Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Take up less space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

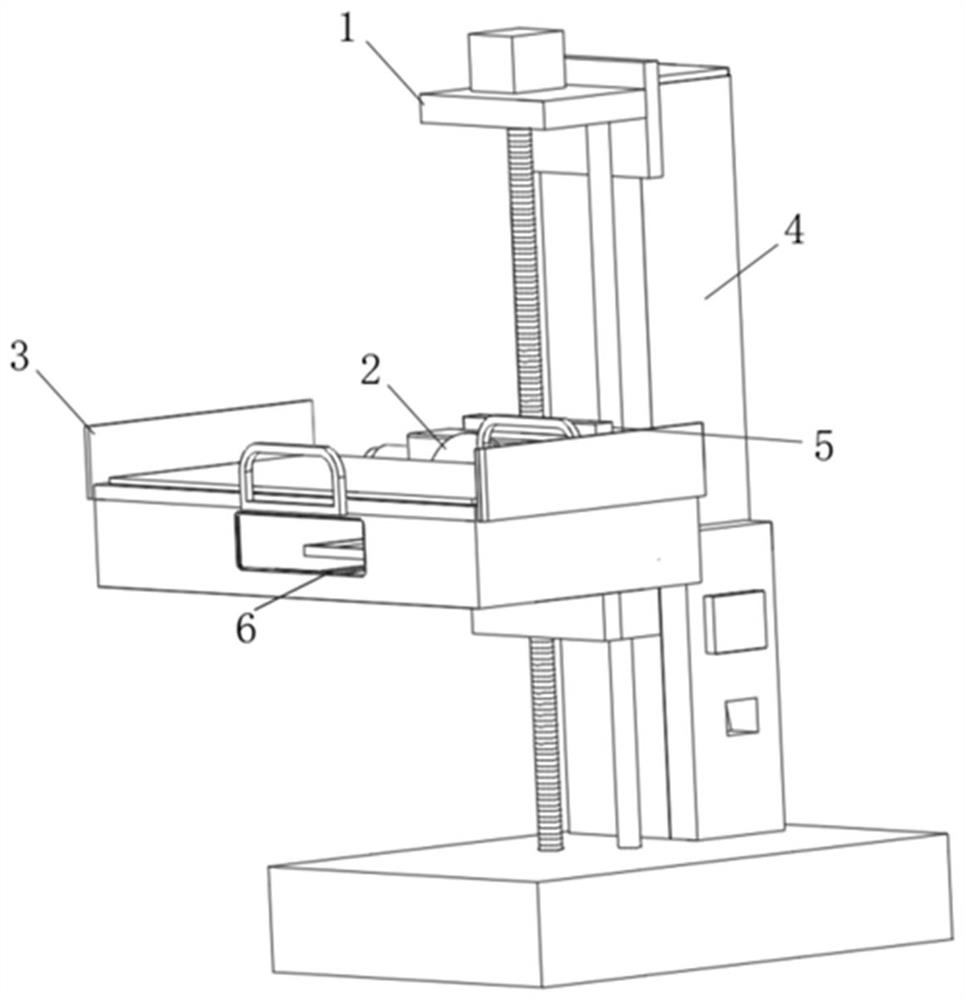

Drying and ironing integrated machine

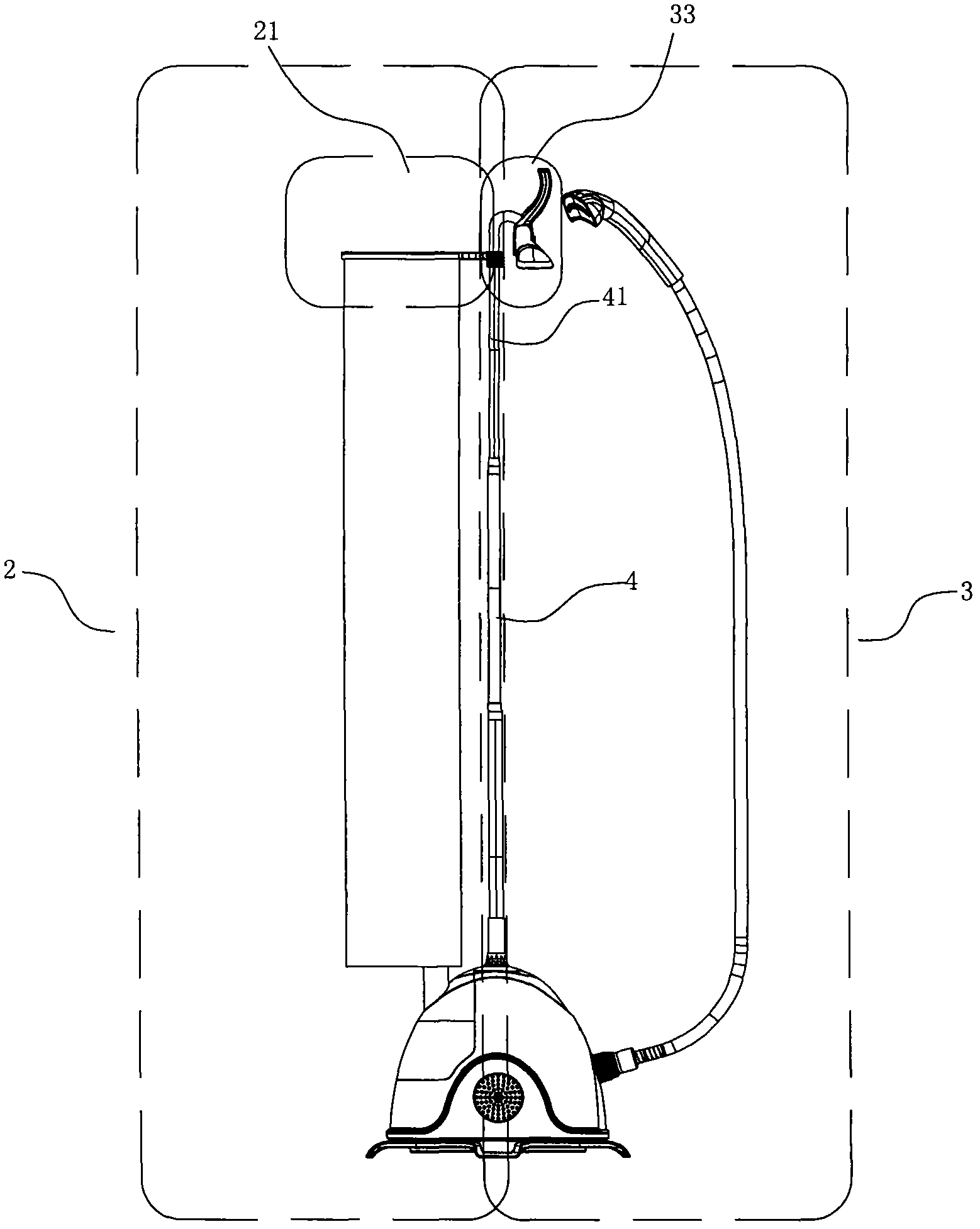

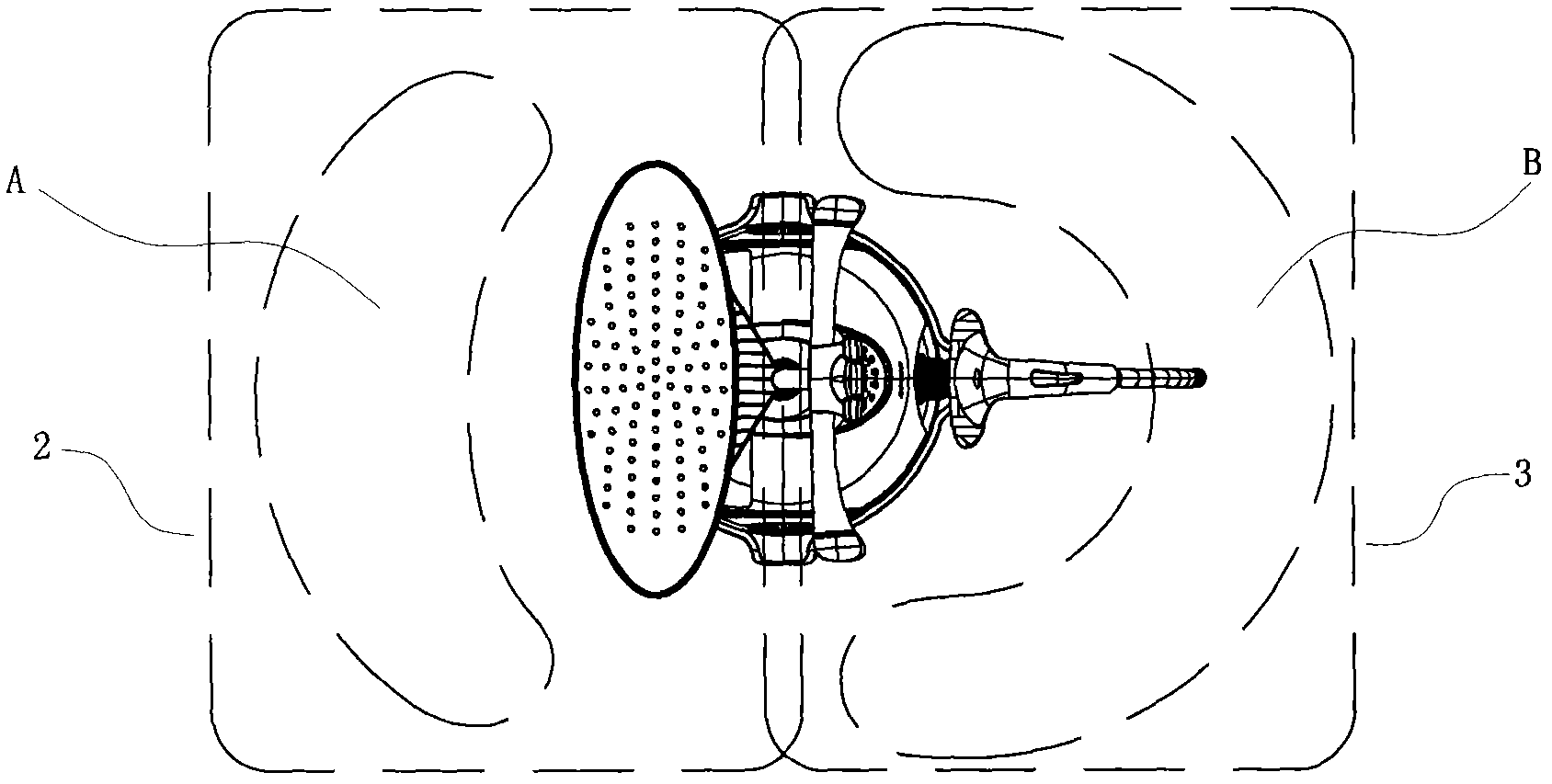

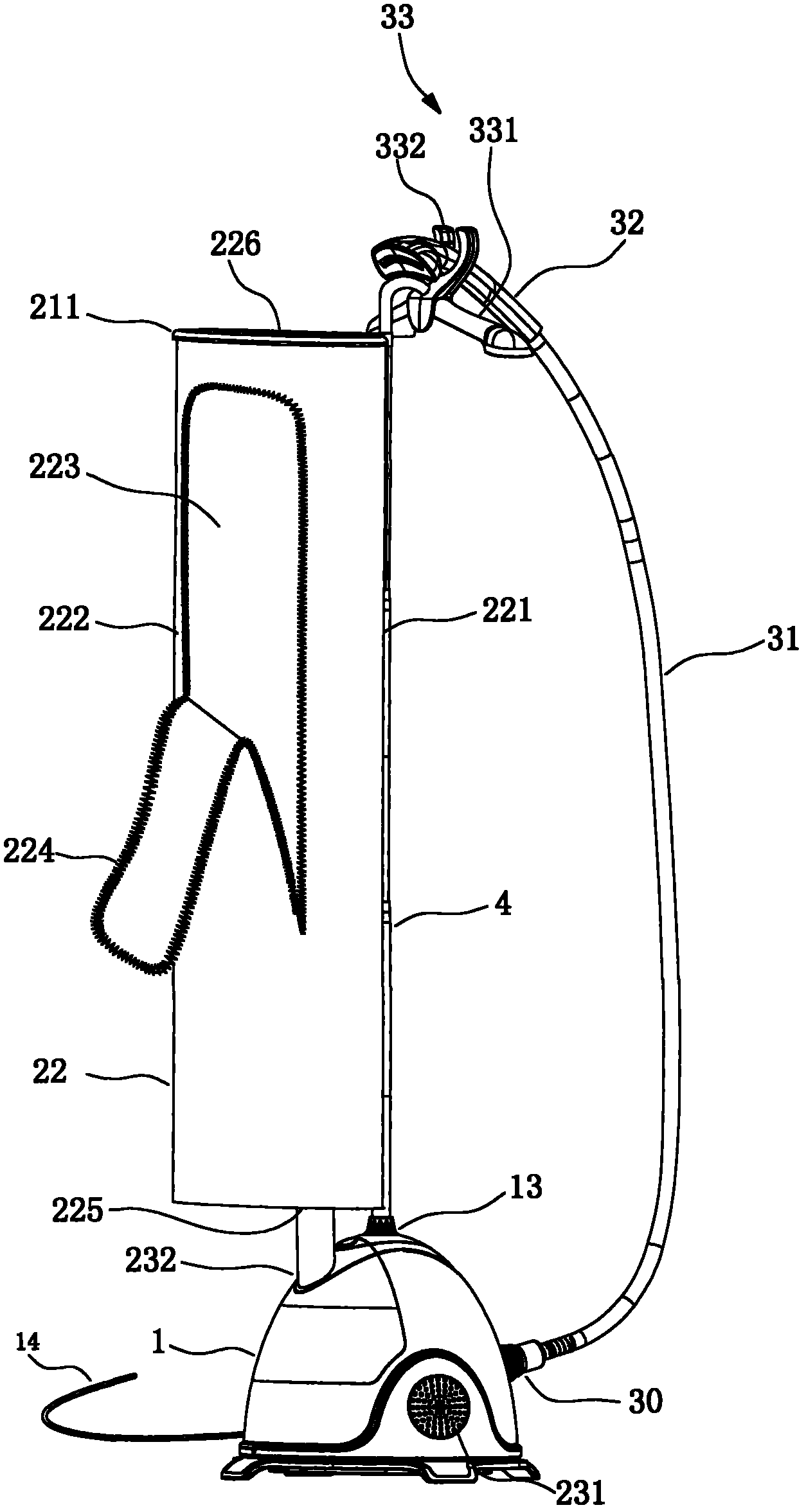

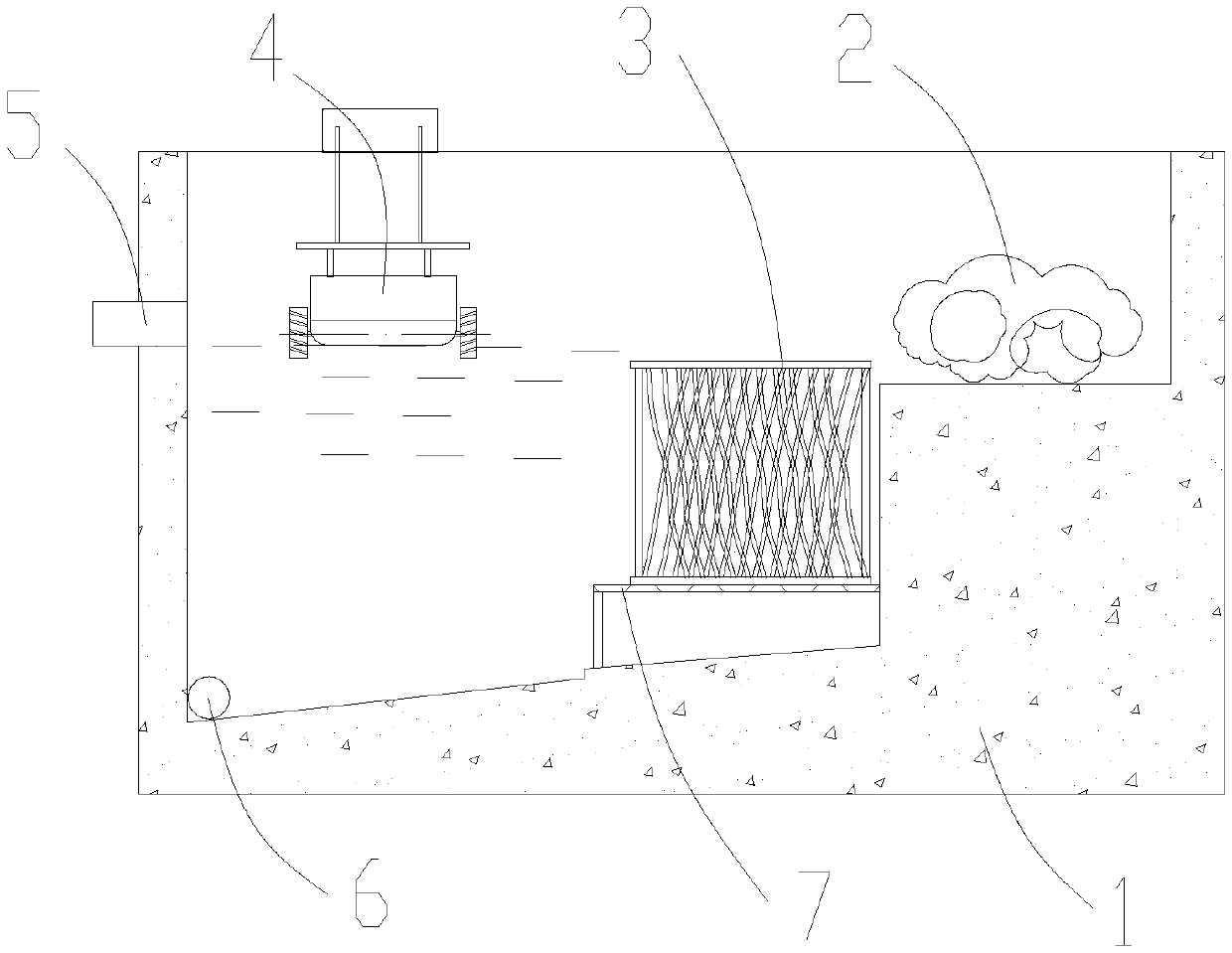

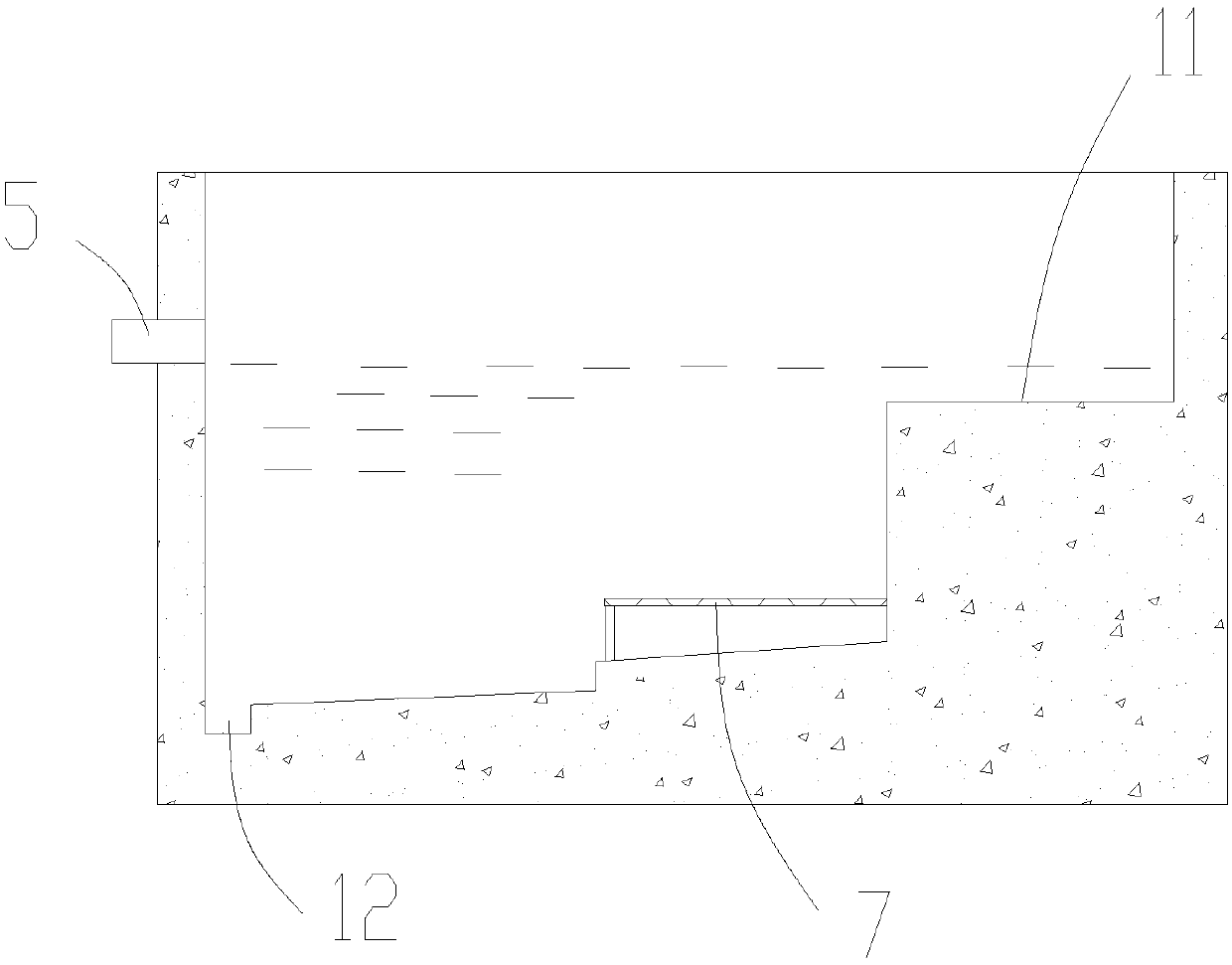

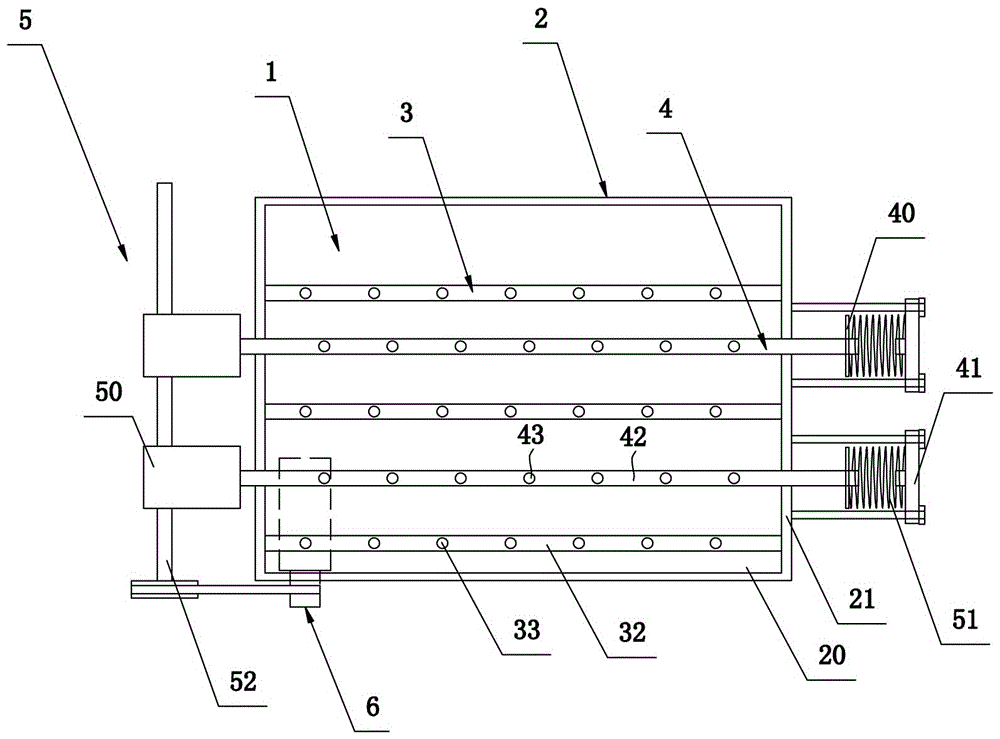

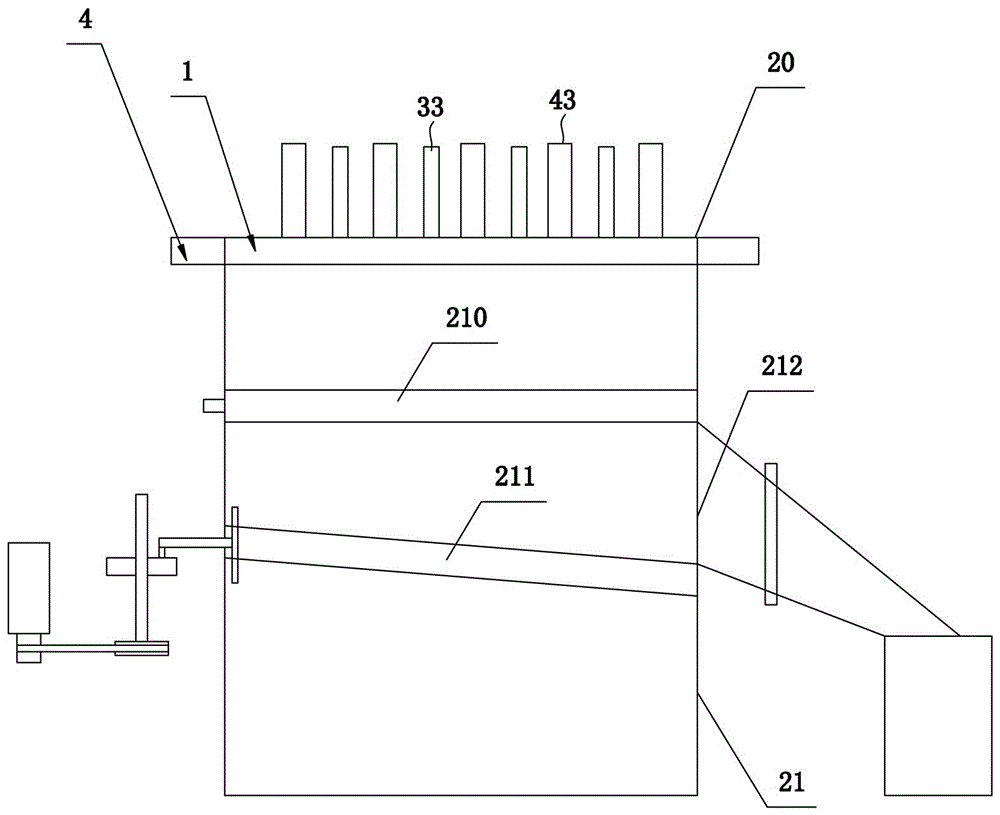

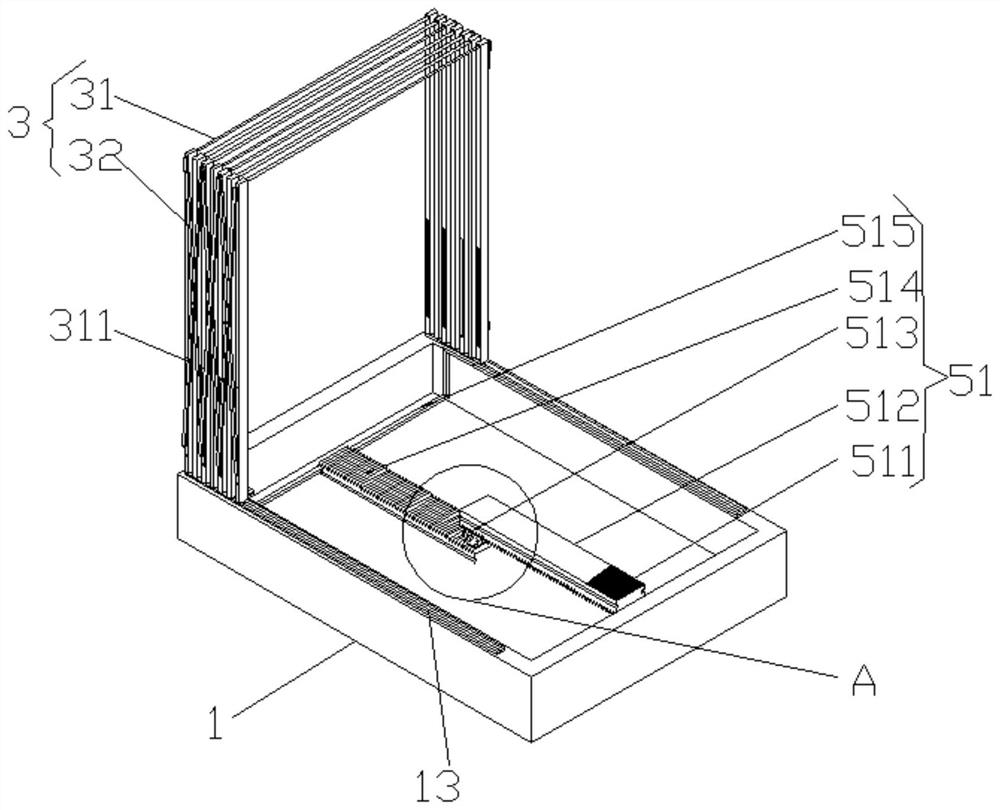

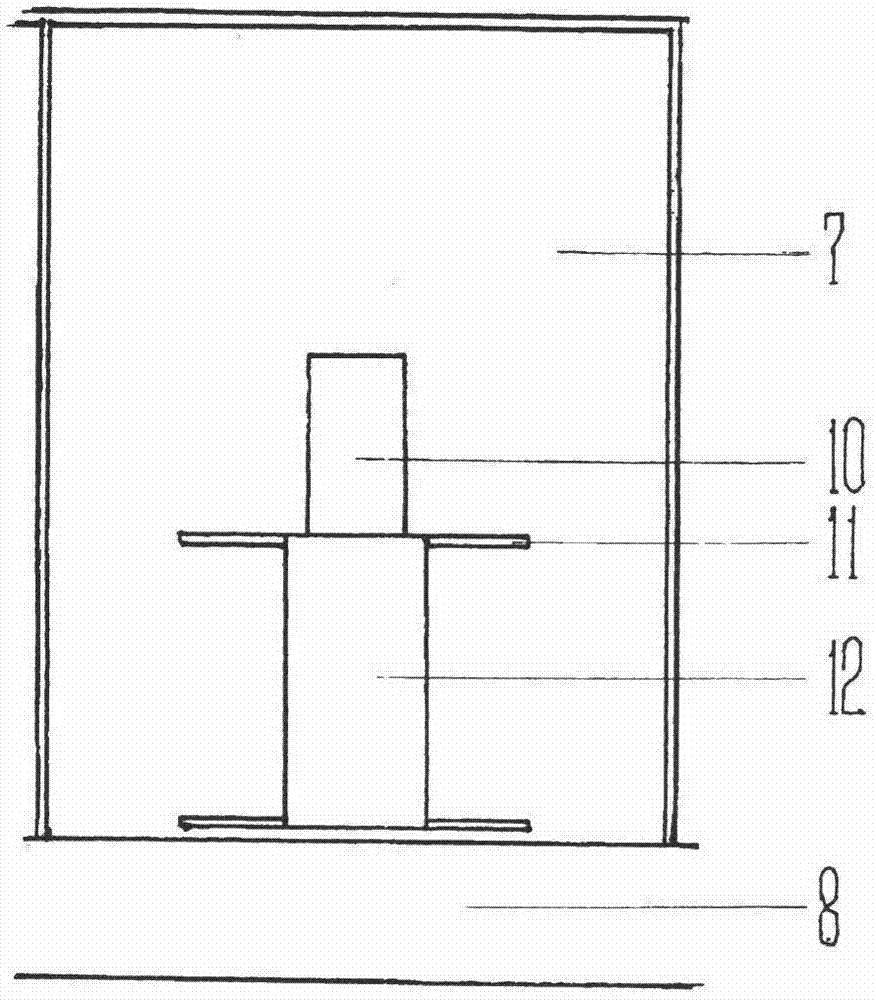

The invention discloses a drying and ironing integrated machine, comprising a support body, a vertical column position on the support body, a drying unit and an ironing unit. The drying unit comprises a drying frame part, a cover body and a heating part, wherein the drying frame part is fixed on the upper end of the vertical column, the cover body is supported on the drying frame part and naturally drops along one side of the stand column to form an accommodating space, the heating part is used for supplying hot air to the accommodating space, an air outlet interface of the heating part is in sealed and through communication with an air inlet of the cover body, and a drying area is formed on the drying unit adjacent to one side of the vertical column; and the ironing unit comprises an ironing device and a coat hanger, wherein an ironing area is formed on the ironing unit adjacent to the other side of the vertical column. The drying and ironing integrated machine can be used for ironing and drying clothes at the same time, ironing and drying are not interfered with each other, so that the capability of the machine in processing dry and wet clothes, the use convenience is promoted, the operation difficulty in a use process is improved, energy waste is completely eliminated, less space is occupied, and the drying and ironing integrated machine is particularly suitable for being widely applied to families with small houses.

Owner:胡杰波

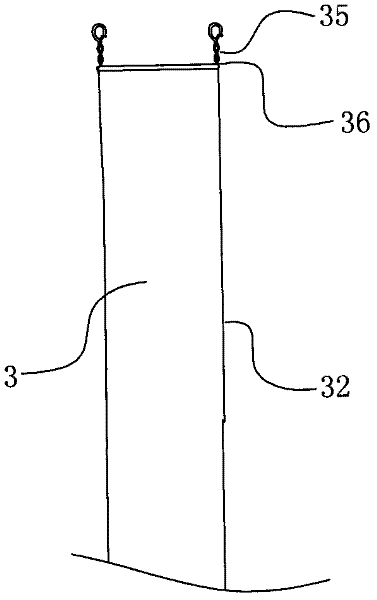

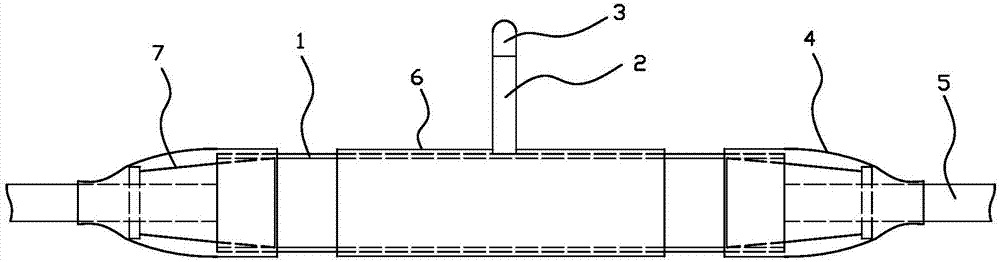

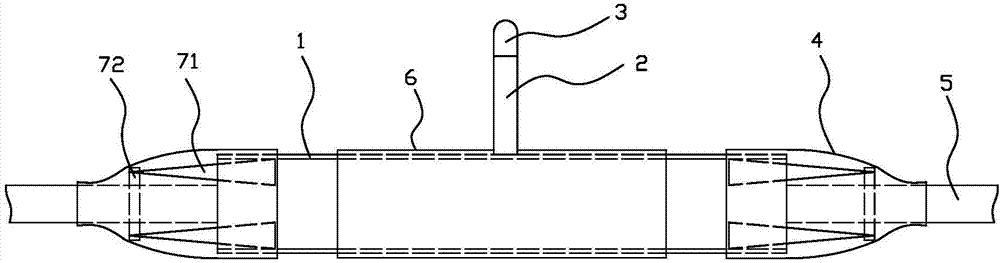

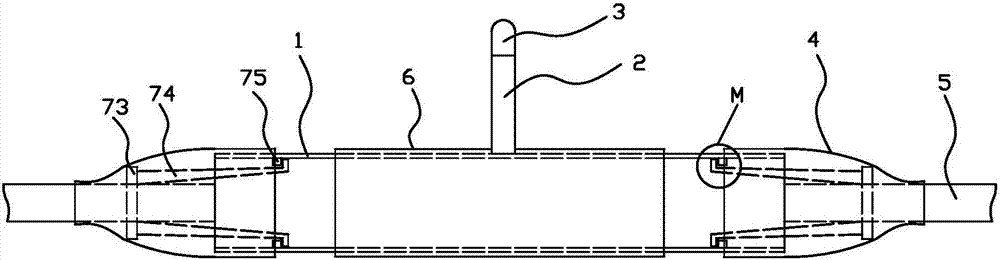

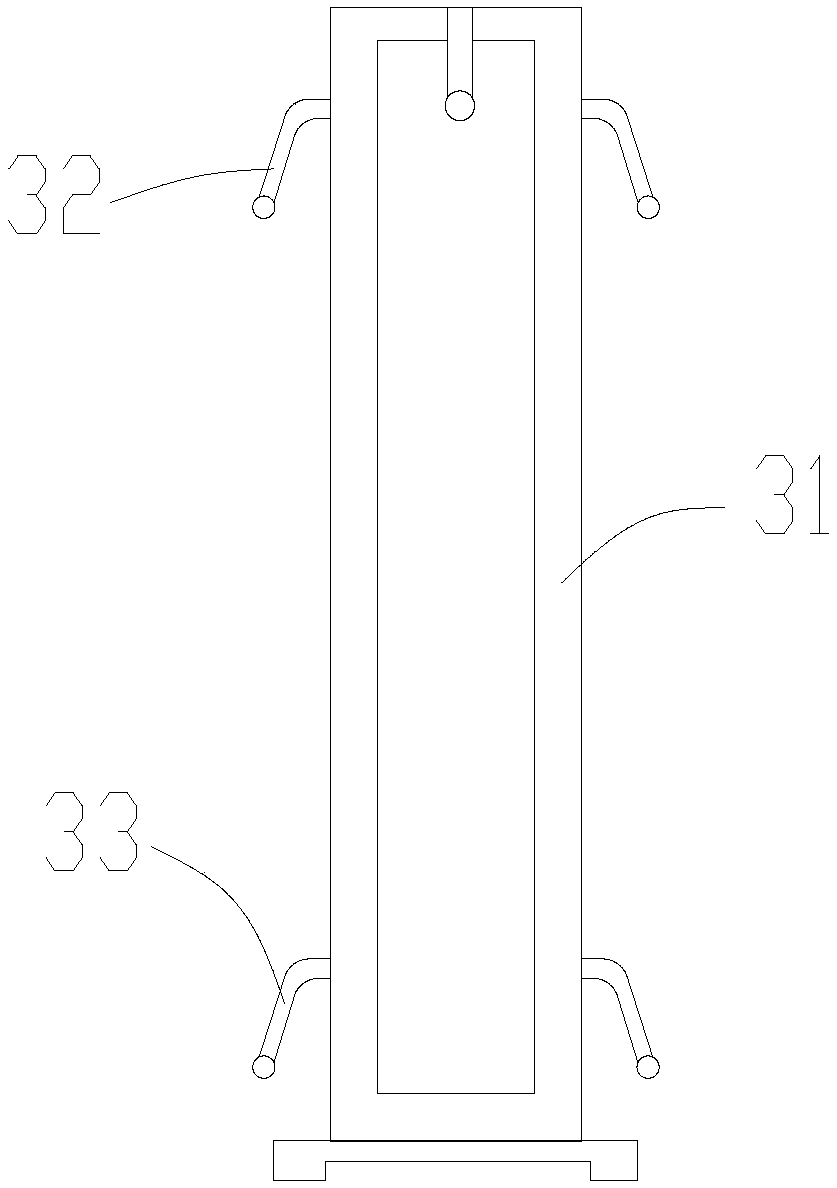

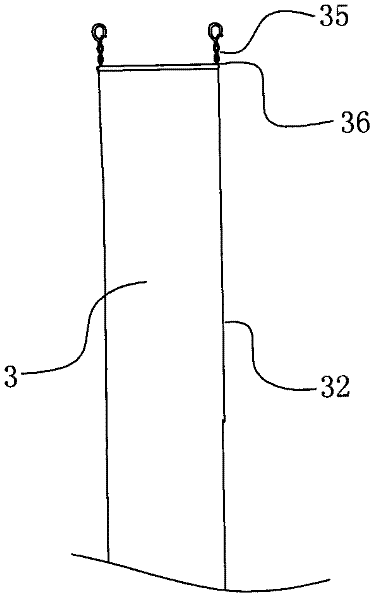

An all-in-one drying and ironing machine

ActiveCN102268805AReduce inconvenienceTake up less spaceHand ironTextiles and paperEngineeringAirflow

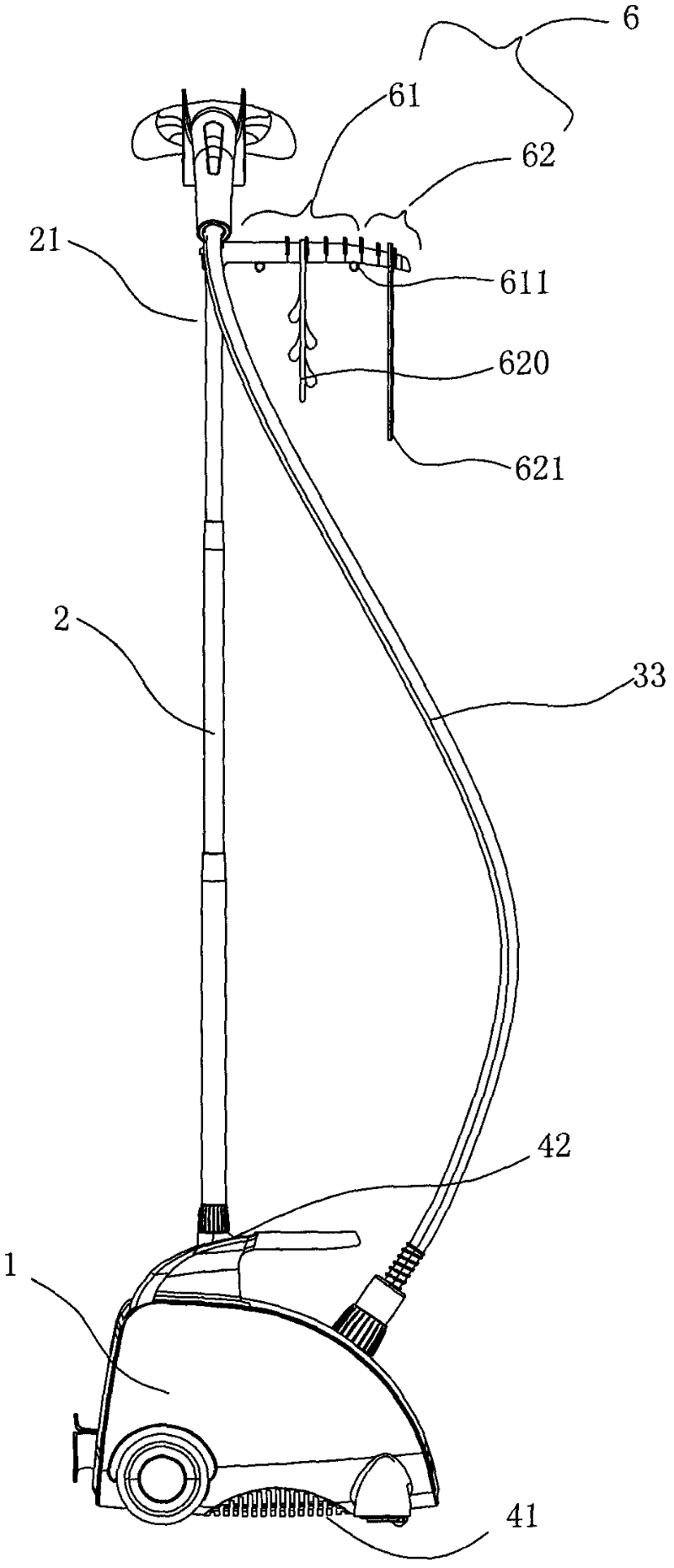

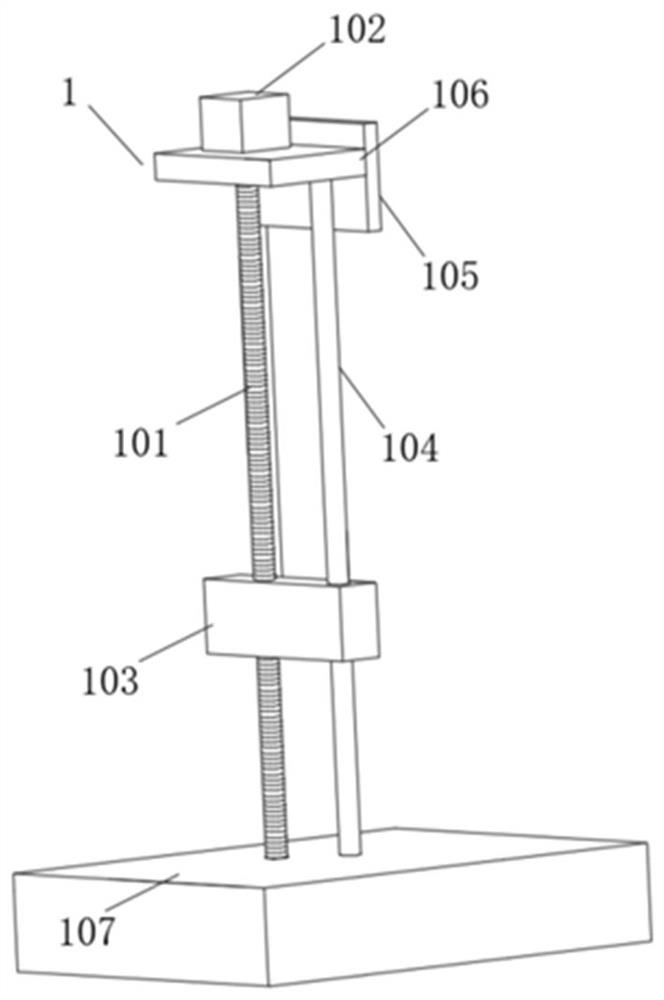

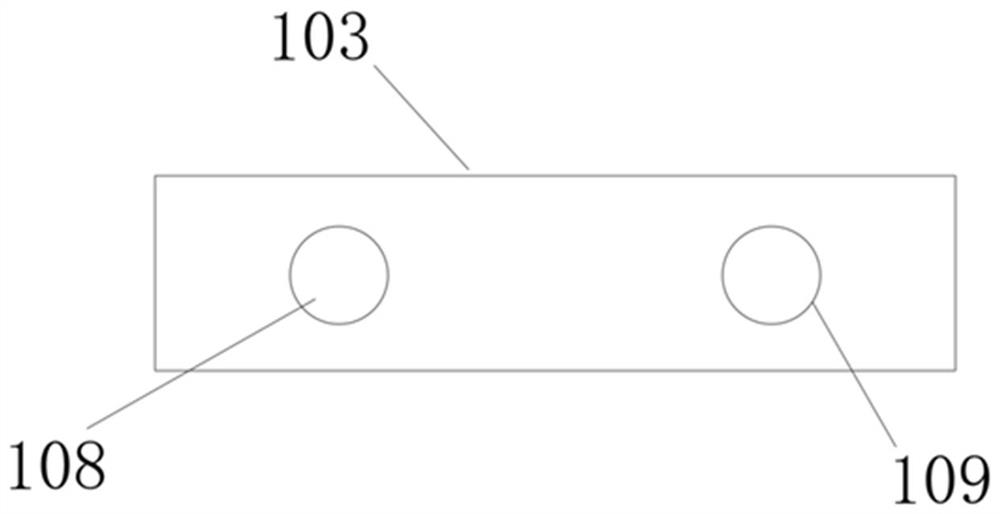

A drying and ironing integrated machine is provided, which comprises a supporting body(1),an upright post(2)with the lower end thereof fixed to the supporting body(1),a cover body(3)forming a accommodation space(33) between the back face(31) and the front face(32) thereof, a heating component for supplying hot air to the accommodation space(33) to dry clothes, and a steam ironing device. It further comprises a bracket component(6) connected with the upper end of an upright post(21),wherein the bracket component(6) is provided with a first branch arm(61) extending toward spaces at one side of the upright post(2) and a second branch arm(62) adjacent to the first branch arm(61) and extending in the extension direction of it. The cover body(3) is suspended on the first branch arm(61) and hangs down naturally under the first branch arm(61), and the front end of the second branch arm(62) extends to the outside space in front of the cover body(3) to form an ironing suspension part(6A). The drying and ironing integrated machine can realize ironing and drying of clothes at the same time without any mutual interference between both, improve the capability to handle dry and wet clothes and also be beneficial to the occupied space reduction, especially suitable to be widely used in families with small-space houses.

Owner:胡杰波

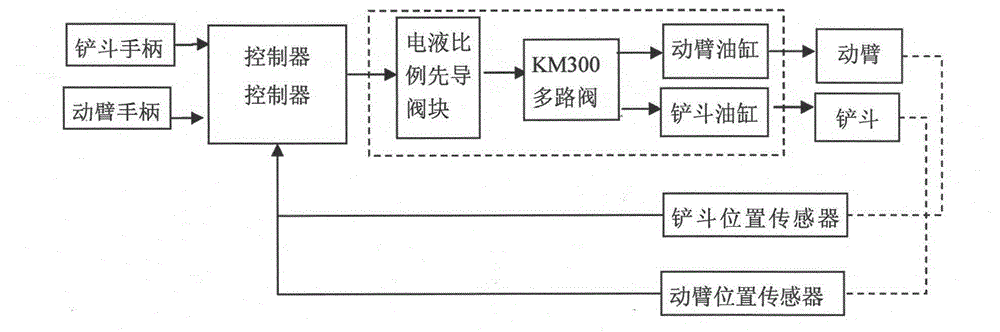

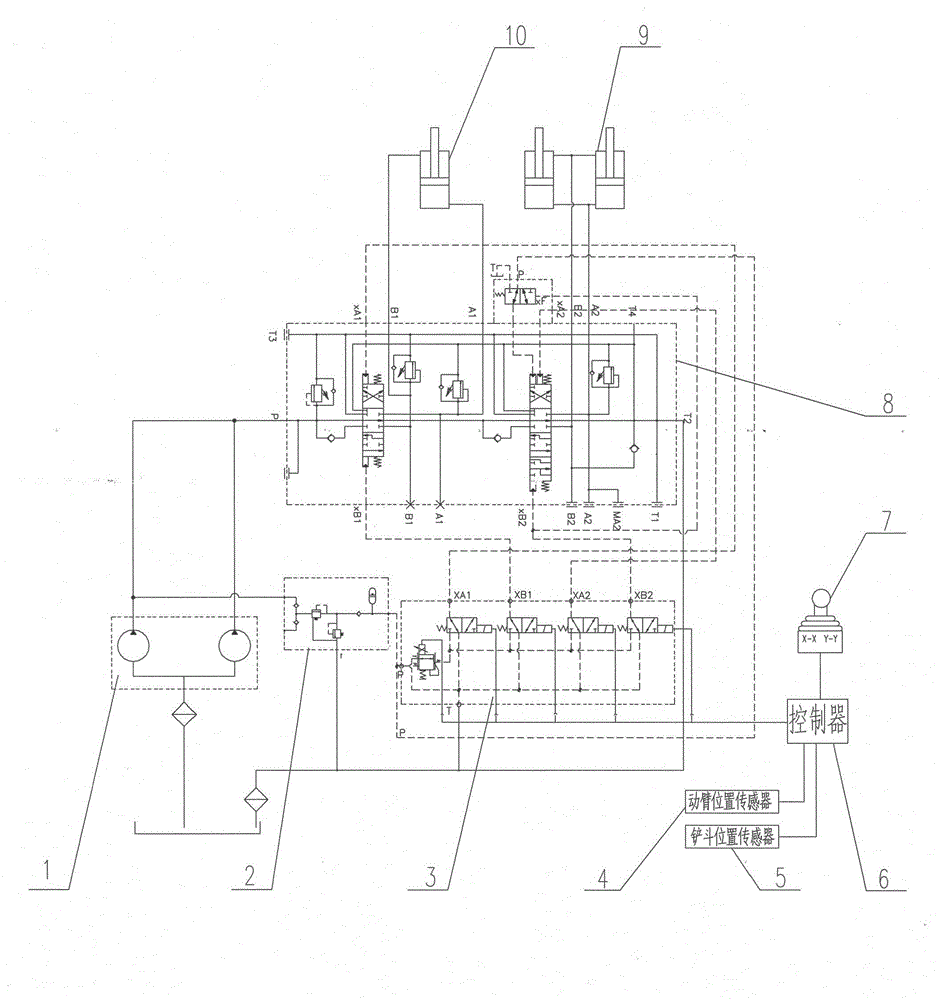

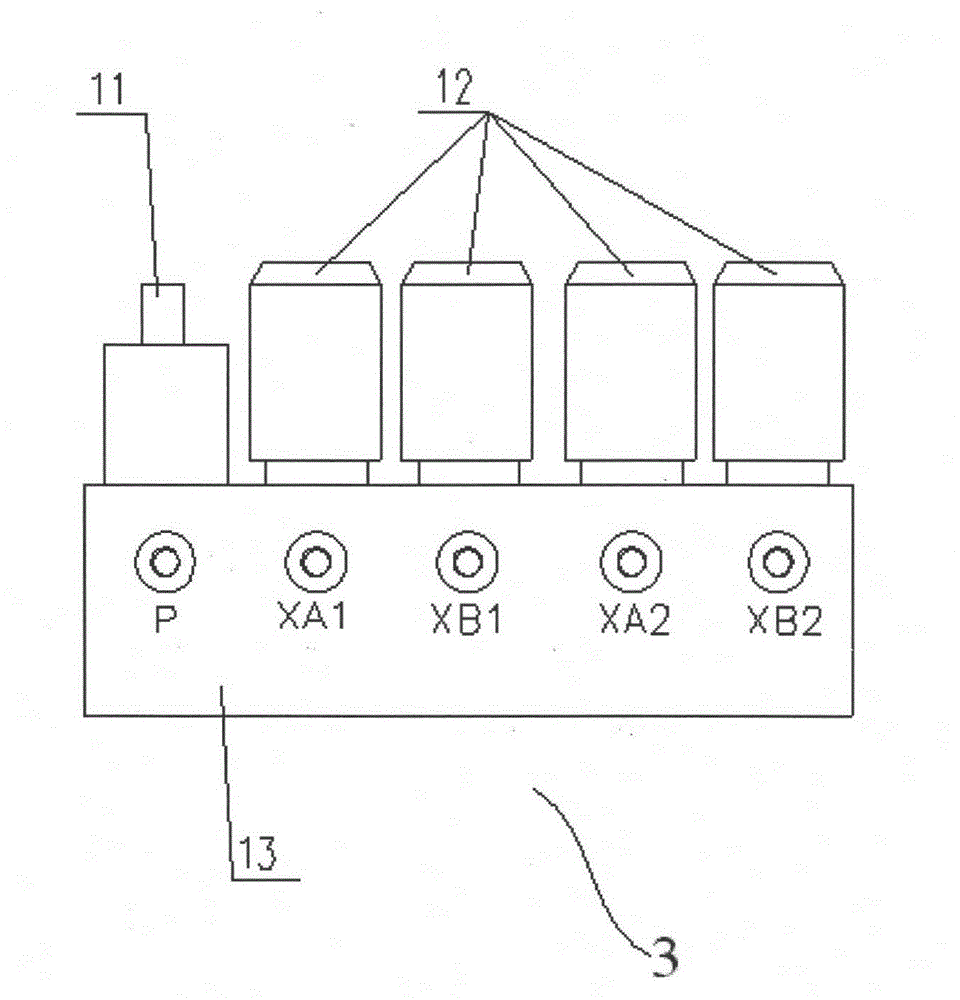

Electro-hydraulic proportional control system and method of working device of loader

InactiveCN103334463ARealize electro-hydraulic proportional controlImprove control effectMechanical machines/dredgersProduction rateProportional control

The invention provides an electro-hydraulic proportional control system of a working device of a loader. The system comprises a controller, wherein the controller is connected with an electric control handle, a movable arm position sensor, a bucket position sensor and an electro-hydraulic proportional pilot valve block, and a movable arm oil cylinder and a bucket oil cylinder are connected with the electro-hydraulic proportional pilot valve block by a KM300-2 multiway valve. The invention further provides a control method of the electro-hydraulic proportional control system of the working device of the loader. The control method comprises the steps of controlling output of the electro-hydraulic proportional pilot valve block according to an electrical signal generated by the electric control handle and position feedback of the movable arm position sensor and the bucket position sensor, controlling a valve core of the KM300-2 multiway valve to move, further controlling the extension of the movable arm oil cylinder and the bucket oil cylinder, and therefore realizing the motion control of a movable arm and a bucket. The system overcomes defects in the prior art, improves the control performance of the loader, reduces the labor intensity of an operator, improves the precision of operation control, increases the production rate, and has the characteristics of simple layout, small occupied space and pipeline saving.

Owner:龙工(上海)机械制造有限公司

Hard alloy sintering process and degumming and vacuum sintering integrated furnace

InactiveCN101596596AAvoid the disadvantage of easy oxidationImprove sintering qualityMuffle furnacesRetort furnacesProduct gasVacuum pump

A hard alloy sintering process comprises the following steps: filling moulded workpiece in a sintering chamber, starting vacuum pump to vacuumize and starting glue pump, raising temperature to 330 to 350 DEG C, making adhesive gasify, at the same time, pumping the gasified adhesive gas from sintering chamber by glue pump, and then, continuously raising temperature to 630 to 660 DEG C, making furnace-residual adhesive gas crack, after finishing degumming, continuously vacuumizing to 140 to 160 Pa and raising temperature to 1410 to 1480 DEG C, at last finishing sintering. The degumming and vacuum sintering integrated furnace of the invention comprises: a furnace, a heat preservation box, a sintering chamber, an adhesive tank, a glue pump and a vacuum pump. The invention has rational design, simple device structure, convenient operation and integration of degumming and vacuum sintering for effectively improving the product sintering quality, shortening sintering period, saving energy resource and reducing product sintering cost. The furnace is a novel product fit for replacing the current hard alloy sintering device because of wide sintering product range, low device cost and safe production process.

Owner:株洲楚天硬质合金股份有限公司

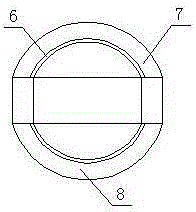

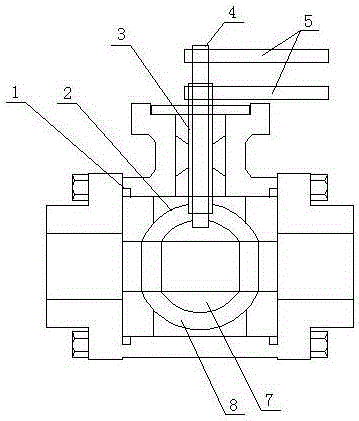

Ball valve

ActiveCN105156712AReduce volumeSmall volumePlug valvesMultiple way valvesSafety coefficientBall valve

The invention discloses a ball valve. A combined valve ball comprises an outer valve ball arranged on the outer layer, an inner valve ball is arranged inside the outer valve ball, and the inner valve ball and the outer valve ball are connected in a rotating mode along the axis of a valve rod. The ball valve comprises a ball valve body, the combined valve ball and operating mechanisms. The combined valve ball is arranged inside the ball valve body, the outer valve ball inside the combined valve ball is connected with the operating mechanisms through an outer ball connecting part, and the inner valve ball is connected with the operating mechanisms through an inner ball connecting part. The double-valve-ball ball valve is small in size, low in cost and easy and convenient to operate synchronously and consumes a few materials. Operation and selection are diversified, the service life of the single ball valve is effectively prolonged to two or more times, and therefore the cost is greatly lowered. The ball valve is simple, convenient to use, practical, small in size, low in cost, high in safety coefficient and worthy of being applied and popularized widely.

Owner:SHANGHAI HUGONG VALVE FACTORY (GRP) CO LTD

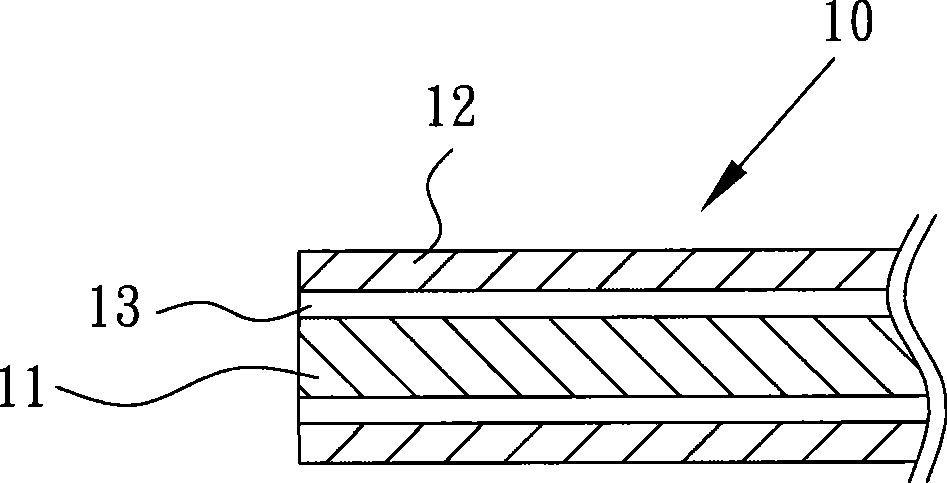

Electro-acoustic conversion device and diaphragm thereof

InactiveCN101453681AOmit to useReduce time-consuming and labor-intensive processesElectrical transducersElectric energyEngineering

The invention provides an electroacoustic conversion device and a vibrating diaphragm. The electroacoustic conversion device comprises a shell, a magnetic loop device, a sound coil and a vibrating diaphragm, wherein the magnetic loop device is arranged in the shell and can generate a magnetic loop; the sound coil is arranged on a route of the magnetic loop and can receive electric energy to generate magnetism; and the vibrating diaphragm is fixedly arranged in the sound coil and made of metal material, and the cross section of the vibrating diaphragm is continuous concave-convex-shaped. When the sound coil of the electroacoustic conversion device generates the magnetism by the electric energy, by the interaction of the sound coil and the magnetic loop, the vibrating diaphragm is caused to vibrate to make a sound. The vibrating diaphragm is arranged in the electroacoustic conversion device and made of metal material, and the cross section of the vibrating diaphragm is continuous concave-convex-shaped. The vibrating diaphragm is directly processed only by a metal plate, thereby saving conventional foam material and further reducing flow; moreover, due to the arrangement of the concave-convex pattern, the vibrating diaphragm can withstand bigger stress and is easily developed toward thinness, and when the vibrating diaphragm is used in the electroacoustic conversion device, the space occupied by the vibrating diaphragm is reduced.

Owner:MERRY ELECTRONICS CO LTD

Stell cable chain band type combined mining machine with driving, conveying, ventilating and signalling functions

InactiveCN1786415AReduce running resistanceReduce energy consumptionSlitting machinesTunnel/mines ventillationEngineeringLinearity

The invention relates to cable chain belt type digging carrying ventilating massage sending combination mining machine. Its main equipment is concave slice link line linearity. Its cross section is far less than common digging machine. The freight volume with 4km / h slow speed can exceed megaton per year. The supporting is also used as main air supplying pipeline or pouring water to prevent fire and the drainage machine is saved. The steel chains could also use to uncut communication channel or constant speed transferring power, or used as track to prevent tank do harm to the road.

Owner:罗晓晖

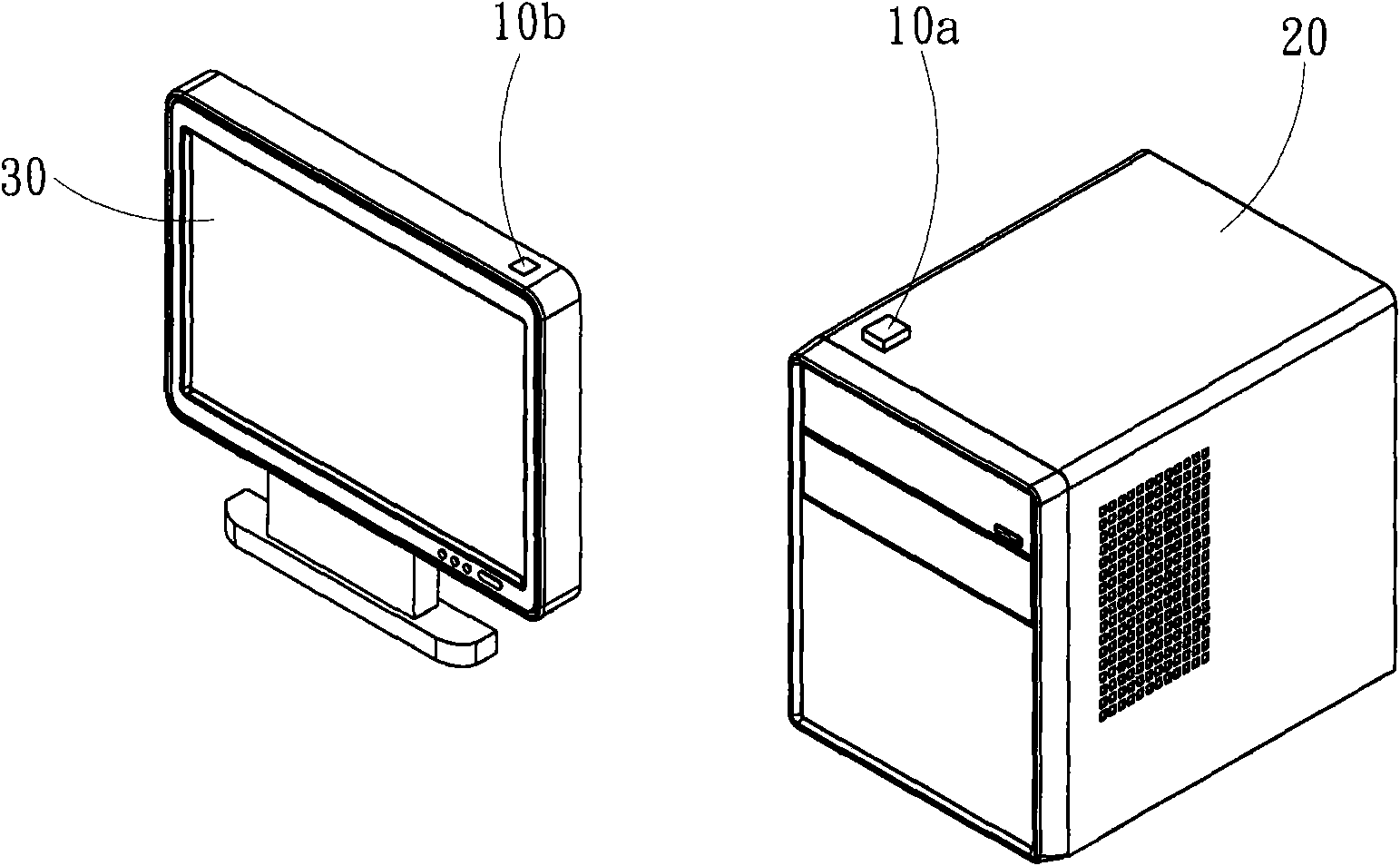

Wireless display system

InactiveCN101566938AAvoid confusionTake up less spaceDigital data processing detailsCathode-ray tube indicatorsComputer hardwareWireless transmission

The invention relates to a wireless display system which is provided with at least one information supplying unit, a display unit, an identification code generating unit and an identification unit, wherein the information supplying unit carries out wireless transmission through a wireless transmission module; the identification code generating unit is arranged in the information supplying unit; the identification unit is arranged in the display unit; the identification code generating unit is used for generating an identification code which corresponds to the information supplying unit for the display unit; and the identification unit is used for receiving the identification code, verifies the received identification code through an authentication database and back feeds a connecting signal to the identification code generating unit to enable the display unit to receive and display image information generated by the information supplying unit through the wireless transmission module when the identification code conforms to the verification of the authentication database. Because the display unit only carries out the wireless image information transmission with the corresponding information supplying unit, the invention avoids the problem of signal confusion caused by receiving image information from different sources.

Owner:SHUTTLE

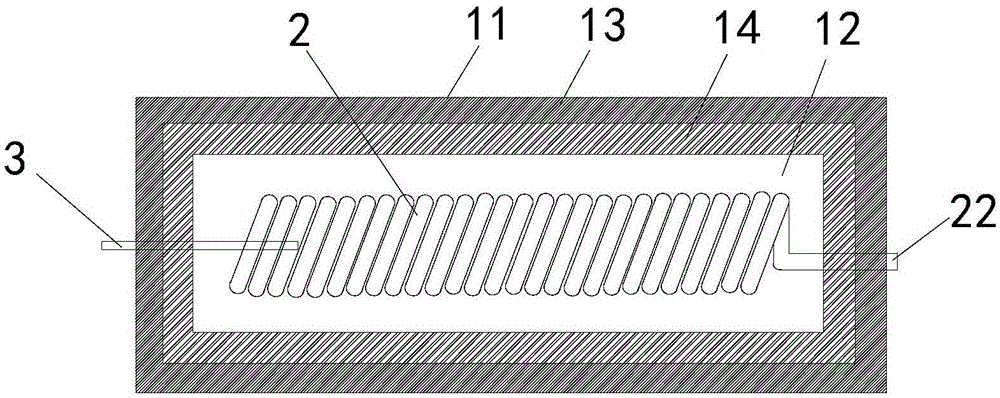

Phase change energy storage electric water heater

InactiveCN105003950AIncrease the heat exchange areaFast heat transferHeat storage plantsCentral heating systemEngineeringWater cooling

The invention provides a phase change energy storage electric water heater, which comprises a water tank and a heat exchange coil and electric heating rods arranged in the water tank. The heat exchange coil is a multilayer horizontal spring coil, and the electric heating rods are arranged in a layering manner corresponding to the multilayer horizontal spring coil. The water tank comprises a shell and a liner, a heat preservation layer and a phase change material energy storage layer are arranged between the shell and the liner sequentially from outside to inside, the heat exchange coil is arranged in the liner, and the liner is filled with a heat aid. The phase change energy storage electric water heater is good in heat exchanging effect, high in heat exchanging speed, slow in water cooling, capable of saving energy and water, capable of realizing heating in a layering manner, and capable of making into water heaters in different sizes and with different usages.

Owner:许求鑫

Cable joint reinforcing device

ActiveCN107104413ATake up less spaceDoes not affect cast workCable junctionsMechanical engineeringEngineering

Owner:YANGZHOU JIANGDU POWER SUPPLY COMPANY OF JIANGSU ELECTRIC POWER +2

A new type of explosion-proof device for intermediate joints of cables

ActiveCN105576596BTake up less spaceDoes not affect cast workCable junctionsEngineeringMechanical engineering

Owner:YANGZHOU JIANGDU POWER SUPPLY COMPANY OF JIANGSU ELECTRIC POWER +2

Aquatic product farm water quality oxygenation purification pool

InactiveCN107751082AEnsure safetyTake up less surface spaceWaste water treatment from animal husbandryPisciculture and aquariaSolar lightWater quality

The invention discloses an aquatic product farm water quality oxygenation purification pool, which comprises a pool body with a step bottom surface. The aquatic product farm water quality oxygenationpurification pool is characterized in that impact rock is arranged in a water inlet position of the pool body; a biological bacterium nesting mechanism is arranged in the pool body; a linear guide rail is arranged at the upper part of the pool body in the length or width direction of the pool body; an oxygenation boat is installed; a solar light plate is arranged on the boat; the top of the boat is provided with a guide wheel matched with the linear guide rail; a negative pressure pollution cleaning pipe is arranged in the lowest position of the bottom of the pool body; the guide wheel is connected with the boat body through a telescopic pull rod. Through the arrangement of the impact rock, the biological bacterium nesting mechanism and the oxygenation boat the effects of obtaining oxygenation, pollution removal, cleaning, trace element supplementation and the like in the whole aquatic product culture process are achieved; through the design of the inclined pool bottom, the pool body has certain self deposition concentration capability; the fast treatment is realized by the negative pressure pollution cleaning pipe; running water can be provided for the aquatic product culture purewater circulation systems; the guarantee is provided for green food production.

Owner:湖州森德高新材料有限公司

Tool for detecting hydraulic pipe on forklift

InactiveCN109141326AEasy to controlAccurate measurement dataMeasurement devicesHollow article cleaningForeign matterEngineering

The invention discloses a tool for detecting the hydraulic pipe on a forklift, and the tool comprises a main body. The external surface of the upper end of the main body is fixedly provided with a display screen, and one side of the display screen is provided with a power switch. The external surface of one side of the main body is fixedly connected with a first wire, and one end, far from the main body, of the external surface of one end of the first wire is fixedly connected with a plug. The external surface of the front end of the main body is provided with an accommodation groove, and theexternal surface of the upper end of the accommodation groove is fixedly provided with a fixed platform. The external surface of the upper end of the fixed platform is fixedly provided with a spring column. The tool provided by the invention can detect the type of foreign matters in the hydraulic pipe and clear the foreign matters, can achieve the functions simultaneously through simple control, and is more convenient and reasonable for the measurement of the basic data of the hydraulic pipe. The accommodation of a flow sensor is more reasonable, and the wire connected with the flow sensor canbe conveniently arranged.

Owner:安徽双兴机械有限公司

Scanning positioning target

The invention provides a scanning positioning target. The scanning positioning target comprises a conversion target and a base, the conversion target is used for controlling conversion of coordinates and scanning coordinates and comprises a target sphere, a reflecting prism and a connecting rod, a groove used for installing the reflecting prism is formed in the target sphere, one end of the connecting rod is connected with the target sphere, and the other end of the connecting rod is connected with the base; the base is used for connecting the conversion target with the scanning target supporting frame and comprises a base body and an illuminating lamp, the upper end of the base body is provided with a target connecting column used for being connected with the connecting rod, and the lower end of the base body is provided with a bottom connecting column used for being connected with the scanning target supporting frame; and the illuminating lamp is arranged on the base body and is used for providing light for the conversion target, especially the reflecting prism, so that the influence of a dark light environment on the conversion measurement work of the control coordinates and the scanning coordinates is avoided.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH +1

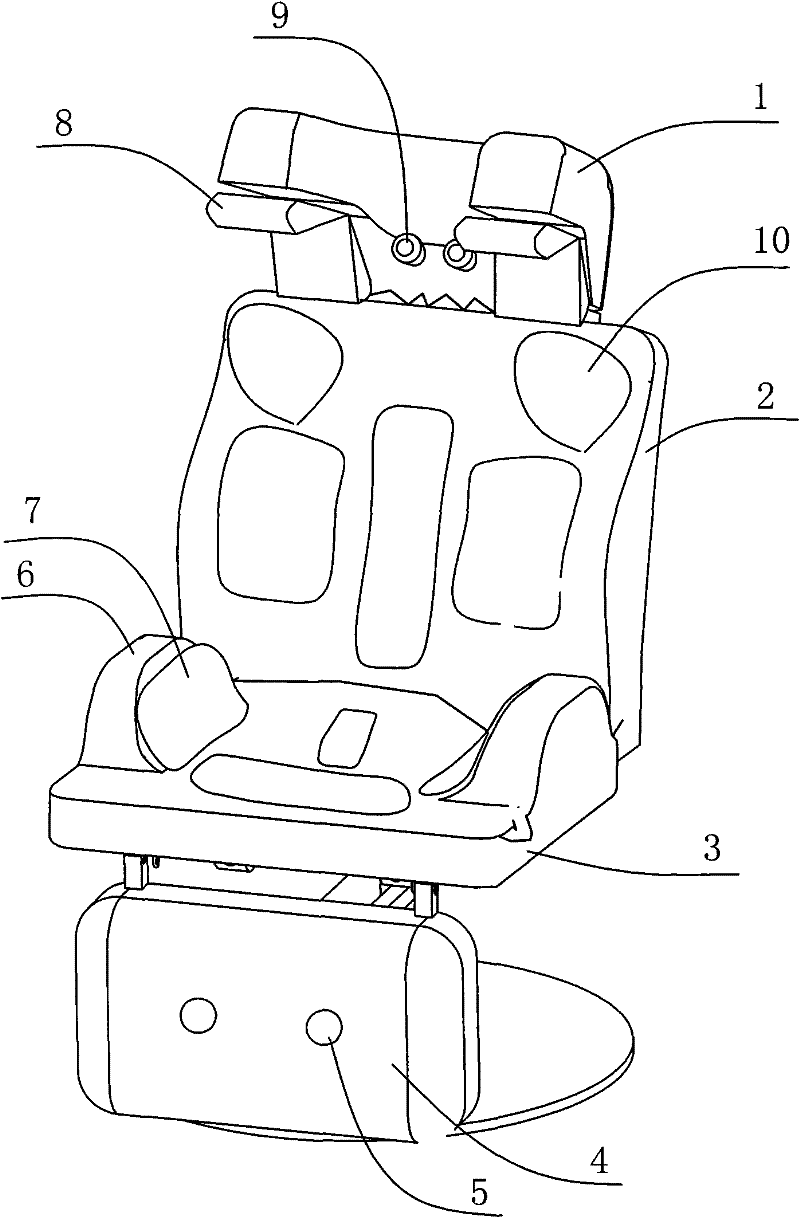

Leisure massage chair

InactiveCN101904797BImprove comfortDoes not interfere with free movementDevices for pressing relfex pointsVibration massageHuman bodyPhysical medicine and rehabilitation

The invention discloses a leisure massage chair. The upper part of a backrest of the leisure massage chair is provided with a shoulder-neck massager for massaging shoulder and neck parts of a human body, the shoulder-neck massager can be turned backwards along the backrest of the leisure massage chair and folded for collection, and the shoulder and neck parts of the shoulder-neck massager are provided with an air bag massager and an electric hammer massager capable of being adjusted along the shoulder breadth direction of the human body; the backrest part, a seat cushion part and a foot part of the leisure massage chair are provided with an air bag massager and an electric hammer massager; when a seat frame of the backrest part of the leisure massage chair is turned backwards, a seat frame of the foot part of the leisure massage chair can be lifted therewith so that the whole massage chair is horizontally spread; a foot cushion block arranged on the seat frame of the foot part can slide along with the lifting of the seat frame of the foot part; and the seat cushion part of the leisure massage chair is provided with lug bosses jointed with two sides of the hip of the human body. Because the leisure massage chair is provided with the turnover folding shoulder-neck massager, the leisure massage chair has complete function and convenient use, can fully and three-dimensionally massage a user and furthest meet the comfortableness requirement of the user, and has high grade.

Owner:北京卓雅信科技发展有限公司

Electric power engineering pipeline and construction method thereof

ActiveCN111614056ATake up less spaceEasy to transport and storeCable installations in underground tubesApparatus for laying cablesPower engineeringEngineering

The invention discloses an electric power engineering pipeline and a construction method thereof. According to the technical scheme, the electric power engineering pipeline comprises an outer pipe, and telescopic pipes are connected to the left and right ends in the outer pipe; and the inner ends of the two telescopic pipes are connected with a moving assembly. A connecting assembly is arranged atthe outer ends of the telescopic pipes; the electric power engineering pipeline is characterized in that the moving assembly comprises two transmission rings located between the two telescopic pipesand rotationally connected with the inner side of the outer pipe. An operation assembly is connected to the transmission rings, the operation assembly can rotate the transmission rings, four guide shafts are fixed to the sides, opposite to each other, of the two transmission rings, the guide shafts are arranged in the pipe walls of telescopic pipes in a penetrating mode, the telescopic pipes are in threaded connection with the inner side of the outer pipe, and the threaded connection directions of the left telescopic pipe and the right telescopic pipe and the outer pipe are opposite. The length of the electric power engineering pipeline is easy to adjust, and people can transport and store the pipeline conveniently.

Owner:浙江康沃电力有限公司

Chain transmission type three-effect speed reducer

The present invention discloses a chain transmission type three function speed reducer, which is characterized in that an input axle and three output axles and three output axles respectively play the function of a speed reduction device, three speed reduction devices are integrated as a machine, thus being called the three function speed reducer.

Owner:张开瑞

Threshing machine convenient to use

A threshing machine convenient to use comprises a threshing mechanism and a grain containing box arranged under the threshing mechanism. The threshing mechanism comprises a plurality of fixed threshing rods which are arranged at intervals, movable threshing rods which are arranged between every two adjacent fixed threshing rods and can do axial back-and-forth movement and an intermittent driving assembly for driving the movable threshing rods to do back-and-forth movement. Due to the fact that the reciprocating translation type threshing machine is adopted, the equipment size and the occupied space are both smaller than those of an existing drum-type threshing machine, the cost is greatly reduced, and the carrying convenience of a user is improved; in addition, due to the fact that stems always stay over the threshing mechanism in the threshing process, grain impurities obtained in threshing are effectively reduced, and the threshing efficiency and quality are greatly improved; furthermore, misoperation basically cannot occur, and therefore injuries to the user in the threshing process can be effectively reduced.

Owner:张克泵

Intelligent telescopic hood

ActiveCN113585835ASolve the problem of shelter from wind and rainEffective protectionParkingsSimulationParking space

The invention provides an intelligent telescopic hood, and relates to the technical field of hoods; the intelligent telescopic hood comprises a parking space base; a protective cover is arranged on one side of the parking space base; a telescopic frame is arranged in the protective cover; tent cloth is mounted on the telescopic frame; a linkage mechanism is further arranged in the parking space base; the linkage mechanism is connected with the telescopic hood; and extension and contraction of the telescopic frame are opened in a linkage mode. According to the intelligent telescopic hood, due to the fixed hood, the problem that a vehicle is sheltered from wind and rain when the vehicle is parked in an outdoor parking space is solved; the problem that a piece of crotch cloth of a cover type structure is not effectively fixed and is easily blown up and even blown away by wind is solved; the telescopic frame of the telescopic hood is unfolded when the vehicle is parked by utilizing the linkage mechanism to connect the telescopic frame; the hood is effectively protected by switching between two states of retraction when the vehicle leaves; the utilization rate of the hood is improved; and the occupied space is small when the hood is not used.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Combined training device for fighting function of gamecocks

InactiveCN104839044ASimple structureEasy to manufactureTaming and training devicesSemi automaticEngineering

The invention provides a combined training device for the fighting function of gamecocks. The combined training device comprises a rearing cage group and a training cage group and is characterized in that a rubber band and a curtain for resisting gamecock pecking are disposed on each rearing cage of the rearing cage group, a running trainer cage, a jumping trainer cage, a striking trainer cage and a grabbing trainer cage which can be used in a combined manner and in an independent manner form the training cage group, and the training device which is scientific, systematic, comprehensive, complete and a standard is formed. Compared with the prior art, the combined training device has the advantages that traditional training manners through holding, tossing, throwing, casting, driving, hitting and the like are replaced by the automatic or semi-automatic training manner, time and labor are saved, training time and strength can be easily controller, training contents are systematic, comprehensive and complete, the training manner is standard, evident technical advantages and effects are achieved, and the combined training device is worthy of popularization and application.

Owner:靖江市华晟重金属防控有限公司

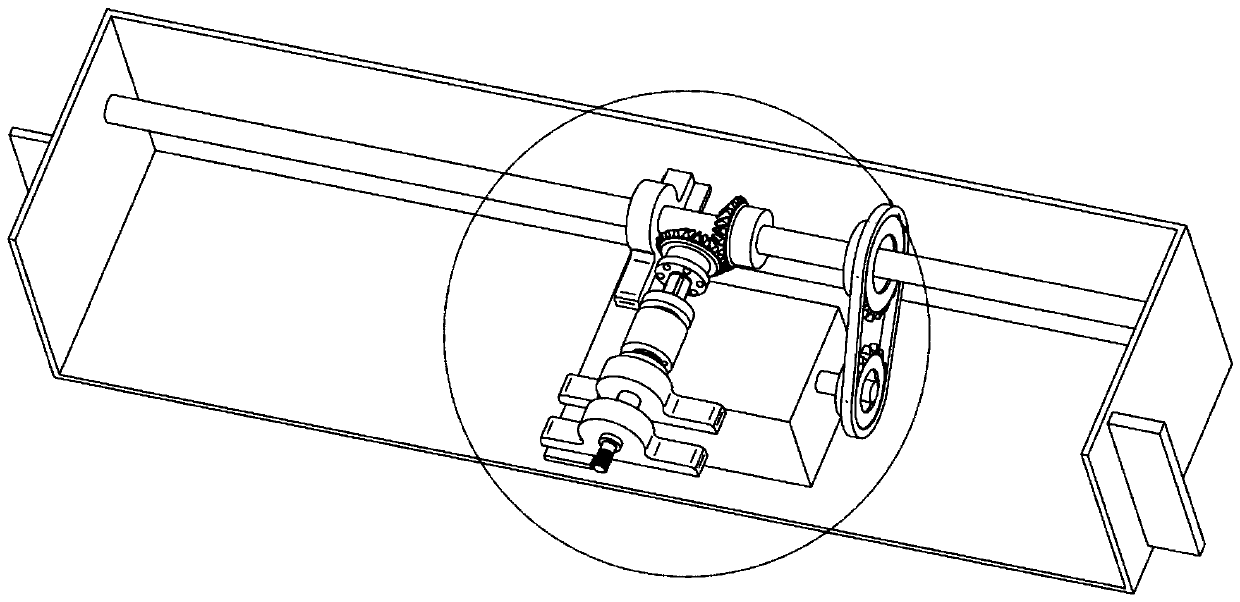

Automatic airing winding machine for fire hose

InactiveCN110465028ATake up less spaceReduce human inputFire rescueWebs handlingWinding machineEngineering

The invention discloses an automatic airing winding machine for a fire hose. The automatic airing winding machine for the fire hose comprises a box body, a frame body, a first drive device and a control mechanism, wherein a transmission mechanism, a braking mechanism and a winding mechanism are arranged on the box body, the braking mechanism is connected with the transmission mechanism, and the transmission mechanism is connected with the winding mechanism; the box body is arranged on the frame body and can move on the frame body; the first drive device is connected with the frame body; and the control mechanism is connected with the first drive device and the transmission mechanism. When the water hose is aired, the occupied space is small, after the drying is finished, the winding mechanism is controlled to wind the water hose by a control box, and when winding is completed, the braking mechanism can brake the transmission mechanism to stop winding, so that the manpower input is saved, and the winding machine is convenient to use and popularize.

Owner:丽水市莲都区林乃龙机械设备加工厂

Cable explosion-proof apparatus

ActiveCN107294047ATake up less spaceDoes not affect cast workCable junctionsEngineeringMechanical engineering

The invention relates to a cable explosion-proof apparatus. The invention provides a cable explosion-proof apparatus, being simple in structure, being convenient to mount and improving the safety. The cable explosion-proof apparatus includes a protection tube, an explosion stack, a thermal shrinkage sealing cap, a reinforcing assembly and a pair of thermal shrinkage sheathes, wherein the explosion stack is communicated with the protection tube, and is arranged at the center of the protection tube; the thermal shrinkage sealing cap sleeves the orifice of the explosion stack; the reinforcing assembly is arranged on the protection tube, and includes a pair of symmetrically arranged reinforcing groups; the pair of reinforcing groups are arranged at two sides of the explosion stack; and the reinforcing groups include a plurality of parallel separation blades; the pair of shrinkage sheathes are respectively arranged at the orifices of two ends of the protection tube; and the shrinkage sheathes successively sleeve the protection tube and the cable. The cable explosion-proof apparatus is convenient to process and is low in cost.

Owner:YANGZHOU JIANGDU POWER SUPPLY COMPANY OF JIANGSU ELECTRIC POWER +3

Drying and ironing all-in-one machine

ActiveCN102268805BReduce inconvenienceTake up less spaceHand ironTextiles and paperEngineeringAirflow

Owner:胡杰波

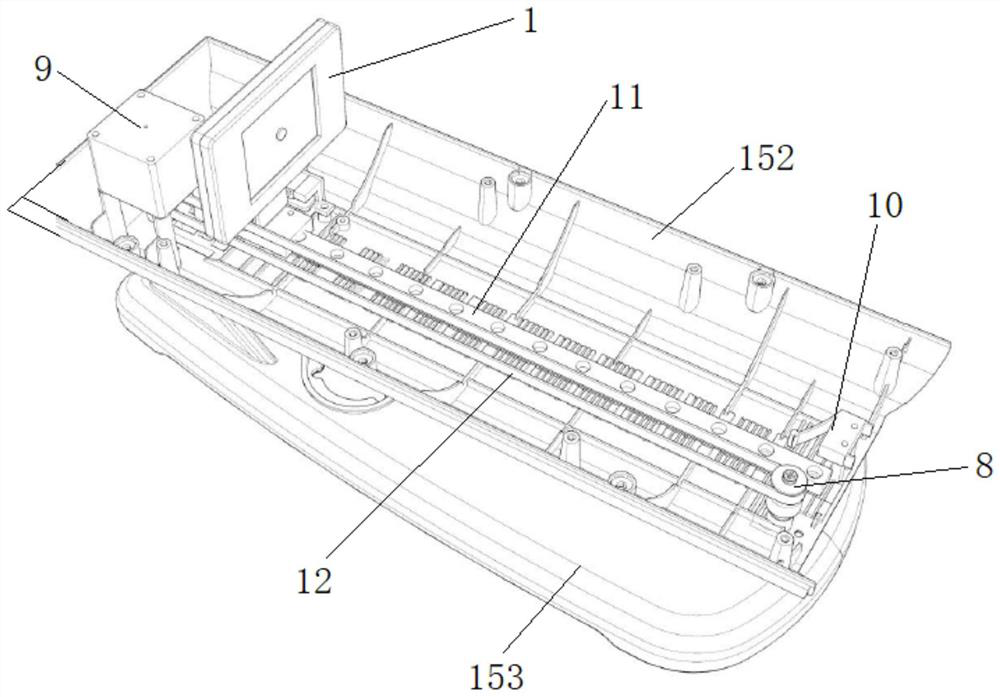

Ciliary muscle training device

PendingCN111888208AReach exerciseTo achieve the purpose of exercising the eye musclesEye exercisersAlarmsEyepieceDisplay device

The invention discloses a ciliary muscle training device. The device comprises a shell (15), a front window (6) arranged at the front end of the shell, a pair of eyepieces (3) detachably installed atthe front end of the shell and located in the front window, a training assembly and a controller arranged in the shell, and a control panel (14) installed on the shell and electrically connected to the controller; and the training assembly comprises a guide mechanism, a transmission mechanism installed on the guide mechanism and a displayer (1) moving back and forth along the guide mechanism through the transmission mechanism, and the guide mechanism is linearly arranged in the visual direction of the eyepiece, so that the displayer can always move within the visual range of the eyepieces. According to the invention, the training of fine adjustment ability and flexibility improvement of the crystalline lens form can be realized, visual impairment caused by defocusing is solved, the abilityof human eyes to see near, far and brain images is improved, the adjustment ability of eye muscle groups is improved, and the purposes of vision stability and normal visual state are realized throughcontinuous stimulation and activation of visual cells.

Owner:上海肃廉医疗设备有限公司

Large-size bag type dust collector without conical dust collection hopper

InactiveCN106492557ALower the altitudeReduced power unitDispersed particle filtrationEngineeringLarge size

The invention discloses a large-size bag type dust collector without a conical dust collection hopper. The large-size bag type dust collector is a large-size dust collector which consists of a plurality of box bodies arranged in parallel; the conical dust collection hopper is canceled; a container being about 1m in height is designed below middle box bodies, wherein the bottom of the container is sealed, and the container is connected with the middle box bodies; the length of the container is greater than the overall length of the large-size dust collector; the width of the container is equal to that of the dust collector; a scraper conveying machine is arranged in the container; an air inlet is formed in each middle box body; an air outlet is formed in each upper box body; and an ash discharge hole is formed in the head of the scraper conveying machine. By adopting the large-size bag type dust collector, the height of the dust collector is effectively reduced, a part of steel is saved, the space can be saved, and power devices for multiple ash discharge holes can be saved as only one ash discharge hole needs ash discharge power.

Owner:天津杰能道然环保科技有限公司

Offline overhaul bag type dust remover without cone-shaped ash deposition hopper

InactiveCN106492558ALower the altitudeReduced power unitDispersed particle filtrationMembrane filtersEngineeringPulley

The invention discloses an offline overhaul bag type dust remover without a cone-shaped ash deposition hopper. The off-line overhaul bag type dust remover is characterized in that a container with a height of about 1 m is designed under middle box bodies, a scraper conveyer is put in the container, and an air inlet is formed in each of the middle box bodies; an ash discharge opening is formed at a machine head of the scraper conveyer; a shutter door horizontally placed in the container is designed in a position, closely attached onto the middle box bodies, at the bottoms of the middle box bodies, and when the shutter door is positioned under a room, a lower opening of the room is just blocked; a track is arranged on each of the two sides of the shutter door; a side room communicated with the container and specially used for allowing the shutter door to be placed in is arranged outside one end surface of the middle box body; one end of the shutter door is connected with a main reel by a pull rope, and the other end is connected with an auxiliary reel in the side room by the pull rope through a guide pulley; the offline overhaul bag type dust remover is free from the cone-shaped ash deposition hopper and can be subjected to offline overhaul. The offline overhaul bag type dust remover has the benefits that the height of the dust remover is effectively reduced, and part of steel products is saved; a less space is occupied; only one ash discharge power for one ash discharge opening exists, so that a plurality of sets of power devices for a plurality of ash discharge openings are saved.

Owner:天津杰能道然环保科技有限公司

A railway track mobile maintenance workshop

ActiveCN112746533BReasonable designExpand the working areaRailway transportRailway track constructionBogieVehicle frame

The invention provides a railway track mobile maintenance workshop, which includes a car body, a side wall, a bolt tightening device and a lifting device; Both cabs can control the driving of the maintenance workshop. The cabs at both ends are connected by frame beams at the upper ends, and the cabs at both ends are hollow, providing installation space for bolt tightening devices and lifting devices and operating space for staff, which is convenient for manual labor. Operation operation, at the same time, the bolt tightening device uses the first sliding module and the second sliding module on the side wall to realize the position movement along the length direction and height direction of the vehicle body, and realizes the vehicle body movement by using the first chute set on the first bracket. The position moves in the width direction of the body, and the three directions are coordinated to move to the fastener of the rail to loosen or tighten the bolt; and use the pulling device at the end of the telescopic bracket to lift the rail to realize the position adjustment of the railway track and the replacement of the fastener.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Heating cable

ActiveCN101902848BAdd ground protectionImprove securityMagnetic/electric field screeningHeating element shapesChromium-Nickel AlloysElectrical conductor

Owner:GUANGXI QUNXING CABLE CO LTD

Coat hanger

The invention relates to a coat hanger which comprises a clothes hook (1). The clothes hook (1) can be hung on a rope and is connected with a main body. The coat hanger is characterized in that: the main body comprises a stripe-shaped hollow annular body (7); an extruding substance (2) is arranged at the long edge of one side of the hollow annular body (7); the substance (2) is internally provided with a cavity which is communicated with the hollow of the annular body; a stop dog (4) is arranged in the cavity; and a long hole is arranged in the long edge of the second side of the hollow annular body (7) along the length of the hollow annular body; the coat hanger also comprises a first coat hanger stay bar (5) and a second coat hanger stay bar (6) which are hinged; the upper ends of the two coat hanger stay bars are respectively provided with an extruding connector; and the length of the connector is greater than the width of the long hole. The coat hanger has the beneficial effects that: the two hinged coat hanger stay bars of the coat hanger can be closed or opened along the long hole; therefore, the length of the coat hanger is adjustable; when no coats are hung on the coat hanger, the two hinged coat hanger stay bars can be closed, thus reducing the occupation of a larger space of the coat hanger in a chest and bringing convenience for users.

Owner:李文印

Hospital physical examination integrated treatment equipment and use method thereof

ActiveCN113499057ASave time for physical examinationAchieve securityBody temperature measurementDiagnostic recording/measuringEngineeringMedical practitioner

The invention discloses hospital physical examination integrated treatment equipment which comprises a lifting assembly, a first adjusting assembly, an operation table and a second adjusting assembly. A display table is arranged on one side of the lifting assembly, the lifting assembly comprises a first lead screw, a first sliding block, a first sliding rod and a fixing plate, and a first motor is mounted at the top of the first lead screw; the first screw rod is connected with the first sliding block. The lifting assembly can be adjusted, so that the height of the operation table can be adjusted conveniently, on one hand, a physical examination object can lie on the operation table to perform various physical examination items by adjusting the height of the operation table, and on the other hand, the height of the operation table is adjusted according to different heights of doctors so that the doctors can perform physical examination on the physical examination object on the operation table conveniently. The first sliding rod is arranged on one side of the first sliding block, it is guaranteed that the operation table is more stable when the height of the operation table is adjusted, a ball bearing is arranged in the middle of a first groove hole, the first sliding block can move up and down more stably, and then the operation table can move up and down more stably.

Owner:THE PEOPLES HOSPITAL OF GUANGXI ZHUANG AUTONOMOUS REGION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com