A chemical industry process performance maintenance control method

A technique for maintaining control, an industrial process, applied in the field of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Take the experiment of controlling the water level of a three-capacity water tank as an example:

[0039] In the three-tank water level experiment, only one injection was used to observe the effect of the controller. Each injection process is regarded as a batch, and then the water filling process of the three-capacity water tank is regarded as a batch process.

[0040] Step 1. Design the model of the water injection process of the three-capacity water tank. The specific steps are:

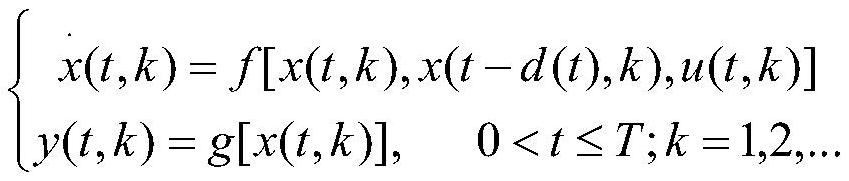

[0041] 1.1 Establish the state model of the water injection process of the three-capacity water tank, which can be described as follows:

[0042]

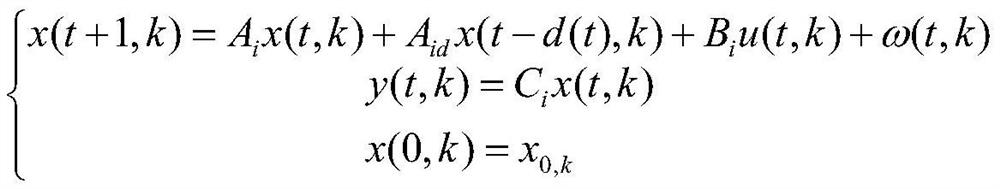

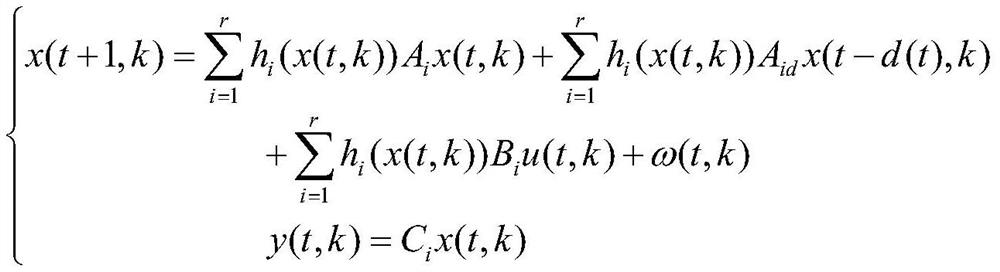

[0043] where t is the discrete time of the system, T is the upper bound of the discrete time, k is the batch index of the injection process; d(t) is the time delay function; x(t,k) and x(t-d(t),k) represent the water level status of the three-capacity water tank at time t and time t-d(t) of the k-th batch, respectively; Indicates the reci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com