Integrated production technology of rock-fill dam high-standard transition material

A production process and transition material technology, which is applied in open-pit mine mining, grain processing, blasting, etc., can solve the problems of high sand and gravel aggregate price, high process cost, and occupancy, so as to reduce construction costs and achieve significant economic benefits. The effect of gradation continuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

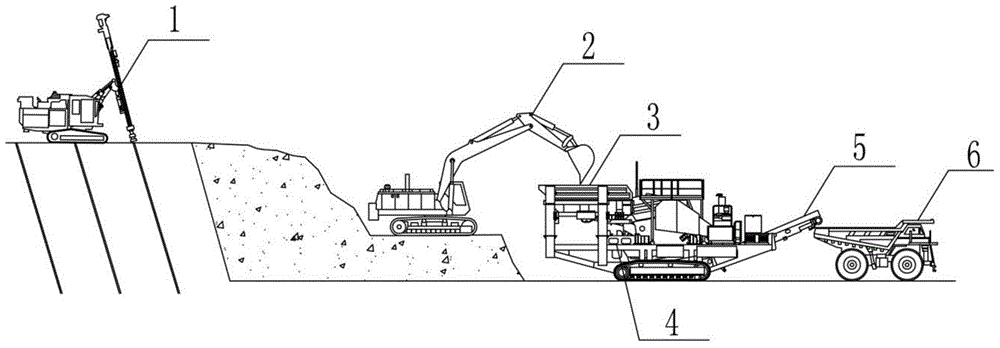

Method used

Image

Examples

Embodiment Construction

[0035] In order to better illustrate the inventiveness of this method, the specific implementation of the present invention will be further described below in conjunction with engineering application examples.

[0036] The dam crest elevation of the gravel earth core wall dam project of the Dadu River Changheba Hydropower Station is 1697m, the maximum dam height is 240m, and the filling volume of the dam is about 33 million cubic meters, of which the filling volume of the dam transition material is 2.46 million m 3 .

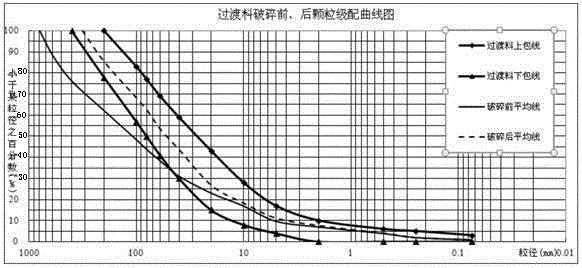

[0037] The maximum particle size of the transition material is not more than 400mm, the particle content of less than 0.075mm is not more than 3%, the particle content of less than 5mm is not more than 17%, not less than 4%, D15≤20mm.

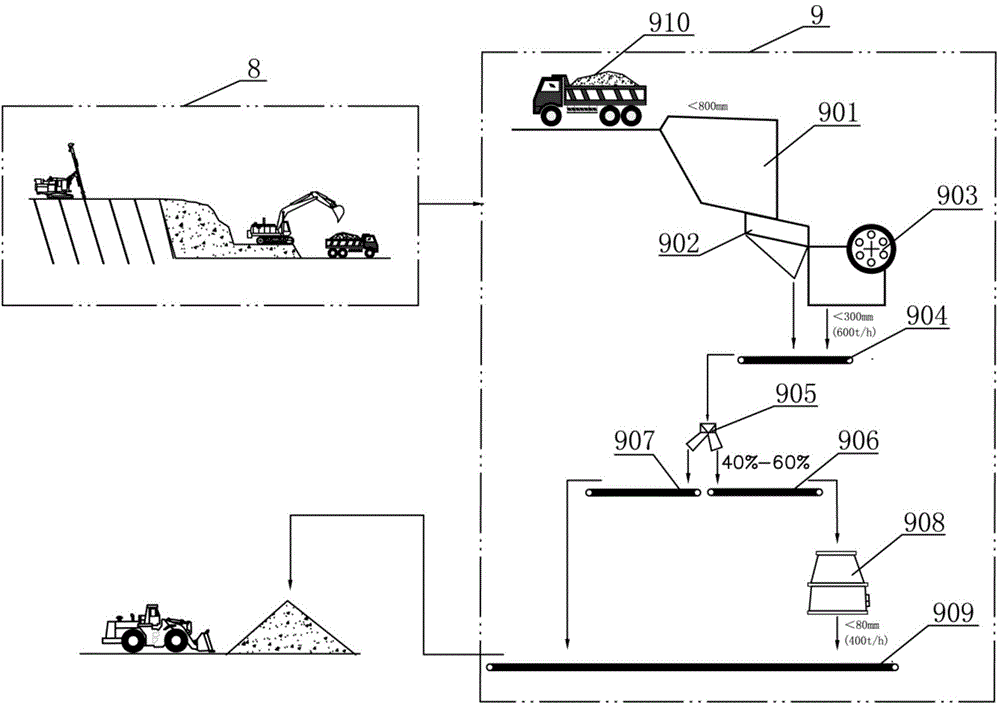

[0038] Due to the poor explosiveness of the rock in the stockyard, coupled with high standard design requirements. The production of transitional materials in the early stage of the Changheba project is obtained by mixing sand a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com