Cleaning and drying device for yam flour processing

A drying device and yam powder technology are applied in the directions of heating to dry solid materials, dry solid materials, and dry goods processing, etc., and can solve problems such as the lack of fine grinding of yam blocks, the influence of the quality of yam powder, and the lack of efficient cleaning and drying of yam powder. Achieve the effect of improving aeration efficiency and improving fine quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

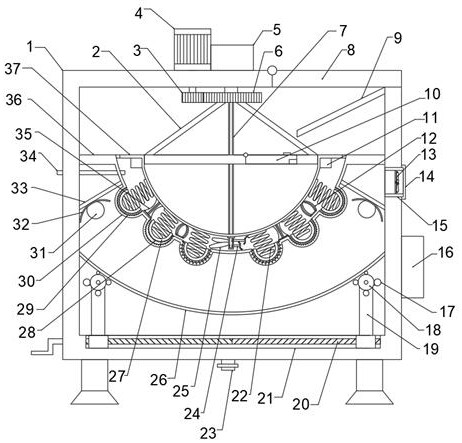

[0029] refer to Figure 1-4 , a cleaning and drying device for yam powder processing, comprising a box body 1, the outer wall of the bottom of the box body 1 is fixedly connected with a foot, the outer wall of one end of the box body 1 is fixedly connected with an electric control box 16, and the top of the box body 1 is rotatably connected with a first cover plate 8. The bottom of the first cover plate 8 is provided with a material guide plate 9, the material guide plate 9 is fixedly connected to the inner wall of the box body 1, and the outer wall of one side of the box body 1 is rotatably connected to a discharge door, which is characterized in that the top of the box body 1 is fixedly connected There is a motor 4, the bottom of the motor 4 is fixedly connected with a driving gear 3, one end of the driving gear 3 is connected with a driven gear 6, the bottom of the driven gear 6 is fixedly connected with a plurality of connecting rods 2, and the bottom of the connecting rod ...

Embodiment 2

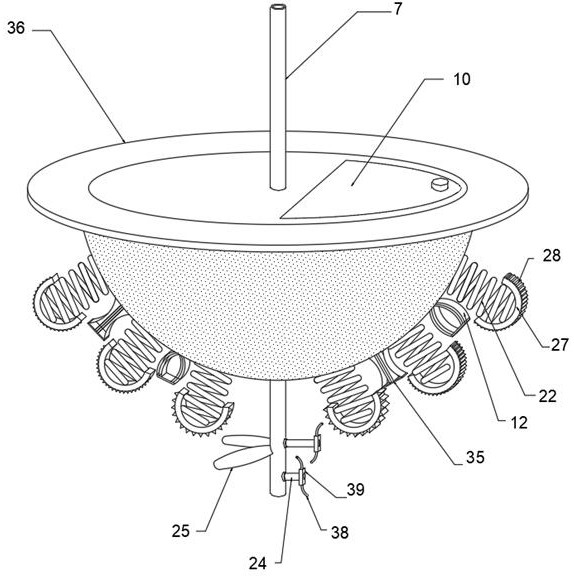

[0039] refer to Figure 2-3 and Figure 5 , a cleaning and drying device for yam powder processing, the top of the inner wall of the drying pocket 26 is fixedly connected with a fixed base 40, and the inner wall of the fixed base 40 is fixedly connected with a heating screen 41, the heating screen 41 is arranged in an arc shape, and the heating screen 41 and electric The control box 16 is electrically connected.

[0040] During use, the yam powder flowing down from the bearing table 36 can be heated and screened by setting the electric control box 16 to control the heating screen 41 in the drying pocket, and the drying pocket 26 is moved while rotating and hitting at the rotating shaft 18 Under the circumstances, realized utilizes the fixed rod 17 of rotating shaft 18 outer wall to extrude drying bag, cooperates heating screen 40 to carry out extruding heating to yam powder, has further improved the efficient drying effect of yam powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com