Presplitting blasting and charging combined structure and method

A technology of pre-splitting blasting and combined packaging, which is applied in blasting and other directions, which can solve the problems of high cost, cumbersome operation of the charging process, and complicated production, and achieve the effects of reducing production costs, improving explosive transmission, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

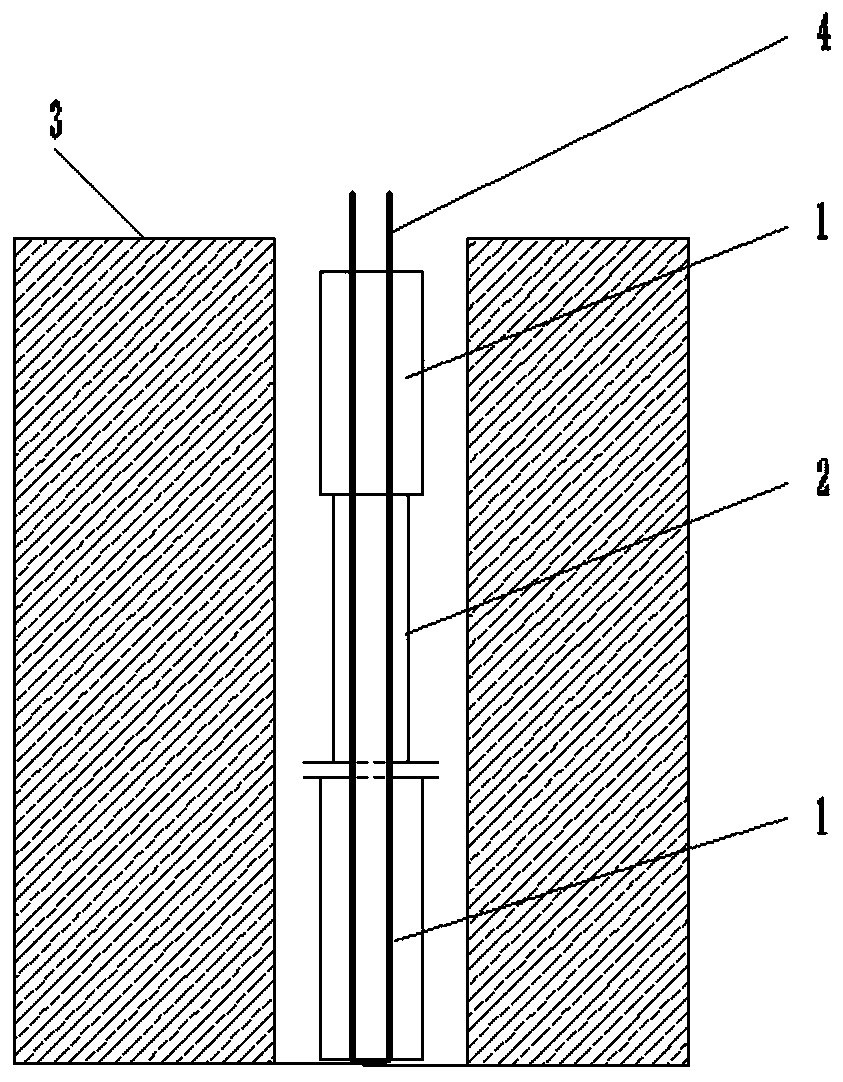

[0024] Such as Figure 1-3 As shown, a pre-splitting blasting combined charge structure includes at least one shaped charge column 1 and at least one PVC pipe 2, and the charge column 1 has a plastic shell with both ends closed. The middle part of the charge 1 is provided with two detonating cord holes 5 passing through the charge 1, and the two ends of a detonating cord 4 respectively pass through the two detonating cords of the charge 1 in the same direction. Hole 5, after covering the charge column 1 at the lowermost end, all charge columns 1 and PVC pipes 2 are connected in series.

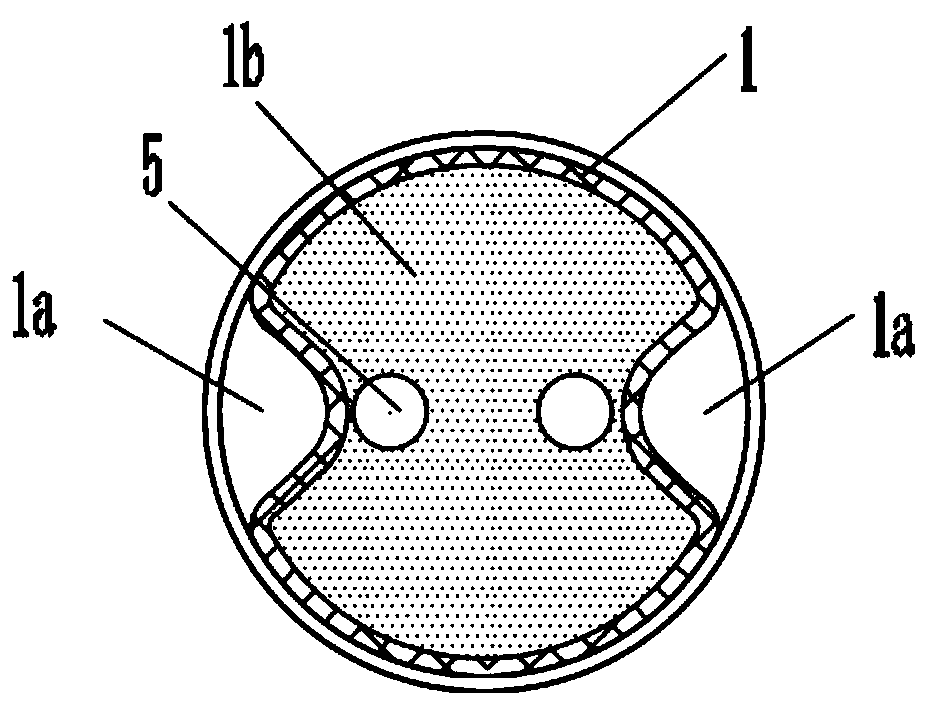

[0025] Wherein, two energy-gathering grooves 1a distributed at 180° are formed on the side wall of the charge column 1, and the energy-gathering grooves 1a are symmetrically arranged on both sides of the detonating cord hole 5. The centerlines of the two energy-gathering grooves 1a on the charge column 5 are located in the same plane, and are fixed to the positions of the detonating cord hole...

Embodiment 2

[0030] Such as Figure 1-3 As shown, a pre-split blasting combined charge method adopts the pre-split blast combined charge structure of embodiment 1 to carry out uncoupled charge, and the specific steps are:

[0031] (1) First pass both ends of a detonating cord 4 in the same direction through the two detonating cord holes 5 on the charge column 1 respectively, and lower the charge column 1 to the blast hole by lowering the detonating cord 4 bottom;

[0032] (2) Continue to directly lower the second charge column 1 or the PVC pipe 2 through the two ends of the detonating cord 4, and so on until the charge is completed.

[0033] Wherein, before the powder charge column 1 is lowered, the two energy-gathering grooves 1a need to be axially extended in the blasthole at the same phase, so that the centerlines of the two energy-gathering grooves 1a are aligned with the centerline of the blasthole.

[0034] The following introduces the practical application of applying the charge m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com