Electrode tip polishing system and polishing method

A technology of electrode head and grinding machine, applied in the field of electrode head, can solve problems such as low degree of automation, and achieve the effect of reducing labor cost, improving production efficiency and suitable spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

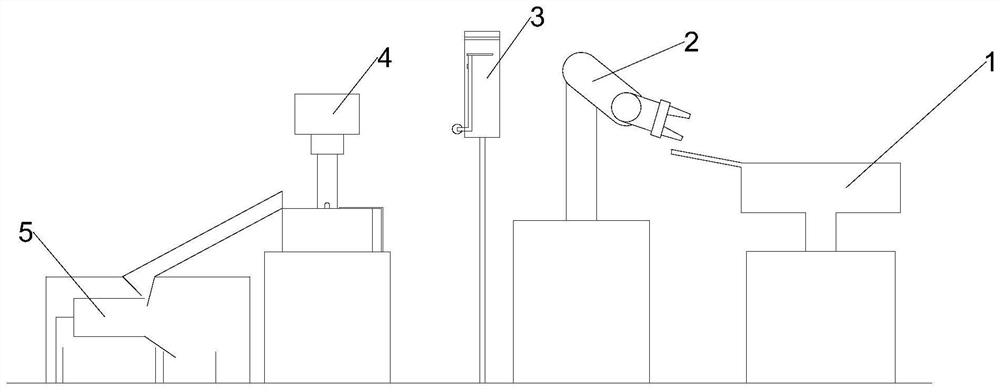

[0049] Such as figure 1 As shown, the embodiment of the present invention discloses an electrode tip grinding system, including: a feeding mechanism 1, an electrode tip gripper 2, an electrode tip screening device 3, and a grinder 4; the feeding mechanism 1 is used to grind the electrode tip to be polished Transport to a preset position; the electrode tip gripper 2 is used to grasp and transport the electrode tip to be polished, and realize the grasping, detection and grinding and feeding of the electrode tip to be polished; the electrode tip screening device 3 is used to realize the length screening and positive and negative detection of the electrode tip to be polished; the grinder 4 is used to grind the electrode tip to be polished.

[0050] Specifically, the electrode head gripper 2 is a multi-axis swing arm manipulator, and the multi-axis swing arm manipulator can realize the 2360° omnidirectional rotation and movement of the electrode head gripper, and the gripping of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com