Stone three-step polishing device

A polishing device and stone technology, applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of difference in grinding effect, long operation time of the device, waste of grinding wheels, etc., so as to avoid stone damage. , moderate strength, increase the effect of grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

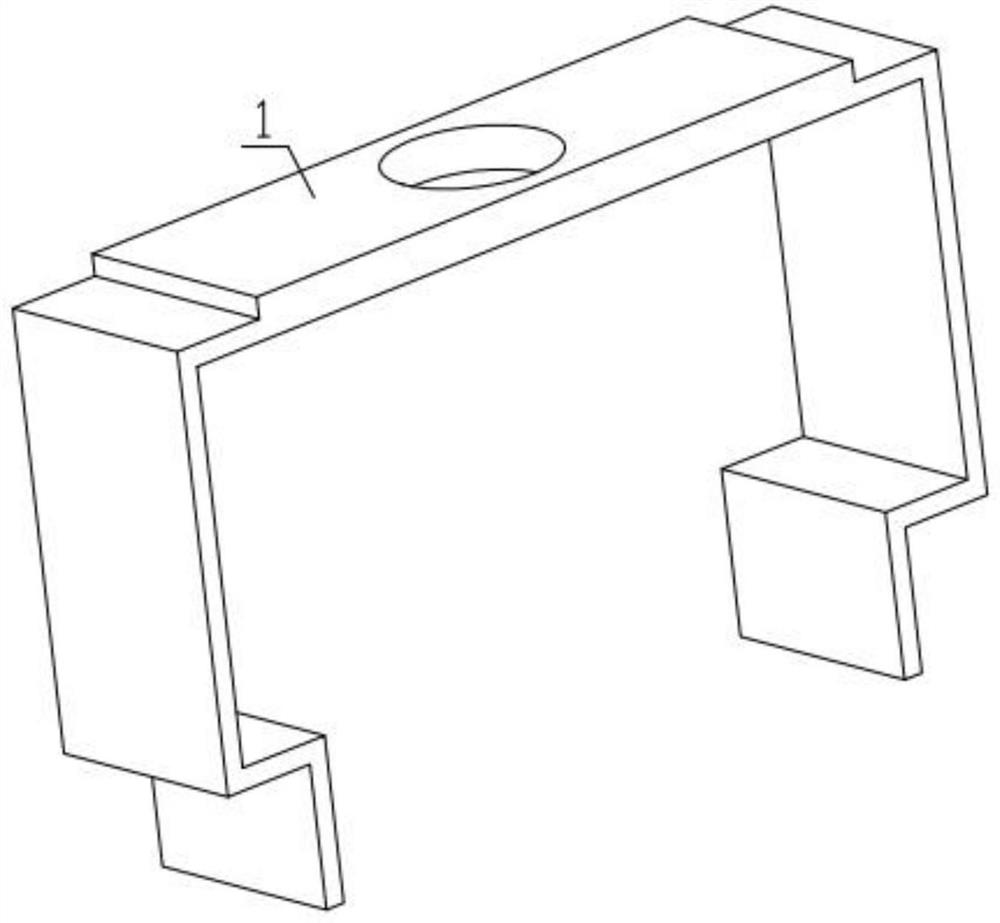

[0041] Combine below Figure 1-17 Describe this embodiment, a stone three-stage polishing device, including a mounting frame 1, a stone lifting mechanism 2, a stone moving mechanism 3, a stone adjusting mechanism 4 and a three-stage polishing mechanism 5, and the stone material is fixedly installed on the mounting frame 1 Lifting mechanism 2, stone moving mechanism 3 is fixedly installed on stone lifting mechanism 2, stone adjusting mechanism 4 is fixedly installed on stone moving mechanism 3, three-stage polishing mechanism 5 is fixedly installed on mounting frame 1.

specific Embodiment approach 2

[0043] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the stone lifting mechanism 2 includes a base frame 2-1, a sliding foot part 2-2, a hinge rod 2-3, a hinge head 2-4, a two-way thread Rod 2-5, sprocket wheel one 2-6, lifting motor 2-7, chain one 2-8, one end of bidirectional threaded rod 2-5 is installed in the groove provided on base frame 2-1 by rotation, and bidirectional threaded rod The other end of 2-5 is fixedly installed with sprocket one 2-6, and the other side of sprocket one 2-6 is fixedly installed on the output end of lifting motor 2-7, and lifting motor 2-7 is fixedly installed on base frame 2- 1, the sliding foot piece 2-2 is slidably installed in the groove provided on the base frame 2-1, the sliding foot piece 2-2 is threaded with the two-way threaded rod 2-5, and the sliding foot piece 2-2 is connected with the hinged rod 2 -3 is hinged, the other end of the hinged rod 2-3 is hinged with th...

specific Embodiment approach 3

[0045] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain Embodiment 2. The stone moving mechanism 3 includes an intermediate frame 3-1, a moving screw 3-2, a sprocket 2 3-3, a chain 2 3-4, Sprocket three 3-5, moving screw two 3-6, moving motor 3-7, moving screw one 3-2 rotates and installs in the groove provided on the middle frame 3-1, moving screw two 3-6 rotates and installs In the groove provided on the intermediate frame 3-1, one end of the moving screw rod one 3-2 is fixedly equipped with a sprocket two 3-3, and one end of the moving screw rod two 3-6 is fixedly installed with a sprocket three 3-5, the chain The second wheel 3-3 is rotatably installed in the groove provided on the intermediate frame 3-1, the sprocket three 3-5 is fixedly installed on the output end of the mobile motor 3-7, and the mobile motor 3-7 is fixedly installed on the intermediate frame In the groove provided on 3-1, the second chain 3-4 is meshed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com