Complete integration of stand-alone batch operator interface capabilities into generic human machine interface using componentized objects

A batch, non-batch technology, applied in the direction of comprehensive factory control, comprehensive factory control, program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

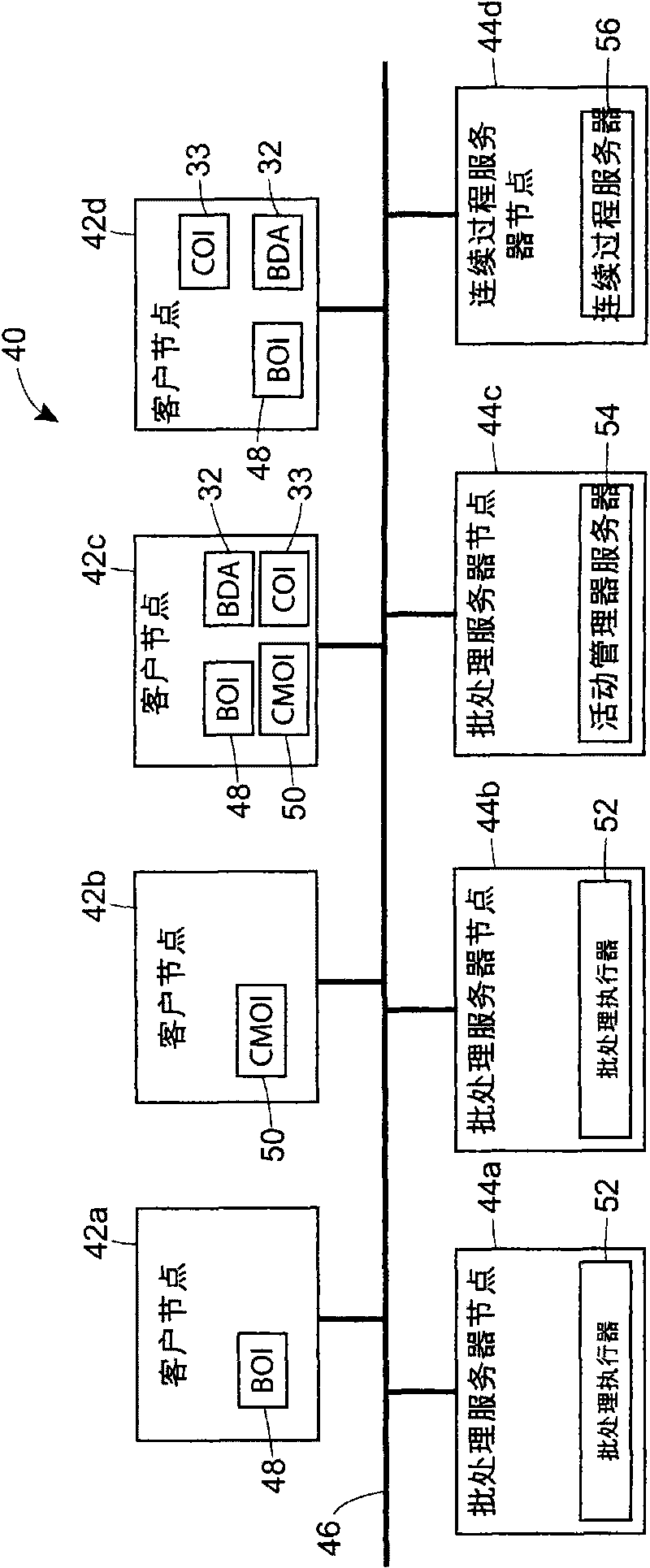

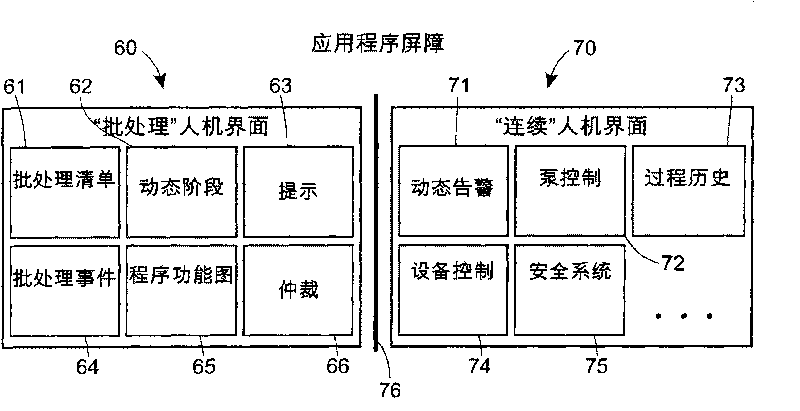

[0026] The present invention relates to a Human Machine Interface (HMI) system for use in an industrial process plant environment. In particular, the present invention discloses an integrated human machine interface system that allows viewing of both batch process data and non-batch process data through a single non-batch process interface application.

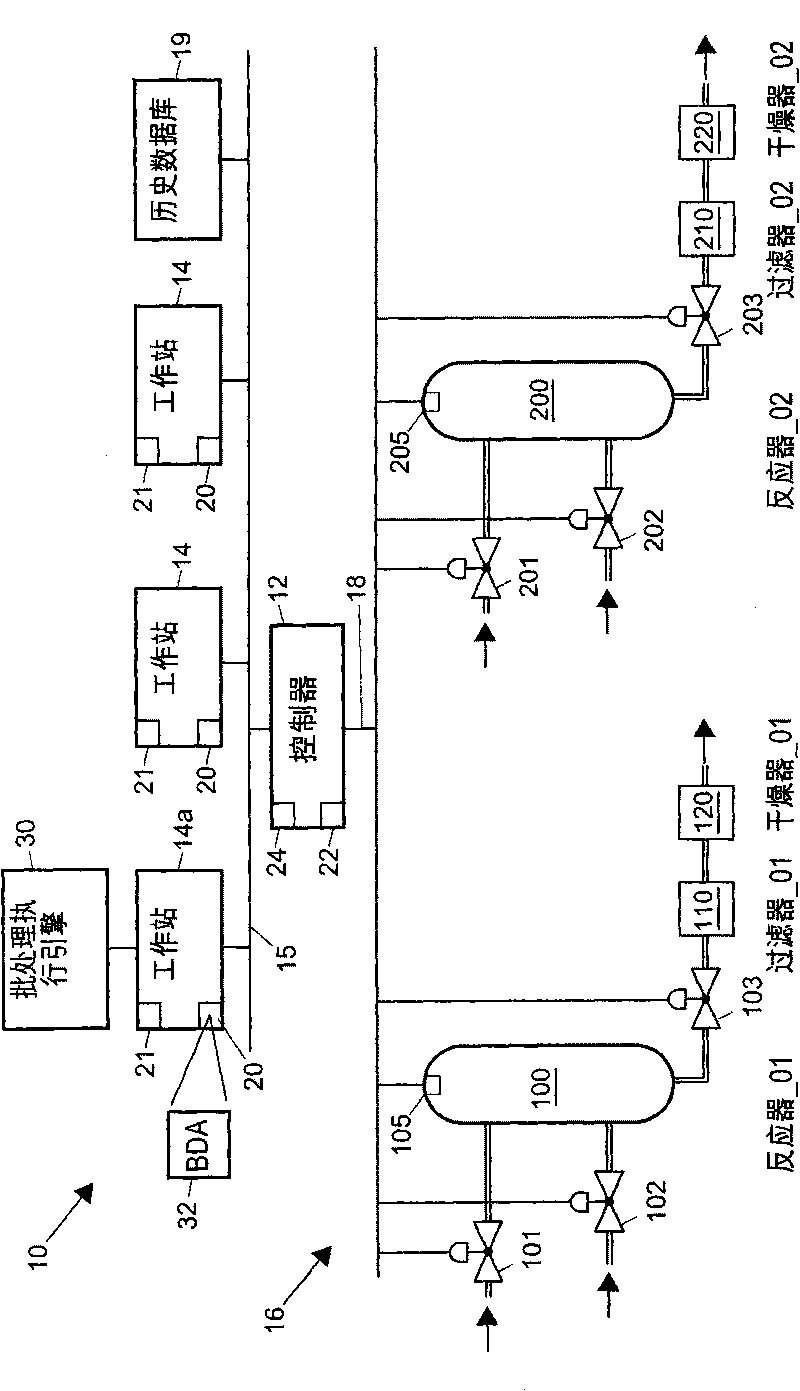

[0027] figure 1 An exemplary portion of a typical process plant control network 10 is shown. The process plant control network 10 includes a controller 12 that is connected via one or more input / output devices (not shown) and a set of communication lines and / or a bus 18 to the devices in the process plant. Lots of equipment and fixtures. The plurality of devices and devices connected to the controller 12 are collectively designated by reference numeral 16 . Controller 12 may be a DeltaV™ Batch controller sold by Emerson Process Management. The controller 12 communicates with various process control elements, such as field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com