Automatic control system for steelmaking inspection and testing production and control method of automatic control system

An automatic control system and control system technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of auxiliary time, clerical errors, easy input errors, etc., achieve considerable economic benefits and shorten the cycle , the effect of saving auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

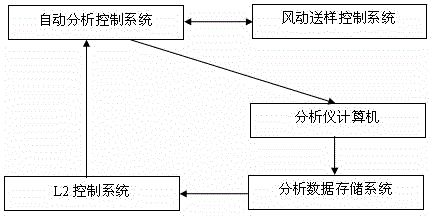

Method used

Image

Examples

Embodiment 1

[0051] Taking the analysis of steelmaking converter samples as an example, it is assumed that a steelmaking plant has 3 converters, corresponding to 3 sample delivery pipelines, and a converter L2 process control system.

[0052] The automatic analysis and control system codes the 3 pipelines and 3 converters and corresponds them one by one. The number of the No. 1 converter is Z01, and the corresponding pipeline is GZ01; the number of the No. 1 converter is Z02, and the corresponding pipeline is GZ02; The serial number is Z03, and the corresponding pipeline is GZ03; the three converters share one L2 system, which is called converter L2. The automatic analysis control system defines the sample code of the converter, the code of the first sample of the No. 1 converter is 1101, the code of the second sample is 1111; the code of the first sample of the No. The code of the sample is 1211; the code of the first sample of converter No. 3 is 1301, and the code of the second sample is...

Embodiment 2

[0060] Taking the sample analysis of vacuum refining furnaces in steelmaking as an example, it is assumed that there are 2 vacuum refining furnaces in a steelmaking plant, corresponding to 2 sample delivery pipelines, and 2 vacuum refining furnace L2 process control systems.

[0061] (1) The automatic analysis and control system coded the 2 pipelines and 2 vacuum refining furnaces and made a one-to-one correspondence. The number of the No. 1 vacuum refining furnace is ZK01, and the corresponding pipeline is GZK01; the number of the No. 2 vacuum refining furnace is ZK02. The corresponding pipeline is GZK02; the 2 L2 systems of the 2 vacuum refining furnaces are respectively ZK1L2 and ZK2L2. The automatic analysis control system defines the sample code of the vacuum refining furnace. The code of the first sample of the No. 1 vacuum refining furnace is 1401, and the code of the second sample is 1411; the code of the first sample of the No. 2 vacuum refining furnace is 1501, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com