Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Wide range of water quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

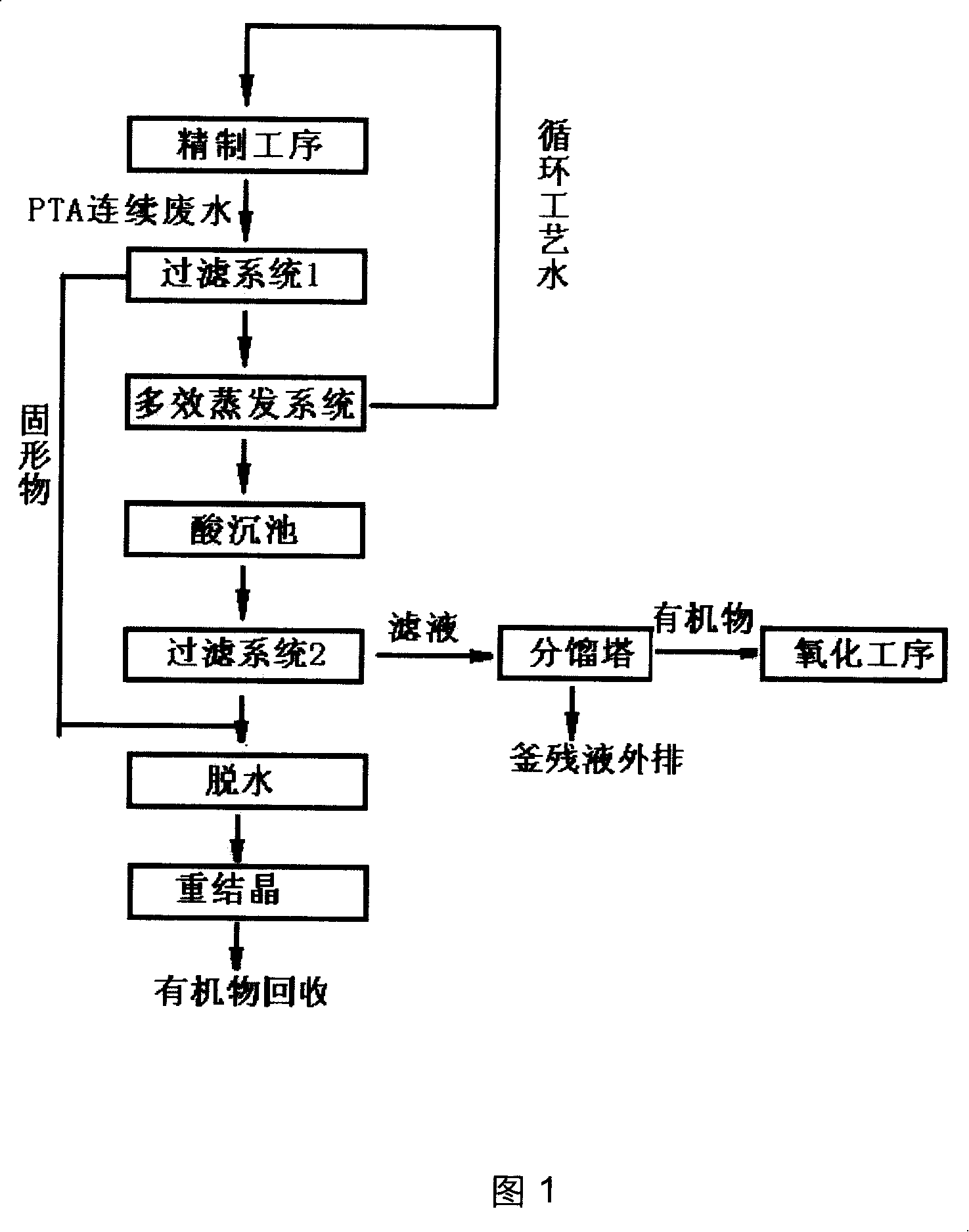

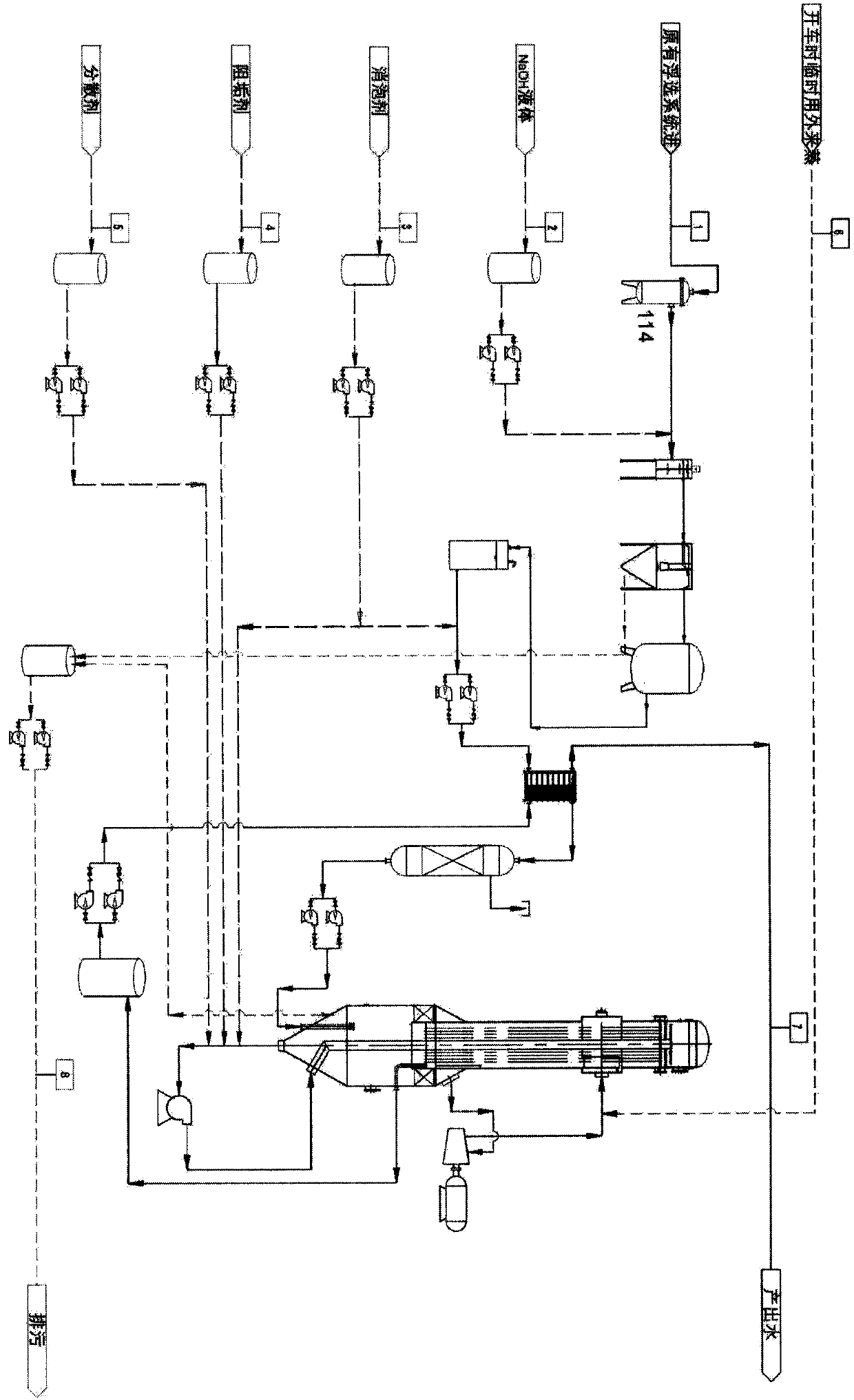

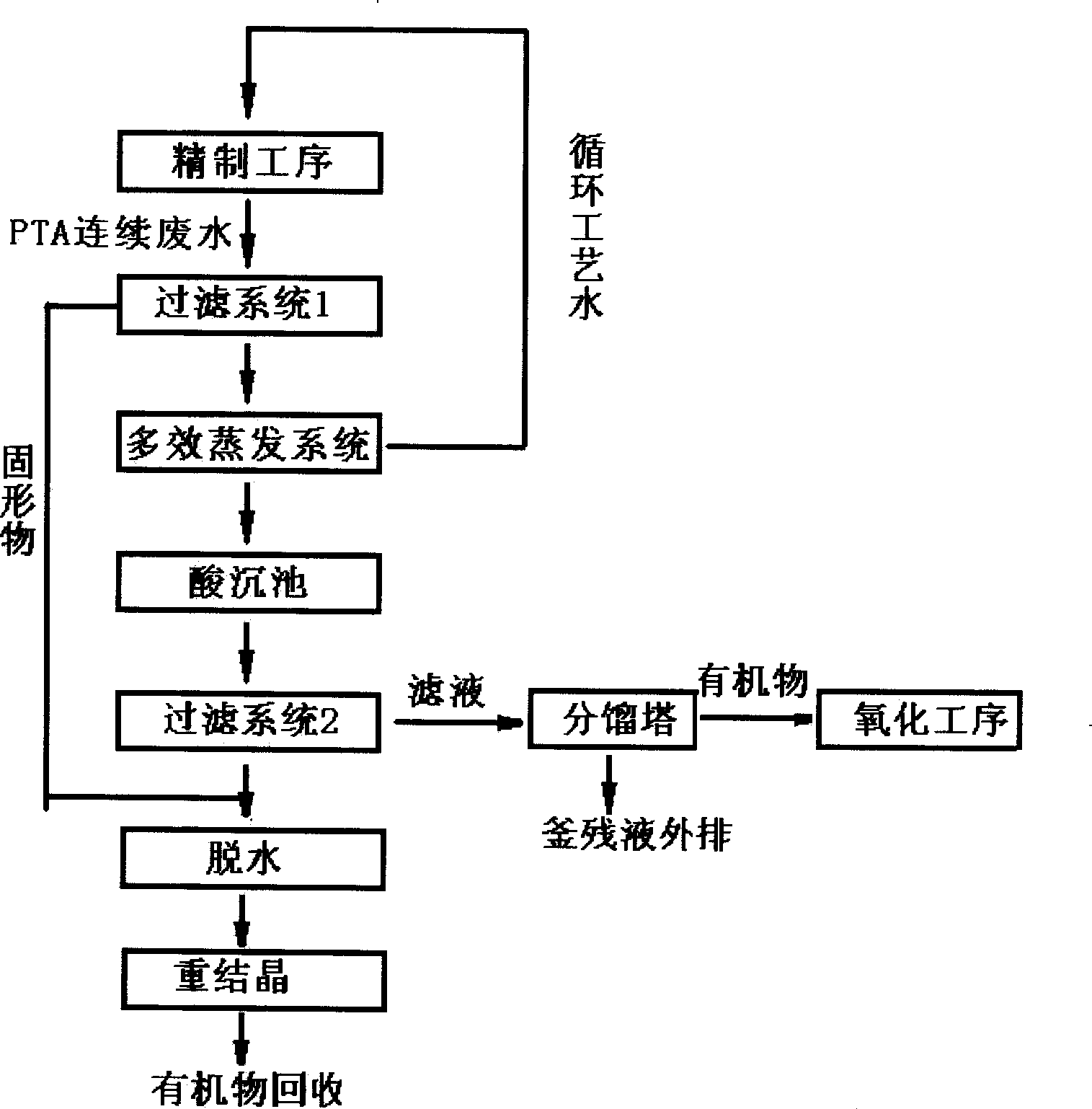

Method of processing p-benzene dicarboxylic acid production wastewater

ActiveCN101152969AEnable direct reuseAchieve recyclingMultistage water/sewage treatmentWater/sewage treatment by heatingSteam condensationEvaporation

The present invention provides a disposal of the phthalic acid production wastewater. The steps are: a. the process wastewater output from a refining process is filtered; filtrate and a solid-form object are gained; b. the filtrate is sent to and processed in a multi-effect evaporation system; steaming condensation water and condensation water with organic compound are gained; then the steaming condensation water is recycled back to the refining process and is reused; c. a solid-liquid mixture is gained by adding acid to the condensation water and precipitating; the solid-form object and the filtrate are gained by processing a solid-liquid separation to the mixture; d. water and various organic compounds are gained by fractionating the filtrate; the water is recycled back to the refining process and is reused; the organic compounds are recycled back to a xylene oxidation process; e. various organic compounds are gained though the combination and re-crystallization of the solid-form object in the step a and the solid-form object in the step c. With the present invention, the majority of the PTA wastewater is capable of being recycled and reused in the production after being disposed; in addition, the majority of the organic compounds in wastewater are reclaimed. So the economically using of the PTA wastewater and the organic compounds in wastewater is realized.

Owner:CHINA PETROLEUM & CHEM CORP

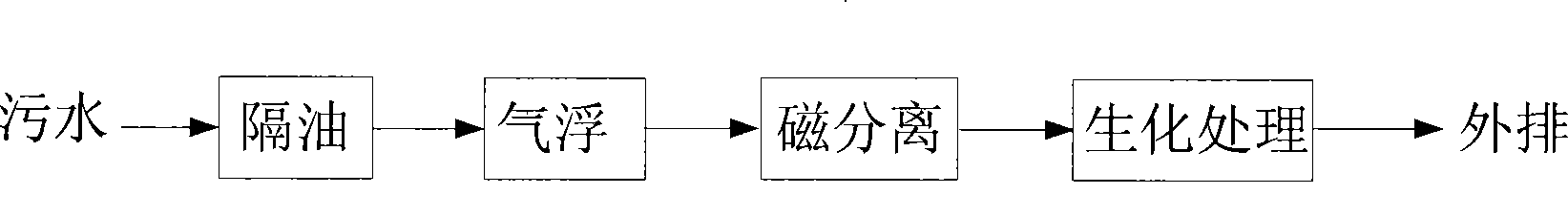

Oil refining sewage treatment technology

ActiveCN101591110AReduce loadAvoid shockFatty/oily/floating substances removal devicesWater/sewage treatment by magnetic/electric fieldsChemical treatmentWater quality

The invention relates to an oil refining sewage treatment technology. Oil refining mixed sewage is sequentially treated by oil removal, air flotation, magnetic separation and biochemical treatment, and then is discharged. On the basis of the original oil refining mixed sewage treatment process flow, the invention adds the step of magnetic separation, which can lighten the load of a secondary bio-chemical treatment device, avoids shock to a biochemical system and greatly improves effluent quality in biochemical treatment. The technology of the invention has the advantages of good treatment effect, wide application range of water quality, stable operation, strong operability, simple flow, small investment, low operation cost, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating waste water generated in production of refined terephthalic acid

ActiveCN101058467AEasy to handleSimple processWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentIon exchangeWater quality

The invention discloses a disposing method of manufacturing waste water of fined terephthalic acid, which comprises the following steps: contacting the waste water and complex extractant; making the CODCr in the waste water not less than 2500ml / L through contacting the manufacturing waste water of fined terephthalic acid and complex extractant; recycling the manufacturing waste water as the technical water; realizing the water circulation; possessing good disposing effect and simple technique with wide applying scale for water quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Terrestrial heat tail water treating process

InactiveCN103011454AWide range of water qualityAchieve integrationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentActivated carbon filtrationReverse osmosis

The invention provides a terrestrial heat tail water treating process which comprises the following steps: (1) controlling the tail water temperature after the terrestrial heat water is subjected to heat energy gradient utilization to be less than 45 DEG C; (2) aerating the terrestrial heat tail water by using an aeration tower; (3) flowing the aerated terrestrial heat tail water through a manganese sand filter to be filtered; (4) carrying out membrane integrated treatment on the filtered terrestrial heat tail water by using a double-membrane method process; (5) carrying out boron selective resin absorption treatment on the reverse osmosis water; and (6) filtering the effluent subjected to boron removal by using an active carbon filter and conveying to a use point. Aiming at the harmful ingredients and pollutant types in terrestrial heat tail water, the invention integrates a plurality of water treatment unit techniques, realizes integration and optimization of process systems, is wide in water quality application range of the terrestrial heat tail water, advanced in process and reliable in technique, and has practical popularization and application values in development and utilization in terrestrial heat tail water, and as a result, significant social, economic and environmental benefits are achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

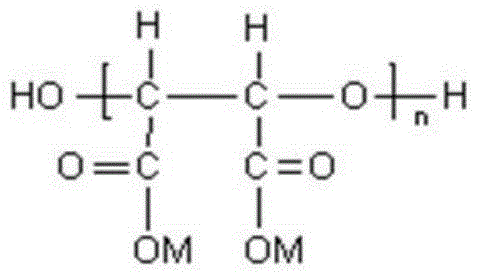

High-efficiency low-phosphorus corrosion and scale inhibiting dispersant and its preparation method

InactiveCN102745825AEasy to realize online automatic dosingImprove controllabilityScale removal and water softeningTungstateTurbidity

The invention discloses a high-efficiency low-phosphorus corrosion and scale inhibiting dispersant and its preparation method. The high-efficiency low-phosphorus corrosion and scale inhibiting dispersant comprises: 2%-12% of sodium benzoate, 1%-5% of molybdate (or tungstate), 1%-2% of thiazole, 3%-6% of anhydrous zinc chloride, 8%-18% of polyphosphonocarboxylate, 5%-15% of acrylic acid-2-methyl-2-acrylamido propane sulfonic acid copolymer, 3%-6% of a stabilizer, 3%-6% of a tracer, and the balance deionized water. The dispersant of the invention can be widely applicable to water quality treatment of circulating water with a sum of hardness and alkalinity of less than 1100mg / L, a chloride ion concentration of less than 1000mg / L, pH of 6.8-9.5, and turbidity of less than 20NTYU. The dispersant provided in the invention has scale and corrosion inhibiting performances able to meet the requirements of industrial circulating water design specifications and a wide source water quality application range, and has the advantages of low phosphorus, environmental protection, strong chlorine resistance, applicability for auto-medicating control, as well as convenient use, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

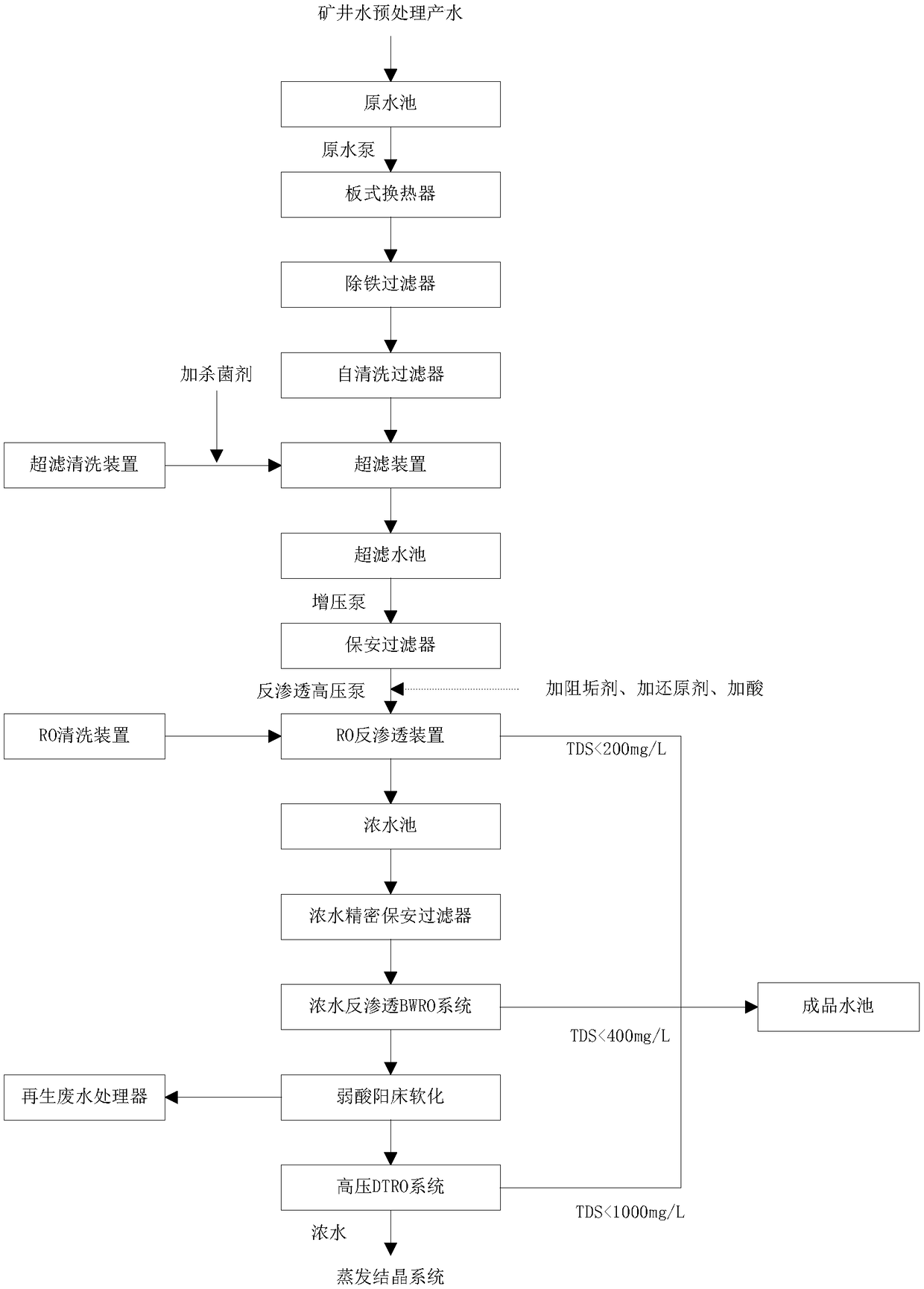

High-mineralization degree mine water treatment method and system

InactiveCN109336323AReduce construction scaleLow investment costTreatment involving filtrationMultistage water/sewage treatmentWater treatment systemEvaporation

The invention relates to the field of mine water treatment, in particular to a high-mineralization degree mine water treatment method and a high-mineralization degree mine water treatment system. Thehigh-mineralization degree mine water treatment method comprises a mine water membrane concentration process and an evaporation crystallization and salt separation process, wherein in the mine water membrane concentration process, after two-stage concentration, disc tube reverse osmosis is then carried out, so that the salt content of concentrated water reaches 5-8%, and the construction scale, the investment cost and the running cost for the subsequent evaporation crystallization of concentrated salt water are reduced; and in the evaporation crystallization and salt separation process, a cocurrent three-effect evaporation and freezing crystallization process is adopted. The operating flexibility is high; and not only can final production of industrial sodium sulfate and sodium chloride with relatively high quality and a small amount of impurity salt be guaranteed, but also the high-mineralization degree mine water treatment method and the high-mineralization degree mine water treatment system can be applied to treatment of water quality with a wider change range.

Owner:内蒙古伊泰广联煤化有限责任公司 +1

Control system and control method for impressed current cathodic protection

The invention discloses a control system and a control method for impressed current cathodic protection. The control method for impressed current cathodic protection comprises the steps that the potential of an inner container is detected; and current output is controlled according to the detected potential of the inner container so that the potential of the inner container can keep within the preset range. According to the control method for impressed current cathodic protection, the applicable water quality range of the inner container is wide, and the protection effect is good.

Owner:GREE ELECTRIC APPLIANCES INC

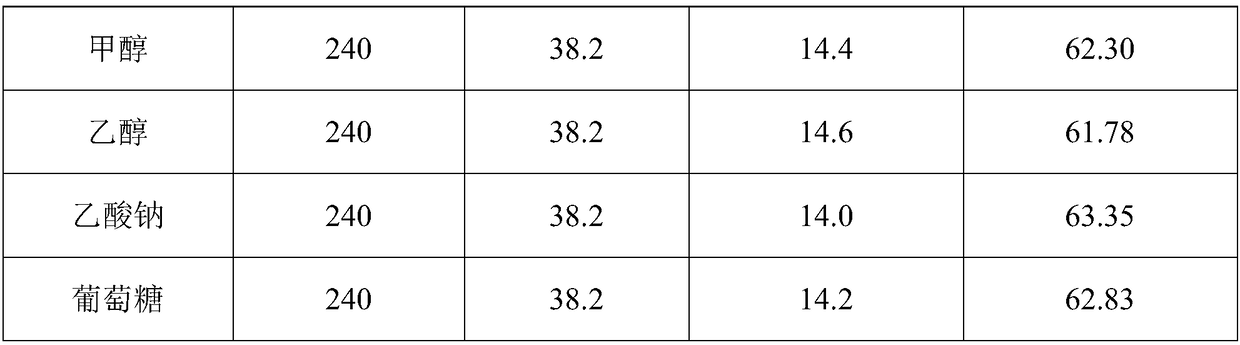

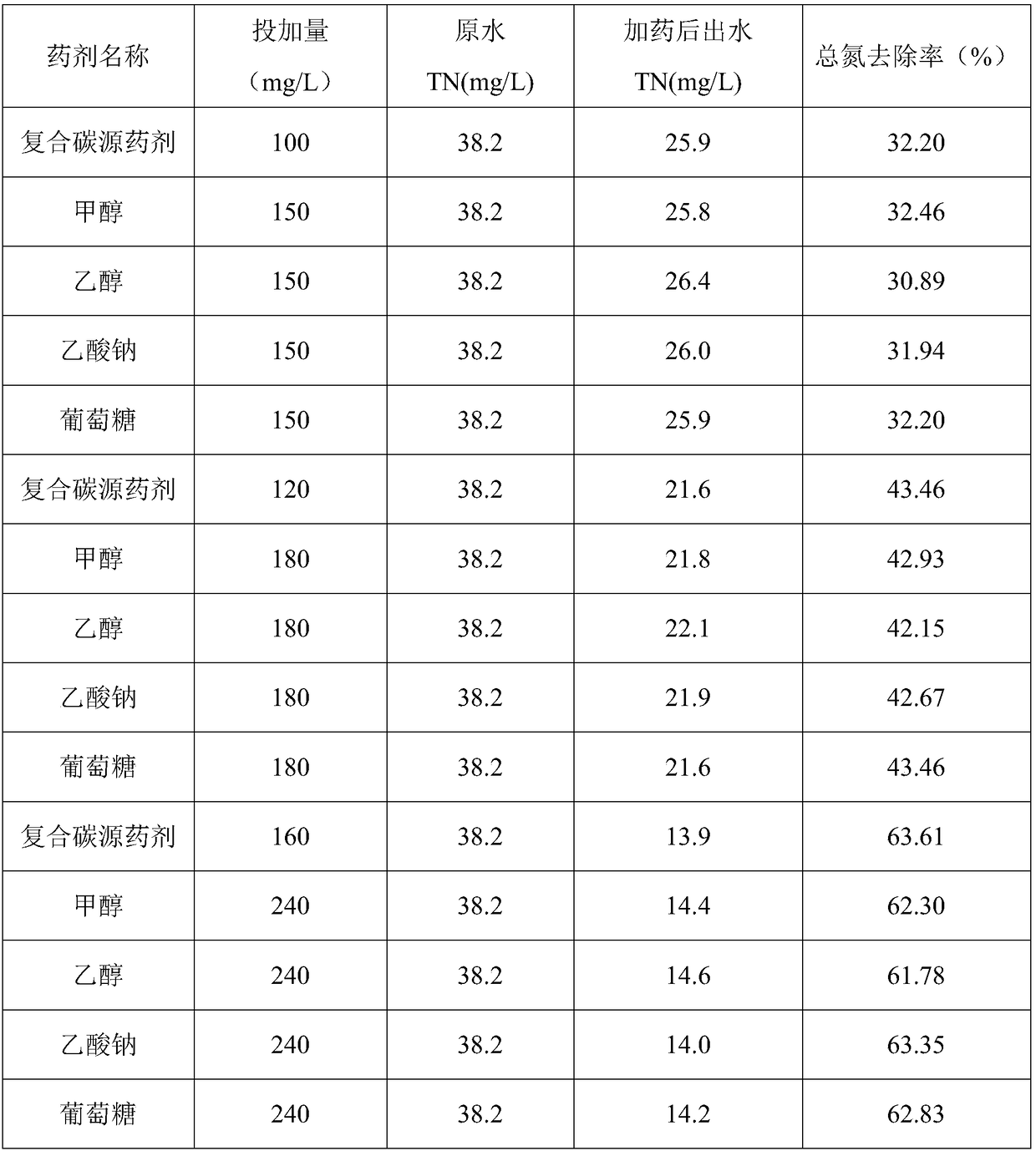

Compound carbon source agent for wastewater treatment

InactiveCN108911131AFast denitrification rateNitrogen removal chemical cost reductionWater treatment compoundsTreatment with anaerobic digestion processesSodium acetateCompound (substance)

The invention discloses a compound carbon source agent for wastewater treatment, wherein the compound carbon source supplement is prepared from the following components by weight: 0.5-1.0% of sodium formate, 4.5-5.5% of sodium acetate, 5-6% of sodium propionate, 40-50% of carbohydrates and 40-45% of water, wherein the carbohydrates are a carbohydrate mixture with the COD more than 300000 mg / ml. The composite carbon source supplement belongs to an energy-saving, high-quality, high-efficiency and environmental-friendly water treatment agent, has the denitrification effect 1.5 times or more thatof traditional water treatment chemicals, and can well adapt to and meet the market demand.

Owner:YIXING HEDA WATER SOLUTION

Method for treating waste water generated in production of refined terephthalic acid

ActiveCN101058467BEasy to handleSimple processWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentIon exchangeWater quality

The invention discloses a disposing method of manufacturing waste water of fined terephthalic acid, which comprises the following steps: contacting the waste water and complex extractant; making the CODCr in the waste water not less than 2500ml / L through contacting the manufacturing waste water of fined terephthalic acid and complex extractant; recycling the manufacturing waste water as the technical water; realizing the water circulation; possessing good disposing effect and simple technique with wide applying scale for water quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing nickel in chemical nickel-plating wastewater

InactiveCN102120659ALow preprocessing requirementsShorten the working cycleWater contaminantsMultistage water/sewage treatmentFlocculationWastewater

The invention discloses a method for removing nickel in chemical nickel-plating wastewater, comprising the steps of: (1) chelation reaction: reacting nickel in wastewater with a chelant to form a nickel chelate; (2) composite flocculation precipitation: subjecting a polymeric Mg-Fe composite flocculant and the nickel chelate obtained in the step (1) to composite flocculation precipitation; and (3) multimedium filtration: filtering the wastewater subjected to the composite flocculation precipitation in the step (2) by adopting a multimedium filter method. The treated wastewater is discharged when nickel content in outflow water reaches the standard. The method has the advantages of good treatment effect, simplicity for operation and management and low operation cost and is a good method for removing the nickel in the chemical nickel-plating wastewater.

Owner:无锡市霄鹰环境科技有限公司

Application of compound carbon-sourced agent in wastewater treatment

InactiveCN108946938AFast denitrification rateNitrogen removal chemical cost reductionWater treatment compoundsTreatment with anaerobic digestion processesSodium acetateSodium propionate

The invention discloses application of a compound carbon-sourced agent in wastewater treatment. The compound carbon-sourced agent is prepared from the following components in percentage by weight: 0.2-1.8 percent of sodium formate, 4-6 percent of sodium acetate, 4-6 percent of sodium propionate, 40-50 percent of carbohydrate, 35-45 percent of water, wherein the carbohydrate is carbohydrate mixturehaving COD being more than 300000mg / ml. The compound carbon-sourced agent is applied to wastewater treatment, has energy conservation, high quality, high efficiency and environmental friendliness, has a denitrification effect of more than 1.5 times that of traditional water treatment chemicals, and can well adaptive to and meet the market requirement.

Owner:YIXING HEDA WATER SOLUTION

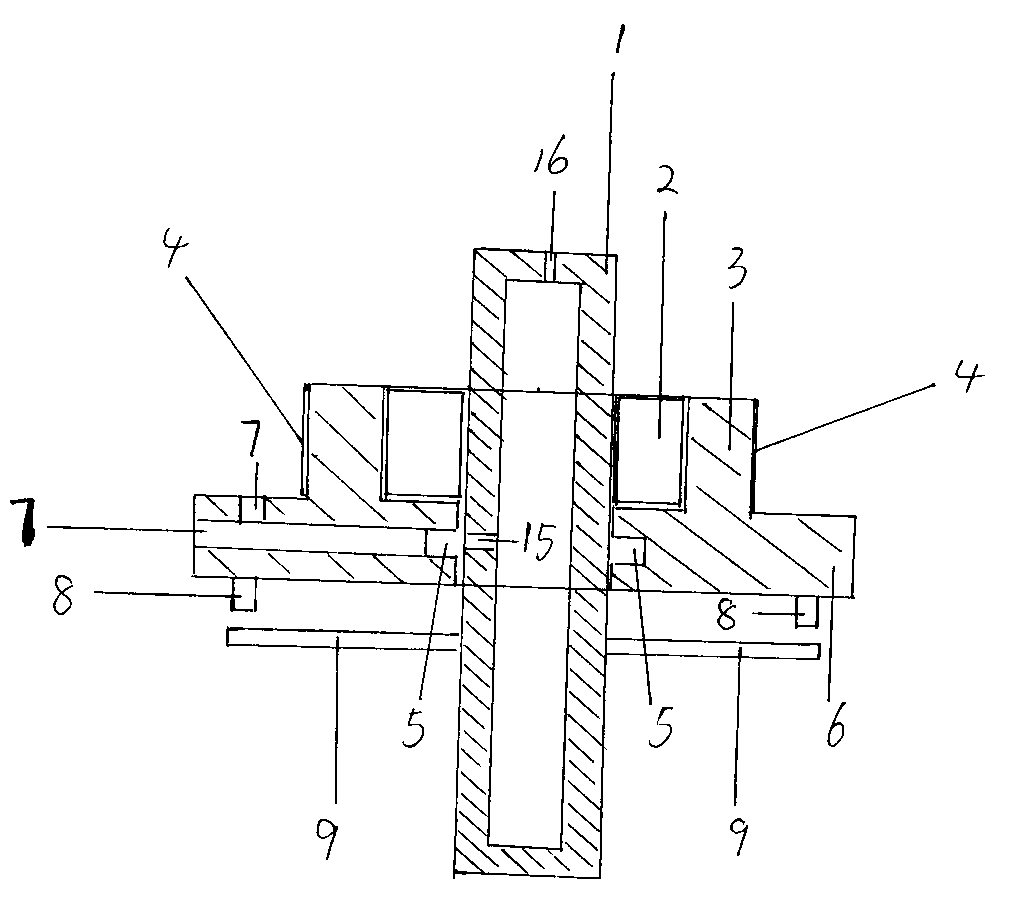

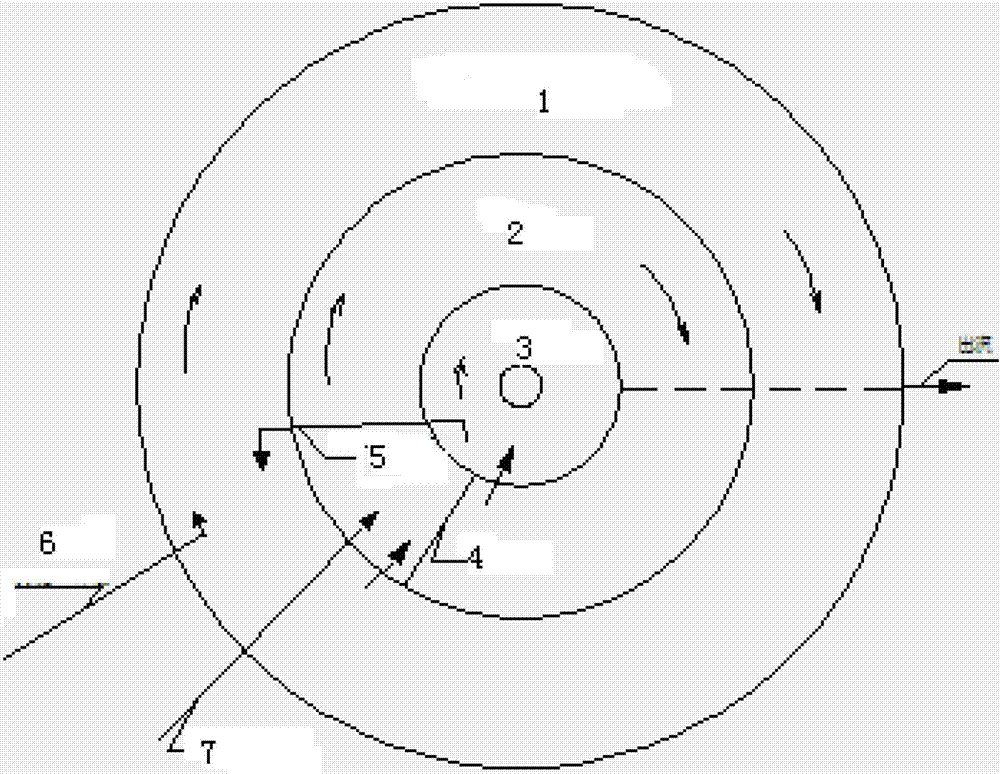

Annular electrode electrolytic tank

ActiveCN104071869AAchieve the purpose of processingEasy to manufactureWater/sewage treatmentEngineeringSewage treatment

The invention provides an annular electrode electrolytic tank, and relates to the technical field of waste water treatment. The annular electrode electrolytic tank adopts the key technology that annular negative and positive electrodes are arranged; the outer ends of negative-positive pole binding posts are fixedly connected with an power cord, the inner ends of the negative poles of the negative-positive pole binding posts are fixedly connected with the negative pole, the inner ends of the negative-positive pole binding posts are fixedly connected with the positive pole, one side of the negative pole is fixedly connected with a water segregator, the water segregator is fixedly connected with a water inlet, the water inlet is fixedly connected with one side of the outer barrel of the electrolytic tank, the other side of the negative pole is fixedly connected with a water collector, the water collector is fixedly connected with a water outlet, the water outlet is fixedly connected with the other side of the outer barrel of the electrolytic tank, and an electrode upper limitation plate is fixedly connected with an electrode can lid; the upper end of the positive pole and the upper end of the negative pole are in embedded connection with the electrode upper limitation plate through buckles, and the lower end of the positive pole and the lower end of the negative pole are in embedded connection with an electrode lower limitation plate through buckles; the electrode lower limitation plate is placed at the bottom of the outer barrel of the electrolytic tank, and the upper end of the outer barrel of the electrolytic tank is connected with the upper end of the outer barrel of the electrolytic tank through a buckle cover. The annular electrode electrolytic tank is used for treating waste water, and is easy to manufacture, high in efficiency, and good in effect.

Owner:宛金晖

Efficient composite carbon source agent and preparation method thereof

InactiveCN111018137AAdapt quicklyReduce outputWater treatment parameter controlWater treatment compoundsSodium acetateCarbon source

The invention discloses an efficient composite carbon source agent for wastewater treatment. The efficient composite carbon source agent comprises the following components in percentage by mass: 4.5-5.5% of sodium acetate, 40-50% of carbohydrates, 1-3% of methanol and the balance of water. According to the invention, the requirements of the market on high-quality and high-efficiency water treatment chemicals can be met; and the efficient biological composite carbon source can effectively provide enough carbon source for biological flora in a biochemical system, and can ensure the safety of theuse process.

Owner:宁夏中宁县兴日晟环保科技有限公司

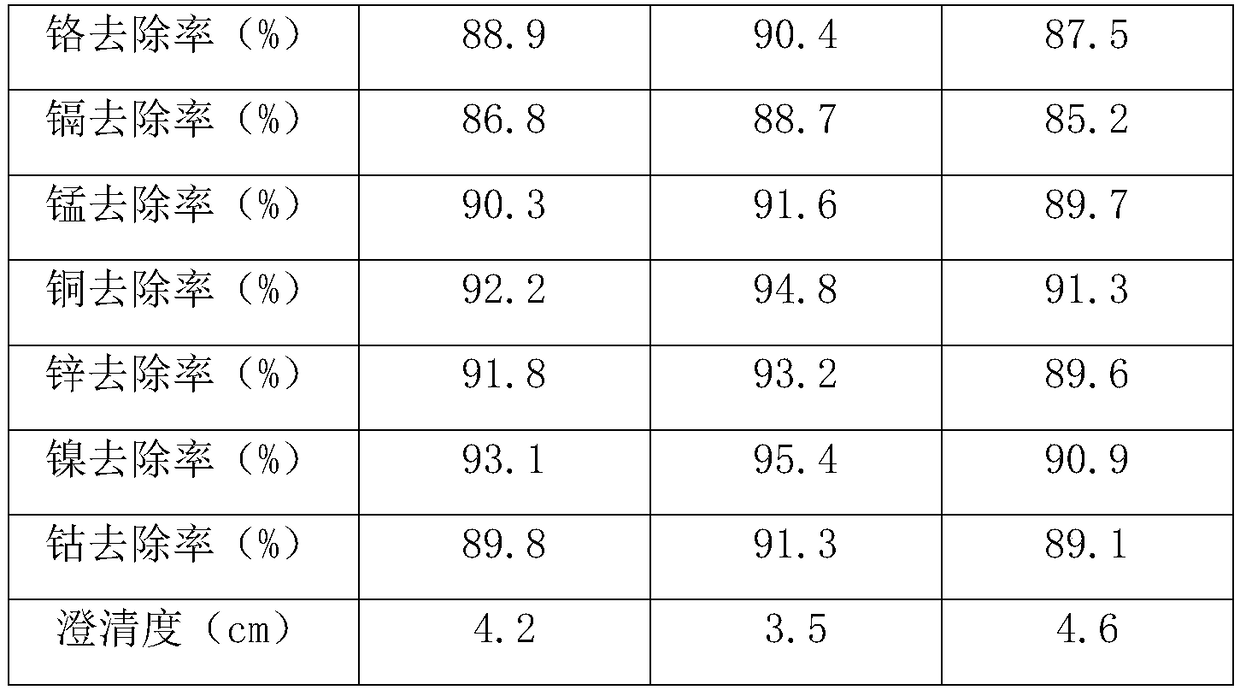

Water body heavy metal ion pollution flocculation sediment preparation and preparation method thereof

InactiveCN108545815AImprove adsorption performanceImprove decolorization performanceSpecific water treatment objectivesWater contaminantsIonChemistry

The invention discloses a water body heavy metal ion pollution flocculation sediment preparation and a preparation method thereof. The water body heavy metal ion pollution flocculation sediment preparation is prepared from the following raw materials in parts by weight: 18 to 26 parts of sodium methallyl sulfonate / acrylamide / acrylic copolymer, 15 to 20 parts of sulfonated styrene-maleic anhydridecopolymers, 13 to 19 parts of 2-amino-3-mercaptoyl chitosan, 5 to 10 parts of hydroxyethylenediamine trisodium triacetate, 16 to 22 parts of polymeric aluminum ferric biacid, 6 to 12 parts of sodium alginate sulfate, 4 to 8 parts of starch xanthate, 14 to 21 parts of alum, 3 to 6 parts of tetradecylpyridinium chloride, 5 to 10 parts of Pulullan, 2 to 5 parts of guar hydroxypropyltrimonium chloride, 1 to 4 parts of behentrimonium methosulfate, 17 to 24 parts of beidellite and 15 to 20 parts of amblygonite. The prepared water body heavy metal ion pollution flocculation sediment preparation has the advantages that the flocculation effect is good; the settlement separation is fast; the efficiency is high; the chemical adding quantity is small; the applicable water quality range is wide; organic matters and various heavy metal ions in the water body can be effectively eliminated; certain sterilization, disinfection and decoloring capability are realized.

Owner:苏州市启献智能科技有限公司

Electric flocculation and oxidation integrated wastewater treatment device and treatment method

PendingCN114212862AEfficient removalEasy to assembleWater contaminantsWater/sewage treatment using germicide/oligodynamic-processFlocculationOrganopónicos

The invention discloses an electric flocculation and oxidation integrated wastewater treatment device and treatment method, and relates to the technical field of wastewater treatment. The device comprises a reactor, a power supply, an electro-oxidation anode plate, an indirect electric flocculation cathode plate and a stirrer, the reactor is used for containing wastewater, the electro-oxidation anode plate and the indirect electric flocculation cathode plate are arranged in parallel, and at least one part of the electro-oxidation anode plate and at least one part of the indirect electric flocculation cathode plate are both located in the reactor; the power supply is communicated with the electro-oxidation anode plate and the indirect electric flocculation cathode plate through wires; the stirrer is used for controlling the mass transfer process of wastewater in the reactor. The method is used for removing suspended pollutants and refractory organic pollutants in the wastewater.

Owner:HARBIN INST OF TECH

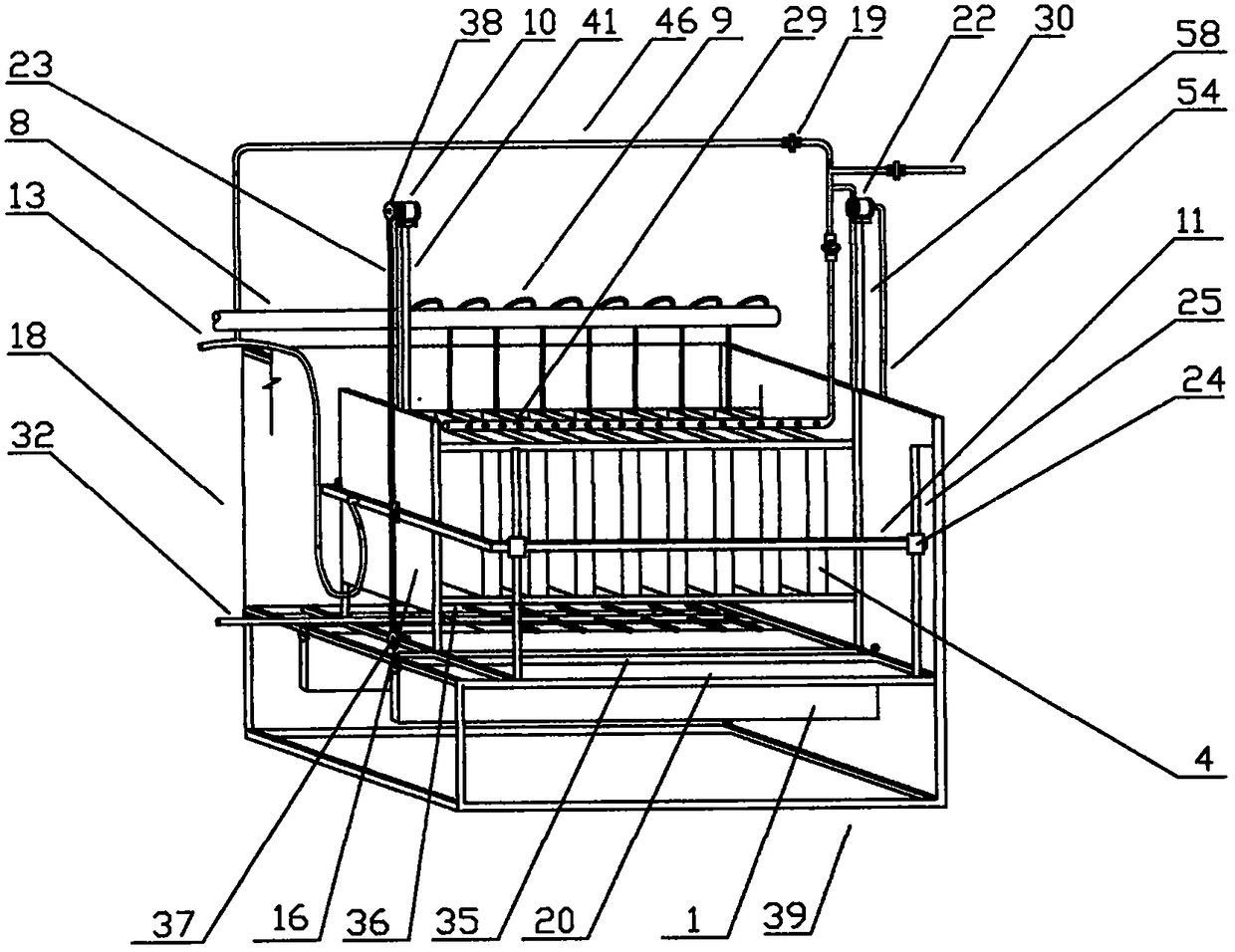

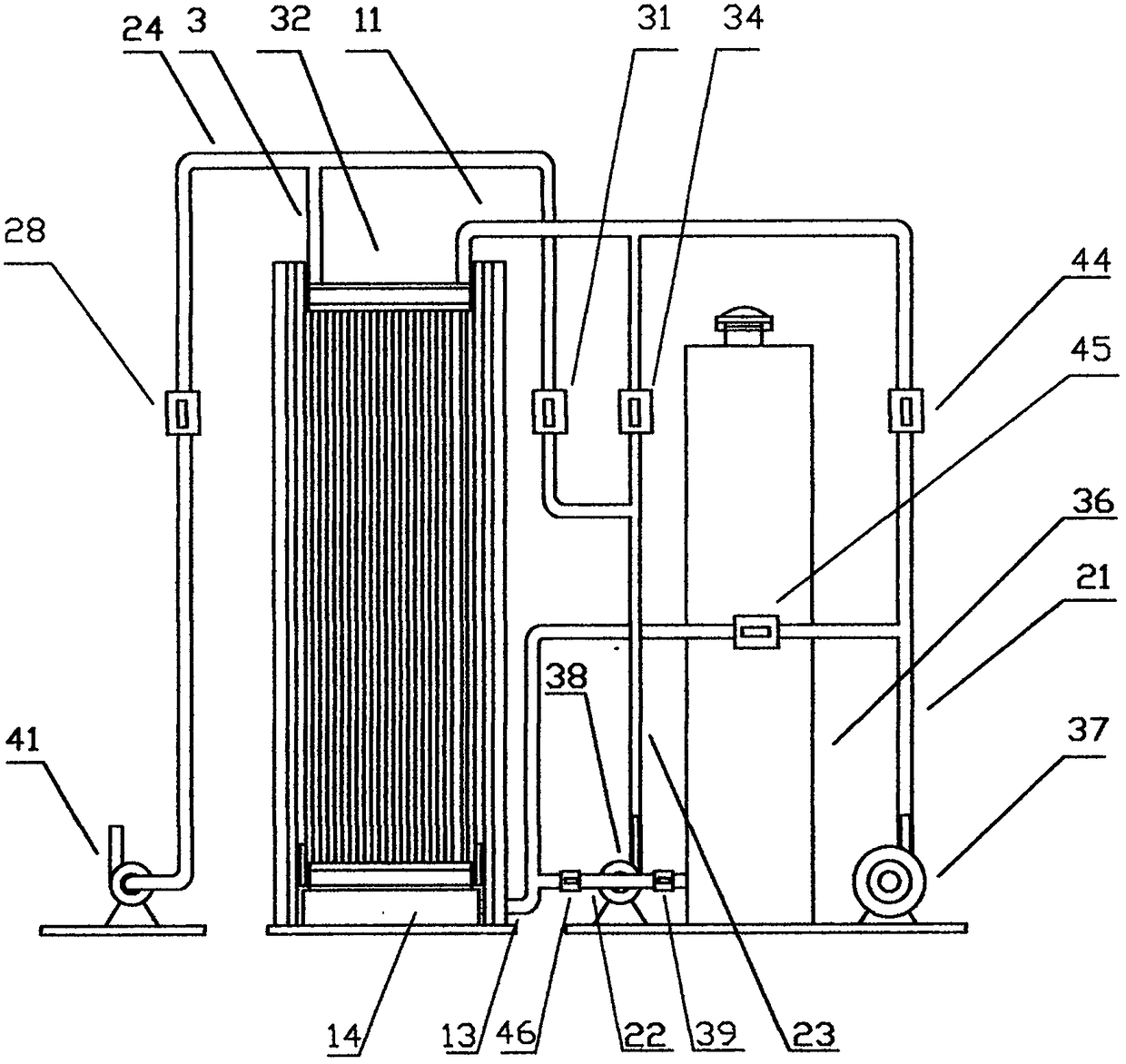

Jet self-cleaning type membrane assembly

InactiveCN108970411AAvoid damageWill not cause serious pollutionWater treatment parameter controlSemi-permeable membranesSludgeWater quality

The invention discloses a jet self-cleaning type membrane assembly, belonging to technical field of environment-friendly sewage treatment. The membrane assembly comprises a frame structure, a fixed cleaning system or a movable cleaning system, a lower gate, a vertical gate, an aeration pipe, a circulating system, a membrane material and a water production pipe, wherein the frame structure comprises an inner framework and an outer framework, the membrane material is arranged on the inner framework, and the cleaning system is arranged between the inner framework and the outer framework. The membrane assembly is wide in sewage quality range and strong in emergency treatment capacity, the chemical cleaning is finished in a biochemical tank, and a membrane material does not need to be added, sothat the damage of the membrane material is avoided, and the sludge is not influenced during the chemical cleaning; the lower gate and the vertical gate are closed, clean water is injected into the membrane assembly, and the membrane assembly can be isolated from sewage which is not suitable for being treated, so that the membrane material is protected; and the biochemical tank can be internallymaintained during the pause in north cold regions, so that the serious pollution of the membrane material is avoided.

Owner:石亮

Toilet and design method

PendingCN110747953AGreat impactReduce occupancyWater closetsFlushing devicesShortest distanceSewage outfall

The invention discloses a toilet design method, and belongs to the field of a toilet. According to the toilet design method, a toilet comprises a toilet piston, a shaft pipe, a toilet basin, a toiletpipeline and a cross shaft pipe; the toilet basin is connected with the toilet pipeline; and the piston is fixed inside the pipeline by the shaft pipe and the cross shaft pipe. The toilet design method is characterized in that the piston is positioned below a toilet outfall; a distance interval is formed between the bottom of the piston and the toilet outfall; excrement falling from the toilet outfall falls on the piston and can slip to the bottom of the pipeline through the interval; the upper surface of the piston is of an eccentric surface structure; a position at the outer edge of the lower bottom of the piston, which is at the shortest distance with the vertex of the piston is a first position; and the first position and the cross shaft rod are positioned on the same side of the piston.

Owner:唐山科理达环保科技有限公司

Oil refining sewage treatment technology

ActiveCN101591110BReduce loadAvoid shockFatty/oily/floating substances removal devicesWater/sewage treatment by magnetic/electric fieldsChemical treatmentWater quality

Owner:CHINA PETROLEUM & CHEM CORP +1

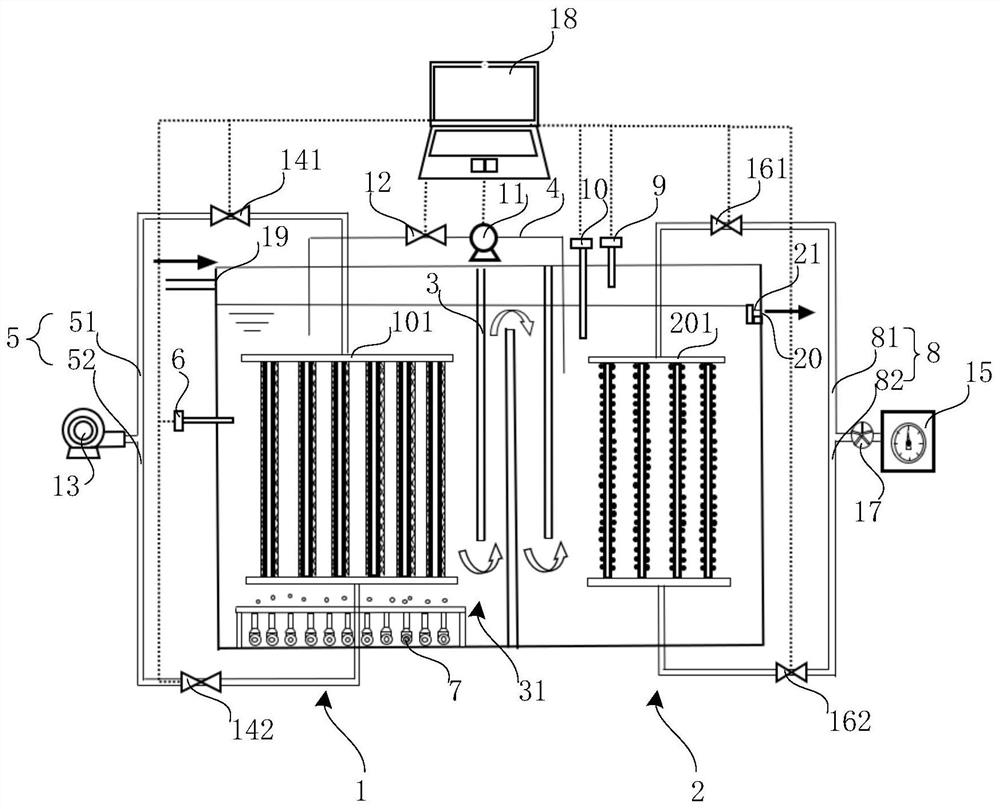

Biological nitrogen and phosphorus removal method and system for sewage

ActiveCN112093899AApplicable to a wide range of water qualityWide range of water qualityWater contaminantsTreatment with aerobic and anaerobic processesTotal nitrogenTreatments water

The invention relates to the field of water treatment, in particular to a biological nitrogen and phosphorus removal method and system for sewage. The method comprises the following steps: 1) performing anaerobic treatment on a to-be-treated water body; 2) carrying out anoxic treatment on the water body obtained by anaerobic treatment; 3) carrying out aerobic treatment on the water body obtained by anoxic treatment; 4) carrying out oxygen elimination treatment on the water body obtained by aerobic treatment; 5) refluxing a part of supernatant of the water body obtained by oxygen elimination treatment to the step 2) for anoxic treatment; 6) carrying out membrane-based biological treatment on part of supernatant of the water body obtained by oxygen elimination treatment; 7) carrying out precipitation treatment on a lower-layer mud-water mixture of the water body obtained by the oxygen elimination treatment; 8) refluxing part of the water body obtained by the membrane-based biological treatment to the step 1) for anaerobic treatment; and 9) refluxing part of the water body obtained by the membrane-based biological treatment to the step 3) for aerobic treatment. The method is good in removal effect of total nitrogen and total phosphorus pollutants, simple and convenient to operate, low in energy consumption and stable in up-to-standard emission.

Owner:TONGJI UNIV

Oily waste liquid treatment technology in machinery industry

InactiveCN109809618AWon't clogReduce foulingMultistage water/sewage treatmentLiquid wasteParticulates

The invention relates to the fields of environmental governance, energy conservation and emission reduction, in particular to an oily waste liquid treatment technology in machinery industry. A methodcomprises the following steps: removing of a sticky matter, removing of particulate matters, oil-water separation and removing of COD (Chemical Oxygen Demand), and a cascade technological route for sequentially removing the sticky matter, the particulate matters, oil and the COD in oily waste liquid is formed. Design optimization is carried out according to the difficulty of impurity removing andthe influence to downstream equipment and treatment efficiency, a filter core type filter is enabled not to be blocked due to removing of the sticky matter in advance, scaling in an evaporator can bereduced through the removing of the particulate matters, and the treatment efficiency of equipment is increased while the equipment is protected; a pure physical method is adopted, no chemical agent is added, generation of oily sludge is avoided, and secondary pollution and input of aftertreatment are reduced; the operating efficiency and the energy utilization rate are high, the applicable waterquality range is wide, and effluent indexes are stable; the investment is saved, and meanwhile, the operating cost is low; an oil concentrated solution can be further subjected to resource utilization, and dual benefits of environment protection and resource saving are realized.

Owner:安洁行方流体管理技术有限公司

Composite coagulant and method for refined oil storage oil-containing sewage treatment

ActiveCN105129937ASolve non-complianceMeet processing needsWater/sewage treatment by flocculation/precipitationOil terminalPrecipitation

The present invention discloses a composite coagulant for refined oil storage oil-containing sewage treatment. The composite coagulant comprises an agent A and an agent B, wherein the agent A is prepared from the following raw materials by weight: 10-40% of Ca(OH)2, 20-50% of sodium carbonate, 15-50% of diatomaceous earth, and 2-20% of powder active carbon, and the agent A is prepared from the following raw materials by weight: 10-30% of magnesium sulfate, 30-60% of ferrous sulfate, and 30-60% of polyferric sulfate. The present invention further discloses a method for refined oil storage oil-containing sewage treatment, wherein the method comprises: 1, deoiling refined oil storage oil-containing sewage, and 2, adding the agent A to the deoiled refined oil storage oil-containing sewage, stirring, adding the agent B after uniformly stirring, and carrying out a precipitation reaction. According to the present invention, the water-soluble organic matters incapable of being removed by the conventional coagulants can be effectively removed, and the oil storage sewage treatment requirements with different pollutant concentrations can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

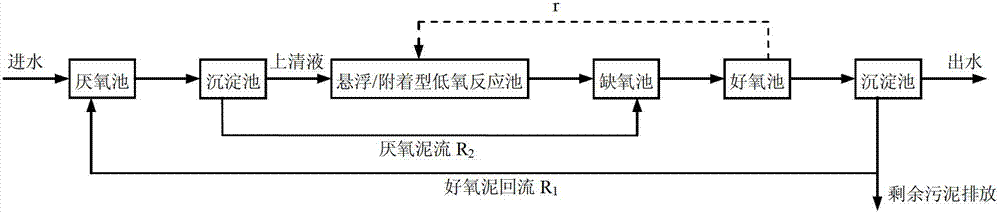

ALOAO double-sludge circulation synchronic denitrification and phosphorus removing process, operation method thereof, and employed biological reaction tank

ActiveCN102730832BReduce demandImprove nitrogen and phosphorus removal efficiencyTreatment with aerobic and anaerobic processesSludgeSewage

The invention relates to an ALOAO double-sludge circulation synchronic denitrification and phosphorus removing process. According to the invention, first, pre-treated sludge is delivered into an anaerobic tank; sludge-water separation is carried out in a first sedimentation tank; an obtained supernatant is delivered into a hypoxic reaction tank; sludge obtained by sedimentation in the first sedimentation tank is directly delivered into an anoxic tank, and is mixed with the liquid discharged from the hypoxic reaction tank; the mixture is delivered into a short-time aerobic tank, and is than delivered into a second sedimentation tank; an obtained supernatant is discharged, and a part of the sludge obtained by sedimentation is delivered back to the anaerobic tank; and the rest of the sludge is discharged as residual waste sludge. According to the invention, mixed liquid reflux is designed on the path from the short-time aerobic tank to the hypoxic reaction tank, and the reflux ratio is set according to requirements. The process and the operation control method provided by the invention have relatively broad adaptability to sewage qualities. The method can be used for removing nitrogen and phosphorus with low carbon source and low consumption on oxygen. Therefore, the method is suitable for the reformation and construction of municipal wastewater treatment plants with requirements on nitrogen and phosphorus removing.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

Ring Electrode Electrolyzer

ActiveCN104071869BAchieve the purpose of processingEasy to manufactureWater/sewage treatmentEngineeringSewage treatment

The invention provides an annular electrode electrolytic tank, and relates to the technical field of waste water treatment. The annular electrode electrolytic tank adopts the key technology that annular negative and positive electrodes are arranged; the outer ends of negative-positive pole binding posts are fixedly connected with an power cord, the inner ends of the negative poles of the negative-positive pole binding posts are fixedly connected with the negative pole, the inner ends of the negative-positive pole binding posts are fixedly connected with the positive pole, one side of the negative pole is fixedly connected with a water segregator, the water segregator is fixedly connected with a water inlet, the water inlet is fixedly connected with one side of the outer barrel of the electrolytic tank, the other side of the negative pole is fixedly connected with a water collector, the water collector is fixedly connected with a water outlet, the water outlet is fixedly connected with the other side of the outer barrel of the electrolytic tank, and an electrode upper limitation plate is fixedly connected with an electrode can lid; the upper end of the positive pole and the upper end of the negative pole are in embedded connection with the electrode upper limitation plate through buckles, and the lower end of the positive pole and the lower end of the negative pole are in embedded connection with an electrode lower limitation plate through buckles; the electrode lower limitation plate is placed at the bottom of the outer barrel of the electrolytic tank, and the upper end of the outer barrel of the electrolytic tank is connected with the upper end of the outer barrel of the electrolytic tank through a buckle cover. The annular electrode electrolytic tank is used for treating waste water, and is easy to manufacture, high in efficiency, and good in effect.

Owner:宛金晖

A system and method for treating heavy oil and super heavy oil chemical sewage

InactiveCN105565562BWide range of water qualityWaste water treatment from quariesMultistage water/sewage treatmentThermodynamicsSewage

The invention discloses a thickened oil and super heavy oil chemical sewage treatment system and method. The thickened oil and super heavy oil chemical sewage treatment system comprises a pretreatment unit and a steam compression unit, wherein the pretreatment unit comprises a precipitation device and a preheating device; solid substances and a part of suspended substances in super heavy oil sewage are precipitated by the precipitation device; the precipitation device is connected with the preheating device so as to preheat and raise the temperature of sewage after precipitation treatment; the steam compression unit comprises an evaporation device and a compression device; sewage treated by the pretreatment unit is fed into the evaporation device for evaporation and concentration; the generated steam passes the compression device and is further fed into the evaporation device for heat exchange evaporation. The thickened oil and super heavy oil chemical sewage treatment system and method can be applicable to a wide raw water quality, and the effects of high quality and high efficiency and the purposes of energy conservation and consumption reduction can be achieved.

Owner:钱孝德

Method and system for biological nitrogen and phosphorus removal of sewage

ActiveCN112093899BApplicable to a wide range of water qualityWide range of water qualityWater contaminantsTreatment with aerobic and anaerobic processesTotal nitrogenTreatments water

The invention relates to the field of water treatment, in particular to a method and system for biological denitrification and dephosphorization of sewage. The method comprises the following steps: 1) performing anaerobic treatment on the water body to be treated; 2) performing anoxic treatment on the water body obtained from the anaerobic treatment; 3) performing aerobic treatment on the water body obtained from the anoxic treatment; The water body is subjected to anaerobic treatment; 5) Part of the supernatant of the water body obtained from the oxygen elimination treatment is returned to step 2) for anoxic treatment; 6) Part of the supernatant of the water body obtained from the oxygen elimination treatment is subjected to membrane-based biological treatment; 7) Precipitate the mud-water mixture in the lower layer of the water obtained from the aerobic treatment; 8) return part of the water obtained from the membrane-based biological treatment to step 1) for anaerobic treatment; 9) return part of the water obtained from the membrane-based biological treatment to step 3 ) for aerobic treatment. The invention has good removal effect of total nitrogen and total phosphorus pollutants, simple and convenient operation, low energy consumption, and stable and up-to-standard discharge.

Owner:TONGJI UNIV

Method and system for deep denitrification of sewage

ActiveCN112429844BAchieving Total Nitrogen Removal EfficiencyApplicable to a wide range of water qualityTreatment with aerobic and anaerobic processesTotal nitrogenTreatments water

Owner:TONGJI UNIV

Preparation method of tracing type phosphorus-free corrosion and scale inhibitor

ActiveCN103523935BGood corrosion inhibitionGood synergyTreatment using complexing/solubilising chemicalsFluorescenceCarboxylic acid

The invention relates to a preparation method of a tracing type phosphorus-free corrosion and scale inhibitor. The preparation method is characterized in that the tracing type phosphorus-free corrosion and scale inhibitor comprises polyepoxysuccinic acid, a tracing type dirt dispersion agent, organic carboxylic acid sodium salt, a zinc salt, imidazolines, azoles and water, and is prepared by stirring, mixing and filtering the components. The tracing type phosphorus-free corrosion and scale inhibitor disclosed by the invention has the advantages of corrosion inhibition synergistic effect, low dosage, good stability, wide application scope and environment friendliness, and particularly due to the introduction of the tracing type dirt dispersion agent, an obvious synergistic effect is achieved, and the on-line detection on the medicament content is realized by detecting the fluorescence value, so that the problem that a general phosphorus-free medicament can not be detected or is difficult to detect can be solved.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Method of processing p-benzene dicarboxylic acid production wastewater

ActiveCN101152969BEnable direct reuseAchieve recyclingMultistage water/sewage treatmentWater/sewage treatment by heatingSteam condensationEvaporation

The present invention provides a disposal method for wastewater produced by phthalic acid. The steps are as follows : a. the process wastewater exported from a refining process is filtered; filtrate and a solid-form object are gained; b. the filtrate is sent to and processed in a multi-effect evaporation system; steaming condensation water and condensation water with organic compound are gained; then the steaming condensation water is recycled back to the refining process and is reused; c. solid-liquid mixture is gained by adding acid to the condensation water and precipitating; the solid-form object and the filtrate are gained by processing a solid-liquid separation to the mixture; d. water and various organic compounds are gained by fractionating the filtrate; the water is recycled backto the refining process and is reused; the organic compounds are recycled back to a xylene oxidation process; e. various organic compounds are gained though the combination and re-crystallization of the solid-form object in the step a and the solid-form object in the step c. With the present invention, the majority of the PTA wastewater is capable of being recycled and reused in the production after being disposed; in addition, the majority of the organic compounds in wastewater are reclaimed. So the economical use of the PTA wastewater and the organic compounds in wastewater is realized.

Owner:CHINA PETROLEUM & CHEM CORP

Process and system for treating electric power plant waste water

ActiveCN101456635BEasy to reuseEfficient removalMultistage water/sewage treatmentWater/sewage treatment by neutralisationSolubilitySulfate radicals

The invention relates to a method for treating waste water from a power plant and a system for realizing the same. The system comprises a pre-treatment system and an evaporative crystallizing system which are connected with each other; the pre-treatment system is connected to the waste water from the power plant, the majority of SS, heavy metals, Mg<2+>, F<-> and sulfate radicals in the waste water from the power plant are removed by coagulating sedimentation, and organic pollutants and ammonia nitrogen are also removed; the CaSO4 content in the waste water is adjusted to be far less than saturated concentration of the CaSO4, and the pH value is adjusted back to make partial CO3<2-> converted into HCO3<->; and the waste water treated by the pre-treatment system flows in the evaporative crystallizing system, by evaporation concentration, the dissolved solids in the waste water reach and exceed the saturated concentration to form salt crystal, and the solid-liquid separation is performed. The method has the advantages of effectively removing suspended matters, organic matters, fluorine and heavy metals in the waste water from the power plant, removing dissolved salt such as Ca<2+>, Mg<2+>, Cl<->, SO4<2-> and the like which can not be removed by the prior method for treating the waste water from the power plant, and basically meeting zero emission, and the treated waste water can be reutilized.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG

Filter membrane equipment adopting self-coupling mounting

InactiveCN109399787AEasy to take outWill not polluteSemi-permeable membranesSpecific water treatment objectivesBreatherAeration system

The invention discloses filter membrane equipment adopting self-coupling mounting, and belongs to the technical field of environment-friendly sewage treatment. A membrane element is arranged in a frame, and the filter membrane equipment is immersed in sewage in an MBR aerobic biochemical pool and comprises a slide rail system, a water retaining system, a lower aeration system, an upper aeration system, a cleaning water pump, a cleaning agent box, a fan, a water producing pump and valves; water outside a filter membrane enters the inner side of the filter membrane through the surface of the filter membrane under negative pressure suction of the water producing pump and flows out through a water producing pipe, and pollutants are retained outside the filter membrane; the membrane element isconvenient to take out by arrangement of slide rails, and offline regenerative cleaning is facilitated; when operation is stopped for a long time or operation is not suitable for sewage treatment, water baffles on the periphery are inserted into grooves, clear water is injected into the frame, the membrane element is isolated from the sewage, so that the membrane element cannot be polluted by thesewage, and by design of an aeration cavity, the upper aeration system and breather pipes in the middle of a membrane bundle, the pollutants cannot be accumulated in the membrane element easily.

Owner:石亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com