Filling method for primary explosive of blasting upward hole mixed explosive

A technology for priming and explosives, which is used in blasting, earth-moving drilling, and open-pit mining. The effect of drug quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

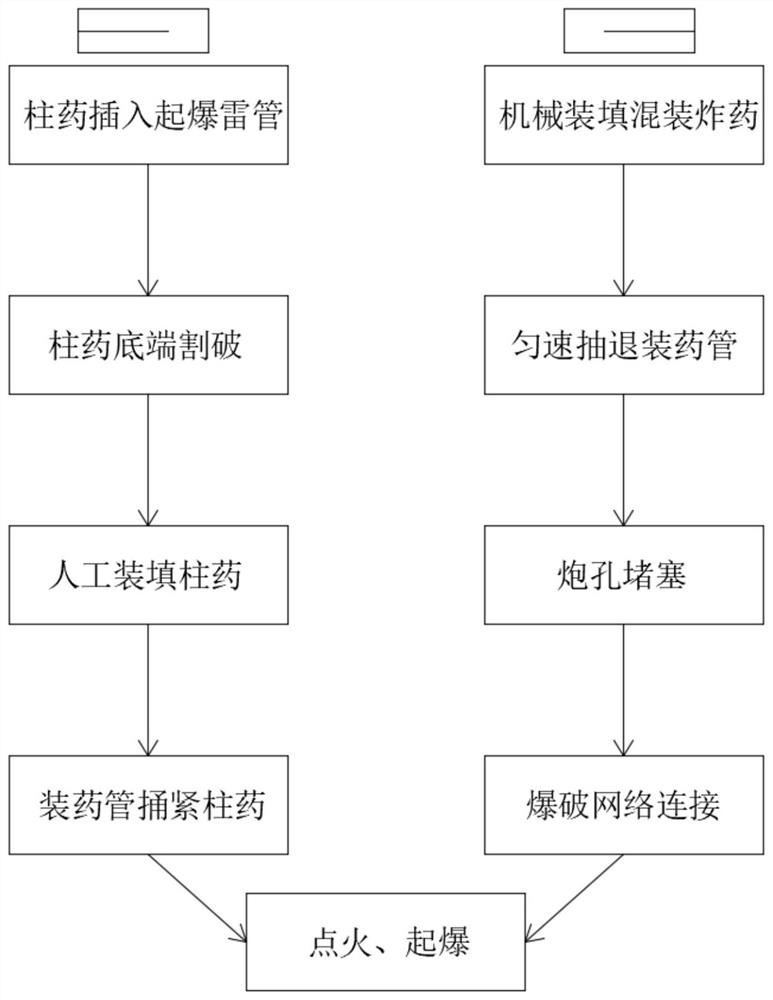

[0020] The present invention provides a method for filling the priming charge of mixed explosives in holes facing upwards in blasting, please refer to figure 1 , including the following specific steps:

[0021] S1, using the column charge as the detonating charge, cut the bottom end of the column charge before charging, wherein the column charge is one of the 50#, 70# and 90# types;

[0022] S2. Manually fill the column charge to the bottom of the blast hole, use the viscosity of the bottom of the column charge to break, prevent the column charge from sliding to the orifice due to the influence of its own weight, and load the charge tube to tighten the column charge. The angle of the blast hole is Greater than 60°;

[0023] S3, the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com