Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Batch process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Batch process control functions. The following describes the means that a recipe would use to make a product. We settled on three kinds of control for batch processes: basic, procedural, and coordination. Basic control is what holds the batch in a state given by one or more setpoints.

Compact Batch Viewing Techniques for use in Batch Processes

ActiveUS20080066019A1Quickly and easily examineEasy to understandComputer controlDigital computer detailsGraphicsData operations

A data collection and viewing application associated with a batch process control system used within a process plant provides a user interface that allows a user to quickly and easily examine a particular batch process or a batch run, to compare separate batch runs and / or to determine whether the particular batch run deviates from a norm, without having to perform a lot of manual data manipulation. To this end, the user interface provides or creates a compact graphical representation of a batch, illustrating a number of different types of batch-related data in relation to one another in a manner that enables a user to easily view or understand the operation of the batch run, either alone or as compared with one or more other batch runs. Generally speaking, the compact batch view includes a number of graphical layers which are juxtaposed or interleaved on a display, with each of the layers providing different types of information about the operation of the batch, time synchronized with one another. A base layer of the compact batch view may describe or indicate the duration of the batch from an activate time to a deactivate time, while different aspects of the procedural elements, steps or stages of the batch process, such as those identified by the S88 standard, may be illustrated in one or more additional layers. Moreover, process alarms, alerts, events, etc. as well as other information may be placed in one or more additional layers, and the various layers may be shown together to provide a compact graphical view of the batch.

Owner:FISHER-ROSEMOUNT SYST INC

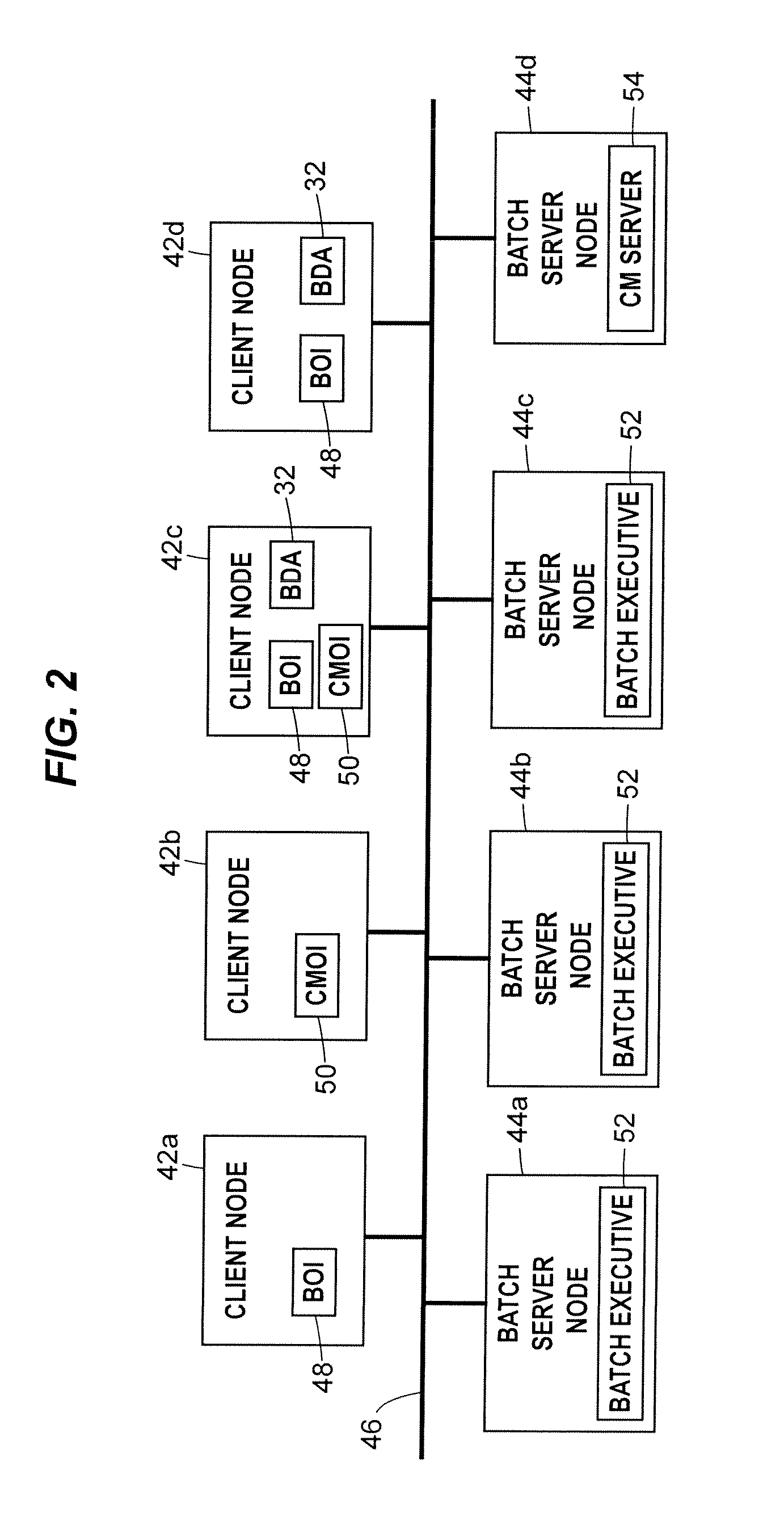

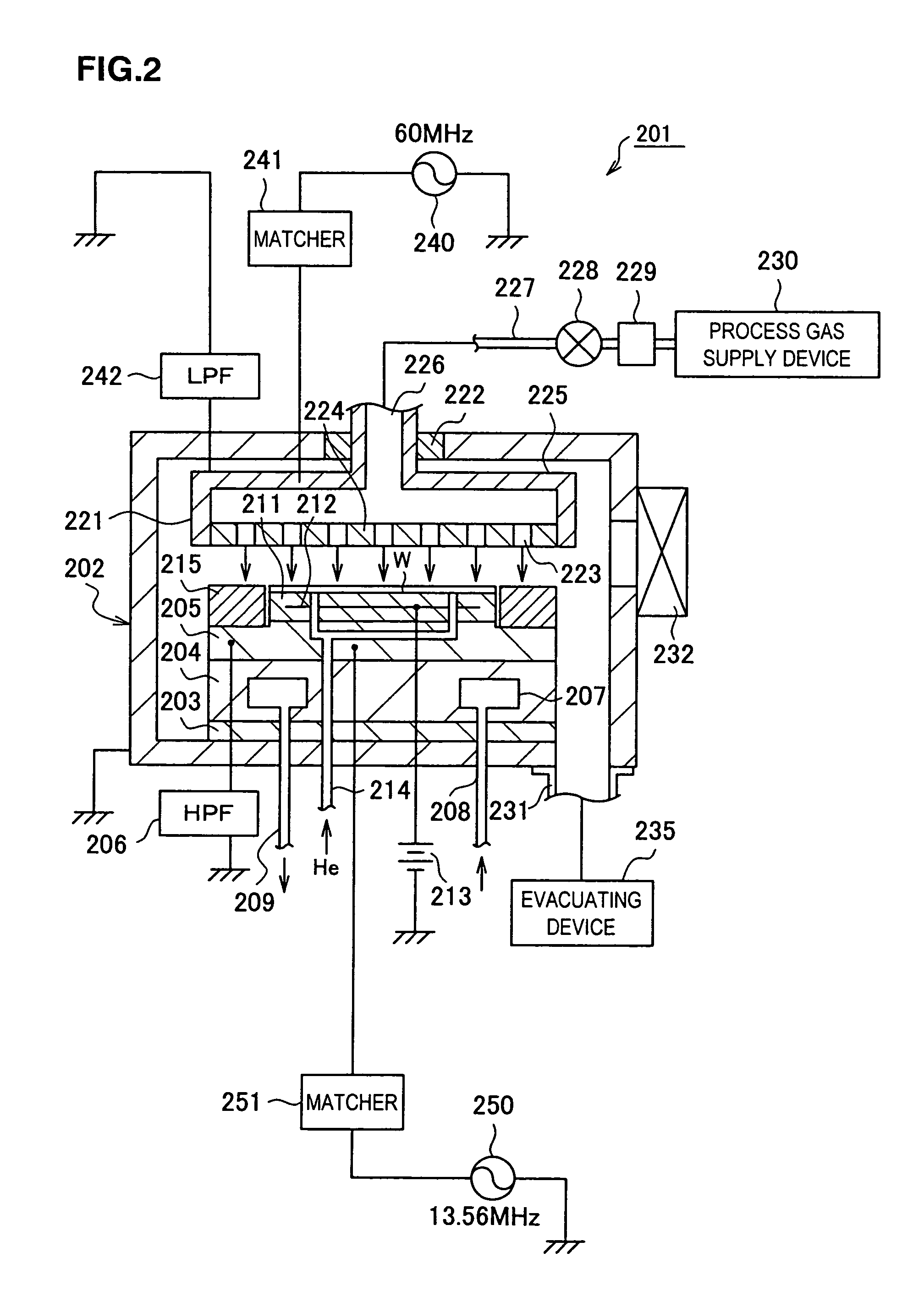

Method for process control of semiconductor manufacturing equipment

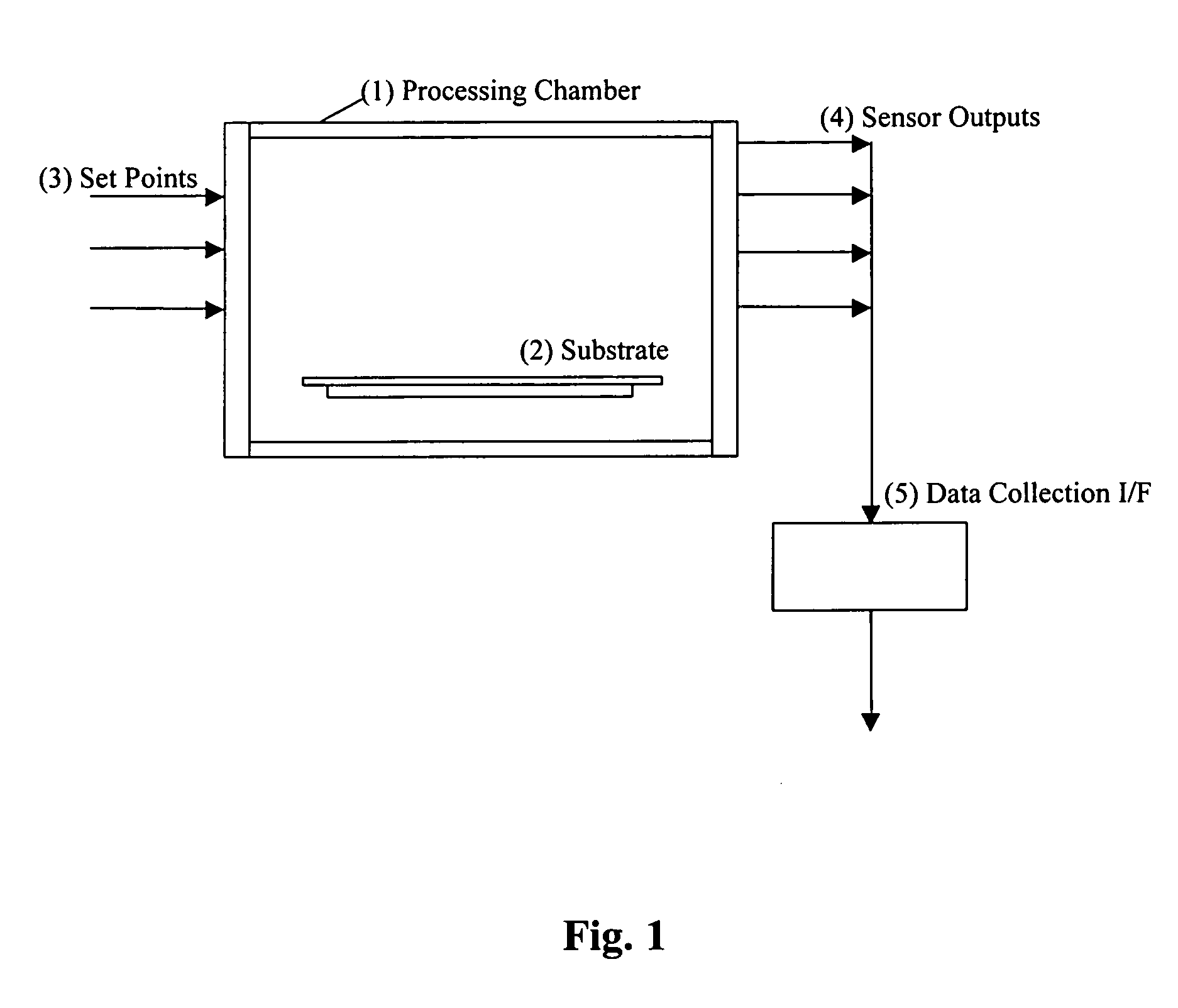

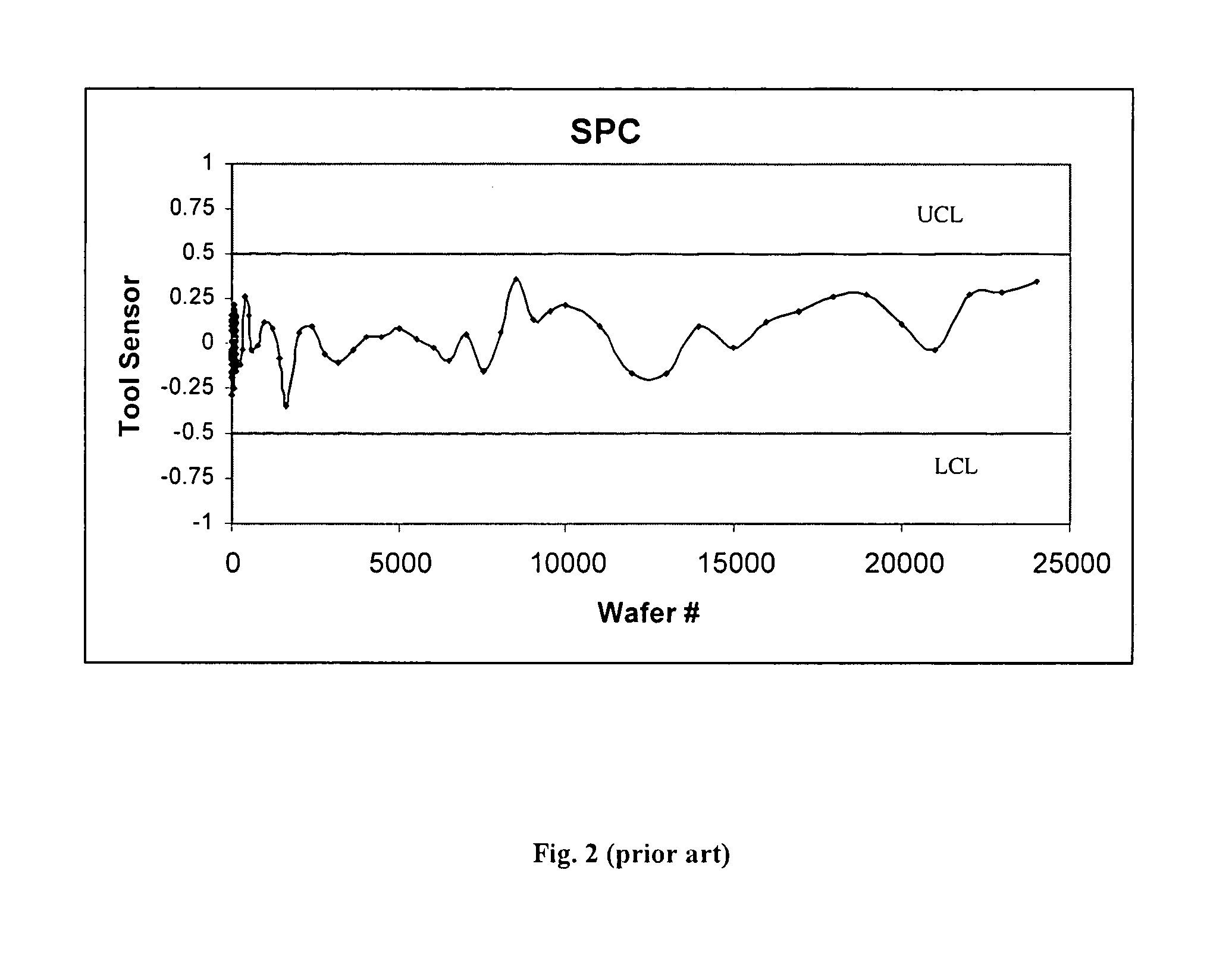

ActiveUS7062411B2Plug gaugesSemiconductor/solid-state device testing/measurementFault recognitionSemiconductor

A method of fault identification on a semiconductor manufacturing tool includes monitoring tool sensor output, establishing a fingerprint of tool states based on the plurality of sensors outputs, capturing sensor data indicative of fault conditions, building a library of such fault fingerprints, comparing present tool fingerprint with fault fingerprints to identify a fault condition and estimating the effect of such a fault condition on process output. The fault library is constructed by inducing faults in a systematic way or by adding fingerprints of known faults after they occur.

Owner:LAM RES CORP

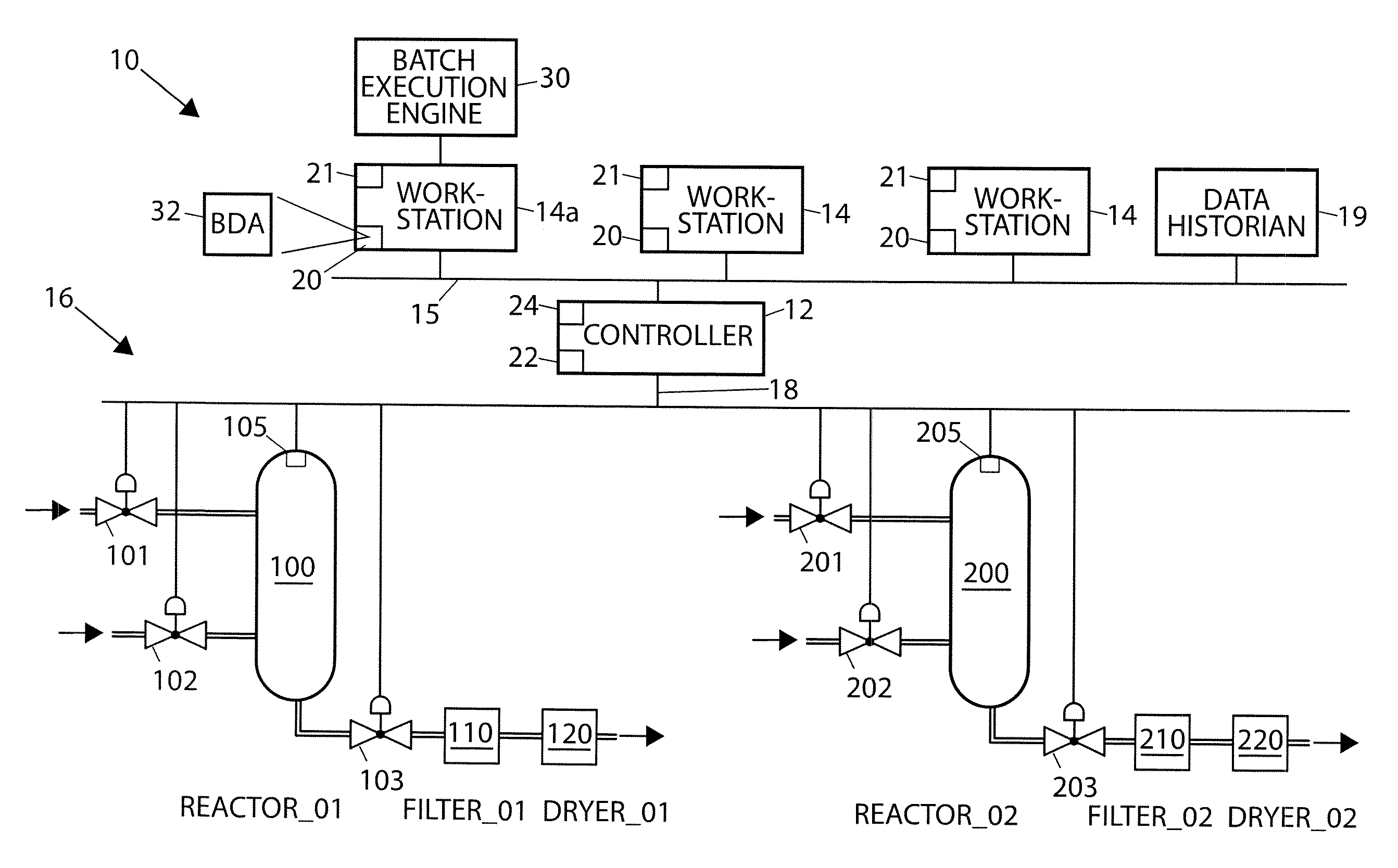

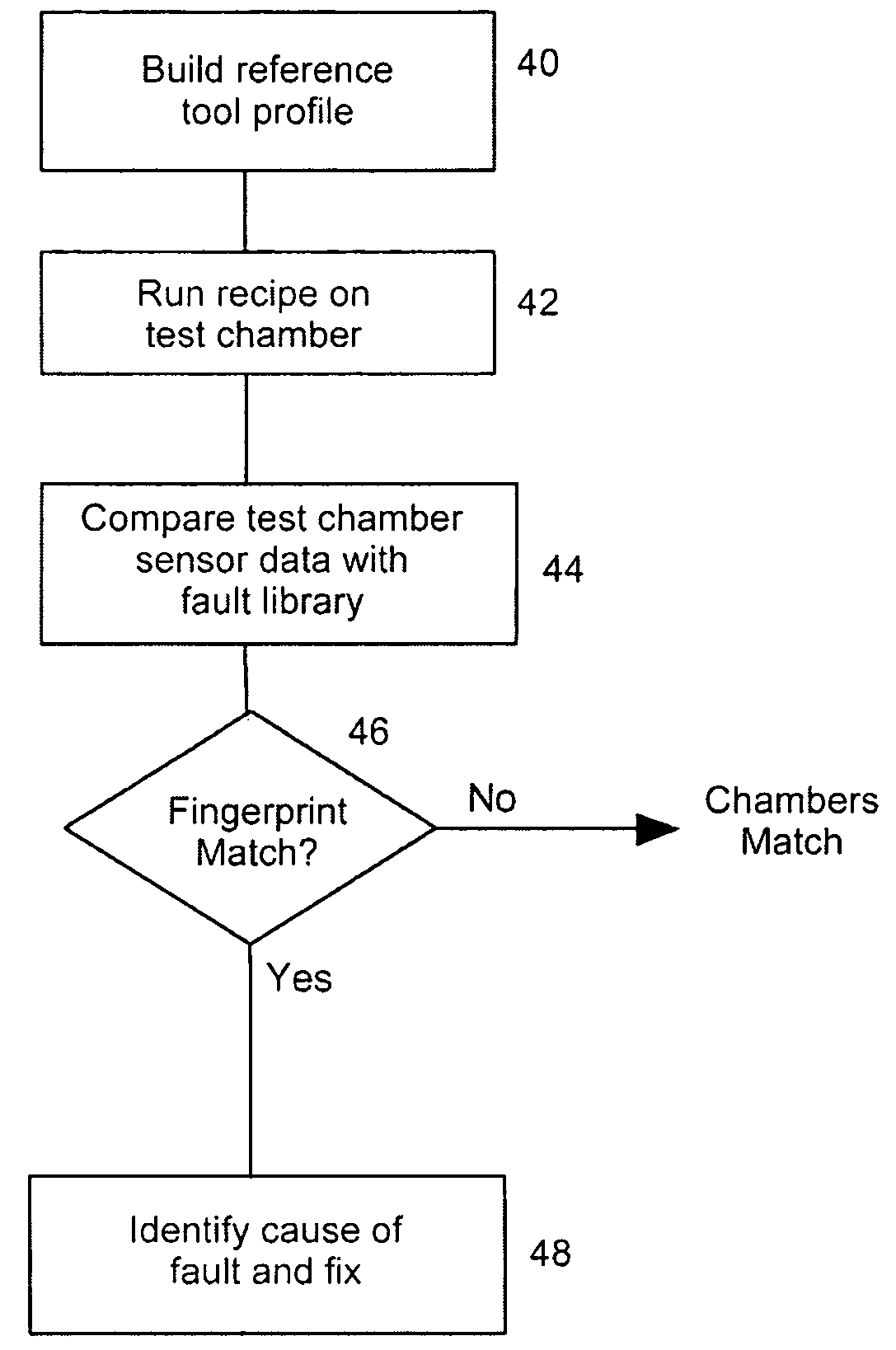

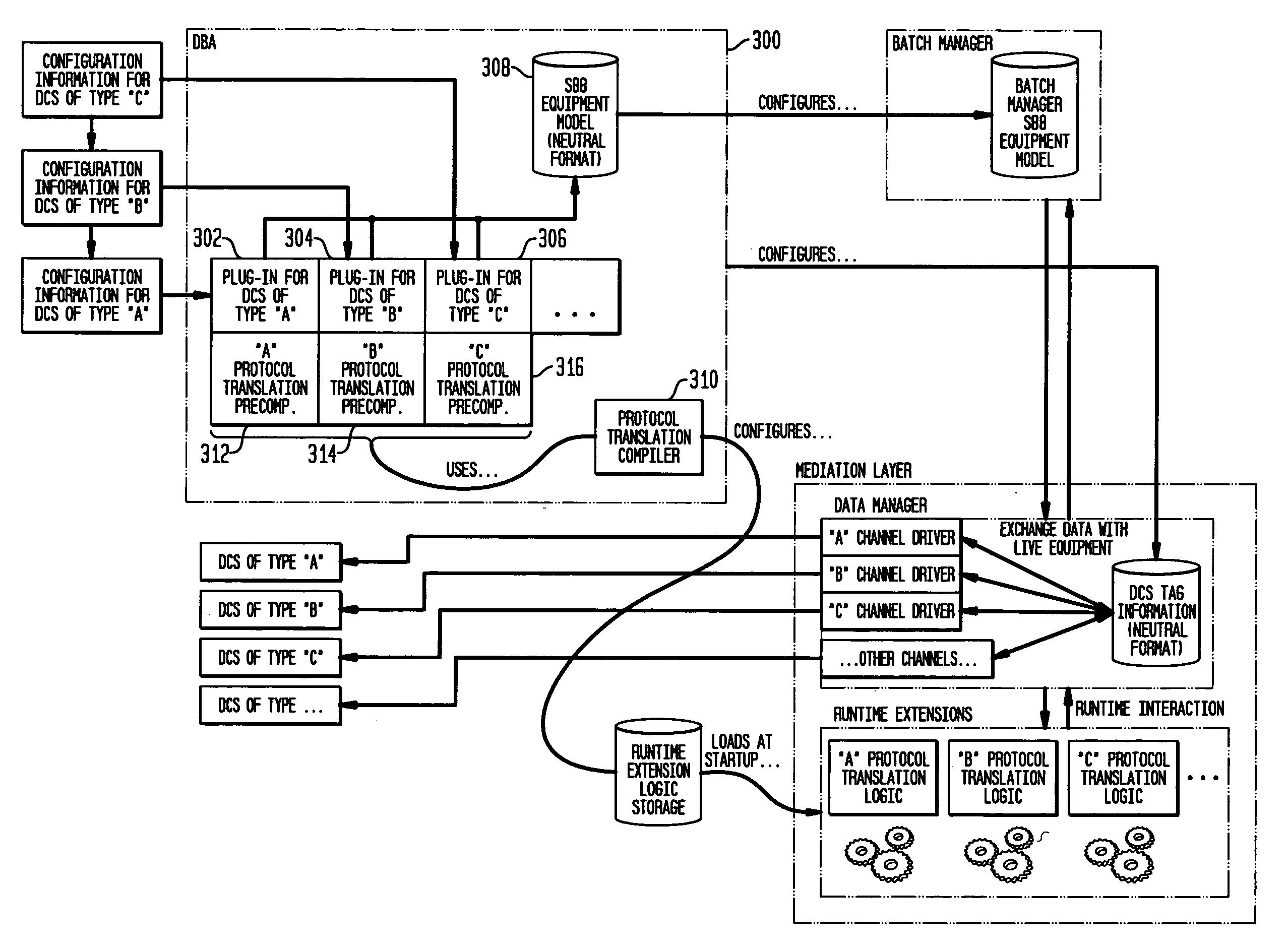

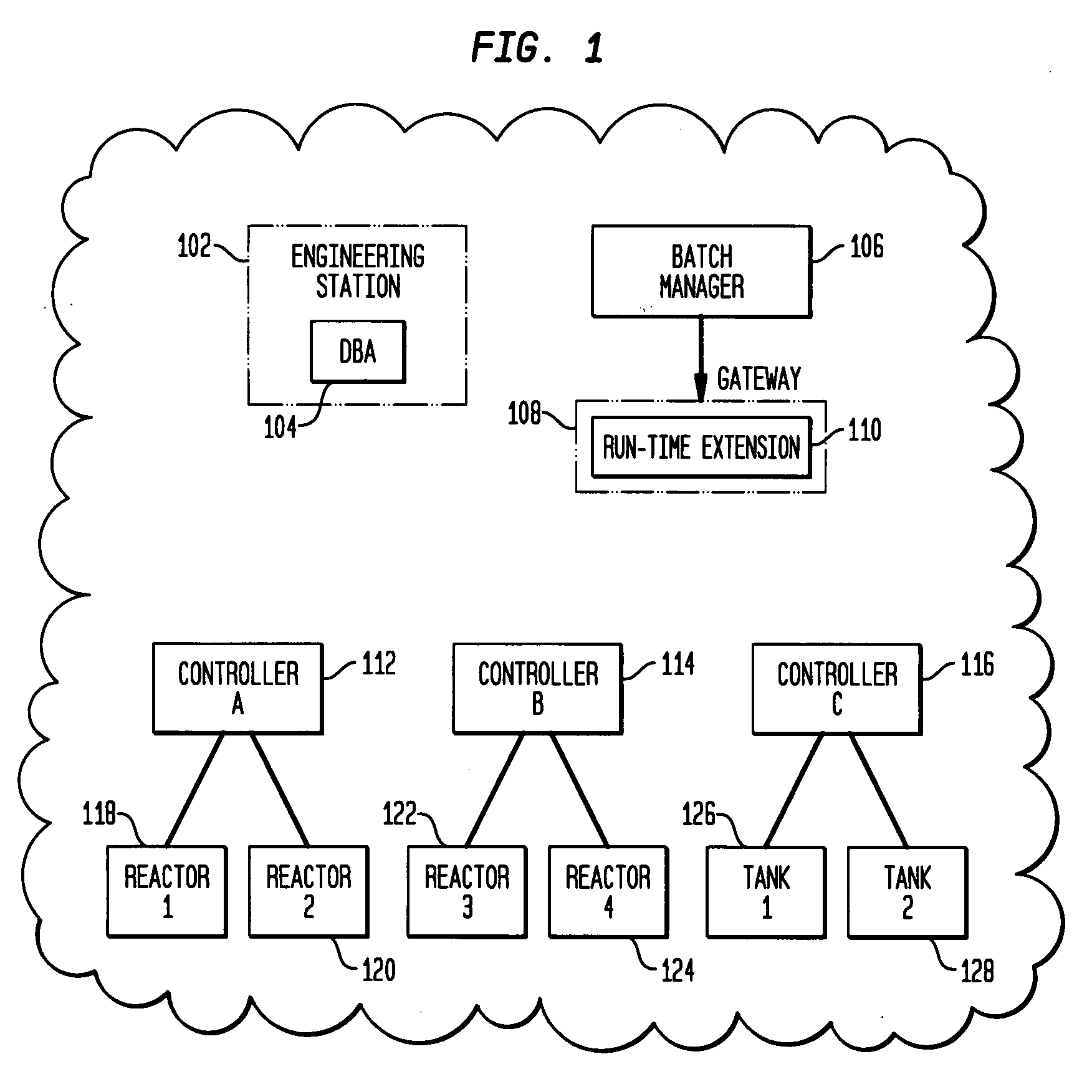

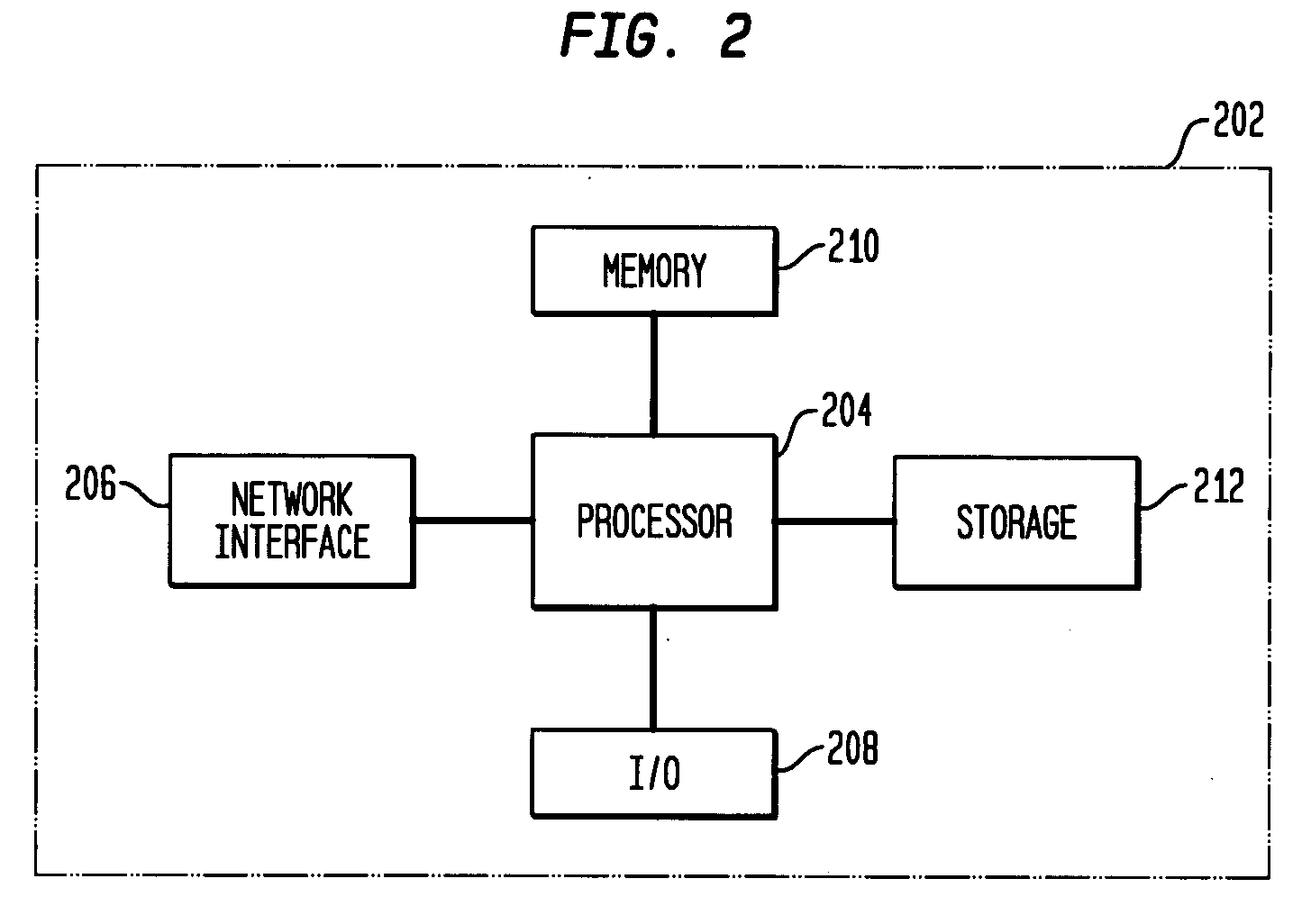

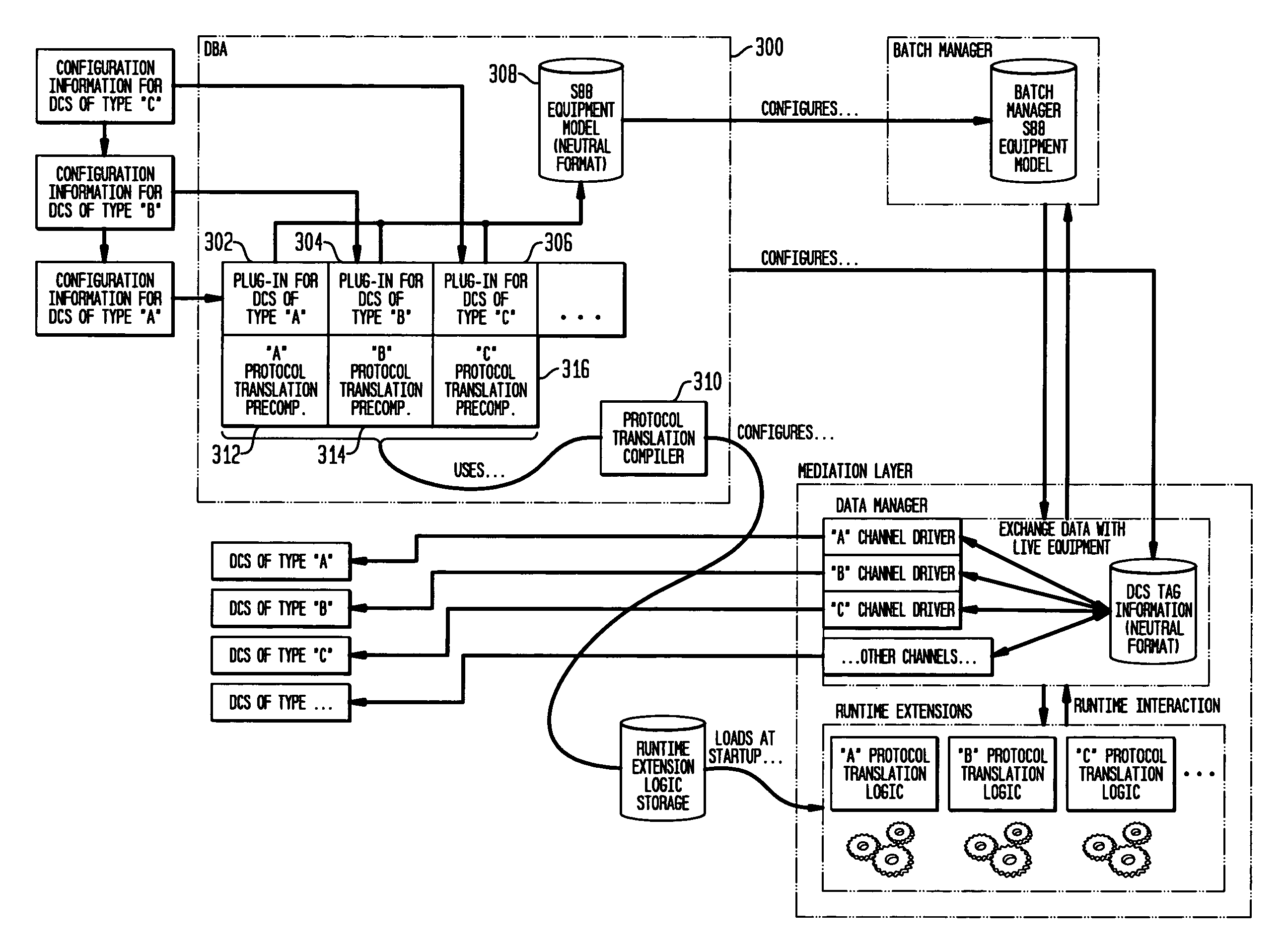

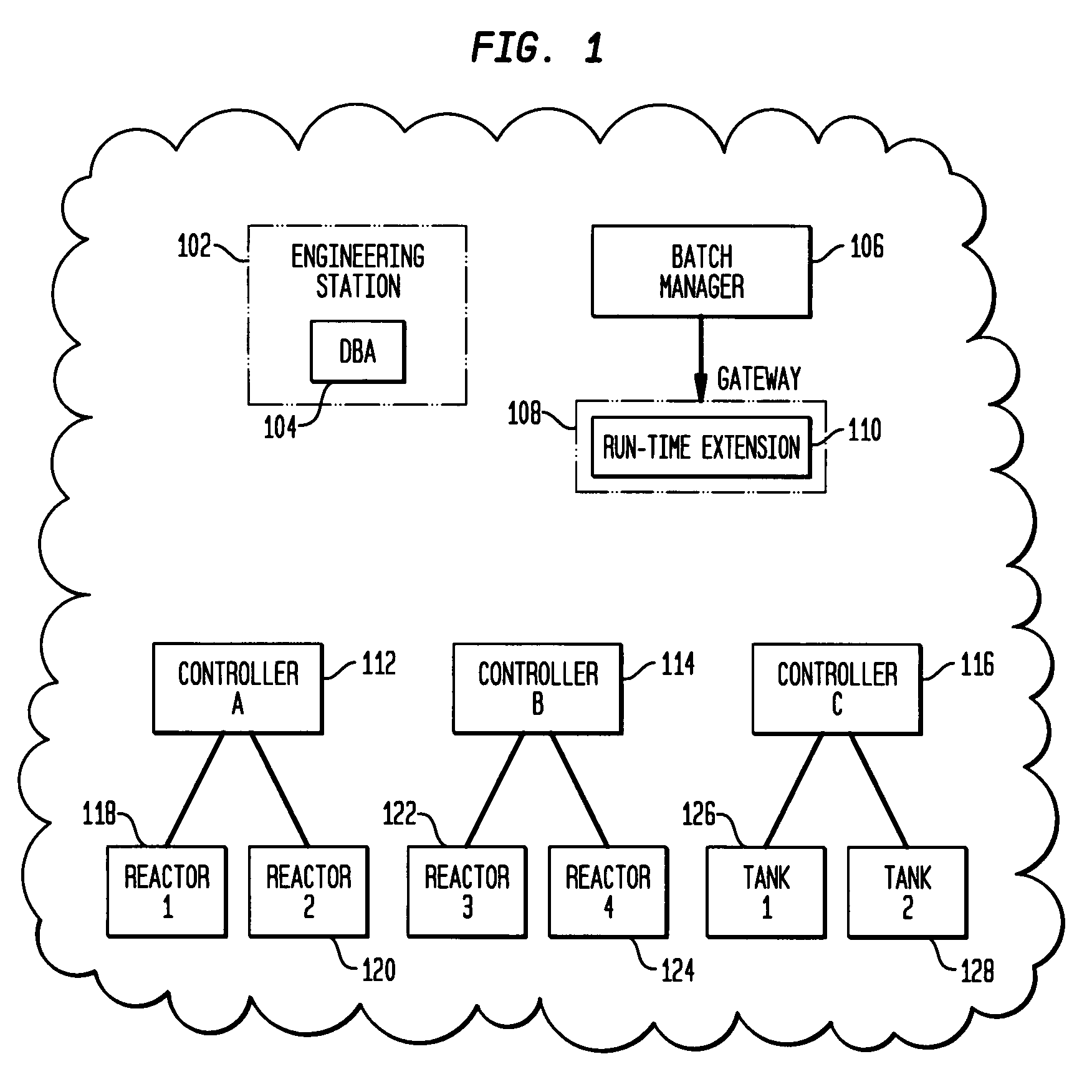

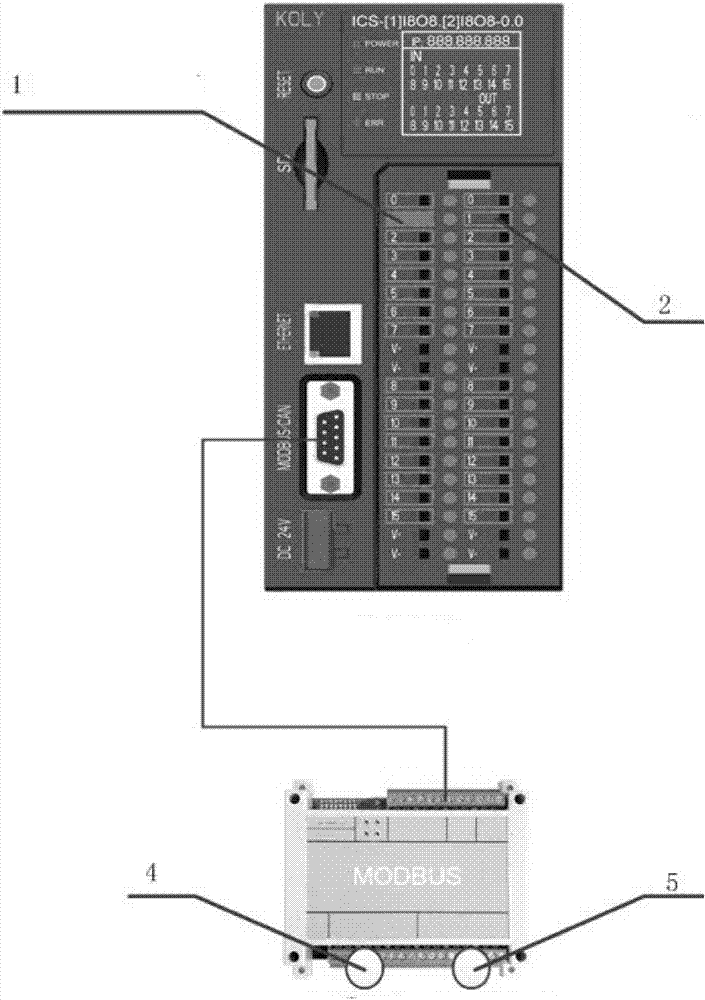

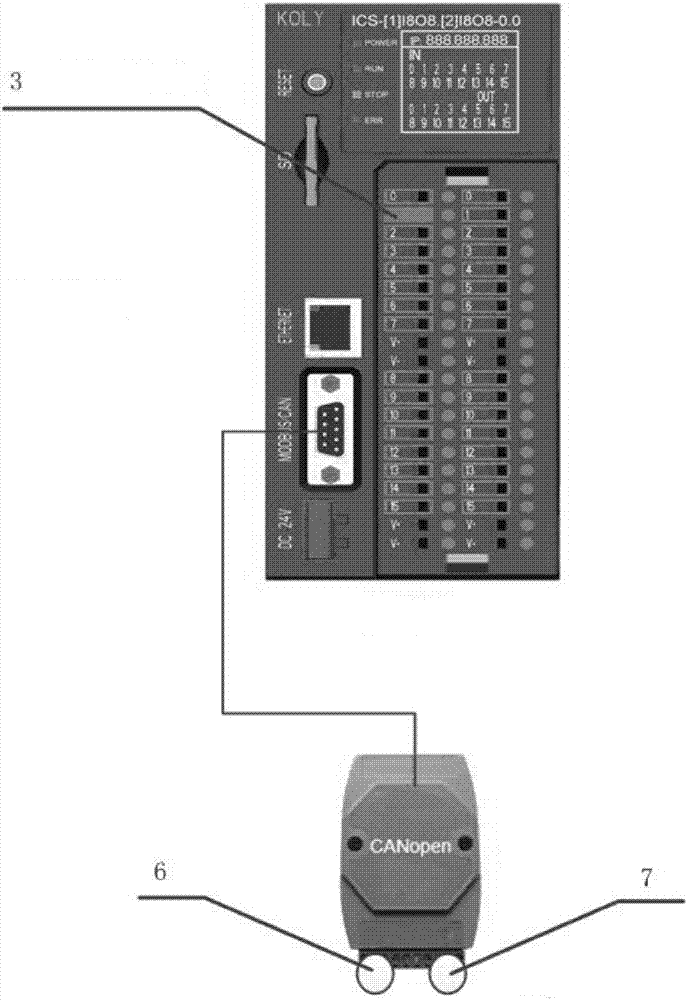

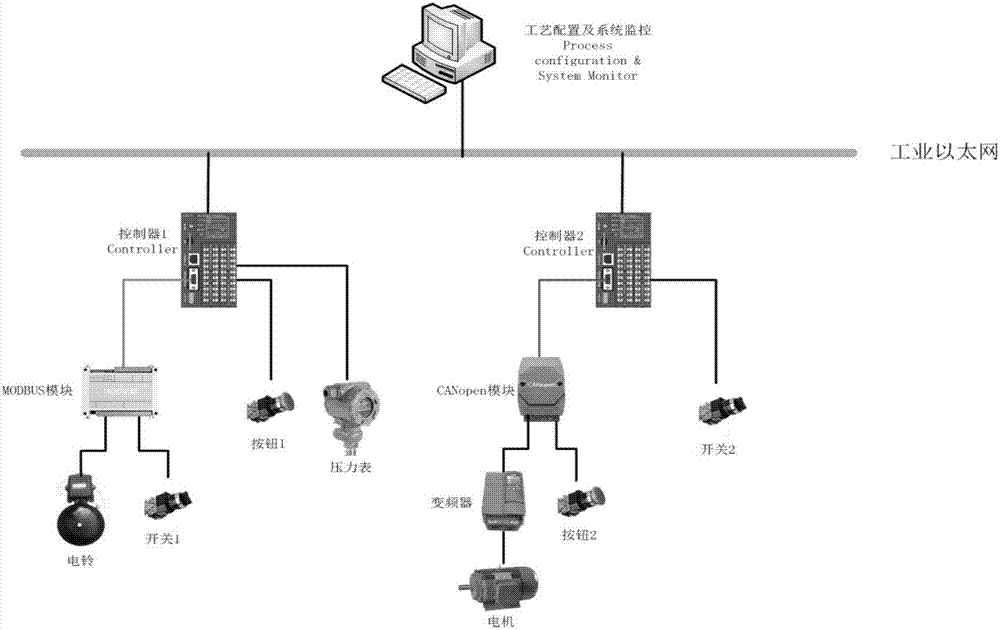

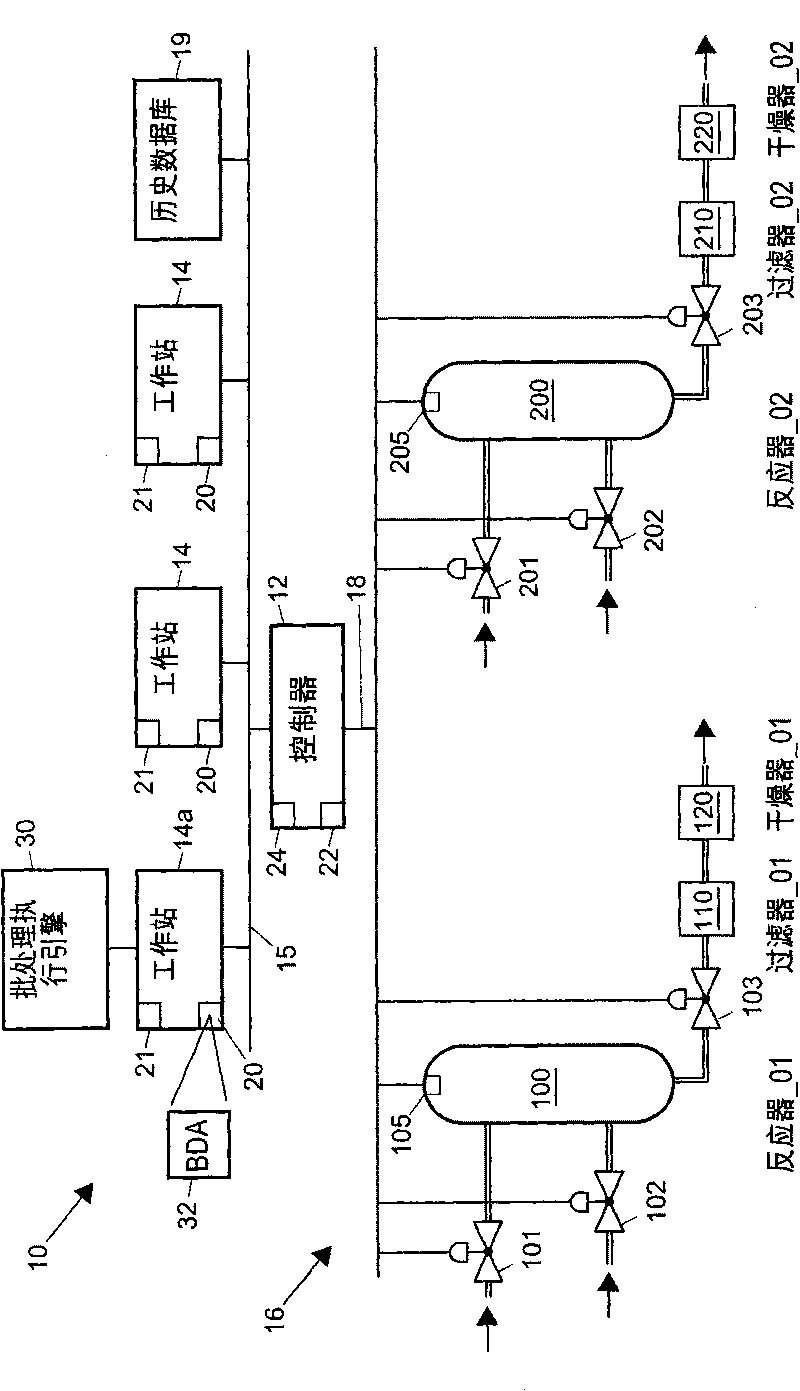

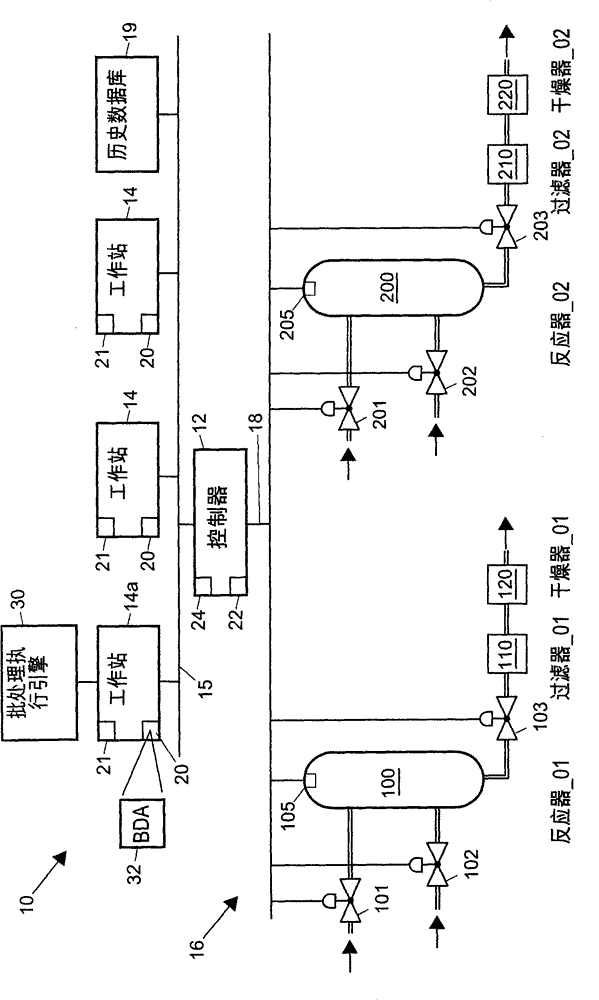

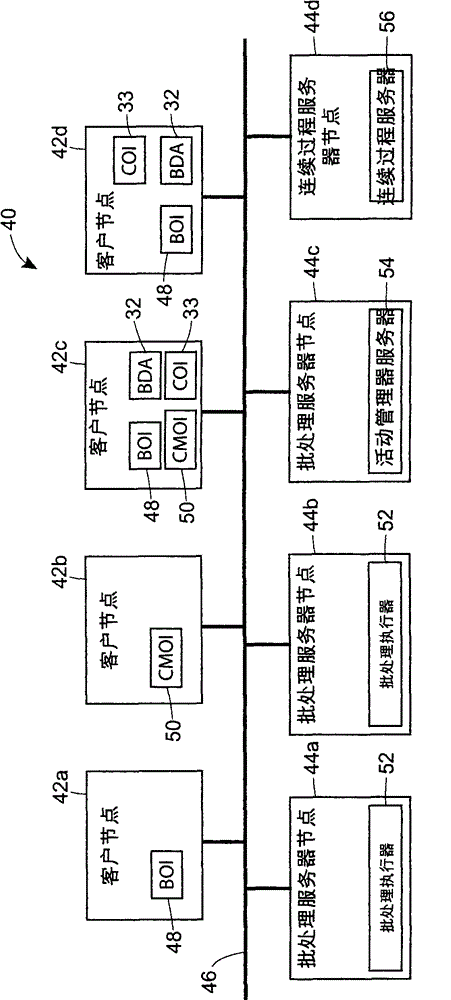

System and method for batch process control with diverse distributed control system protocols

InactiveUS20070283030A1Enhanced interactionProgramme controlMultiple digital computer combinationsDistributed control systemRunning time

A system and method for batch process control with diverse distributed control system (DCS) protocols is disclosed. A run-time extension acts as an adaptation layer that allows a single batch manager to supervise controllers utilizing diverse DCS protocols. The run-time extension receives commands transmitted from the batch supervisor in a first DCS protocol, translates the commands to a second DCS protocol utilized by a controller, and transmits the translated command to the controller to control various equipment associated with the controller. A database automation object (DBA) inputs configuration information from controllers utilizing diverse DCS protocols, extracts equipment information from the configuration information, generates protocol translation logic based on the configuration information, and translates recipe and formula information included in the configuration information into a common format.

Owner:SIEMENS AG

System and method for batch process control with diverse distributed control system protocols

InactiveUS7747416B2Enhanced interactionProgramme controlError detection/correctionDistributed control systemRunning time

A system and method for batch process control with diverse distributed control system (DCS) protocols is disclosed. A run-time extension acts as an adaptation layer that allows a single batch manager to supervise controllers utilizing diverse DCS protocols. The run-time extension receives commands transmitted from the batch supervisor in a first DCS protocol, translates the commands to a second DCS protocol utilized by a controller, and transmits the translated command to the controller to control various equipment associated with the controller. A database automation object (DBA) inputs configuration information from controllers utilizing diverse DCS protocols, extracts equipment information from the configuration information, generates protocol translation logic based on the configuration information, and translates recipe and formula information included in the configuration information into a common format.

Owner:SIEMENS AG

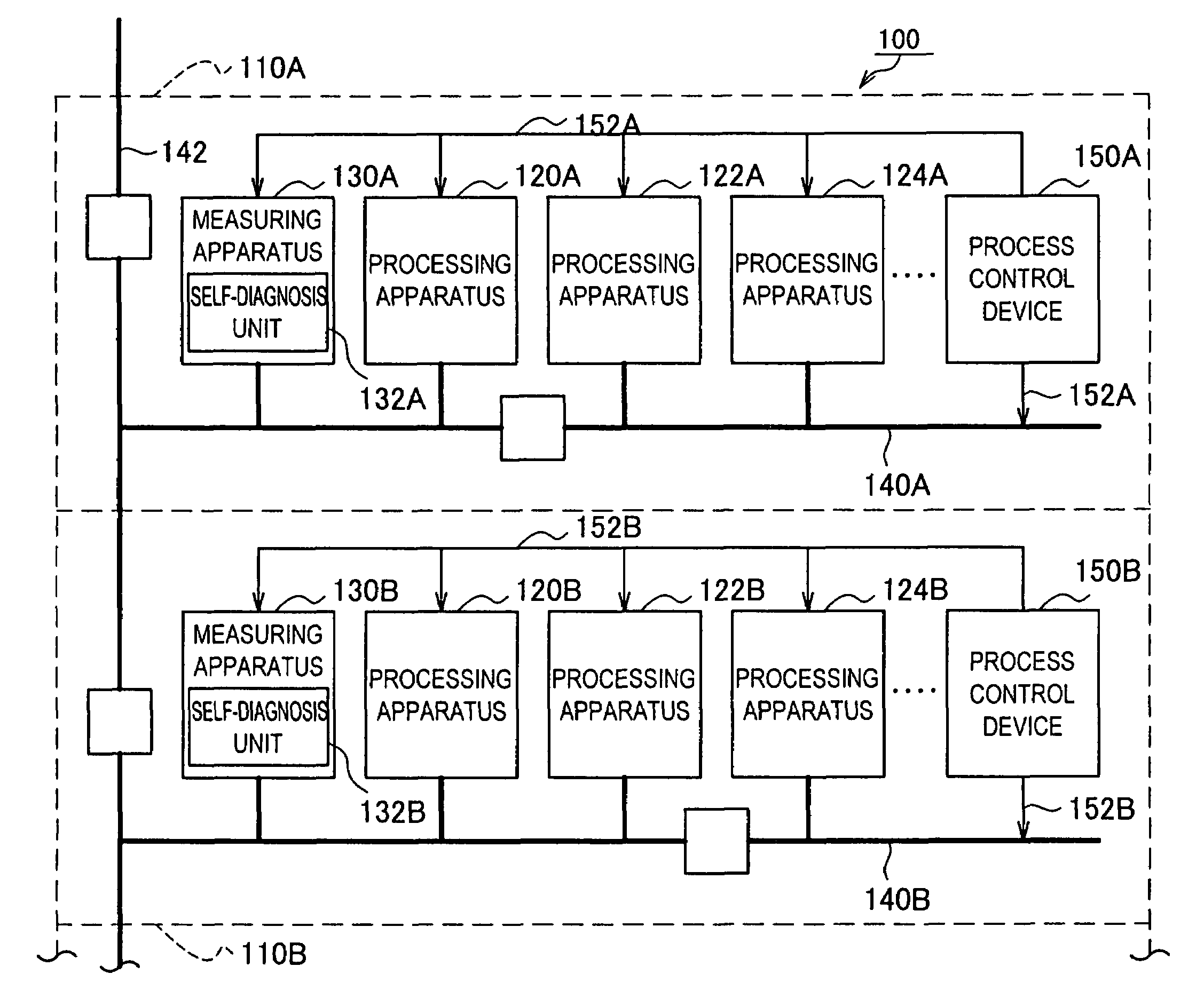

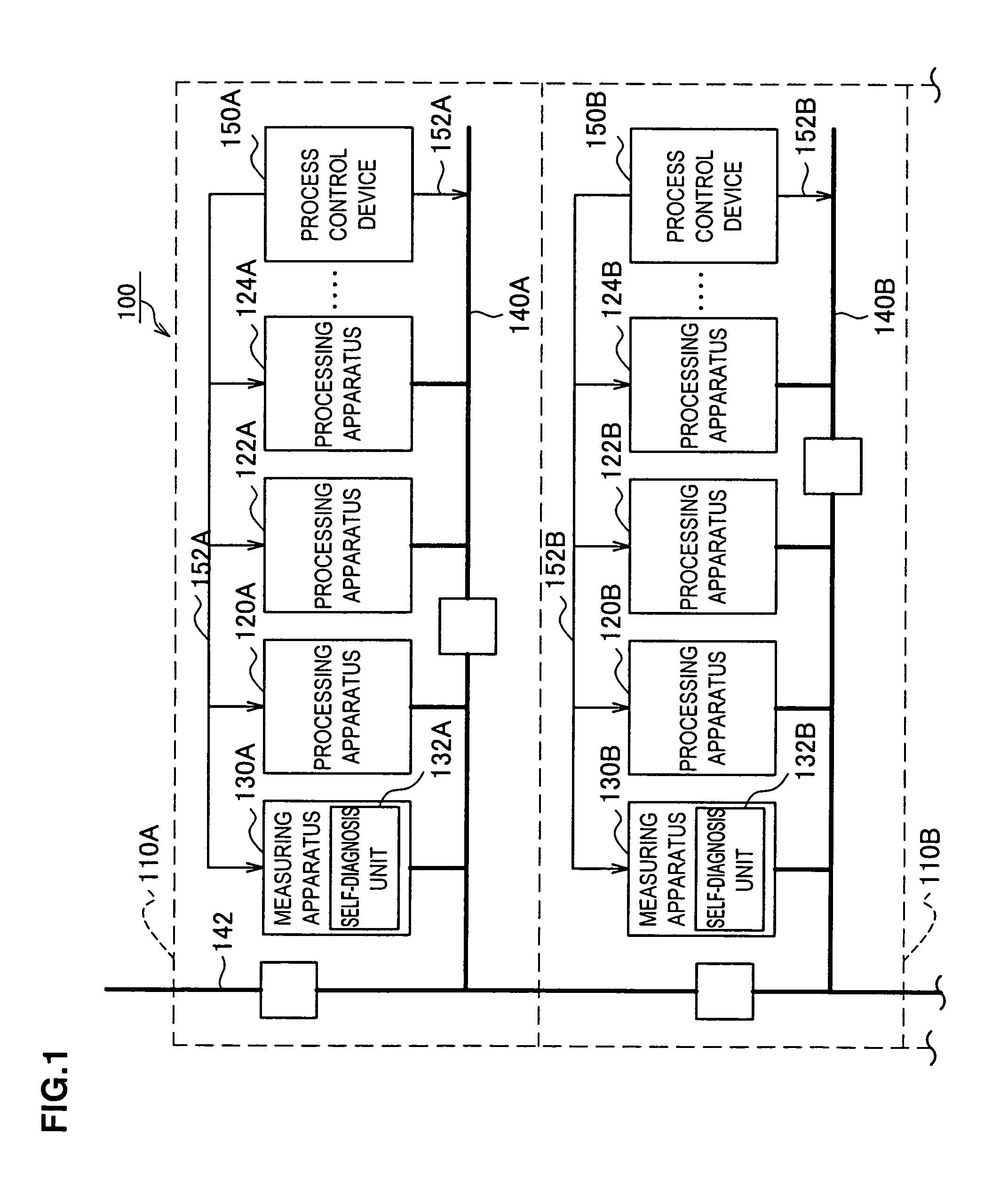

Process control system and process control method

ActiveUS7047095B2Reduce decreaseMaximizes operating rateDigital computer detailsNuclear monitoringControl systemProcess engineering

A process control system that controls processing executed on semiconductor wafers by processing apparatuses 120, 122, 124 installed in each bay (area) 110 inside a factory the processing results of which are predictable, having installed in the corresponding bay, at least one measuring apparatus 130 that executes a measuring operation on workpieces undergoing the processing in the bay, a transfer path 140 of a transfer apparatus, through which the workpieces are transferred among various apparatuses installed within the bay including the individual processing apparatuses and the measuring apparatus and a process control device 150 that controls the processing apparatuses, the measuring apparatus and the transfer apparatus in the bay. This structure reduces the length of time (cycle time) to elapse from the processing through the inspection operation and also improves the operating rate of each processing apparatus.

Owner:TOKYO ELECTRON LTD

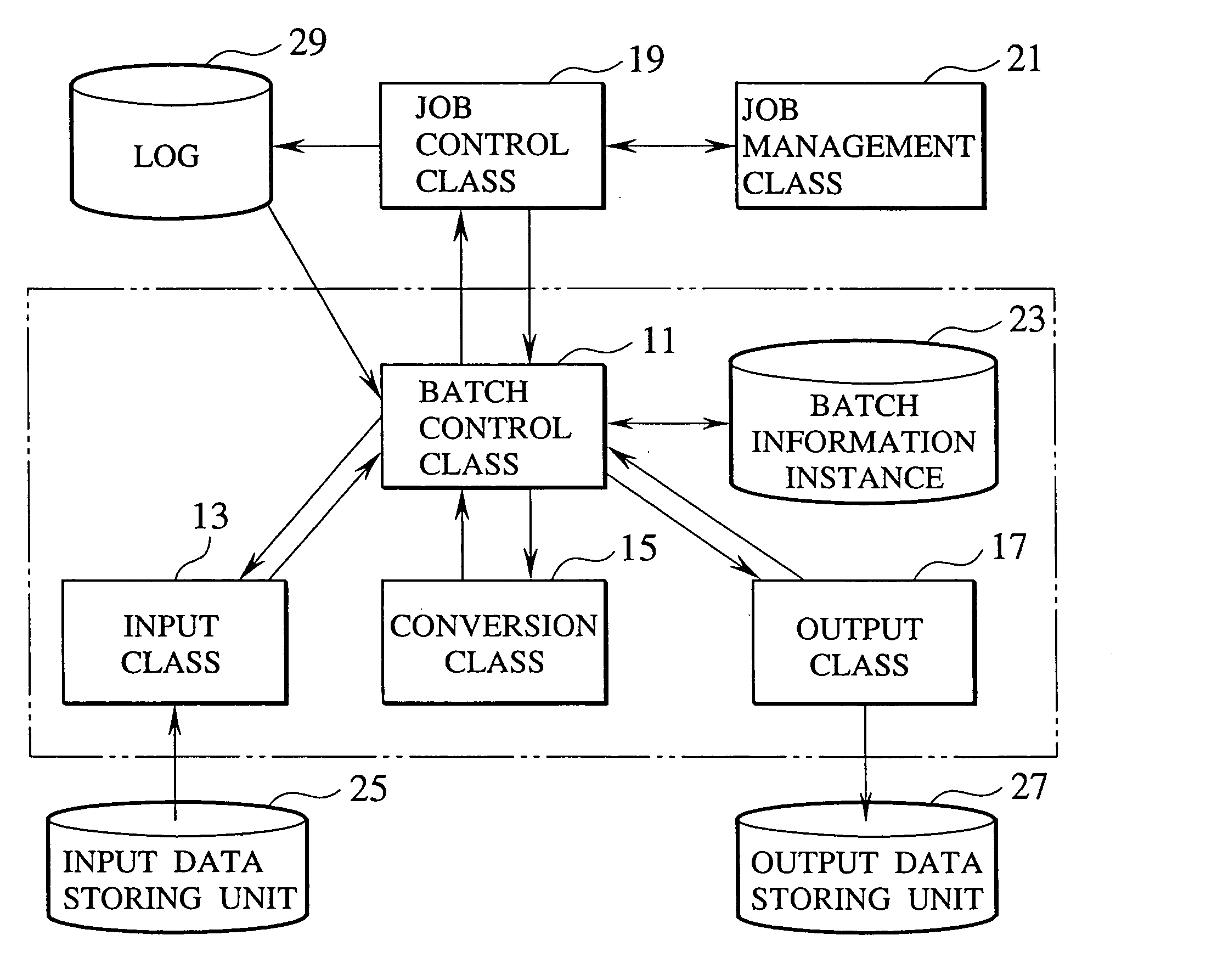

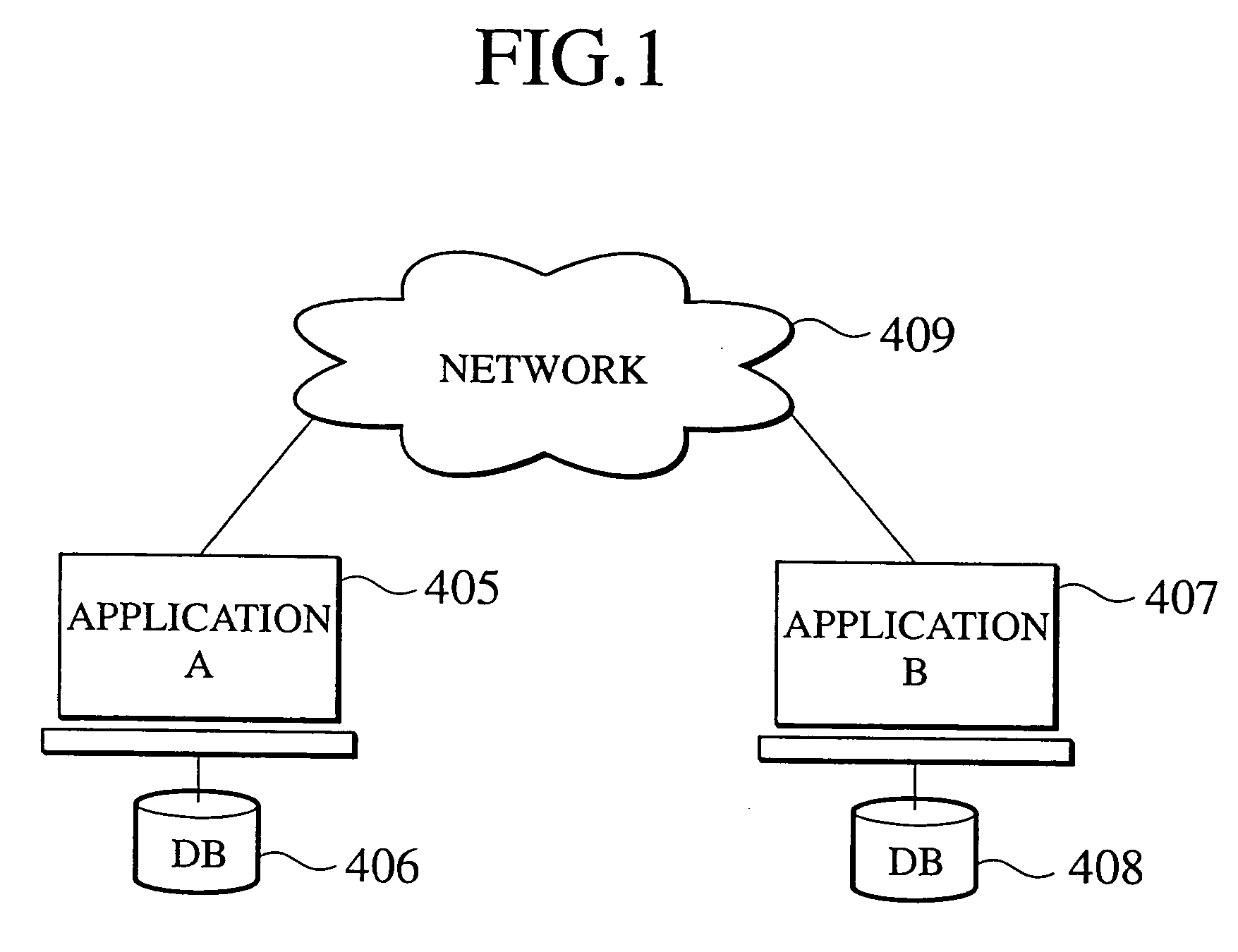

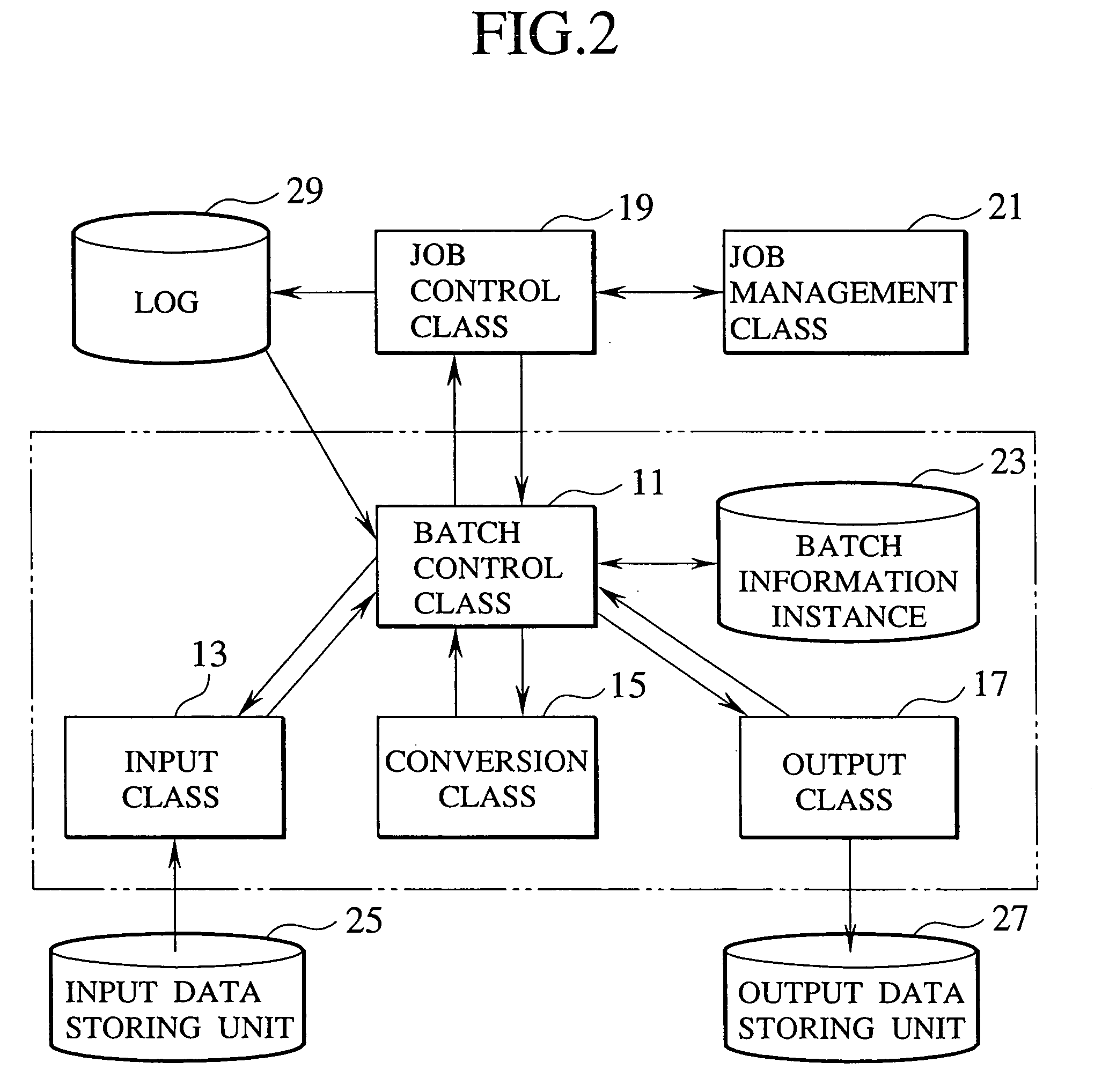

Information processing system and method for communications between application systems

InactiveUS20040049773A1Shorten programming timeInterprogram communicationSpecific program execution arrangementsInformation processingMessage delivery

An information processing system comprises a batch control class for passing a beginning message, and scheduling after receiving a completion message an input class for inputting data based on conditions when receiving the beginning message from the batch control class and passing the completion message to the batch control class upon completion of input processing, a conversion class for converting the input data based on conditions upon receiving the beginning message from the batch control class, and passing the completion message to the batch control class upon completion of conversion processing, and an output class for outputting data based on conditions upon receiving the beginning message from the batch control class.

Owner:CLASS TECH

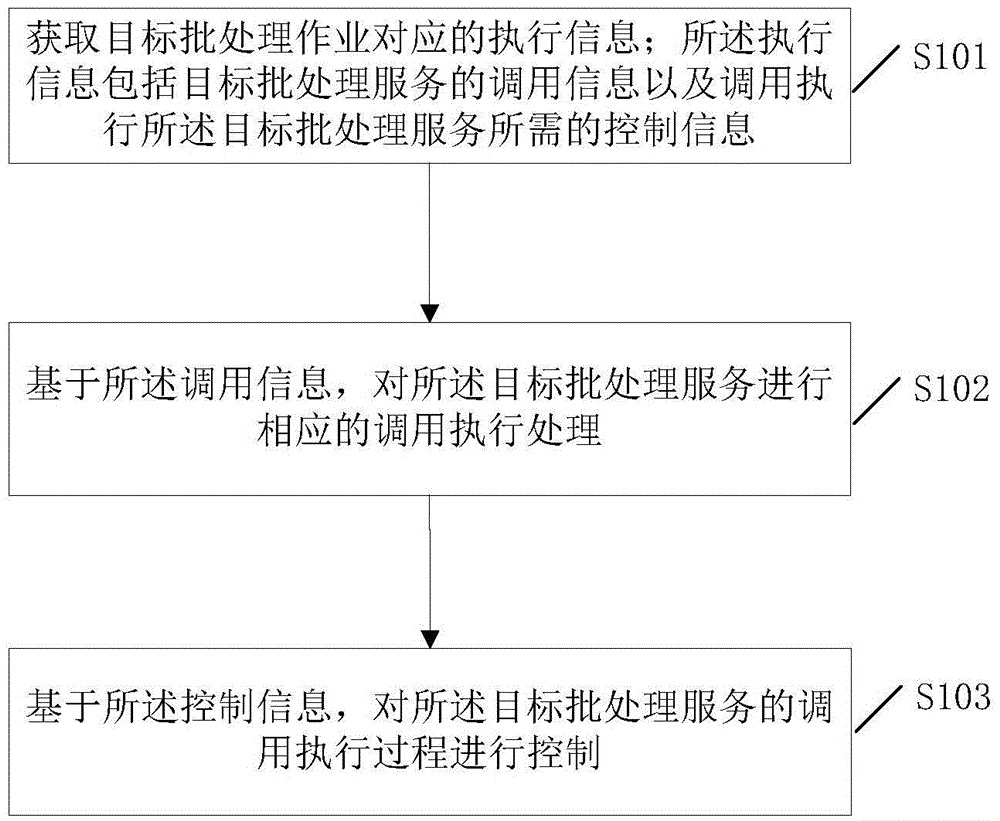

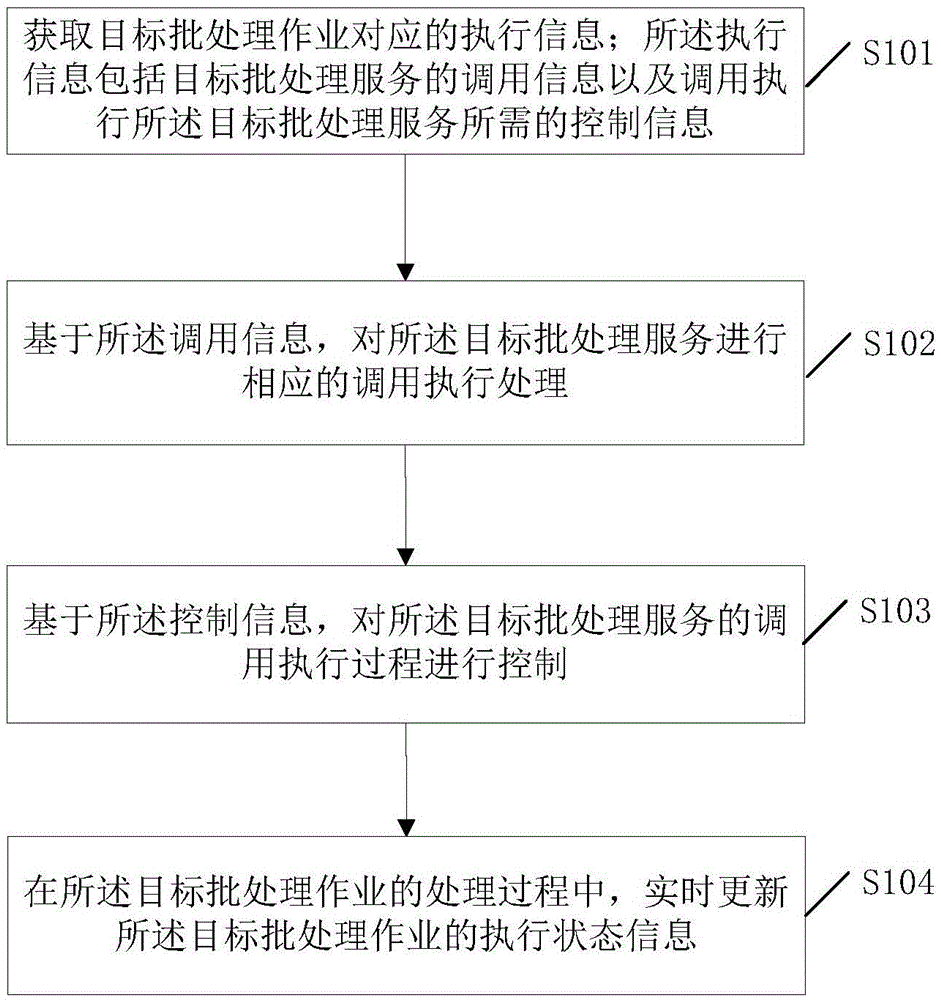

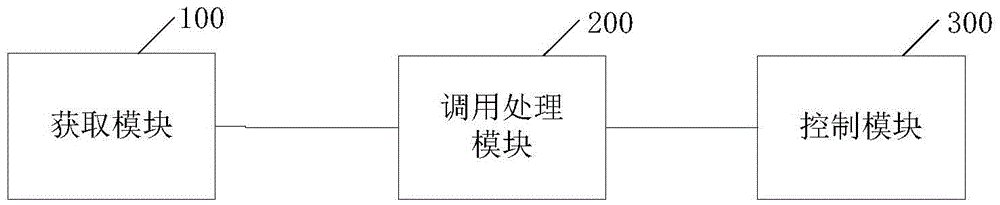

Batch processing controlling method and device

ActiveCN105487924ARealize the control functionReduce development complexityProgram initiation/switchingInformation needsBatch process control

The invention discloses a batch processing controlling method and device. The method comprises the followings steps: obtaining the corresponding executive information of a target batch processing job, wherein the executive information comprises call information of a target batch processing service and control information needed by the call execution of the target batch processing service; carrying out corresponding call execution processing on the target batch processing service on the basis of the call information; and control the call execution process of the target batch processing service on the basis of the control information. According to the method disclosed by the invention, the function of controlling the batch processing service is realized while the entry function of the batch processing service is provided, so that by applying the method, the function of a batch processing trigger can be effectively extended, and when the batch processing service is developed by technical personnel, only the business logic implementation of the batch processing service is needed to be concerned and the developing complexity of the batch processing service is effectively reduced.

Owner:CHINA CONSTRUCTION BANK

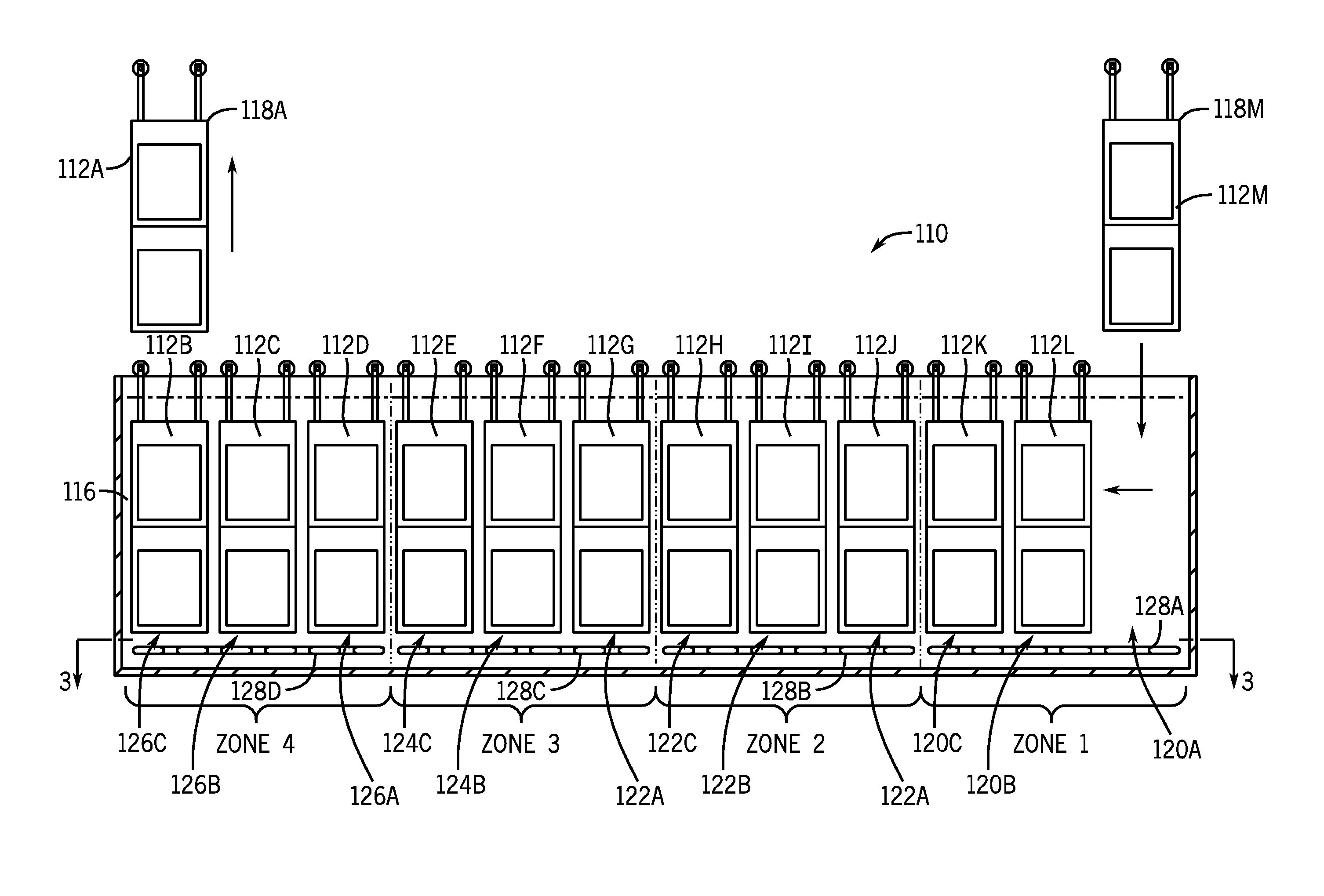

Shell Egg Pasteurization System and Method

ActiveUS20110300023A1Accelerate temperature recoveryImprove system throughputTemperatue controlEggs preservation by heatingControl systemPasteurization

A batch processing control system for a shell egg pasteurizer controls the time and temperature in which batches of shell eggs are held in a pasteurization bath in accordance with a predetermined pasteurization protocol for designated egg size and start temperature. The predetermined pasteurization protocol is preferably statistically verified to optimize batches of eggs having the designated size and start temperature. The system also includes reporting software that generates daily reports to track each respective batch and verify that the batch has been pasteurized according to the statistically verified protocol.

Owner:NAT PASTEURIZED EGGS

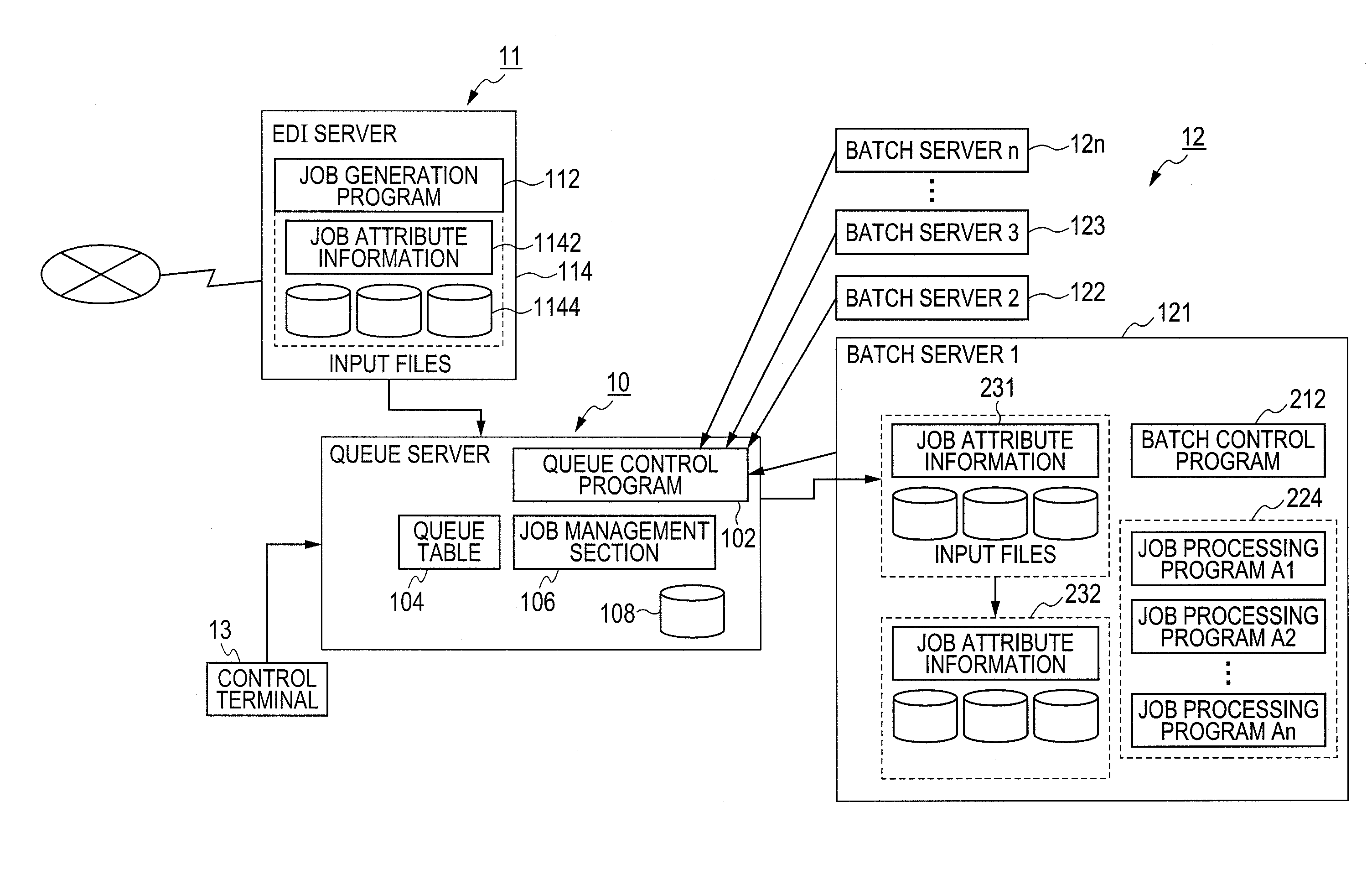

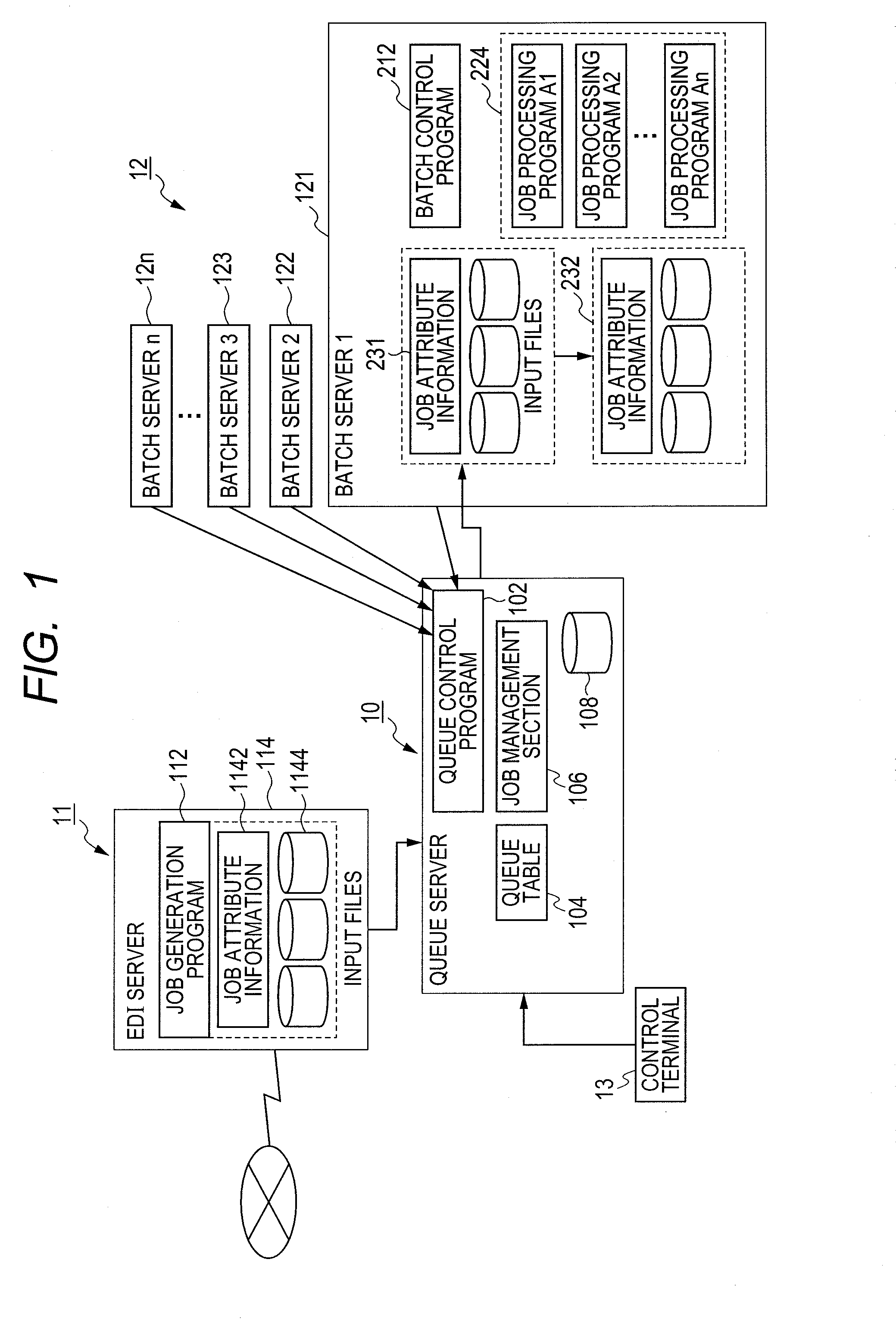

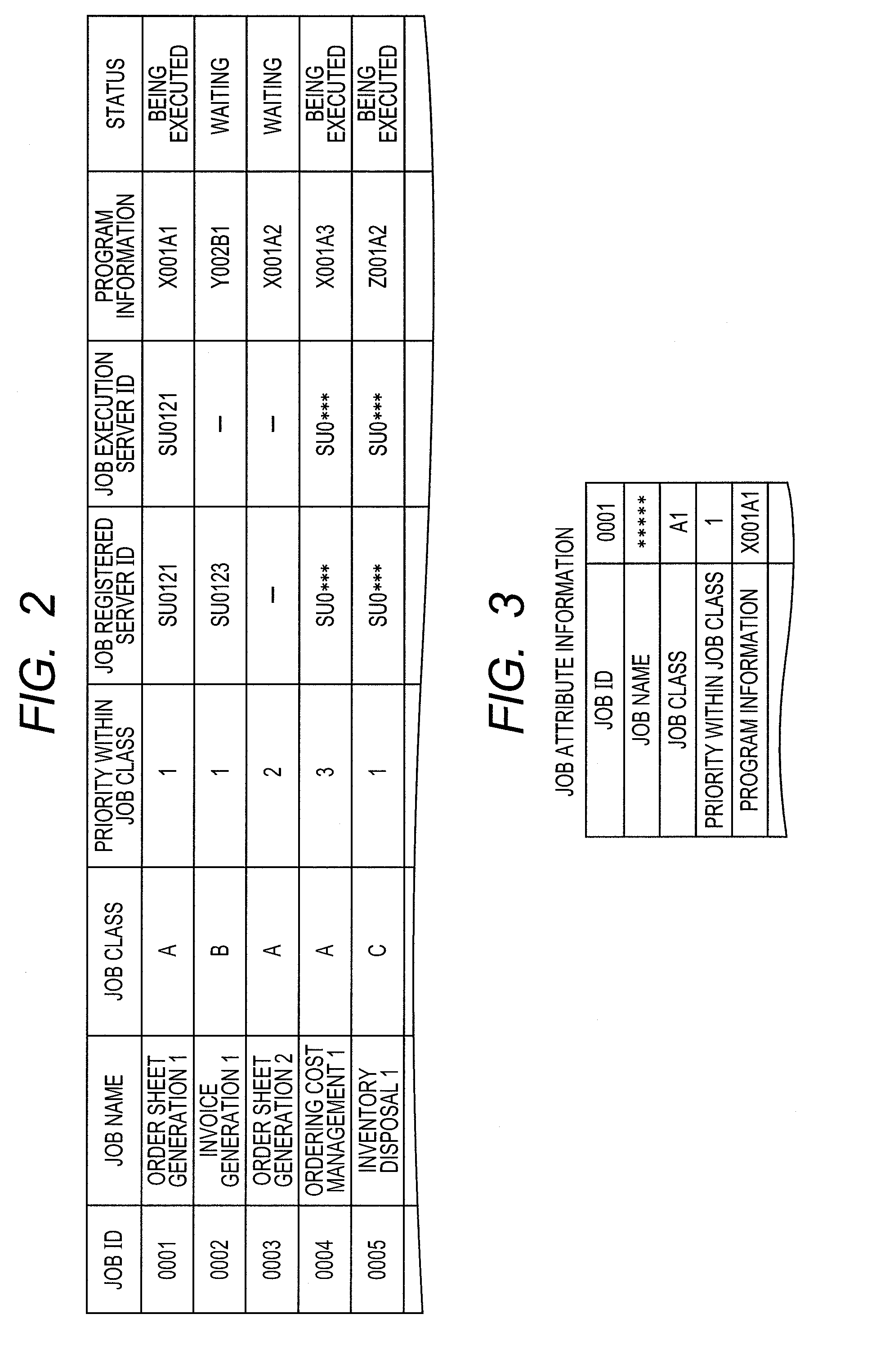

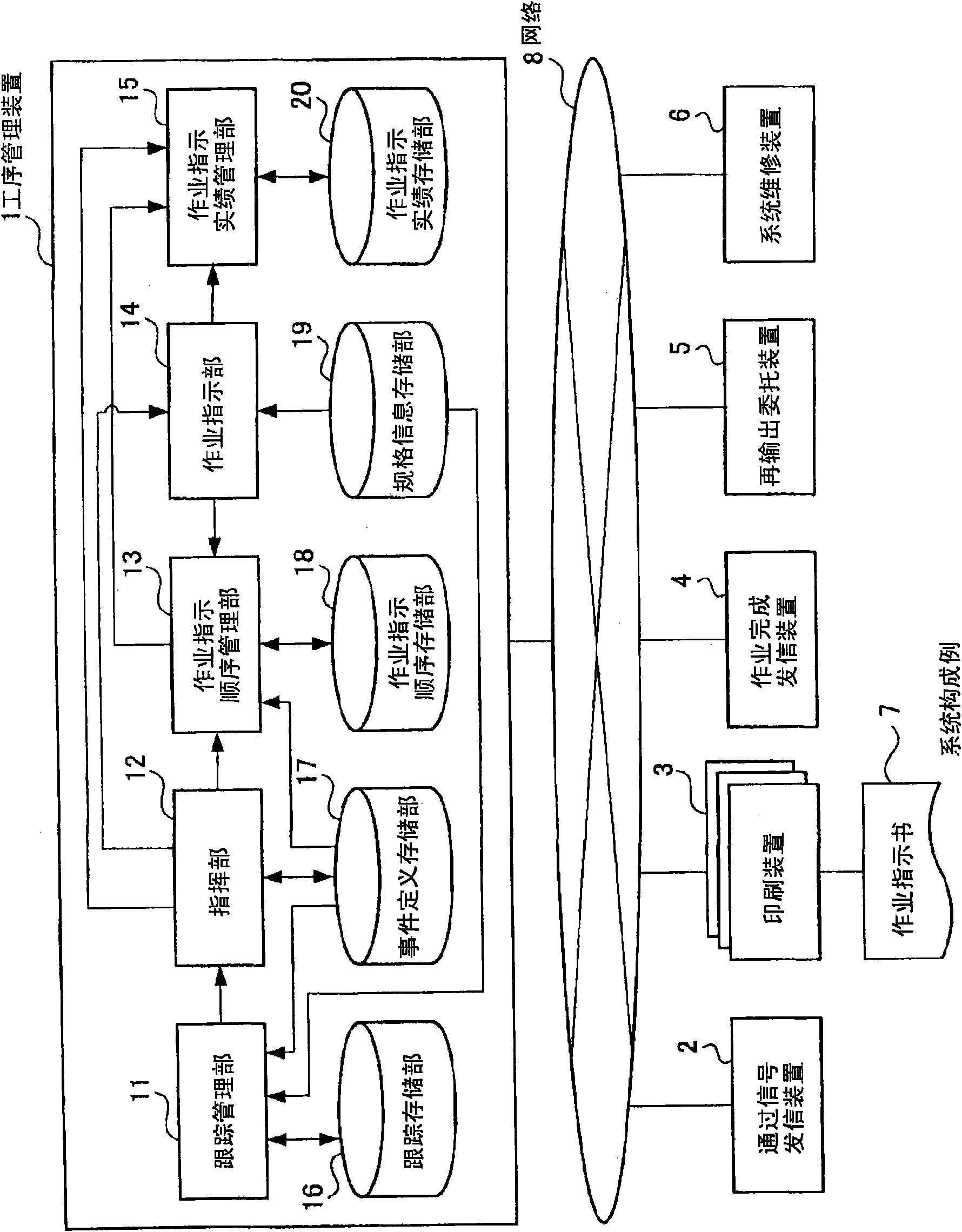

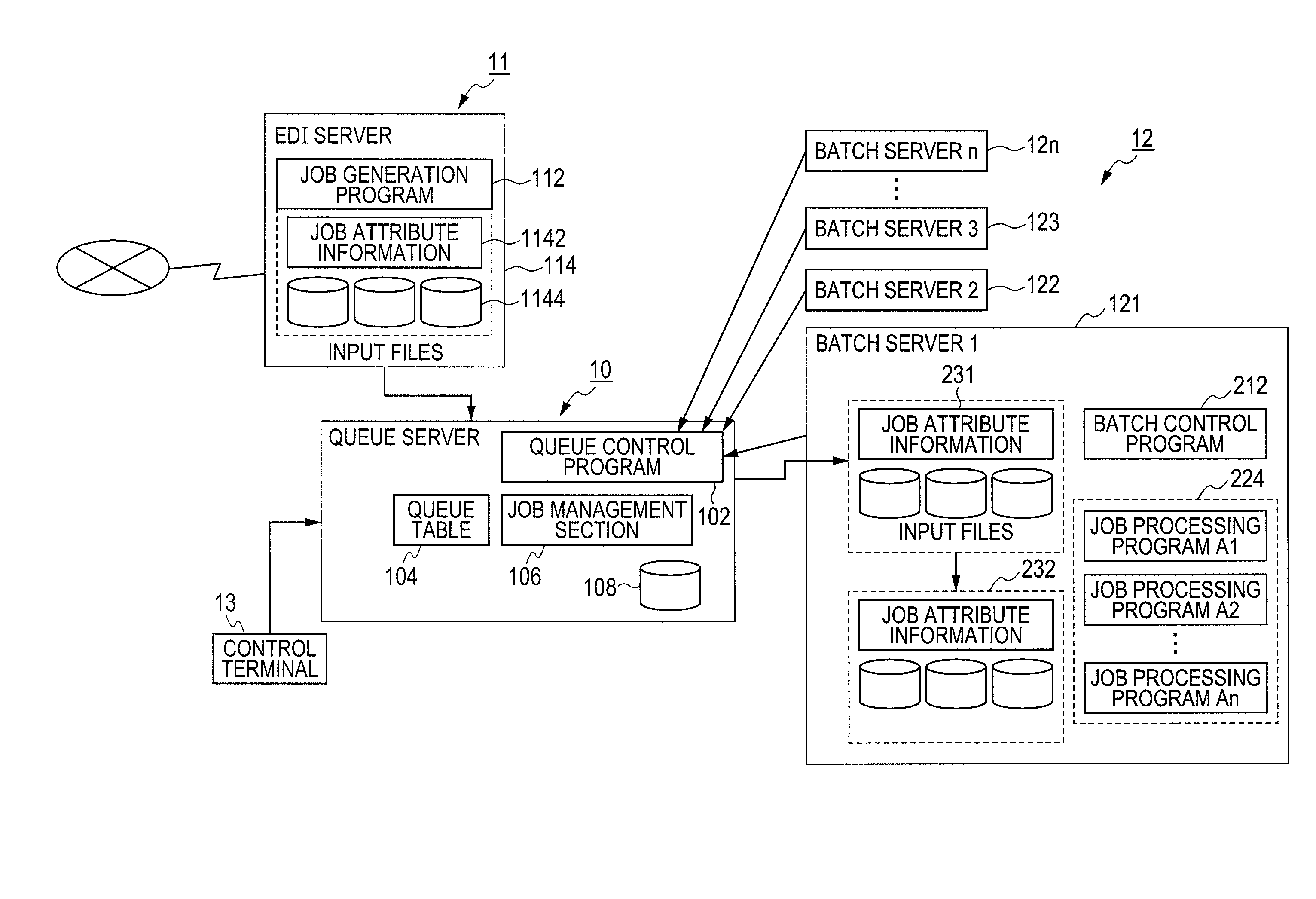

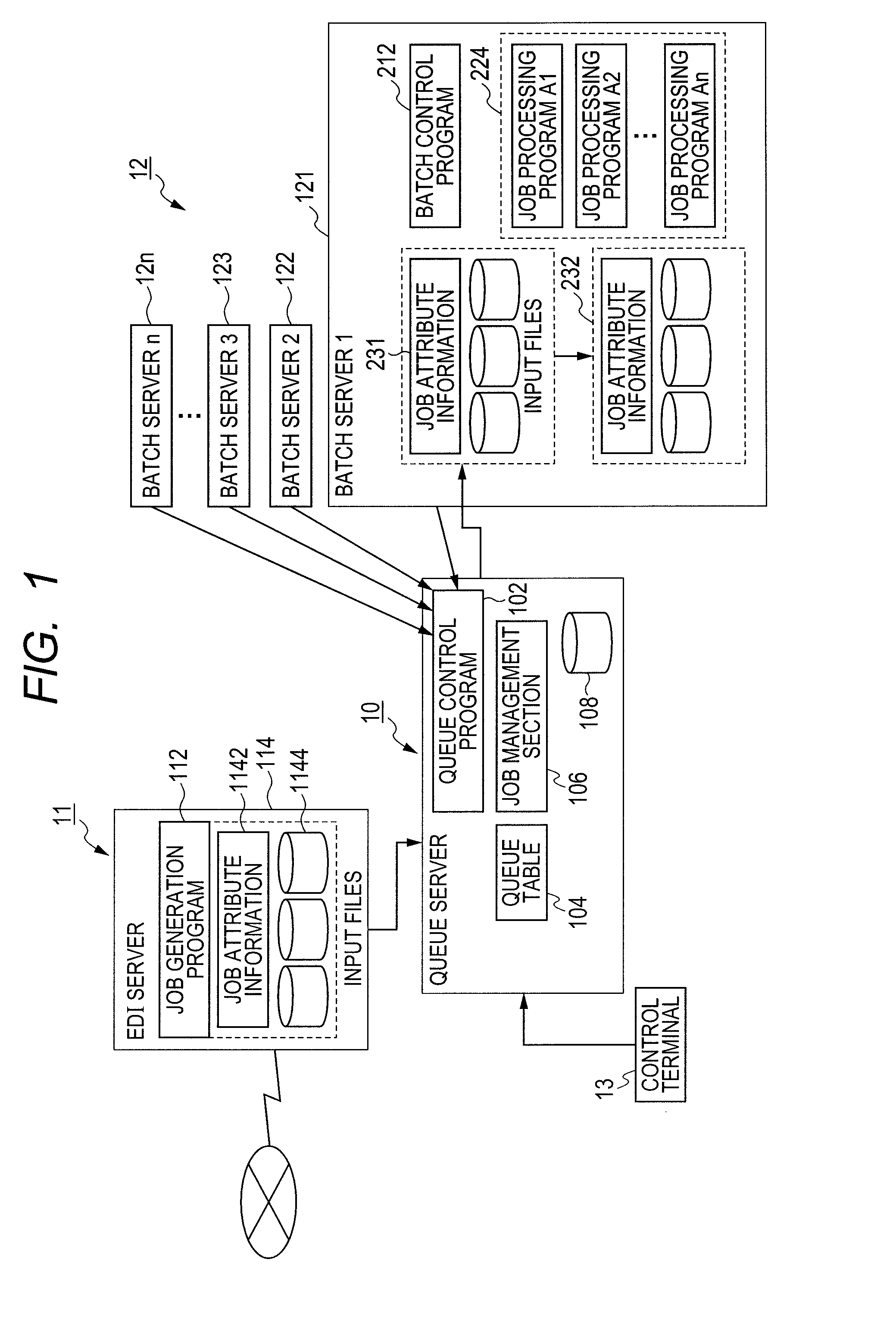

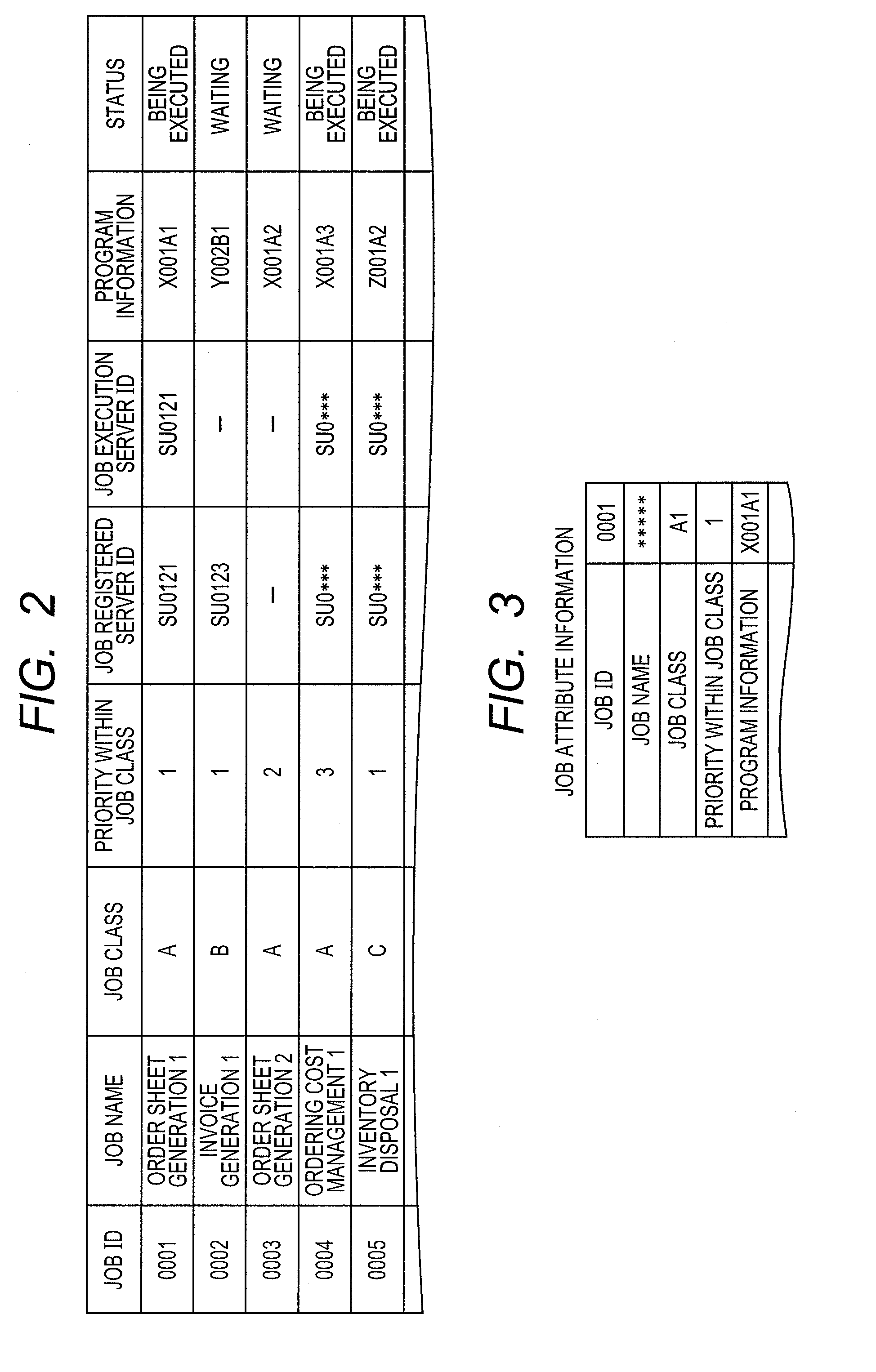

Job processing system, method and program

ActiveUS20110078297A1Process stabilityEasy to processData processing applicationsDigital computer detailsJob managementBatch process control

A job processing system has first to third servers. The first server has a job generation program for generating jobs as requested. The second server has a storage device for storing attribute information on and a file for use in processing each job generated by the first server, a management table for managing job management information on each job by assigning a unique ID to each job, and a queue control program for registering job management information in the management table, referring to the management table, and registering the file for and attribute information on each job in the storage device. The third server has one or more job processing programs for processing jobs acquired from the second server, batch control program for acquiring jobs from the second server and issuing responses concerning the processed jobs, and a storage device for storing attribute information on and a file for each job acquired.

Owner:HITACHI SYST

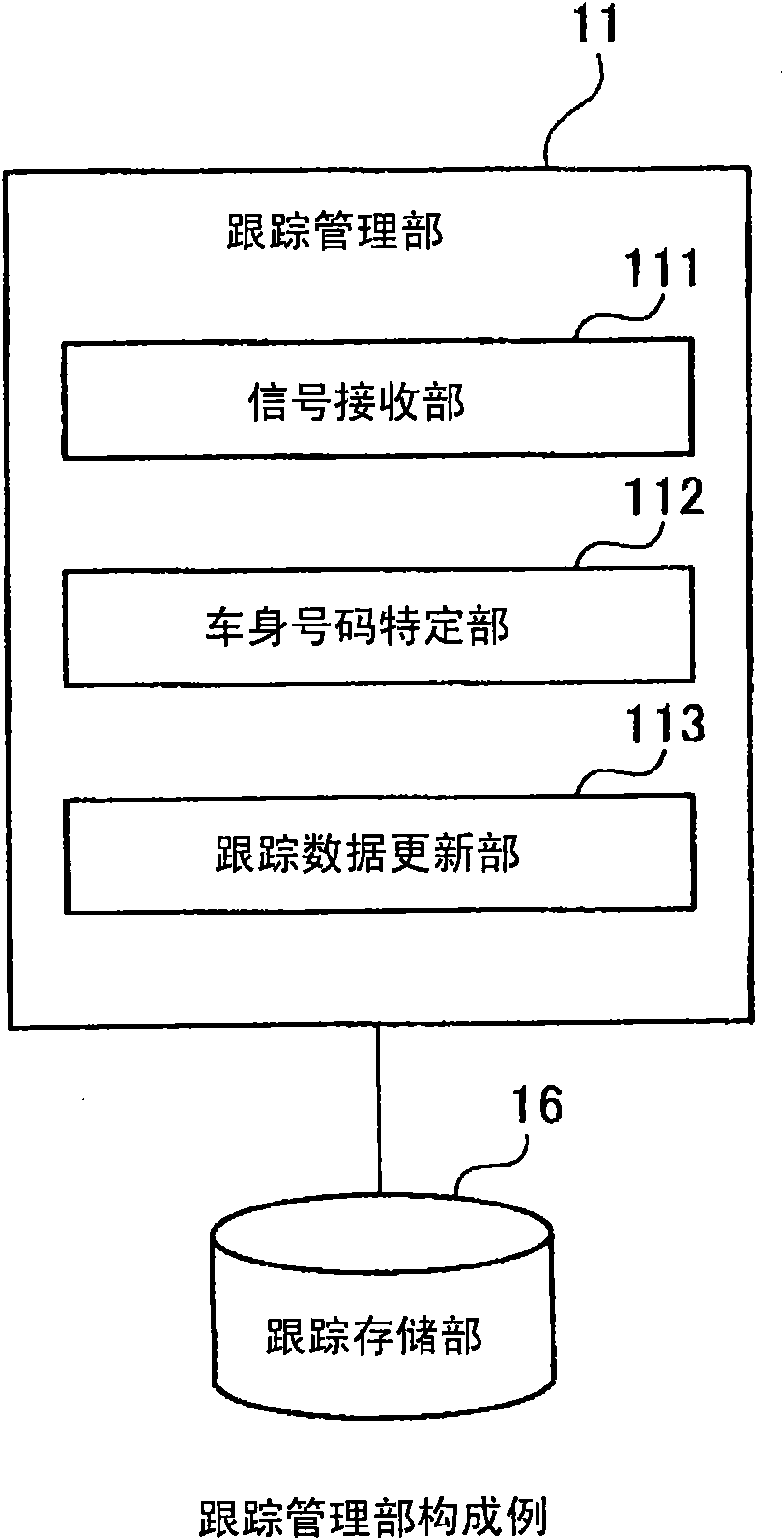

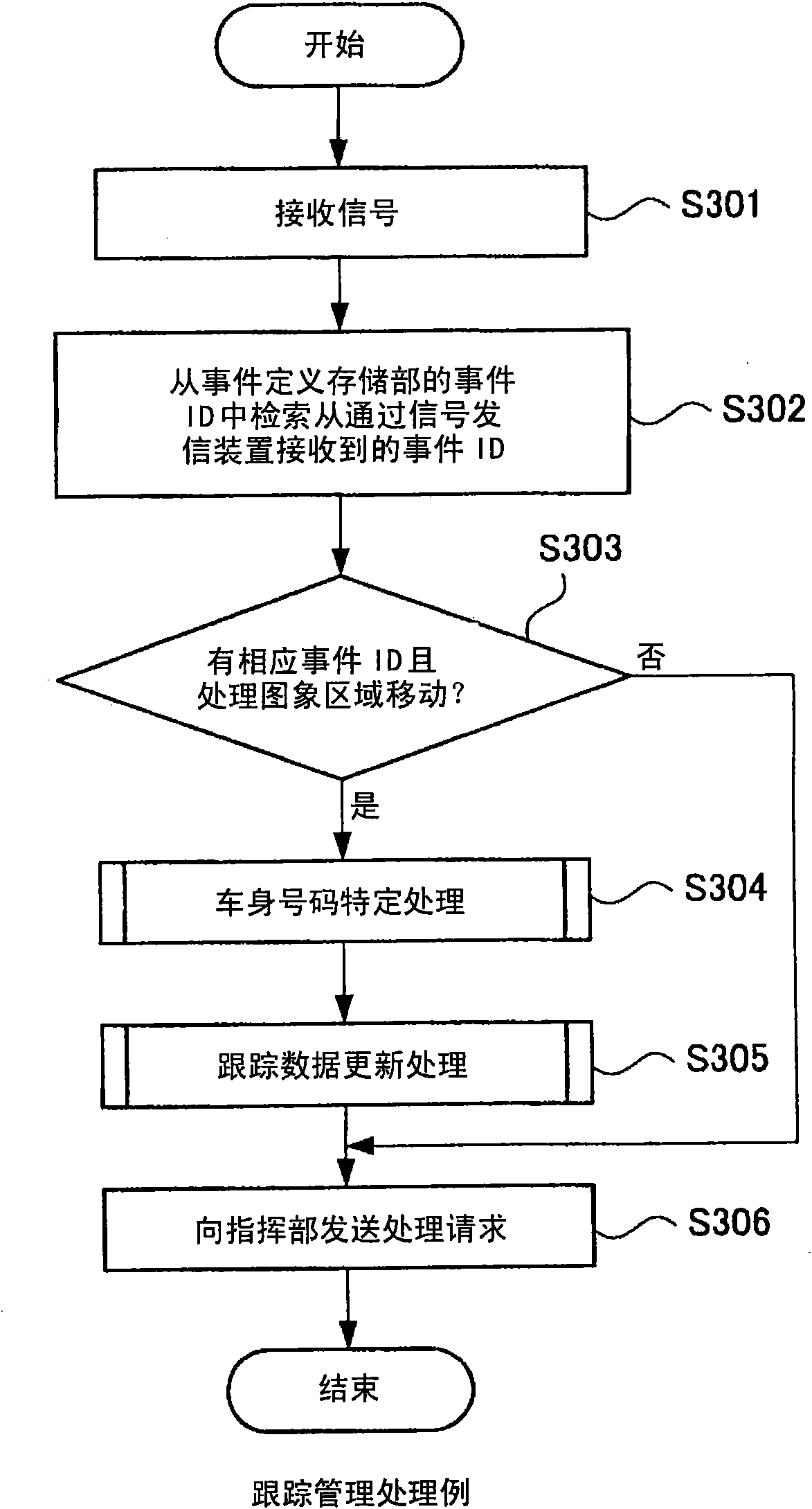

Process control device, process control method, and process control system

ActiveCN101644930AEasy to graspSuppress job stopData processing applicationsTotal factory controlProduction lineOrder control

The invention provide a process control system that can issue a work instruction sheet in the initially planned sequence order in the sub-line production process, even if the sequence order of the product in the main production line is changed. The process control device includes a tracking controller (11) receiving event information indicating that a product pass a predetermined location is received, and controlling the current position and sequence status of the products; a conductor unit (12) for determining a corresponding process based on the event information; and a work instruction unit(14) for issuing a work instruction for the product in the production line in response to the request from the conductor unit. The device further includes a work instruction past record control unit(15) for controlling past record of the work instructions in response to an issue of the work instruction; a work instruction sequence order control unit (13) for controlling a sequence order of the work instructions; and a work instruction sequence order storage (18) for storing information of the sequence order of the work instructions. Thereby, the control to the information of the sequence order of the work instructions in addition to the current location information of the product is realized.

Owner:HITACHI INFORMATION & CONTROL SOLUTIONS LTD

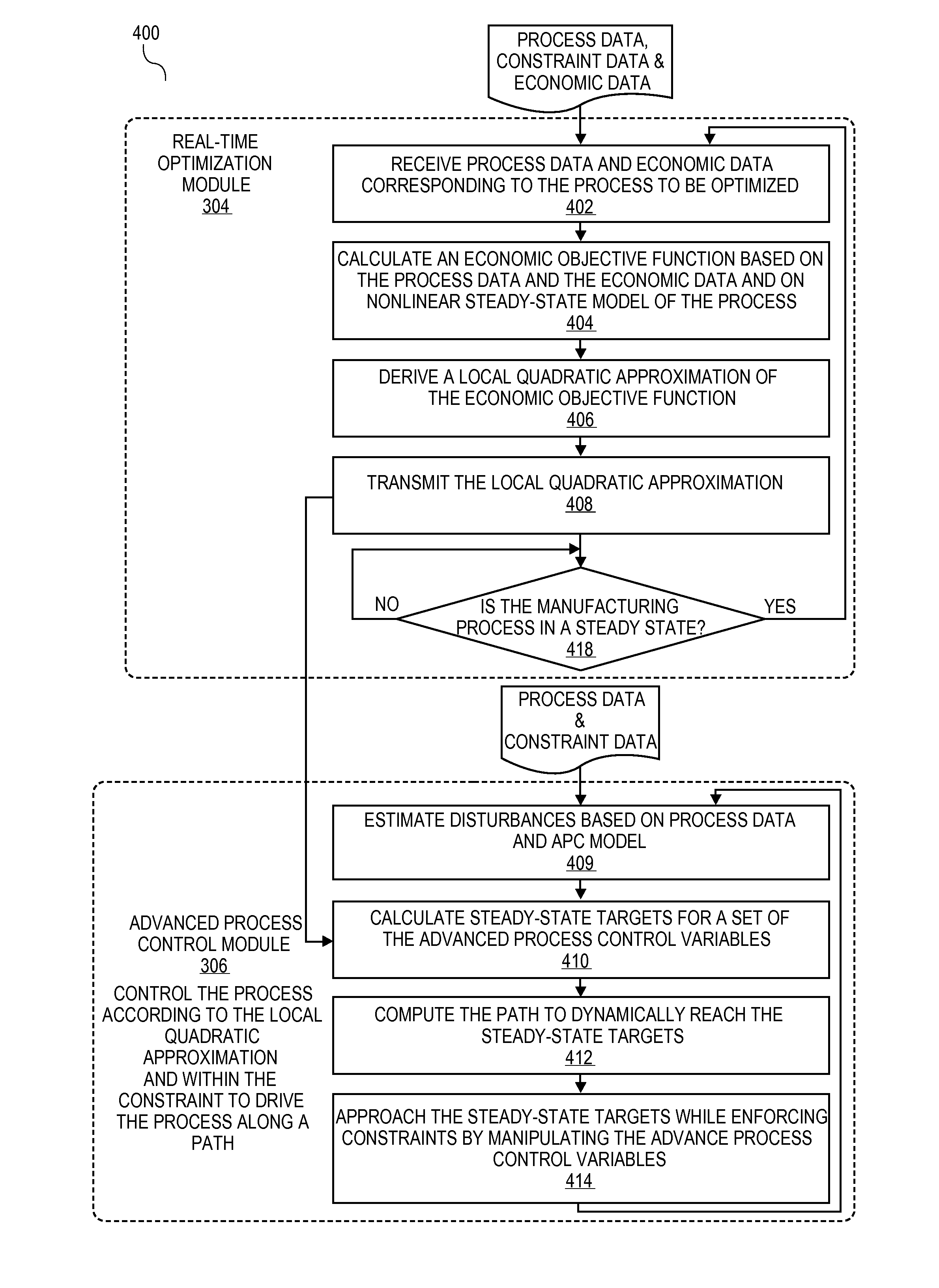

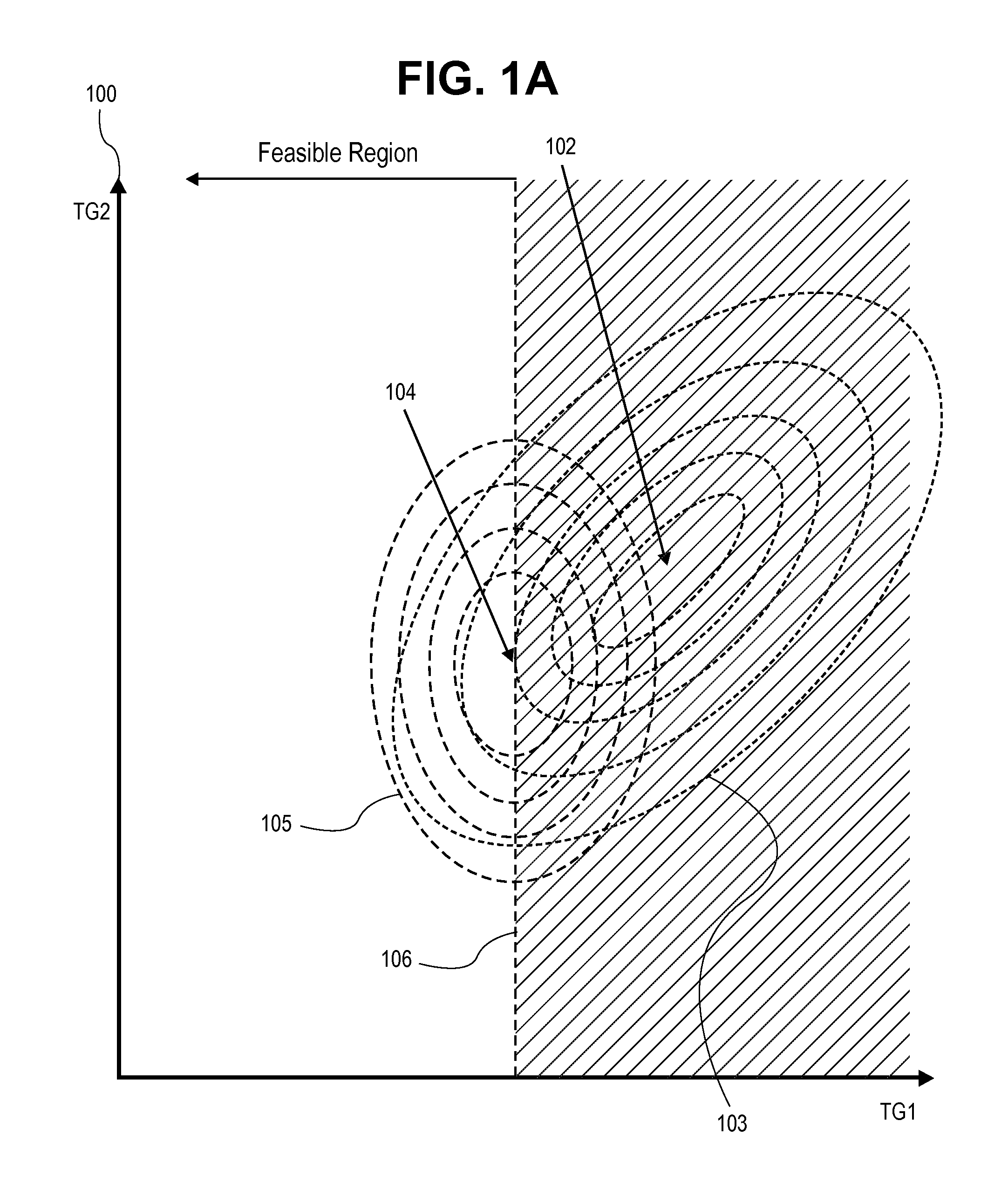

Economics-based coordination of advanced process control and real-time optimization

A system and method for coordinating advanced process control and real-time optimization of a manufacturing process are provided. The system and method receive process data and economic data corresponding to the manufacturing process to be controlled and optimized. Based on the process data, the economic data and a nonlinear steady-state model of the process, an economic objective function is calculated by a real-time optimization module. A reduced-order non-linear approximation of the economic objective function is thereafter calculated by the real-time optimization module and transmitted to an advanced process control module. The advanced process control module utilizes the reduced-order non-linear approximation of the economic objective function to control the manufacturing process towards the constrained economic optimum.

Owner:SHELL USA INC

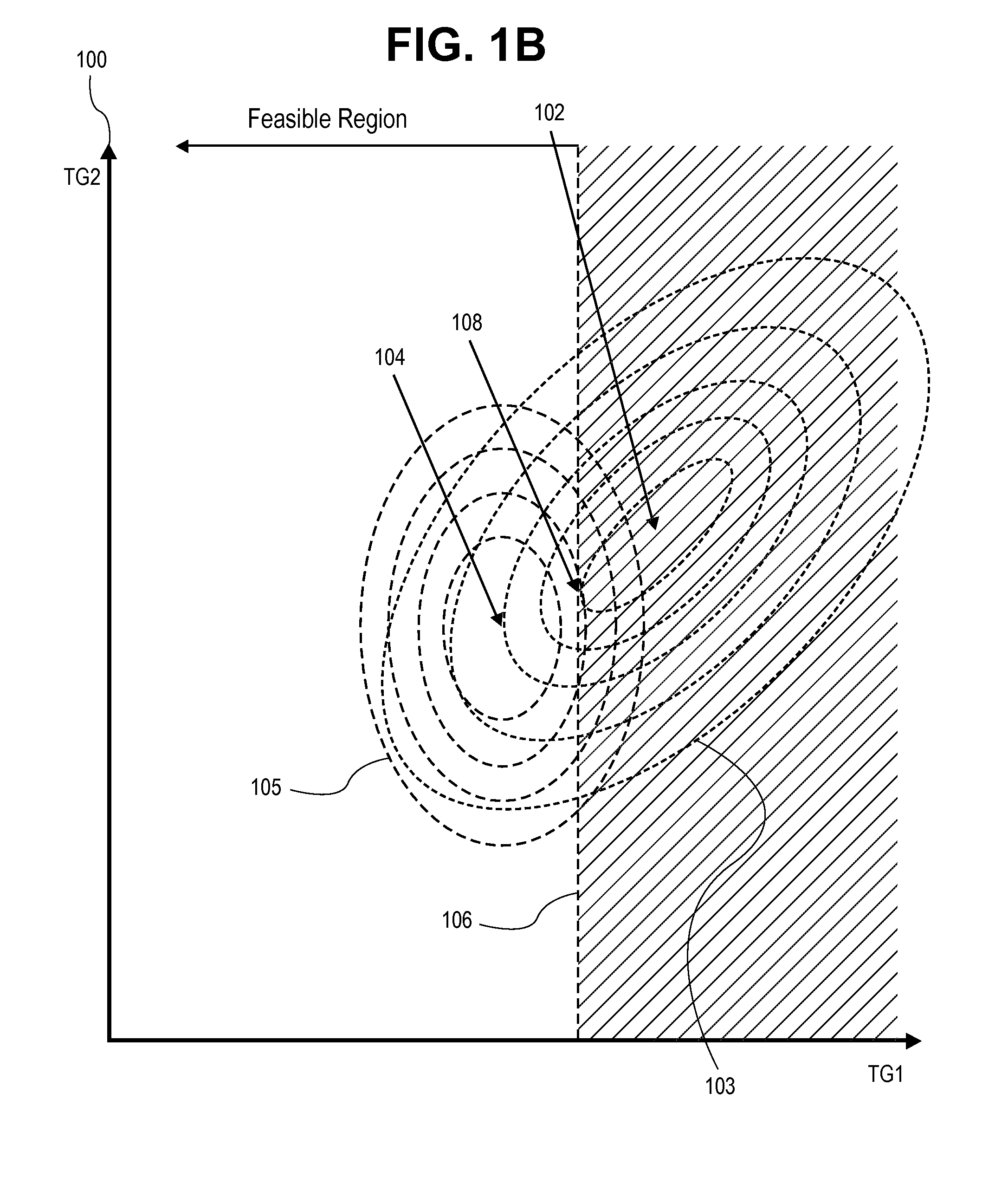

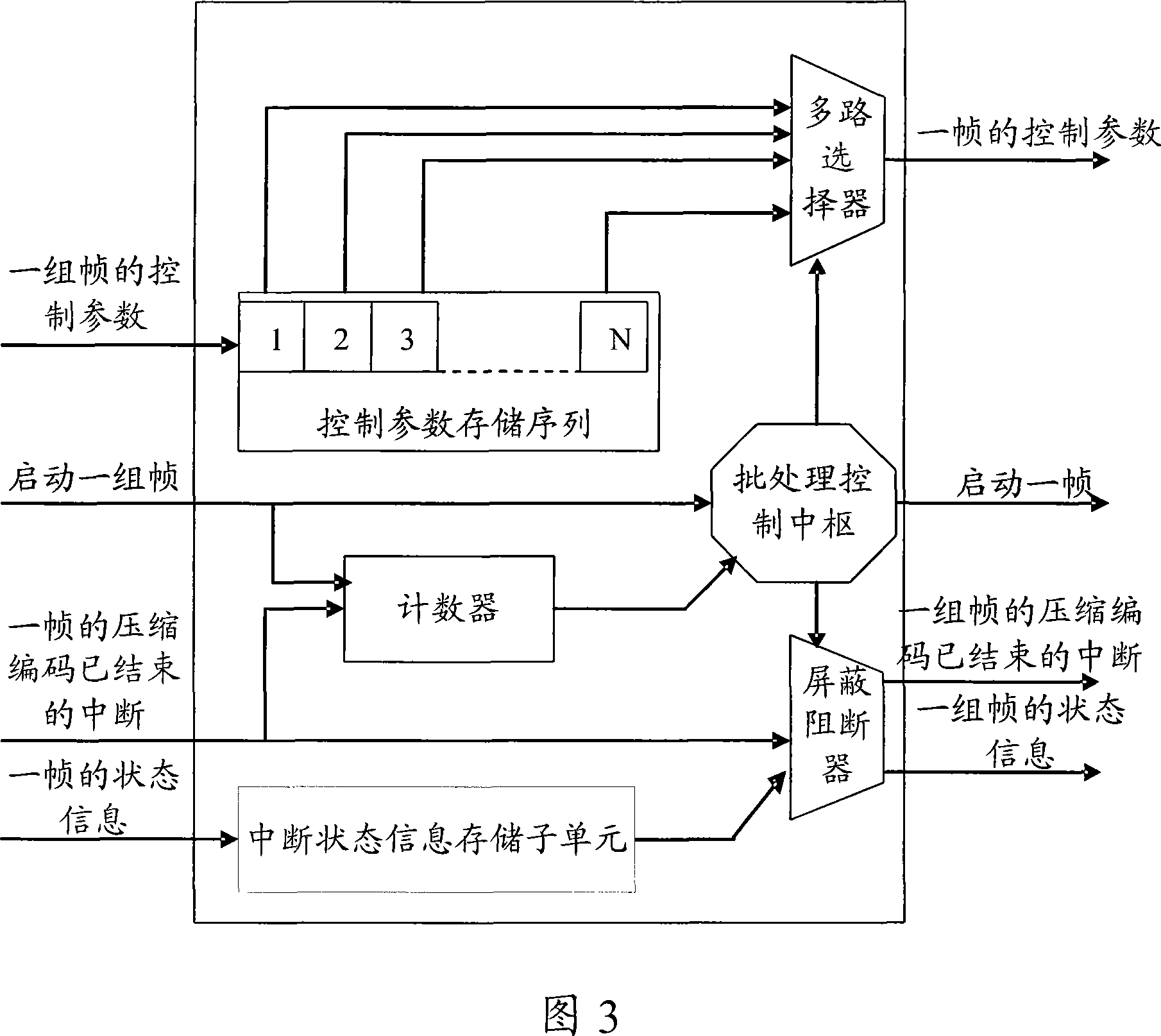

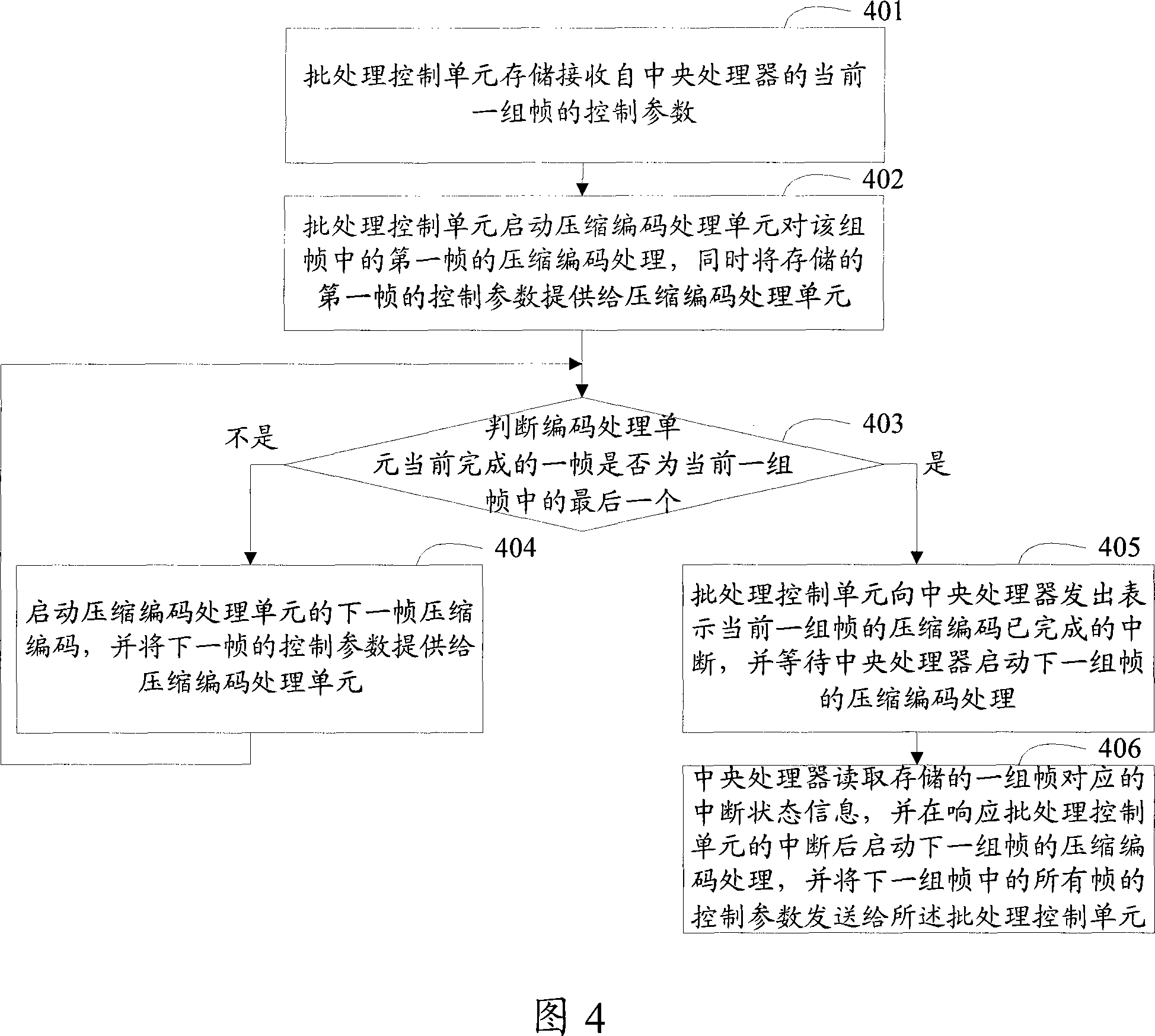

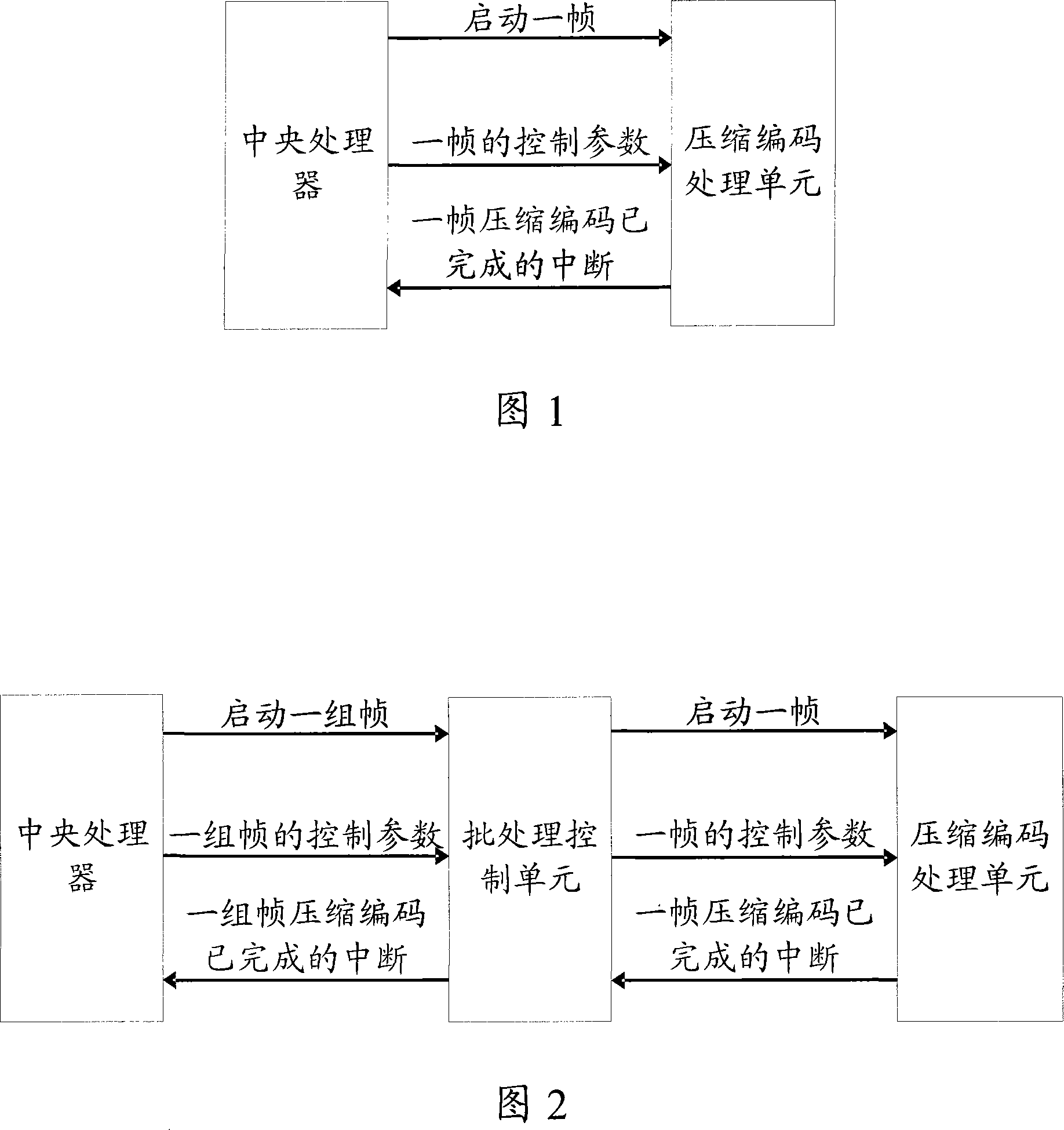

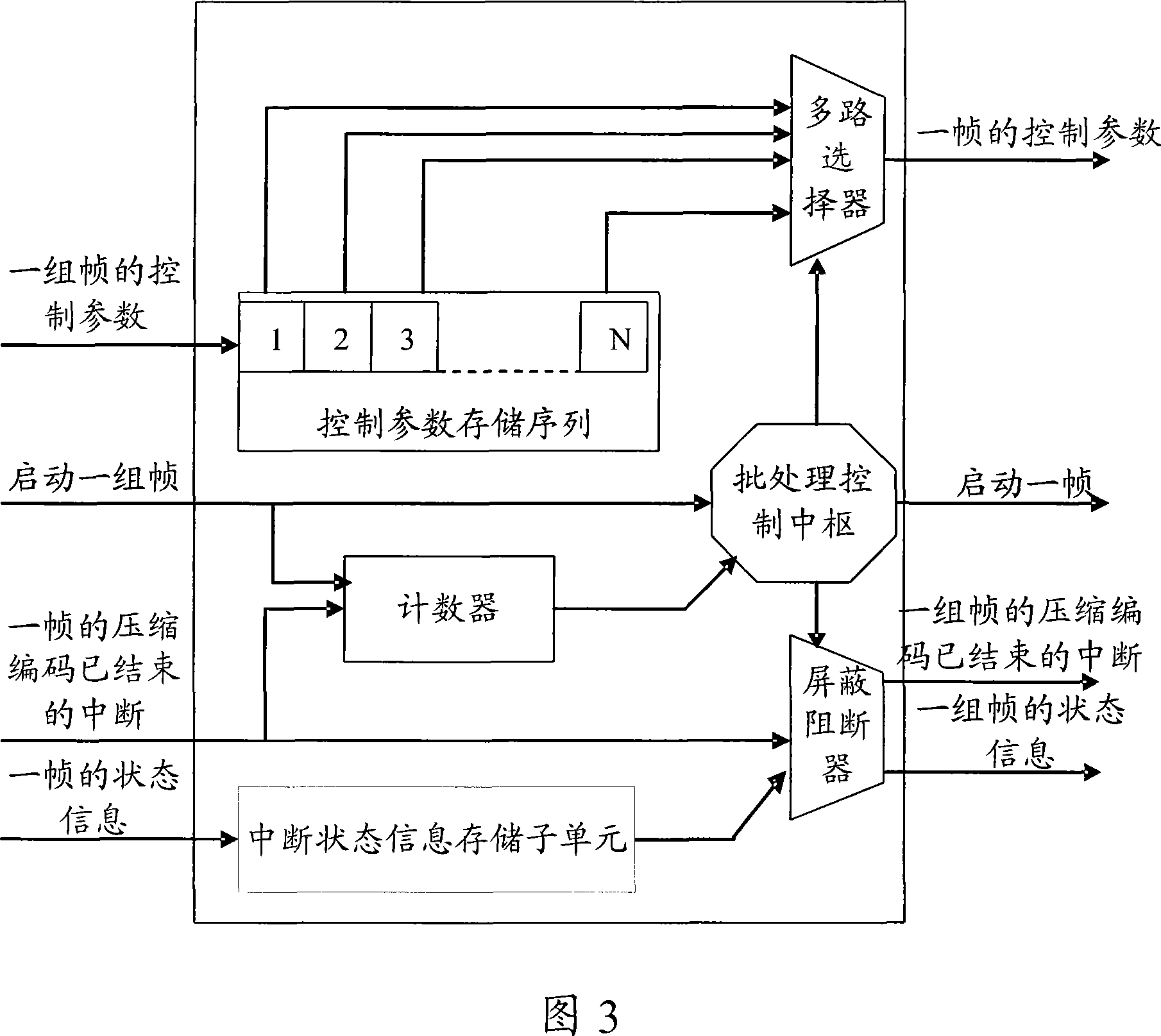

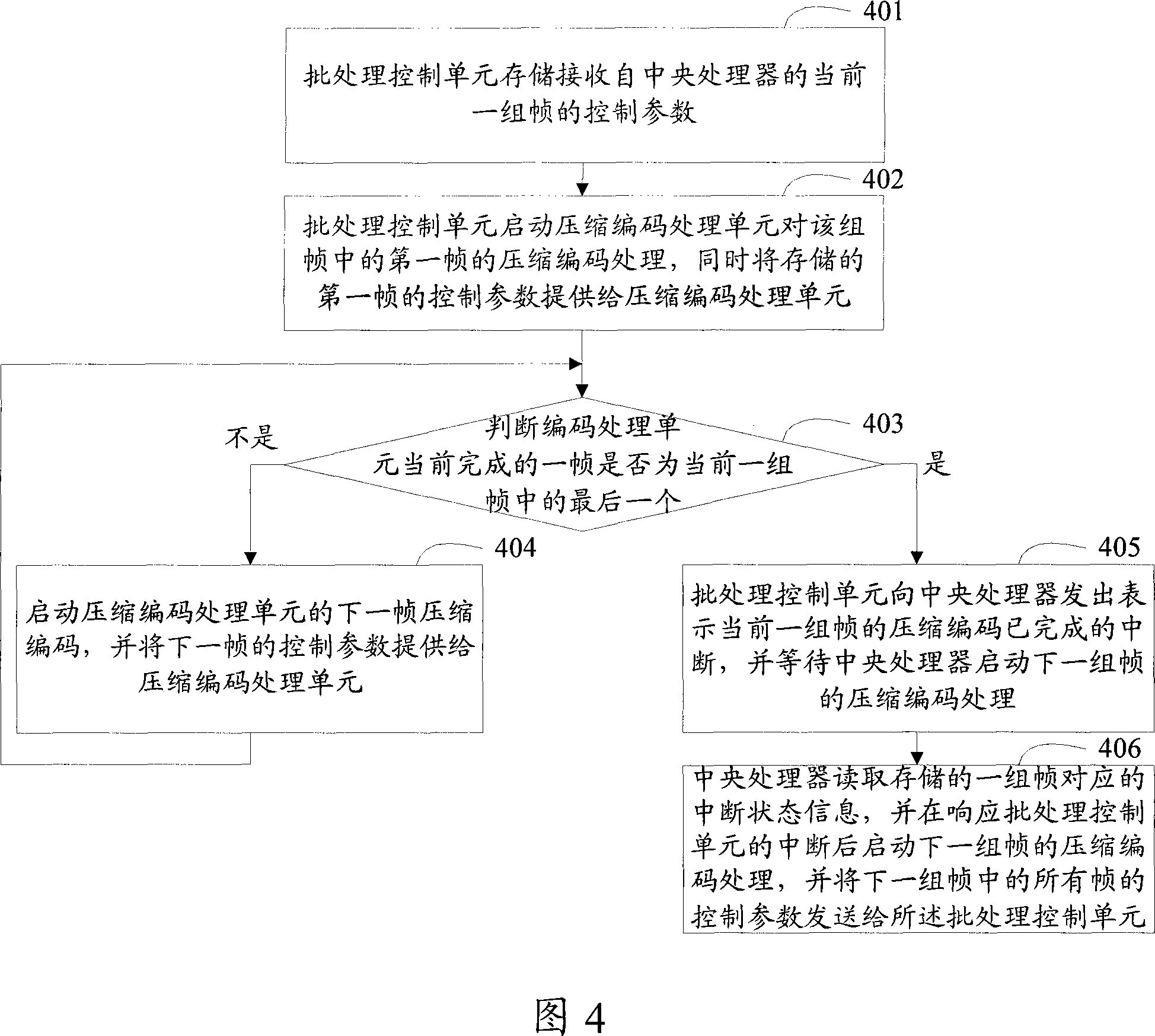

Compressed encoding control circuit and control method of compressed encoding

InactiveCN101179727AReduce frequencyIncrease frame rateTelevision systemsDigital video signal modificationControl circuitFrame rate

The invention discloses a control circuit and a control method for compression coding. The invention sets a batch processing control unit between a central processing unit and a processing unit of compression coding; the batch processing control unit assists the processing unit of compression coding to conduct batch processing for compression coding of a plurality of frames; thus the processing unit of compression coding requires no communication interruption from the central processing unit, and the time interval of a plurality of frames which are processed in batches does not include the waiting latency of response interruption of the central processing unit; besides, after the processing unit finishes the processing of compression coding for a plurality of fames, a communication interruption is conducted between the batch processing control unit and the central processor; therefore, the frequency of communication interruption between the central processing unit and the batch processing control unit is relatively low, thereby increasing the frame rate of video stream from compression coding.

Owner:VIMICRO CORP

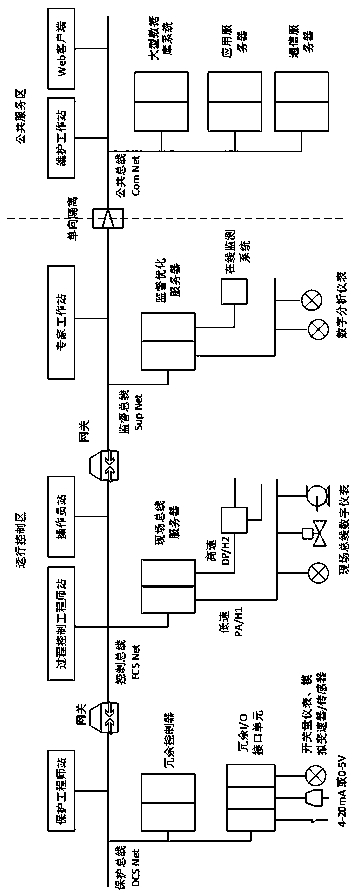

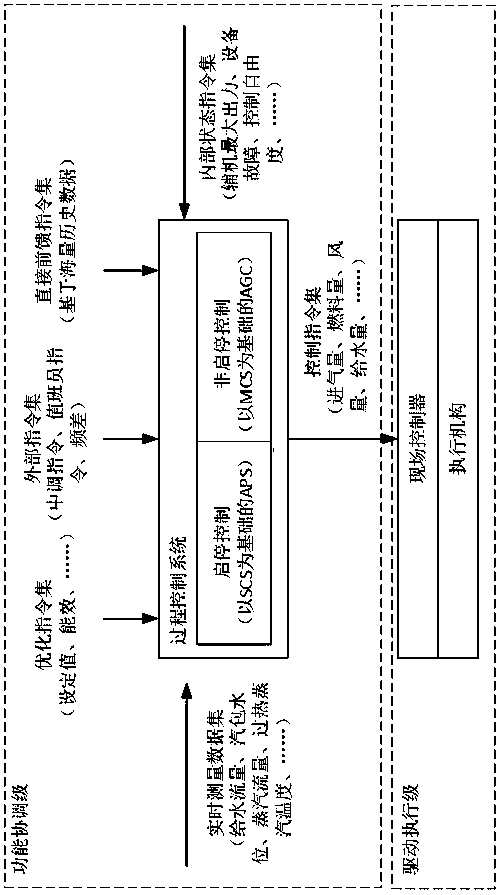

Overall structure of thermal automation system of thermal power plant

ActiveCN109189022ARealize production supervisionRealize APSTotal factory controlProgramme total factory controlData setData platform

The invention discloses an overall structure of a thermal automation system of a thermal power plant, composed of four parts as follows: measurement communication, protection, process control and supervision optimization, wherein the measurement communication consists of a field sensor, a transmitter, an actuator, and a communication network; the communication network includes protection, control,supervision, and a common bus; the protection includes equipment protection and protection management; the process control includes a two-level mode consisting of a function coordination level and adrive execution level; the function coordination level includes performing start-stop and non-start-stop control, accepting an optimized instruction set, an external instruction set, a direct feed-forward instruction set, a real-time measurement data set, and an internal state instruction set as input signals, and establishing a parallel control system that simultaneously faces the entire power generation production process; and the supervision optimization realizes the online monitoring for the integrated data platform and thermal process optimization and equipment in the operational controlzone. The overall structure of a thermal automation system of a thermal power plant respectively provides an implementation manner of a capital construction and a production plant, which provides a reference for the construction of a smart power plant.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Process guidance system for industrial process control

ActiveCN107037795AEasy to buildBuild simplicityTotal factory controlProgramme total factory controlDecompositionControl system

The invention discloses a process guidance system for industrial process control. The system comprises a process guidance module, a data acquisition and monitoring control system, a process analysis module and an interface drive module, wherein the process guidance module is used for performing action decomposition and attribute configuration on a controlled element, and performing simple imaging and drag operation on the process of a user to generate intelligent guidance data that can be recognized by the system; the data acquisition and monitoring control system is used for monitoring the running state of the process control system and adjusting parameters; the process analysis module is used for analyzing the data generated by the process guidance module via a controller, and implementing process control on the user process; and the interface drive module is used for driving peripheral interface equipment according to the analysis result of the process analysis module. The system does not need to concern the specific detail and network topology structure of the controlled element, the user process control program is completely replaced by intelligent data via data drive thought, the controller user process program is free from being compiled, and the process control of the user becomes simple, transparent, direct and flexible.

Owner:唐志

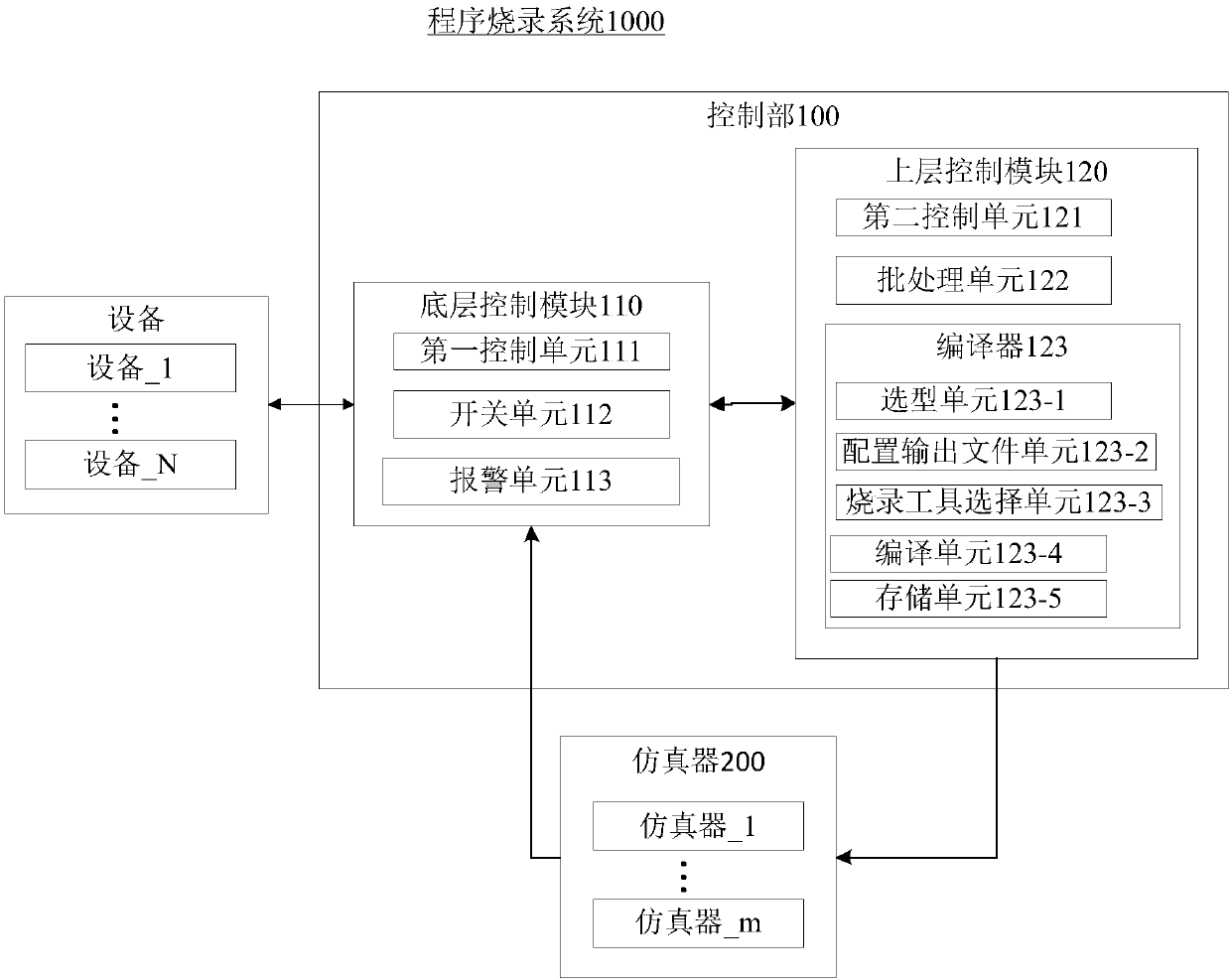

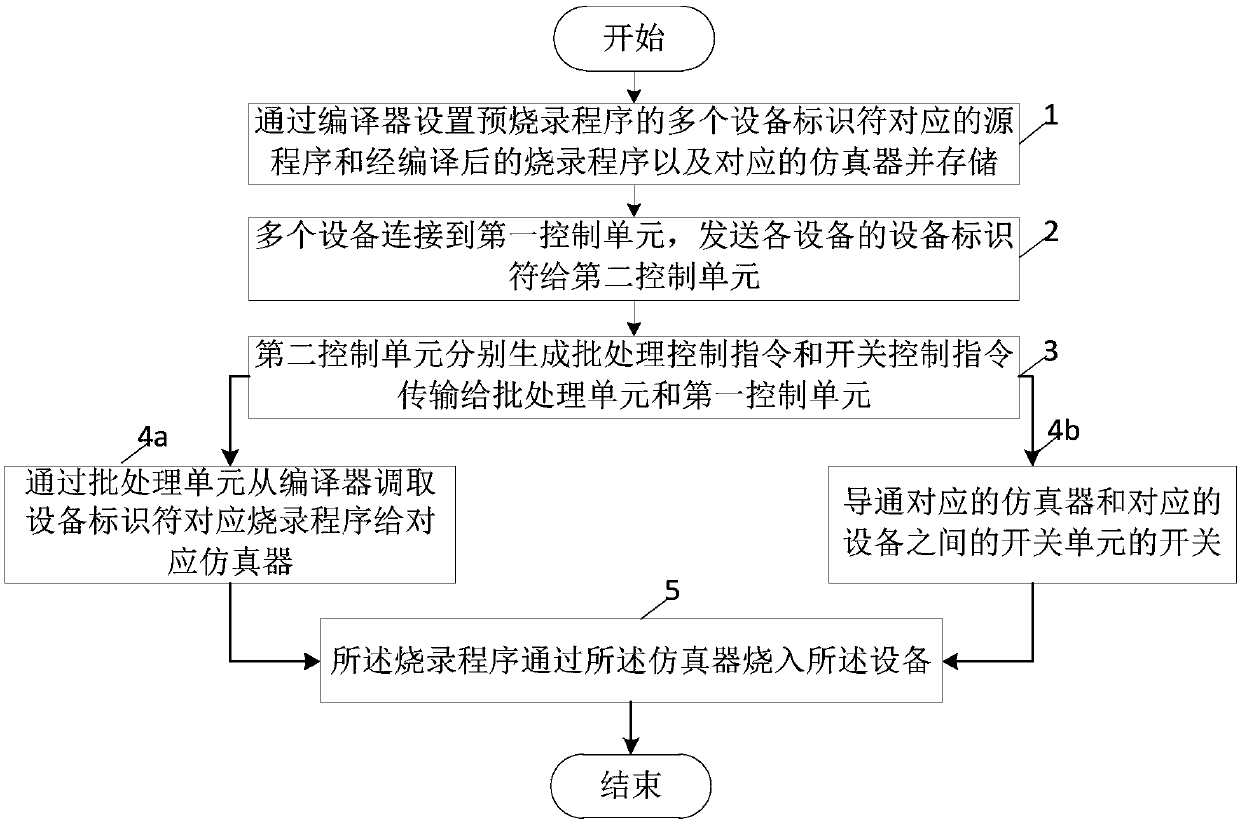

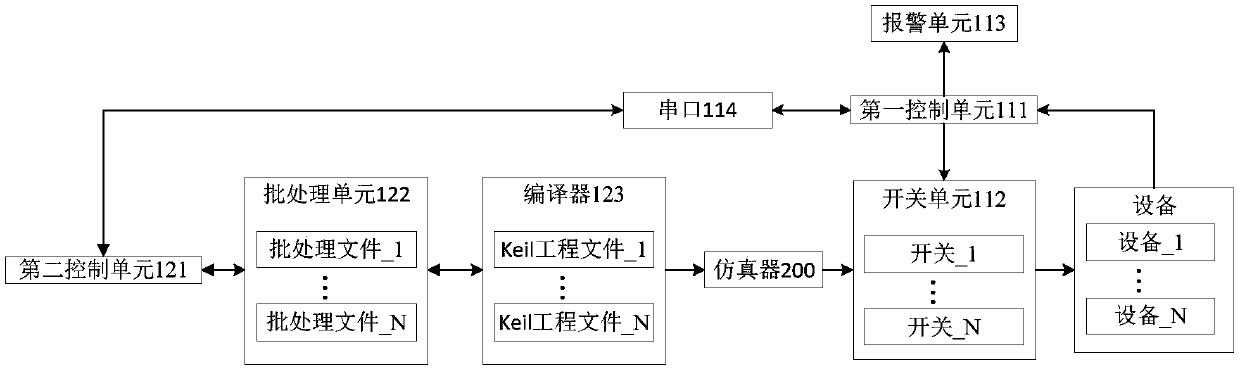

Program programming system and method

The invention provides a program programming system and method. The system includes a control part and at least one simulator. The control part includes an upper-layer control module and a bottom-layer control module. The bottom-layer control module includes a first control unit and a switch unit. The first control unit is connected with multiple pieces of equipment, and sends a command to the upper-layer control module. The command includes each equipment identifier. The switch unit is connected with the simulator and the equipment. The upper-layer control module includes a second control unit, a batch processing unit and a compiler. The compiler sets a source program and a programming program, which correspond to each equipment identifier, and the simulator. The second control unit receives the command of the first control unit, and generates a batch processing control instruction and a switch control instruction. The batch processing control instruction is of retrieving the programming program, which corresponds to each equipment identifier, from the compiler to the corresponding simulator through the batch processing unit. The switch control command is sent to the first controlunit to control a switch, which corresponds to the switch unit, to be in conduction. The programming program is sent into the equipment for programming through the simulator.

Owner:GOERTEK OPTICAL TECH CO LTD

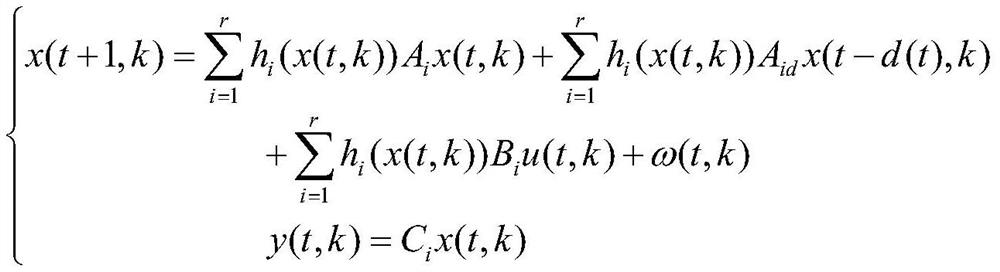

Chemical batch process control system stability maintenance method

InactiveCN107942675AImprove control effectImprove performanceAdaptive controlState dependentState model

The present invention discloses a chemical batch process control system stability maintenance method. The method comprises the steps of: applying related theories of system conversion, establishing state models with different sizes, constructing corresponding conversion sequences and state matrixes according to relations between adjacent stages, designing conversion signals related to the states,establishing full conditions of ensuring index stability, designing a reliable control method, and achieving full conditions of stable operation of the control system in a lower bound of operation time. The chemical batch process control system stability maintenance method improves the defect that a traditional control strategy only considers a single variable to cause delay of a controller, effectively improves the integral performance of the controller, improves the control performances of a chemical batch process controller and ensures the product quality.

Owner:HANGZHOU DIANZI UNIV

Job processing system, method and program

ActiveUS8639792B2Process stabilityEasy to processData processing applicationsDigital data processing detailsHandling systemJob management

A job processing system has first to third servers. The first server has a job generation program for generating jobs as requested. The second server has a storage device for storing attribute information on and a file for use in processing each job generated by the first server, a management table for managing job management information on each job by assigning a unique ID to each job, and a queue control program for registering job management information in the management table, referring to the management table, and registering the file for and attribute information on each job in the storage device. The third server has one or more job processing programs for processing jobs acquired from the second server, batch control program for acquiring jobs from the second server and issuing responses concerning the processed jobs, and a storage device for storing attribute information on and a file for each job acquired.

Owner:HITACHI SYST

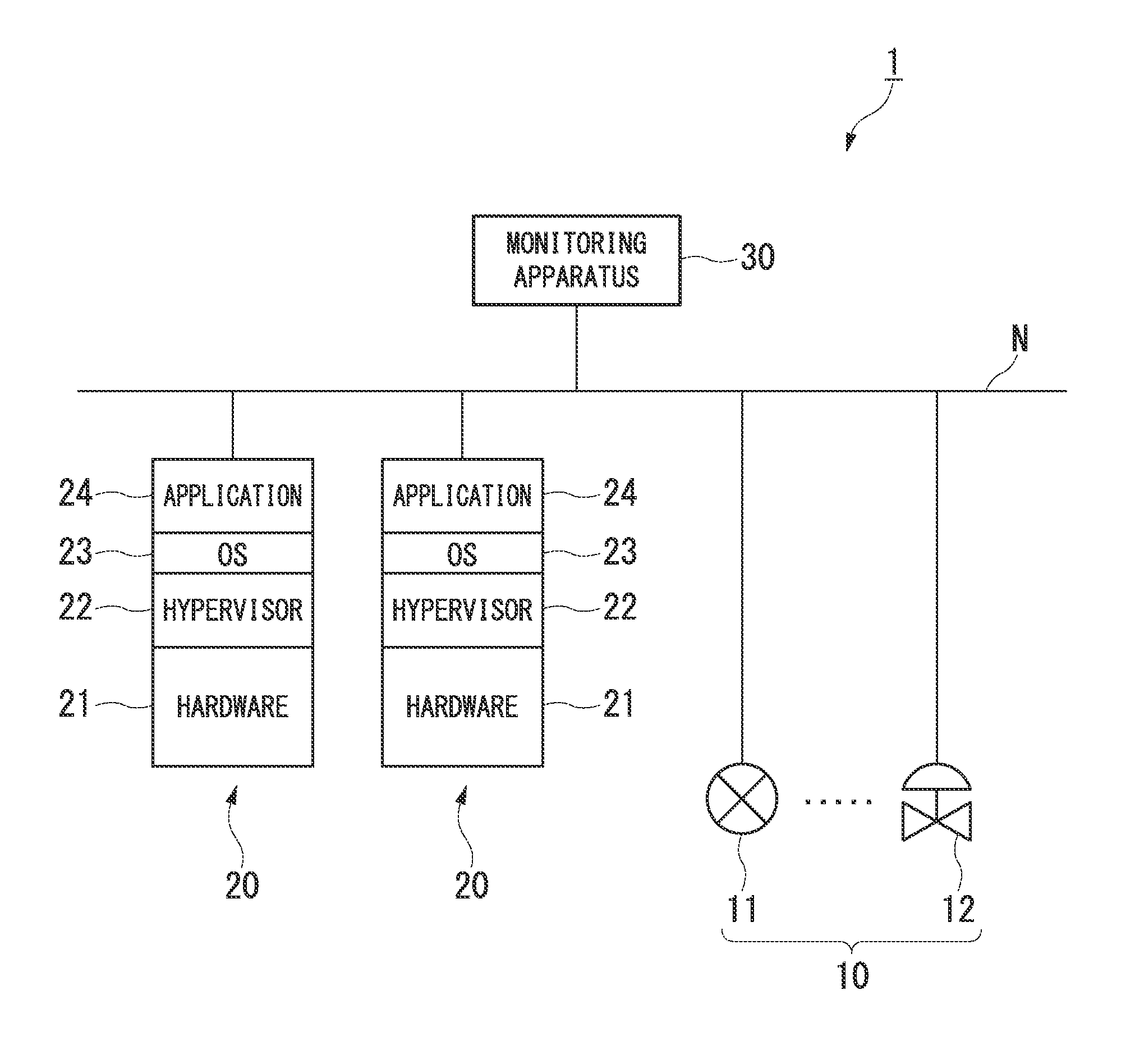

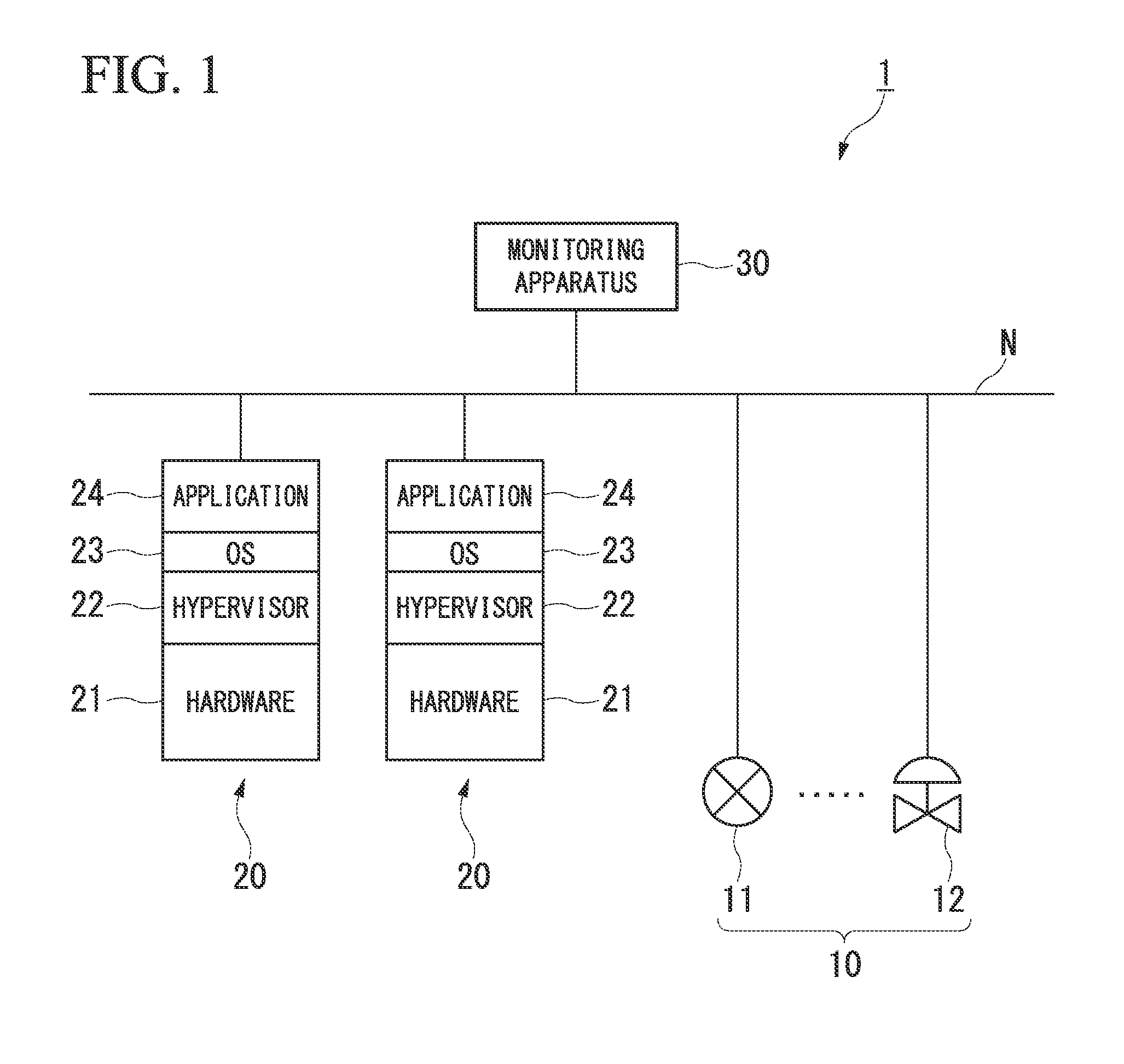

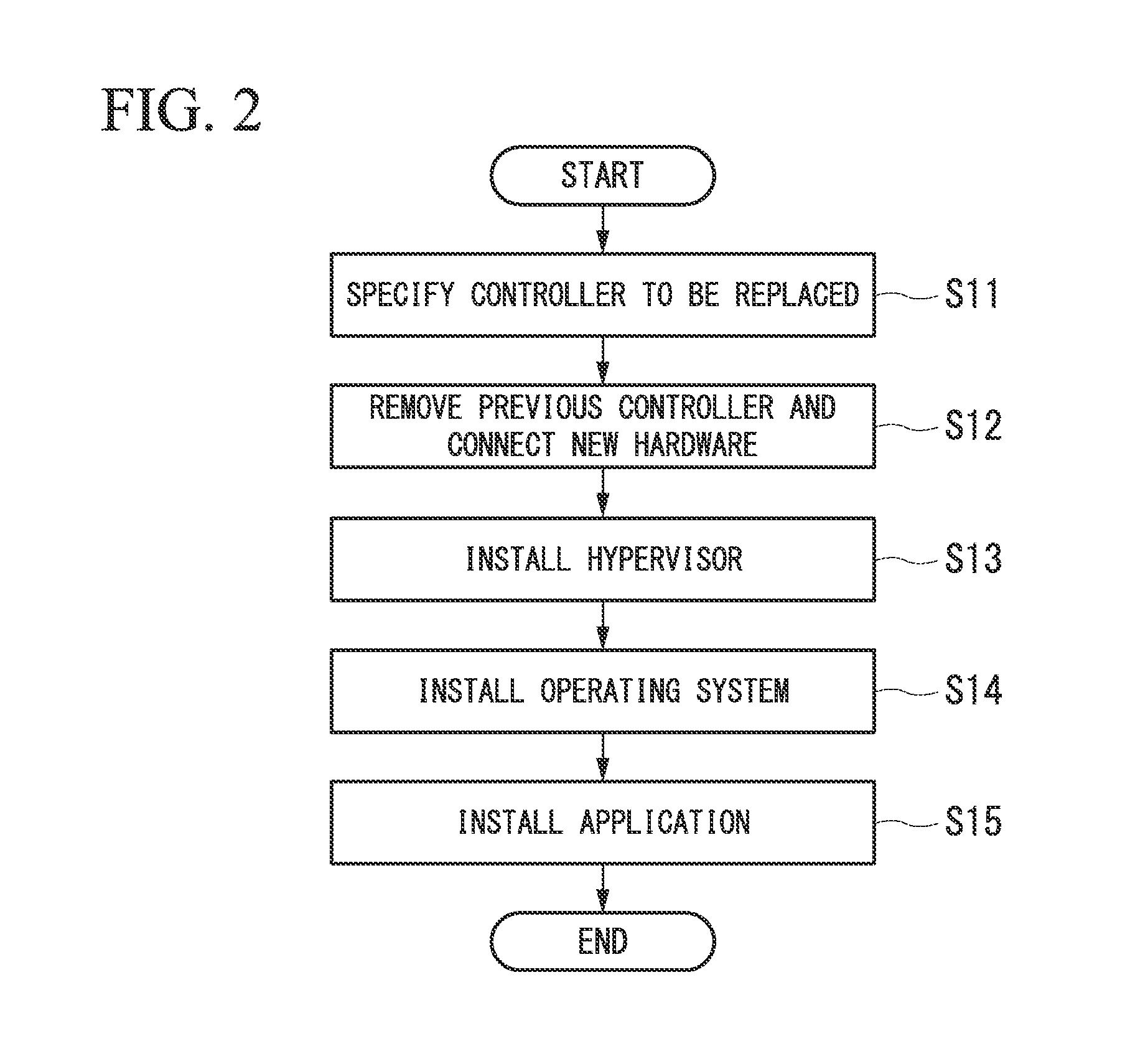

Process control system

A process control system performing control of an industrial process implemented in a plant, may include: a network provided in the plant; a plurality of field devices connected to the network, each of the plurality of field devices is configured to perform at least one of measurement and actuation required for control of the industrial process; and a controller, connected to the network, having a virtual part configured to operate in hardware in place of hardware, and a control unit configured to operate in the virtual part and to control operations of the field devices via the network, the controller being configured to enable replacement of hardware without changing the control unit.

Owner:YOKOGAWA ELECTRIC CORP

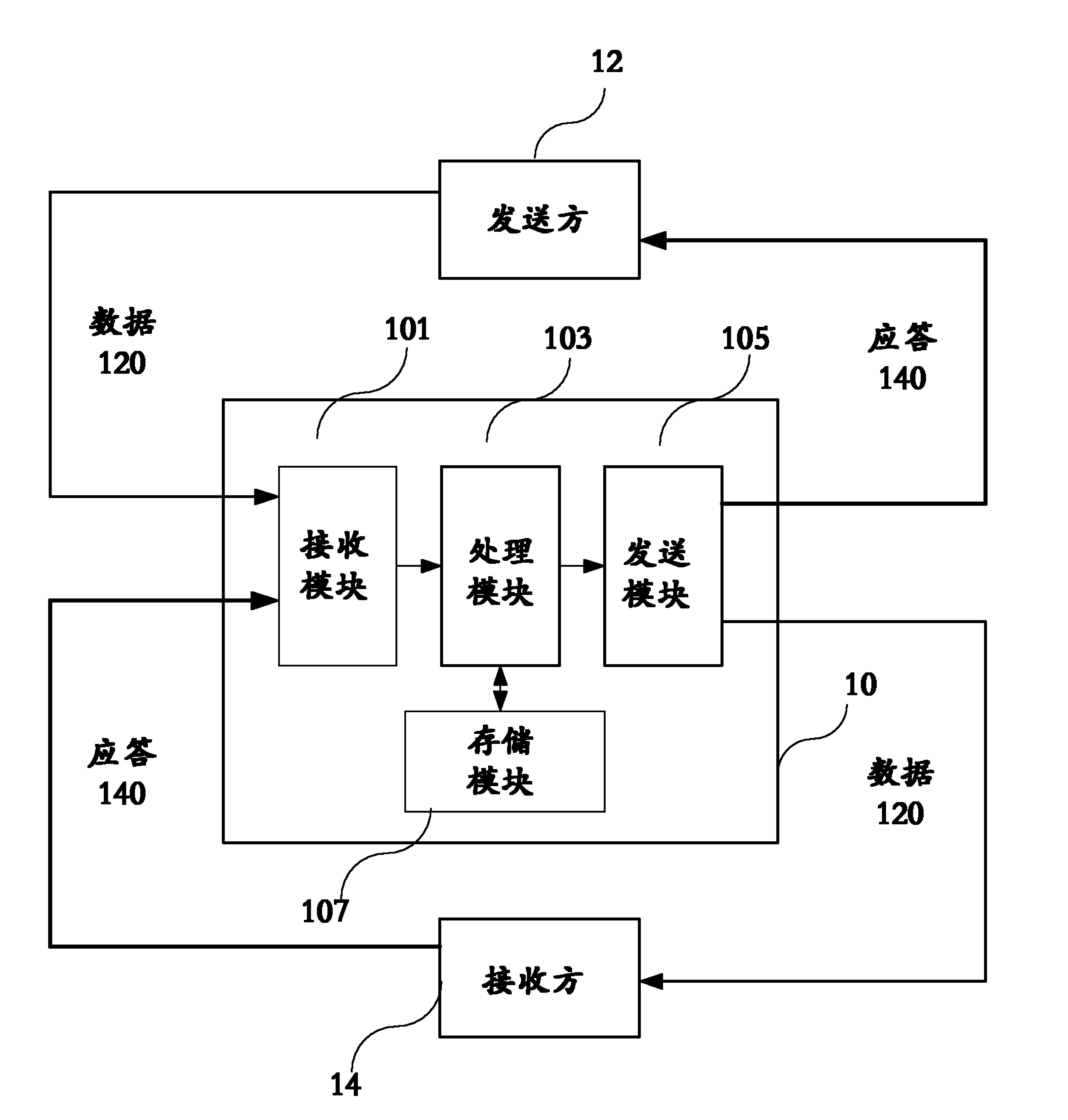

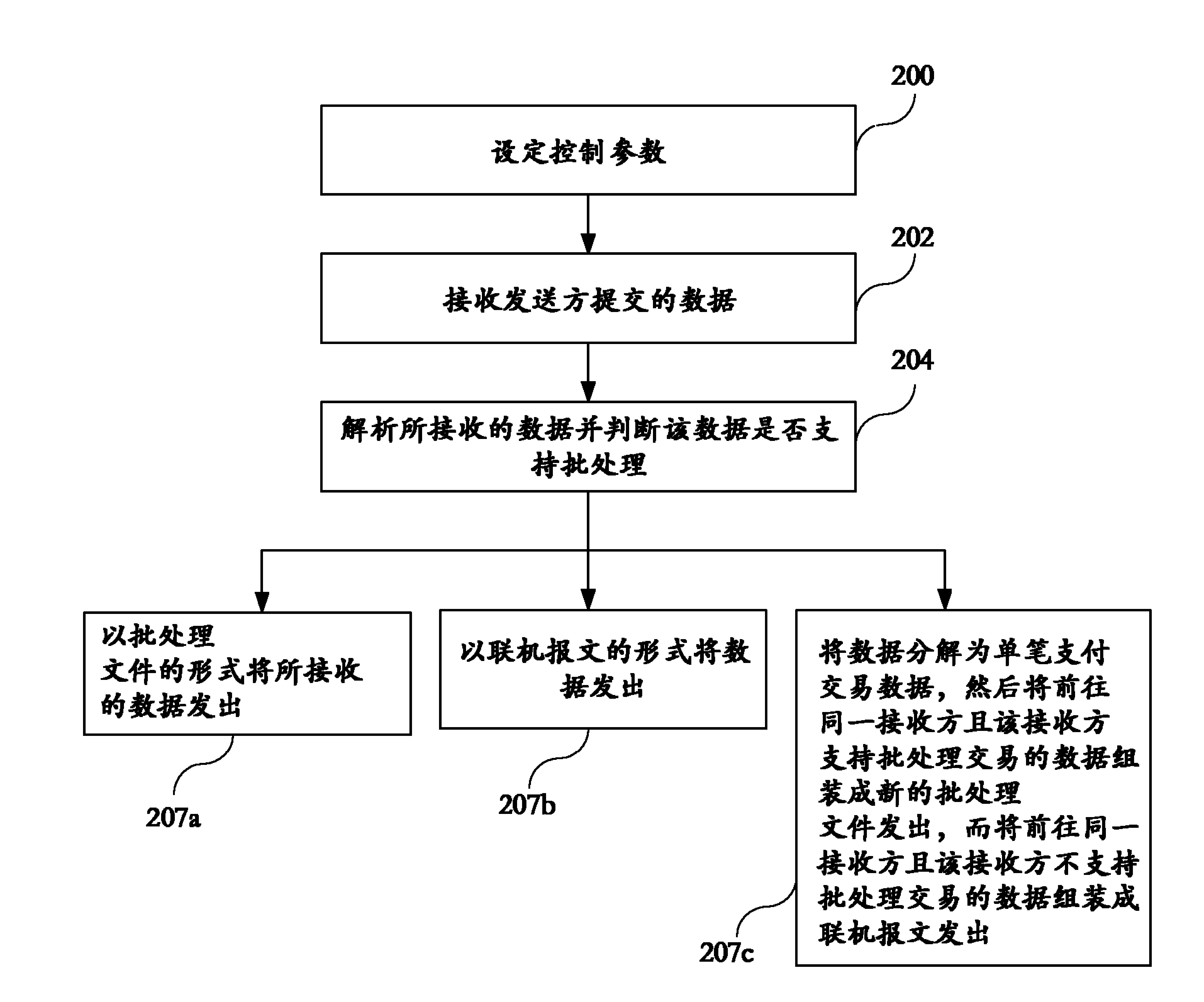

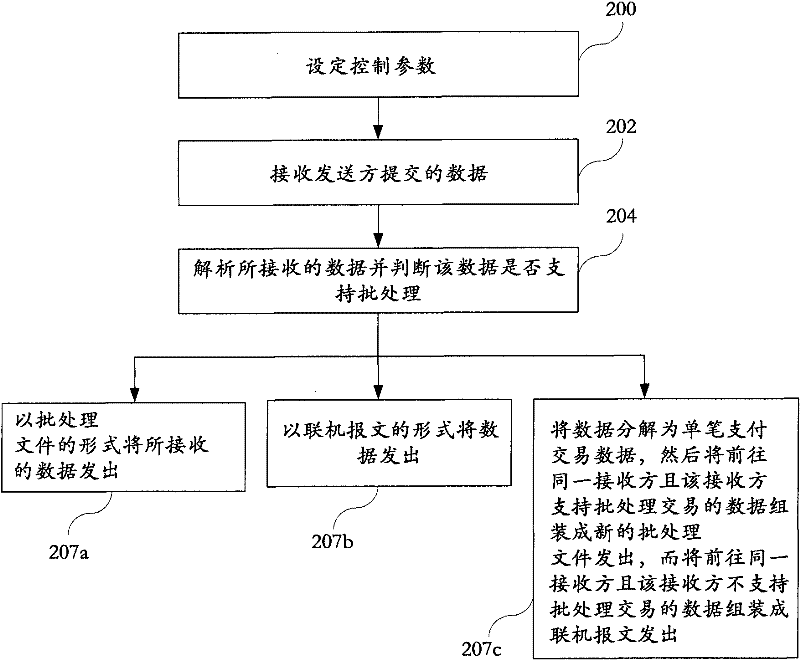

Data processing method

ActiveCN103310369AReduce the number of interactionsSave resourcesBuying/selling/leasing transactionsData processing systemTransaction data

The invention provides a data processing method and system. The data processing method comprises the following steps: setting a batch processing control parameter, wherein the batch processing control parameter is relevant to a receiving party and indicates whether the receiving party supports the batch processing or not; receiving data from a sending party; according to the data, obtaining the receiving party corresponding to the data; and according the control parameter, determining whether the receiving party supports the batch processing or not. The invention also provides the data processing method system, and the data receiving party in the system can process transaction data in a batch processing mode. According to the data processing method and the data processing system, the transaction receiving party can process the transaction data in a batch file mode, and the processing efficiency of the transaction data is increased.

Owner:CHINA UNIONPAY

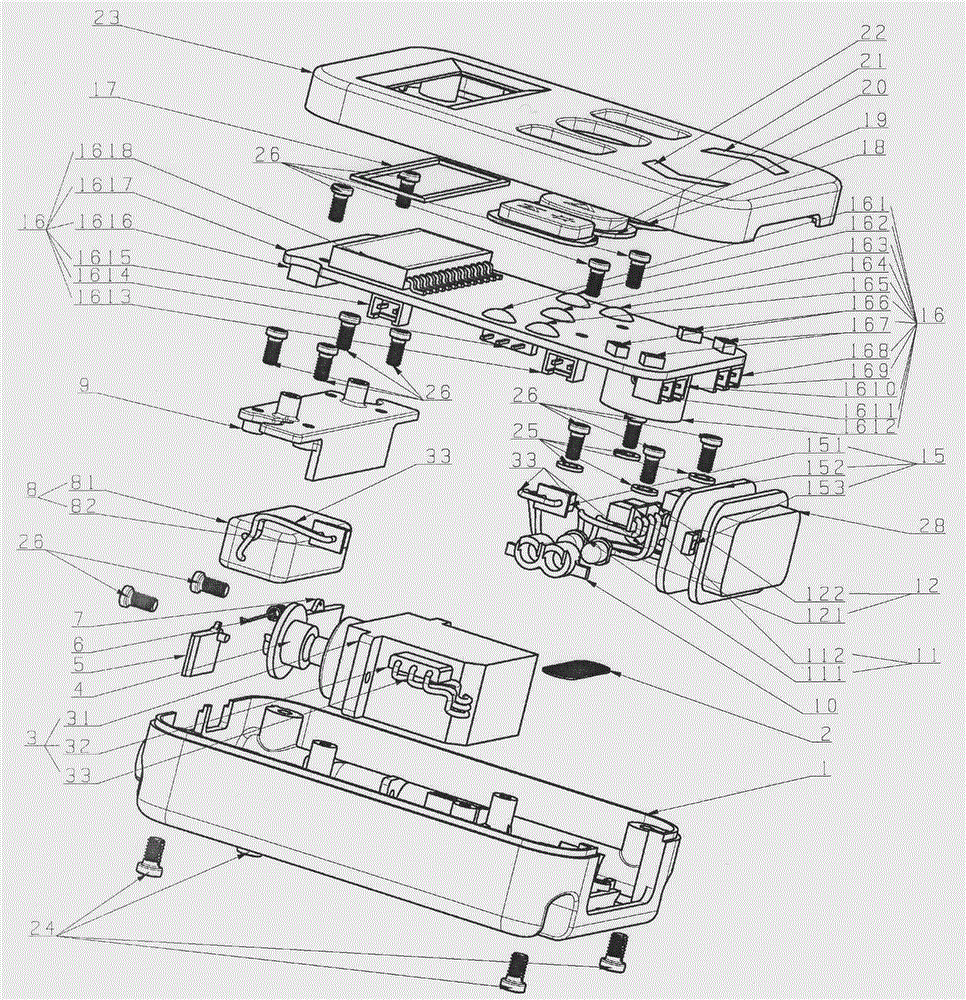

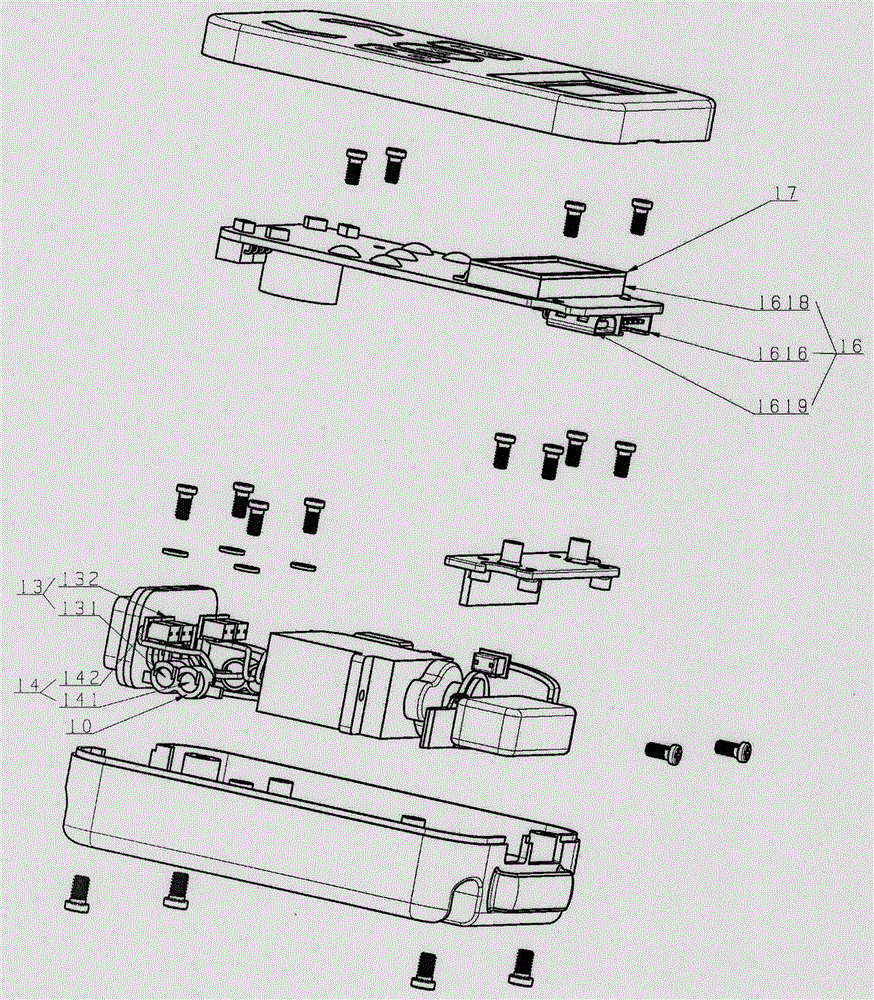

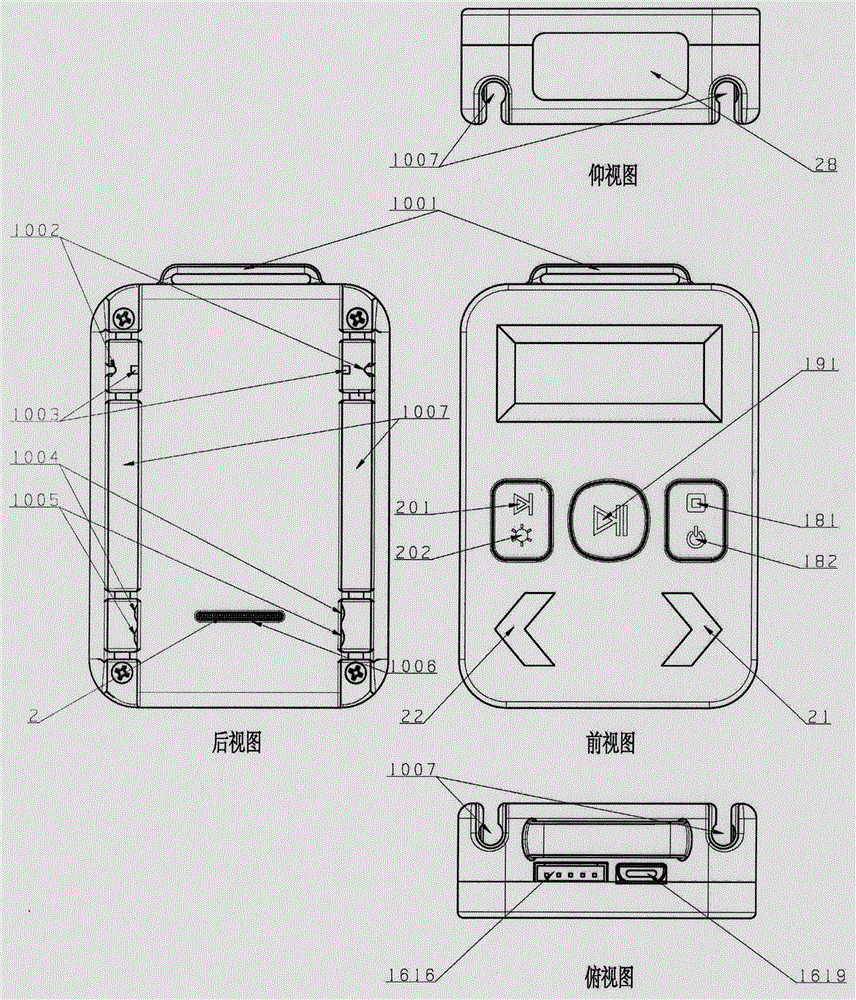

Miniature intelligent drip controller

The invention provides a miniature intelligent drip controller, which comprises mechanical executing parts, a control module, a sensor, an illuminating module, lampshades, buttons and a shell. The control module, through information acquired by the sensor, is used for controlling the mechanical executing parts so as to achieve whole-process control over the automation of entire infusion without human intervention. By adopting the combination of a steering engine and a cam to drive a bolt, a purpose of independently controlling each of a plurality of infusion tubes is achieved through the rotating range of the steering engine within 180 degrees, and with the control of the control module, selection among a plurality of modes is achieved; for example, the controller can monitor a patient who is subjected to multiple bottles of drips in order and can simultaneously monitor the one-to-one infusion mode of multiple patients, and the controller can adopt different alarm forms in accordance with the different modes since the controller detects the completion of the infusion so as to facilitate distinguishing; therefore, the working efficiency is greatly improved and the labor intensity of doctors and nurses is reduced. In addition, the drip controller, which is provided with a power supply and the illuminating module, can conduct normal infusion activities under the circumstance without a light source and the power supply.

Owner:张皓崎

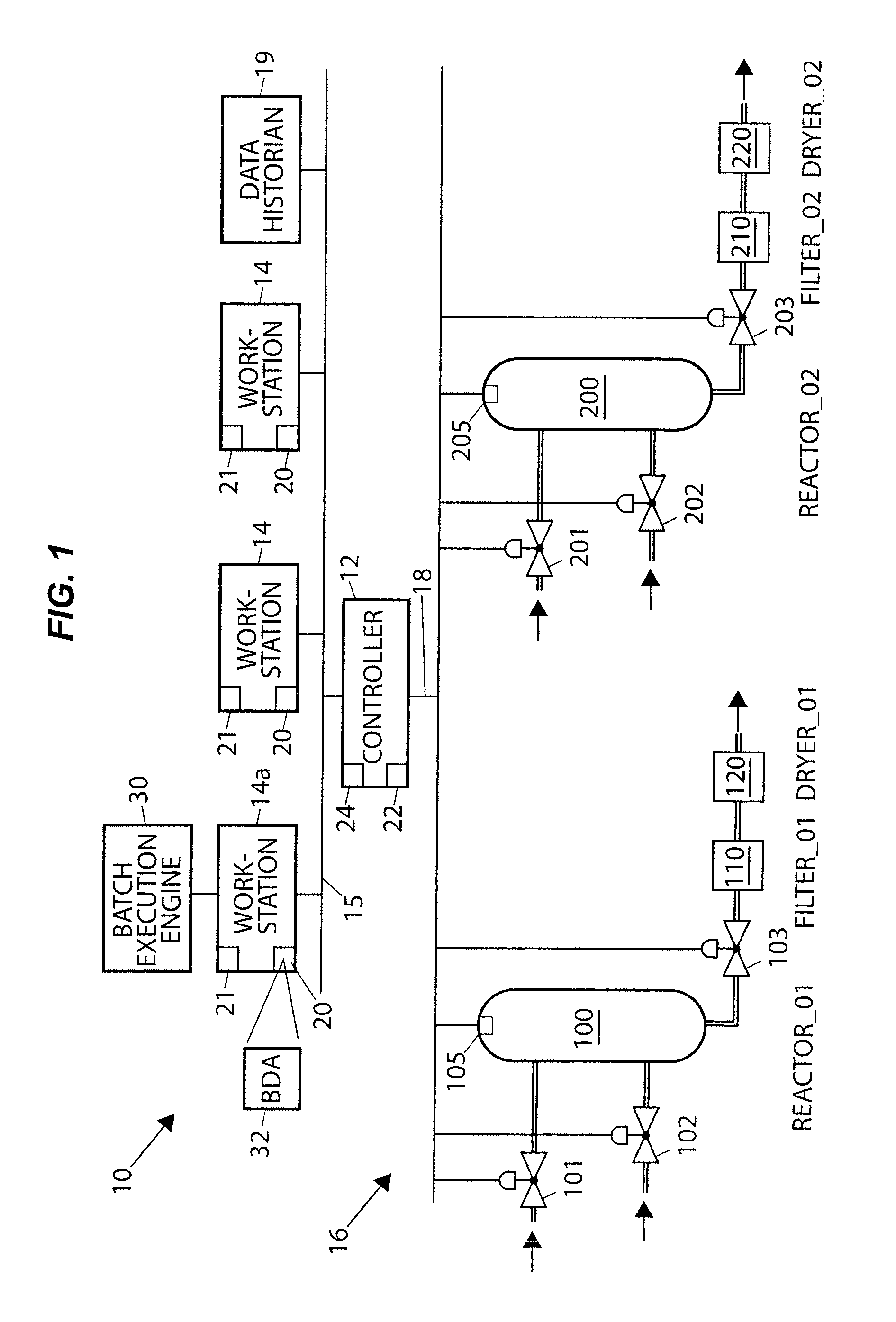

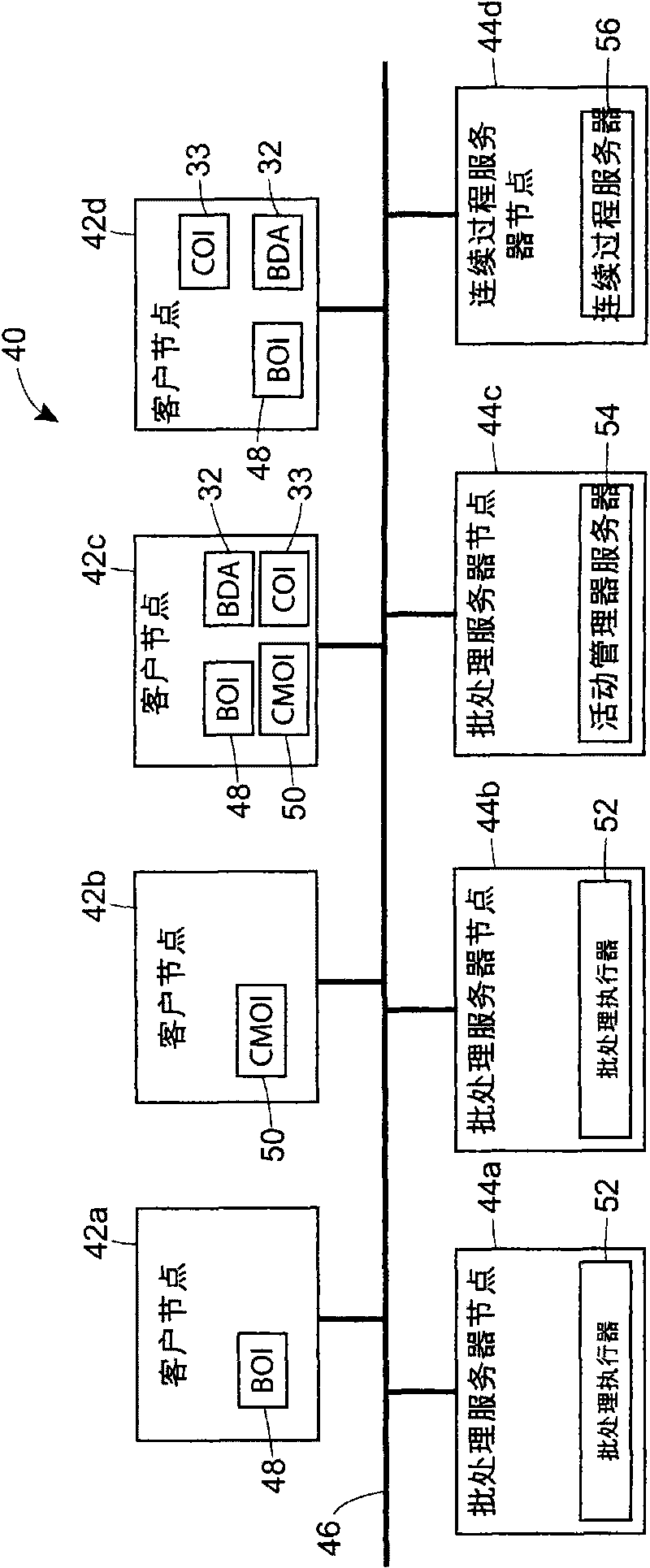

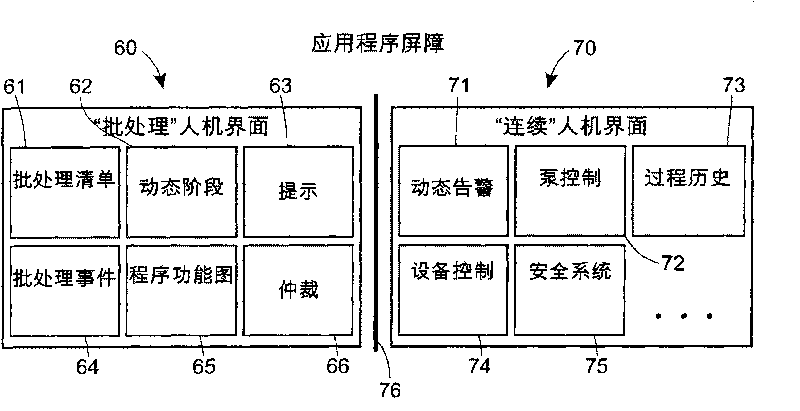

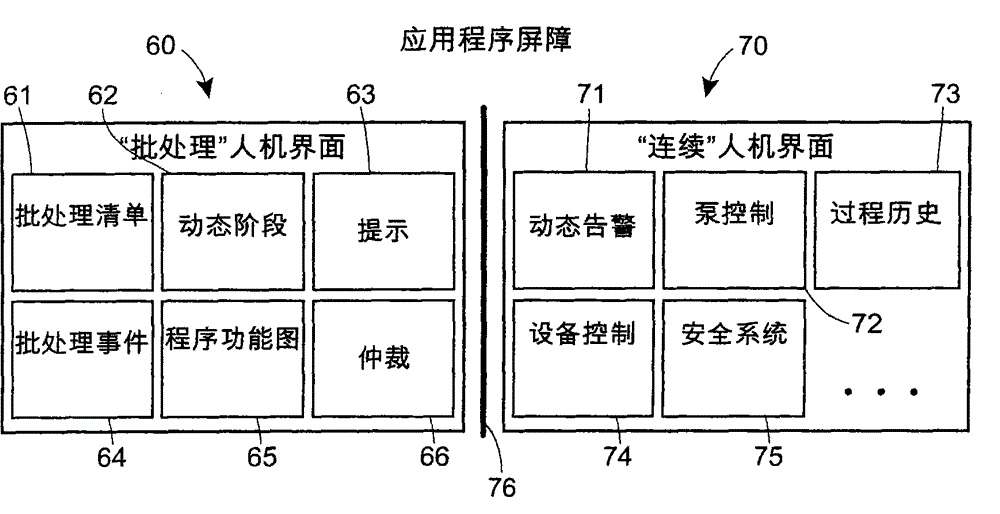

Complete integration of stand-alone batch operator interface capabilities into generic human machine interface using componentized objects

ActiveCN101713986ATotal factory controlInput/output processes for data processingOperator interfaceUser input

The present invention relates to complete integration of stand-alone batch operator interface capabilities into generic human machine interface using componentized objects. Systems and methods for providing an integrated HMI application for monitoring and interacting with both batch and non-batch processes in a process plant are disclosed. A plurality of independent stand-alone software objects defining various batch process interface views are embedded within a non-batch process control interface application. A blackboard service is provided for storing batch control data used by the various stand alone software objects. The blackboard service may be adapted to communicate with a batch control server to receive batch control data for populating the various batch interface views with data relating to various batch processes being carried out in the process plant and to send instructions for controlling the various batches input by users via the various batch interface views. When executed by a processor, the stand alone software objects defining the various batch interface views read data from and write data to the blackboard service to communicate data between batch process interface views and preserve contextual information between interface views to allow efficient and intuitive navigation between batch process interface views.

Owner:FISHER-ROSEMOUNT SYST INC

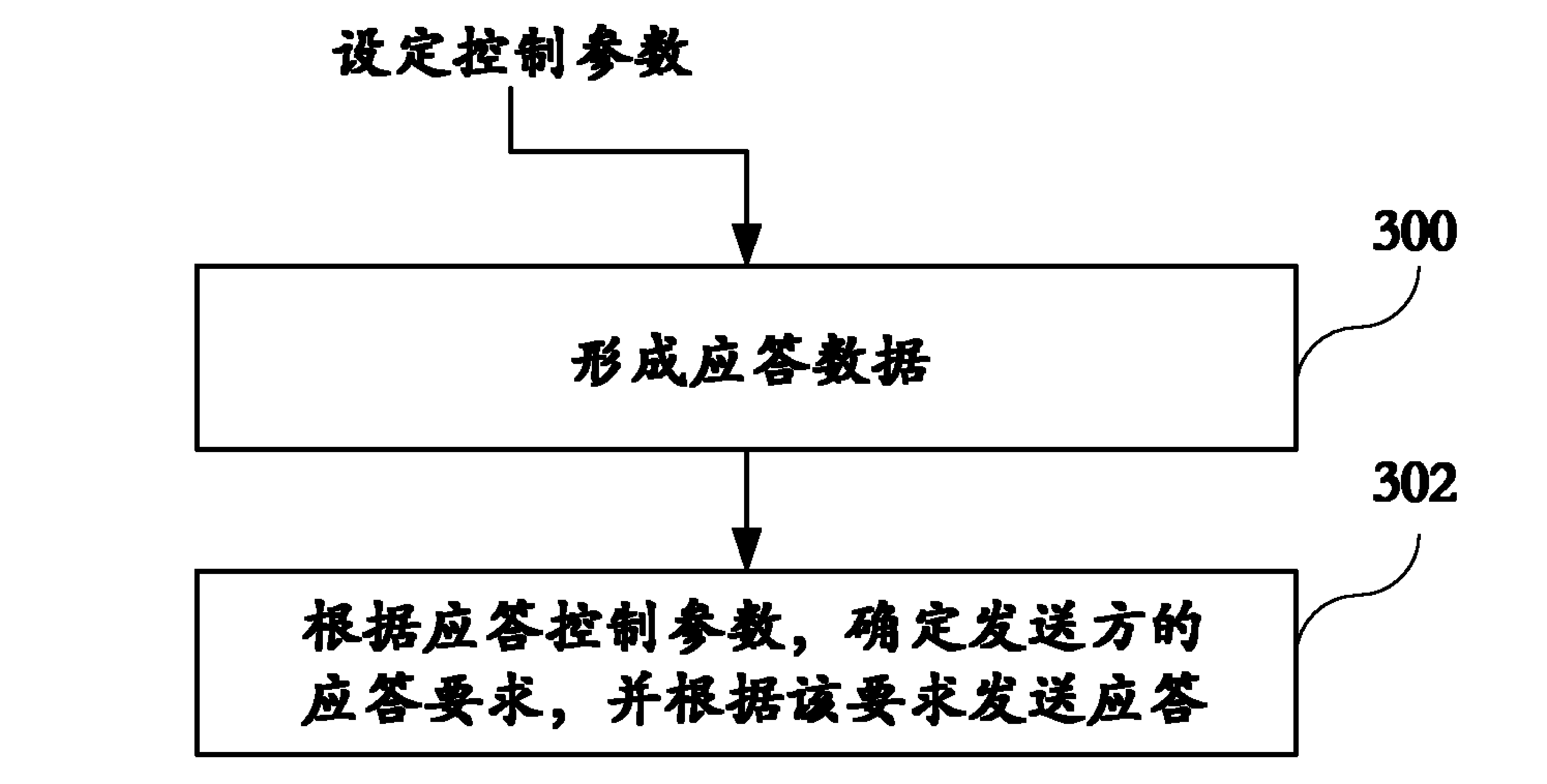

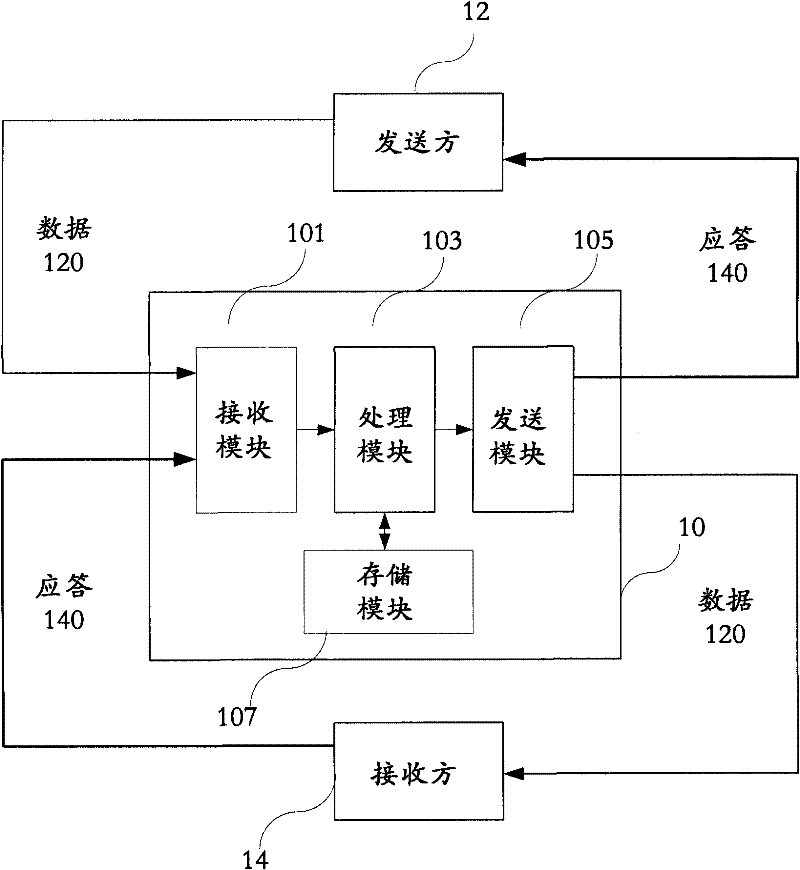

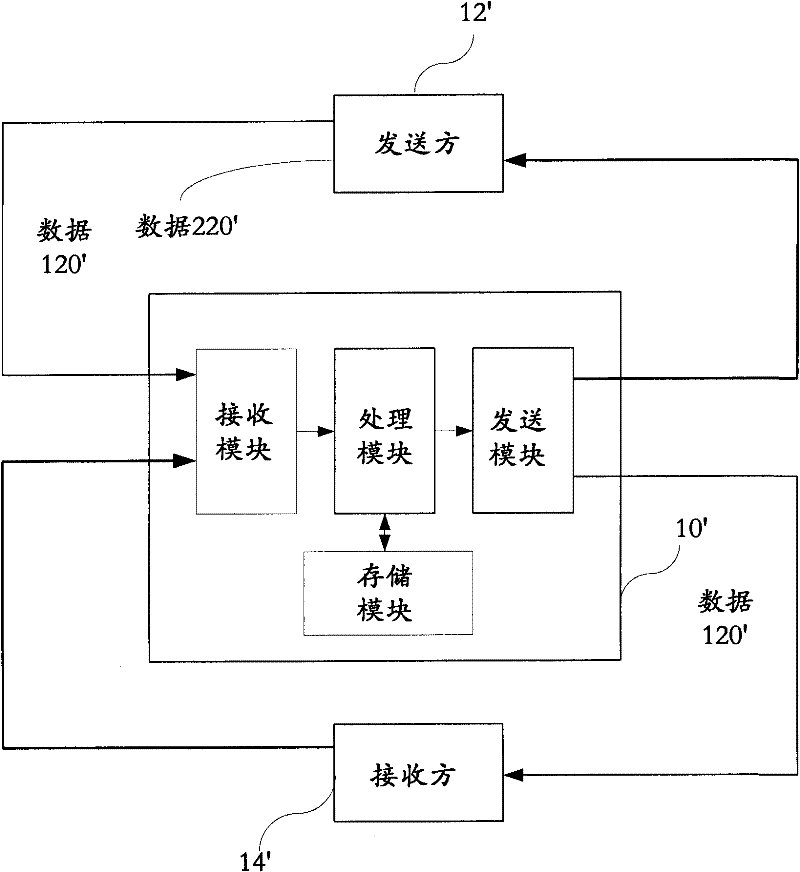

Data processing method and system thereof

InactiveCN102222297AReduce the number of interactionsSave resourcesCommerceData processing systemTransaction data

The invention provides a data processing method and a system thereof. The data processing method comprises the following steps: setting a control parameter of a batch processing, wherein the control parameter of the batch processing is associated with a receiver and designates whether the receiver supports the batch processing; receiving data from a sender; obtaining a receiver corresponding to the data according to the data; and determining whether the receiver supports the batch processing according to the control parameter. Moreover, the invention also provides a data processing system, wherein the data receiver of the system is capable of dealing with transaction data in a batch processing manner. According to the data processing method and a system thereof, a transaction receiver is capable of dealing with transaction data in a batch processing manner, so that processing efficiency of the transaction data can be improved.

Owner:CHINA UNIONPAY

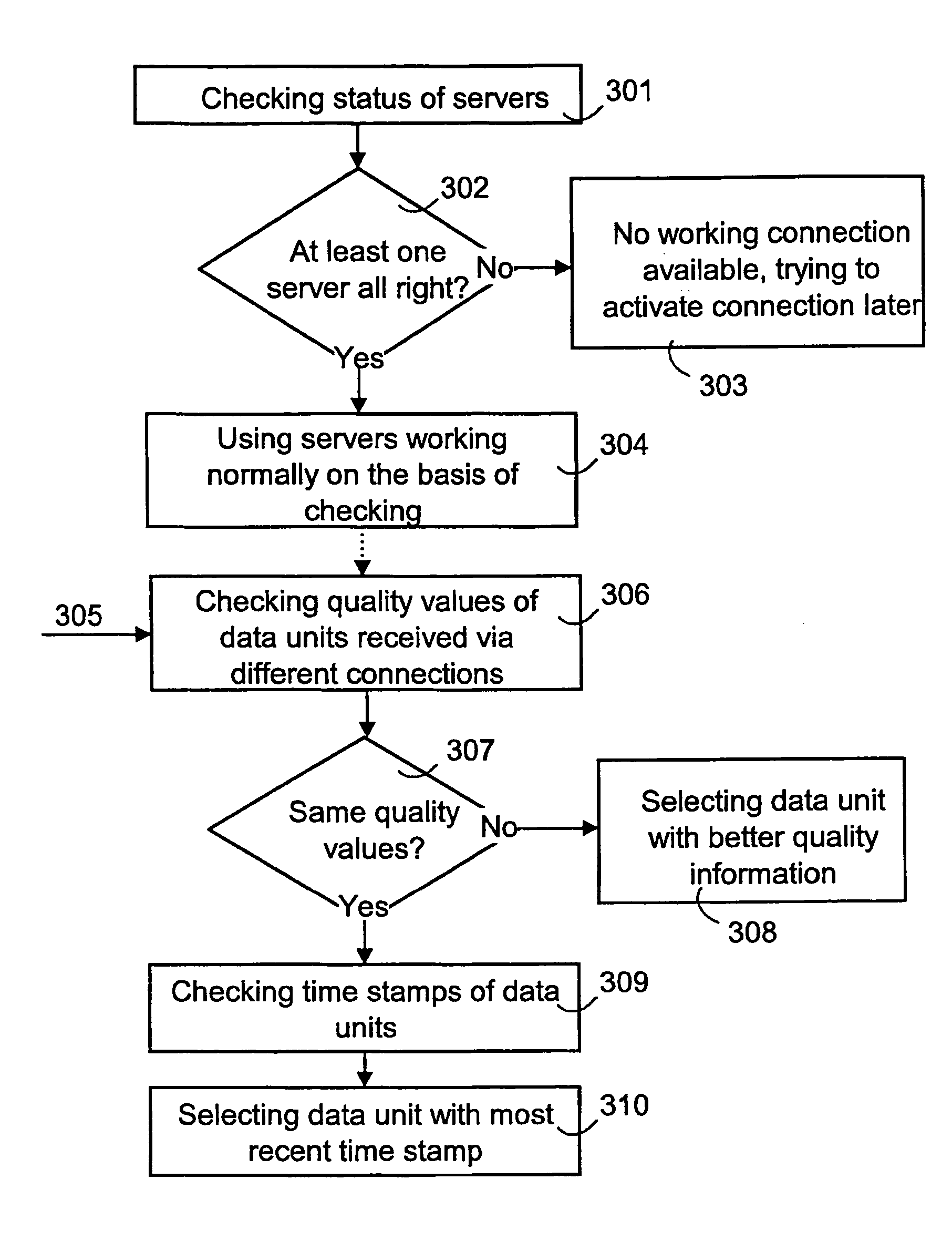

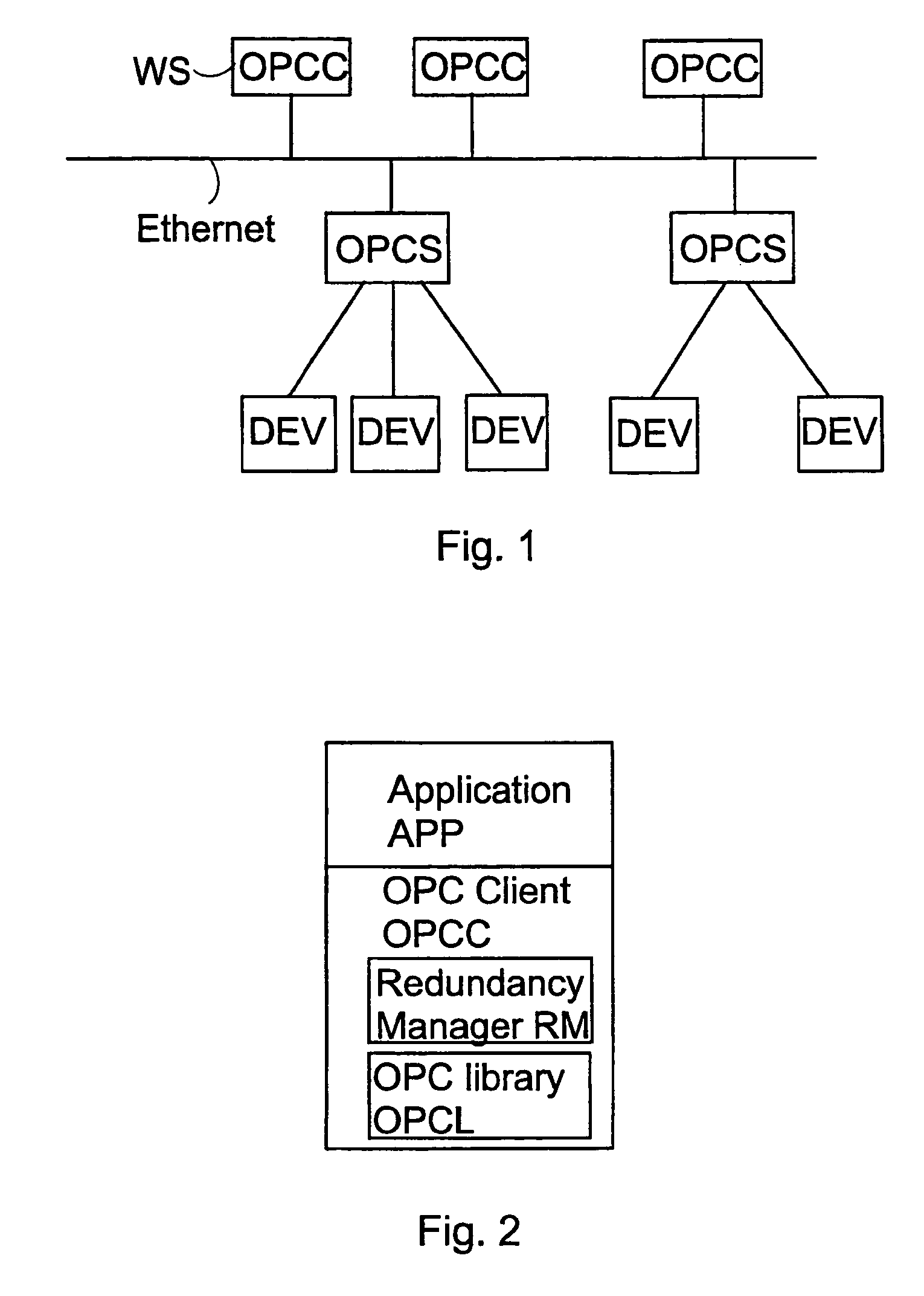

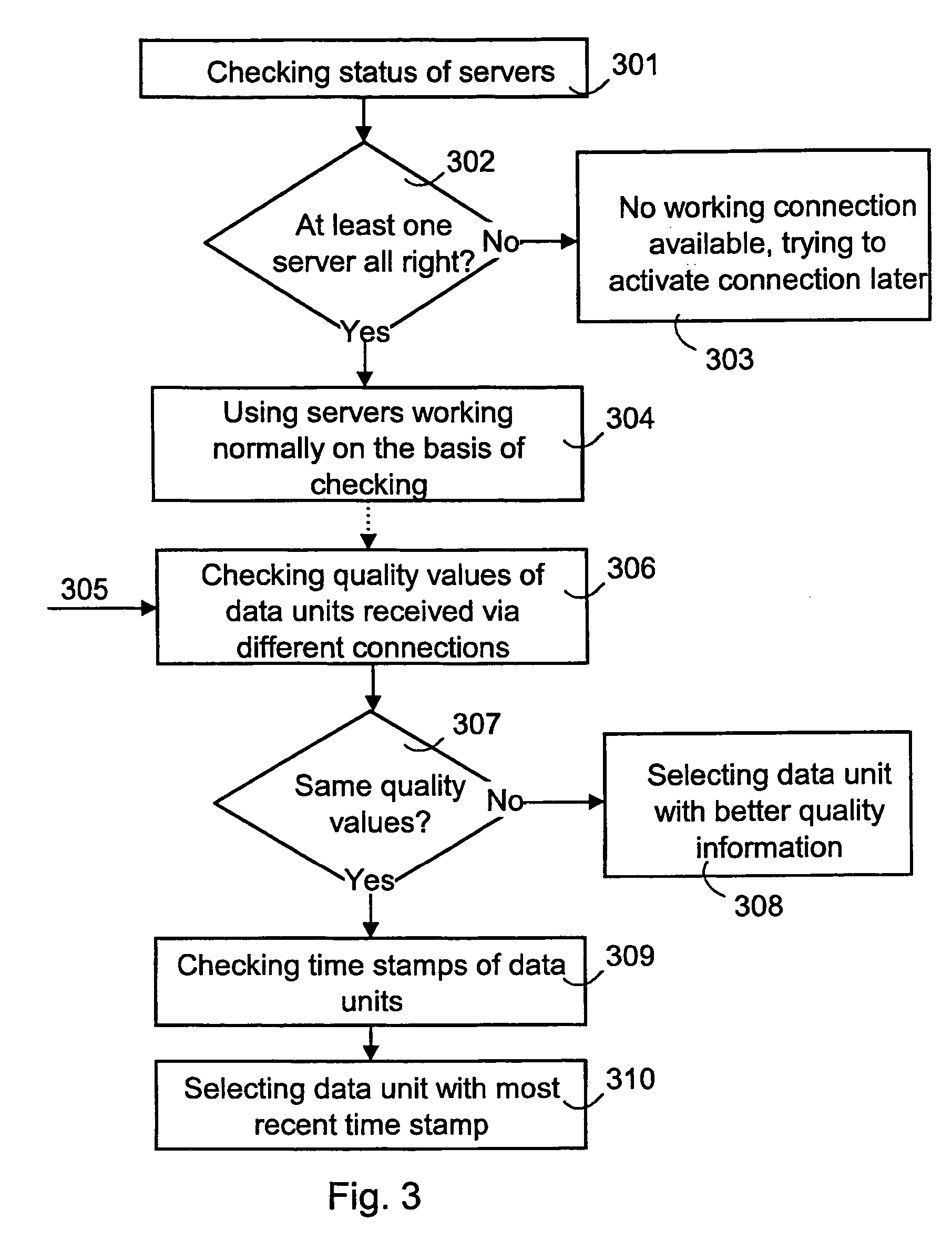

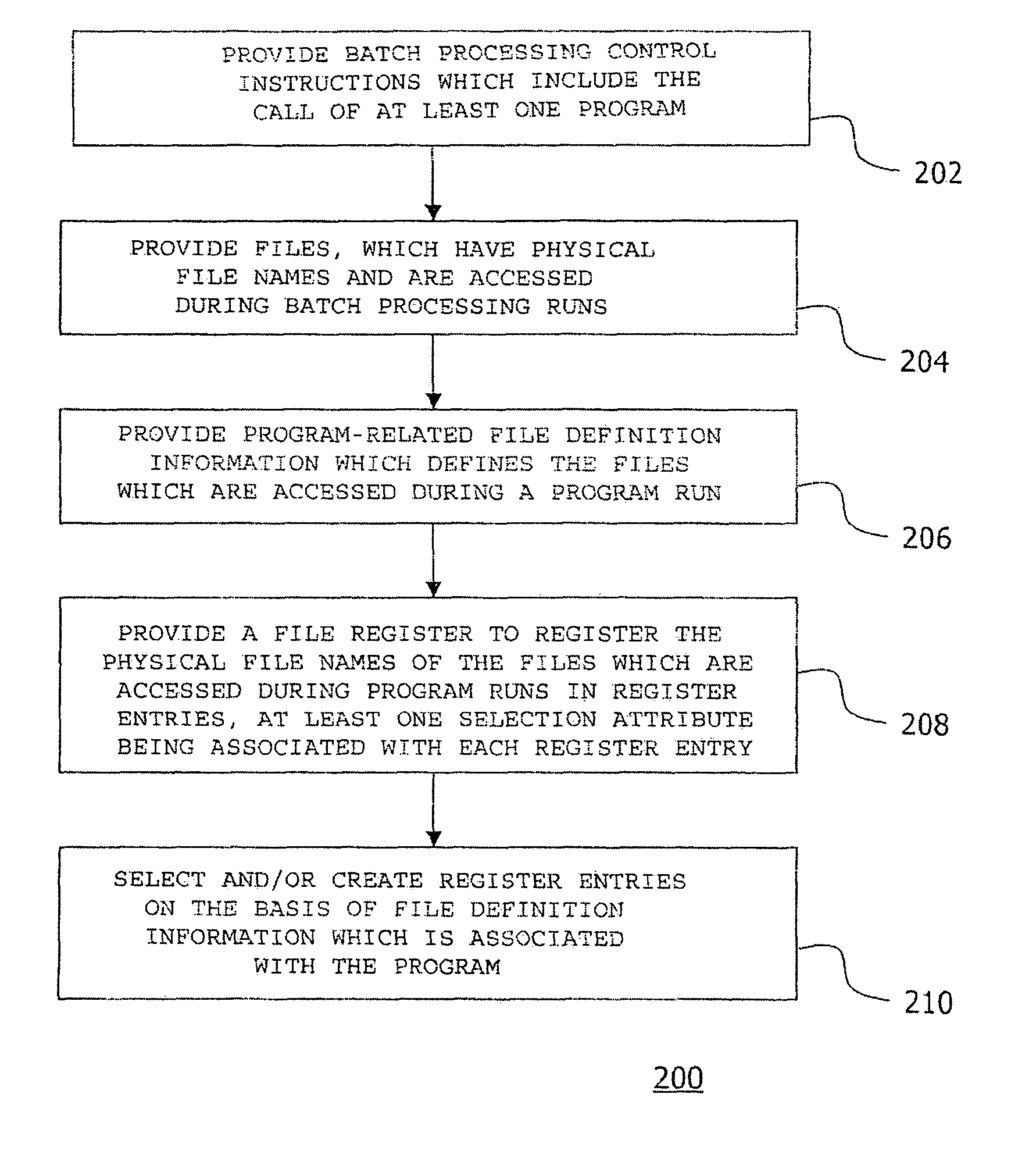

Redundancy in process control system

InactiveUS8856345B2Possible to selectSafety arrangmentsMultiple digital computer combinationsControl systemOrder form

The invention relates to a method and an apparatus for arranging redundancy in a process control system comprising at least one client device, at least one data source and at least one server device providing data transfer between the client device and the data source. The method comprises arranging, for the client device, at least two parallel logical connections for transferring substantially the same data between at least one data source and the client device. At the client device, property information on data units transferred via different logical connections is checked, the client device being provided with predetermined order criteria for the property information. At the client device, property information on parallel data units transferred via different logical connections is compared. Data units delivered via the logical connection having, according to the predetermined order criteria, the best property information are selected for the use of one or more applications processing the data units.

Owner:METSO AUTOMATION OY

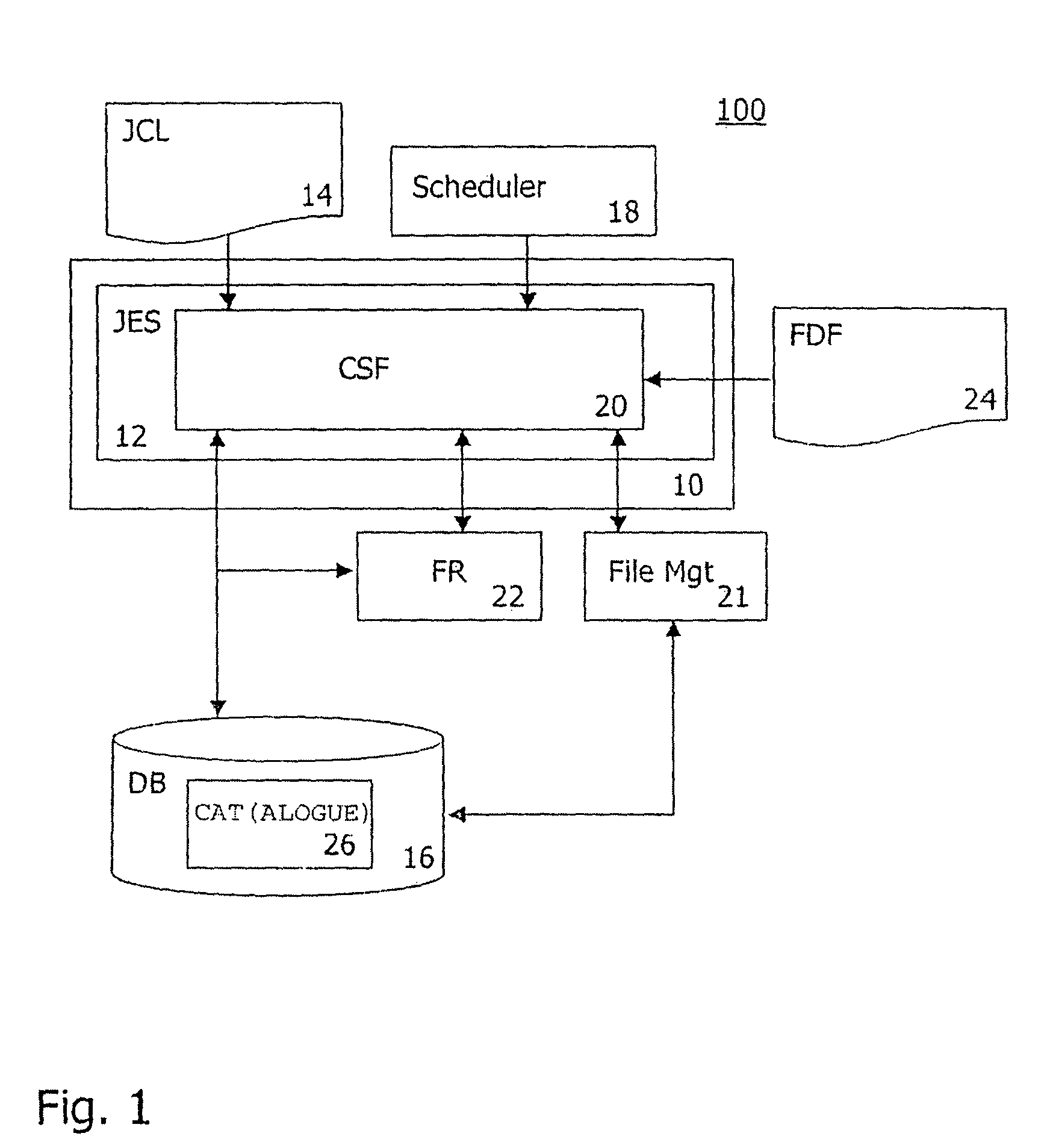

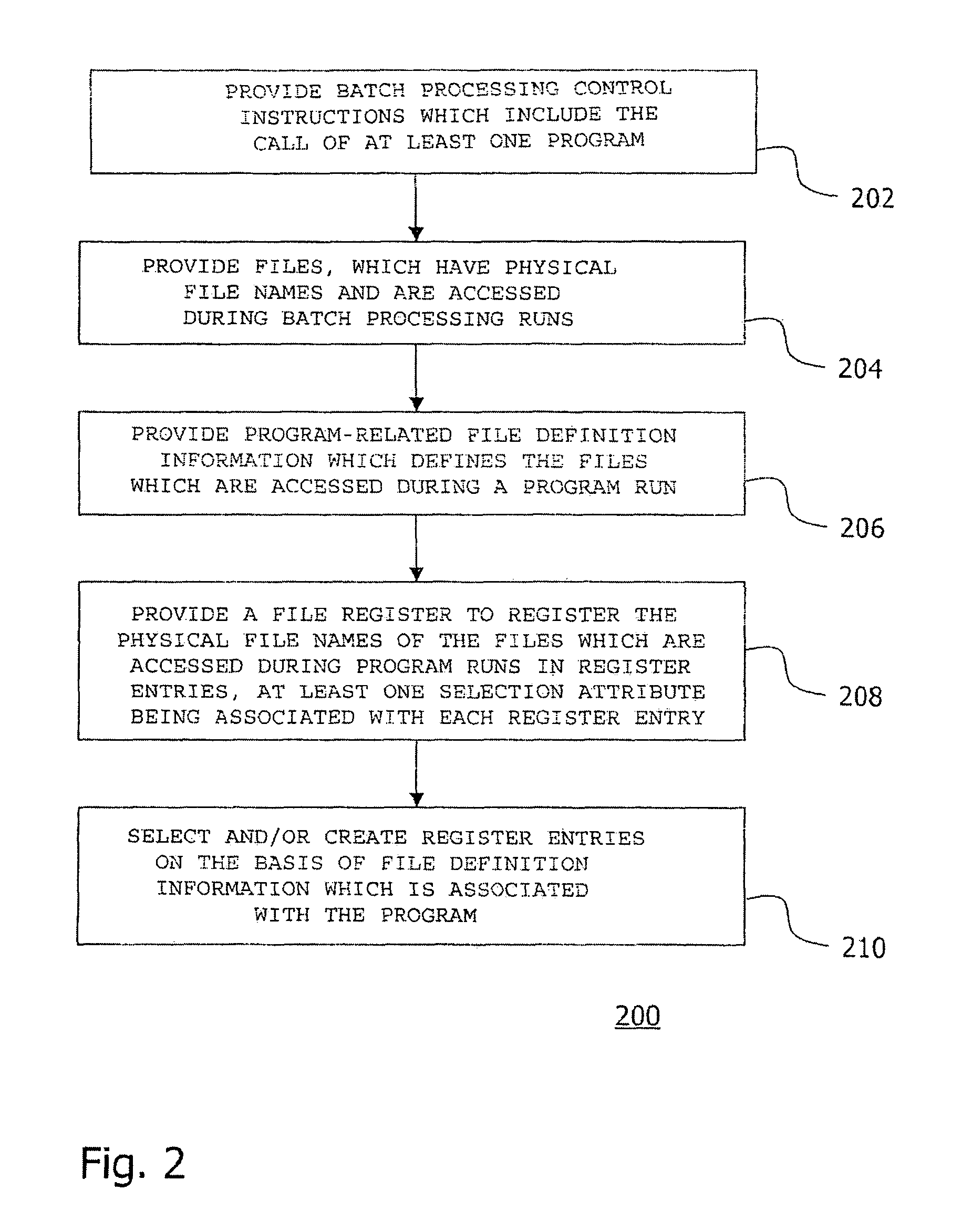

Dynamic registration of batch files by abstract selection criteria

To detect files which are generated unnecessarily or no longer required, and for reliable file versioning, in a batch-processing-oriented environment, a dynamic batch processing system is proposed. The system includes a batch processing control component to process batch processing control instructions, which include the call of at least one program, and a database with files, each of which has a physical file name. The system also includes a component to provide program-related file definition information, which defines the files which are required for a program run by abstract selection criteria. In a file register, the physical file names of the files which are created for the program runs are registered in the form of register entries, which associate at least one selection attribute with each physical file name. A service component which communicates with the control component has access to the file register and the file definition component. The service component selects and / or creates register entries on the basis of file definition information which is associated with the program to be called.

Owner:UBS BUSINESS SOLUTIONS AG

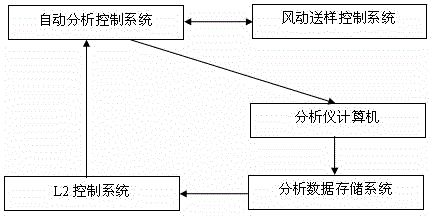

Automatic control system for steelmaking inspection and testing production and control method of automatic control system

ActiveCN104635668AShorten the smelting cycleReduce auxiliary timeTotal factory controlProgramme total factory controlSteelmakingAutomatic control

The invention discloses an automatic control system for steelmaking inspection and testing production. The automatic control system comprises an L2 control system, an automatic analysis control system, a pneumatic sample transporting control system, an analyzer computer and an analyzed data storage system, wherein the L2 control system is used for process control of each steelmaking production unit, the automatic analysis control system is used for automatic control of an analysis system, the pneumatic sample transporting control system is used for pneumatic sample transporting control of each steelmaking production unit, and the analyzer computer receives sample information transmitted down from the automatic analysis control system and uploads the sample information to the analyzed data storage system automatically via a network. By the automatic control system, a great amount of auxiliary time can be saved, molten steel smelting period can be shortened and considerable economic benefit can be created.

Owner:SHANGHAI MEISHAN TECH DEV

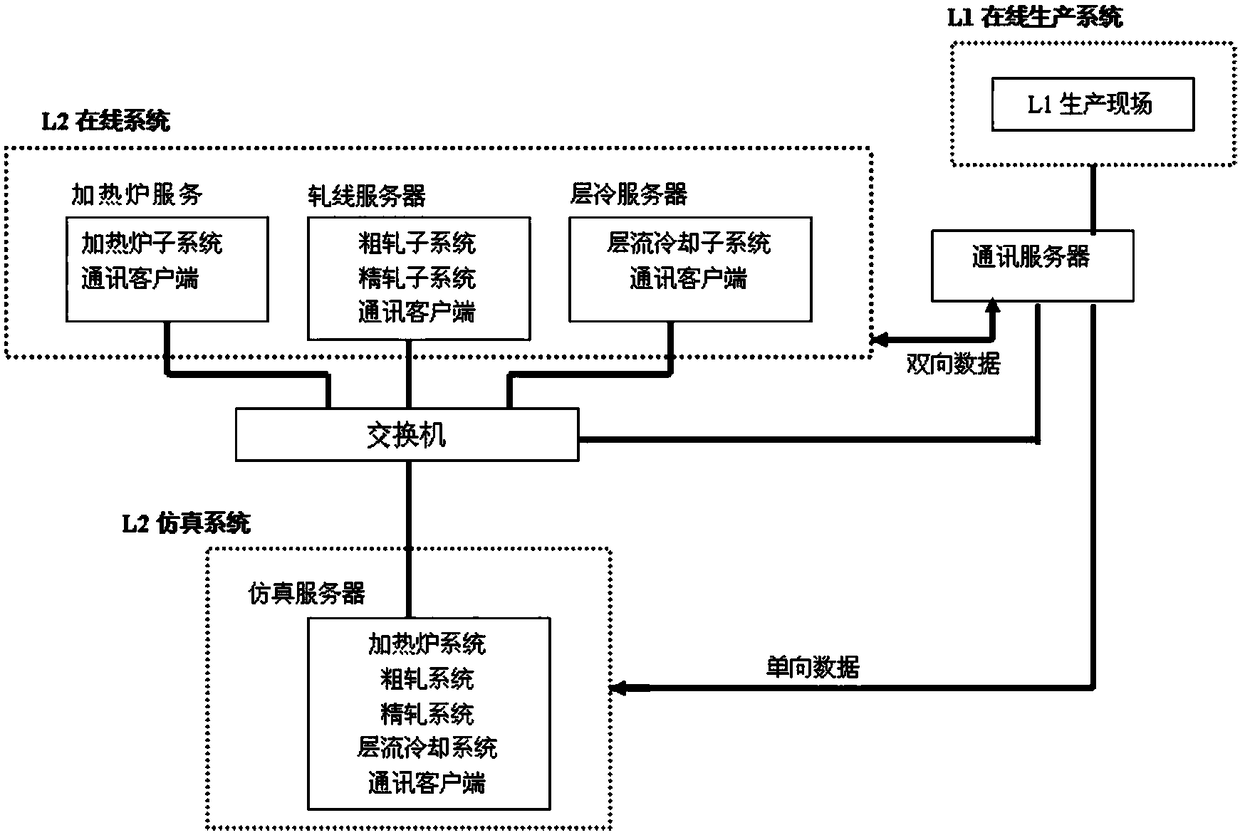

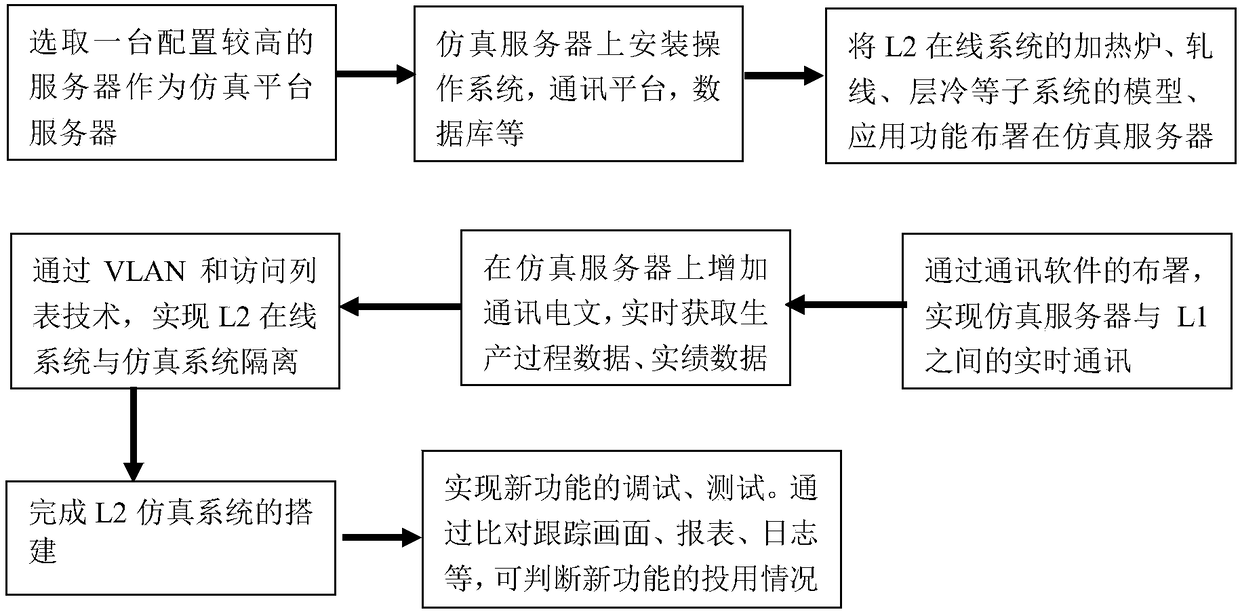

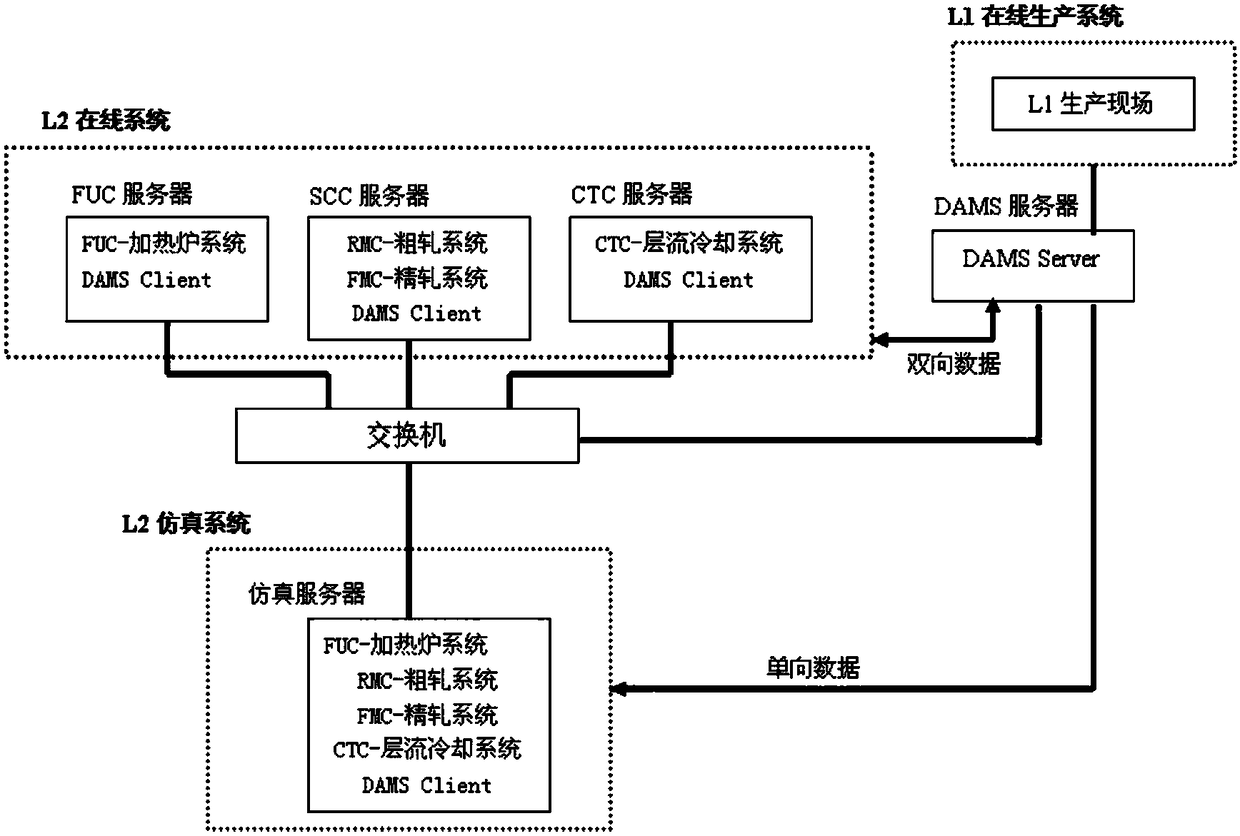

Construction method for simulation system based on hot-rolling L2 process control system

InactiveCN109388072AThe test environment is realReliable test environmentSimulator controlCommunication interfaceCommunications system

The invention provides a construction method for a simulation system based on a hot-rolling L2 process control system. The method comprises the steps: S1, equipment selection of the simulation system,network design and application work platform integration; S2, deployment of all regional subsystem modules of the simulation system, wherein each regional subsystem includes a heating furnace system,a rough rolling system, a finish rolling system, and a laminar cooling system; S3, design of a parallel mode of the simulation system and processing of a parallel message; S4, data management of a simulation process, installation of database software, management of process data; S5, design of an L2 communication system and an L1 communication interface, and achieving of a purpose that the simulation system receives L1 actual strip steel data in real time. The simulation system of the invention can provide a stable, reliable, real and effective test environment and can ensure the successful use of the functions once, and the new function can be directly debugged and tested on the simulation system, and the rolling line production is not affected, thereby reducing the halt production and steel waste of a rolling line, and improving the progress of functional use.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

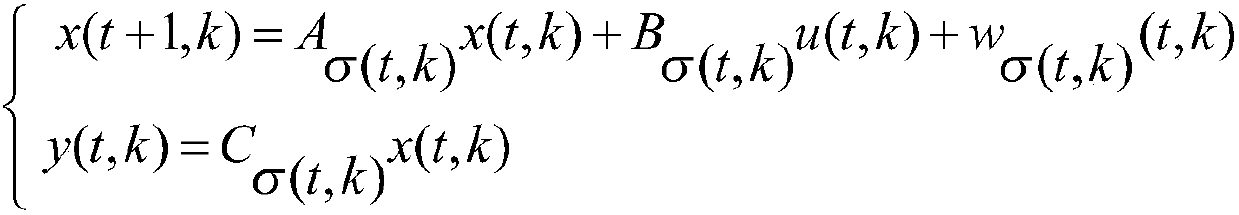

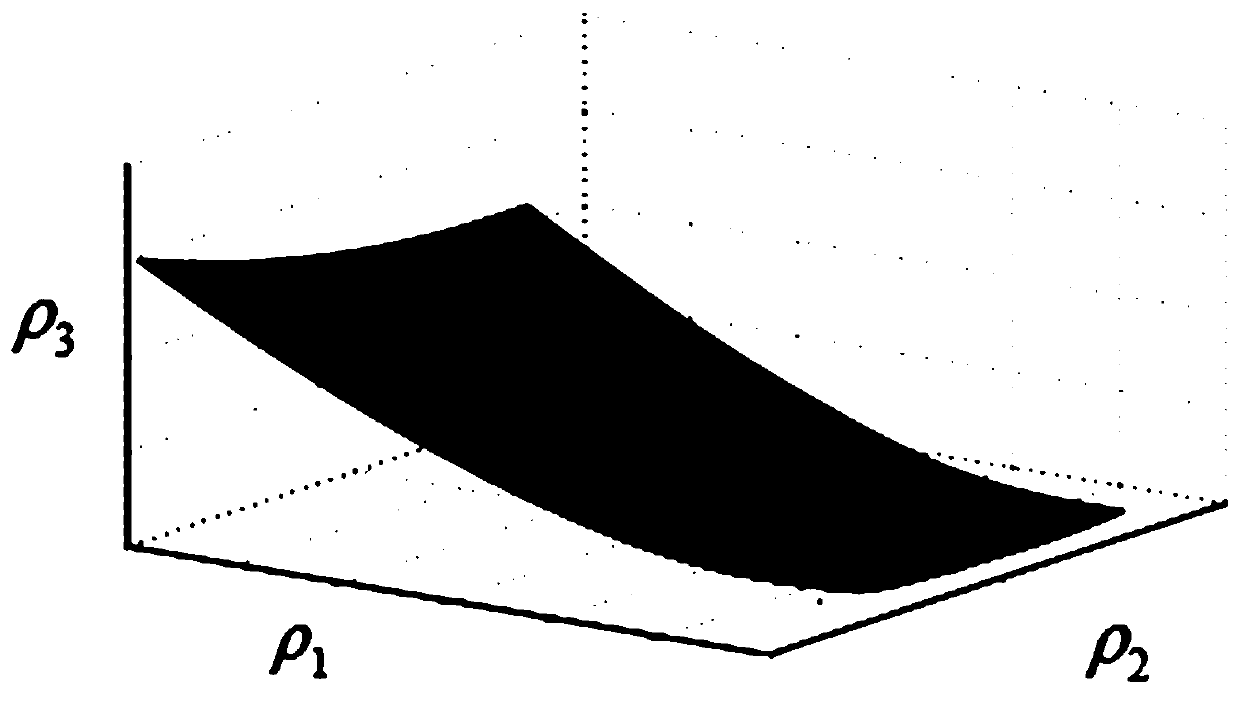

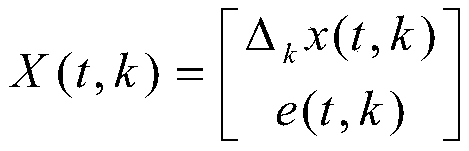

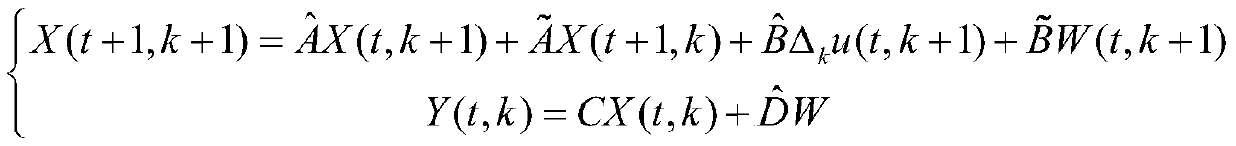

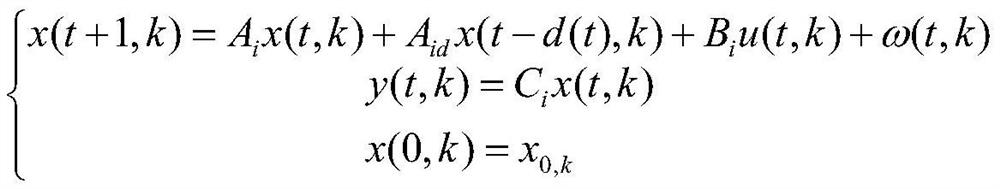

Industrial process performance determination method based on two-dimensional LQG benchmark

The invention discloses an industrial process performance determination method based on a two-dimensional LQG benchmark. The method comprises the following steps of step1, collecting batch process operation data and establishing a batch process state space model; and step2, according to the state space model and an output error, establishing a new batch process state space model, using the two-dimensional LQG benchmark to obtain an optimal batch state variation variance, a tracking error variance, and a batch dimension input variation variance of a system, and establishing a performance tradeoff curved surface of a controlled object. In the invention, batch process control accuracy can be ensured and simultaneously convergence performance of a batch process state and batch iteration inputcan be considered so as to realize stable and high precision control of an industrial batch production process.

Owner:HANGZHOU DIANZI UNIV +1

Compressed encoding control circuit and control method of compressed encoding

InactiveCN101179727BReduce frequencyIncrease frame rateTelevision systemsDigital video signal modificationControl circuitFrame rate

The invention discloses a control circuit and a control method for compression coding. The invention sets a batch processing control unit between a central processing unit and a processing unit of compression coding; the batch processing control unit assists the processing unit of compression coding to conduct batch processing for compression coding of a plurality of frames; thus the processing unit of compression coding requires no communication interruption from the central processing unit, and the time interval of a plurality of frames which are processed in batches does not include the waiting latency of response interruption of the central processing unit; besides, after the processing unit finishes the processing of compression coding for a plurality of fames, a communication interruption is conducted between the batch processing control unit and the central processor; therefore, the frequency of communication interruption between the central processing unit and the batch processing control unit is relatively low, thereby increasing the frame rate of video stream from compression coding.

Owner:VIMICRO CORP

Complete integration of stand-alone batch operator interface capabilities into generic human machine interface

ActiveCN101713986BTotal factory controlInput/output processes for data processingOperator interfaceHuman–machine interface

Systems and methods for providing an integrated HMI application for monitoring and interacting with both batch and non-batch processes in a process plant are disclosed. A plurality of independent stand-alone software objects defining various batch process interface views are embedded within a non-batch process control interface application. A blackboard service is provided for storing batch control data used by the various stand alone software objects. The blackboard service may be adapted to communicate with a batch control server to receive batch control data for populating the various batch interface views with data relating to various batch processes being carried out in the process plant and to send instructions for controlling the various batches input by users via the various batch interface views. When executed by a processor, the stand alone software objects defining the various batch interface views read data from and write data to the blackboard service to communicate data between batch process interface views and preserve contextual information between interface views to allow efficient and intuitive navigation between batch process interface views.

Owner:FISHER-ROSEMOUNT SYST INC

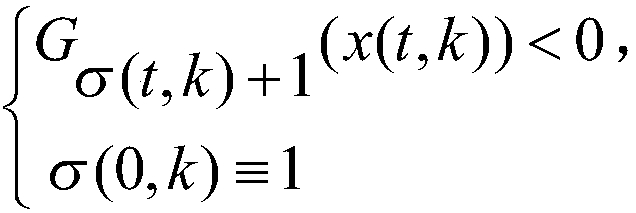

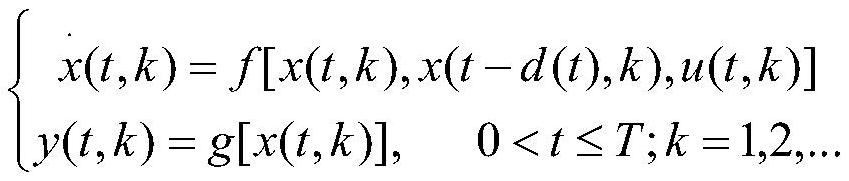

A chemical industry process performance maintenance control method

The invention discloses a chemical industry process performance maintenance control method, comprising the following steps: step 1, establishing a system batch process model; and step 2, designing a controller for the batch process. The method first establishes a state model with time-delay through the analysis of the continuous nonlinear model; then, iteratively learns the control quantity by designing the batch process, and defines the state error and output tracking error, and combines the error compensation technology to obtain A control update law based on tracking error is proposed, and then acts on the controlled object. The design of this batch process performance maintaining control method not only solves the nonlinear and uncertain problems in batch process control, but also ensures the stable operation of the system.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com