Photo-Fenton catalyst and preparation method and application thereof

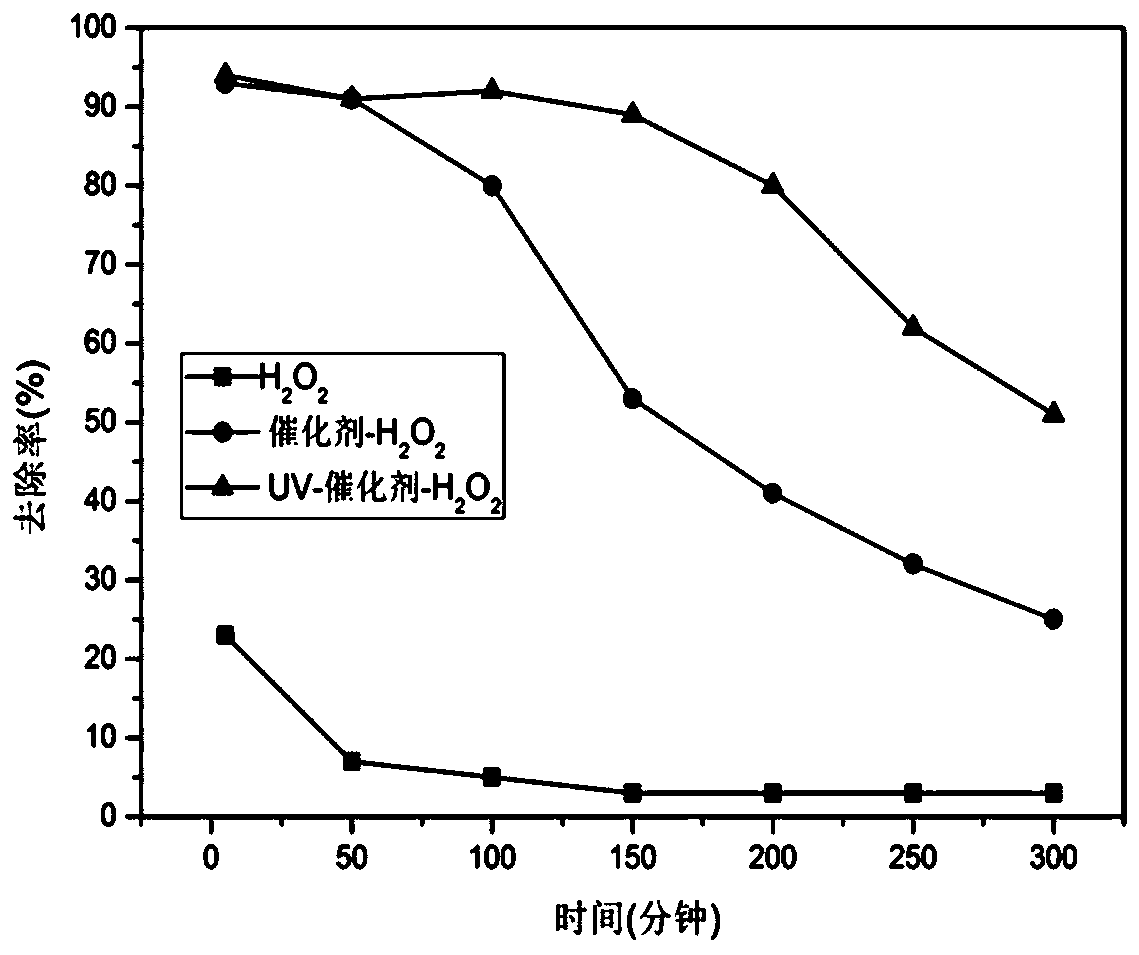

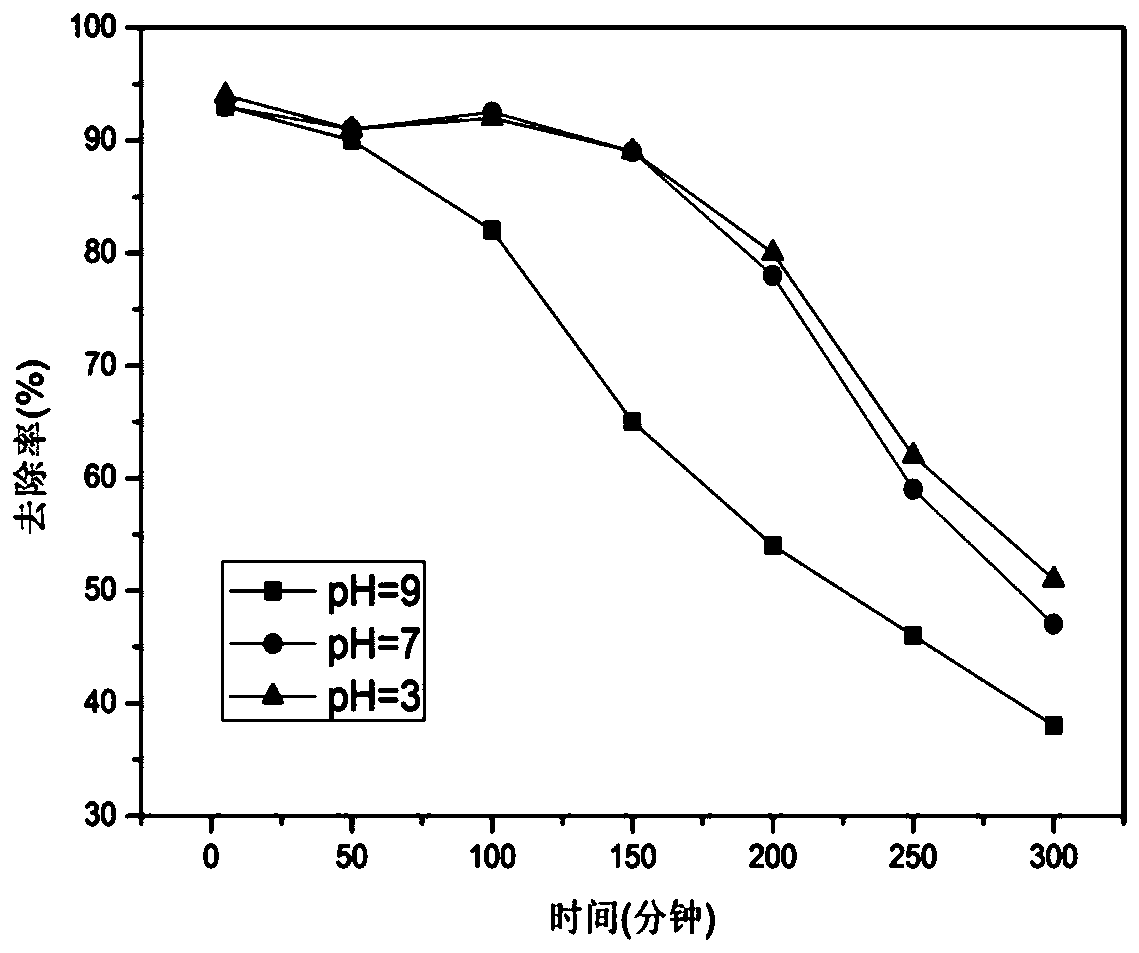

A catalyst, Fenton's technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of poor degradation effect, low light utilization efficiency, poor adsorption of organic waste gas, etc., and achieve good degradation effect , Increase adsorption performance, easy to recycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

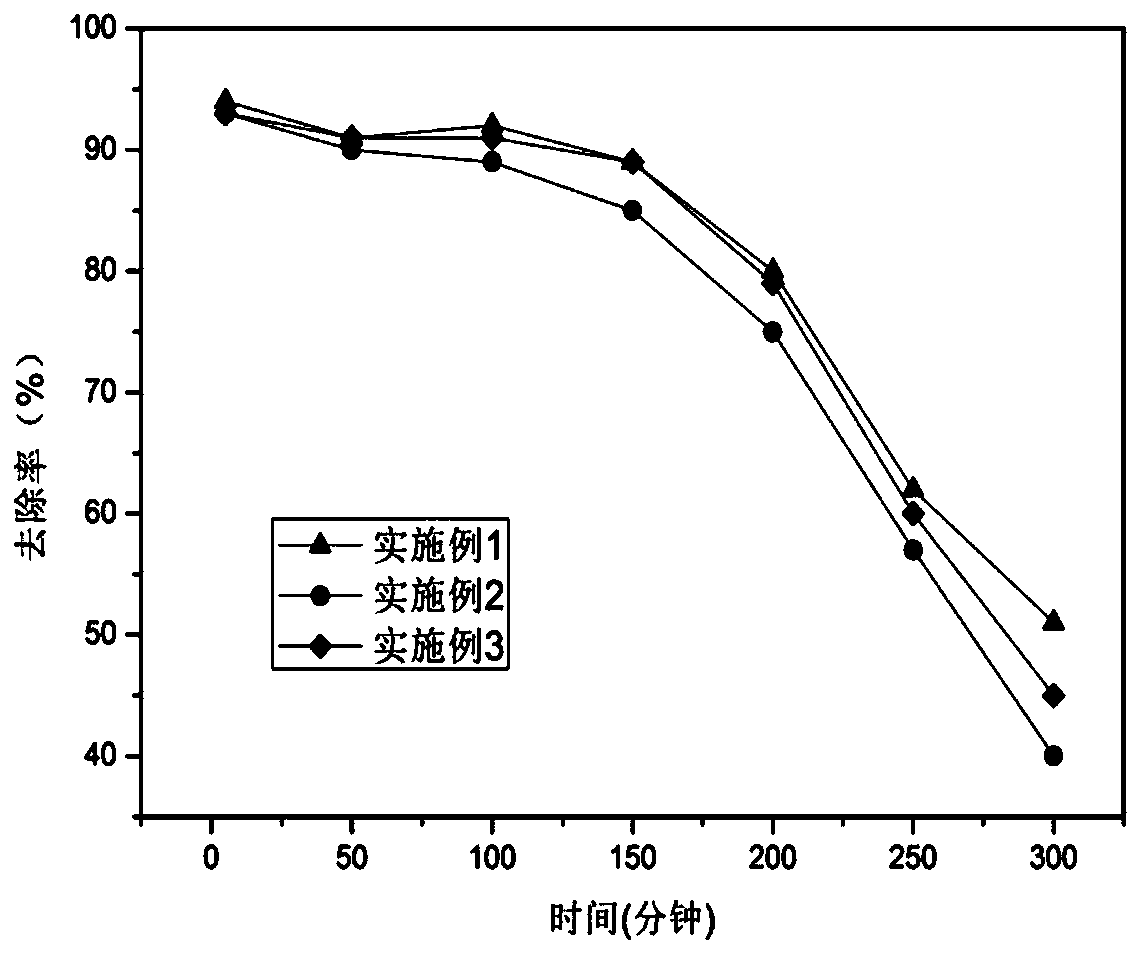

Embodiment 1

[0020] (1) Add 0.434 g Ce(NO 3 ) 3 6H 2 O was dissolved in 4.5 mL deionized water and stirred continuously to obtain a uniform cerium nitrate solution, which was designated as solution A. 1.5 g carrier γ-Al 2 o 3 After soaking in the above solution A, continue to stir for 2 h;

[0021] (2) Dissolve 5.5 g of 2-methylimidazole in 20 mL of deionized water and stir it so that the 2-methylimidazole is completely dissolved, which is recorded as solution B, and the B solution is transferred to a pear-shaped separatory funnel , slowly drop it into the mixture formed by the carrier and solution A, and stir for 6 h during the dropwise addition;

[0022] (3) After the stirring, the mixed solution formed by the above solution B, solution A and the carrier was washed with methanol solution, filtered and the pH was adjusted to neutral, and then dried in a vacuum oven at 80 °C for 12 h to obtain Ce -MOF / γ-Al 2 o 3 spare;

[0023] (4) Dissolve 0.085 g of o-phthalaldehyde (OPA) in 25 m...

Embodiment 2

[0027] (1) Add 0.868 g Ce(NO 3 ) 3 6H 2 O was dissolved in 9 mL of deionized water and stirred continuously to obtain a uniform cerium nitrate solution, which was designated as solution A, and 2 g of carrier γ-Al 2 o 3 Immerse in the above solution A, and continue to stir for 2 h;

[0028] (2) Dissolve 5 g of 2-methylimidazole in 20 mL of deionized water, and stir it to completely dissolve the 2-methylimidazole, record it as solution B, and transfer solution B to a pear-shaped separatory funnel , slowly drop it into the mixture formed by the carrier and solution A, and stir for 6 h during the dropwise addition;

[0029] (3) After the stirring, the mixed solution formed by the above solution B, solution A and the carrier was washed with methanol solution, filtered and the pH was adjusted to neutral, and then dried in a vacuum oven at 60 °C for 12 h to obtain Ce -MOF / γ-Al 2 o 3 spare;

[0030] (4) Dissolve 0.085 g of o-phthalaldehyde (OPA) in 25 mL of absolute ethanol so...

Embodiment 3

[0034] (1) Add 0.434 g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 4.5 mL deionized water and stirred continuously to obtain a uniform cerium nitrate solution, which was designated as solution A. 1.5 g carrier γ-Al 2 o 3 After soaking in the above solution A, continue to stir for 2 h;

[0035] (2) Dissolve 5 g of 2-methylimidazole in 20 mL of deionized water, and stir it to completely dissolve the 2-methylimidazole, record it as solution B, and transfer solution B to a pear-shaped separatory funnel , making it dropwise slowly into the mixture formed by the carrier and solution A, stirring for 8 h during the dropwise addition;

[0036] (3) After the stirring, the mixed solution formed by the above solution B, solution A and carrier was washed with methanol solution, filtered and the pH was adjusted to neutral, and then dried in a vacuum oven at 80 °C for 8 h to obtain Ce -MOF / γ-Al 2 o 3 spare;

[0037] (4) Dissolve 0.085 g of o-phthalaldehyde (OPA) in 25 mL of absolute ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com