Water body heavy metal ion pollution flocculation sediment preparation and preparation method thereof

A technology of heavy metal ions and flocculation, applied in water pollutants, flocculation/precipitation water/sewage treatment, water/sewage treatment, etc., can solve the problems of high cost of chemicals, small flocs, poor settling properties, etc., to improve the flocculation effect, The effect of small dosage and improved adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

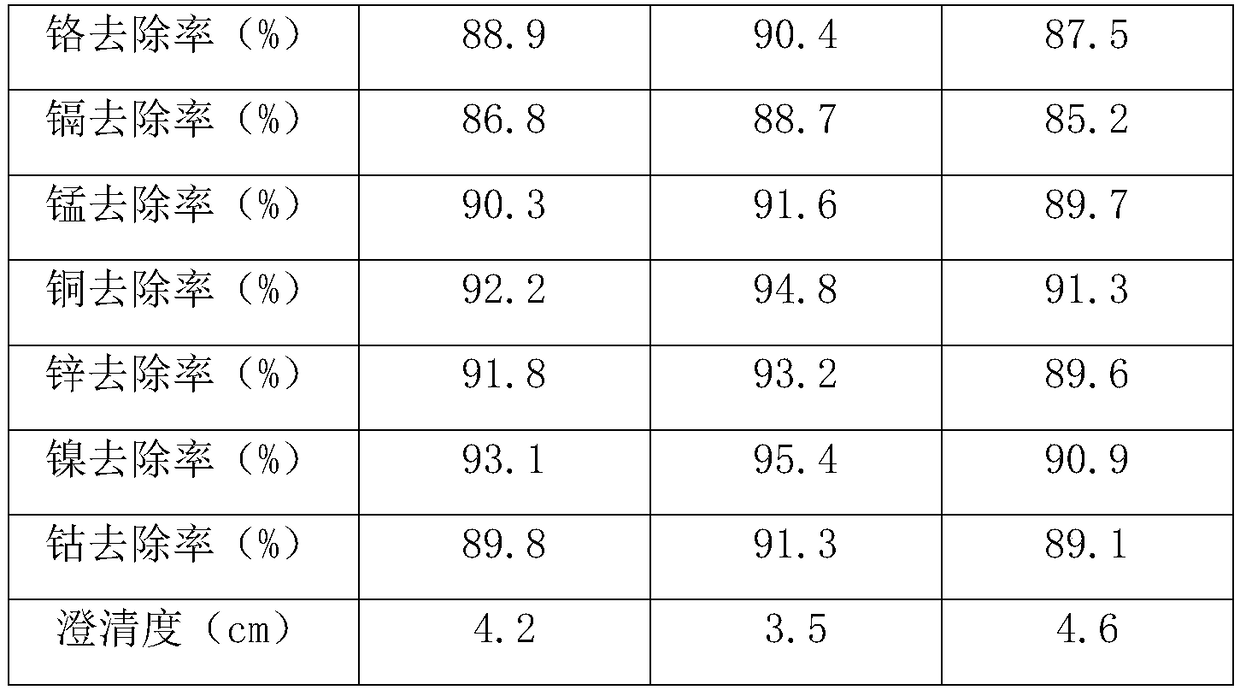

Embodiment 1

[0026] A water heavy metal ion pollution flocculation deposition preparation, which is made of the following raw materials in parts by weight: sodium methacrylate / acrylamide / acrylic acid copolymer 18, sulfonated styrene-maleic anhydride copolymer 15, 2-amino -3-Mercaptopropionyl chitosan 13, trisodium hydroxyethyl ethylenediamine triacetate 5, polymeric aluminum iron bis-acid 16, sodium alginate sulfate 6, starch xanthate 4, alum 14, tetradecane Pyridinium chloride 3, pullulan 5, guar hydroxypropyl trimethyl ammonium chloride 2, behenyl trimethyl ammonium methosulfate 1, beidellite 17, phosphatite 15.

[0027] A preparation method for water heavy metal ion pollution flocculation deposition preparation, comprising the following steps:

[0028] (1) Mix beidellite and phosphate-aluminite evenly, heat up to 380°C, keep warm for 2h, continue to heat up to 450°C, keep warm for 1h, then cool down to 300°C, keep warm for 3h, air-cool to room temperature, according to the solid-liquid ...

Embodiment 2

[0033]A water heavy metal ion pollution flocculation deposition preparation, which is made of the following raw materials in parts by weight: sodium methacrylate / acrylamide / acrylic acid copolymer 22, sulfonated styrene-maleic anhydride copolymer 18, 2-amino -3-Mercaptopropionyl chitosan 16, trisodium hydroxyethyl ethylenediamine triacetate 8, polymeric aluminum iron bis-acid 19, sodium alginate sulfate 9, starch xanthate 6, alum 18, tetradecane Pyridinium Chloride 4.5, Pullulan 7, Guar Hydroxypropyl Trimethyl Ammonium Chloride 3.5, Behenyl Trimethyl Ammonium Methosulfate 2.5, Beidellite 21, Phosphorite 18.

[0034] A preparation method for water heavy metal ion pollution flocculation deposition preparation, comprising the following steps:

[0035] (1) Mix beidellite and apatite evenly, raise the temperature to 400°C, keep it warm for 1.5h, continue to heat up to 480°C, keep it warm for 45min, then cool down to 320°C, keep it warm for 2.5h, air cool to room temperature, accordi...

Embodiment 3

[0040] A water heavy metal ion pollution flocculation deposition preparation, which is made of the following raw materials in parts by weight: sodium methacrylate / acrylamide / acrylic acid copolymer 26, sulfonated styrene-maleic anhydride copolymer 20, 2-amino -3-Mercaptopropionyl chitosan 19, trisodium hydroxyethyl ethylenediamine triacetate 10, polymeric aluminum iron bis-acid 22, sodium alginate sulfate 12, starch xanthate 8, alum 21, tetradecane Pyridinium Chloride 6, Pullulan 10, Guar Hydroxypropyl Trimethyl Ammonium Chloride 5, Behenyl Trimethyl Ammonium Methosulfate 4, Beidellite 24, Phosphorite 20.

[0041] A preparation method for water heavy metal ion pollution flocculation deposition preparation, comprising the following steps:

[0042] (1) Mix beidellite and phosphate-aluminite evenly, heat up to 420°C, keep warm for 1h, continue to heat up to 500°C, keep warm for 0.5h, then cool down to 350°C, keep warm for 2h, air cool to room temperature, according to the solid-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com