Industrial process performance determination method based on two-dimensional LQG benchmark

A technology of industrial process and determination method, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of control system control accuracy decline, operating cost increase, poor robust performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] Take the injection molding process as an example:

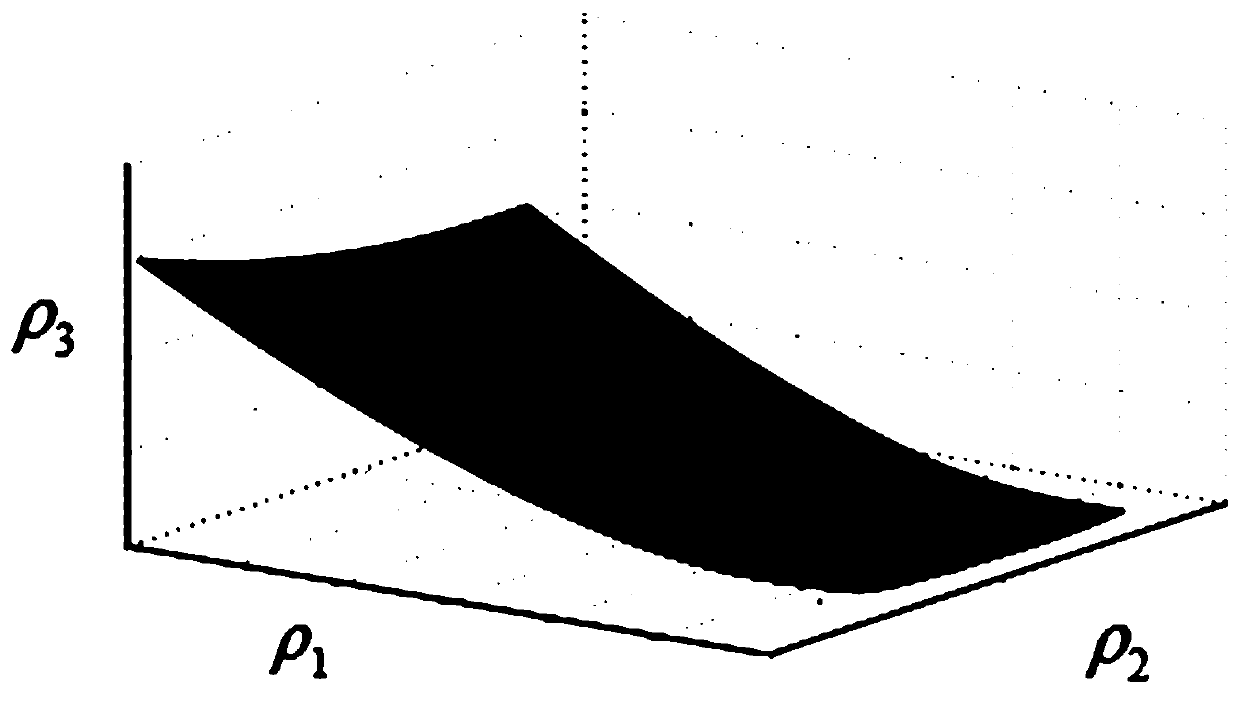

[0040] like figure 1 As shown, the main parameter of the filling process in the injection molding process, that is, the injection speed, is described here as an example, and the adjustment method is to control the valve opening of the proportional valve.

[0041] Step 1. Establish the state space model of the proportional valve in the injection molding process. The specific steps are:

[0042] 1-1. First collect the real-time operation data of the injection molding process, and establish the system model of the injection molding process under uncertain disturbance in the following form:

[0043] x(t+1,k)=Ax(t,k)+Bu(t,k)+w(t,k)

[0044] y(t+1,k)=Cx(t+1,k)+v(t,k)

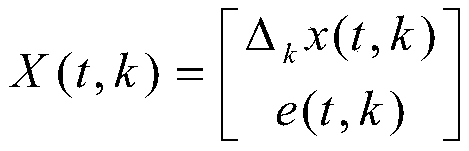

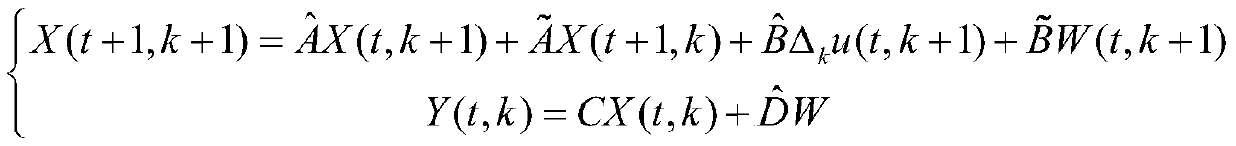

[0045] Where k and t represent the batch and batch running time in the injection molding process, respectively, x(t+1,k), x(t,k) are the process of bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com