Shape-adjustable optical lens edge grinding device

An optical lens and edging technology, which is applied in the direction of grinding drive device, grinding automatic control device, grinding machine, etc., can solve the problems of lens edging and low practicability, so as to prevent grinding failure, reduce difficulty, and avoid position deviation moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

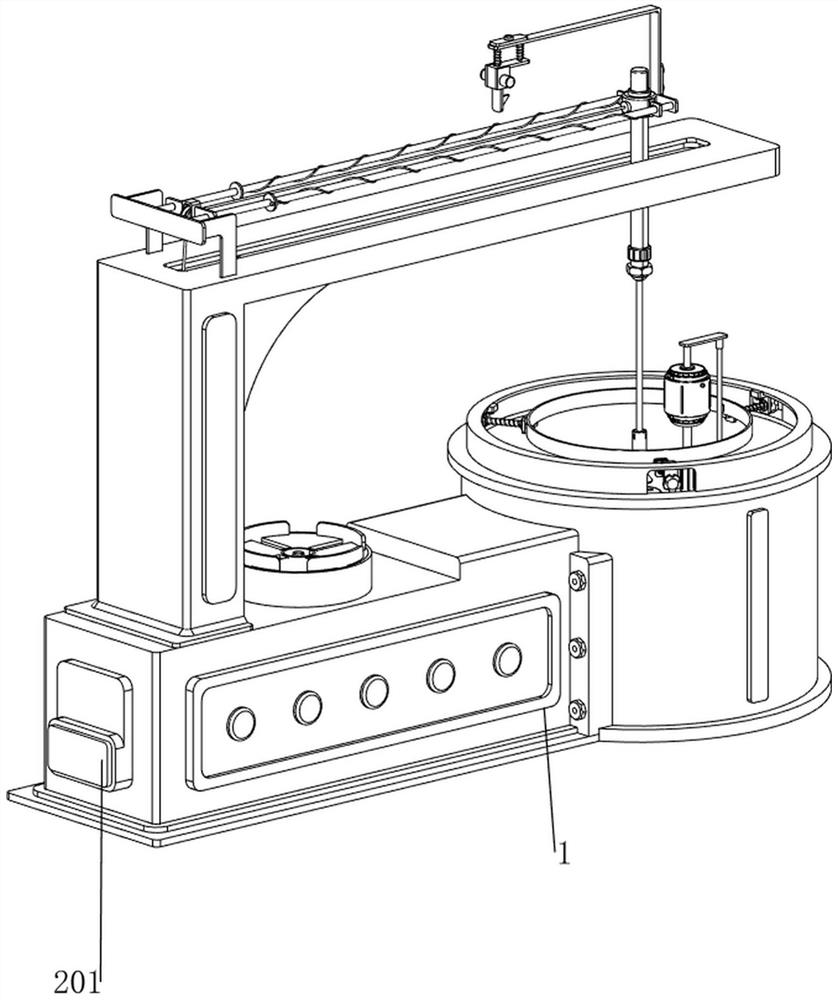

[0038] see Figure 1-Figure 5 , an optical lens edging device with adjustable shape, including a first connecting frame 1, a connecting frame 2, a rotating disk 3, a first connecting rod 4, a sliding rod 5, a grinder 501, a first spring 6 and a fixing mechanism 7. The connecting frame 2 is welded on the right side of the first connecting frame 1, and the upper part of the connecting frame 2 is rotatably connected to the rotating disk 3. The right side of the rotating disk 3 is provided with a first connecting rod 4, and the first connecting rod 4 is slidingly connected with a Sliding rod 5, two first springs 6 are connected between the lower right side of sliding rod 5 and the first connecting rod 4, a polisher 501 is provided on the upper side of sliding rod 5, and a fixing mechanism 7 is provided on the right side of the first connecting frame 1 .

[0039] see Figure 2-Figure 5 , the fixing mechanism 7 includes a connecting plate 71, a threaded sleeve 72, a clamping block 7...

Embodiment 2

[0042] On the basis of Example 1, please refer to figure 2 , Figure 6 and Figure 7 , also includes a discharge mechanism 8, the discharge mechanism 8 includes a second connection frame 81, a second connection rod 82, a clamping plate 83 and a second spring 84, the left side of the first connection frame 1 is welded with a second connection frame 81, the second connecting frame 81 top is welded with the second connecting rod 82, and the four sides of the second connecting rod 82 are slidably connected with clamping plates 83, and the lower sides of the four clamping plates 83 are connected with the second connecting rod 82 A second spring 84 is connected therebetween.

[0043] see figure 2 , Figure 8 and Figure 9 , also includes a pick-and-place mechanism 9, the pick-and-place mechanism 9 includes a fixed frame 91, a third connecting rod 92, a first electric push rod 93, a fourth spring 94, a photoelectric sensor 95, a first distance sensor 905, and a connecting pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com