Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "To achieve the purpose of grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional efficient rice husking machine

InactiveCN108160146ALow frictionLess corrosiveGrain huskingGrain polishingHydraulic cylinderPulp and paper industry

The invention discloses a multifunctional efficient rice husking machine and relates to the field of cereal processing equipment. The multifunctional efficient rice husking machine comprises a rice husking machine body, a feeding hopper, a control box and a hydraulic cylinder, wherein the hydraulic cylinder is arranged above the control box, the top of the hydraulic cylinder is connected to a telescopic rod, the upper end of the telescopic rod is connected to a platform plate, a first motor is arranged on the platform plate, a first rotating shaft is arranged below the first motor, the upper end of the first rotating shaft penetrates through the platform plate and is connected to the output end of the first motor, the lower end of the first rotating shaft extends into the rice husking machine, a grinding cone is arranged in the rice husking machine, a grinding disc matched with the grinding cone is arranged on the inner wall of the rice husking machine, and discharge ports are formed in the side walls of the left and right sides of the bottom of the rice husking machine. The rice husking machine disclosed by the invention is high in grinding efficiency and good in grinding effect,and the degree of purity of ground white rice meets the using demand. The multifunctional efficient rice husking machine has a function of adjusting the grinding strength, and is simple to operate andhigh in working reliability.

Owner:马斌祥

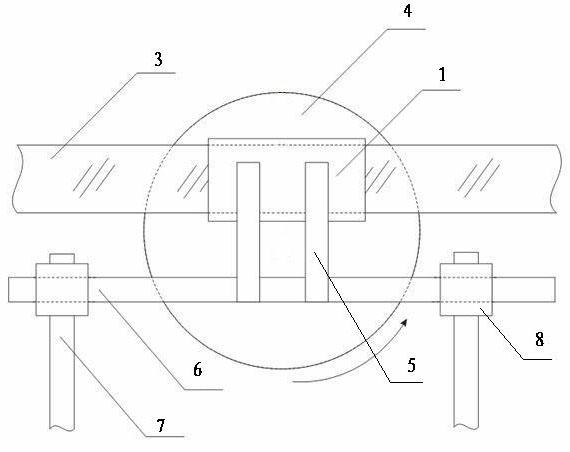

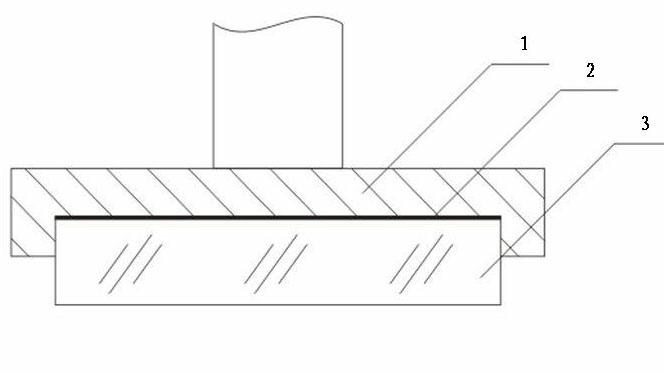

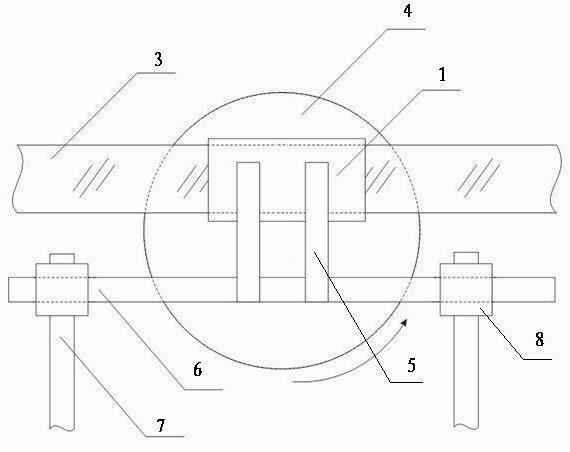

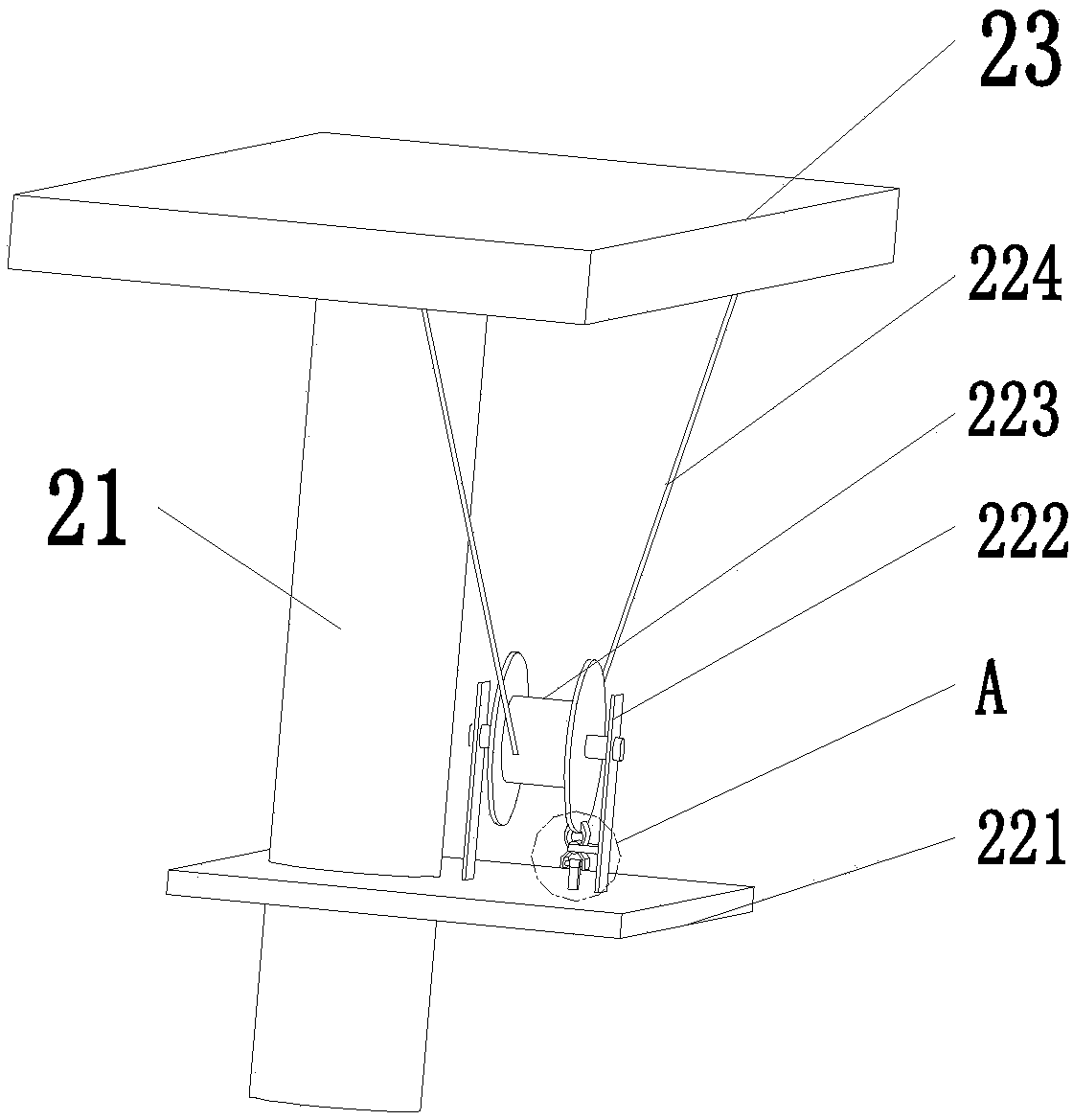

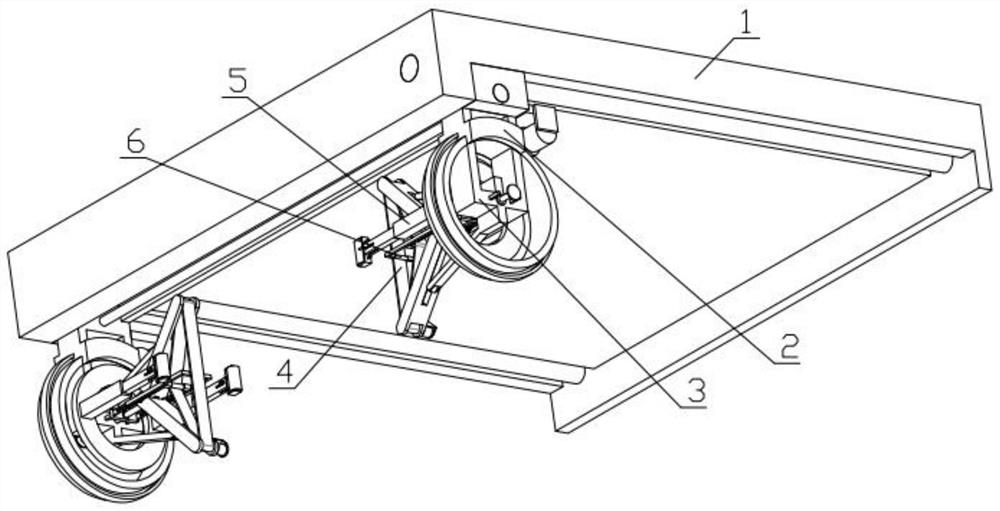

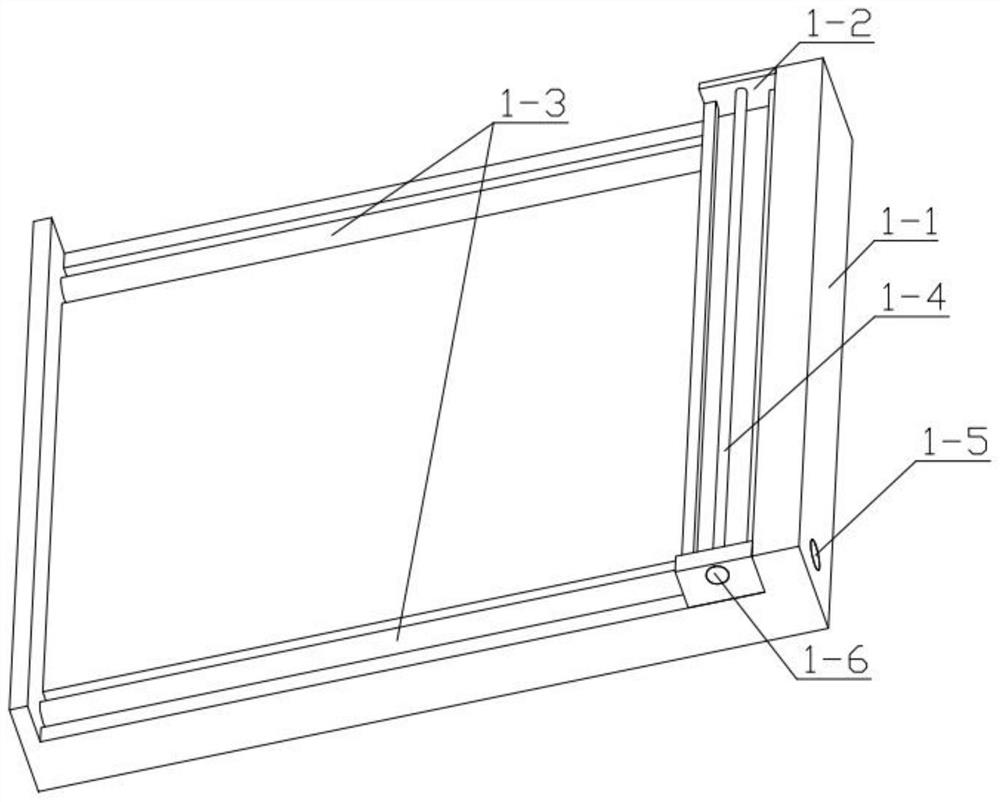

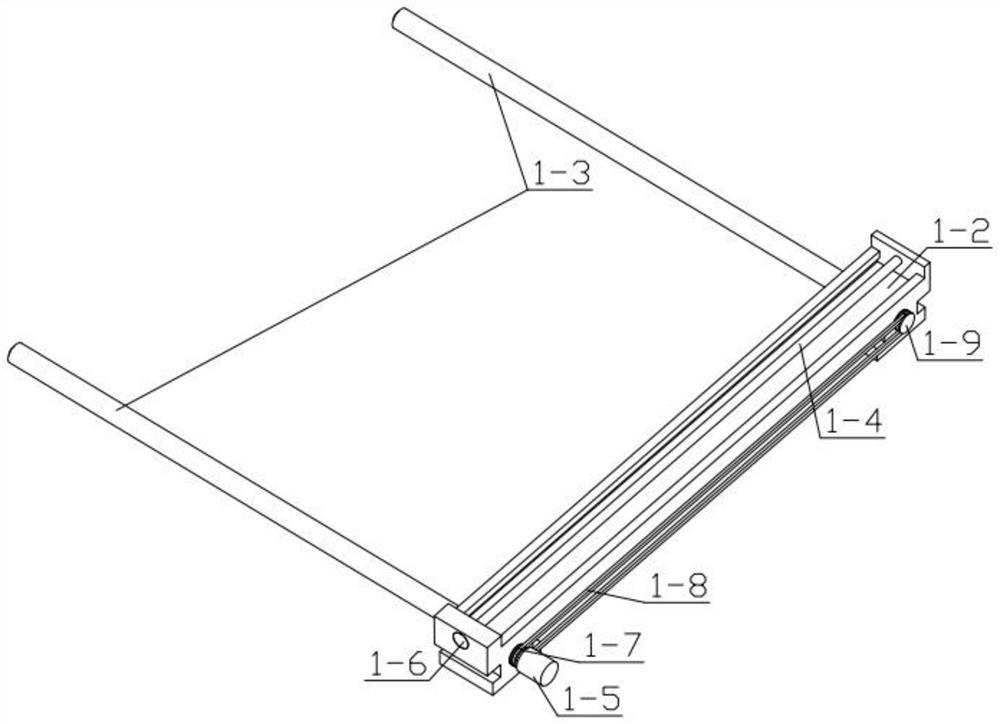

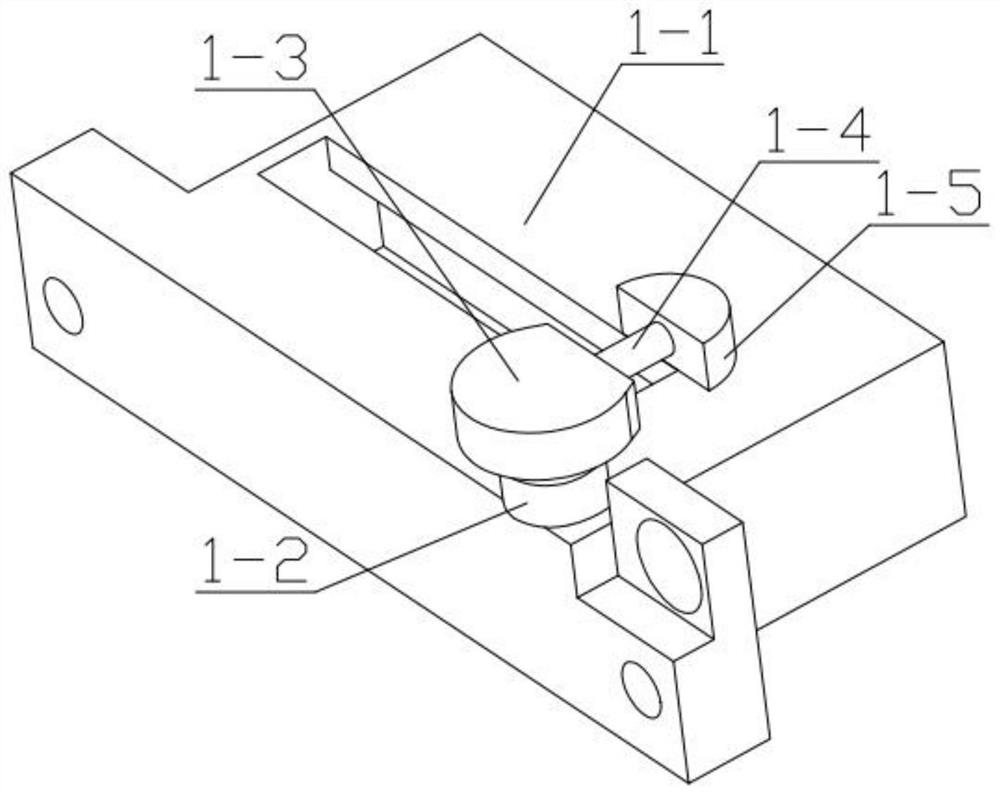

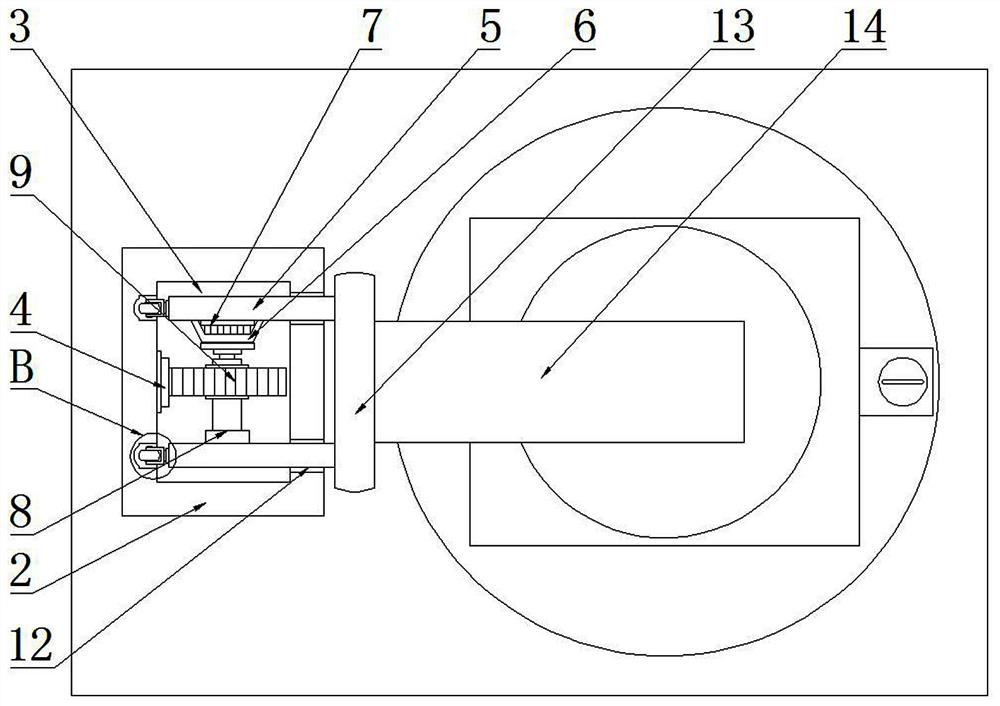

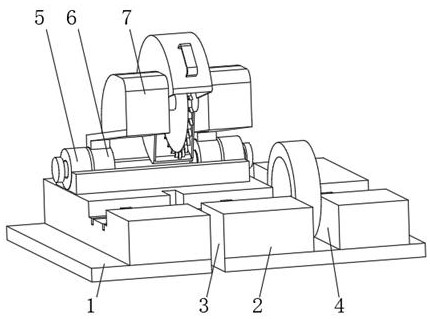

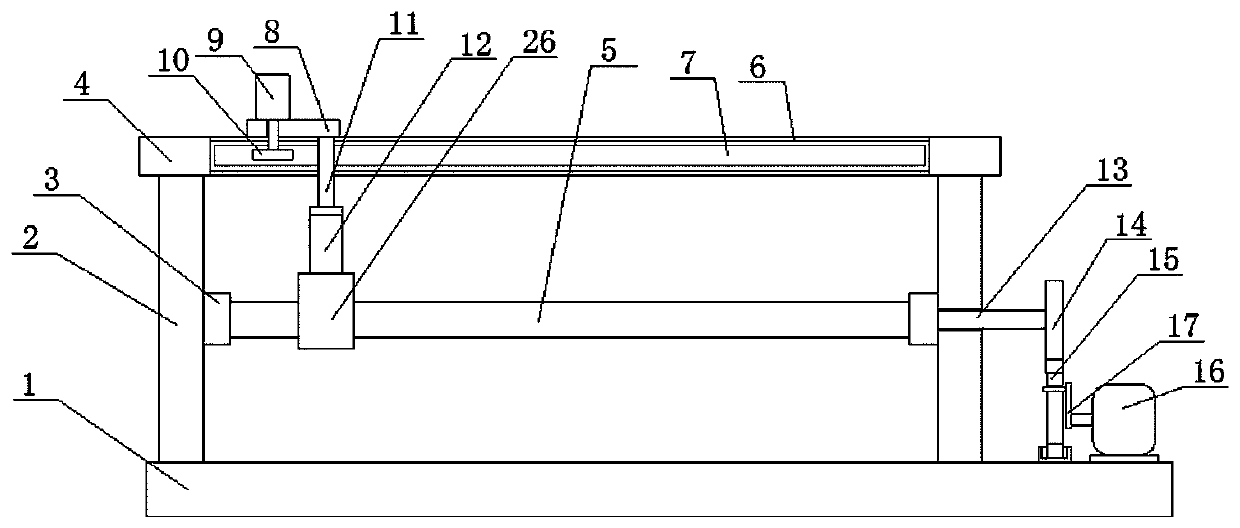

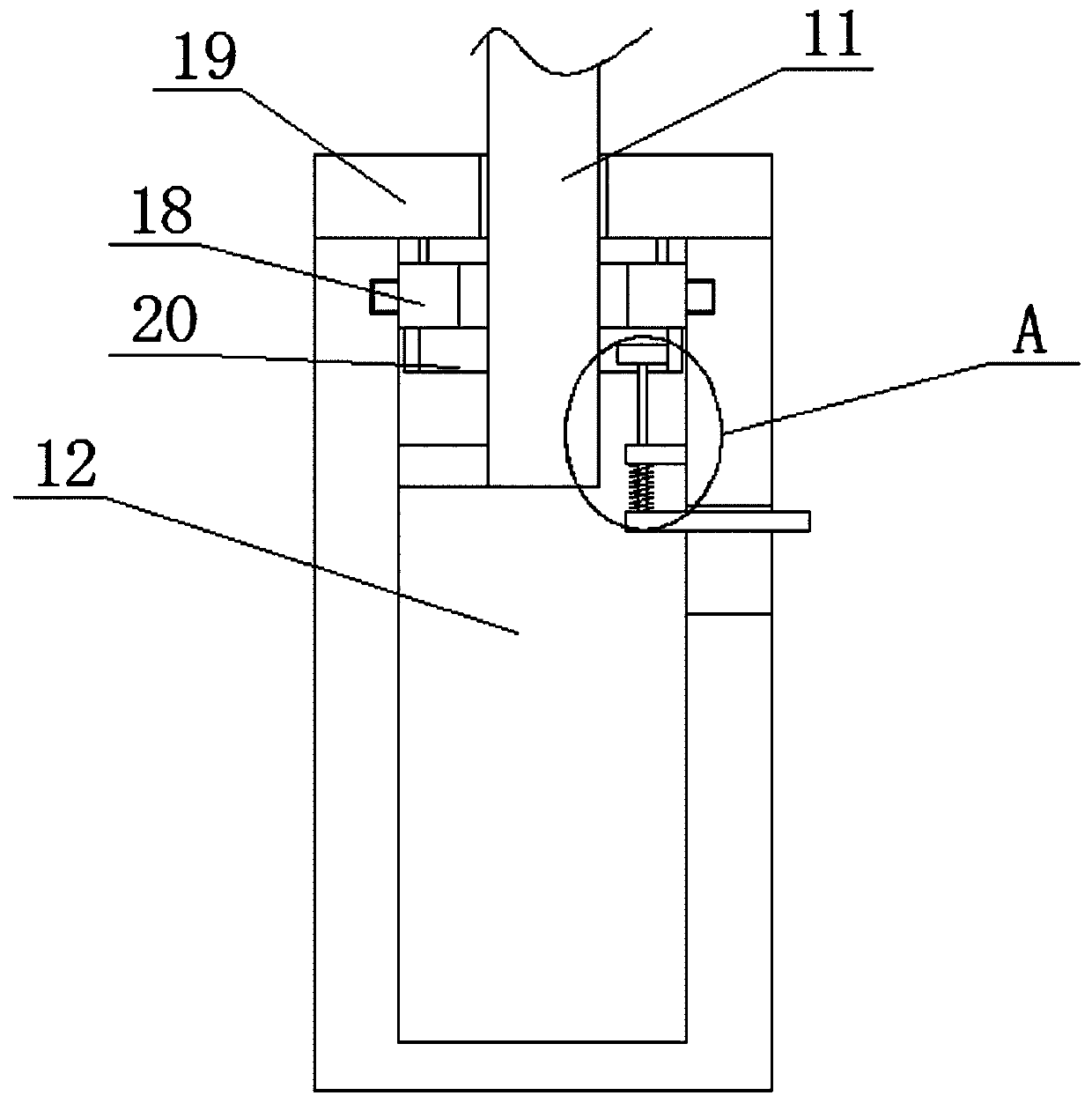

Machine and method for grinding and polishing ultra-long and ultra-thin quartz plate

InactiveCN102554764AGuaranteed smoothTo achieve the purpose of grindingLapping machinesWork carriersEngineeringMaterials science

The invention discloses a machine for grinding and polishing an ultra-long and ultra-thin quartz plate, which comprises a grinding disc. A cover die is arranged above the grinding disc; a workpiece placing slot is arranged on the cover die; the bottom of the workpiece placing slot is provided with a gasket; the cover die is fixedly connected on a translational shaft by a connecting rod; the translational shaft is connected with a guide rail which moves back and forth through a sliding block; and the translational shaft and the guide rail are connected with a motor respectively through a transmitting mechanism. The invention further discloses a process for grinding and polishing the ultra-long and ultra-thin quartz plate. The machine is suitable for grinding the ultra-long and ultra-thin quartz plate, is convenient to use, has a more reasonable structure, strong applicability and high use efficiency and can guarantee the quality and the rate of finished products effectively. The process for grinding and polishing the ultra-long and ultra-thin quartz plate is easy to operate and can guarantee the rate of finished products and the production efficiency.

Owner:蔡桂芳

Automobile part grinding device

InactiveCN108296930AAchieve grindingTo achieve the purpose of grindingGrinding drivesSpherical surface grinding machinesHydraulic cylinderEngineering

The invention particularly discloses an automobile part grinding device which comprises a rack. A base is arranged in the center of the bottom of the rack, and a first motor is arranged on the base. Arotary disc is arranged on an output shaft of the first motor, and a grinding groove with the middle provided with a spherical sunken part is fixedly formed in the rotary disc. An abrasive layer is arranged on the inner wall of the grinding groove. Hydraulic cylinders are symmetrically mounted on the side walls of the two sides of the rack, and supporting rods are arranged at the output ends of the hydraulic cylinders. Rotary wheels are mounted at the output ends of a second motor and a third motor correspondingly, and dents are evenly distributed in the surfaces of the rotary wheels. The rotary wheels can make contact with the surface of a to-be-ground automobile part in the grinding groove, and the contacting positions of the rotary wheels and the to-be-ground spherical automobile partare located below the horizontal plane where the sphere center of the automobile part is located. The depth of the spherical sunken part of the grinding groove is smaller than the radius of the groundspherical automobile part. According to the scheme, the spherical automobile part is automatically ground, grinding devices do not need to be manually operated, the working efficiency is improved, and the working intensity is reduced.

Owner:CHONGQING JIANAN IND & TRADE

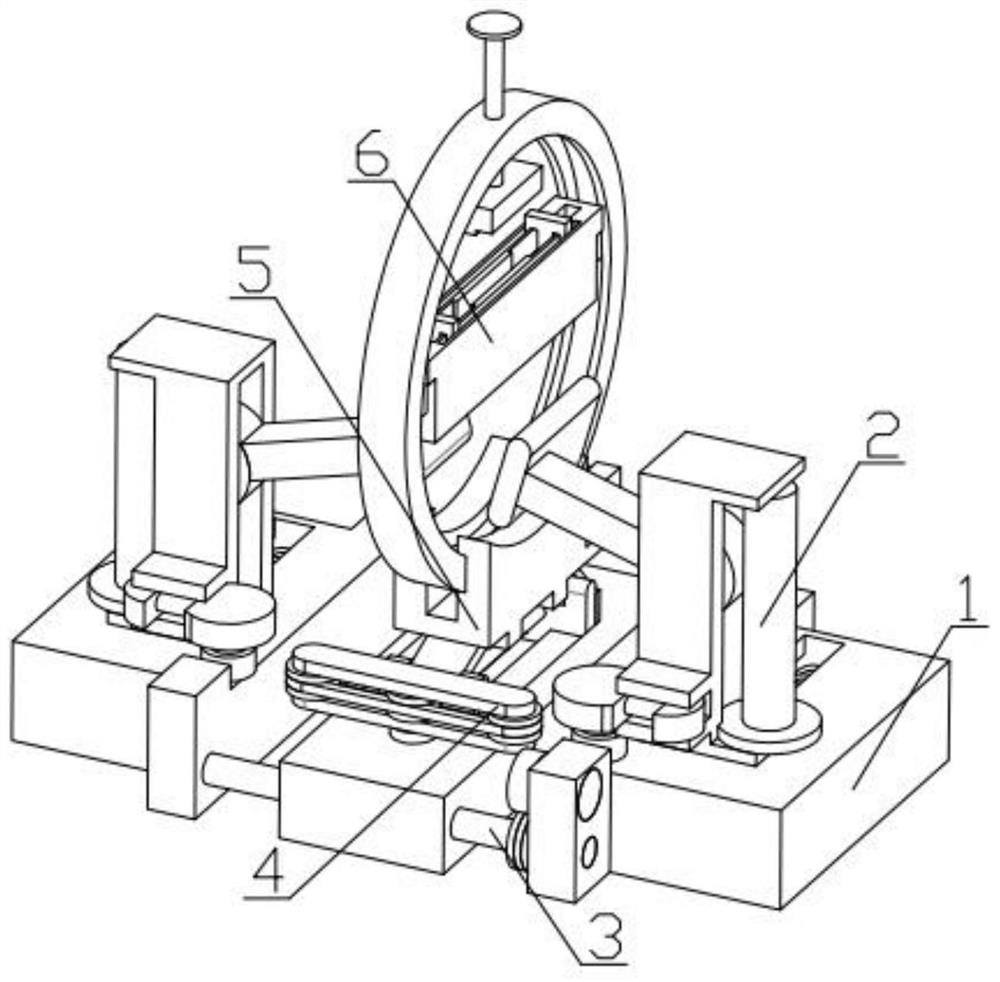

Multi-angle machining device and multi-angle machining method for PVC transparent plastic plate

ActiveCN109048554AAdjust the tilt angleAchieve fixationEdge grinding machinesGrinding drivesEngineeringMachining

The invention relates to a multi-angle machining device and a multi-angle machining method for PVC transparent plastic plates. The device comprises a bottom plate, a grinding device, and a moving device. The grinding device and the moving device are separately mounted on the upper end surface of the bottom plate from left to right. The grinding device comprises a grinding support frame, grinding fixing mechanisms, a grinding bearing plate, grinding half gear discs, grinding gear discs, grinding adjusting motors, grinding connecting plates, infrared lamps, adjusting dials, adjusting dial supports, a grinding rotating motor, and a grinding disc. The grinding support frame is mounted on the left side of the upper end surface of the bottom plate. The grinding fixing mechanisms are mounted in the middle of the grinding support frame. According to the multi-angle machining device and the multi-angle machining method for PVC transparent plastic plates, the problems of measuring the grinding angle is difficult, the grinding angle is not accurate, the grinding effect is poor, and the like when the multi-angle grinding of the PVC transparent plastic plates are performed can be solved; the function of multi-angle grinding of the PVC transparent plastic plates can be realized; and the grinding device has the advantages of being convenient to measure the grinding angle, flexible in grindingangle adjustment, accurate in grinding angle control, and good in grinding effect.

Owner:FOSHAN MINGDE PLASTIC CO LTD

Furniture plate processing device

ActiveCN111805369AAdjustable spacingGuaranteed smoothnessGrinding carriagesBelt grinding machinesStructural engineeringMechanical engineering

The invention relates to a wood furniture processing machinery, specifically to a furniture plate processing device. The furniture plate processing device comprises a displacement mechanism, an angleadjusting mechanism, a range adjusting mechanism, a grinding component, a wood chip cleaning mechanism and a grinding adjusting component and is characterized in that the angle adjusting mechanism ismounted in a groove, formed in the displacement mechanism, in a sliding manner; the range adjusting mechanism is fixedly mounted on the angle adjusting mechanism; the wood chip cleaning mechanism is fixedly mounted on the range adjusting mechanism; the grinding component is fixedly mounted on the range adjusting mechanism; the grinding adjusting mechanism is mounted on the range adjusting mechanism is a sliding manner; and the grinding component is connected with the grinding adjusting mechanism in a contacting manner. The furniture plate processing device has the advantages that grinding surfaces with different angles can be ground, a plate groove surface can be ground, the phenomenon that burrs are formed on the side boundary in the grinding process is avoided, and meanwhile, an accuratewood chip cleaning function is realized for the ground plate surface.

Owner:邵阳县辰宜居家具有限公司

Flexible circuit board shaping device

InactiveCN111818732ATo achieve the purpose of grindingAvoid the disadvantages of longInsulating layers/substrates workingTool bitFlexible circuits

The invention discloses a flexible circuit board shaping device, which comprises a punching platform and a tool bit punching driving device. A plurality of separated movable tool bits which are arranged at intervals are installed on the punching platform in a stacked mode, the separated movable tool bits are installed on the punching platform through a lower female die with a female die punching opening, and the separated movable tool bits are installed in the female die punching opening with a burr grinding assembly in a sliding mode through a tool bit limiting and rebounding assembly. Transmission, limiting and resetting between the adjacent separated movable tool bits are achieved through the tool bit limiting and rebounding assembly. Each layer of base plate is punched through mutual cooperation of an independent movable cutter and a lower female die, so that the defect that burrs are long due to overlapping punching is overcome; and the burr grinding assembly in the punching opening of the female die grinds the edge of the flexible circuit board in the reset process of the separated movable tool bits, so that simplification of the production process of the flexible circuit board is facilitated, and therefore the production efficiency is further improved.

Owner:广东勤天投资有限公司

Stone three-step polishing device

InactiveCN112338778AControl the moving distanceAvoid breakingGrinding carriagesPolishing machinesPolishingStructural engineering

The invention relates to a building material processing device, in particular to a stone three-step polishing device. The stone three-step polishing device comprises an installing frame, a stone lifting mechanism, a stone moving mechanism, a stone adjusting mechanism and a three-step polishing mechanism, wherein the stone lifting mechanism is fixedly installed on the installing frame, the stone moving mechanism is fixedly installed on the stone lifting mechanism, the stone adjusting mechanism is fixedly installed on the stone moving mechanism, and the three-step polishing mechanism is fixedlyinstalled on the installation frame. According to the stone three-step polishing device, the device is readjusted to adapt to stones during stone grinding each time, guarantees the grinding and polishing effect, has the function of adjusting the grinding depth, has the function of adapting to the stones with different sizes and thicknesses, has the function of assisting in improving the grinding and polishing effect, and has the function of adjusting the grinding range according to the sizes of the stones.

Owner:卞智昆

Building template surface building repairing device

InactiveCN112324138AEasy to polishTo achieve the purpose of grindingGrinding carriagesGrinding drivesControl switchBuilding restoration

The invention belongs to the technical field of building construction, and relates to a building template surface building repairing device. The building template surface building repairing device comprises a fixed table and a box body, wherein the box body is fixedly connected to the upper surface of the fixed table; an adjusting bin is arranged inside the box body; a fixing frame is fixedly connected to the side face of the adjusting bin; a positive and negative motor is fixedly connected to the interior of the fixing frame; an output shaft of the positive and negative motor is fixedly connected with a first rotating shaft; the surface of the first rotating shaft is fixedly connected with a conveying roller; and the surface of the conveying roller is sleeved with a conveying belt. The building template surface building repairing device has the beneficial effects that the positive and negative motor is arranged, when a worker grinds a template, the worker only needs to start the positive and negative motor through a control switch, under the cooperation of the conveying roller and the conveying belt, a supporting plate can drive a grinding roller to move through a third rotating shaft, so that the template can be comprehensively ground.

Owner:刘伟

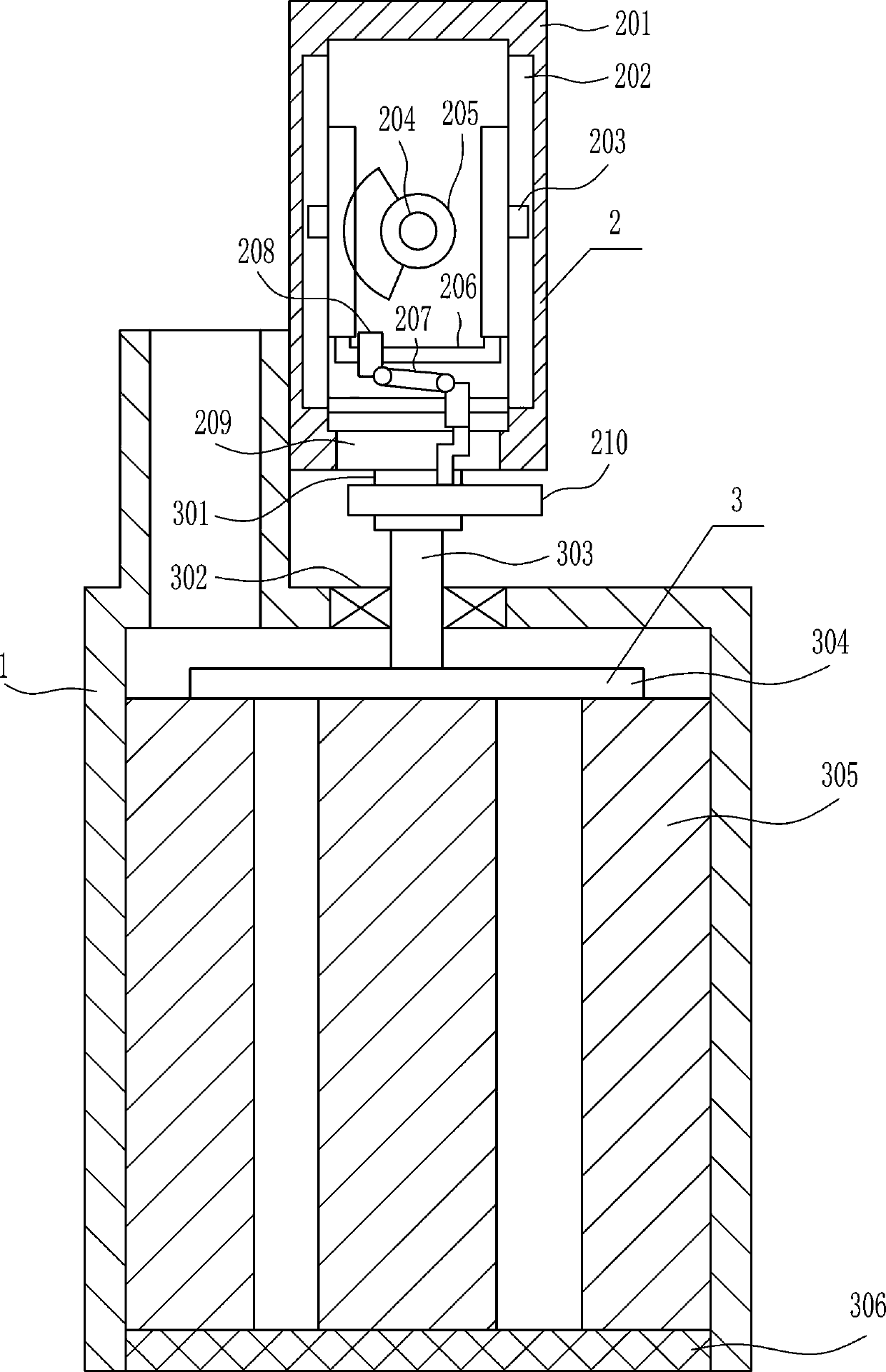

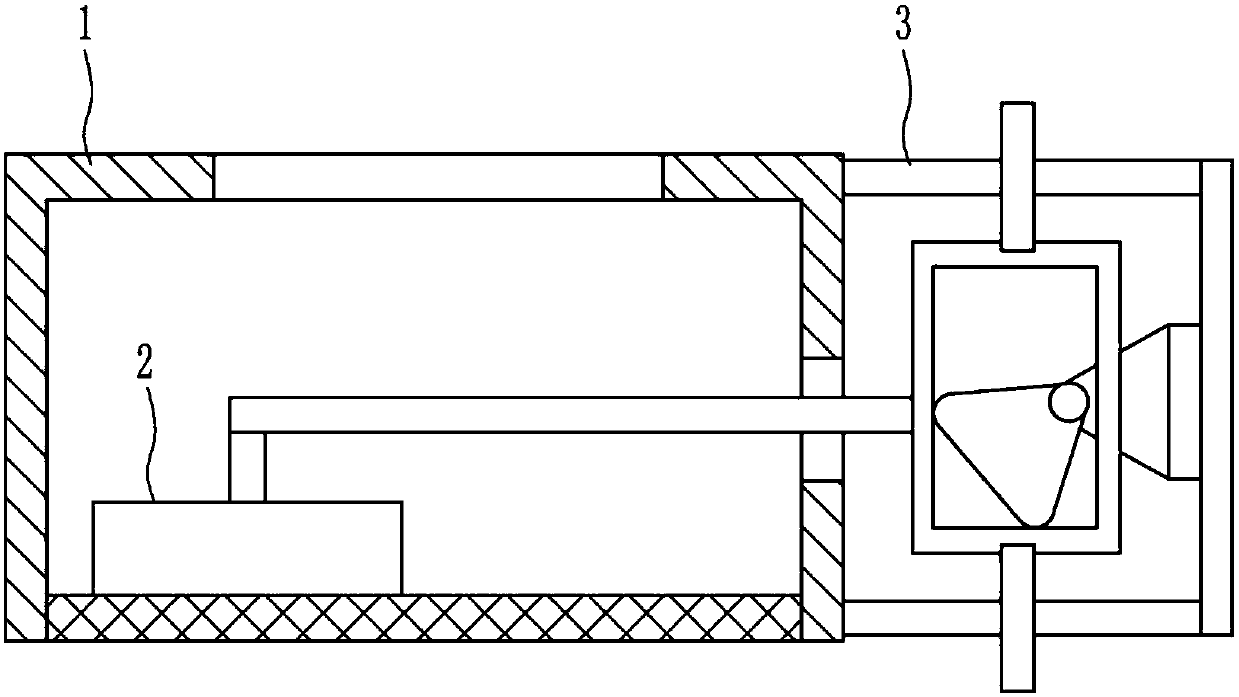

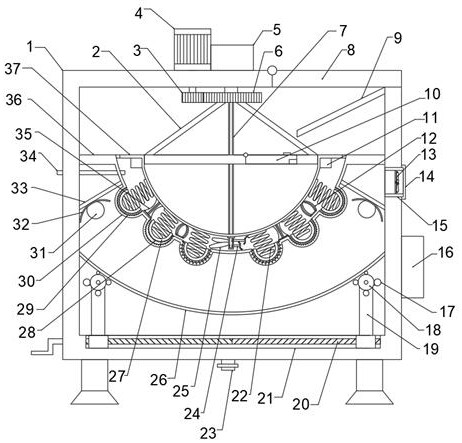

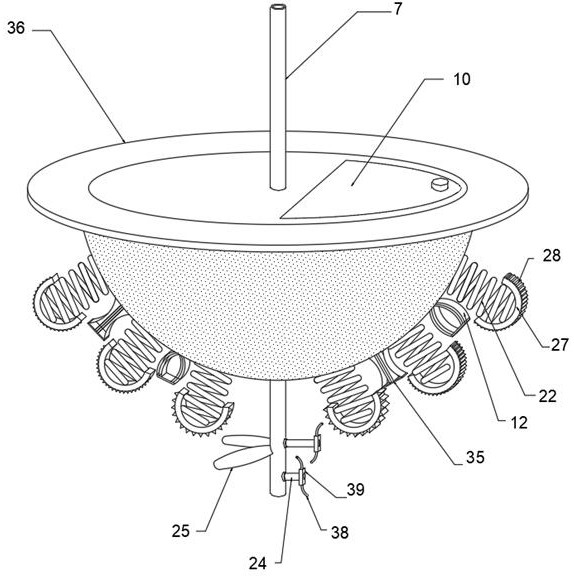

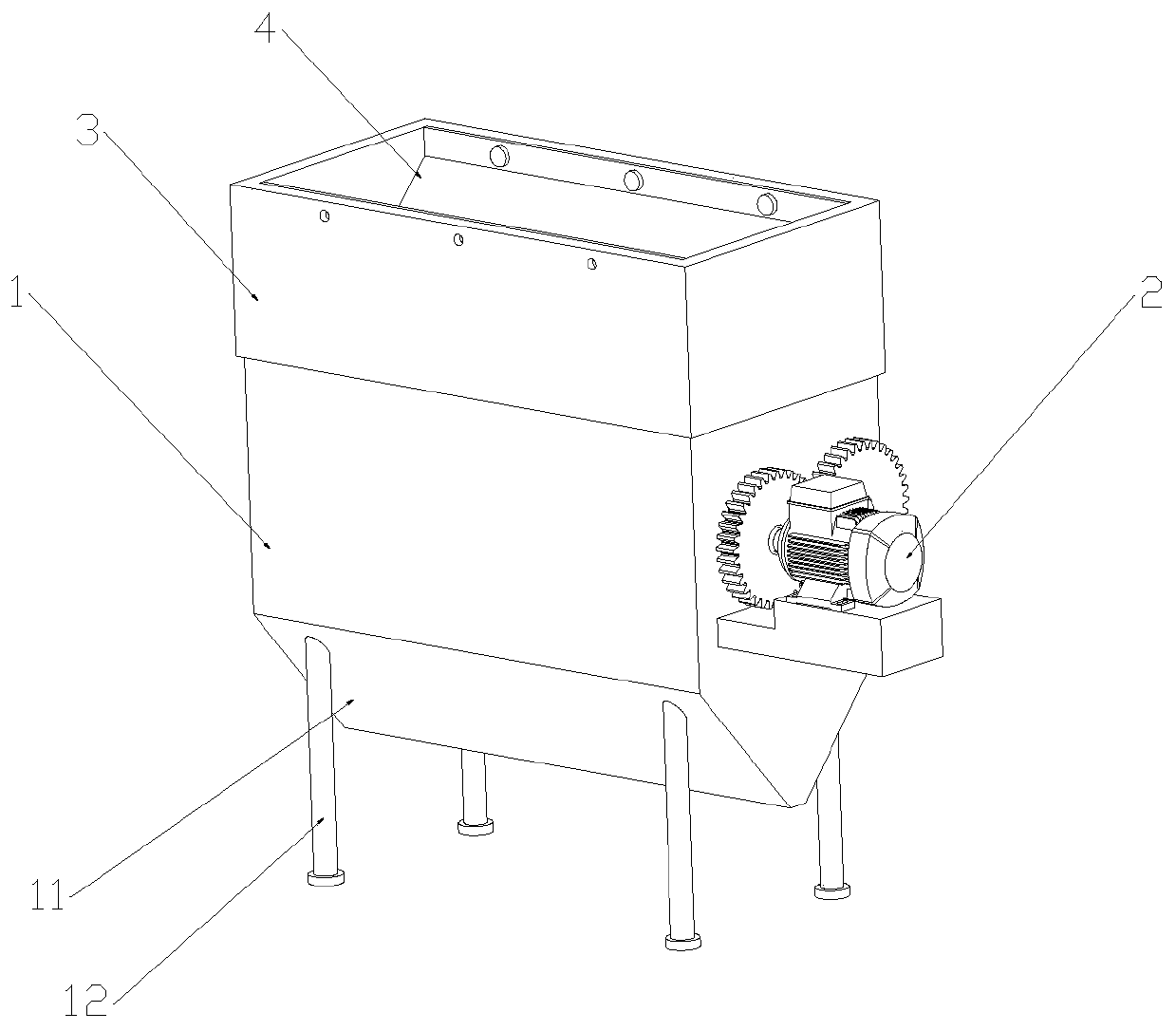

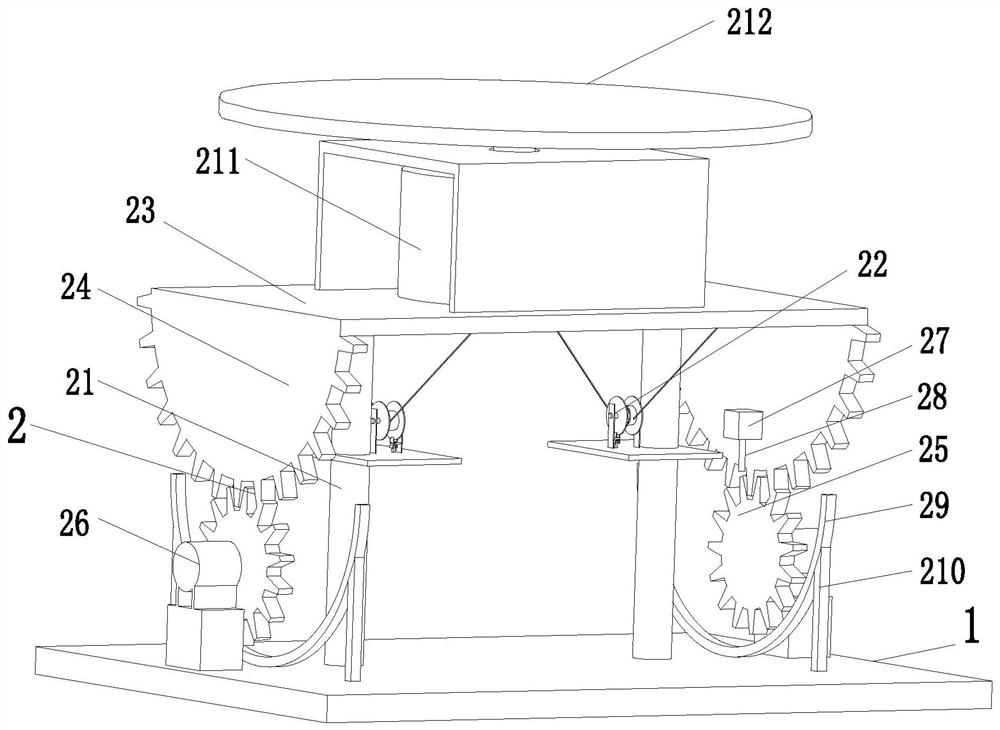

Waste gypsum grinding and recovering equipment for orthopedics department

InactiveCN107694678ATo achieve the purpose of grindingAchieve rotationDirt cleaningGrain treatmentsOrthopedic departmentGypsum

The invention relates to grinding and recovering equipment, in particular to waste gypsum grinding and recovering equipment for the orthopedics department. The invention aims to solve the technical problem so as to provide the waste gypsum grinding and recovering equipment for the orthopedics department, which can be used for grinding sufficiently, is labor-saving and can prevent ground powdered gypsum powder from flying at the same time. In order to solve the technical problem, the invention provides the waste gypsum grinding and recovering equipment for the orthopedics department, which comprises a grinding tank and the like. A driving mechanism is connected to the uppermost part of the right side of the grinding tank; and a grinding mechanism is arranged in the grinding tank and is connected with the driving mechanism. According to the waste gypsum grinding and recovering equipment for the orthopedics department provided by the invention, the driving mechanism and the grinding mechanism are arranged, so that the aim of grinding gypsum is achieved; a handle is held to rotate so as to drive the grinding tank to rotate through a third slide block, so that the aim of more sufficientgrinding is achieved; and an outer gearing ring drives the grinding tank to rotate through the third slide block, so that the aim of more sufficient grinding is achieved, and meanwhile, the manpowercan be saved.

Owner:姚鲁兰 +1

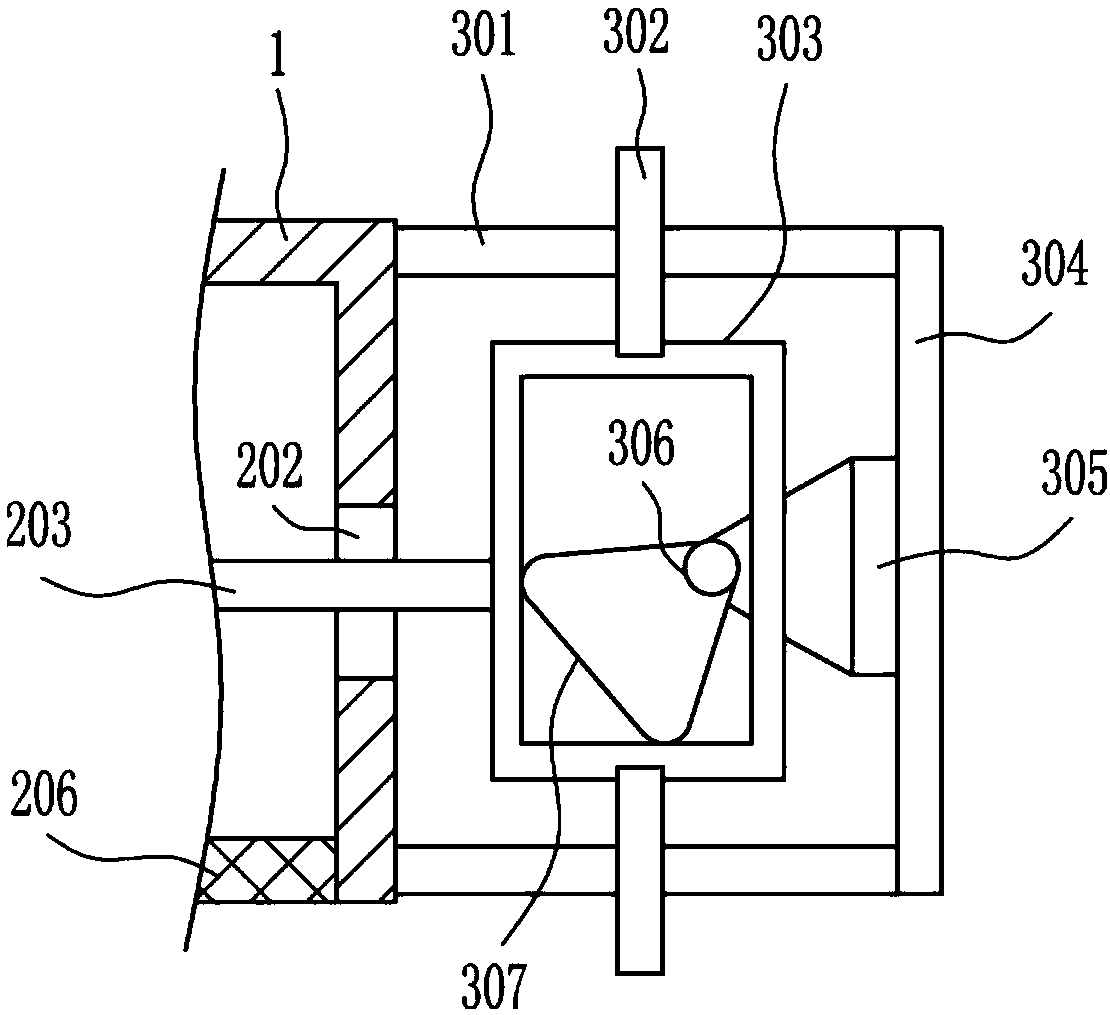

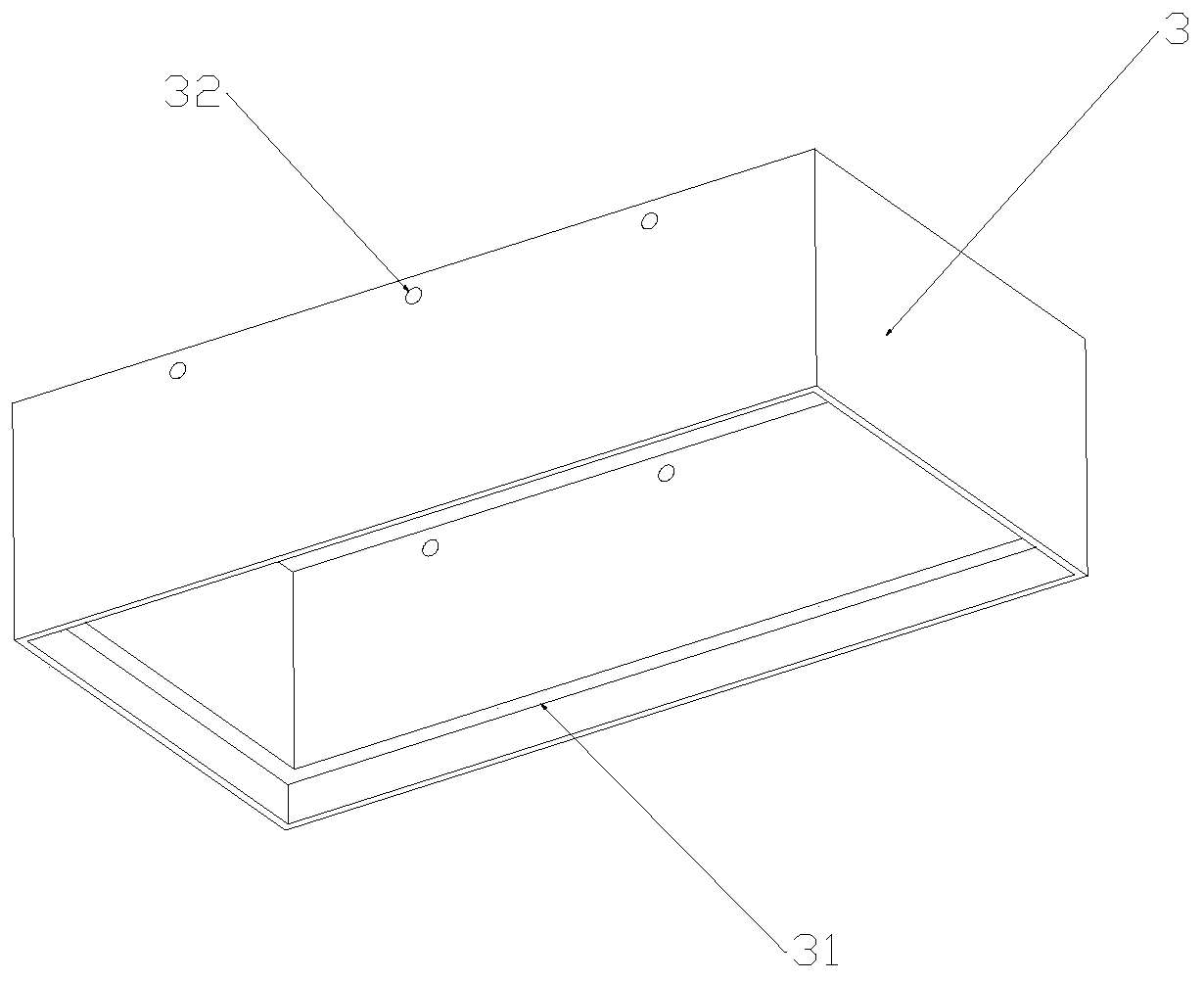

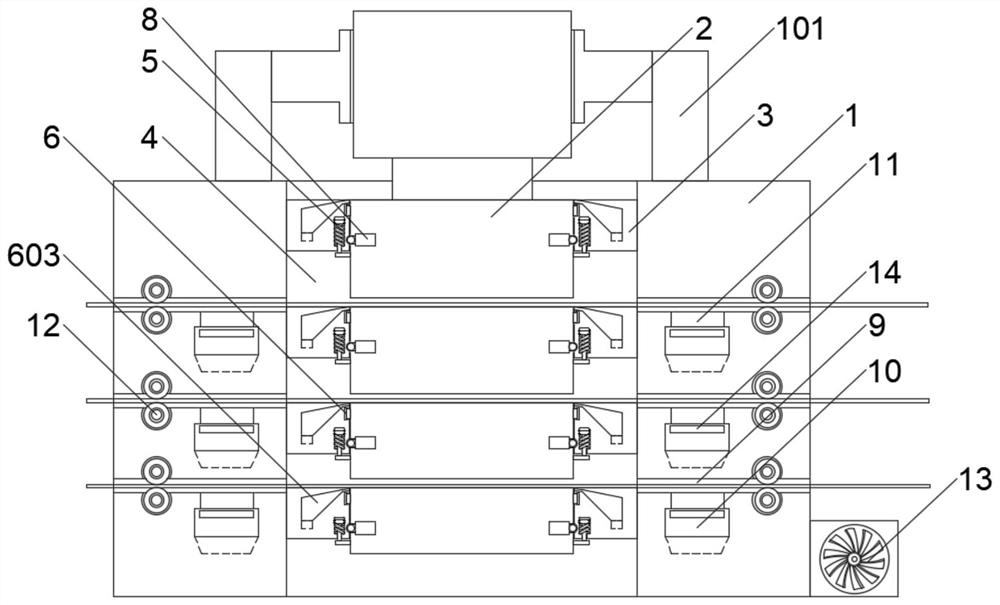

Gypsum grinding device for orthopedics department

ActiveCN107583727AAvoid cloggingTo achieve the purpose of grindingSievingScreeningOrthopedic departmentPolymer chemistry

The invention relates to a grinding device, and in particular, relates to a gypsum grinding device for orthopedics department. The technical problem to be solved by the invention is to provide the gypsum grinding device for orthopedics department, wherein the gypsum grinding device can be used for multi-stage grinding, can be used for grinding under closed conditions and can prevent blockage. Forsolving the technical problem, the invention provides the gypsum grinding device for orthopedics department, wherein the gypsum grinding device includes a grinding box and the like; a grinding mechanism is arranged in the grinding box, a driving mechanism is connected to the right side of the grinding box, and the driving mechanism is connected with the grinding mechanism. By arrangement of the grinding mechanism and the driving mechanism, the purpose of grinding of gypsum is achieved, a first sliding block at lower side can continuously slide left and right to make a second grinding roller move left and right constantly, and the purpose of regrinding of gypsum powder falling from a filter screen is reached; through constant pulling of a pull ring loosely, the purpose that a collision block constantly knocks the right end of a screening plate from side to side is achieved.

Owner:滕仁杰

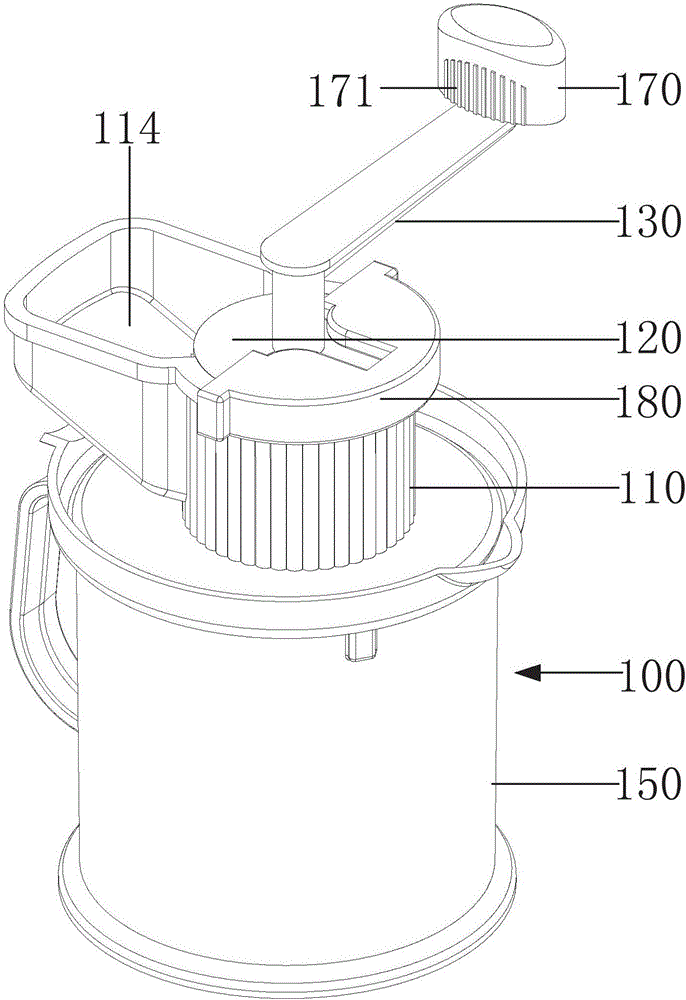

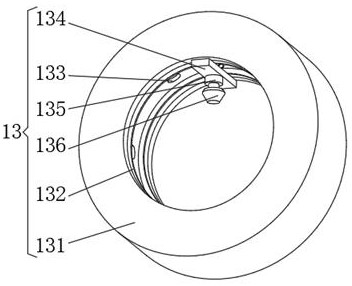

Hand-cranking stirring machine

The invention discloses a hand-cranking stirring machine which comprises a grinder, a grinding body, a hand rocker and a fixing part, wherein the grinder comprises a charging hopper and a grinding bin; a discharge hole is formed in the bottom of the grinding bin; a plurality of spaced first grinding strips are arranged on the inner surface of the grinding bin; the grinding body is arranged in the grinding bin and is used for grinding materials located in the grinding bin; the grinding body comprises a bearing rod, a grinding block arranged at the bottom of the bearing rod, grinding pieces arranged around the bearing rod and a top cover located at the top of the bearing rod; a plurality of spaced second grinding strips are arranged on the periphery of the grinding block; the grinding pieces are of a spiral structure; the top cover is arranged to be adapted to the size of an opening of the grinding bin; one end of the hand rocker is fixedly connected with the top of the grinding body, and a handle is arranged on the other end; a rotor sleeves the handle; the rotor can rotate on the handle; the fixing part comprises a sleeving groove; when the grinding body is placed in the grinder, the fixing piece is sleeved to the edge of the grinder through the sleeving groove and covers the top cover of the grinding body.

Owner:尚艳燕

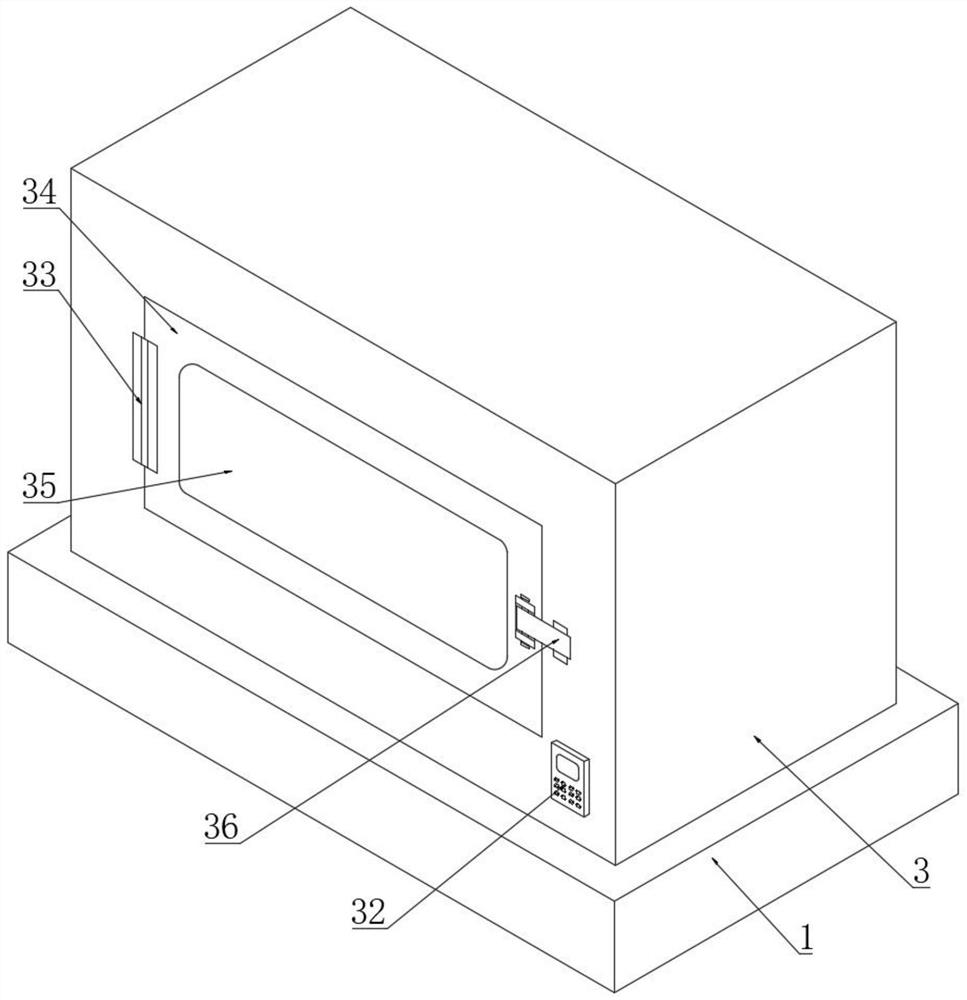

Cleaning and drying device for yam flour processing

InactiveCN112539603ATo achieve the purpose of grindingImprove fine qualityDrying solid materials with heatDrying chambers/containersElectric machineryAgricultural engineering

The invention belongs to the technical field of yam flour processing, particularly relates to a cleaning and drying device for yam flour processing, and provides the following scheme for solving the problem that many impurities are left in yam flour or part of yam blocks are not finely ground in the yam flour processing process. The cleaning and drying device comprises a box body, supporting feetare fixedly connected to the outer wall of the bottom of the box body, an electric control box is fixedly connected to the outer wall of one end of the box body, a first cover plate is rotatably connected to the top of the box body, a material guide plate is arranged at the bottom of the first cover plate, and the material guide plate is fixedly connected with the inner wall of the box body. According to the cleaning and drying device, a motor is arranged to drive a driving gear to rotate so as to drive a driven gear and a processing table connected with the bottom of the driven gear through aconnecting rod to rotate, the processing table can vibrate and screen yam flour through a vibration motor arranged on the outer wall of the processing table, the yam flour leaks out from filtering holes at the bottom of a bearing table after being processed by the processing table, and the fine quality of yam is improved.

Owner:朱南方

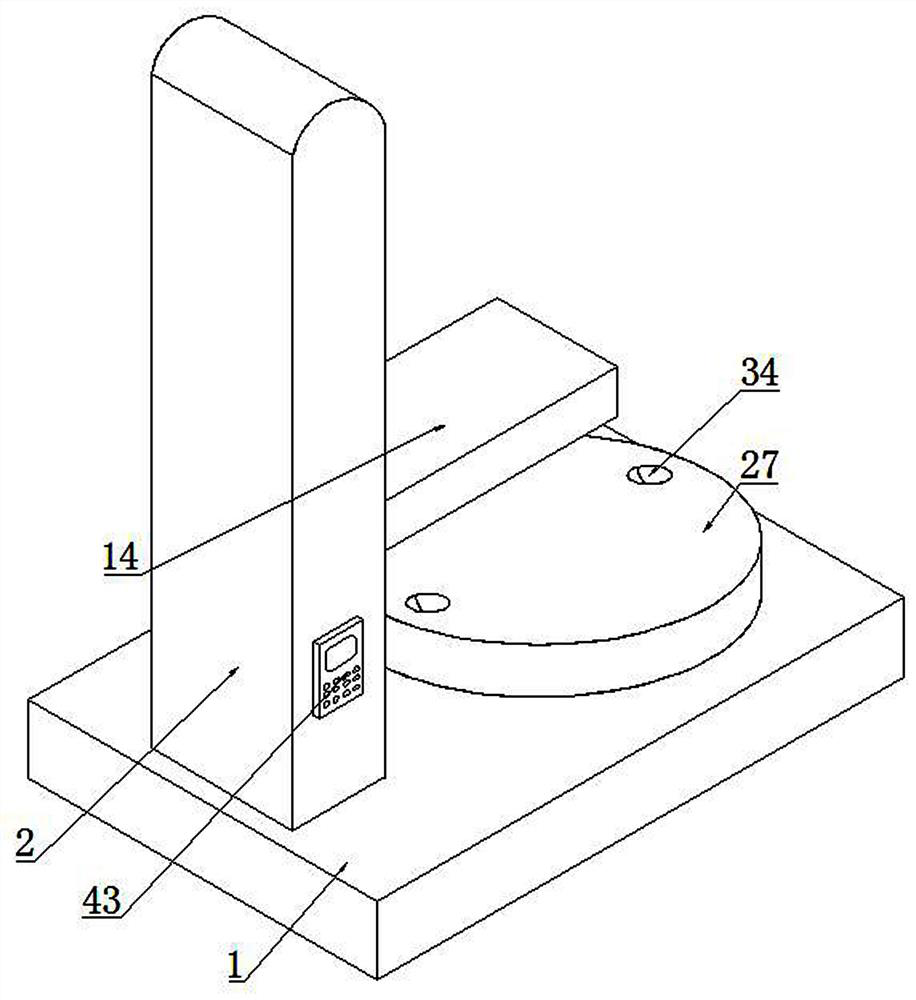

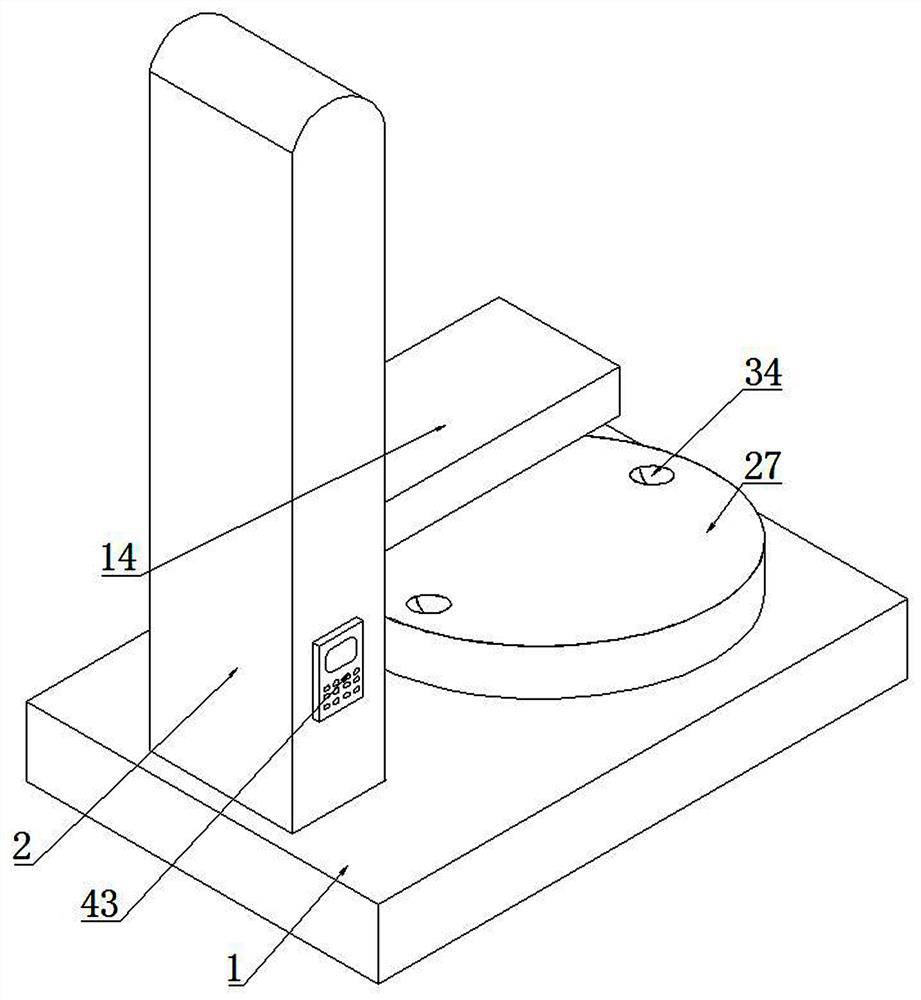

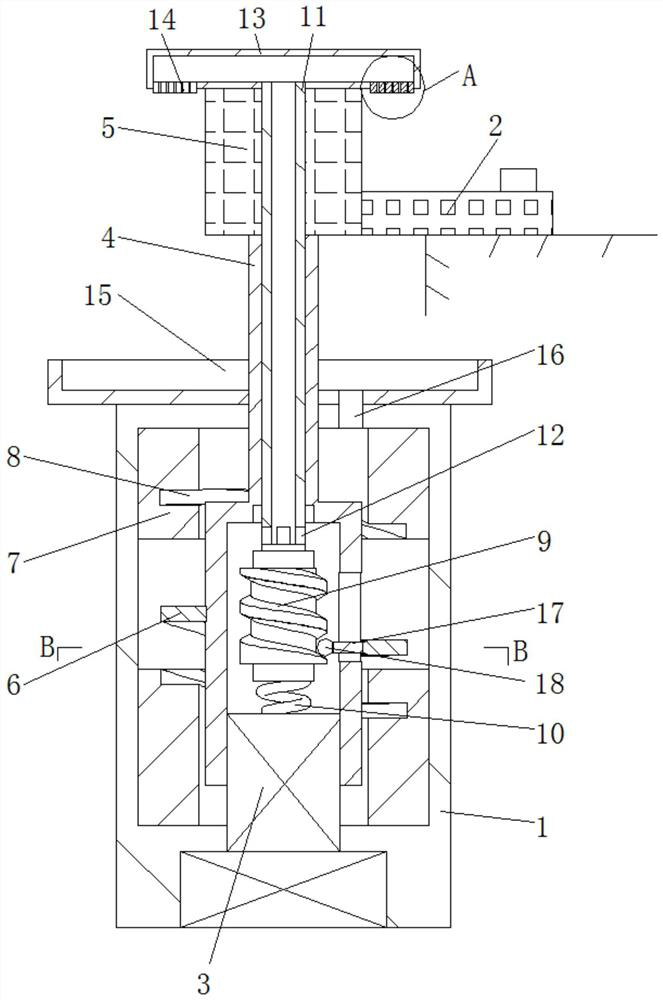

Grinding device for vitamin C sodium phosphate and use method of grinding device

InactiveCN112808433AHeight adjustableTo achieve the purpose of grindingGrain treatmentsVitamin CSodium phosphates

The invention belongs to the technical field of grinding devices, and particularly relates to a grinding device for vitamin C sodium phosphate. The grinding device for the vitamin C sodium phosphate comprises a fixed table and a supporting column, wherein the supporting column is fixedly connected to the upper surface of the fixed table; an adjusting bin is formed inside the supporting column; a rack is fixedly connected to the inside of the adjusting bin; a movable plate is arranged inside the adjusting bin in a penetrating mode; a first fixing frame is fixedly connected to the surface of the movable plate; a forward and reverse motor is fixedly connected to the inside of the first fixing frame; and an output shaft of the forward and reverse motor is fixedly connected with a first rotating shaft. The grinding device for the vitamin C sodium phosphate has the beneficial effects that by arranging the forward and reverse motor, when a worker uses the device to grind the vitamin C sodium phosphate, the worker only needs to start the forward and reverse motor through a control switch, and then under the cooperation of a gear and the rack, the movable plate can drive a grinding roller on the lower surface of a mounting plate to move through a connecting plate, so that the effect of adjusting the height of the grinding roller is achieved.

Owner:ANHUI AIWEI BIOTECH CO LTD

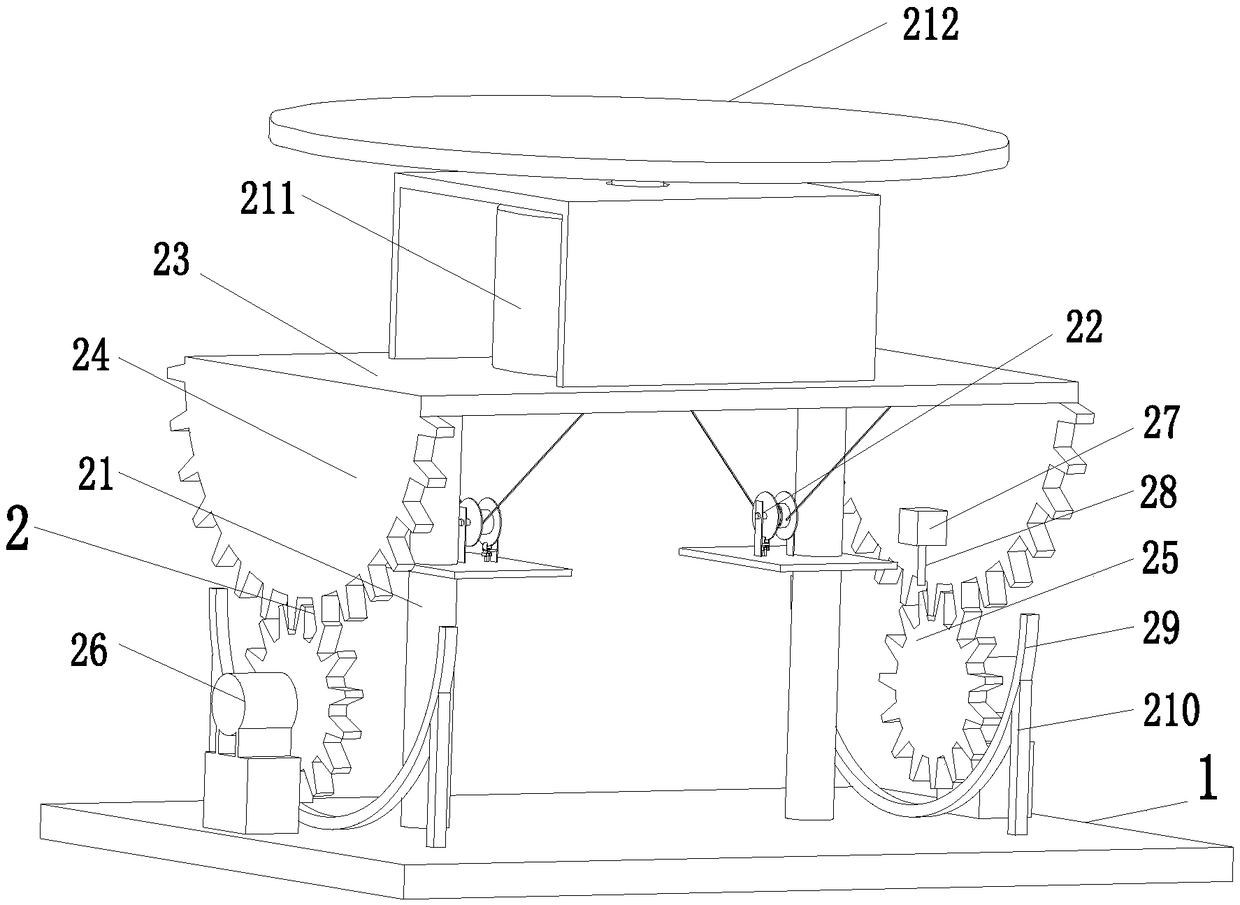

Cutter grinding device

InactiveCN112059748AFixed effect is stableEffective positioningGrinding drivesOther manufacturing equipments/toolsGrindingEngineering

The invention relates to the field of machining and manufacturing, in particular to a cutter grinding device. The cutter grinding device comprises shifting gears and bases, grinding adjusting mechanisms, a position adjusting mechanism, a one-way power mechanism, an angle adjusting mechanism and a cutter fixing mechanism. The grinding adjusting mechanisms are mounted in grooves in the shifting gears and bases in a sliding manner. The shifting gears and bases are fixedly mounted on the two sides of the position adjusting mechanism correspondingly, the one-way power mechanism is fixedly mounted on the position adjusting mechanism, the angle adjusting mechanism is fixedly mounted on the position adjusting mechanism, and the cutter fixing mechanism is fixedly mounted on the angle adjusting mechanism. The device has the function of adjusting the grinding angle and the grinding direction, different grinding manners are adopted for different kinds of cutters, the functions that the grinding effect is optimal and the cutter height is specifically adjusted are achieved, the device adapts to cutters with different widths, the function of adjusting the single-time grinding distance is achieved, and the device adapts to cutters with different lengths.

Owner:哈尔滨市阿城区胜达建筑材料厂

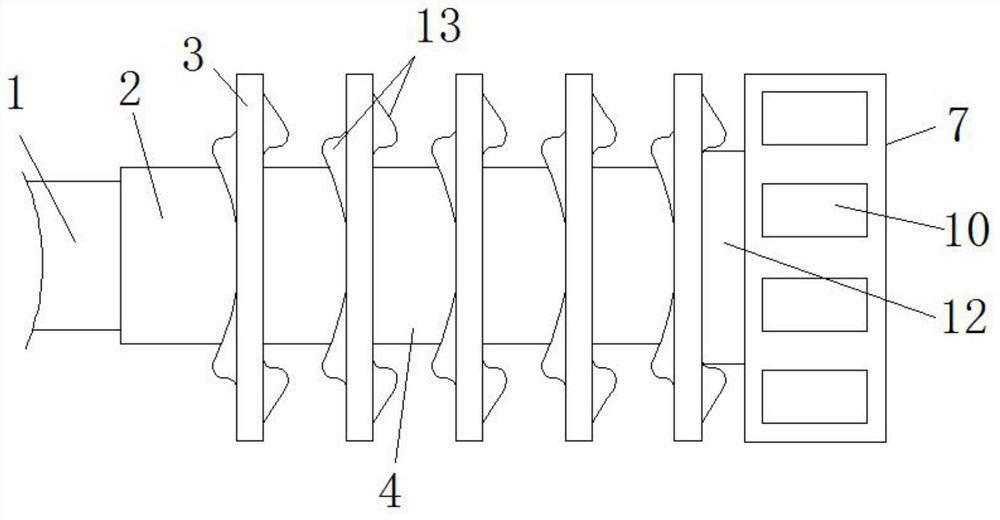

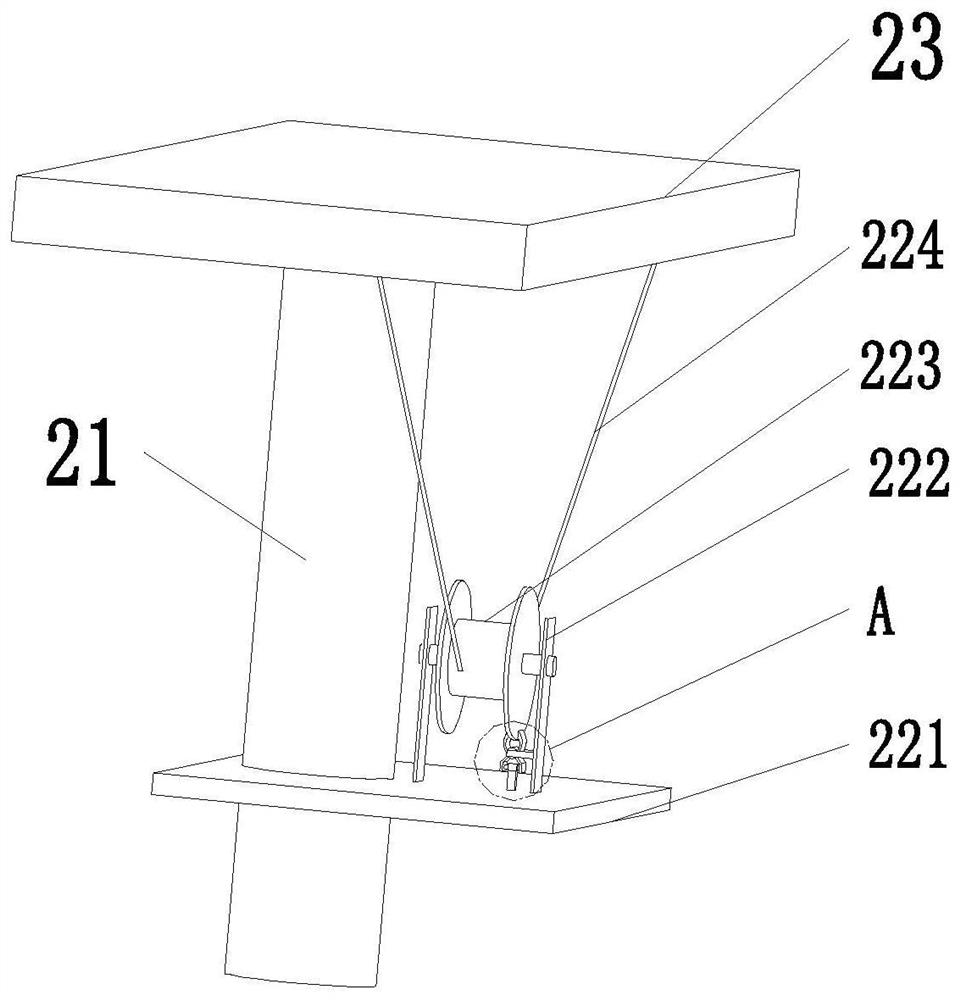

Novel disc type spacer block efficient grinding device

PendingCN112958230ATo achieve the purpose of grindingDischarge in timeGrain treatmentsRotational axisEngineering

The invention provides a novel disc type spacer block efficient grinding device which is used for improving the grinding efficiency and the grinding quality when being used for grinding materials. The novel disc type spacer block efficient grinding device comprises a rotating shaft, a grinding shaft and a grinding assembly, wherein one end of the rotating shaft is connected with a driving mechanism; the other end of the rotating shaft is connected with the grinding shaft; the end, away from the rotating shaft, of the grinding shaft is connected with the grinding assembly; the end, away from the rotating shaft, of the grinding assembly is connected with a material distributing pipe through a pressing ring; and the material distributing pipe is used for distributing and guiding out ground materials.

Owner:SHANGHAI HOOSUN INTELLIGENT TECH CO LTD

External traditional Chinese medicine composition for treating various muscle and bone diseases and preparation device thereof

InactiveCN111419924AReasonable collocationReduce fatigue strengthHydroxy compound active ingredientsInorganic active ingredientsDiseaseSenile osteoporosis

The invention discloses an external traditional Chinese medicine composition for treating various muscle and bone diseases and a preparation device thereof. The traditional Chinese medicine composition provided by the invention is divided into a formula I and a formula II. The formula 1 is used for stopping bleeding, stopping pain, and relieving swelling, and can be used for treating early traumatic injury; and the formula 2 is used for dispelling pathogenic wind and cold, removing dampness, promoting blood circulation, removing blood stasis, dredging collaterals, and promoting bone regeneration. The formula I and the formula II are matched for use, and have good effects. Meanwhile, all the raw materials of the invention are reasonably matched and have synergistic effect, and the formulasare combined and matched, so that the composition has the effects of dispelling pathogenic wind and cold, removing dampness, stopping bleeding, stopping pain, promoting blood circulation, dispelling blood stasis, and dredging channels and collaterals, and is widely applicable to myofascitis, lumbar muscle strain, cervical and lumbar disc herniation and senile osteoporosis accompanied with compression fracture caused by traumatic injury, sprain and exogenous evil, blue soft tissues and blood stasis caused by fracture caused by trauma, and pain, swelling, and limb function limitation caused by bone injury.

Owner:孙全才

Grinding device for vitamin C sodium phosphate

InactiveCN112808434AHeight adjustableTo achieve the purpose of grindingGrain treatmentsVitamin CSodium phosphates

The invention relates to a grinding device for vitamin C sodium phosphate. The grinding device for the vitamin C sodium phosphate comprises a fixed table and a supporting column, wherein the supporting column is fixedly connected to the upper surface of the fixed table; an adjusting bin is formed inside the supporting column; a rack is fixedly connected to the inside of the adjusting bin; a movable plate is arranged inside the adjusting bin in a penetrating mode; a first fixing frame is fixedly connected to the surface of the movable plate, a forward and reverse motor is fixedly connected to the inside of the first fixing frame; and an output shaft of the forward and reverse motor is fixedly connected with a first rotating shaft. The grinding device for the vitamin C sodium phosphate has the beneficial effects that by arranging the forward and reverse motor, when a worker uses the device to grind the vitamin C sodium phosphate, the worker only needs to start the forward and reverse motor through a control switch, and then under the cooperation of a gear and the rack, the movable plate can drive a grinding roller on the lower surface of a mounting plate to move through a connecting plate, so that the effect of adjusting the height of the grinding roller is achieved.

Owner:ANHUI AIWEI BIOTECH CO LTD

Novel flaky rod pin type grinding device

PendingCN112958229ATo achieve the purpose of grindingEasy to replaceGrain treatmentsEngineeringMaterials science

The invention provides a novel flaky rod pin type grinding device which is suitable for machines for superfine dispersion and nanoscale grinding of water-based and solvent materials, is applied to the industries of ink printing, industrial coatings, pigment filler, color paste, medicines, cosmetics and the like, and is used for realizing that a grinding mechanism can be replaced when being abraded, so that the purposes that the grinding mechanism is easy to replace, and the maintenance cost is reduced are achieved. The novel flaky rod pin type grinding device comprises a first disc body, a grinding assembly and a pressing ring, wherein a first through hole is formed in the center of the first disc body; multiple second sinking grooves are evenly distributed in one side of the first disc body with the first through hole as the center; the bottoms of the second sinking grooves communicate with first assembly holes one by one; the first disc body is connected with the grinding assembly through the first assembly holes; and the side, away from the first disc body, of the grinding assembly and the first disc body are fixed into a whole through the pressing ring and a fixing rod.

Owner:SHANGHAI HOOSUN INTELLIGENT TECH CO LTD

A flexible circuit board shaping device

InactiveCN111818732BTo achieve the purpose of grindingAvoid the disadvantages of longInsulating layers/substrates workingTool bitPunching

Owner:广东勤天投资有限公司

A multi-angle grinding device and grinding method for pvc plastic plate side cutting edge

ActiveCN109048554BRealization of multi-angle grindingEasy to measure grinding angleEdge grinding machinesGrinding drivesInfrared lampElectric machine

The invention relates to a multi-angle machining device and a multi-angle machining method for PVC transparent plastic plates. The device comprises a bottom plate, a grinding device, and a moving device. The grinding device and the moving device are separately mounted on the upper end surface of the bottom plate from left to right. The grinding device comprises a grinding support frame, grinding fixing mechanisms, a grinding bearing plate, grinding half gear discs, grinding gear discs, grinding adjusting motors, grinding connecting plates, infrared lamps, adjusting dials, adjusting dial supports, a grinding rotating motor, and a grinding disc. The grinding support frame is mounted on the left side of the upper end surface of the bottom plate. The grinding fixing mechanisms are mounted in the middle of the grinding support frame. According to the multi-angle machining device and the multi-angle machining method for PVC transparent plastic plates, the problems of measuring the grinding angle is difficult, the grinding angle is not accurate, the grinding effect is poor, and the like when the multi-angle grinding of the PVC transparent plastic plates are performed can be solved; the function of multi-angle grinding of the PVC transparent plastic plates can be realized; and the grinding device has the advantages of being convenient to measure the grinding angle, flexible in grindingangle adjustment, accurate in grinding angle control, and good in grinding effect.

Owner:FOSHAN MINGDE PLASTIC CO LTD

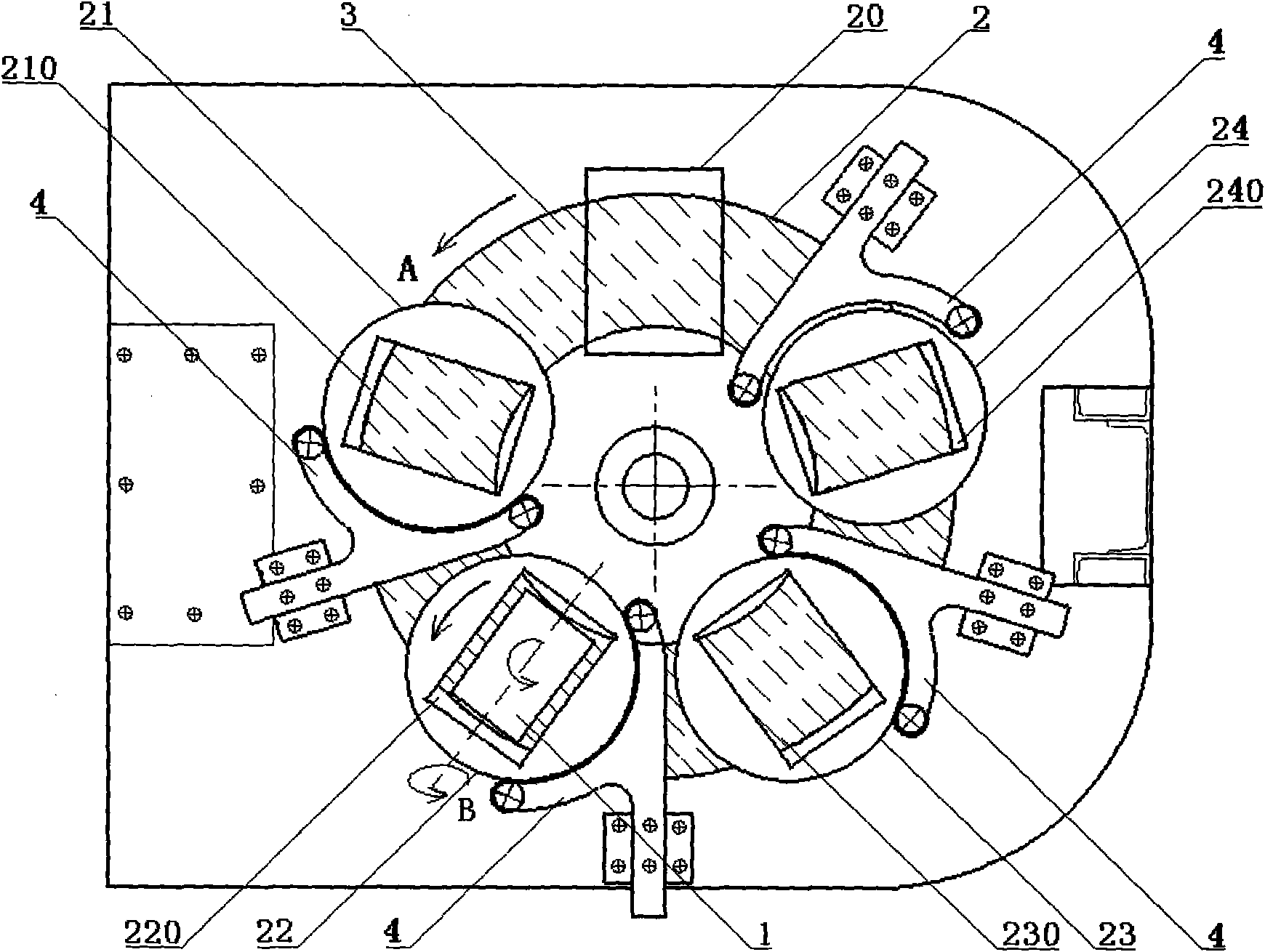

Method for grinding solar silicon rod

ActiveCN102039554BTo achieve the purpose of grindingImprove pass rateFinal product manufactureLapping machinesEngineeringSilicon

The invention provides a method for grinding a solar silicon rod, which is used for grinding the solar silicon rod with four surfaces to be ground, and mainly provides an annular rotary table with four circular grinding areas. The four circular grinding areas are blocked in the rotating direction of the annular rotary table, so that when the annular rotary table is directionally rotated, the circular grinding areas are forced to autorotate at the set position; grinding fluid or a grinding cushion is arranged on the annular rotary table; the solar silicon rod is arranged in the circular grinding areas, and the surfaces to be ground are contacted with the grinding fluid or the grinding cushion; when the circular grinding areas autorotate, the solar silicon rod is driven to rotate to make the surfaces to be ground and the grinding fluid or the grinding cushion relatively move so as to grind the surfaces. By the method, the problem that the silicon rod is easily scratched when ground in the prior art is solved, so that the product qualification rate and the operation efficiency of equipment are improved.

Owner:海宁市日进科技有限公司

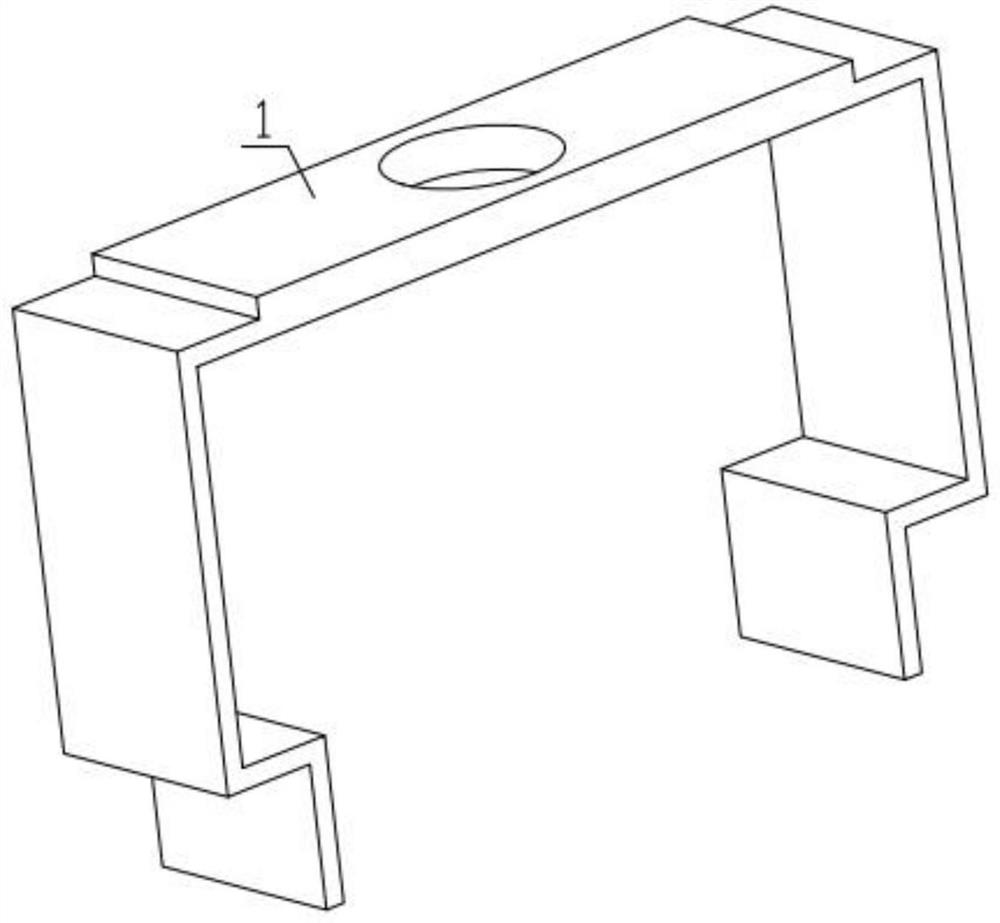

5G transmitting assembly assembling equipment

ActiveCN113070780ARealize intermittent conversionRealize the pick-up functionGrinding drivesGrinding machinesStructural engineeringMechanical engineering

The invention discloses 5G transmitting assembly assembling equipment, and particularly relates to the technical field of 5G transmitting base stations. The 5G transmitting assembly assembling equipment comprises a support, a convex rubber part and an arc-shaped metal part, the cross section of one end of the convex rubber part is rectangular, a convex groove is formed in the arc-shaped metal part, a fixed disc is fixedly mounted at the upper end of the support, an arc-shaped discharging opening is formed in one side of the fixed disc, a rotary disc is rotationally connected to the outer side of the fixed disc, and discharging receding openings are formed in the periphery of the interior of the rotary disc. Through rotation of a crescent rotating block and a shifting rod, intermittent conversion of stations is achieved in one direction, the function of taking a convex rubber part is achieved in the other direction, and on the other hand, the purpose of assembling the convex rubber part and an arc-shaped metal part is further achieved; and meanwhile, a baffle is pushed through the shifting rod, a polishing piece can continuously swing back and forth, the purpose of polishing the convex rubber part is achieved, and the purpose of discharging can be achieved by extruding a discharging rod on the shifting rod.

Owner:陕西立博源科技有限公司

Gypsum Grinding Equipment for Orthopedics

ActiveCN107583727BTo achieve the purpose of grindingAvoid cloggingSievingScreeningOrthopedic departmentGypsum

The invention relates to a grinding device, and in particular, relates to a gypsum grinding device for orthopedics department. The technical problem to be solved by the invention is to provide the gypsum grinding device for orthopedics department, wherein the gypsum grinding device can be used for multi-stage grinding, can be used for grinding under closed conditions and can prevent blockage. Forsolving the technical problem, the invention provides the gypsum grinding device for orthopedics department, wherein the gypsum grinding device includes a grinding box and the like; a grinding mechanism is arranged in the grinding box, a driving mechanism is connected to the right side of the grinding box, and the driving mechanism is connected with the grinding mechanism. By arrangement of the grinding mechanism and the driving mechanism, the purpose of grinding of gypsum is achieved, a first sliding block at lower side can continuously slide left and right to make a second grinding roller move left and right constantly, and the purpose of regrinding of gypsum powder falling from a filter screen is reached; through constant pulling of a pull ring loosely, the purpose that a collision block constantly knocks the right end of a screening plate from side to side is achieved.

Owner:滕仁杰

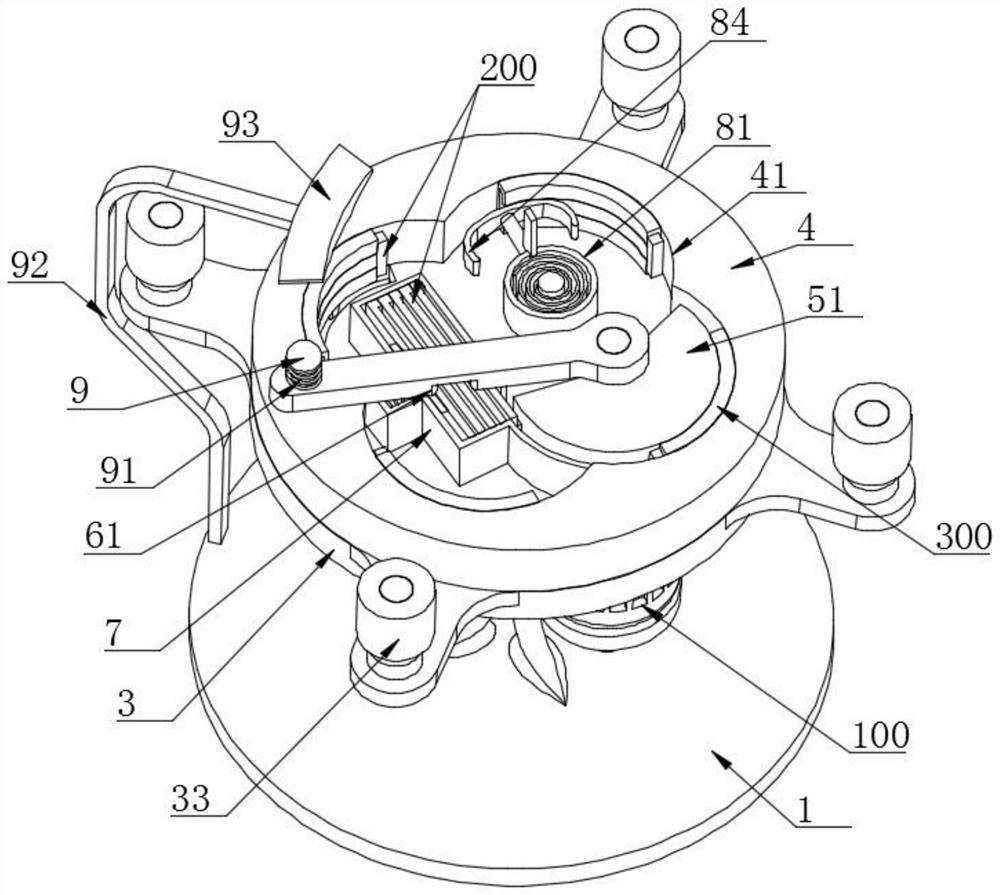

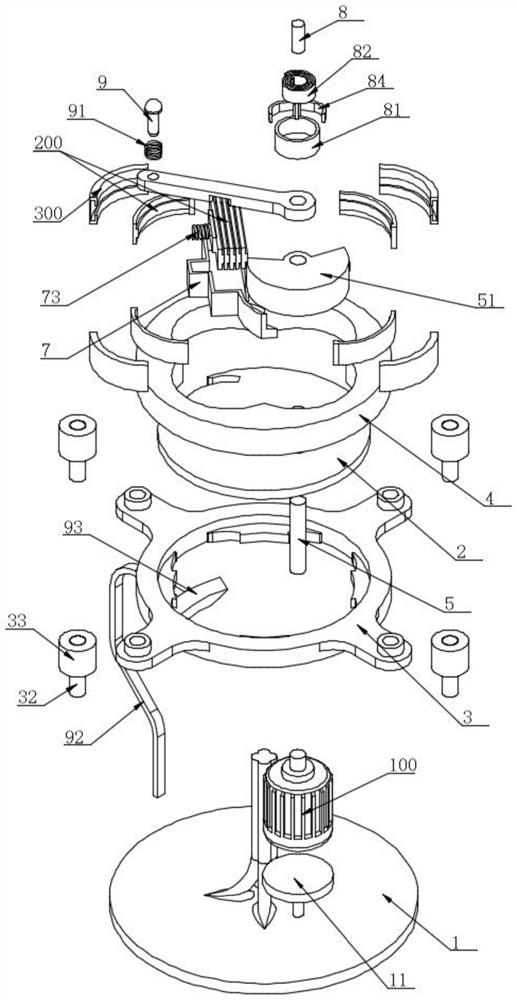

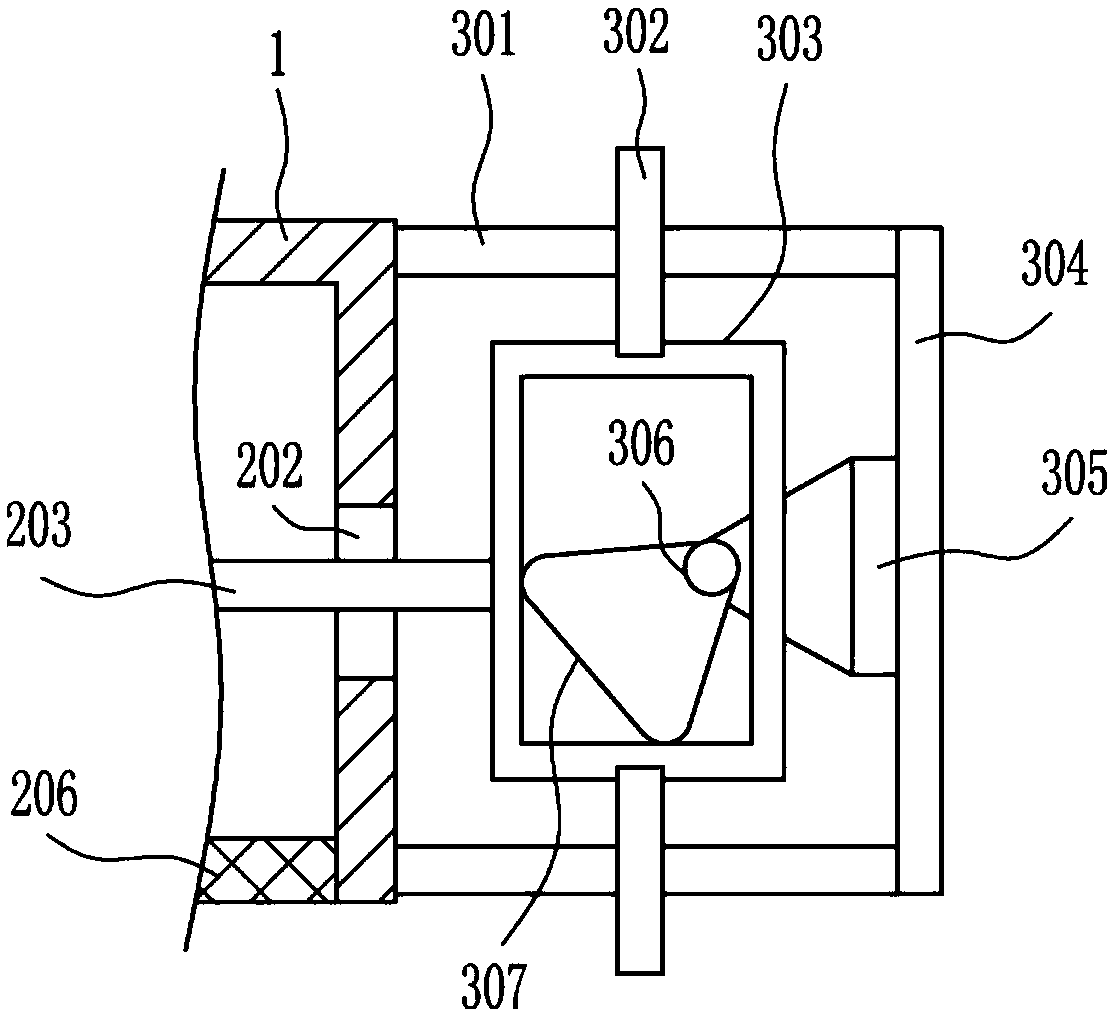

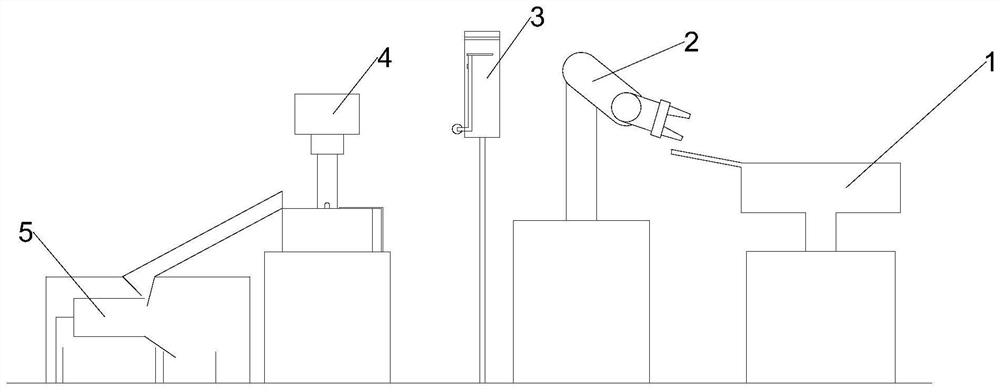

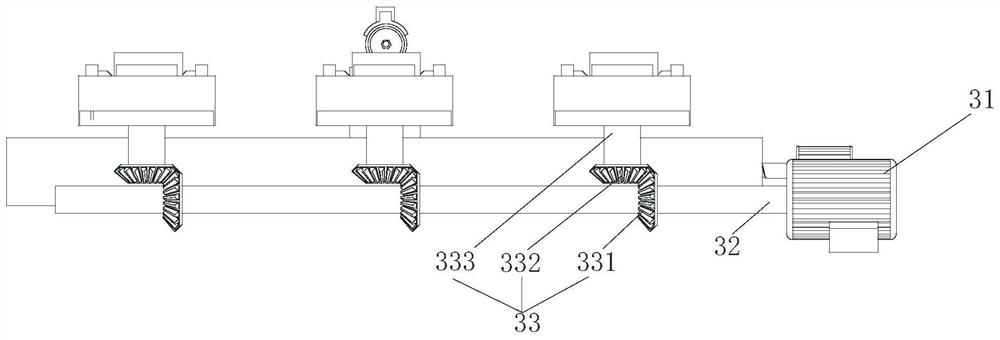

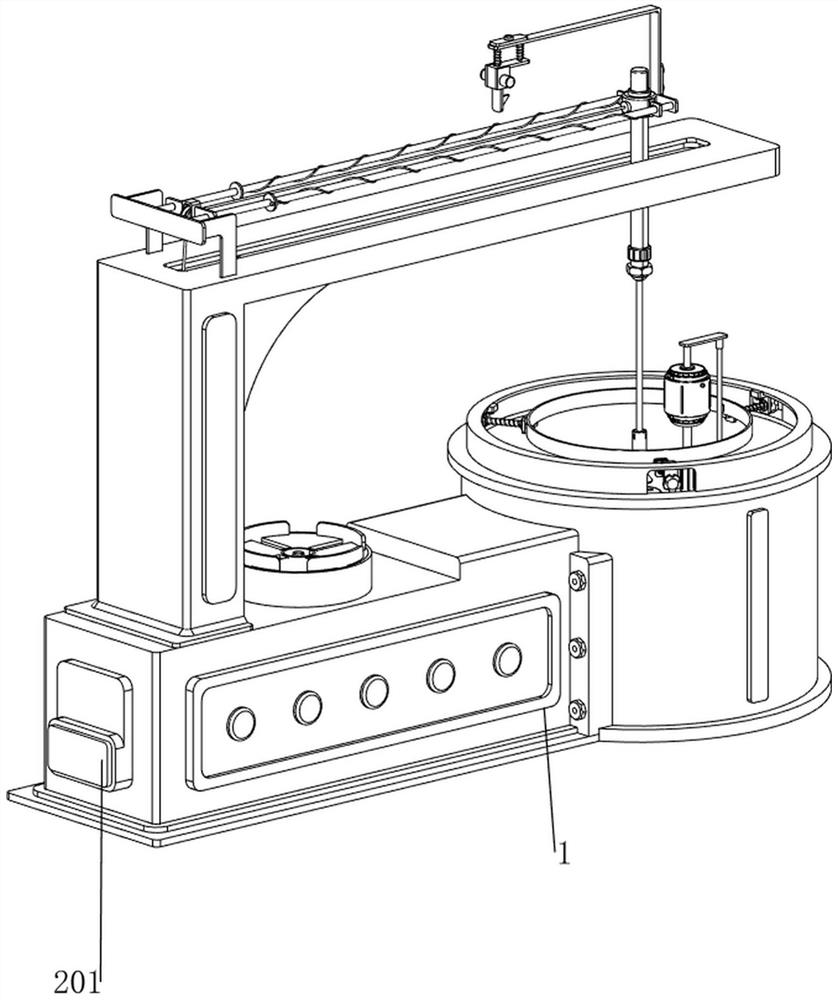

Electrode tip polishing system and polishing method

ActiveCN113305703AImplement automatic filteringTo achieve the purpose of grindingGrinding machinesGrinding feedersMechanical engineeringMaterials science

The invention discloses an electrode tip polishing system and polishing method. The electrode tip polishing system comprises a feeding mechanism, an electrode tip gripper, an electrode tip screening device and a grinding machine. The feeding mechanism is used for transporting to-be-polished electrode tips to a preset position; the electrode tip gripper is used for gripping and transporting the to-be-polished electrode tips, and gripping, detecting, grinding and feeding the to-be-polished electrode tips; the electrode tip screening device is used for achieving length screening and front and back detection of to-be-polished electrode tips; and the grinding machine is used for grinding the to-be-polished electrode tips. Through the structural design, the purpose of automatically screening and grinding the electrode tips can be achieved, the grinding efficiency is improved, and the labor cost is reduced.

Owner:一汽丰田汽车(成都)有限公司

Grinding device for treating metal surface of steel structure

InactiveCN113829186AAvoid dentsUniform wearGrinding drivesGrinding machinesElectric machineryEngineering

The invention relates to the technical field of metal grinding equipment, and discloses a grinding device for treating the metal surface of a steel structure. The grinding device comprises a machine body and a workpiece, a driving motor is fixedly mounted at the bottom of the machine body, and a transmission sleeve located in an inner cavity of the machine body is movably mounted on an output shaft of the driving motor; and a grinding wheel located above the machine body is fixedly installed at the top end of the transmission sleeve, and the side wall of the grinding wheel is slidably connected with the side surface of the workpiece. A reversing belt is arranged in the machine body, turning blocks used for changing the rotating direction of the reversing belt are arranged on the upper portion and the lower portion of the inner wall of the machine body, and a cooling medium is contained in the inner cavity of the machine body, so that in the rotary grinding process of the grinding wheel, movement of the grinding wheel can be achieved through movement of the reversing belt in the cooling medium in the machine body; and the rotating direction of the reversing belt is changed through the turning blocks, so that the grinding wheel moves up and down in a reciprocating mode, the phenomenon of sinking caused by local continuous abrasion of the side wall of the grinding wheel is avoided, and the purpose of even abrasion is finally achieved.

Owner:蔡兴隆

A cutting device for metal decorative strips

ActiveCN113635072BImprove cut qualityTo achieve the purpose of grindingMetal sawing devicesEdge grinding machinesMetal stripsMetal machining

The invention discloses a metal decorative strip cutting device, which comprises a bottom plate, a cutting table is fixedly connected to the top of the bottom plate, a cutting opening is opened on one side of the cutting table, and a device groove is opened on the top of the cutting table. The top of the cutting table is rotatably connected with a rotatable block through a rotatable seat, and the rotatable block is provided with two groups, and the top of the rotatable block is fixedly connected with a fixed plate, and a dust cover is fixedly connected between the fixed plates. The outer side of the dust-proof cover is fixedly connected with a handle, the inner wall of the dust-proof cover is installed with a drive motor, the output end of the drive motor is rotatably connected with a rotating rod, and a cutting knife is set on the outer side of the rotating rod. The present invention relates to The field of metal processing technology. The metal decorative strip cutting device achieves the purpose of grinding the cut surface of the metal strip after cutting, smooths the burrs generated at the incision of the metal strip during cutting, and greatly improves the cutting quality of the metal decorative strip.

Owner:南通航远机械设备有限公司

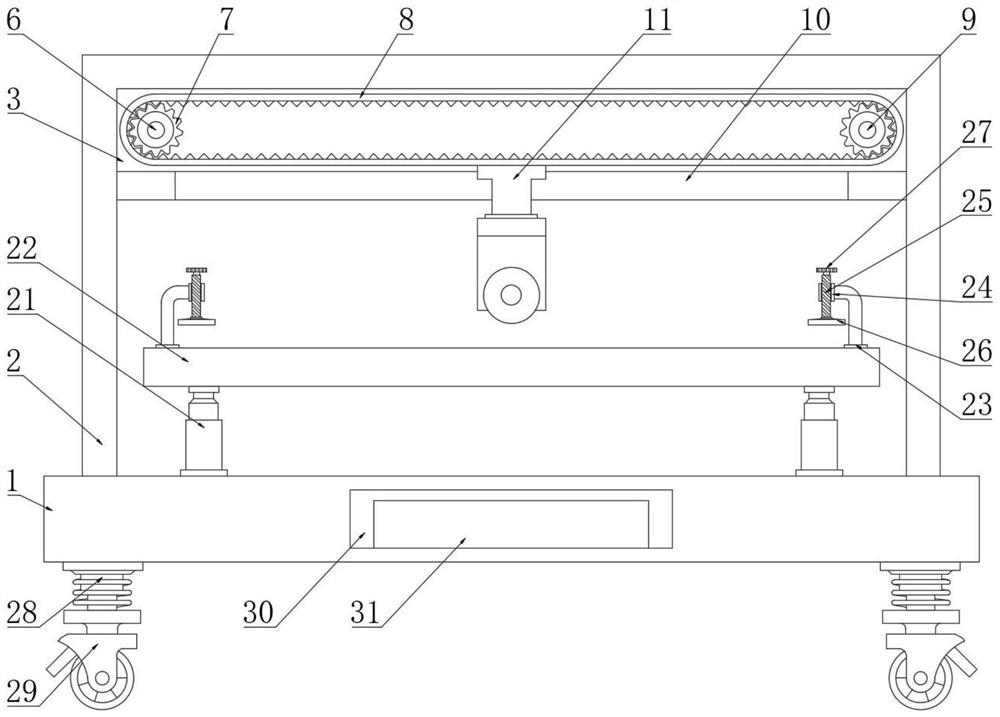

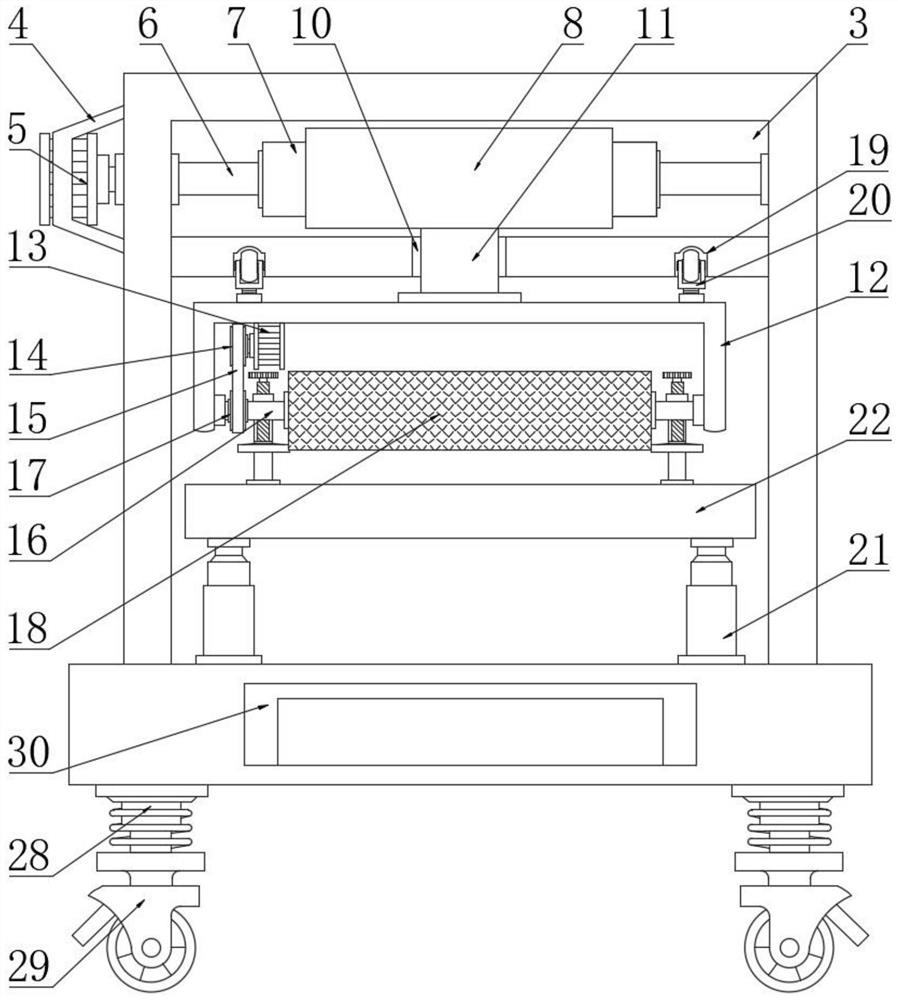

Smart grinding and polishing machine for semiconductor materials

PendingCN110653697AEasy to polishReduce manual operationsBelt grinding machinesSemiconductor materialsElectric machine

The invention belongs to the field of semiconductors, and particularly relates to a smart grinding and polishing machine for semiconductor materials. In order to solve the problems that when an existing semiconductor polishing machine is used for polishing a semiconductor, the semiconductor is generally fixed on the polishing machine, and the position need to be manually adjusted after one face ofthe semiconductor is polished, the smart grinding and polishing machine is provided; the smart grinding and polishing machine includes a base, the top of the base is fixedly provided with two posts,the ends, getting close to each other, of the two posts are rotatably connected with clamping covers, one same semiconductor rod is clamped to the two clamping covers, one same beam is fixedly mountedon the top ends of the two posts, and a U-shaped plate is slidably connected to the beam. According to the machine, the semiconductor rod is clamped on the two clamping covers, then a driving motor,a polishing motor and a rotating motor are started in sequence, then comprehensive polishing of the semiconductor rod can be realized, manual adjustment of the position of the semiconductor rod is notneeded, manual operation is reduced, and the machine is very convenient to use.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

A nozzle cleaning and processing device for a die-casting power box

ActiveCN111889645BTo achieve the purpose of grindingPrevent splashControl engineeringElectrical and Electronics engineering

The invention relates to the technical field of nozzle removal processing of die-casting power boxes, in particular to a nozzle removal processing device for die-casting power boxes, including a bearing platform, a drainage mechanism, a rotating mechanism, a fixing mechanism, a grinding mechanism, a filtering mechanism, a safety mechanism and an auxiliary box, the drainage mechanism is arranged obliquely on the top of the bearing platform, the rotating mechanism is arranged in the bearing platform along the length direction of the bearing platform, and the fixing mechanism includes a plurality of fixing mechanisms, each of which is arranged above the bearing platform in sequence And it is located on the top of the rotating mechanism, the grinding mechanism is fixedly arranged on one side of the bearing platform and the grinding mechanism cooperates with the fixing mechanism, the safety mechanism is arranged on the top of the grinding mechanism, and the filter component is fixedly arranged on the bearing platform On the other side, the auxiliary box is arranged on the outer wall at one end of the carrying platform. Through the operation of the above components, a cleaning processing device capable of batch processing the nozzles of the die-casting power box and a high safety factor is realized.

Owner:惠州市卓创伟业实业有限公司

Shape-adjustable optical lens edge grinding device

InactiveCN114406843ATo achieve the purpose of grindingReduce difficultyEdge grinding machinesGrinding drivesOptic lensOptics

The invention relates to an optical lens edge grinding device, in particular to a shape-adjustable optical lens edge grinding device. The shape-adjustable optical lens edge grinding device provided by the invention can be used for grinding the edges of lenses in different shapes. An optical lens edge grinding device with the adjustable shape comprises a first connecting frame, a connecting frame, a rotating disc, a first connecting rod, a sliding rod, a grinding device, a first spring and the like, the connecting frame is connected to the right side of the first connecting frame, the rotating disc is rotationally connected to the upper portion of the connecting frame, and the first connecting rod is arranged on the right side of the rotating disc; the sliding rod is slidably connected into the first connecting rod, the two first springs are connected between the lower right side of the sliding rod and the first connecting rod, and the polisher is arranged on the upper side of the sliding rod. According to the lens polishing device, the guide ring in the same shape as the lens is replaced, so that the guide ring guides the sliding rod, and therefore, the purpose of polishing the lenses in different shapes can be achieved.

Owner:江西超联光电科技有限公司

A furniture panel processing device

ActiveCN111805369BAdjustable spacingGuaranteed smoothnessGrinding carriagesBelt grinding machinesStructural engineeringMechanical engineering

The invention relates to a wooden furniture processing machine, in particular to a furniture board processing device, including a displacement mechanism, an angle adjustment mechanism, a range adjustment mechanism, a grinding assembly, a sawdust cleaning mechanism and a grinding adjustment mechanism, and is characterized in that: the angle The adjustment mechanism is slidably installed on the groove provided on the displacement mechanism, the range adjustment mechanism is fixedly installed on the angle adjustment mechanism, the sawdust cleaning mechanism is fixedly installed on the range adjustment mechanism, the grinding assembly is fixedly installed on the range adjustment mechanism, and the grinding adjustment mechanism slides Installed on the range adjustment mechanism, the grinding component is in contact with the grinding adjustment mechanism; it can grind the grinding surface at different angles, and can grind the groove surface of the plate, avoiding the phenomenon of burrs on the edge during the grinding process, and at the same time It has the function of accurately cleaning sawdust on the polished board surface.

Owner:邵阳县辰宜居家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com