A cutting device for metal decorative strips

A technology for metal decorative strips and cutting devices, which is applied to metal sawing equipment, sawing machine devices, metal processing equipment, etc. It can solve the problems of cutting surface grinding and metal strips can not be realized, and achieve the effect of improving work efficiency and cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

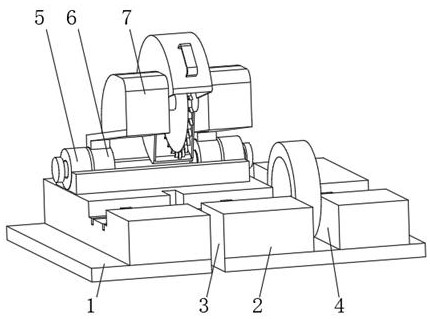

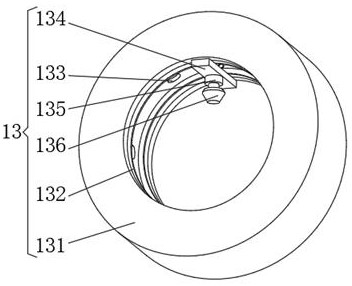

[0029] see Figure 1-5 , the present invention provides a technical solution: a metal decorative strip cutting device, including a base plate 1, a cutting table 2 is fixedly connected to the top of the base plate 1, a cutting opening 3 is opened on one side of the cutting table 2, and a cutting port 3 is opened on the top of the cutting table 2 There is a device groove 4, the top of the cutting table 2 is connected with a rotating block 6 through the rotating seat 5, the rotating block 6 is provided with two groups, the top of the rotating block 6 is fixedly connected with a fixed plate 7, and the fixed plate 7 is fixedly connected. Dust cover 8, the outer side of dust cover 8 is fixedly connected with handle 9, and the inner wall of dust cover 8 is installed with drive motor 10, and the output end of drive motor 10 is connected with rotating rod 11 in rotation, and the outer cover of rotating rod 11 is provided with cutting Knife 12, one end of rotating rod 11 away from drive...

Embodiment 2

[0038] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, the clamping device 16 includes a sliding block 161, the sliding block 161 is provided with two groups, and the two groups of sliding blocks 161 are connected by a moving column, the sliding block 161 and The slide block inside the electronic rail 15 is fixedly connected, the top of the slide block 161 is equipped with a rubber splint 162, the bottom of the slide block 161 is fixedly connected with a magnet block 163 by extruding springs, the bottom of the magnet block 163 is equipped with a cleaning plate 164, and the magnet block 163 is rotatably connected with a scraper 165 near the side of the cleaning plate 164 .

[0039] When in use, the electronic guide rail 15 drives the clamping device 16 to move the metal strip to the cutting opening 3. At this time, the magnet block 163 moves along the electronic guide rail 15 along with the slider inside the electronic guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com