Chemical batch process control system stability maintenance method

A technology of process control system and process system, which is applied in the field of control system stability maintenance in chemical batch industrial process, can solve the problems of control system delay, increase the risk of controller failure, and not consider the running time, etc., to achieve the goal of improving control performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Take the cycle injection molding process as an example: the cycle injection molding process is a typical multi-period intermittent process, and the product quality of the cycle injection molding process is guaranteed by controlling the minimum running time.

[0048] Step 1. Aiming at the shortcomings of the traditional control strategy without considering the running time, design a new hybrid control model. The specific method is:

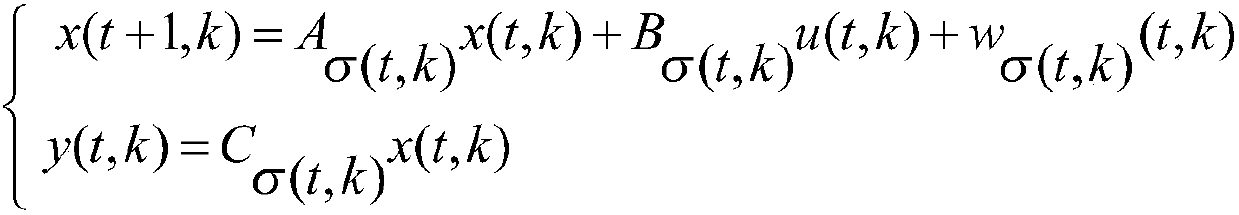

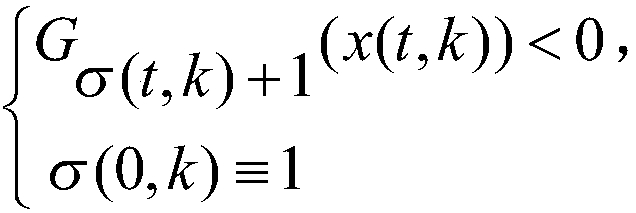

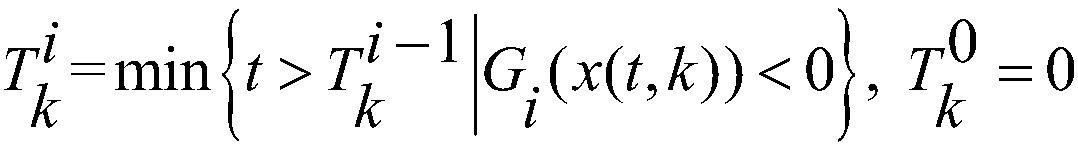

[0049] 1.1 Use mathematical equations to describe the dynamic changes of the cycle injection molding process system

[0050]

[0051] t=0,1,2,LT k ;k=1,2,L K k

[0052] where t and k are the time step and cycle index, respectively, and x(t,k)∈R n , u(t,k)∈R 1 , y(t,k)∈R 1 Respectively represent the state, input and output at the time t of the kth cycle in the cycle injection molding process, and x(t+1,k) represents the state at the time t+1 of the kth cycle in the cycle injection molding process. T k Indicates the duration of the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com