A blasting charge structure

A charge and detonating charge technology, applied in blasting, explosives, etc., can solve problems such as high construction intensity, mining loss, and unsatisfactory blasting effects, and achieve strong operability and obvious economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

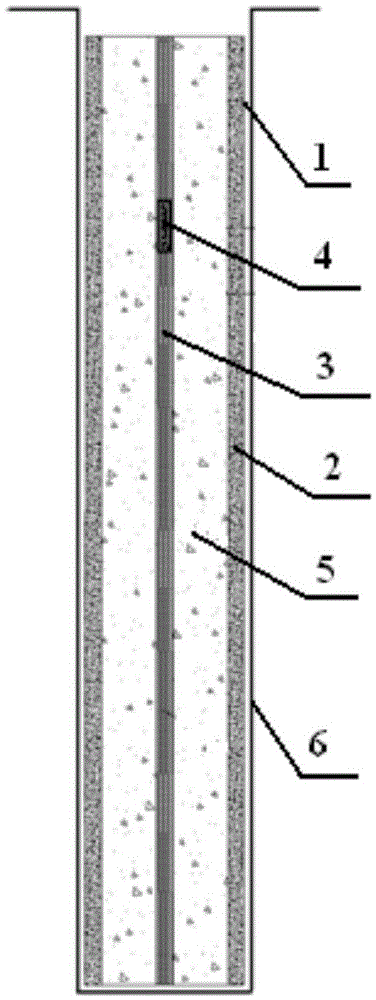

[0035] Such as figure 1 As shown, the explosive charge structure of the present invention includes a shell 1 and a sulfur-free black powder 2 filled therein. The sulfur-free black powder 2 is composed of the following parts by mass: 80 parts of potassium nitrate; 20 parts of charcoal; The sulfur-free black gunpowder 2 is provided with a detonating core 3 and a detonating device inside. The detonating device is a detonator 4, and the detonator 4 is an electric detonator or a nonel detonator. The detonating charge 3 is fixed on the central part of the shell body 1 by a plastic cap, and the top of the shell 1 has a slot, the detonator 4 is fixed in the slot.

[0036] The impact sensitivity of the sulfur-free black powder 2 is 0, and its 5s burst point is above 600°C.

[0037] The tube body of the shell 1 has a length of 1000 mm, an outer diameter of 130 mm, and an inner diameter of 90 mm.

[0038] Both ends of the casing 1 have a thread or a bayonet structure that connects mul...

Embodiment 2

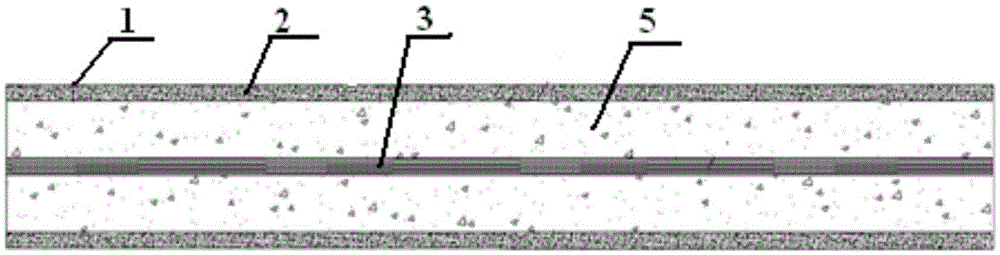

[0040] Such as figure 2 As shown, a blasting charge structure includes a tubular casing 1, the center of the casing 1 is filled with industrial explosives 5, and the gap between the industrial explosives 5 and the casing 1 is filled with sulfur-free black powder 2. The detonating device is a detonator 4, and the detonator 4 is an electric detonator or a nonel detonator, and the detonating charge core 3 is fixed on the center of the shell 1 body through the plastic caps at both ends of the shell 1, and the shell 1 The top is also provided with a slot, and the detonator 4 is fixed on the slot.

[0041] The filling ratio of the sulfur-free black powder 2 and the industrial explosive 5 is: 30 parts of sulfur-free black powder; 70 parts of industrial explosive; wherein, the industrial explosive 5 is composed of the following parts by mass: the industrial explosive 5 It is composed of ammonium nitrate and light diesel oil with a mass ratio of 94.5:5.5 or 96:4; the sulfur-free blac...

Embodiment 3

[0044] Such as image 3 As shown, the difference from Example 2 is that the detonator 4 is not included; the body length of the shell 1 is 200mm, the outer diameter is 50mm, and the inner diameter is 46mm; the industrial explosive 5 is an emulsion explosive, consisting of the following parts by weight Composition: 42.7-58.5 parts of ammonium nitrate, 8-12 parts of sodium nitrate, 15-25 parts of methylamine nitrate, 1.0-2.5 parts of urea, 8-10 parts of water, 4-6 parts of composite oil phase, 0.5-1.0 parts of aluminum powder share. The composite oil phase is composed of Span-80, soybean lecithin, petroleum jelly, microcrystalline wax, paraffin wax and composite wax with a mass ratio of 1:0.5:0.1:0.5:1:1. When producing emulsion explosives, the emulsifier is mixed with The waxes are melted and mixed according to the mass ratio of 1:2 or melted and mixed to obtain a special composite oil phase for emulsion explosives. The emulsifier refers to a mixture of Span-80, soybean lecit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com