Welding platform parameter management method and system

A welding platform and parameter management technology, which is applied in the direction of program control device, hardware monitoring, user interface execution, etc., can solve the problems of inability to alarm in time and inconvenient query of all parameters of the same welding platform, so as to solve hidden troubles and improve operation Reliability, the effect of ensuring production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

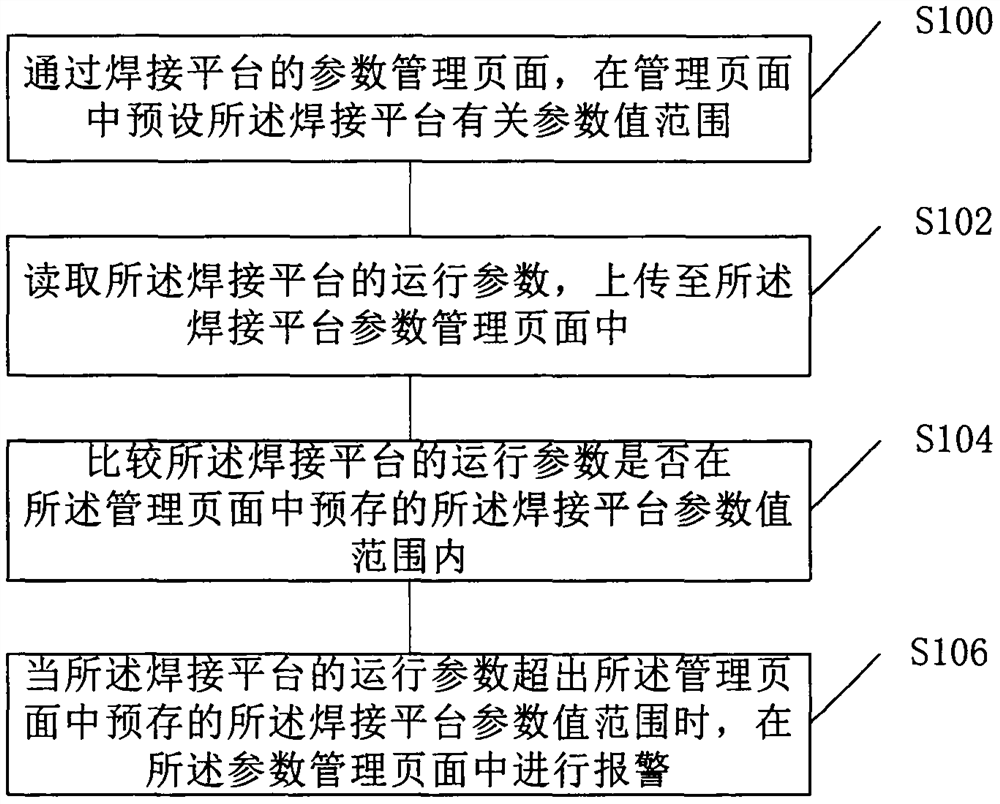

[0029] figure 1 It is a flow chart of the welding platform parameter management method provided by the embodiment of the present invention. refer to figure 1 As shown, the welding platform parameter management method of the present invention is used to manage the parameters of the welding platform in the automobile production line, comprising the following steps:

[0030] S100, through the parameter management page of the welding platform, preset the relevant parameter value range of the welding platform in the management page;

[0031] S102, read the operating parameters of the welding platform, and upload them to the parameter management page of the welding platform;

[0032] S104, comparing whether the operating parameters of the welding platform are within the parameter value range of the welding platform pre-stored in the management page;

[0033] S106. When the operating parameter of the welding platform exceeds the range of the welding platform parameter value presto...

Embodiment 2

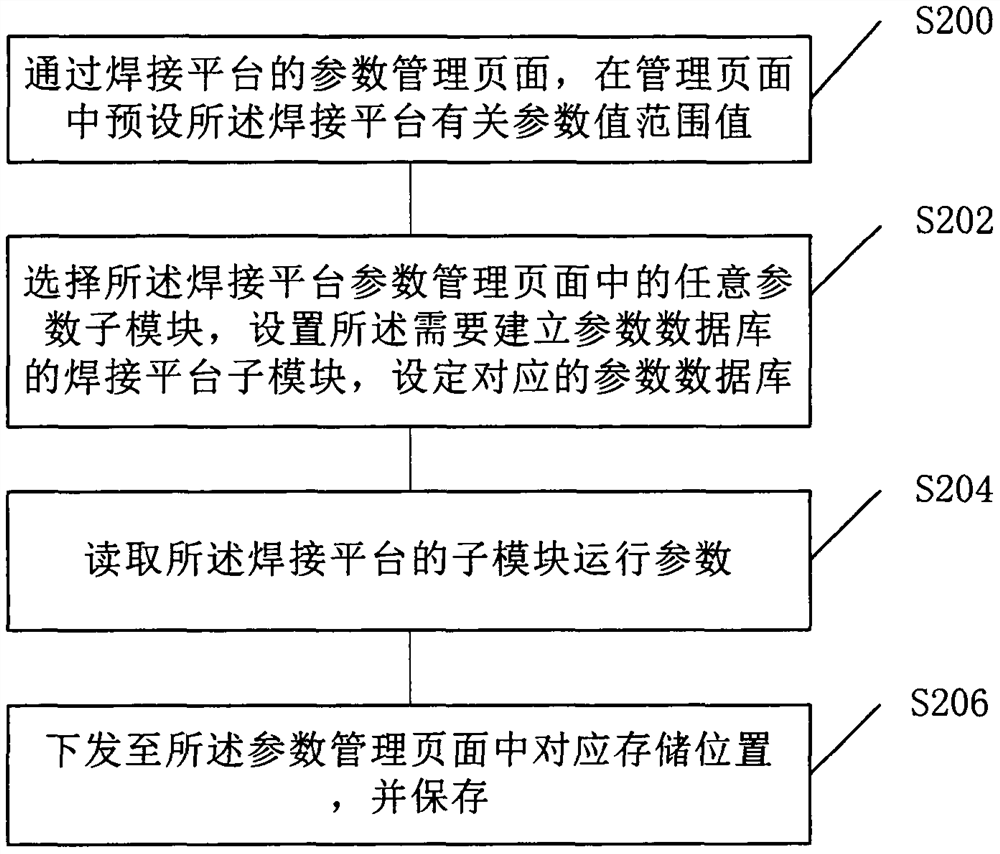

[0042] figure 2 It is a flow chart of the welding platform parameter management method of the present invention provided by Embodiment 2 of the present invention. refer to figure 2 As shown, the welding platform parameter management method of the present invention includes the following steps:

[0043] S200, through the parameter management page of the welding platform, preset the relevant parameter value range of the welding platform in the management page;

[0044] Wherein, step S200 is the same as step S100 in the first embodiment, and will not be repeated here.

[0045] S202. Select any parameter sub-module in the welding platform parameter management page, set the welding platform sub-module for which a parameter database needs to be established, and set a corresponding parameter database;

[0046] S204, reading the sub-module operating parameters of the welding platform;

[0047] S206. Deliver to the corresponding storage location in the parameter management page, an...

Embodiment 3

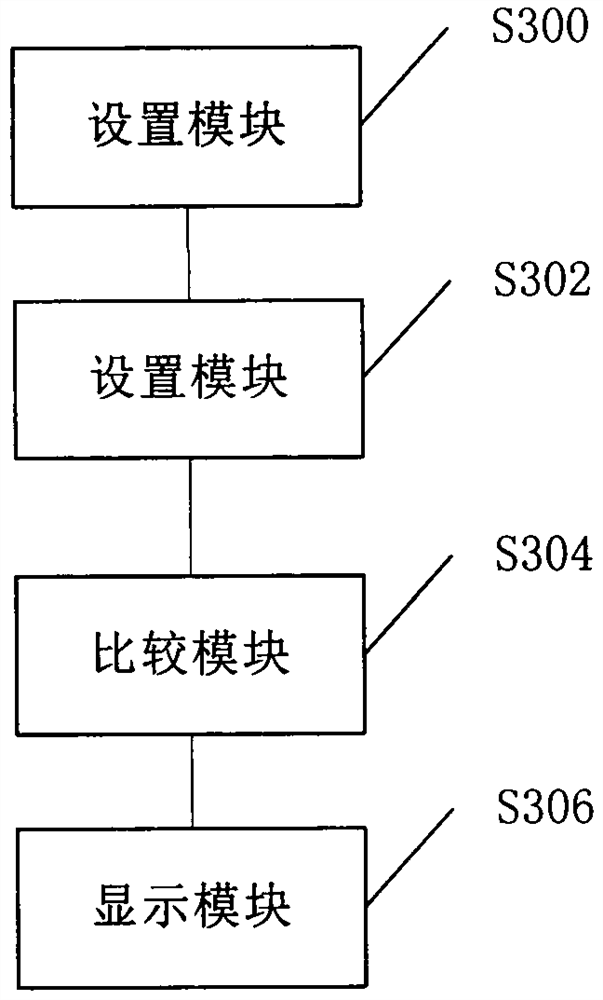

[0054] image 3 The structural diagram of the welding platform system provided by the third embodiment of the present invention. refer to image 3 As shown, the welding platform parameter management system of the present invention is used to manage the parameters of the welding platform in the automobile automatic production line, including the following modules:

[0055] Setting module 300, the setting module 300 presets the relevant parameter value range of the welding platform in the management page through the parameter management page of the welding platform;

[0056] An acquisition module 302, the acquisition module 302 is used to read the operating parameters of the welding platform and upload them to the welding platform parameter management page;

[0057] A comparison module 304, the comparison module 304 is used to compare whether the operating parameters of the welding platform are within the range of the welding platform parameter values pre-stored in the manag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com