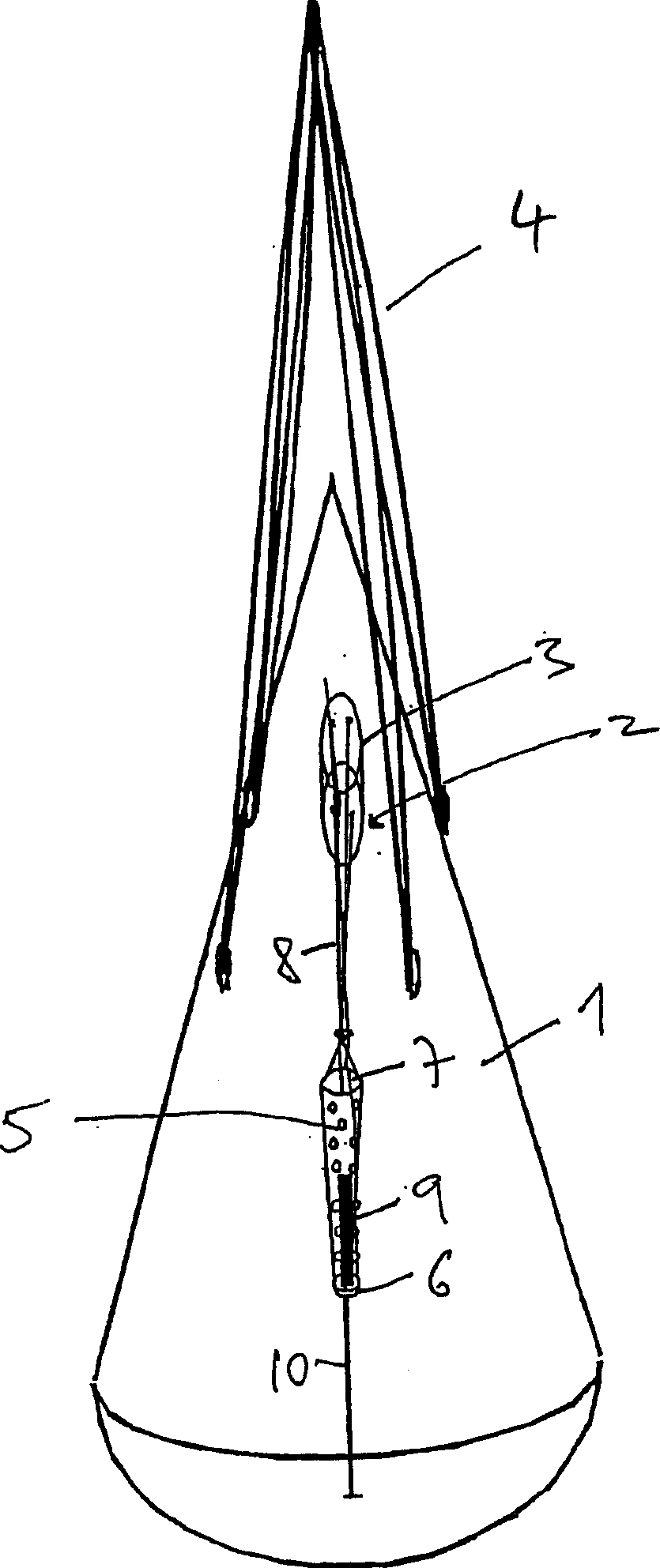

Training rocket for smoke development

A training rocket for smoke development. The training rocket includes a rocket tube which contains powder and constitutes a propulsion motor for the rocket. The rocket includes a forward training head which contains a smoke composition adapted to emit visible smoke upon impact. An igniter charge, such as a tracer charge, which can be ignited by the propellant powder is situated in the rearmost of the training head, behind a bursting charge which can be ignited by the igniter charge. The igniter charge and the bursting charge are situated behind the smoke composition in the training head, for igniting the smoke composition, in a capsule which can be forced rearwardly from the training head due to the increased pressure caused by combustion of the smoke composition, whereby an aperture is formed for passage of smoke gases rearwardly in the rocket, through the rocket tube and out of it.

Owner:NAMMO RAUFOSS

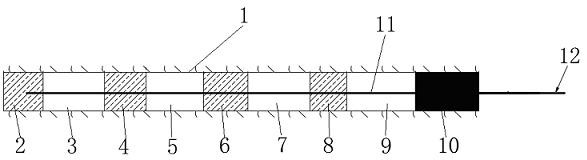

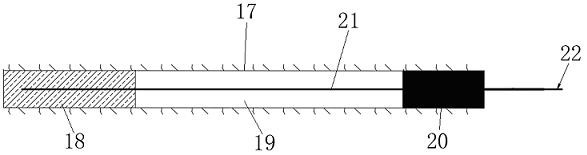

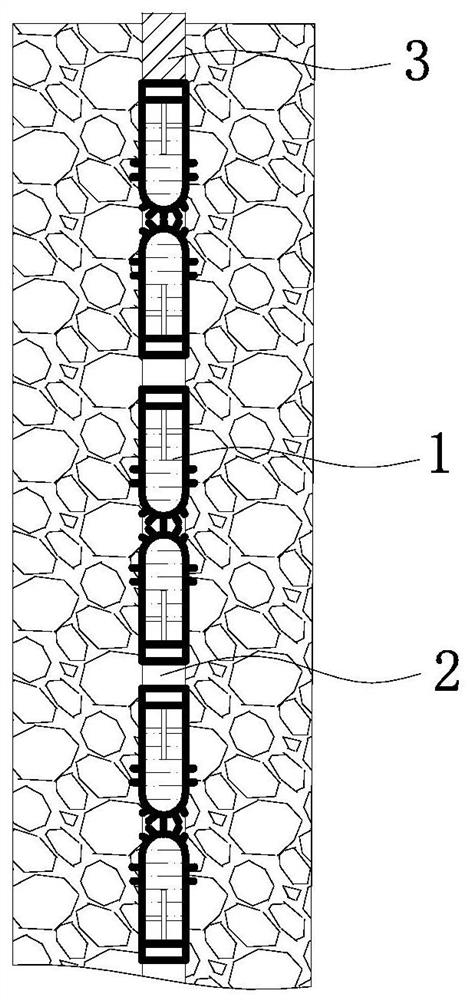

Energy-saving and environment-friendly digital detonator hydraulic blasting charge structure for tunnels

PendingCN111928746AAvoid local overexcavationAvoid the phenomenon of crushing damage of surrounding rockUsing liquid separation agentBlastingDetonatorArchitectural engineering

The invention relates to an energy-saving and environment-friendly digital detonator hydraulic blasting charging structure for tunnels. The structure comprises a peripheral hole, an auxiliary hole anda cutting hole, wherein the peripheral hole is formed in the outermost ring of the surrounding rock of a tunnel face, the auxiliary hole and the cutting hole are formed in the inner ring. A discontinuous peripheral hole charging structure is arranged in a blast hole of the peripheral hole, the peripheral hole charging structure comprises a first bottom explosive roll, a first water bag, a first reinforcing explosive roll, a second water bag, a second reinforcing explosive roll, a third water bag, an energy-saving explosive roll, a fourth water bag and first sealing gun mud which are arrangedat the bottom of the blast hole of the peripheral hole; a first detonating cord is arranged in the first bottom explosive roll, the first detonating cord sequentially penetrates through the first reinforcing explosive roll, the second reinforcing explosive roll, the energy-saving explosive roll and the first sealing gun mud, and a first digital electronic detonator with a detonating tube is arranged at one end outside the blast hole of the peripheral hole; and both the auxiliary hole and the cutting hole adopt a traditional charging structure of sequentially conducting continuous charging, additional arranging of a fifth water bag and sealing through second sealing gun mud. The charging structure is safe, reliable, energy-saving, environment-friendly, simple and easy to operate, and is suitable for initial excavation work of rock tunnel III and IV surrounding rocks.

Owner:GANSU ROAD & BRIDGE CONSTR GROUP +1

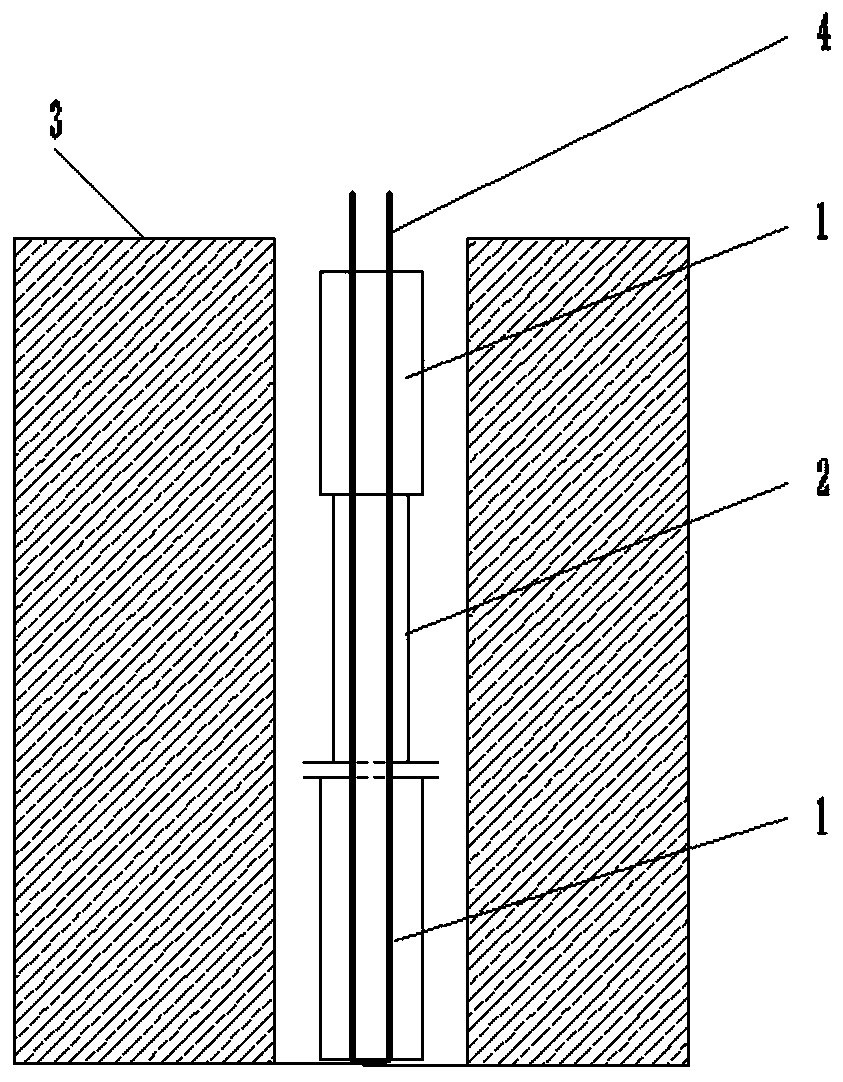

Blast treatment method and blast treatment device

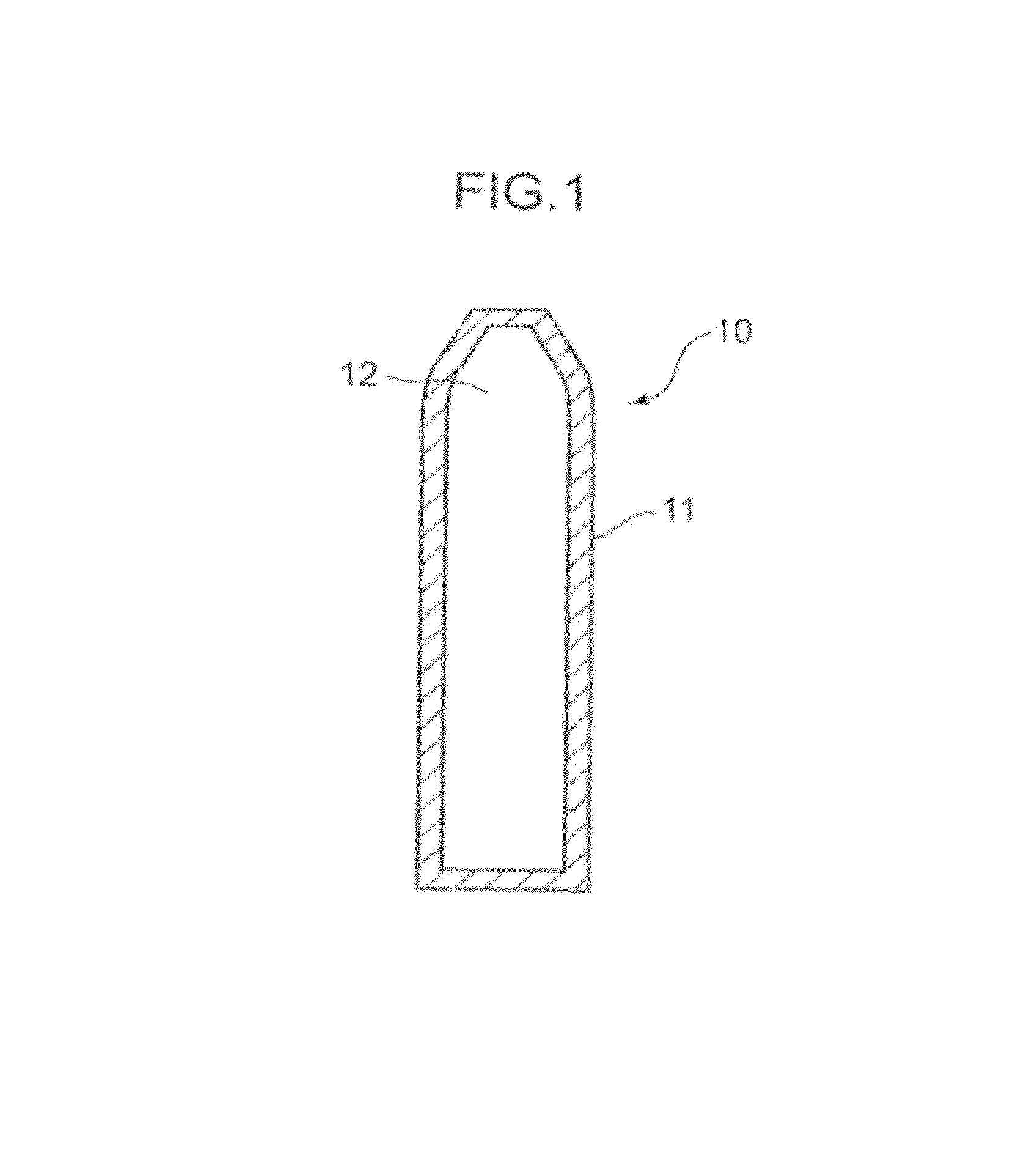

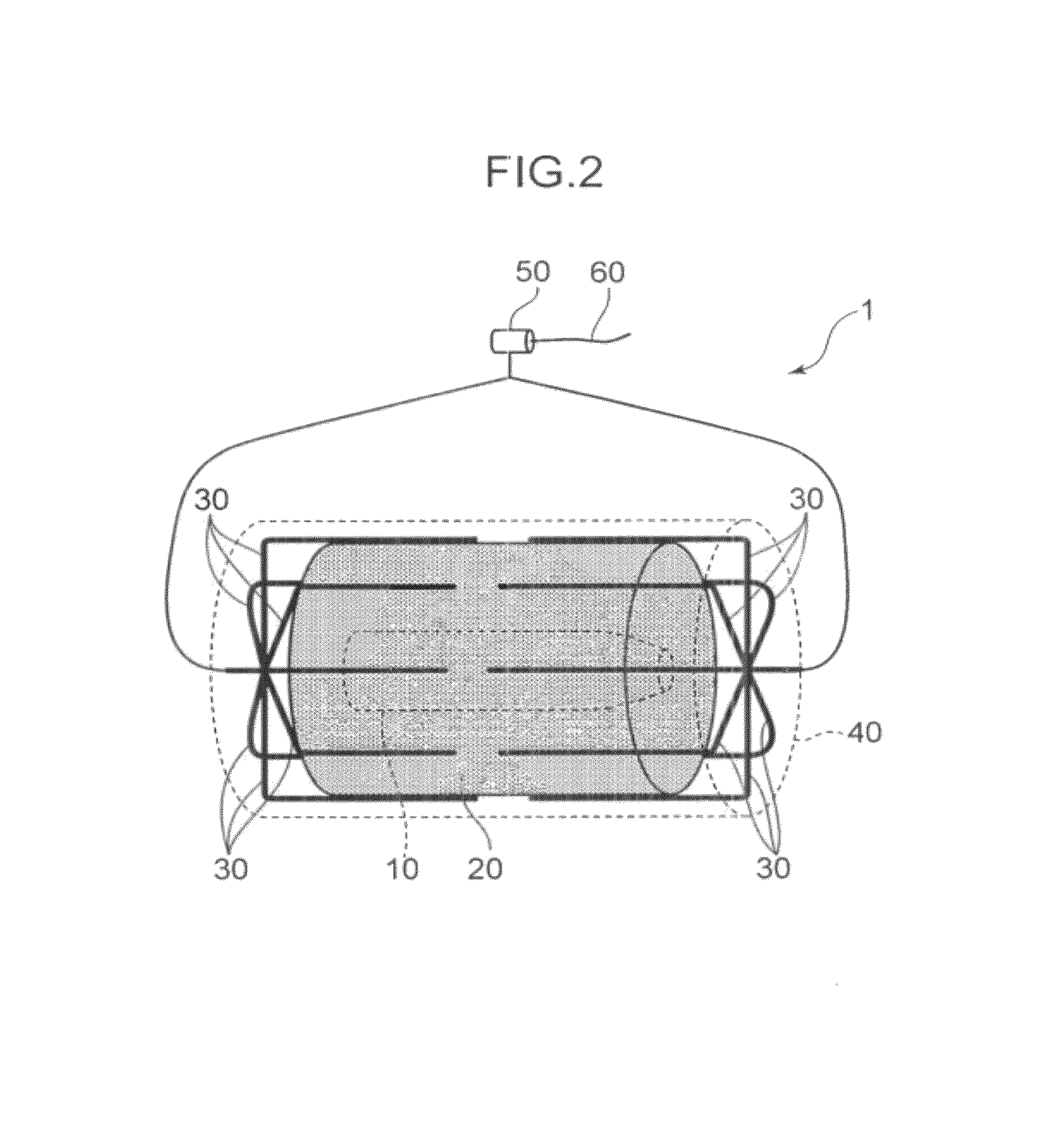

Provided is a blast treatment method that can be implemented simply and efficiently blast a treatment subject while preventing fragments of the subject from scattering outward. The blast treatment method is used to blast a treatment subject 10 having a bursting charge 12 and a shell 11, and includes: an inside explosive disposing step of arranging an inside explosive 20 to be used to blast the treatment subject 10 around the treatment subject 10; an outside explosive disposing step of arranging an outside explosive 34 having a greater detonation velocity than the inside explosive 20 at positions on an outer side of the inside explosive 20; and a blast step of simultaneously initiating detonation of the outside explosive 34 at a plurality of positions spaced from each other at predetermined intervals along a particular direction to thereby simultaneously initiate detonations of the inside explosive 20 at a plurality of positions along the particular direction by the detonation of the outside explosive 34, and thereby blasting the treatment subject in such a manner that the detonations of the inside explosive 20 are completed before the detonation of the bursting charge 12 initiated by the detonations of the inside explosive 20 is completed.

Owner:KOBE STEEL LTD

Convenient blast hole stemming device

ActiveCN107246830AImprove the accuracy of plugging operationIncrease profitBlastingCircular discExplosive Agents

The invention belongs to the technical field of blast charging and particularly relates to a convenient blast hole stemming device mainly composed of a handle, a bottom cover, a sleeve, a threaded rod, a buckle, a dowel bar base, a dowel bar, a disk and a tray. The convenient blast hole stemming device is characterized in that the tray is drawn from the sleeve and is built on a blast hole, a blast line is fixedly arranged on the tray, a stemming material is placed on the tray according to design length, the sleeve is fixed, the handle is rotated, the dowel bar base is pushed to advance under the rotation action of the threaded rod to drive the disk to advance to further push the stemming material to enter the blast hole, the handle is reversely rotated, the disk is retreated into the sleeve, the tray is pushed into the disk, and thus, the operation of blast hole stemming is completed. The convenient blast hole stemming device is simple in structure, convenient to use and capable of improving the operation precision of stemming and the stemming quality, reducing the manual labor intensity, also increasing the stemming efficiency, improving the blasting effect, increasing the utilization ratio of an explosive and reducing the construction cost.

Owner:ANHUI UNIV OF SCI & TECH

Fire extinguisher

The invention relates to a flame extinguisher comprising a container for extinguishing liquid and an inner bag used as a holder for a blasting charge.

Owner:POHLER CARL

Bidirectional shaped charge blasting charging structure with slotted sleeve

ActiveCN112393654APlay a guiding roleConcentrated explosion energyBlastingDetonationExplosive Agents

The invention relates to a bidirectional shaped charge blasting charging structure with a slotted sleeve, and belongs to the technical field of explosive blasting. The bidirectional shaped charge blasting charging structure comprises a sleeve, a shaped charge liner and explosive, wherein the sleeve is arranged in a blast hole in an inserted mode, the shaped charge liner is coaxially arranged in the sleeve and is filled with the explosive; through kerfs are formed in the two sides of the sleeve in the axial direction; the center lines of the two kerfs are coplanar with the axis of the sleeve; the two sides, close to the kerfs, of the shaped charge liner are sunken inwards in a V shape to form a wedge-shaped shaped charge groove; and the outer side edge of the shaped charge liner is fixedlyconnected to the inner wall of the sleeve through an axial supporting partition plate. According to the bidirectional shaped charge blasting charging structure, detonation energy can be concentrated in the specific direction, the utilization rate of the explosion energy is increased, damage to rock mass in other directions is reduced, and a smooth wall surface is conveniently formed.

Owner:ARMY ENG UNIV OF PLA

Novel firework bursting charge

InactiveCN103739413AEasy to operateReduce sensitivityInorganic oxygen-halogen salt explosive compositionsPotassiumFireworks

The invention relates to a firework bursting charge, which belongs to the firework field. The novel firework bursting charge is composed of 60-70 parts of charcoal powder, 15-25 parts of potassium perchlorate and 5-15 parts of potassium biphthalate by weight. Compared with the prior art, the potassium biphthalate has the following advantages that 1)the operation is simple, a few white explosive is not required in the firework bursting charge; and 2) the bursting charge sensitivity is reduced, and the safety coefficient is increased.

Owner:JIANGXI PROVINCE LIDU FIREWORKS

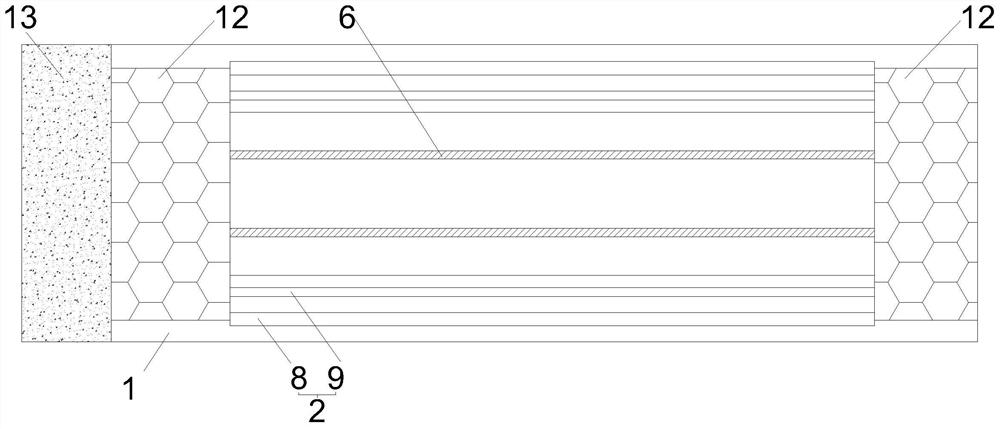

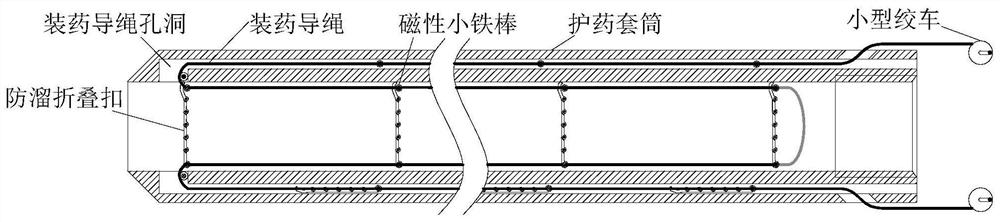

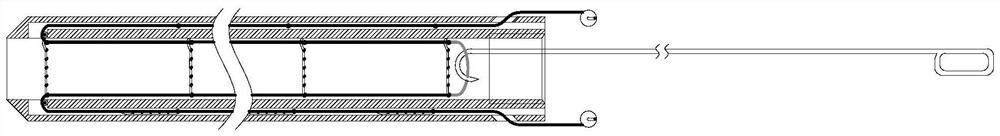

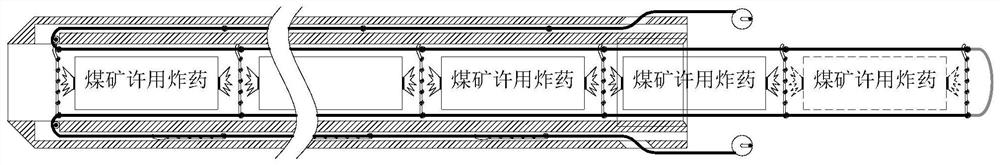

Coal mine underground deep hole blasting charging method

The invention discloses a coal mine underground deep hole blasting charging method, and relates to the technical field of mine blasting. Due to the fact that when deep hole blasting construction is conducted under a coal mine, in an original charging method, an anchor cable of 30 m is originally adopted to push explosive cartridges with the length of about 50 cm to the bottom of a hole section by section in the charging process, operation is quite complex and low in efficiency, time and labor are wasted, and the labor cost is high, the coal mine underground deep hole blasting charging method is invented. According to the method, the coal mine underground deep hole blasting charging device is designed, and the charging device is simple in structure and easy and convenient to operate. By means of the method and the explosive charging device, the explosive charging process is safer, more convenient and more efficient, the labor intensity of workers is greatly reduced, the working efficiency is improved, meanwhile, in the method, drilling equipment is fully utilized, the explosive charging quality is guaranteed, the blasting effect is improved, safety in the construction process is also guaranteed, and the method has great significance in guiding safety production for subsequent coal mine production design.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

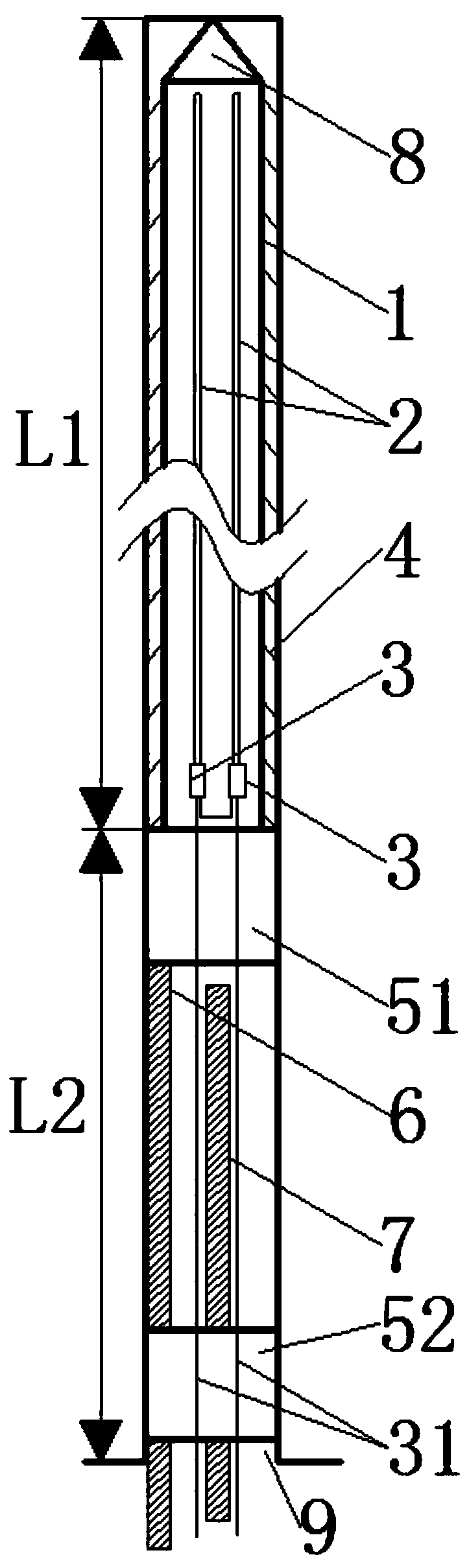

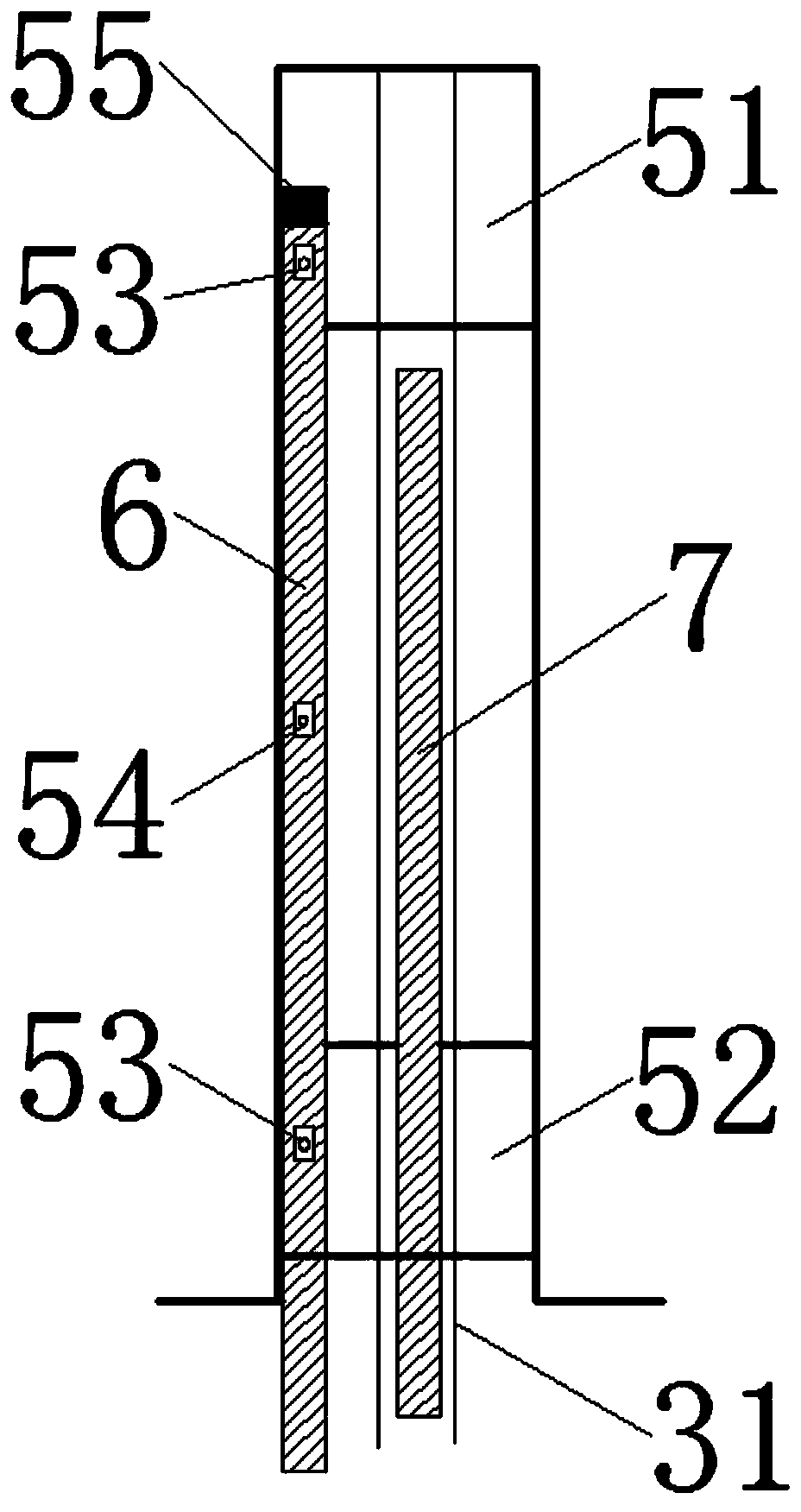

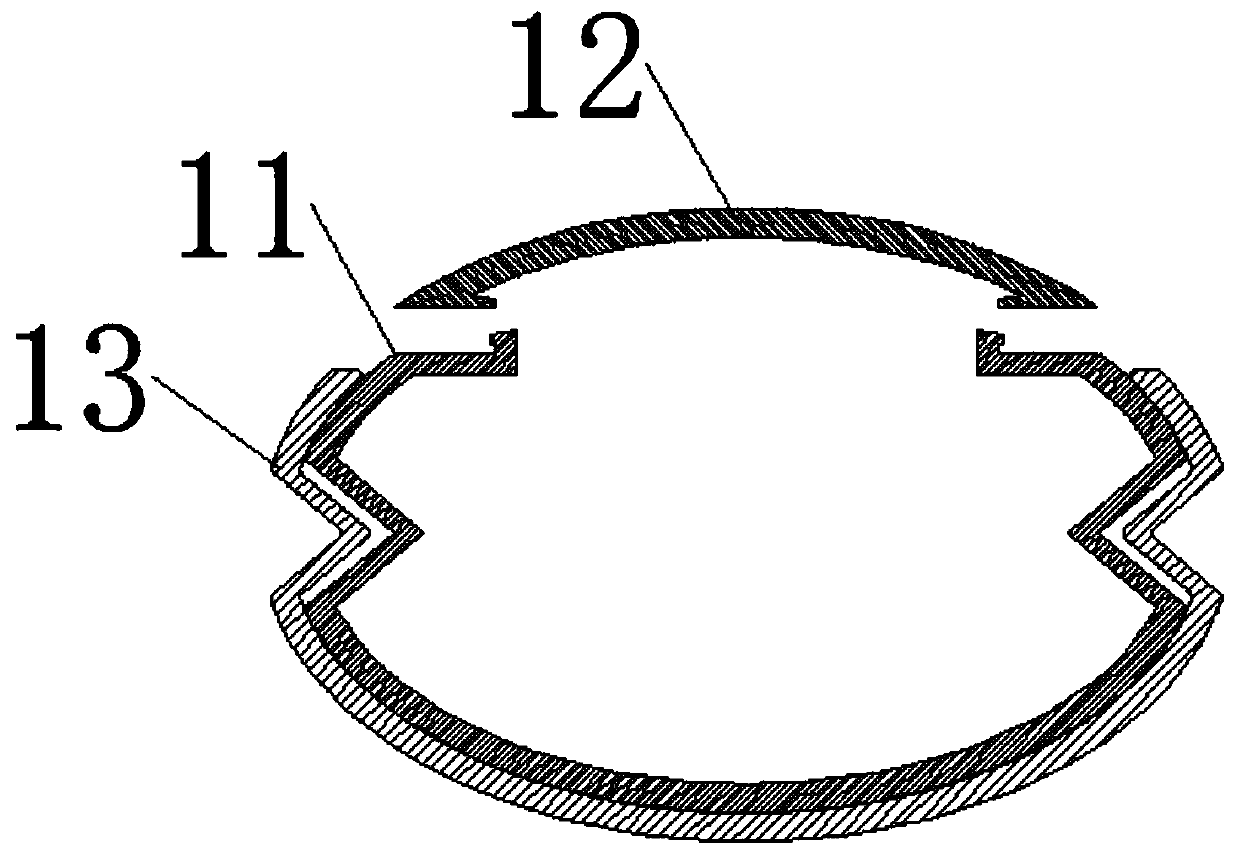

Deep hole blasting charging hole sealing device and using method thereof

The invention provides a deep hole blasting charging hole sealing device and a using method thereof. The deep hole blasting charging hole sealing device comprises a blasting tube, a detonating cord, an electric detonator, a hole sealing bag, a grouting tube and an exhaust slurry return tube; the blasting tube comprises a plurality of pipeline units which are tightly connected end to end; the detonating cord is arranged in the blasting tube; the electric detonator is located at one end of the detonating cord at the tail part of the blasting tube and is connected with the electric detonator; thehole sealing bag comprises a first hole sealing bag and a second hole sealing bag, and a grouting area is formed in a space between the first hole sealing bag and the second hole sealing bag; one endof the grouting tube penetrates through the second hole sealing bag and is inserted into the first hole sealing bag through the grouting area; and one end of the exhaust slurry return tube penetratesthrough the second hole sealing bag and enters the grouting area. The deep hole blasting charging hole sealing device is convenient to construct and operate, time-saving, labor-saving, low in cost, capable of greatly improving the construction efficiency, and high in hole sealing quality and safety, normal initiation is ensured, and blasting punching and blown-out shot are avoided.

Owner:河南力行科创矿山技术开发有限公司

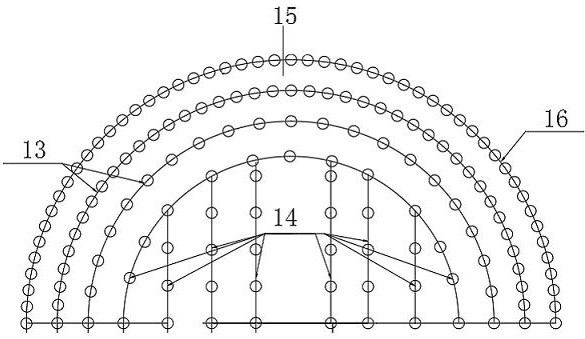

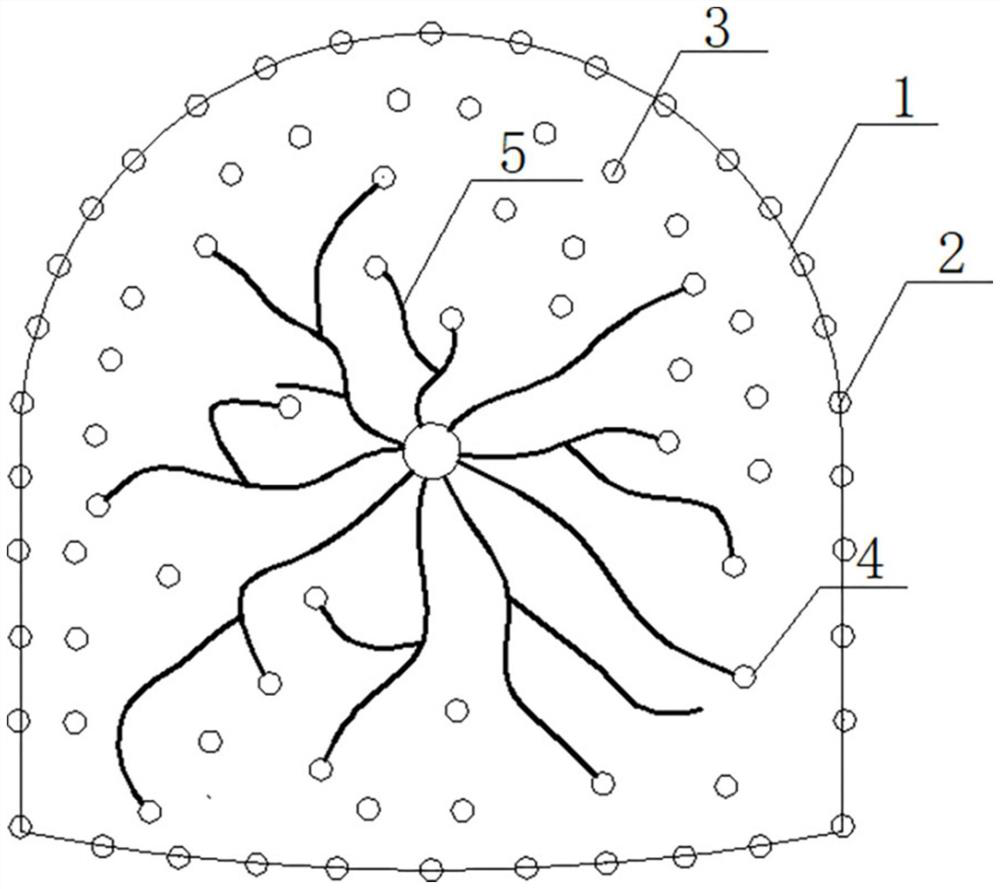

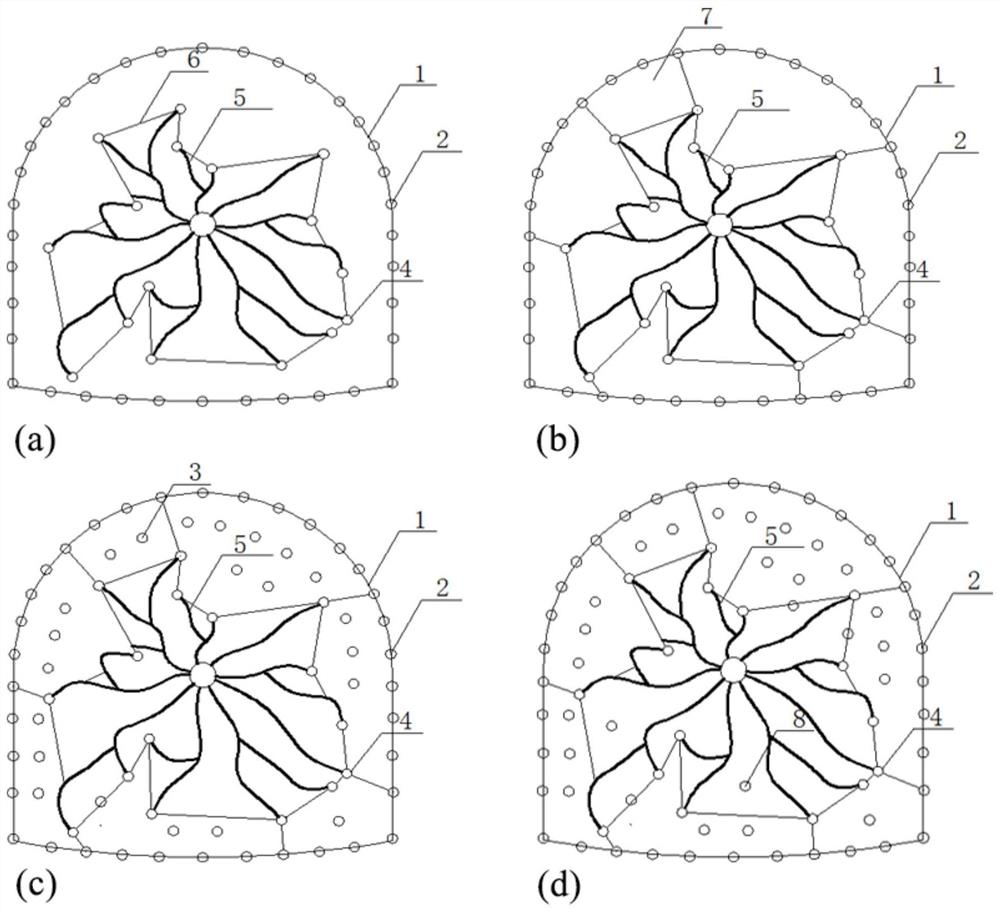

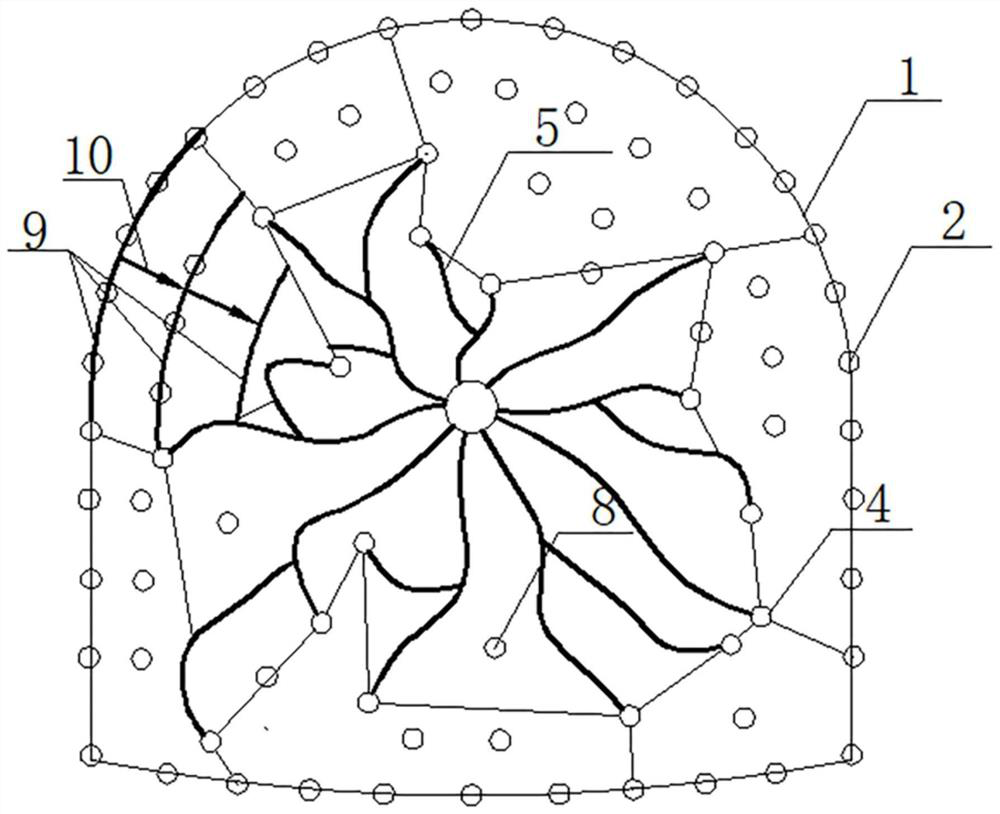

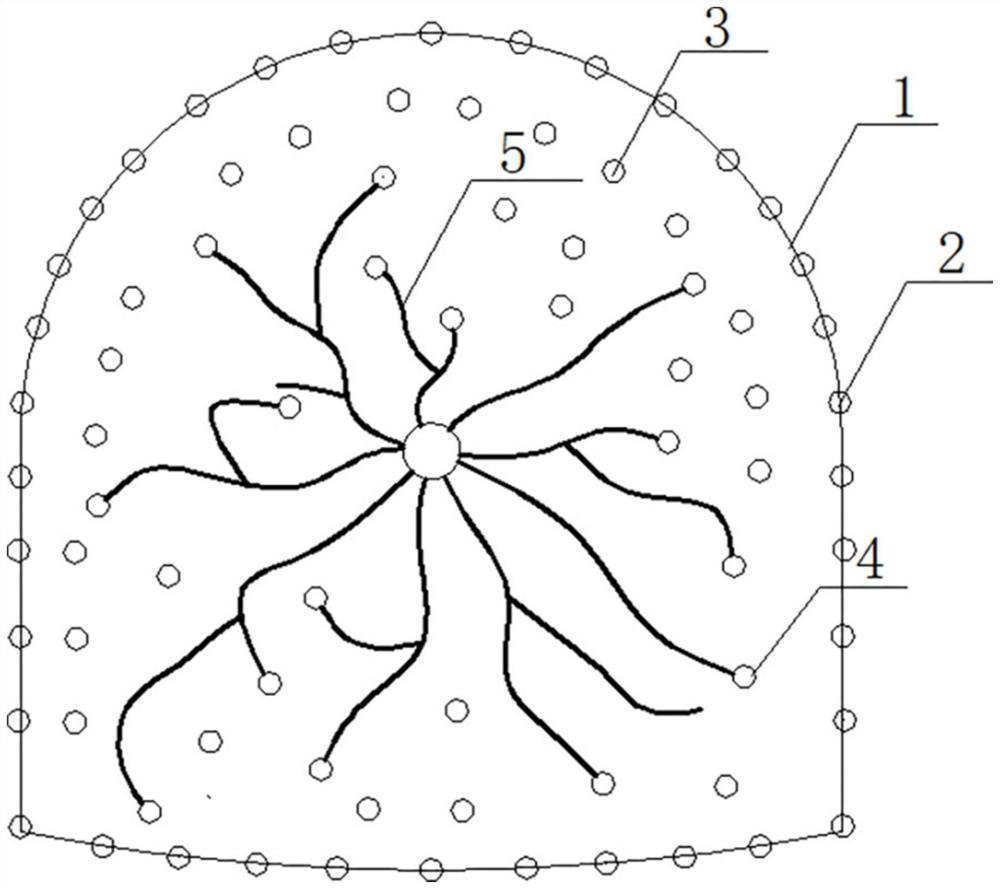

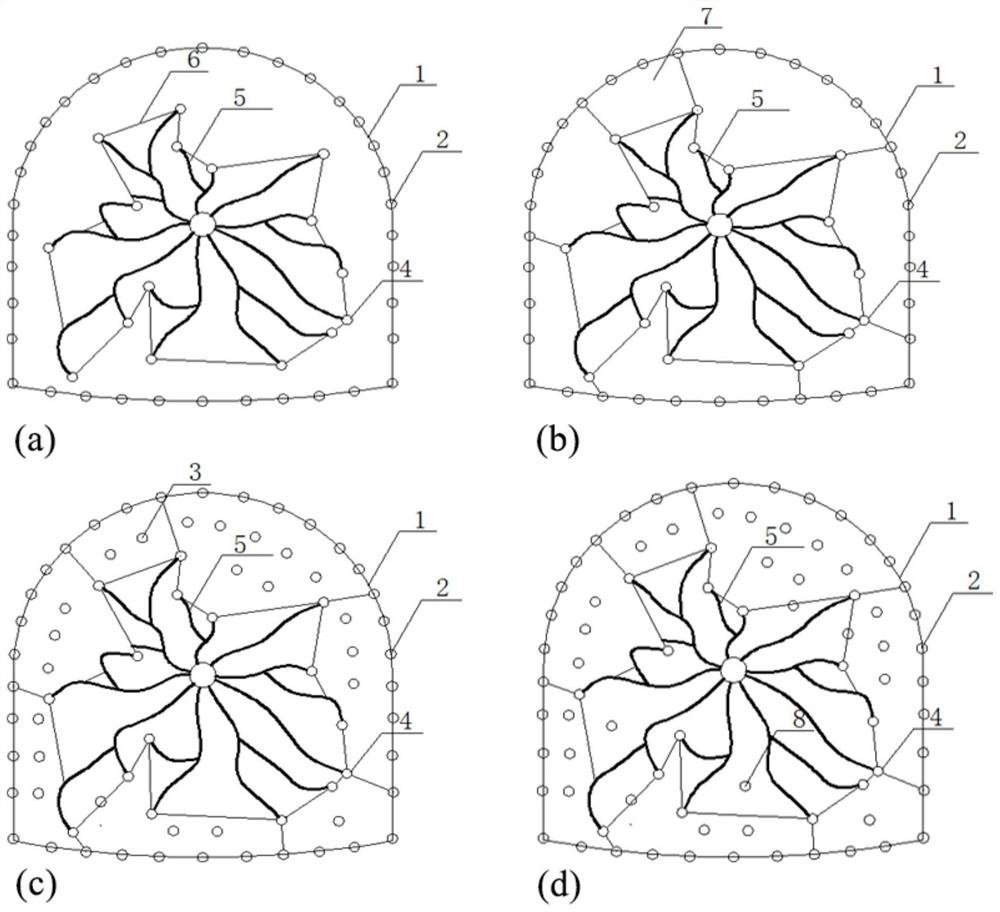

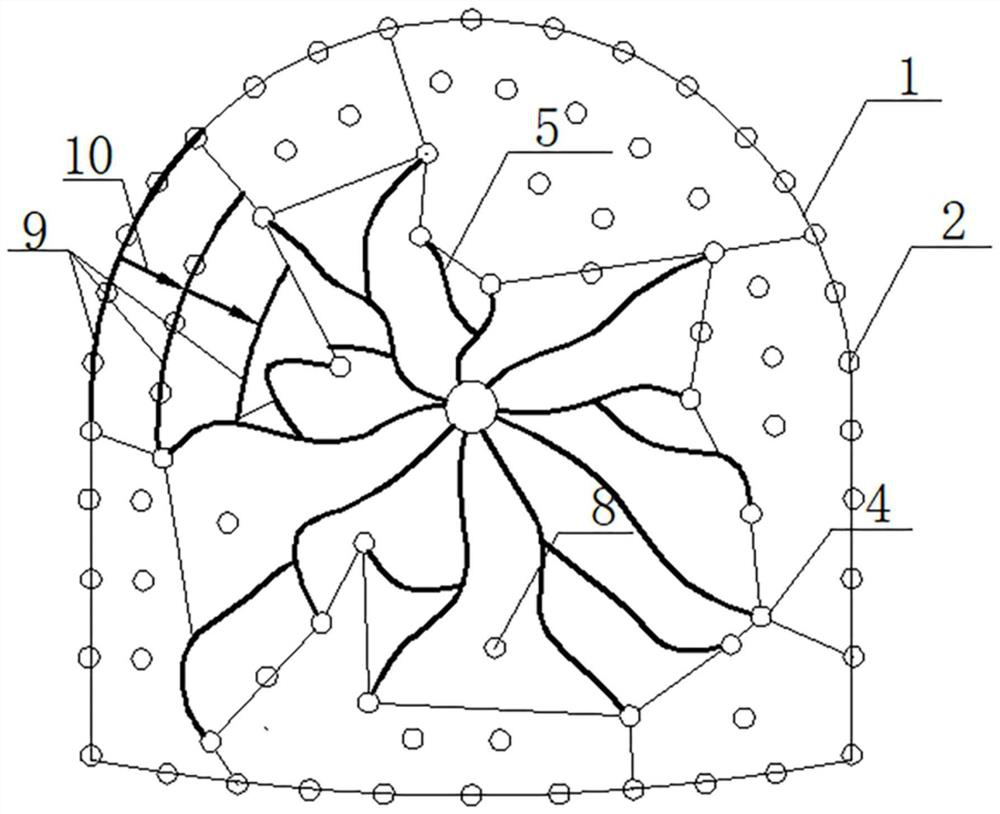

Tunnel blasting intelligent hole distribution method

The invention discloses a tunnel blasting intelligent hole distribution method which comprises the following steps: perforating periphery holes and positioning holes, blasting the periphery holes andthe positioning holes, precisely positioning and arranging cutting holes and auxiliary holes; blasting the cutting holes and the auxiliary holes; carrying out powder charge on the periphery holes according to smooth blasting; adopting a non-coupling charging structure to blast the periphery holes first; enabling the positioning holes to be at the center of the mass point of an excavation face, andadopting an energy-gathering hydraulic pressure blasthole device; and after blasting the positioning holes, according to the crack development direction, adopting a positioning device to determine the cutting hole positions, determining the auxiliary hole positions by combining with a calculation method, then, blasting the cutting holes, and finally blasting the auxiliary holes. According to thetunnel blasting intelligent hole distribution method, the blasthole positions are positioned through the crack development direction, the explosive detonation energy is utilized to the maximum, levelling of the overall outline is ensured after blasting the periphery holes, the explosive usage amount is greatly reduced, the economic cost and disturbance of blasting impact to surrounding rock mass are reduced, and the overall blasting effect is safe and reliable.

Owner:NANJING INST OF RAILWAY TECH

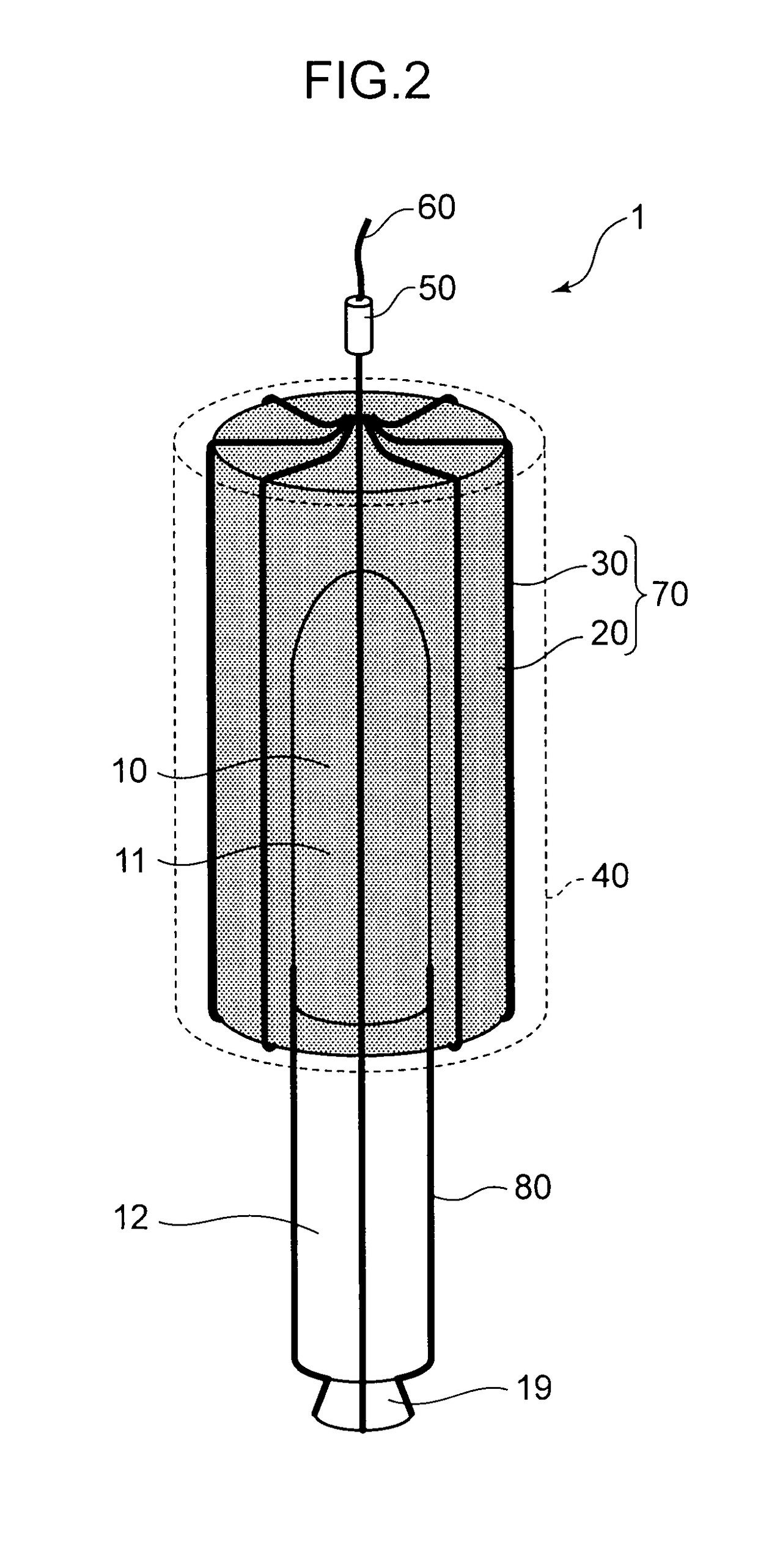

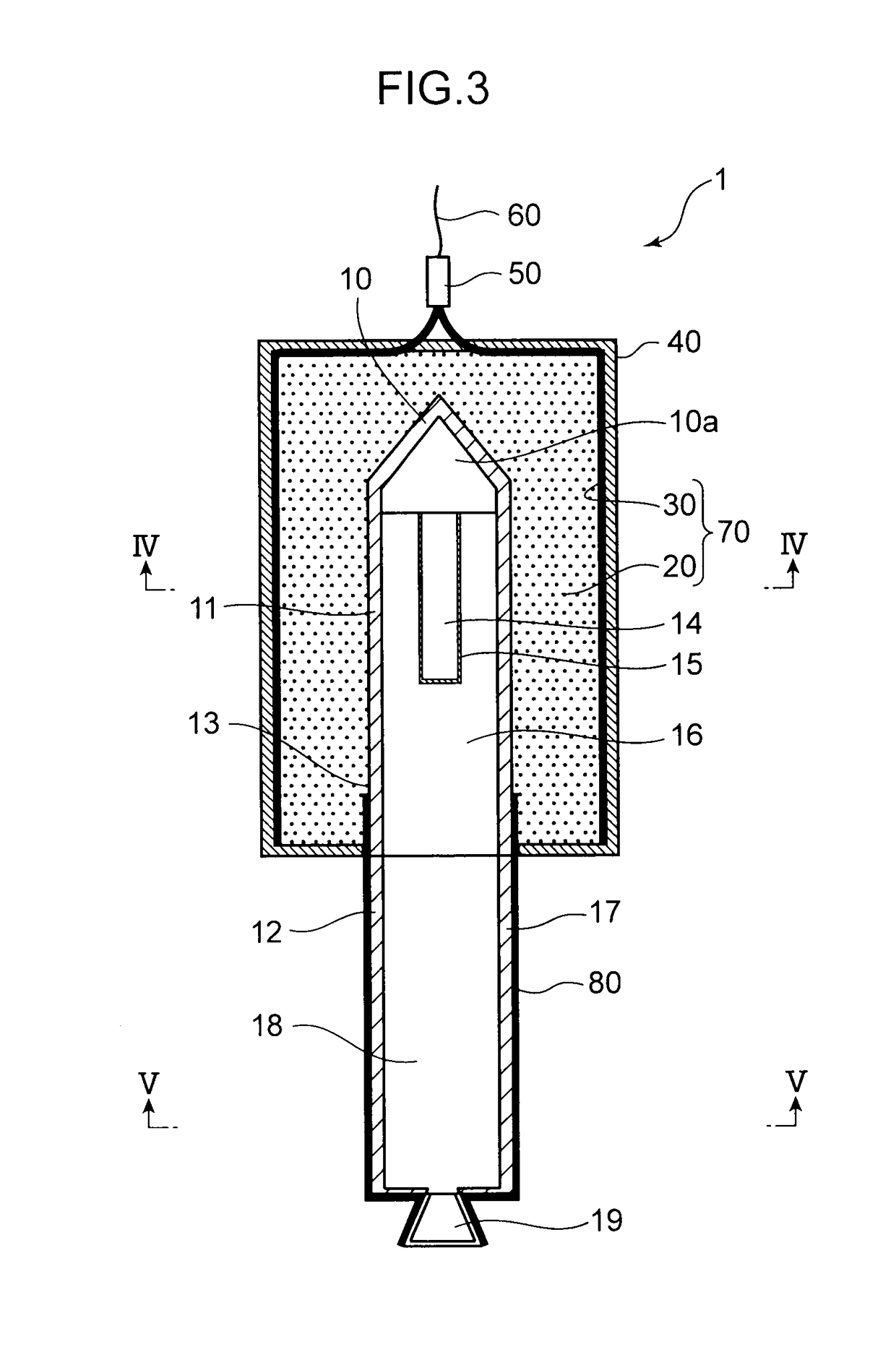

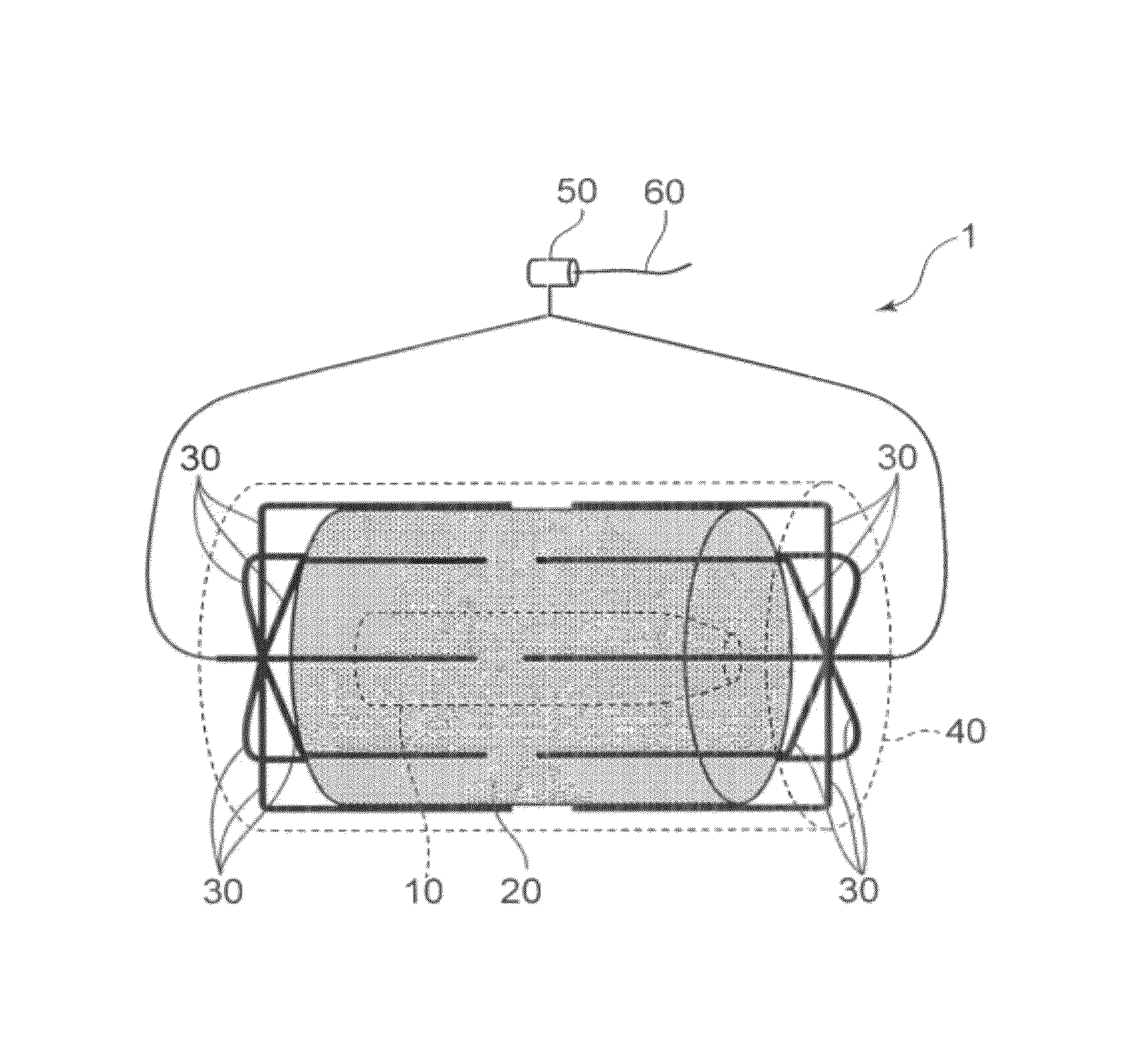

Blast treatment method and blast treatment device

InactiveUS8468945B2Simple configurationTreatment safetyDefence devicesBlasting cartridgesCombustionBurst charge

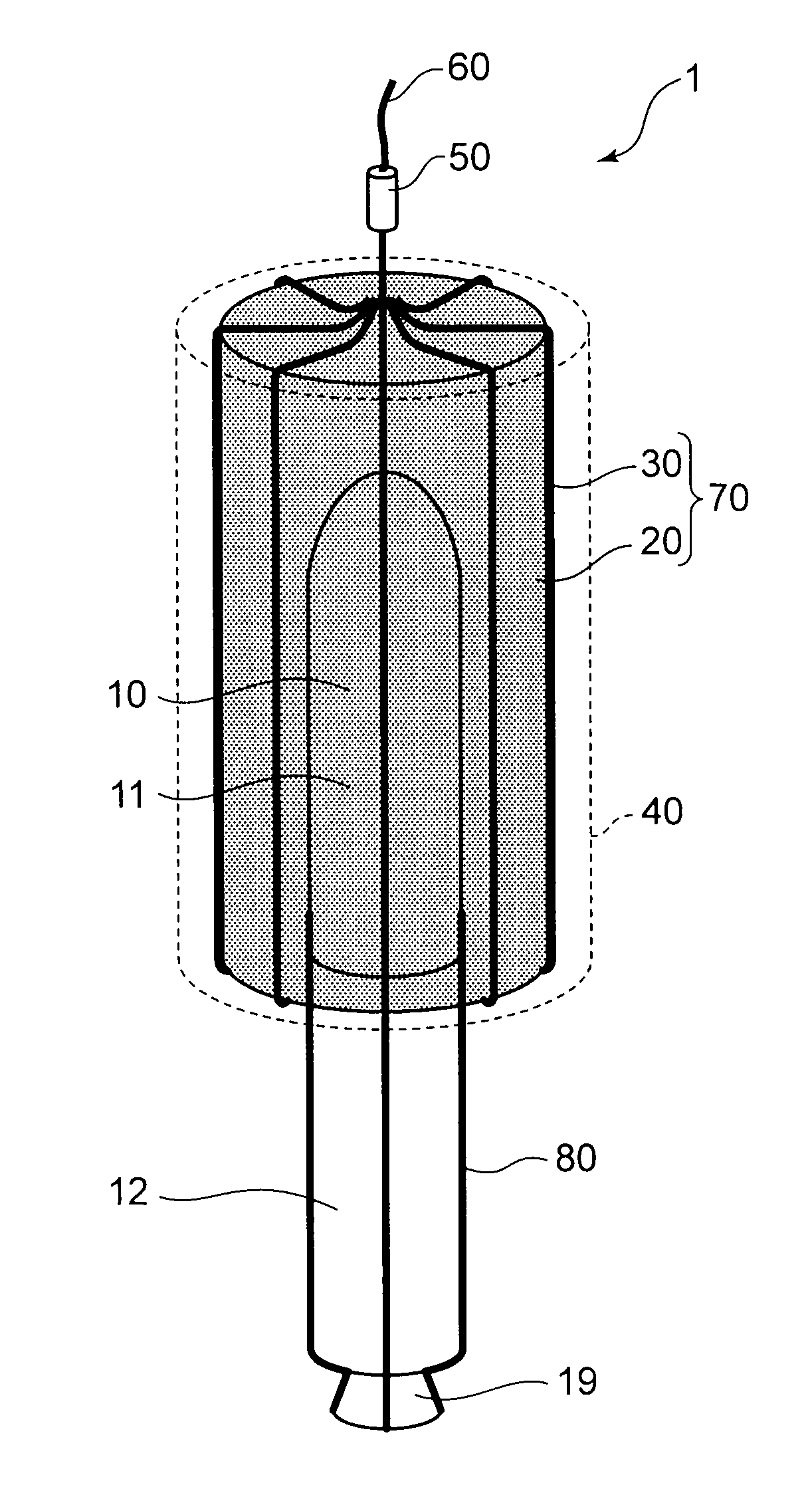

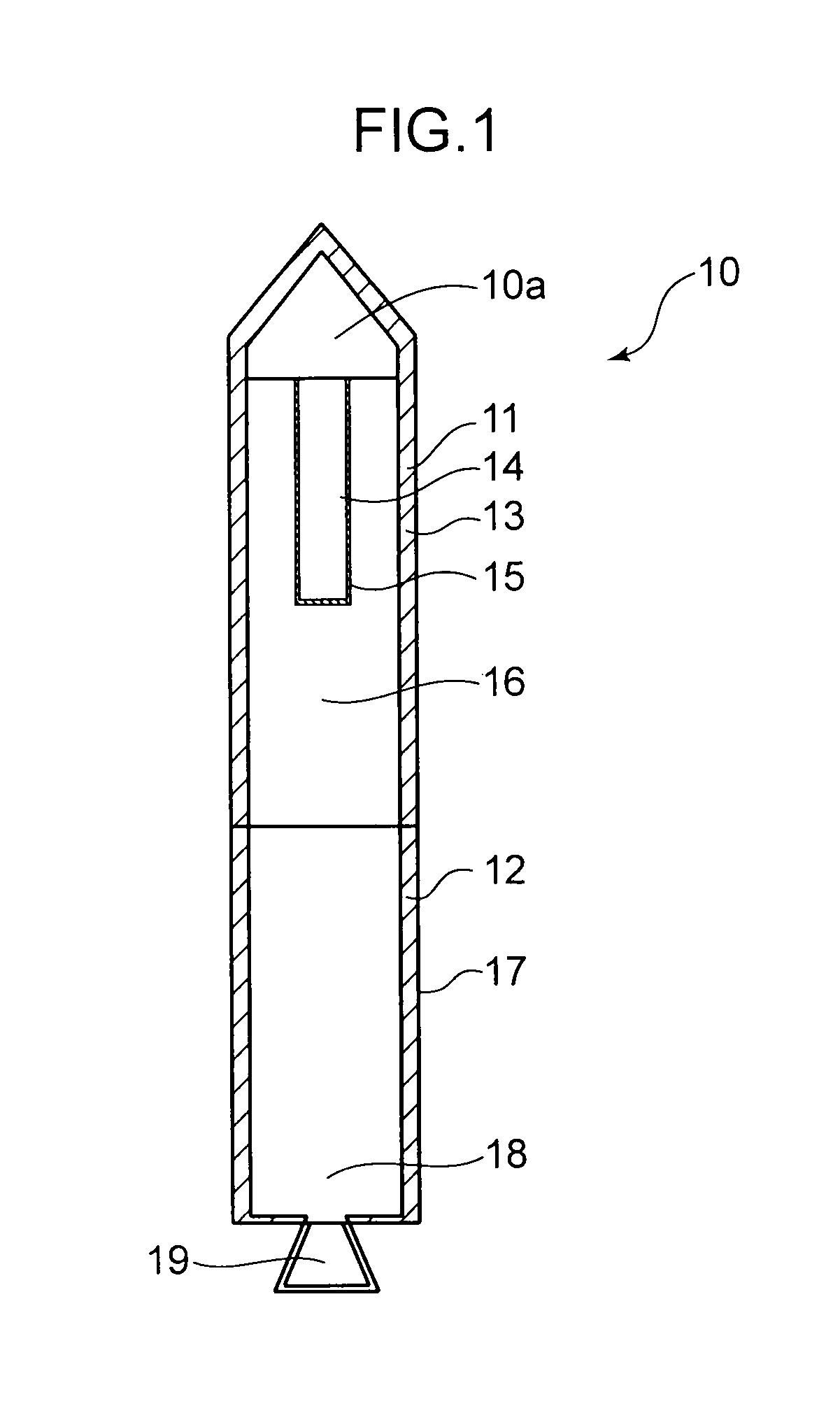

A blast treatment method enables easy and safe blast treatment of ammunition having propellant provided with a warhead having a bursting charge and a propulsion unit having a propellant. Comprised are a first explosive arrangement step of arranging a first explosive 70 on the outside of a warhead 11; a second explosive arrangement step of arranging a plurality of explosive members 80 including a second explosive 84 on the outside of the propulsion unit 12; a warhead blast step of causing detonation of a bursting charge 14 by detonation of a first explosive 70, thereby blasting the warhead 11; and a propulsion unit treatment step of causing deflagration of a propellant 18 by detonation of the second explosive 84, thereby performing combustion of the propulsion unit 12; the first explosive 70 is arranged at a position covering the periphery of the warhead 11, a high-pressure field is generated on the periphery of the warhead 11 by detonation of this first explosive 70, and by means of this high-pressure field, divergence of detonation energy of the bursting charge 14 to outside this high-pressure field is suppressed, and moreover the explosive members 80 are arranged at mutually separated positions whereby divergence of the combustion energy of the propellant 18 to the outside from the explosive members 80 is allowed, by which detonation of the propellant 18 is suppressed.

Owner:KOBE STEEL LTD

Remotely controlled ignition system for pyrotechnics

A remote pyrotechnic ignition system includes a power supply for producing an electrical current in a transmitting induction coil to induce an electrical current in a receiving induction coil for igniting a pyrotechnic device. Thus, a wireless ignition communication section allows pyrotechnic mortars to be reused and substantially reduces set-up time by eliminating the wiring of fireworks normally required for a pyrotechnic production. Optionally, a capacitor is charged by the power source via a charging circuit and discharged via a firing circuit to produce the electric current in the transmitting coil in a pulse. The capacitor provides a two-stage firing safety feature. An electronic control device such as a circuit board may be mounted on the pyrotechnic device for controlling ignition of the pyrotechnic device and is especially useful in controlling ignition sequencing and overall ignition timing of a lift charge and burst charge of the pyrotechnic device.

Owner:DEYE JAMES G

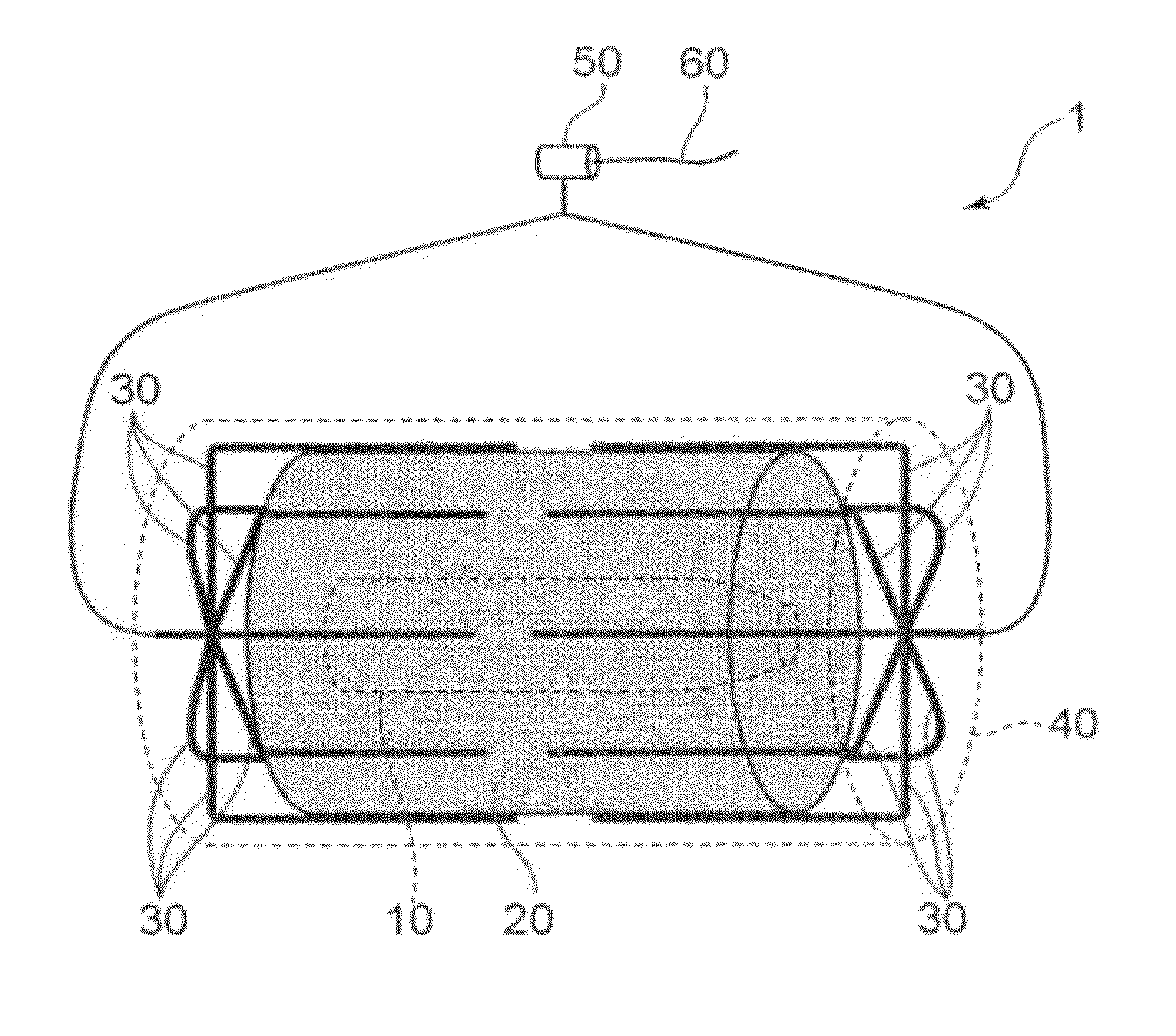

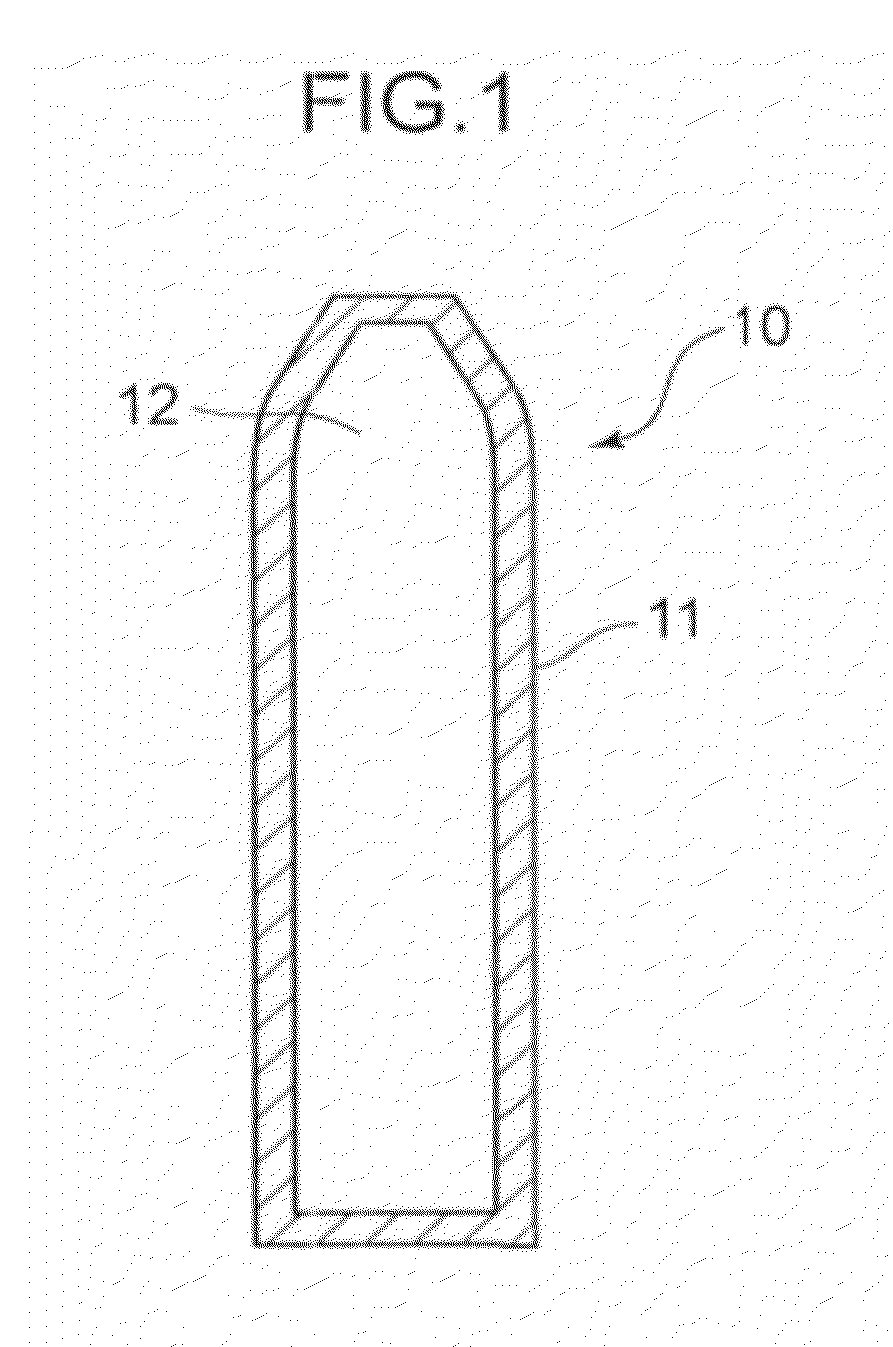

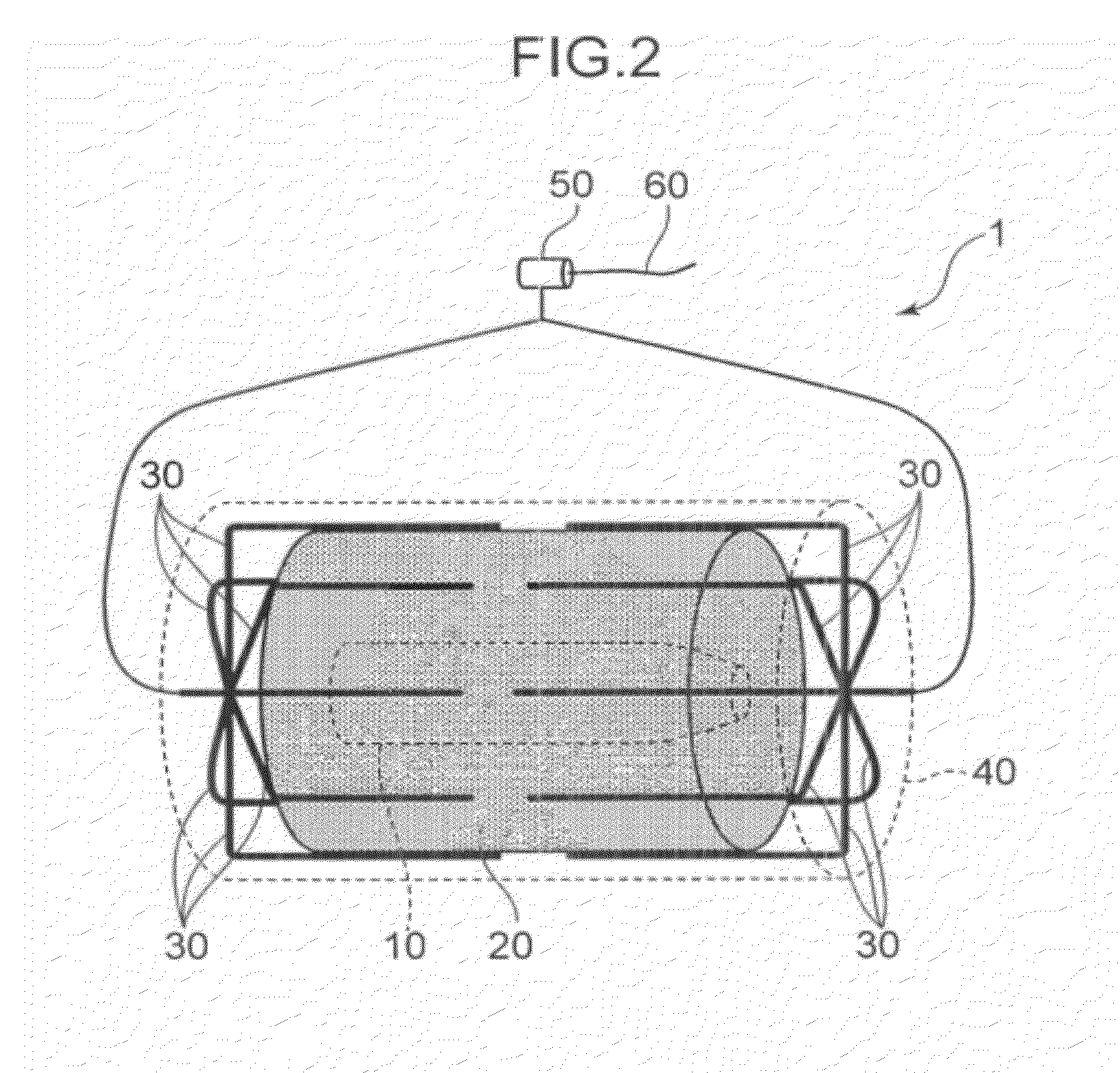

Blast treatment method and blast treatment device

Provided is a blast treatment method that can be implemented simply and efficiently blast a treatment subject while preventing fragments of the subject from scattering outward. The blast treatment method is used to blast a treatment subject 10 having a bursting charge 12 and a shell 11, and includes: an inside explosive disposing step of arranging an inside explosive 20 to be used to blast the treatment subject 10 around the treatment subject 10; an outside explosive disposing step of arranging an outside explosive 34 having a greater detonation velocity than the inside explosive 20 at positions on an outer side of the inside explosive 20; and a blast step of simultaneously initiating detonation of the outside explosive 34 at a plurality of positions spaced from each other at predetermined intervals along a particular direction to thereby simultaneously initiate detonations of the inside explosive 20 at a plurality of positions along the particular direction by the detonation of the outside explosive 34, and thereby blasting the treatment subject in such a manner that the detonations of the inside explosive 20 are completed before the detonation of the bursting charge 12 initiated by the detonations of the inside explosive 20 is completed.

Owner:KOBE STEEL LTD

Blast treatment method and blast treatment device

InactiveUS20120017752A1Safe blastingOccurrence is suppressedDefence devicesBlasting cartridgesCombustionBurst charge

A blast treatment method enables easy and safe blast treatment of ammunition having propellant provided with a warhead having a bursting charge and a propulsion unit having a propellant. Comprised are a first explosive arrangement step of arranging a first explosive 70 on the outside of a warhead 11; a second explosive arrangement step of arranging a plurality of explosive members 80 including a second explosive 84 on the outside of the propulsion unit 12; a warhead blast step of causing detonation of a bursting charge 14 by detonation of a first explosive 70, thereby blasting the warhead 11; and a propulsion unit treatment step of causing deflagration of a propellant 18 by detonation of the second explosive 84, thereby performing combustion of the propulsion unit 12; the first explosive 70 is arranged at a position covering the periphery of the warhead 11, a high-pressure field is generated on the periphery of the warhead 11 by detonation of this first explosive 70, and by means of this high-pressure field, divergence of detonation energy of the bursting charge 14 to outside this high-pressure field is suppressed, and moreover the explosive members 80 are arranged at mutually separated positions whereby divergence of the combustion energy of the propellant 18 to the outside from the explosive members 80 is allowed, by which detonation of the propellant 18 is suppressed.

Owner:KOBE STEEL LTD

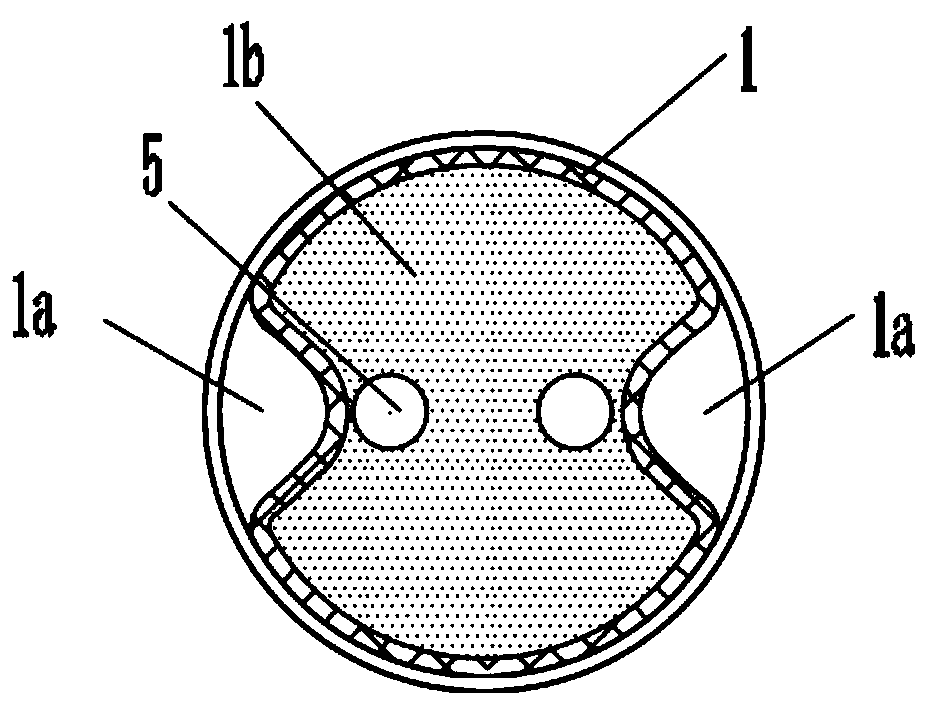

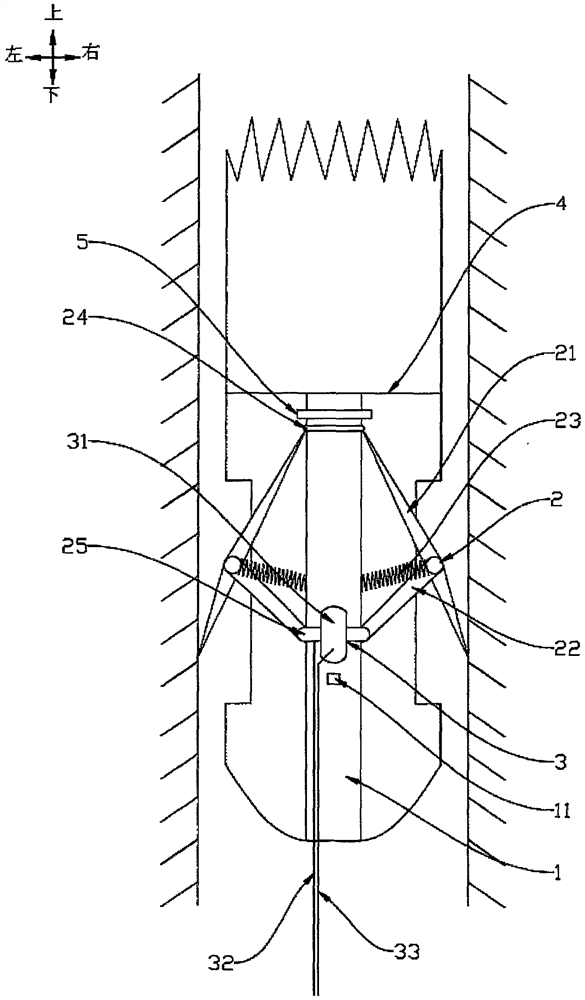

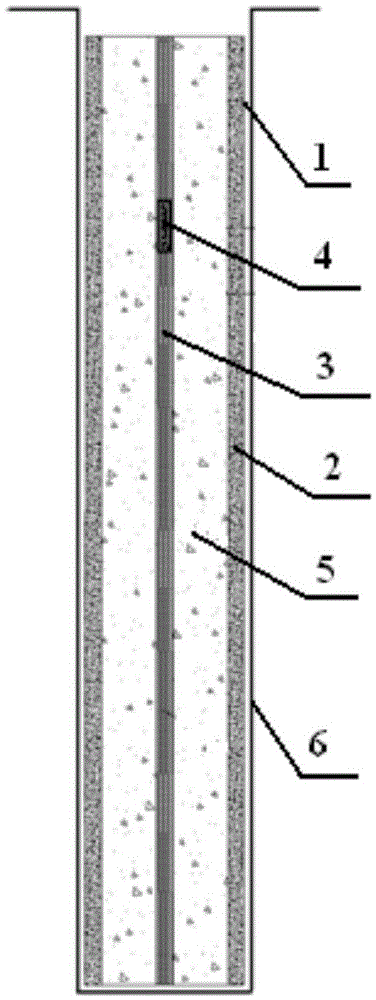

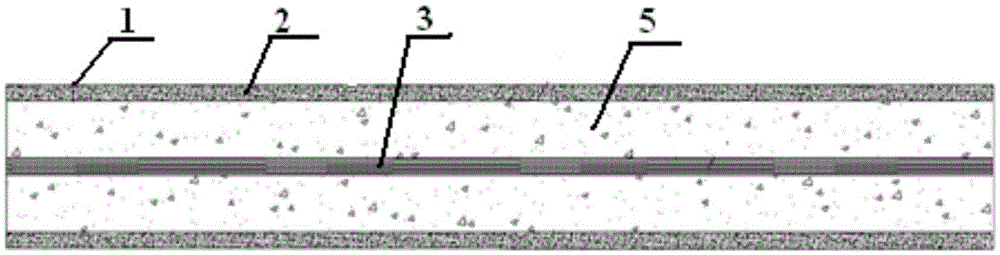

Presplitting blasting and charging combined structure and method

InactiveCN110671983AEasy to makeIncrease contact areaBlastingArchitectural engineeringStructural engineering

The invention provides a presplitting blasting and charging combined structure and method. The presplitting blasting and charging combined structure comprises at least formed charging explosive columnand at least one PVC pipe. Each charging explosive column is provided with a plastic shell with two ends sealed. The middle of each charging explosive column is provided with two detonating cord holes running through the charging explosive column. The two ends of a detonating cord penetrate through the two detonating cord holes of each charging explosive column in the same direction correspondingly. All the charging explosive columns are connected with the PVC pipes in series after the charging explosive column at the bottommost end is held. The presplitting blasting and charging combined structure is easier to manufacture, and only the explosive columns need to be customized through a die; the charging explosive columns and the PVC pipes are connected through the detonating cords, and the manufacturing cost is reduced; and no auxiliary tools need to be additionally used in the charging method, the operation process is simpler, and cost is lower.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

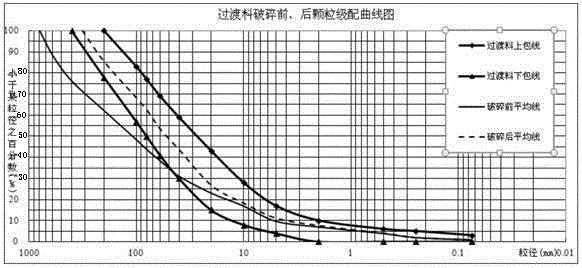

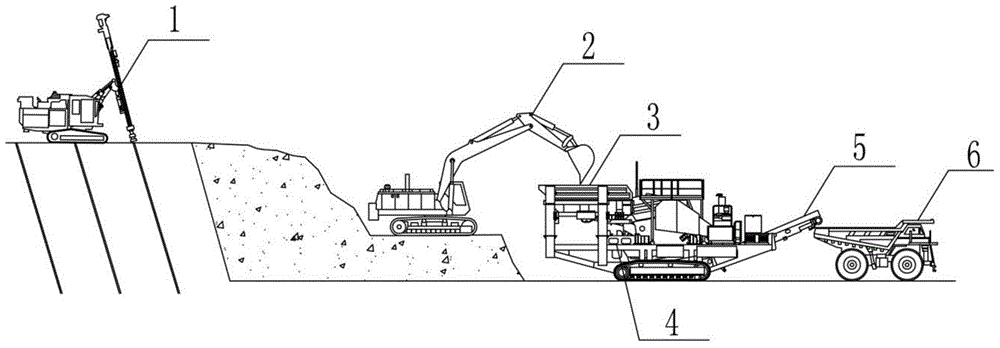

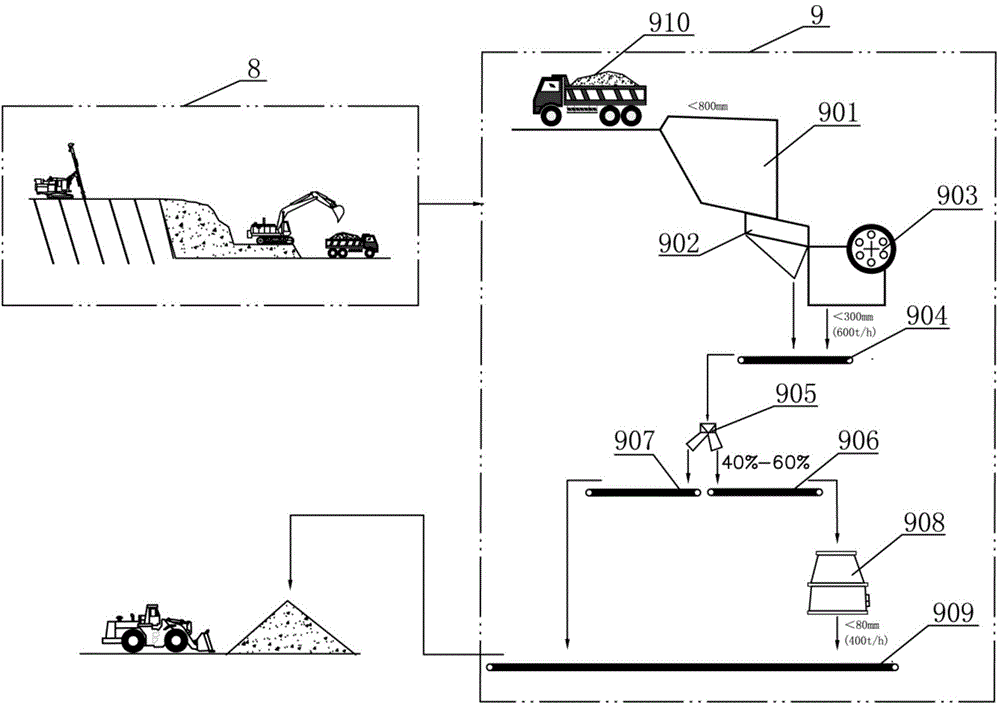

Integrated production technology of rock-fill dam high-standard transition material

ActiveCN104475215ASolve the problem of direct miningEnsure production qualityBlastingOpen-pit miningCrushed stoneEconomic benefits

An integrated production technology of a rock-fill dam high-standard transition material comprises the following steps: carrying out blasting exploitation on stones in an economic unit consumption manner; carrying out coarse crushing and middle crushing on the blasted stones, wherein the middle crushed stones account for 40-60% of the amount of the coarse crushed stones; carrying out mixing conveying on 10-40% of the coarse crushed stones and 40-60% of the middle crushed stones; and transporting the stones to a rock-fill dam construction filed through a self-unloading automobile. The technology solves the disadvantages of present blasting direct exploitation methods and sand and stone aggregate mixing methods, guarantees the quality of the transition material, and also has the characteristics of great reduction of the material field blasting cost, improvement of the bursting charge utilization rate, improvement of the construction benefit, and very substantial economic benefit.

Owner:SINOHYDRO BUREAU 5

Method and device for improving blasting propagation reliability of plastic film-packaged emulsified explosive

The invention provides a method and device for improving the blasting propagation reliability of a plastic film-packaged emulsified explosive. The method is characterized by comprising the steps that when blasting charging is conducted on site, the plastic film-packaged emulsified explosive is taken out first, one end of a plastic film-packaged emulsified explosive cartridge is inserted into the device, the explosive cartridge is rotated a round when the explosive cartridge is inserted into the portion, where a blade is arranged, of the bottom of the device, an explosive cartridge buckle and plastic film remnants are cut off and fall from a hole formed in the bottom, operation in the above steps is conducted on the other end of the explosive cartridge, blast hole charging is conducted on the explosive cartridge of which the two-end remnants are cut off, and then the charging continuity is guaranteed. The device is portable, simple and convenient to carry and can be used on a blasting construction site. The blade is arranged, and therefore the buckles and the plastic film remnants on the two end faces of the plastic film-packaged emulsified explosive can be cut off through the blade. According to the device, the buckles can be efficiently and quickly cut off, the on-site charging efficiency is improved, the blasting propagation reliability is improved, blasting sympathetic detonation incompletion is avoided, and the safety in blasting engineering is improved.

Owner:FUJIAN HAIXIA KEHUA FUXING CONSTR ENG CO LTD

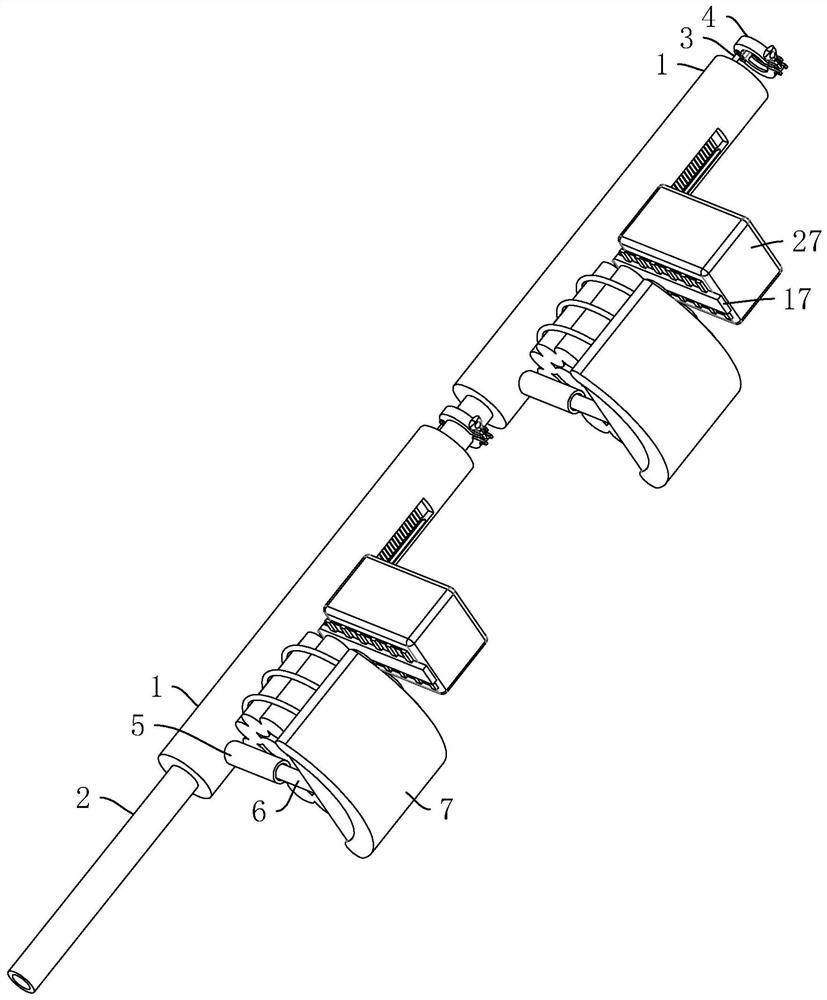

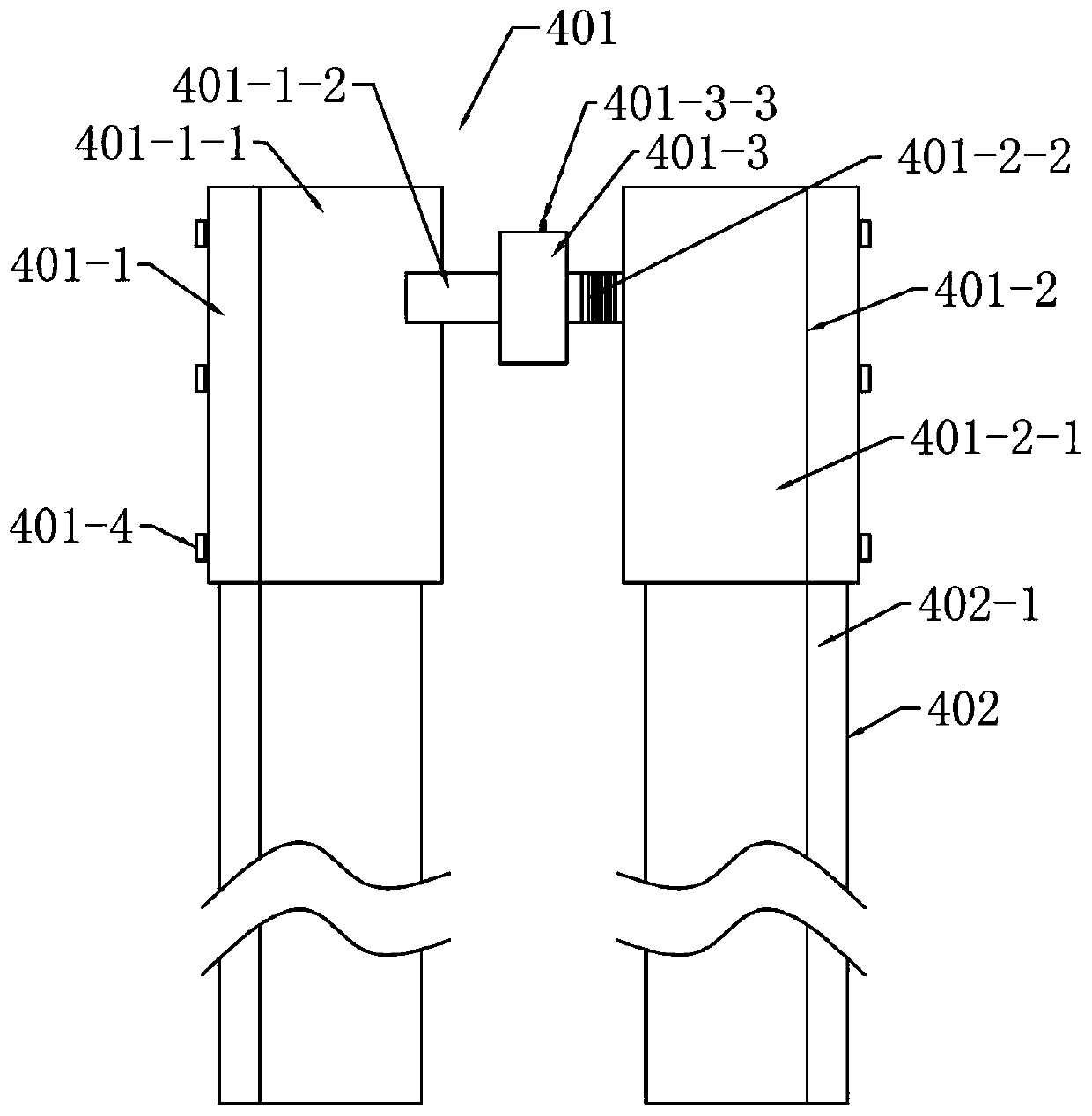

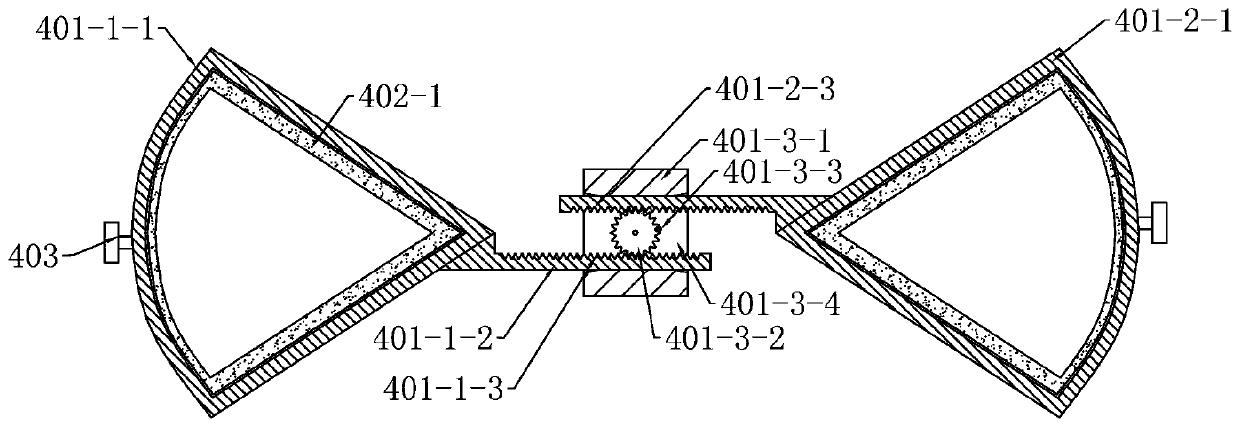

Bidirectional anti-skid device for blasting charge

The invention discloses a bidirectional anti-skid device for blasting charge. The bidirectional anti-skid device for the blasting charge comprises a guide rod, a supporting assembly and a control assembly, wherein the supporting assembly comprises a plurality of fixing pieces, a plurality of supporting rods, a plurality of supporting elastic pieces, a first axial ring and a second axial ring, one ends of the plurality of fixing pieces are pivoted to the first axial ring, the first ends of the plurality of supporting rods are pivoted to the second axial ring, the second ends of the plurality of supporting rods are hinged to the middles of the fixing pieces in a one-to-one correspondence mode, the first ends of the plurality of supporting elastic pieces are connected with the peripheral surface of the guide rod, the second ends of the plurality of supporting elastic pieces are hinged to the second ends of the supporting rods together in a one-to-one correspondence mode, and the control assembly is used for controlling the second axial ring to be away from or close to the first axial ring in the axial direction of the guide rod. The bidirectional anti-skid device for the blasting charge has the characteristics of being simple in structure and high in reliability.

Owner:CCTEG CHINA COAL RES INST +1

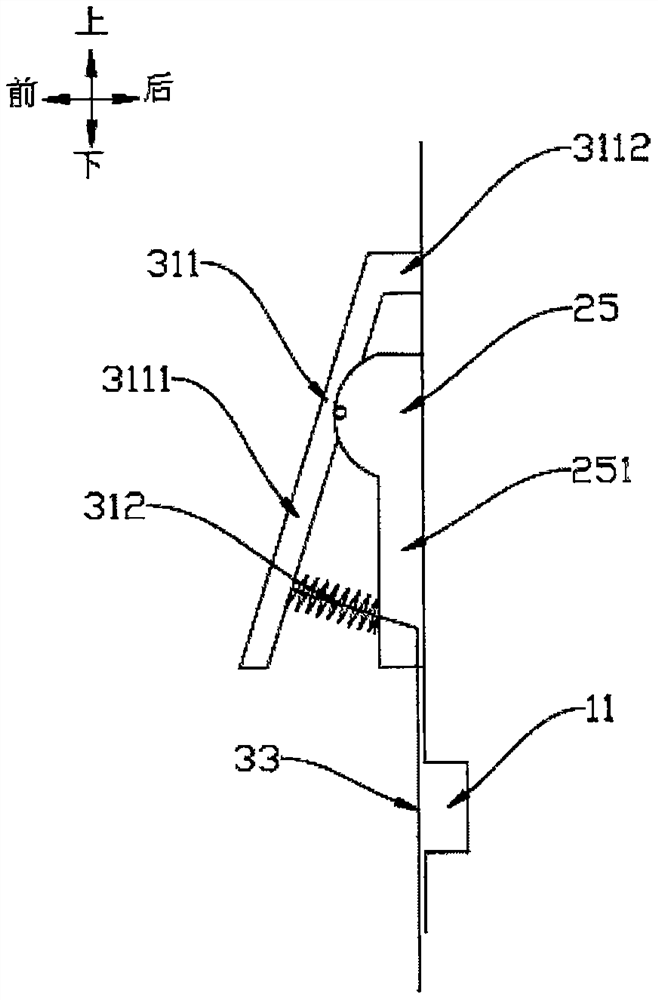

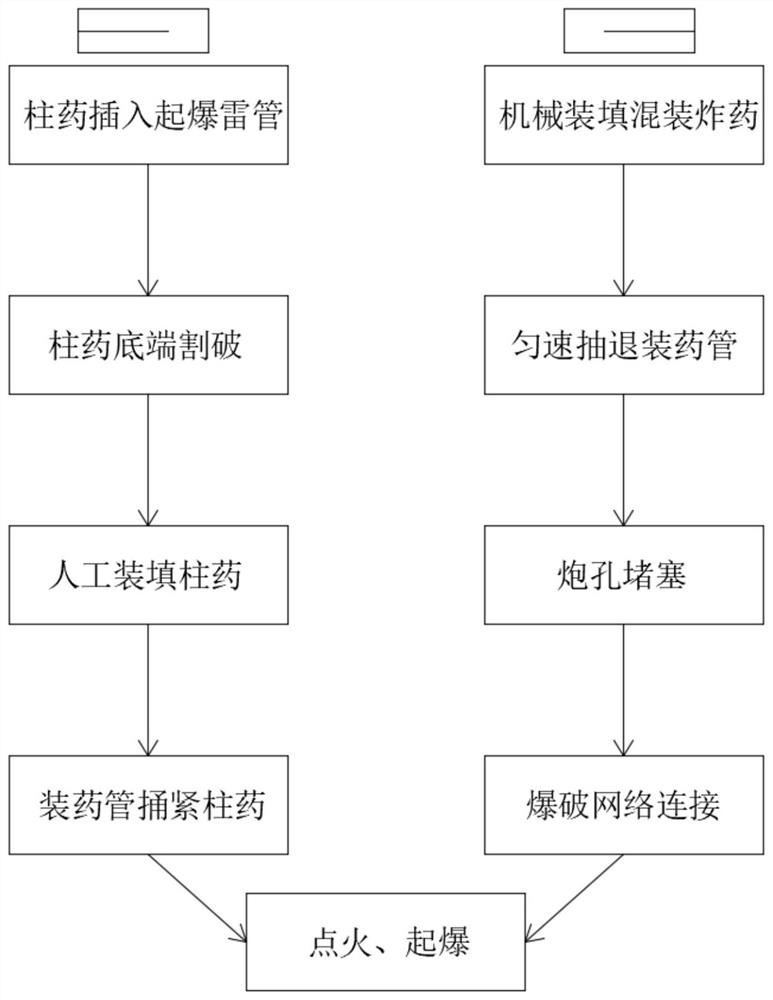

Filling method for primary explosive of blasting upward hole mixed explosive

ActiveCN113983884APrevent slippingGood effectBlastingOpen-pit miningExplosive AgentsStructural engineering

The invention belongs to the technical field of blasting, and relates to a filling method for the primary explosive of a blasting upward hole mixed explosive. The method comprises the following specific steps that: S1, a column explosive serves the primary explosive, and the bottom end of the column explosive is cut before explosive charging; S2, the column explosive is manually filled to the bottom of a blast hole, the column explosive is prevented from sliding towards the hole opening of the blast hole under the influence of self weight by means of the viscosity of the broken bottom end of the column explosive, and the column explosive is filled into an explosive tube so as to be poked tightly; S3, the mixed explosive is mechanically filled, the mixed explosive is completely coupled with the hole wall of the blast hole through continuous filling, the mixed explosive is not affected by the self weight of the initiating explosive, the mixed explosive is completely bonded with the hole wall of the blast hole after being foamed, excessive explosive returning can be avoided, and the blast hole is blocked; and S4, while the mixed explosive is mechanically loaded, an explosive loading tube is withdrawn at a constant speed. According to the method, the problem of explosive returning in the explosive charging process and after explosive charging is solved, the blasting explosive charging quality is ensured; the application effect of the method in a blast hole with the inclination angle being 60 degrees or above is extremely obvious, and particularly in a vertical hole of a cutting groove, and the explosive returning problem is solved.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

Electric match assembly with isolated lift and burst function for a pyrotechnic device

Electric match assembly for initiating a pyrotechnic device in response to a signal, the assembly comprising a first element for connection to a leader carrying the signal; a first electric match component for connection to the lift charge of the pyrotechnic device, the first electric match component being connected to the first element such that when the first element is connected to the leader and the first electric match component is connected to the lift charge, the signal is applied to the lift charge; a second electric match component for connection to the time fuse connected to the burst charge of the pyrotechnic device, the second electric match component being connected to the first element such that when the first element is connected to the leader and the second electric match component is connected to the time fuse, the signal is applied to the time fuse of the burst charge.

Owner:MAGICFIRE

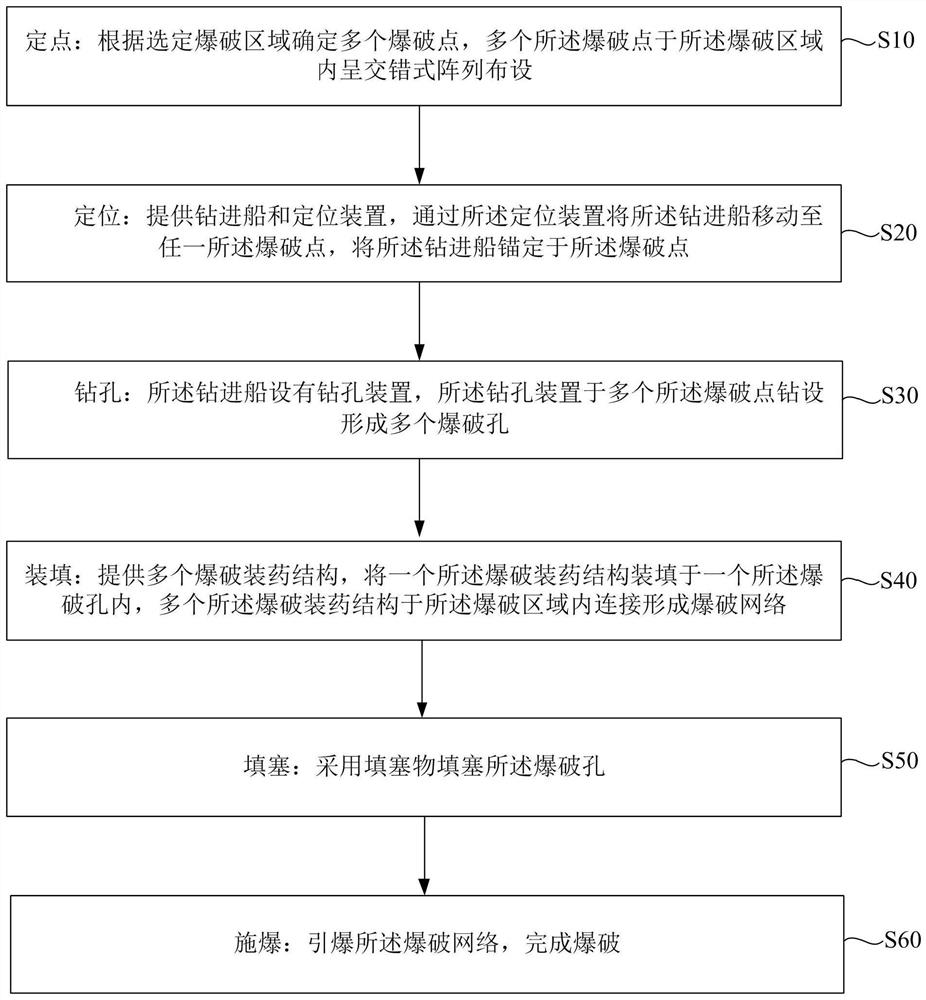

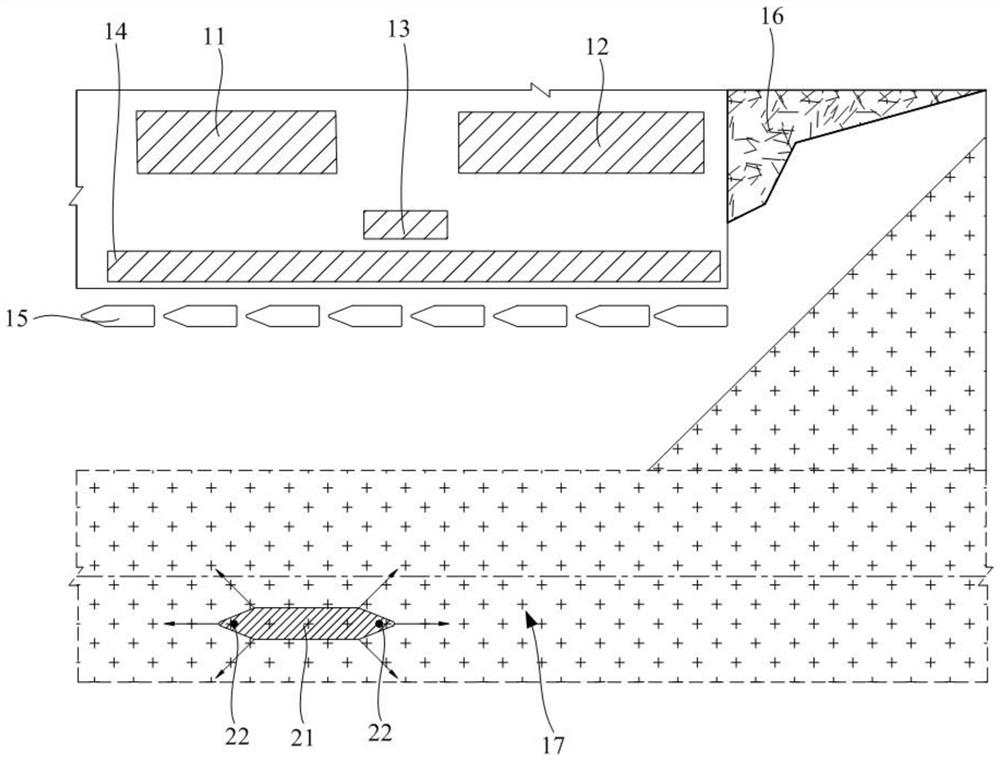

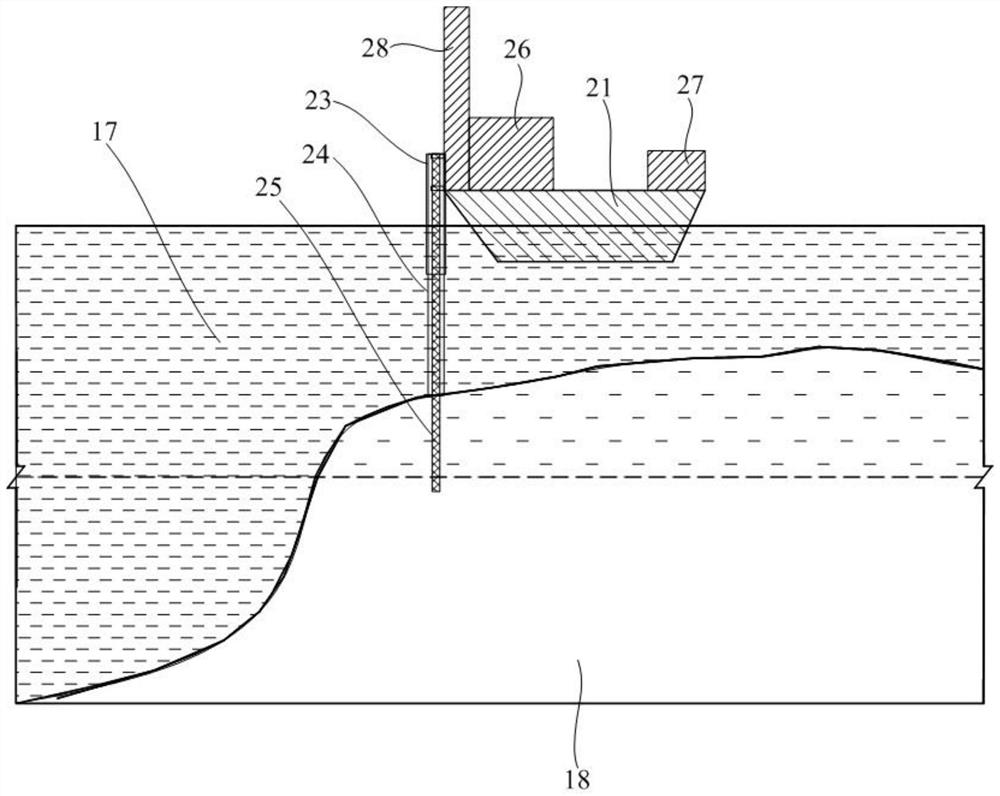

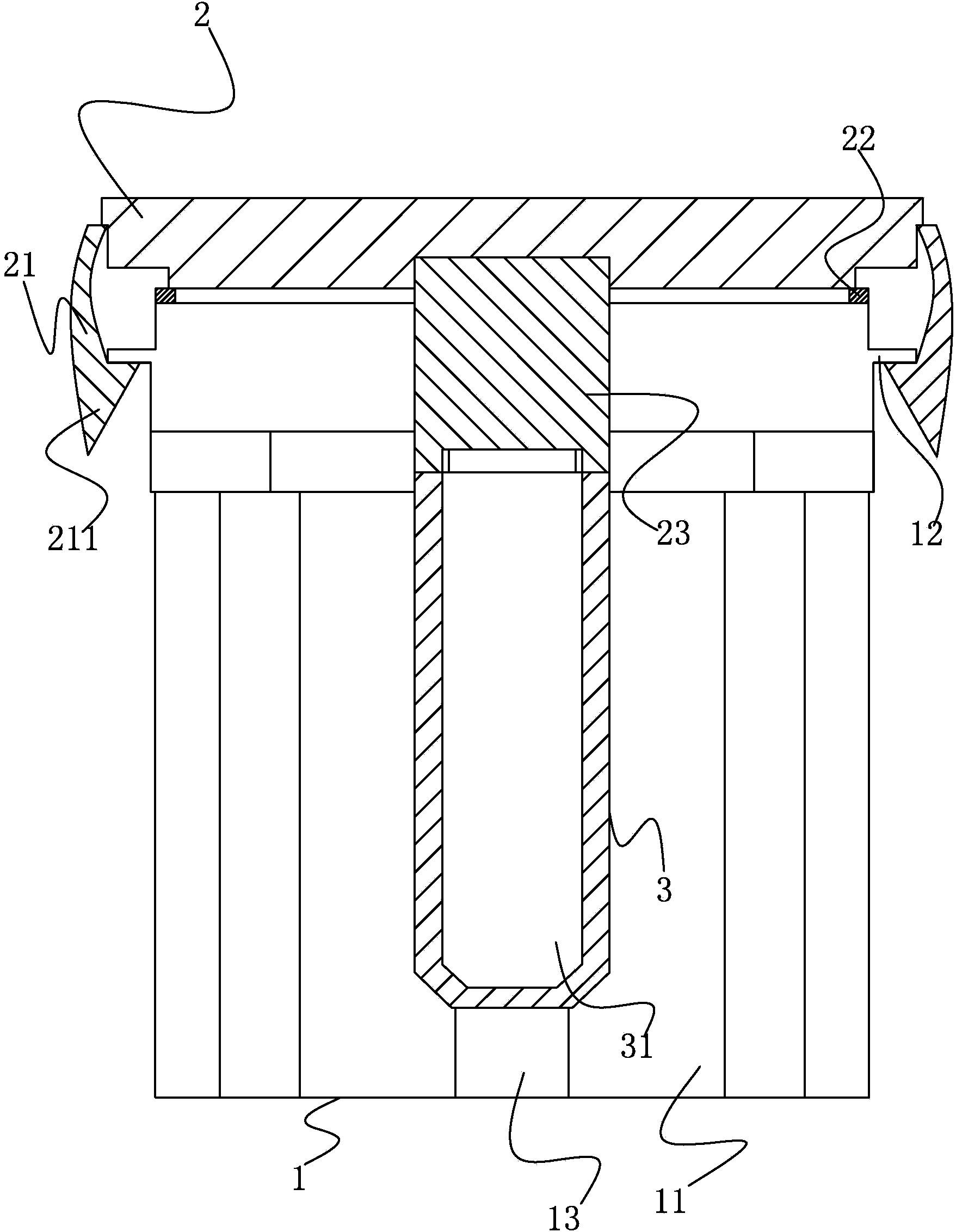

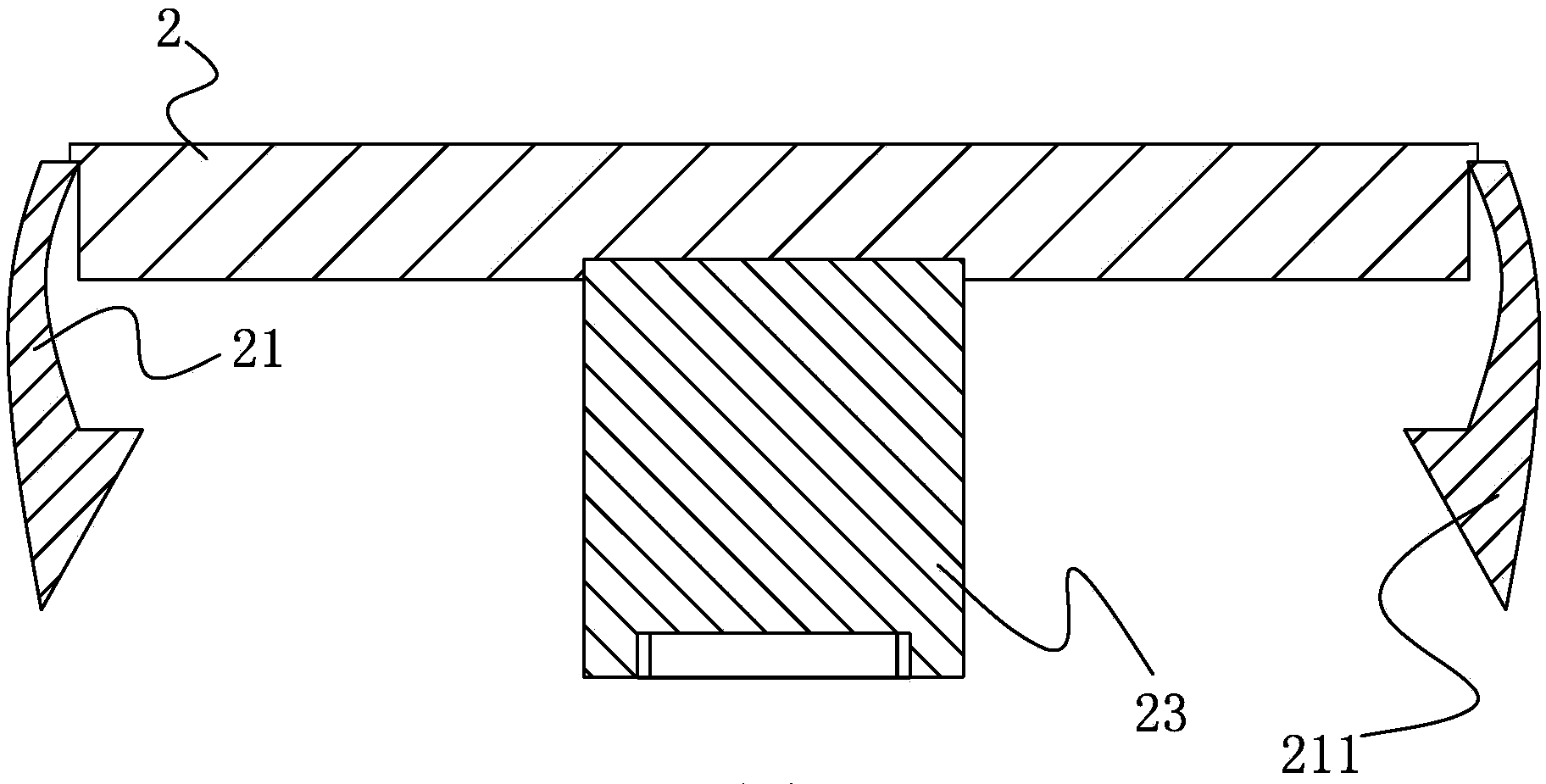

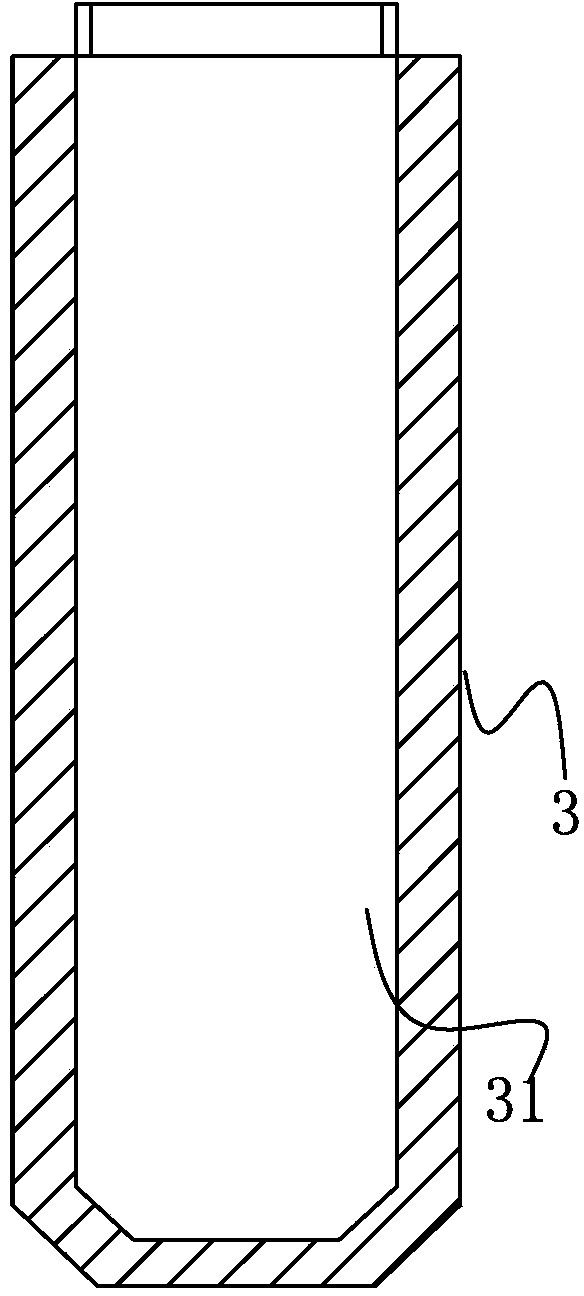

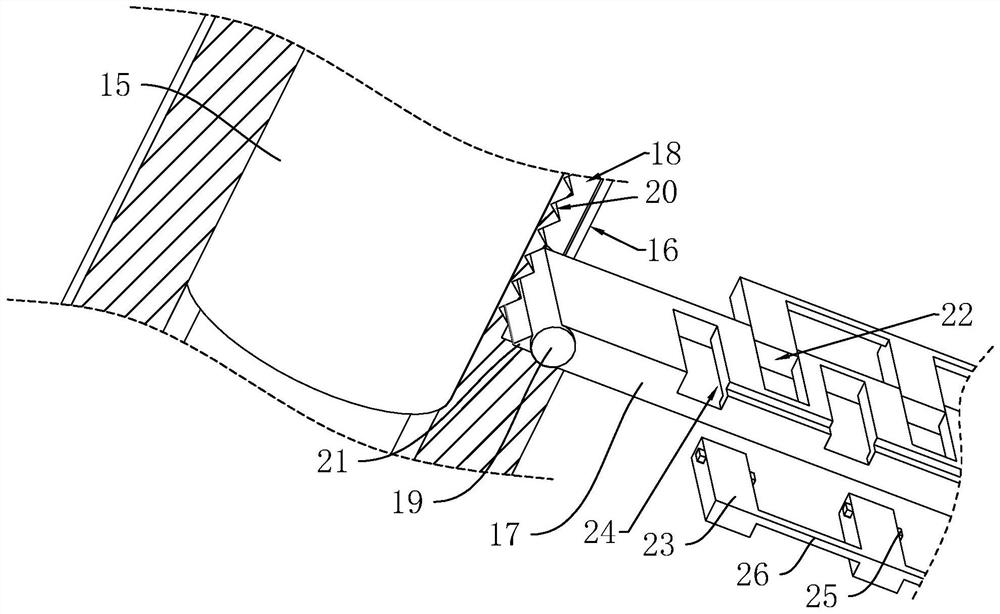

Inshore underwater slope bedrock blasting excavation construction method and blasting charging structure

PendingCN114877769AUniform impact loadReduce unit consumptionDrilling using explosivesBlastingExplosive AgentsStructural engineering

The invention discloses an offshore underwater slope bed rock blasting excavation construction method and a blasting charging structure applied to the method, and the offshore underwater slope bed rock blasting excavation construction method sequentially comprises the steps of point fixing, positioning, drilling, filling and blasting. Specifically, a plurality of blasting points are determined according to a selected blasting area, the blasting points are distributed in the blasting area in a staggered array mode, a drilling ship is moved to the blasting points through a positioning device, the drilling ship is anchored to the blasting points, and a plurality of blasting holes are formed in the blasting points through drilling accurately determined by a drilling device. And the multiple blasting holes are sequentially filled with the multiple blasting charging structures, a blasting network is completed according to design connection, the blasting network is set to be in a millisecond delay blasting mode, the blasting network is excited and detonated, and blasting is completed. According to the offshore underwater slope bedrock blasting excavation construction method, the blasting effect is good, the unit consumption of blasting explosives is low, and the blasting construction cost is low.

Owner:广西桂物爆破工程有限公司 +1

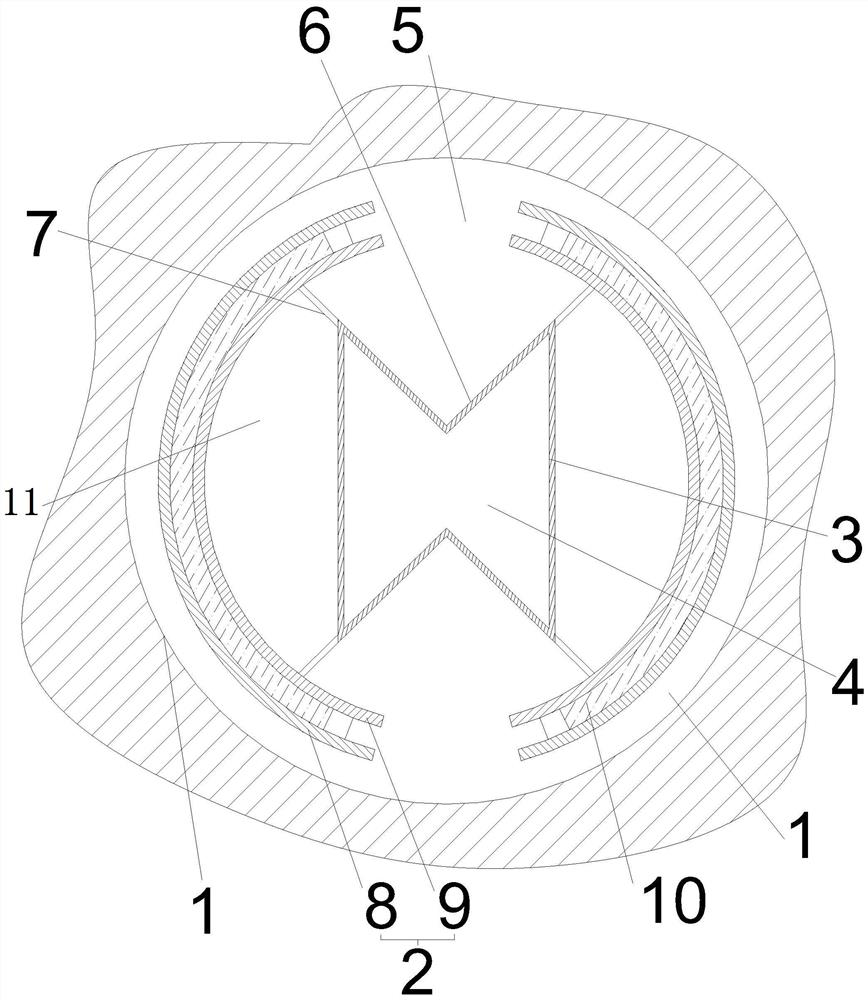

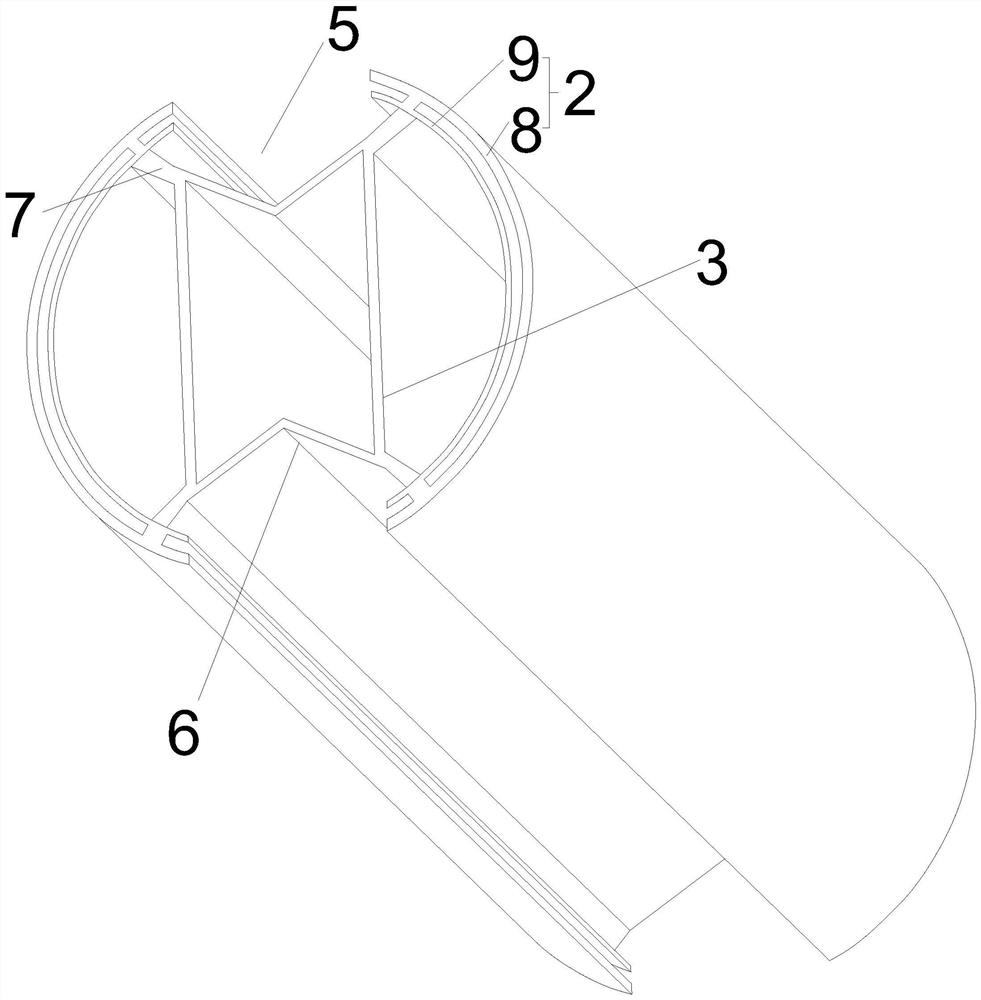

Interlocking fire extinguishing apparatus and sealing method thereof

The invention relates to an interlocking automatic fire extinguishing apparatus and a sealing method thereof, relates to a portable fire extinguishing apparatus and a sealing method thereof, particularly relates to a fire extinguishing apparatus with a container being opened or destroyed by means of bursting charge and a sealing method thereof, and aims at providing the interlocking automatic fire extinguishing apparatus which is simple in structure, convenient to assemble and disassemble and safe to use. The interlocking automatic fire extinguishing apparatus provided by the invention comprises the container, sealing bosses, a sealing cover, sealing claws and a sealing cover bulge, wherein the container is filled with a fire extinguishing agent, the symmetrical sealing bosses are arranged at the upper part of a circumferential surface of the container, the sealing cover is matched with the container in shape, the sealing claws are arranged on the circumferential surface of the sealing cover, are matched with the sealing bosses and are L-shaped, the upper ends of the sealing claws are in hinge joint with the sealing cover, the lower end of the sealing cover is fastened on the sealing cover bosses, the sealing cover bulge is arranged on the lower end surface of the sealing cover, and a detonating pipe is arranged below the sealing cover bulge, is fixedly connected to the sealing cover bulge and is filled with an ignition material.

Owner:BEIJING LONGYANG JICHENG SAFETY TECH

Deep hole blasting charging hole sealing method

The invention discloses a deep hole blasting charging hole sealing method, which comprises the following steps: sequentially putting a plurality of sections of carbon dioxide cracking devices into a blast hole, sealing the opening of the blast hole through hole sealing devices, grouping the plurality of sections of carbon dioxide cracking devices pairwise from top to bottom, and arranging release heads of the carbon dioxide cracking devices positioned at the upper part in each group downwards; the release heads of the carbon dioxide cracking devices located on the lower part are arranged upwards, and during detonation, the multiple sections of carbon dioxide cracking devices are detonated at the same time. Blasting punching can be avoided, and the blasting safety is improved.

Owner:CENT SOUTH UNIV

A blasting charge structure

The invention provides a blasting charge structure. The blasting charge structure comprises an outer shell and sulfur-free black powder filled in the outer shell, wherein a detonating device and / or a detonating powder core are / is arranged in the sulfur-free black powder. The sulfur-free black powder includes, by mass, 80 parts of potassium nitrate and 20 parts of charcoal. The impact sensitivity of the sulfur-free black powder is 0, and the 5s bursting point of the sulfur-free black powder is at the temperature above 600 DEG C. Industrial explosives are further contained between the sulfur-free black powder and the detonating device, the outer shell is tubular, the industrial explosives are filled in the middle in the outer shell, and the sulfur-free black powder is filled between the industrial explosives and the outer shell. The detonating powder core is fixed to the center of the tube body of the outer shell through a plastic cap. An inserting groove is formed in the top of the outer shell, and a detonator is fixed in the inserting groove.

Owner:ANHUI UNIV OF SCI & TECH

Composite aluminum powder for fireworks bursting charge

InactiveCN106631643AExcellent detonation performanceExcellent safety indexExplosivesGallic acid esterFireworks

The invention discloses composite aluminum powder for fireworks bursting charge. The composite aluminum powder comprises components in parts by weight as follows: 65-75 parts of aluminum powder, 17-21 parts of magnesium carbonate, 8-12 parts of ferric oxide and 0.5-1.5 parts of sodium bismuthate. The components are mixed uniformly with a common method. The fireworks bursting charge prepared from the aluminum powder does not contain sulfur and does not contain prohibited chlorate, arsenic compounds, mercury compounds, gallic acid, picric acid, magnesium powder, phosphorus, lead compounds, hexachlorobenzene or fireworks promoters and is an environment-friendly fireworks bursting charge; bursting performance of the fireworks bursting charge is better than that of traditional bursting charge under the same condition; the detection of the National Supervision and Inspection Center for Safety and Quality of Fireworks and Firecracker indicates that friction sensitivity of the composite aluminum powder is 0, impact sensitivity is 0, the ignition temperature is not lower than 410 DEG C, all safety indexes are better than those of the traditional bursting charge, and potential safety hazard is reduced fundamentally; the composite aluminum powder has excellent storage stability.

Owner:罗建社

An intelligent hole-arrangement method for tunnel blasting

The invention discloses an intelligent hole layout method for tunnel blasting. Peripheral eye is blasted by smooth surface and adopts uncoupled charge structure, and peripheral eye is blasted first; the positioning eye is located at the center of the excavation surface particle, and the focused water pressure blasting device is used; after the positioning eye is blasted, according to the crack development The positioning device is used to determine the position of the undercut hole, and the auxiliary eye position is determined in combination with the calculation method, and then the undercut hole is blasted, and finally the auxiliary eye is blasted. The invention locates the position of the blast hole through the crack development direction, utilizes the detonation energy of the explosive to the greatest extent, and at the same time ensures the smoothness of the overall contour after the peripheral eye is detonated, greatly reduces the amount of explosive used, and reduces the use and cost of economic costs. The disturbance of the blasting impact to the surrounding rock mass makes the overall blasting effect safe and stable.

Owner:NANJING INST OF RAILWAY TECH

Mine blasting charging device

ActiveCN113932672AMeet the needs of blastingReduce generationBlastingClassical mechanicsStructural engineering

Owner:浙江秦核环境建设有限公司

Deep hole blasting charge structure

ActiveCN110906821ANovel structural designIncrease the amount of gasBlastingExplosive AgentsClassical mechanics

The invention provides a deep hole blasting charge structure. The deep hole blasting charge structure comprises a blast hole. A filling layer is arranged at an orifice of the blast hole. A blasting bag, a first charge layer, a second charge layer and a hole bottom energy gathering ring are sequentially included in the depth direction of the blast hole from top to bottom. The first charge layer comprises an adjustable energy gathering pipe combined structure and an explosive. The adjustable energy gathering pipe combined structure comprises at least one adjusting assembly and two sets of energygathering pipe sets of the same structure. The energy gathering pipe sets are symmetrically arranged in the blast hole and are connected and fixed through the adjusting assemblies. The energy gathering pipe sets are arranged in the adjusting assemblies correspondingly in a sleeved manner, and the space between the energy gathering pipe sets is filled with the explosive. Each energy gathering pipeset comprises at least one energy gathering pipe. The second charge layer is an explosive column. Compared with the prior art, according to the deep hole blasting charge structure, the adjustable energy gathering pipe assembly is adopted by the first charge layer and can be suitable for blast holes of different sizes, the energy gathering pipes are of sector structures, the blasting cutting effect is good, and the crushing range is wide.

Owner:HUIZHOU XING LU ENERGY SAVING TECH CO LTD

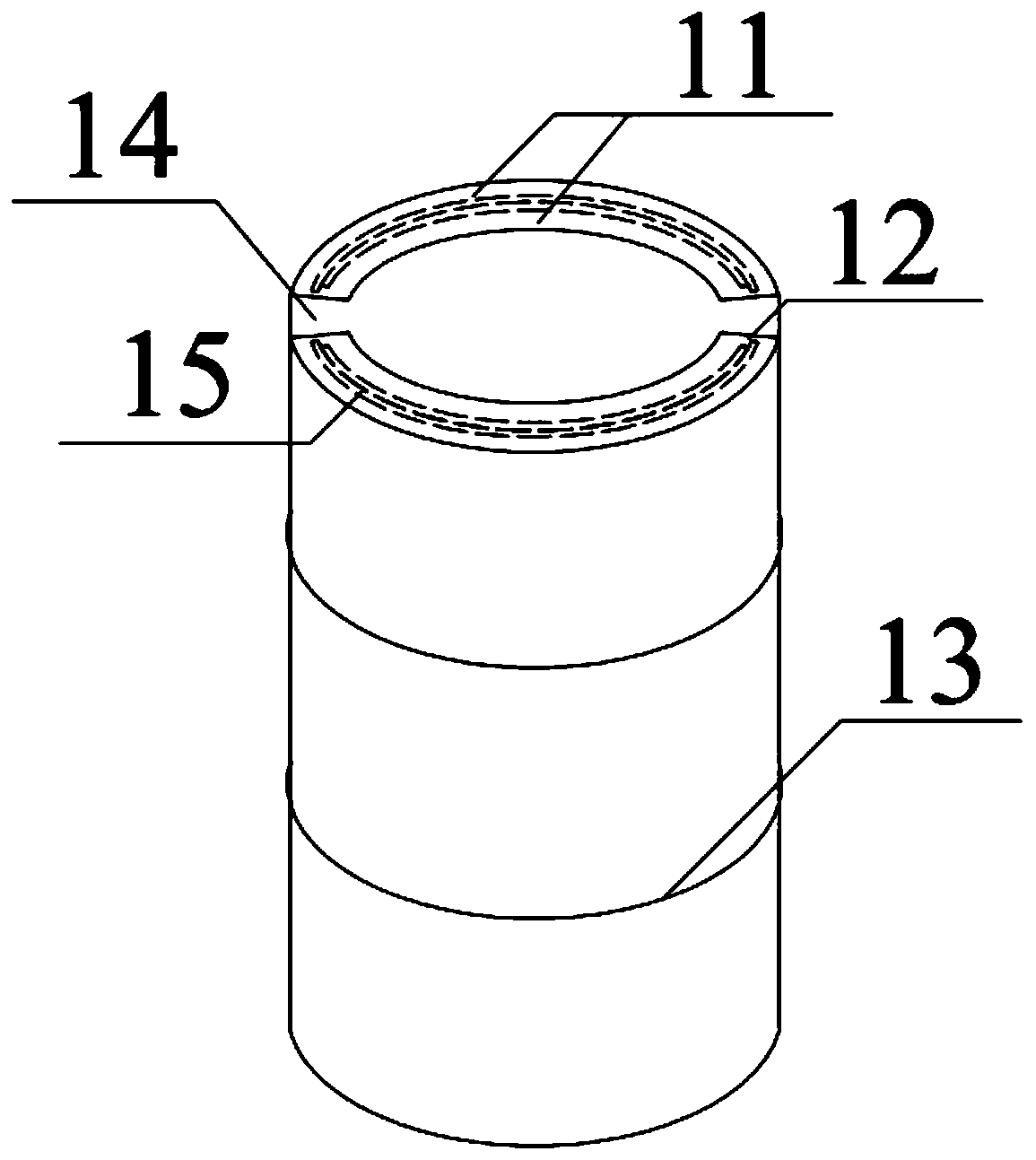

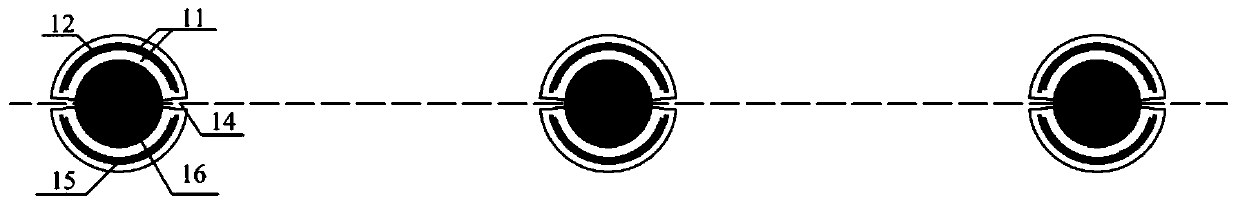

Weak-vibration blasting charging device and using method thereof

The invention discloses a weak-vibration blasting charging device and a using method thereof. The device comprises a plurality of sections of cylindrical damping pipes, reinforcing rings and a mounting rod; each single section of cylindrical damping pipe is formed by splicing two damping sheets, and two symmetrical notches are formed in each cylindrical damping pipe; the damping sheets are made ofperipheral flexible materials and middle hard shaping materials; the reinforcing rings are arranged outside the cylindrical damping pipes at equal intervals; and the mounting rod is the hollow straight rod, and hook-shaped protruding blocks are arranged on the mounting rod at equal intervals. According to the device, the cost is low, and the damping effect is good; the flexible materials are wrapped around a hardened interlayer, so that the damping and buffering effects are achieved in the blasting process, and the blasting vibration strength is greatly reduced; and meanwhile, under the different effects of detonation gas on the cylindrical damping pipe structures and rock masses at the reserved notches in the two sides of the cylindrical damping pipe structures, the rock masses at the notches can be cut and damaged, so that fissures are firstly generated on the hole walls near the notches, and under the effect of the detonation gas, the fissures are further expanded and connected with fissures generated by adjacent blast holes to form the cracks.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com