Machine and method for grinding and polishing ultra-long and ultra-thin quartz plate

A quartz plate and polishing machine technology, applied in the field of grinding and polishing machines, can solve the problems of large and heavy equipment, and achieve the effects of simple operation, convenient use and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

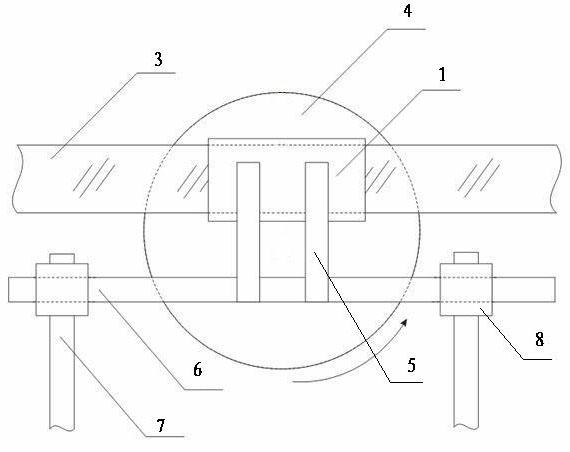

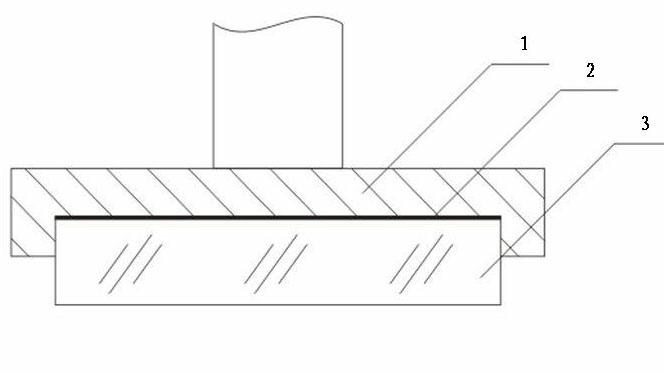

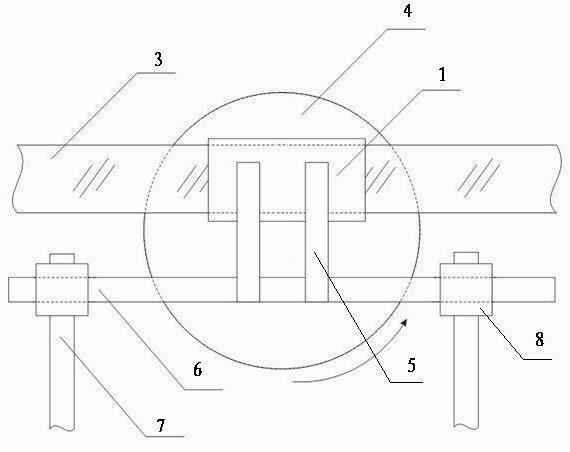

[0014] Embodiment 1, with reference to figure 1 , 2, a kind of lapping and polishing machine that is applicable to ultra-long and ultra-thin quartz plate, it comprises millstone 4, is provided with cover mold 1 above millstone 4, is provided with workpiece placement groove on cover mold 1, and workpiece placement groove bottom is provided with The gasket 2 and the mold set 1 are fixedly connected to the translation shaft 6 through the connecting rod 5, and the translation shaft 6 is connected to the front and rear movement guide rail 7 through the slider 8, and the translation shaft 6 and the front and rear movement guide rail 7 respectively pass through The transmission mechanism is connected with the motor.

Embodiment 2

[0015] Embodiment 2, a grinding and polishing method for an ultra-long ultra-thin quartz plate, which uses the grinding and polishing machine described in Embodiment 1; before polishing, the workpiece 3 to be ground is installed in the workpiece placement groove set on the sleeve mold 1 , and the lower surface of the workpiece 3 to be ground protrudes from the workpiece placement groove of the mold 1 by 0.5 mm, and the width of the workpiece placement groove is 0.2 mm wider than the workpiece 3 to be ground; during processing, the grinding disc 4 rotates, and the translation shaft 6 or the forward and backward movement guide rail 7 Driven by the motor, it moves forward, backward, left or right, thereby driving the mold 1 and the workpiece 3 to be ground to move forward, backward, left or right.

Embodiment 3

[0016] Embodiment 3, a grinding and polishing method for an ultra-long and ultra-thin quartz plate, which uses the grinding and polishing machine described in Embodiment 1; before polishing, the workpiece 3 to be ground is installed in the workpiece placement groove set on the sleeve mold 1 , and the lower surface of the workpiece 3 to be ground protrudes from the workpiece placement groove of the mold 1 by 0.8 mm, and the width of the workpiece placement groove is 0.5 mm wider than the workpiece 3 to be ground; during processing, the grinding disc 4 rotates, and the translation shaft 6 or the forward and backward movement guide rail 7 Driven by the motor, it moves forward, backward, left or right, thereby driving the mold 1 and the workpiece 3 to be ground to move forward, backward, left or right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com